Page 1

GAS COOKTOPS

INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

INSTRUCTIONS D’INSTALLATION

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLATIONSANWEISUNGEN

Page 2

Page 3

3

ENGLISH 4

ESPÃNOL 18

FRANÇAIS 32

ITALIANO 46

DEUTSCH 60

Page 4

As you follow these instructions, you will

notice WARNING and CAUTION symbols. This

blocked information is important for the safe

and efficient installation of Wolf equipment.

There are two types of potential hazards that

may occur during installation.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

WOLF®is a registered trademark of Wolf Appliance, Inc.

CONTACT

INFORMATION

Website:

wolfappliance.com

Page 5

5

INSTALLATION REQUIREMENTS

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch.

Do not use any phone in your

building.

Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

If you cannot reach your gas

supplier, call the fire department.

WOLF GAS COOKTOPS

IMPORTANT NOTE:

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Do not store or use gasoline or

other flammable vapors and liquids

in the vicinity of this or any other

appliance.

The use of a gas cooking appliance

results in the production of heat and

moisture in the room in which it is

installed. Ensure that the kitchen is

well ventilated; keep natural ventilation holes open or install a mechanical ventilation device (mechanical

extractor hood)

Prolonged intensive use of the appliance may for additional ventilation,

for example opening of a window, or

more effective ventilation, for

example increasing the level of

mechanical ventilation where

present.

This appliance shall be installed

in accordance with the regulations in force and only used in a

well ventilated space. Read the

instructions before installing or

using this appliance.

Page 6

6

INSTALLATION REQUIREMENTS

IMPORTANT NOTE: This installation must

be completed by a qualified installer,

service agency or gas supplier.

IMPORTANT NOTE:

Save these Installation

Instructions for the local inspector’s use.

Please read the entire Installation Instructions prior to installation.

Installer:

please retain these instructions

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep these

instructions for future reference and be sure

to read the entire Use & Care Information

prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with local codes. The

correct voltage, frequency and amperage must

be supplied to the appliance from a dedicated,

grounded circuit which is protected by a

properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and

amperage ratings are listed on the product

rating plate.

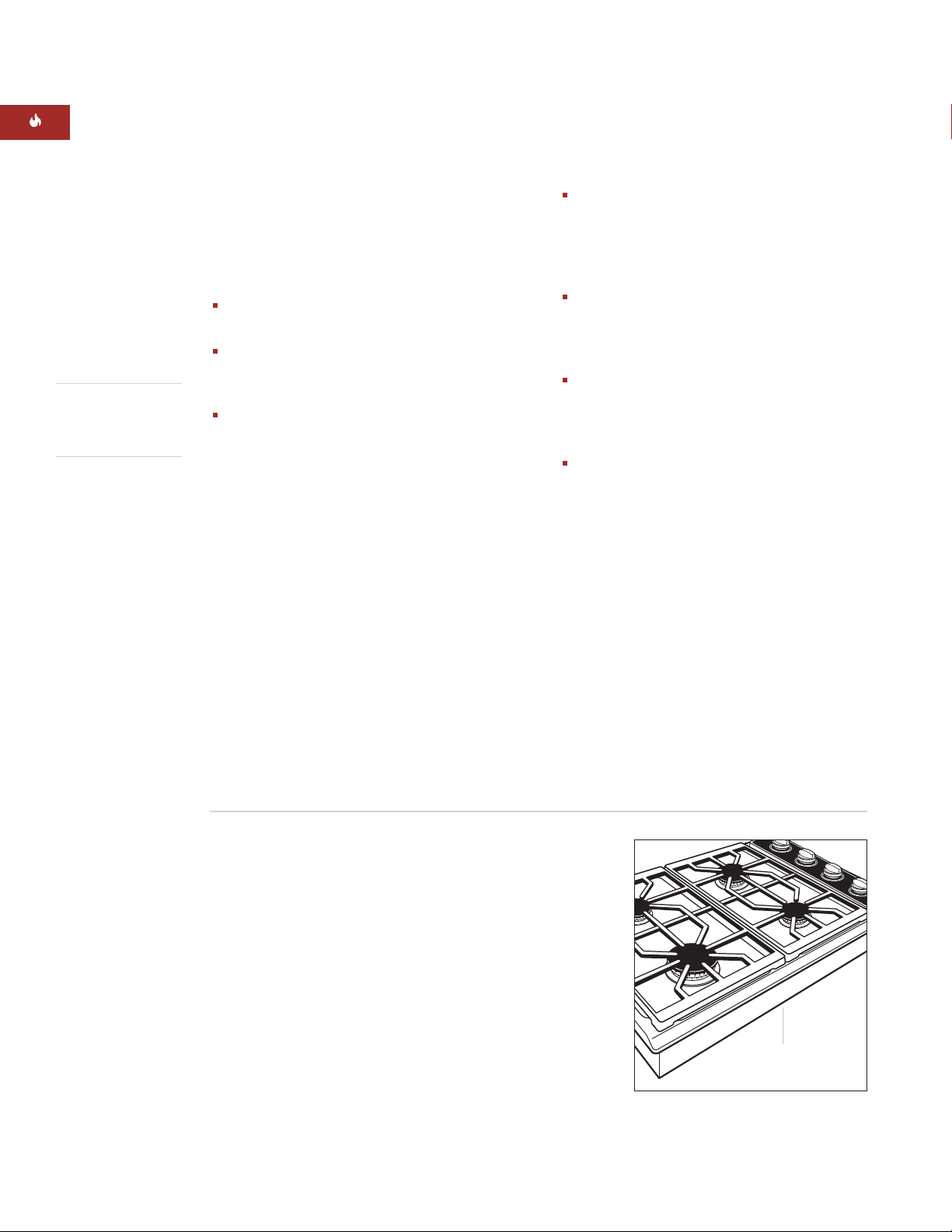

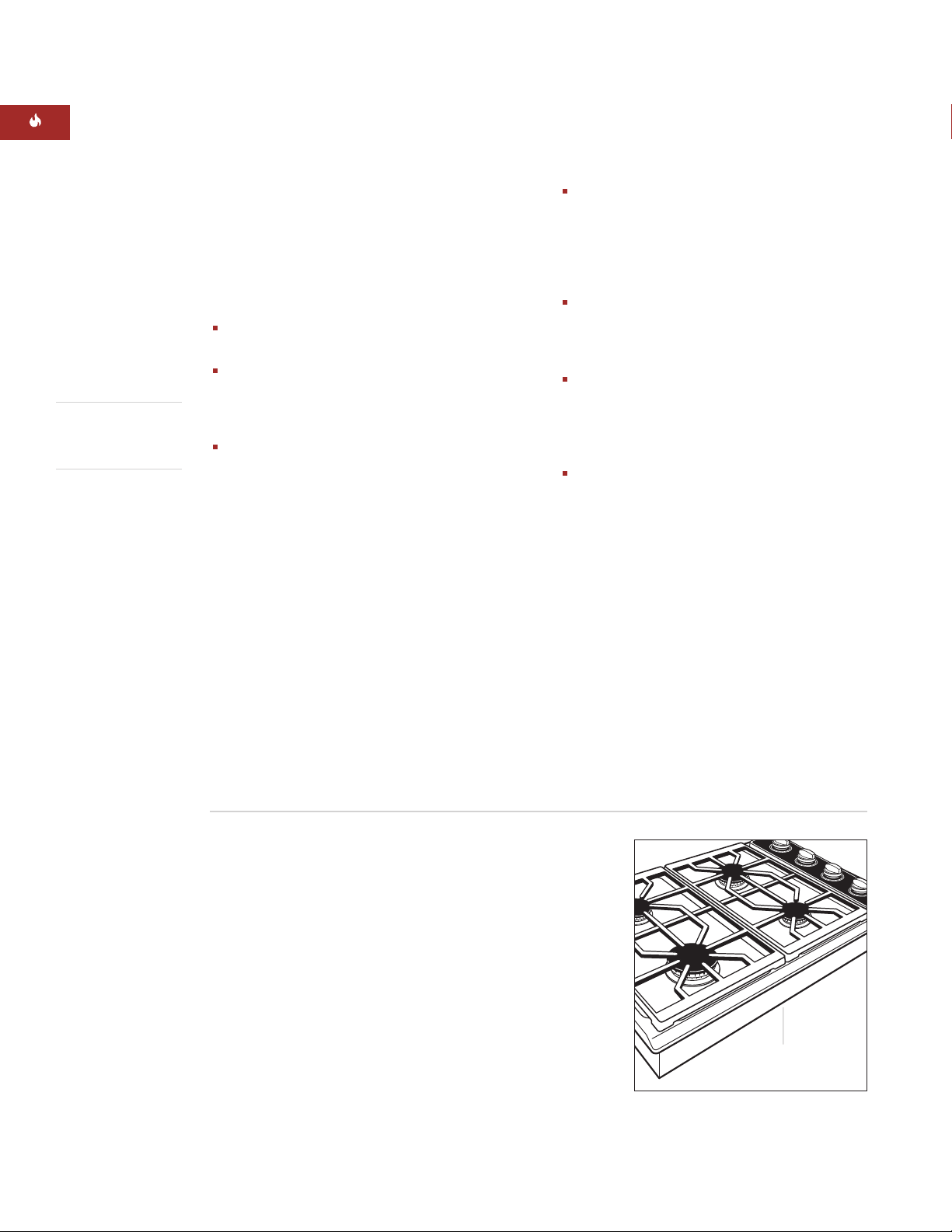

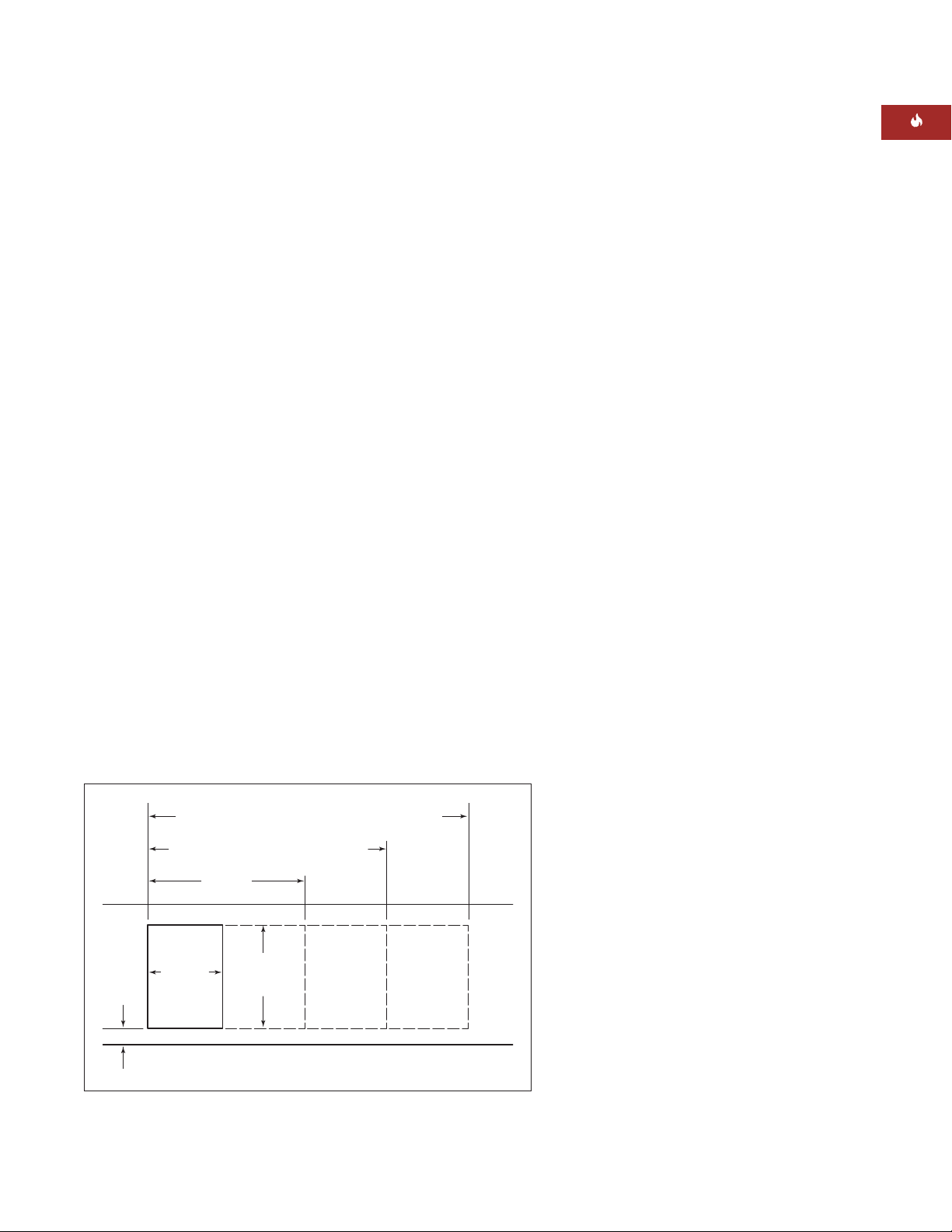

Record the model and serial numbers before

installing the cooktop. Both numbers are listed

on the rating plate, located on the underside of

the cooktop. Refer to the illustration below.

BEFORE YOU START

Proper installation is your responsibility.

Have a qualified technician install this

cooktop. You must also assure that electrical installation is adequate and in compliance with all local codes and ordinances.

Prior to installation, ensure that the local

distribution conditions (nature of the gas

and gas pressure) and the adjustment of

the appliance are compatible.

Proper gas supply connection must be

available; refer to Gas Supply Requirements

on page 12. Electrical ground is required;

see Electrical Requirements on page 13.

The adjustment conditions for this appliance are stated on the label (or rating

plate). The data plate can be found on the

underside of the cooktop.

WOLF GAS COOKTOPS

Rating plate location

Location of rating

plate under cooktop

RATING PLATE

INFORMATION

Model Number

Serial Number

Page 7

7

INSTALLATION INSTRUCTIONS

LOCATION REQUIREMENTS

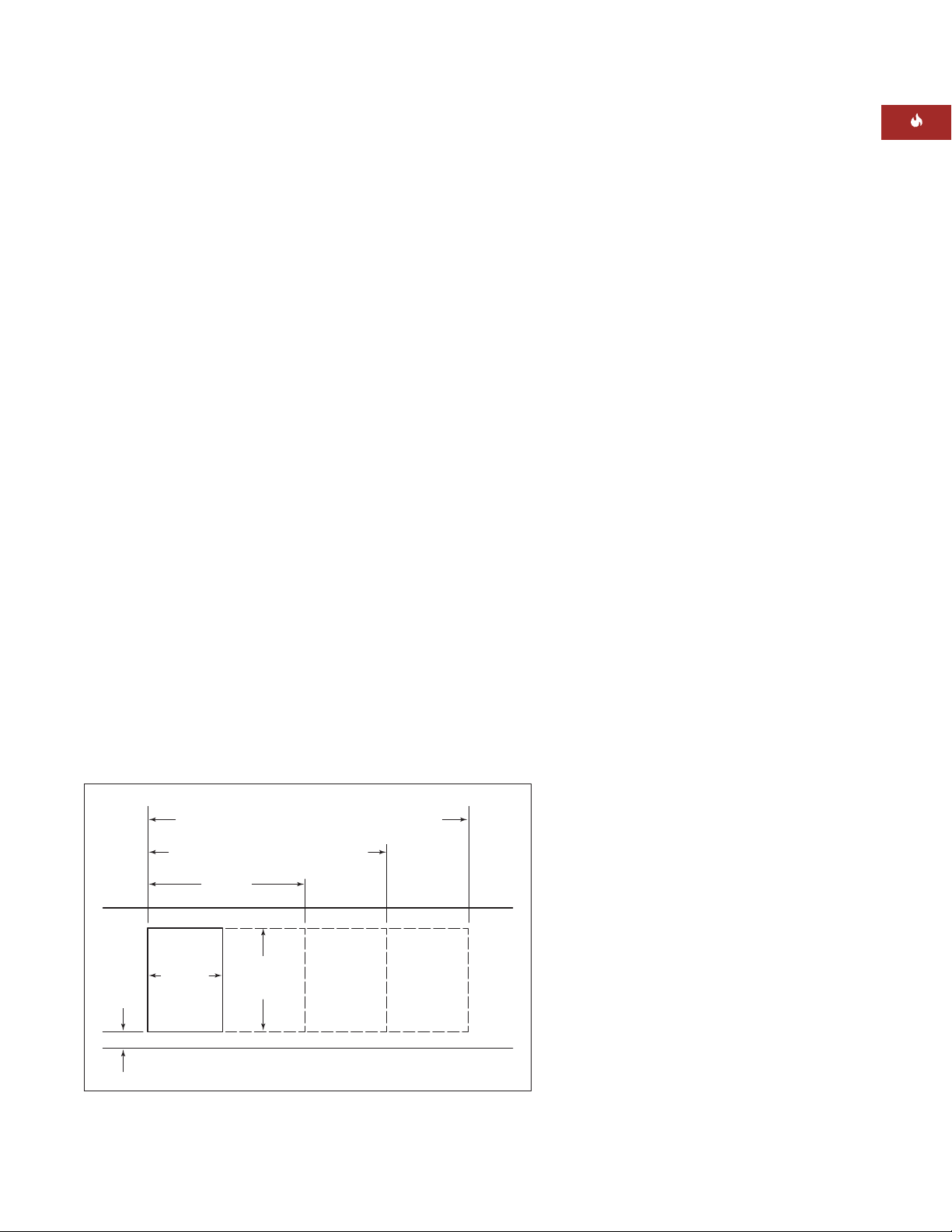

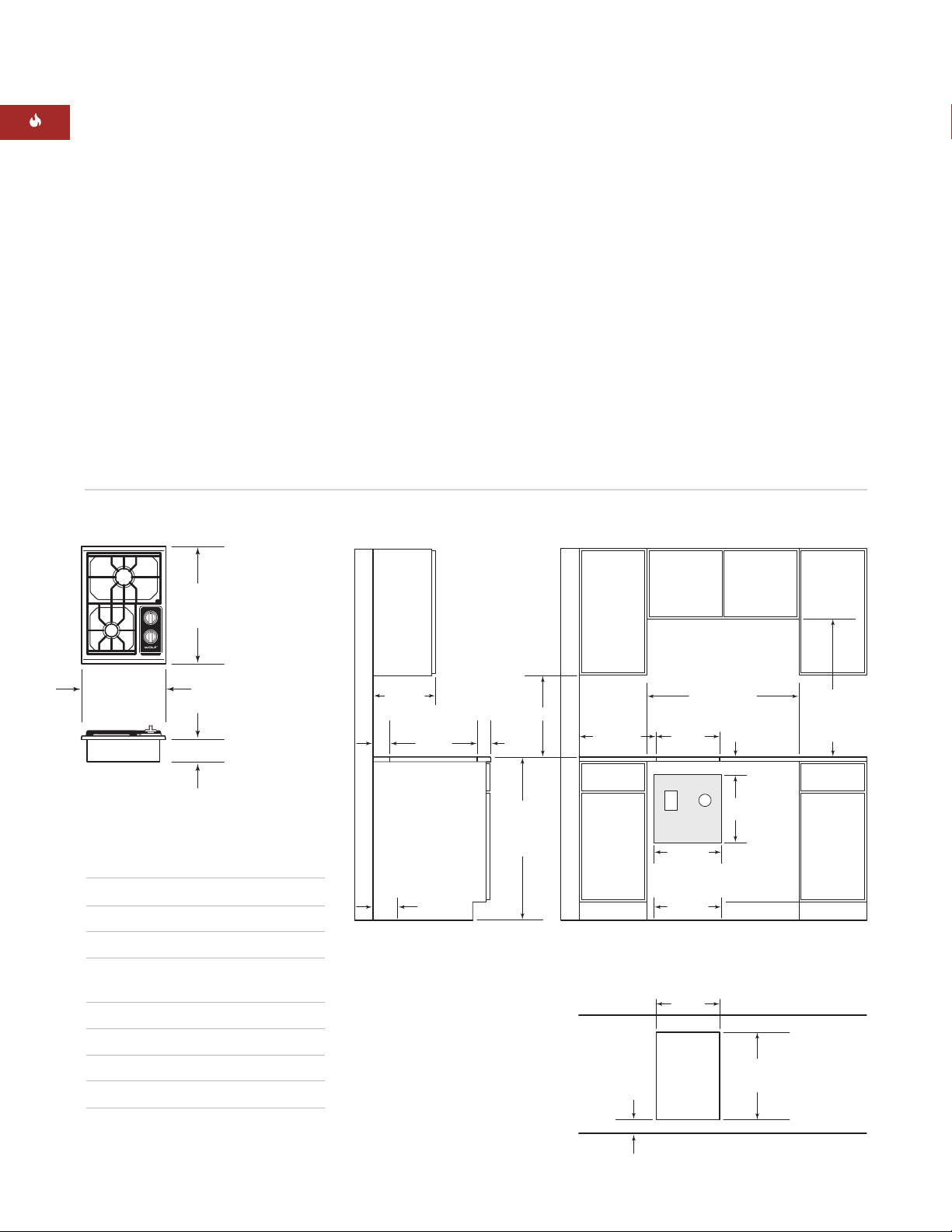

Illustrations on the following pages provide the

overall dimensions, countertop cut-out and

installation specifications for Wolf gas

cooktops. Maintain the following minimum

installation dimensions:

Minimum horizontal clearance from the

sides and back of the cooktop cut-out to

adjacent vertical combustible construction,

extending a minimum of 457 mm above the

countertop, is as follows: 178 mm from side

edges of cut-out for the 381 mm cooktop;

229 mm from side edges of cut-out for the

762 mm and 914 mm cooktops; 64 mm

from rear edge of cut-out.

Minimum vertical distance between the

countertop and combustible materials

above the cooktop must be 762 mm.

Maximum 330 mm depth of overhead side

cabinets directly above and within side

clearance.

IMPORTANT NOTE:

When installing a ventilation hood, refer to the specific requirements

of the hood for the minimum dimension to

countertop.

BEFORE YOU START

Check the location where the cooktop will

be installed. The location should be away

from strong draft areas, such as windows,

doors and strong heating vents or fans. Do

not obstruct flow of combustion and

ventilation air.

This appliance is not connected to a

combustion products evacuation device. It

shall be installed and connected in accordance with current installation regulations.

Particular attention shall be given to the

relevant requirements regarding ventilation.

SITE PREPARATION

COUNTERTOP CUT-OUT DIMENSIONS

IMPORTANT NOTE:

Countertop opening

dimensions shown on the following pages

must be used. The dimensions shown provide

for required clearances.

These cooktops are designed to fit a standard

610 mm deep base cabinet with a 635 mm

deep countertop. Before making the countertop cut-out, verify that the cooktop will clear

the side walls of the base cabinet below. There

should be at least 140 mm clearance between

the countertop and any combustible surface

directly below the unit.

IMPORTANT NOTE:

Do not seal the cooktop

to the countertop. It must be removed if

service is necessary.

Failure to locate the cooktop without the

proper clearances will result in a fire

hazard.

This cooktop is intended for indoor use.

Page 8

8

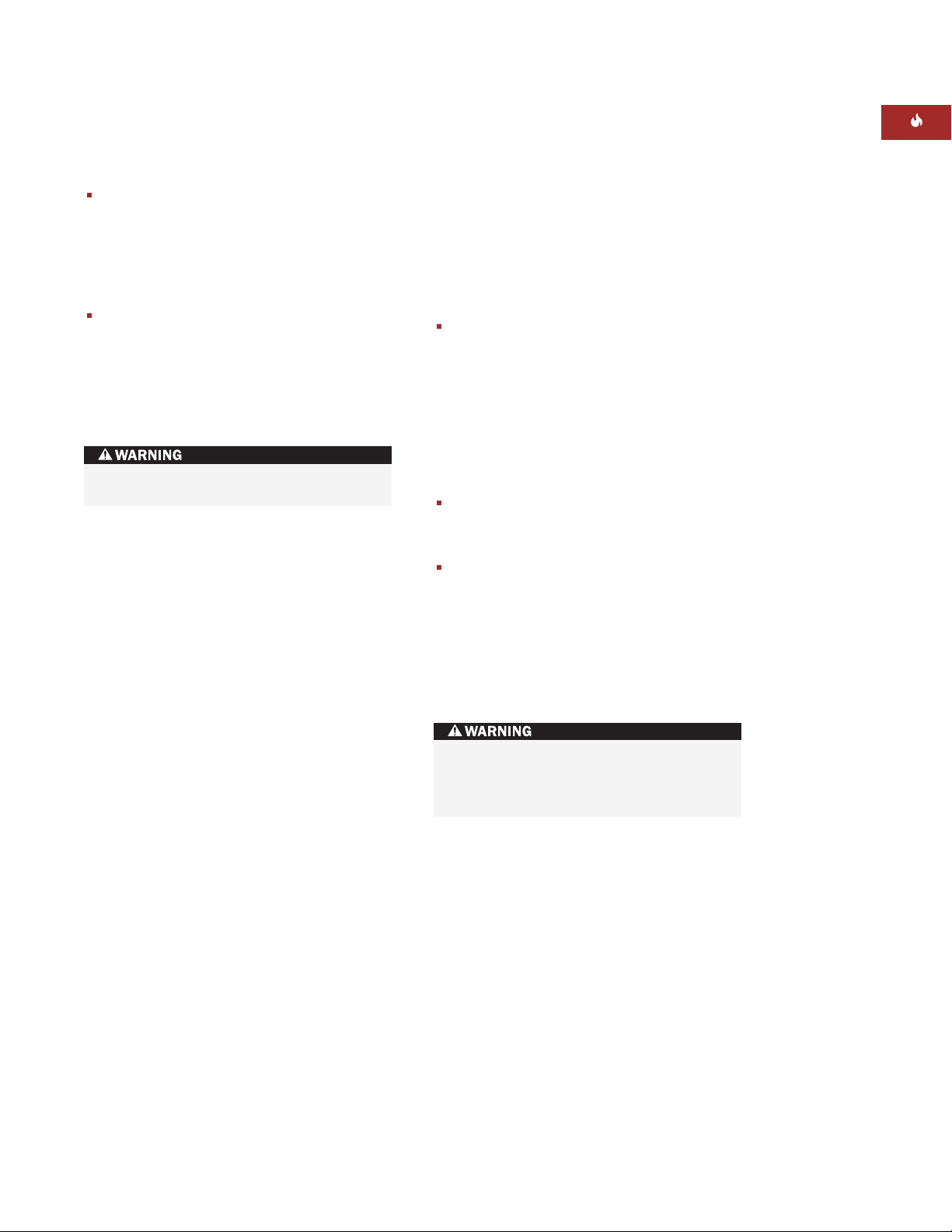

INSTALLATION SPECIFICATIONS

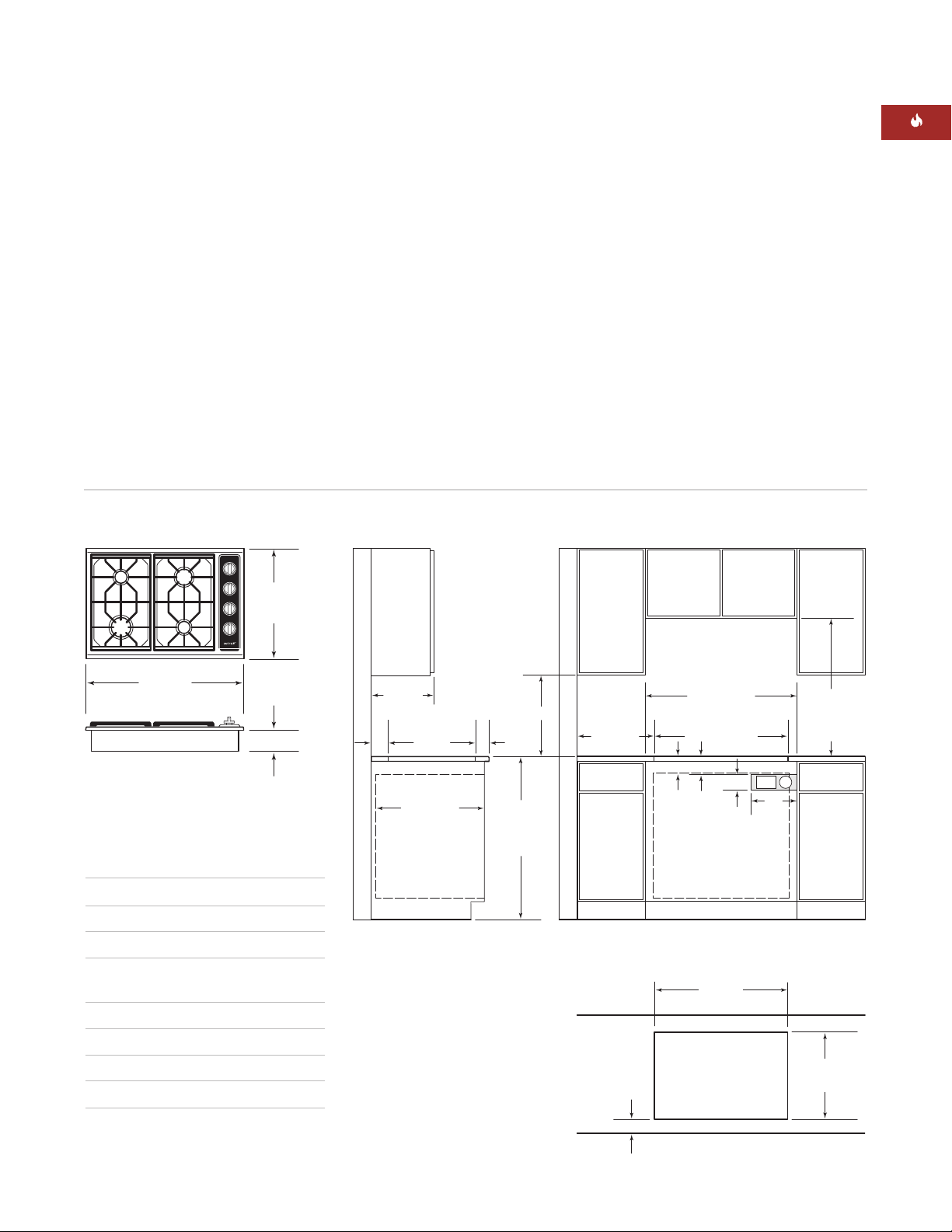

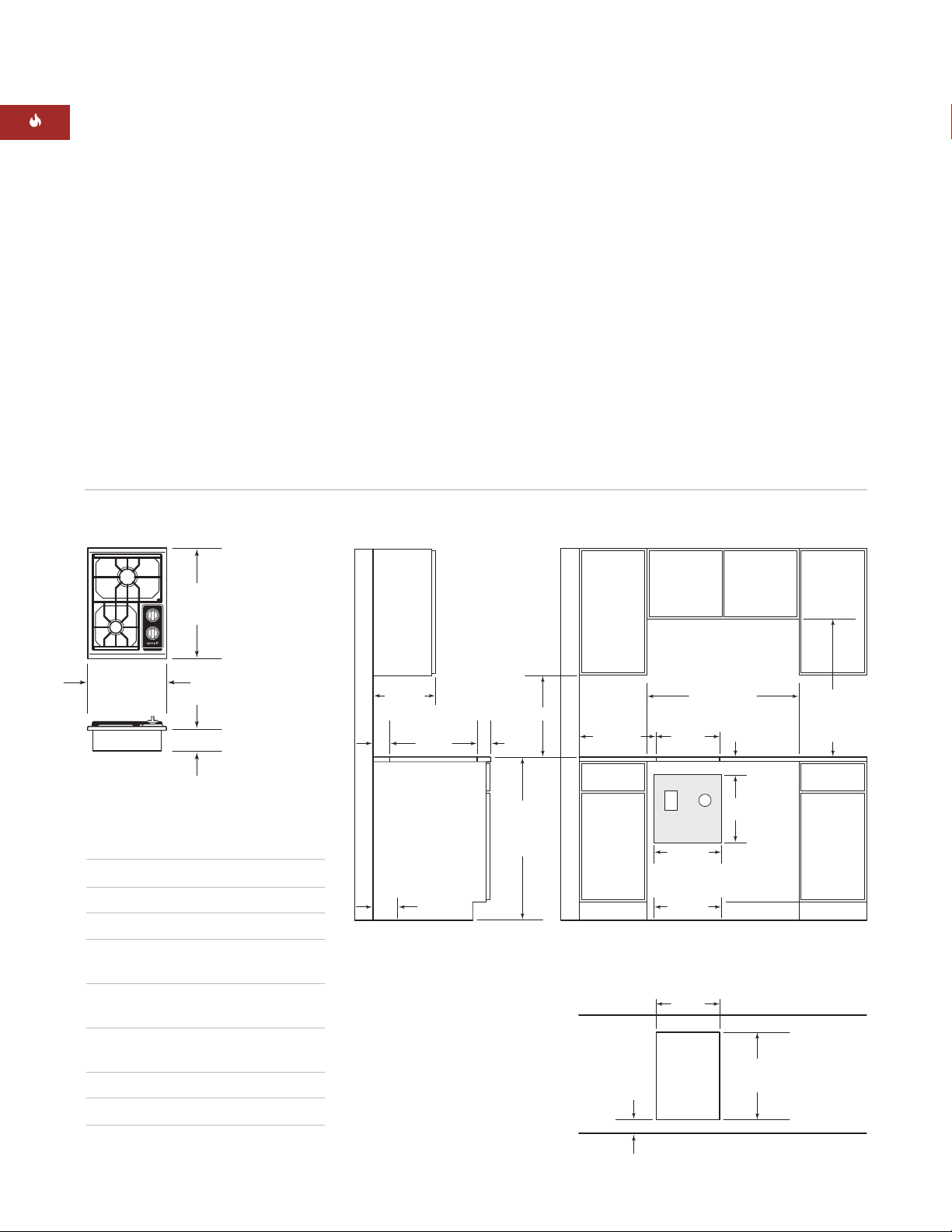

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT15G.

For Model ICBCT15G, the gas service may be

supplied through the floor if the cooktop is not

installed above an oven. Refer to the illustration

for specifics on placement of gas and electrical.

E

102 mm

G

381 mm

381 mm

381

mm

LOCATION OF GAS SUPPLY

MAY ALSO EXTEND 127 mm ON

FLOOR FROM BACK WALL

178 mm*

min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

356 mm

COOKTOP CUT-OUT

WIDTH

356 mm

COOKTOP CUT-OUT

WIDTH

838 mm

RECOMMENDED

CABINET WIDTH

457 mm

NOTE: Application shown allows for installation of two 381 mm modules side-by-side with 838 mm recommended cabinet width. 457 mm

recommended cabinet width for installation of single 381 mm cooktop or module. *Minimum clearance from both side edges of cooktop cut-out

to combustible materials up to 457 mm above countertop. **Minimum clearance from rear edge of cooktop cut-out to combustible materials up

to 457 mm above countertop.

489 mm

COOKTOP CUT-OUT

DEPTH

64 mm

min

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

330 mm

max

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

64**

mm

127

mm

LOCATION OF GAS

SUPPLY MAY ALSO

EXTEND 127 mm ON

FLOOR FROM BACK WALL

FRONT OF COUNTERTOP

64 mm

min

489 mm

COOKTOP

CUT-OUT DEPTH

WOLF GAS COOKTOPS

Overall Dimensions

Countertop Cut-Out

381 mm

OVERALL WIDTH

533 mm

OVERALL

DEPTH

102 mm

MODEL ICBCT15G

DIMENSIONS

Overall Width 381 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 838 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 356 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

INSTALLATION SPECIFICATIONS – MODEL ICBCT15G

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 11.

Page 9

9

INSTALLATION INSTRUCTIONS

229 mm*

min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

457 mm

489 mm

COOKTOP CUT-OUT

DEPTH

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

330 mm

max

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

610 mm

min

*Minimum clearance from both side edges of cooktop cut-out to combustible materials up to 457 mm above countertop.

**Minimum clearance from rear edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

102 mm

254

mm

89 mm

E

95 mm

min

G

762 mm OVEN OPENING

737 mm

COOKTOP

CUT-OUT WIDTH

737 mm

COOKTOP CUT-OUT WIDTH

FRONT OF COUNTERTOP

64 mm

min

489 mm

COOKTOP

CUT-OUT DEPTH

838 mm

RECOMMENDED

CABINET WIDTH

762 mm

min

64**

mm

64 mm

min

Overall Dimensions

Countertop Cut-Out

533 mm

FONDO

TOTAL

762 mm

ANCHURA TOTAL

102 mm

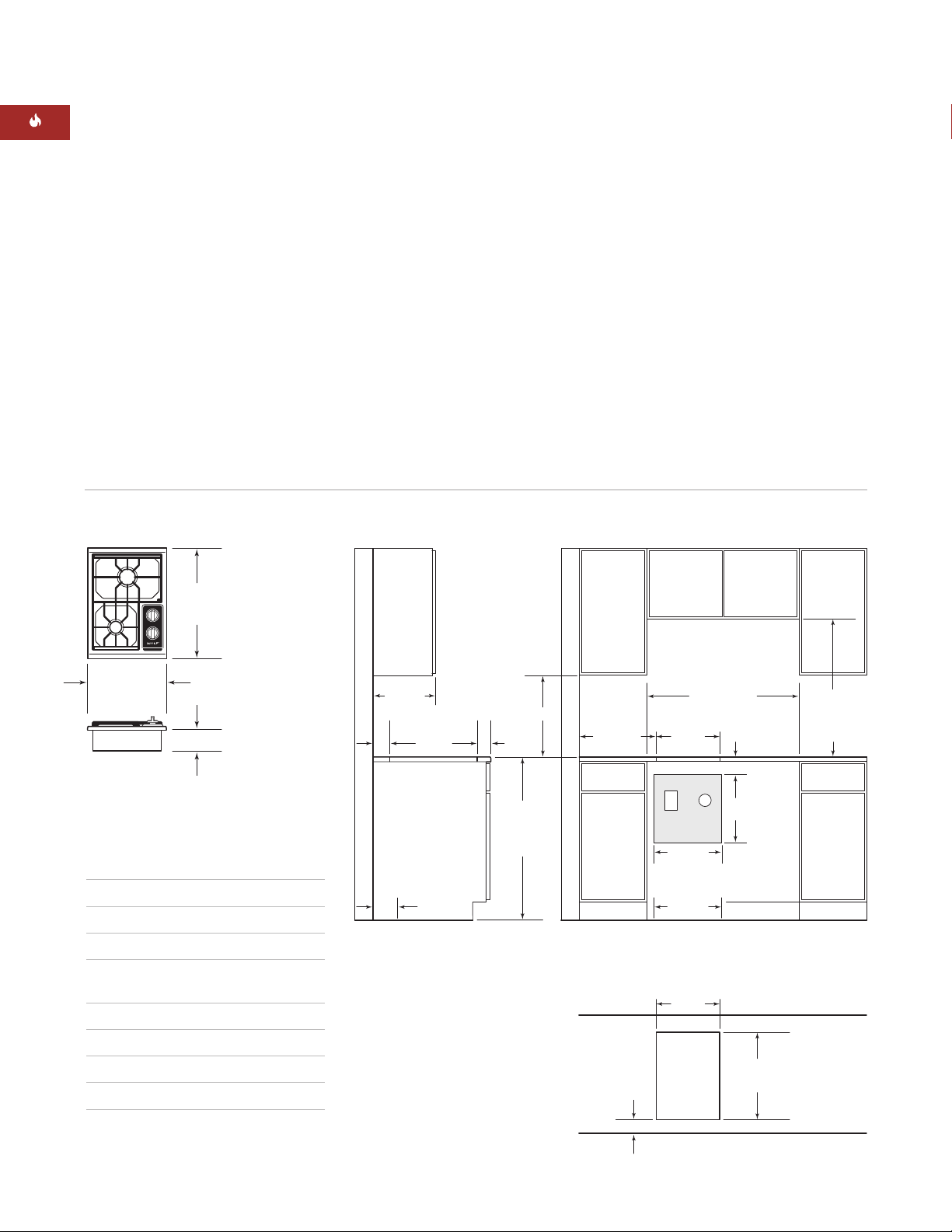

INSTALLATION SPECIFICATIONS

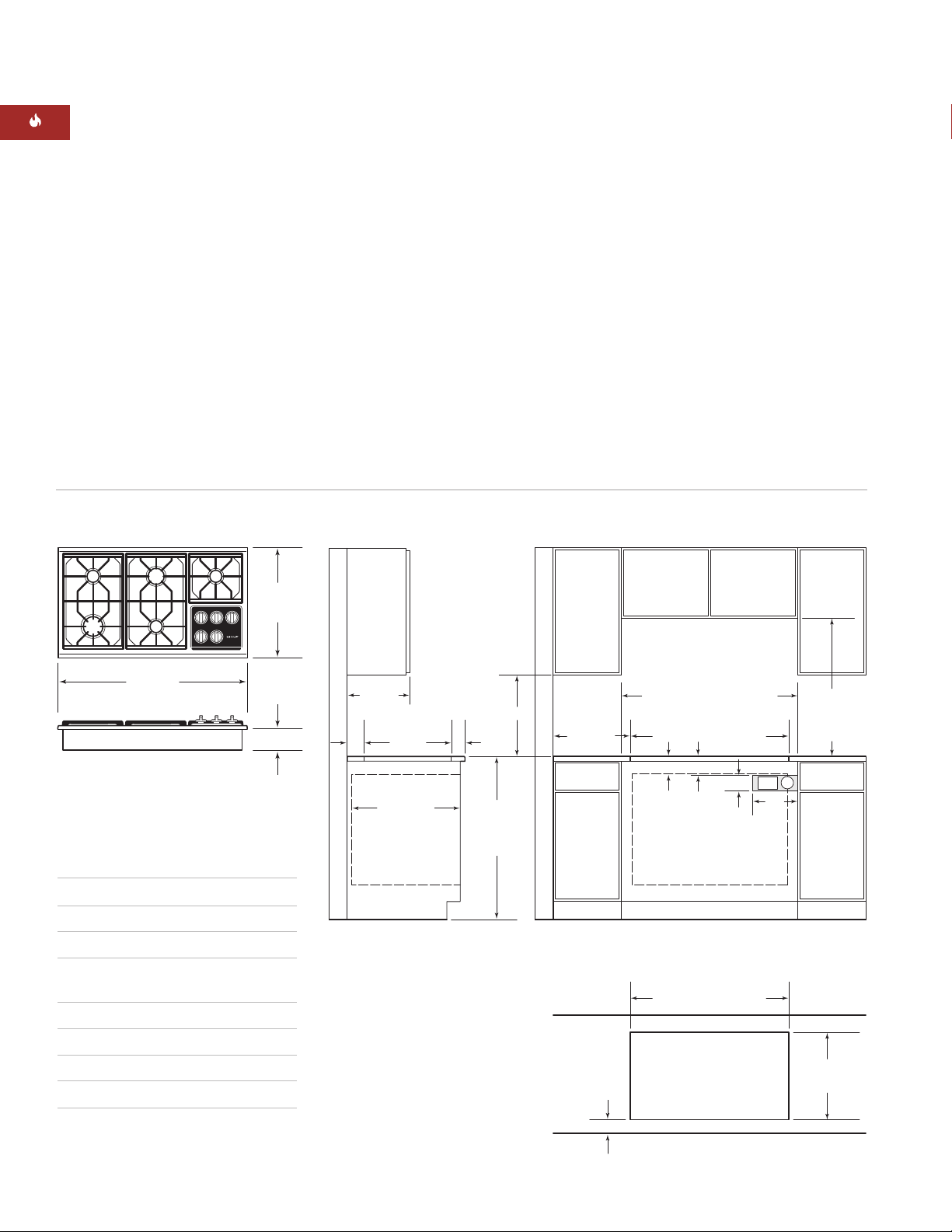

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT30G.

IMPORTANT NOTE:

838 mm wide cabinets are

recommended for installation of Model

ICBCT30G.

A Wolf 762 mm single built-in oven may be

installed below Model ICBCT30G. For this

installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical and gas supply be placed in the

base cabinet to the right of the oven. Refer to

installation instructions provided with the builtin oven for additional specifications.

If the Model ICBCT30G is installed above

cabinets, the gas and electrical placement is not

critical. A grounded outlet needs to be placed

within 1.2 m of the right rear of the cooktop.

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 11.

MODEL ICBCT30G

DIMENSIONS

Overall Width 762 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 838 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 737 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

INSTALLATION SPECIFICATIONS – MODEL ICBCT30G

Page 10

10

WOLF GAS COOKTOPS

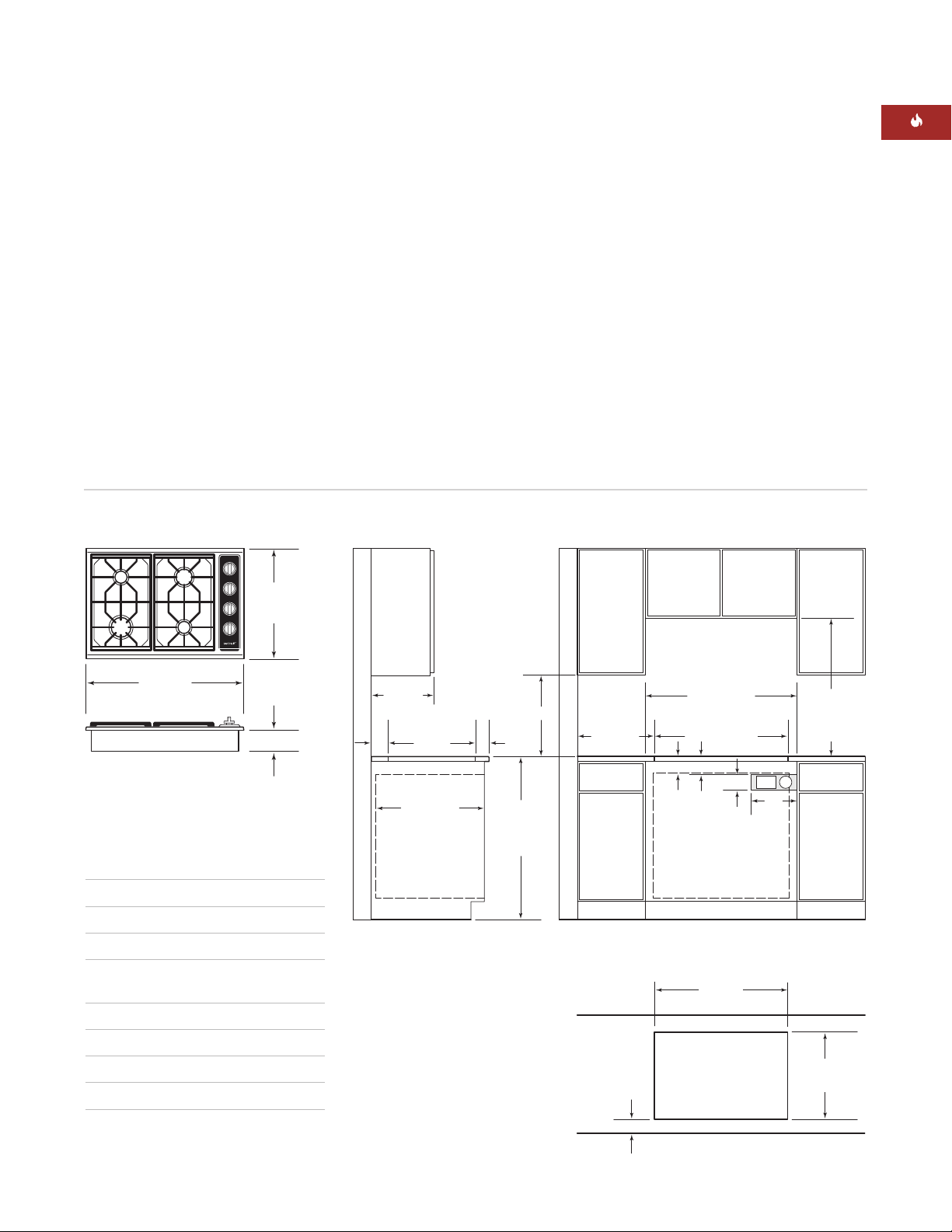

INSTALLATION SPECIFICATIONS

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT36G.

IMPORTANT NOTE:

991 mm wide cabinets are

recommended for installation of Model

ICBCT36G.

A Wolf 914 mm built-in oven may be installed

below Model ICBCT36G. For this installation,

unless you are using cabinets deeper than 610

mm, it is recommended that the electrical and

gas supply be placed in the base cabinet to the

right of the oven. Refer to installation instructions provided with the built-in oven for additional specifications.

If the Model ICBCT36G is installed above

cabinets, the gas and electrical placement is not

critical. A grounded outlet needs to be placed

within 1.2 m of the right rear of the cooktop.

When a 914 mm built-in oven is installed below

Model ICBCT36G, it is recommended that the

rough opening for the oven be 197 mm from

the floor to ease the use of the oven door.

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 11.

229 mm*

min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

457 mm

489 mm

COOKTOP CUT-OUT

DEPTH

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

330 mm

max

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

610 mm

min

*Minimum clearance from both side edges of cooktop cut-out to combustible materials up to 457 mm above countertop.

**Minimum clearance from rear edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

889 mm

COOKTOP CUT-OUT WIDTH

889 mm

COOKTOP CUT-OUT WIDTH

991 mm

RECOMMENDED CABINET WIDTH

914 mm

min

102 mm

254

mm

89 mm

E

G

914 mm OVEN OPENING

95 mm

min

64 mm

min

FRONT OF COUNTERTOP

489 mm

COOKTOP

CUT-OUT DEPTH

64**

mm

64 mm

min

Overall Dimensions

Countertop Cut-Out

533 mm

OVERALL

DEPTH

914 mm

OVERALL WIDTH

102 mm

MODEL ICBCT36G

DIMENSIONS

Overall Width 914 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 991 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 889 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

INSTALLATION SPECIFICATIONS – MODEL ICBCT36G

Page 11

11

INSTALLATION INSTRUCTIONS

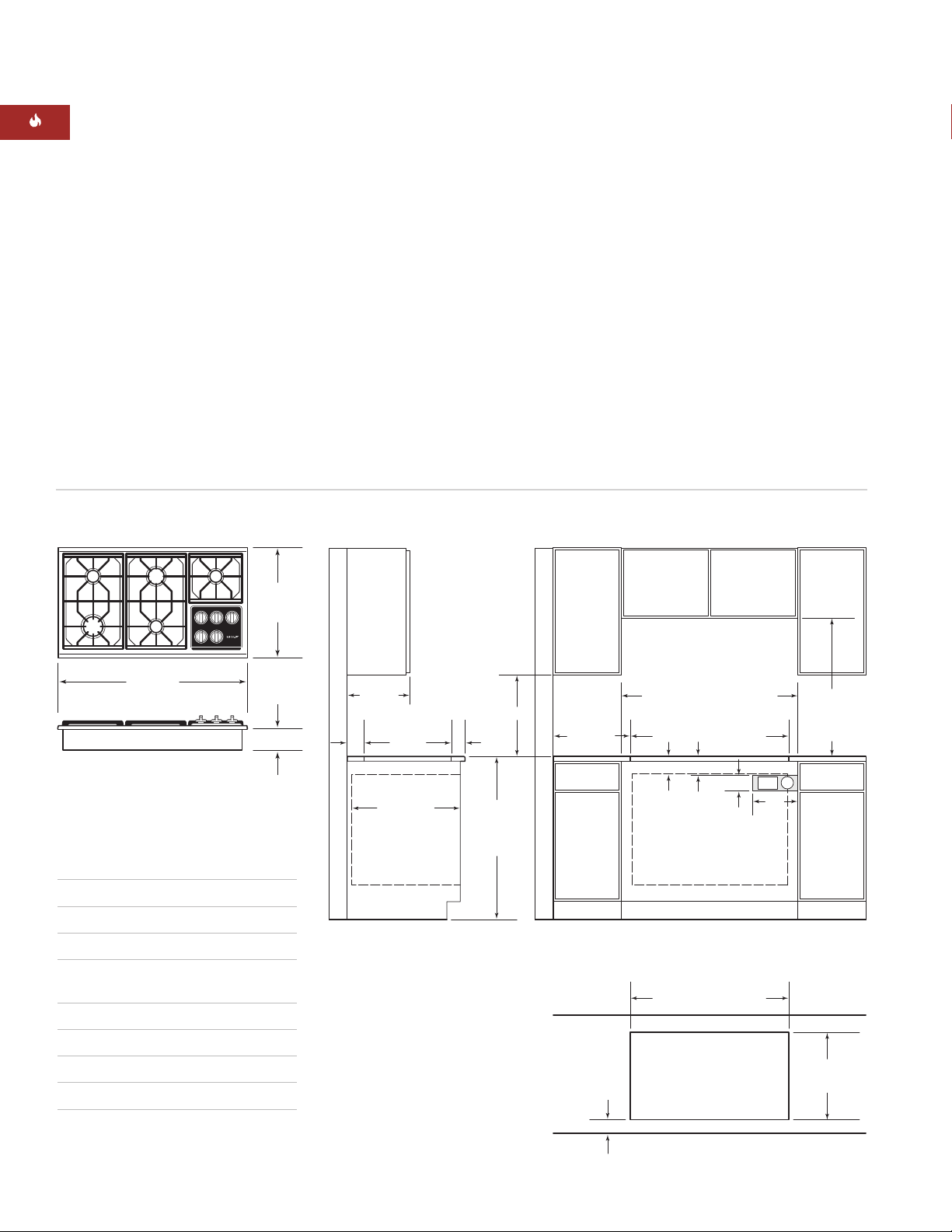

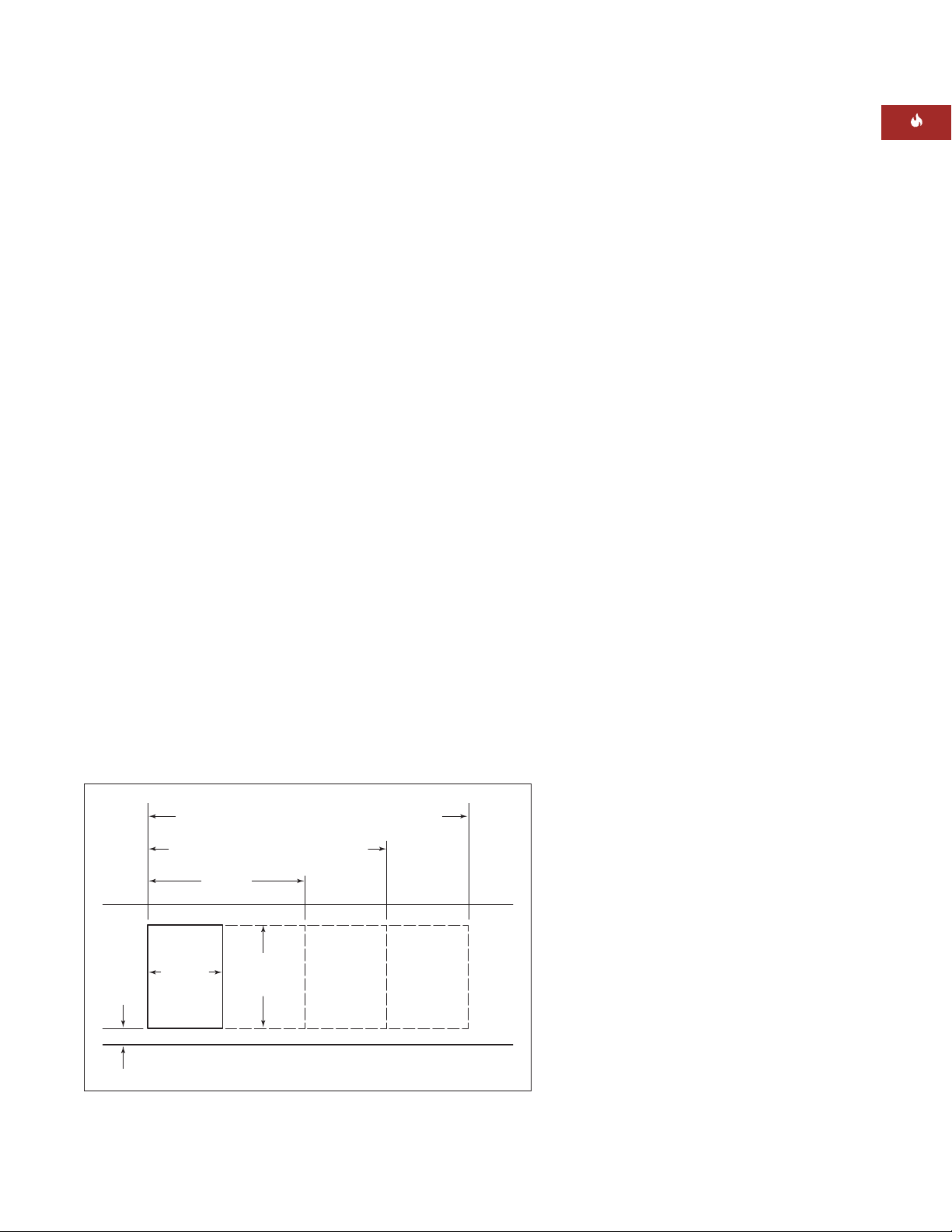

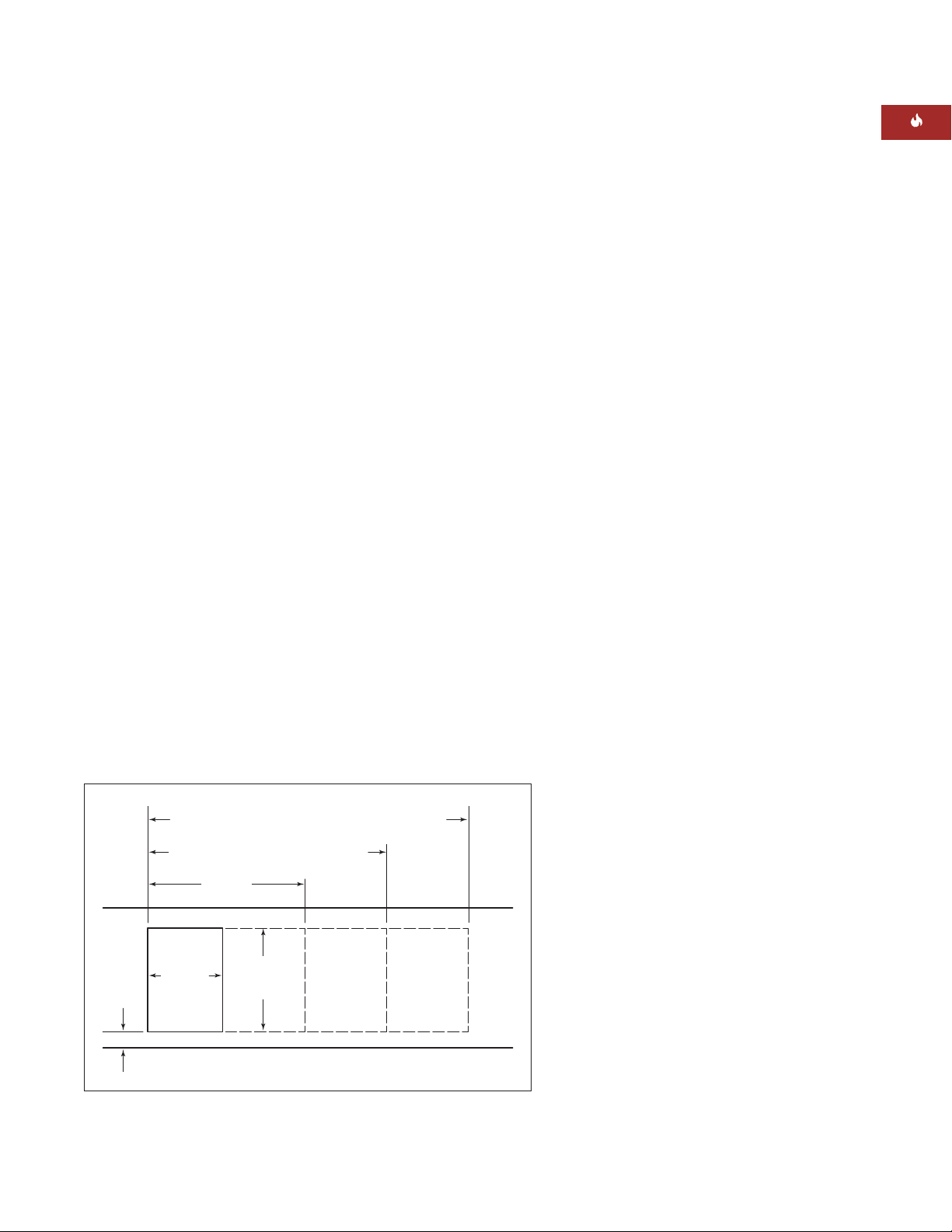

INSTALLATION OPTIONS

MULTIPLE COOKTOP INSTALLATION

If the gas cooktop is to be used with any

combination of additional cooktop units or

modules with a filler strip, the cut-out width is

calculated by adding the corresponding units'

cut-out dimensions plus 32 mm for each additional unit. Refer to the illustration below.

IMPORTANT NOTE:

When multiple units are

installed side by side, each unit must have its

own separate recommended electrical circuit.

When two or more modules are installed

together, an integrated module filler strip

(IFILLER/S) is recommended. Contact your

Wolf dealer for information on these accessory

components.

64 mm

min

FRONT OF COUNTERTOP

489 mm

CUT-OUT

DEPTH

743 mm

TWO MODULES WIDTH

1130 mm –

THREE MODULES WIDTH OR

1124 mm –

762 mm COOKTOP AND ONE MODULE

1518 mm –

FOUR MODULES WIDTH OR

1511 mm –

762 mm COOKTOP AND TWO MODULES OR

1276 mm –

914 mm COOKTOP AND ONE MODULE

356 mm

CUT-OUT

WIDTH

Countertop cut-out dimensions for installation of multiple cooktops

OPTIONAL

INSTALLATIONS

Dimensions will

vary according to

the specific installation.

Page 12

12

WOLF GAS COOKTOPS

IMPORTANT NOTE:

The gas cooktop must be

connected to a regulated gas supply.

IMPORTANT NOTE:

This installation must

conform with local codes and ordinances.

IMPORTANT NOTE:

The natural gas cooktop

is rated for elevations up to 2438 m without

adjustment. Install a high altitude kit for elevations from 2438 to 3084 m. The LP gas cooktop

is rated for 3084 m.

The rating plate, located on the underside of

the burner box, has information on the type of

gas that should be used. If this information

does not agree with the type of gas available,

check with the local gas supplier.

EXPLOSION HAZARD—

Securely tighten all external gas

connections.

Failure to do so can result in explosion,

fire or death.

GAS SUPPLY REQUIREMENTS

Provide a gas supply line of 19 mm rigid pipe

to the cooktop location. A smaller size pipe on

long runs may result in insufficient gas supply.

Pipe joint compounds, suitable for use with LP

gas should be used. For LP gas, piping or

tubing size can be 13 mm minimum. LP gas

suppliers usually determine the size and materials used on the system.

If local codes permit, a flexible metal appliance

connector is recommended for connecting this

cooktop to the gas supply line. Do not kink or

damage the flexible connector when moving

the cooktop. You will need to determine the

fittings required, depending on the size of your

gas supply line, flexible metal connector and

shut-off valve.

If rigid pipe is used as a gas supply line, a

combination of pipe fittings must be used to

obtain an in-line connection to the cooktop. All

strains must be removed from the supply and

gas lines so the cooktop will be level and in

line.

IMPORTANT

NOTE

This installation

must conform with

local codes and

ordinances.

GAS RATING

Total Heat Electrical Types and

Output Gas Rating Appliance Pressures

Model # (Gas) Units (Watts) Category (mbar) Country of Destination

I2H G20 at 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT15G/S 6.8 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

ICBCT15G/S-LP 494 g/h 230 I3P G31 at 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

I2H G20 at 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT30G/S 14.7 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

ICBCT30G/S-LP 1069 g/h 230 I3P G31 at 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

I2H G20 at 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT36G/S 17.7 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

ICBCT36G/S-LP 1287 g/h 230 I3P G31 at 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

Page 13

13

INSTALLATION INSTRUCTIONS

ELECTRICAL REQUIREMENTS

ELECTRICAL SHOCK HAZARD—

Plug into a grounded 3-prong adapter.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these instructions can

result in electric shock, fire or death.

RECOMMENDED GROUND METHOD

IMPORTANT NOTE:

For your personal safety,

this cooktop must be grounded. This cooktop

is equipped with a 3-prong ground plug. To

minimize possible shock hazard, the cord must

be plugged into a mating 3-prong ground-type

outlet, grounded in conformance with all local

codes and ordinances. If a mating outlet is not

available, it is the obligation of the customer to

have a properly grounded, 3-prong outlet

installed by a qualified electrician.

IMPORTANT NOTE:

If product is connected to

a GFCI protected outlet, nuisance tripping of

power supply may occur, resulting in loss of

product operation.

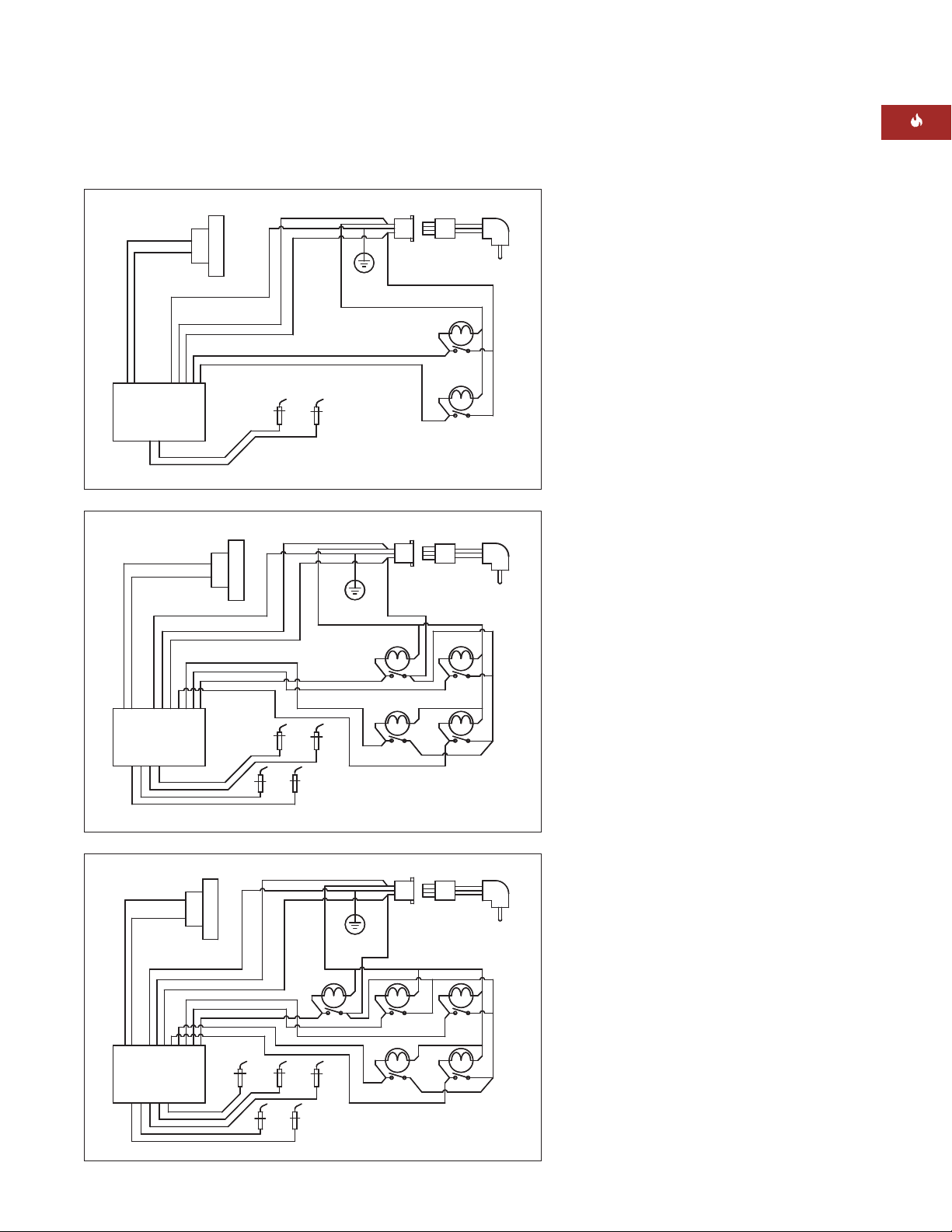

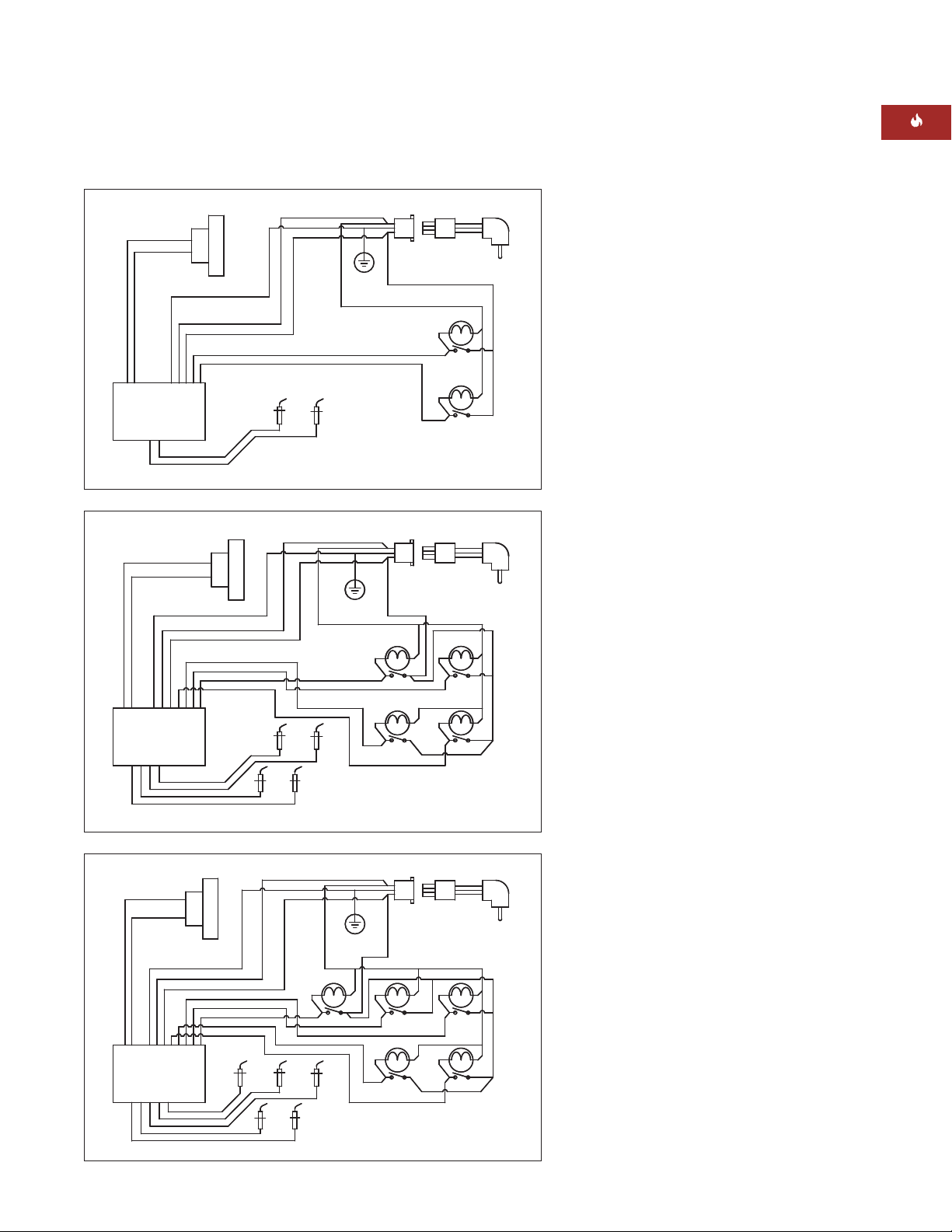

WIRING DIAGRAM

A wiring diagram covering the control circuit

for each Wolf gas cooktop model can be found

on page 17.

IMPORTANT NOTE:

If codes permit and a

separate ground wire is used, it is recommended that a qualified electrician determine

that the ground path is adequate.

IMPORTANT NOTE:

Check with a qualified

electrician if you are not sure whether the

cooktop is properly grounded.

IMPORTANT NOTE:

Do not ground to a gas

pipe.

A 220-240 VAC, 50/60 Hz, fused electrical

supply is required. A time-delay fuse or circuit

breaker is recommended. It is recommended

that a separate circuit serving only this appliance be provided.

Electronic ignition systems operate within

wide voltage limits, but proper ground and

polarity are necessary. In addition to checking

that the outlet provides 220-240 VAC power

and is correctly grounded, the outlet must be

checked by a qualified electrician to see if it is

wired with correct polarity. A wiring diagram is

provided in the literature package.

This appliance, when installed, must be electrically grounded in accordance with local codes.

Page 14

14

COOKTOP INSTALLATION

Remove the cooktop, burner grates and burner

caps from the shipping package.

Lower the cooktop into the countertop cut-out

opening. Center the cooktop in the opening

and check that the front edge of cooktop is

parallel to the front edge of the countertop.

Check that all required clearances are met. Use

a pencil to outline the rear edge of the cooktop

on the countertop. Remove the cooktop from

the countertop opening.

IMPORTANT NOTE:

When repositioning the

cooktop in the countertop cut-out opening, lift

the entire cooktop up from the opening to

prevent scratching the countertop.

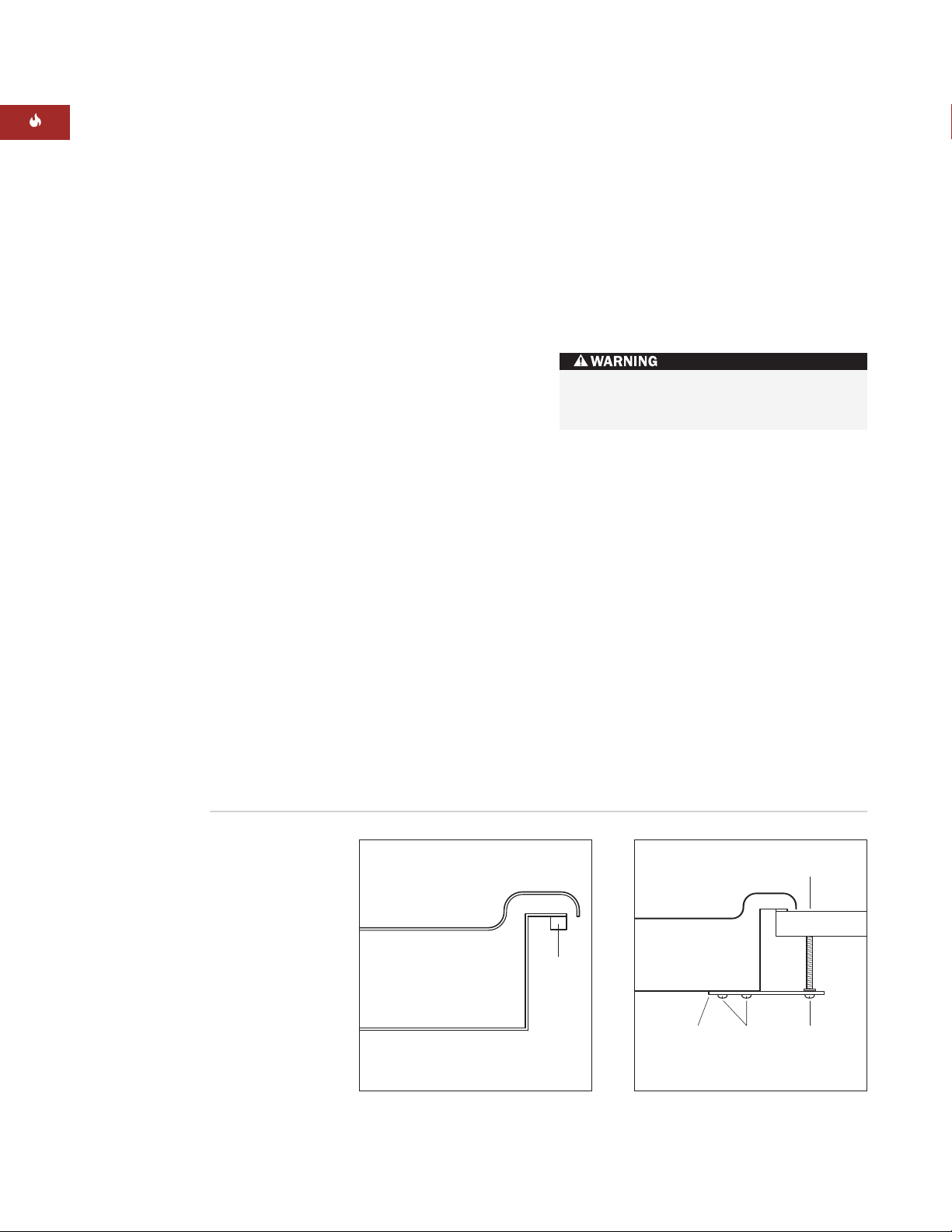

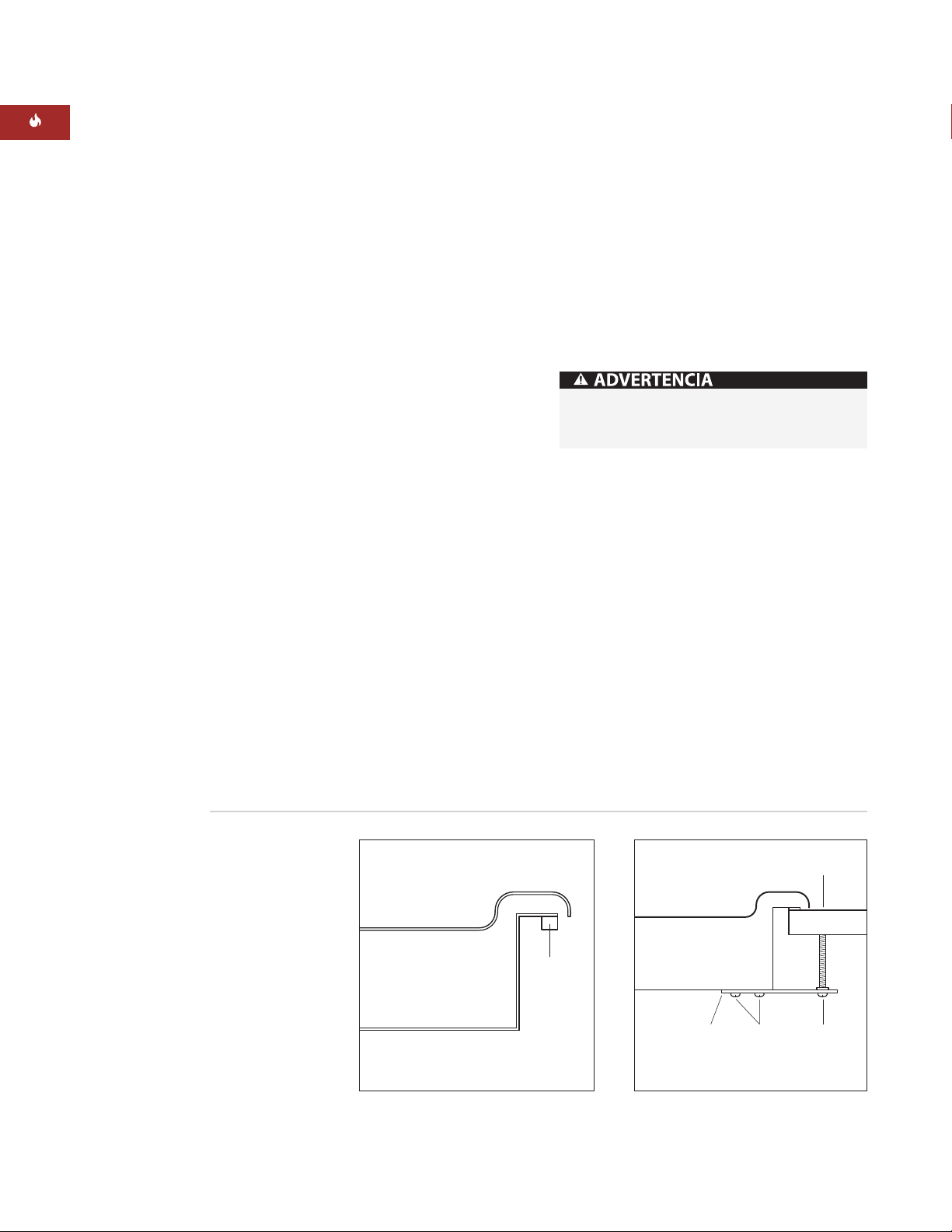

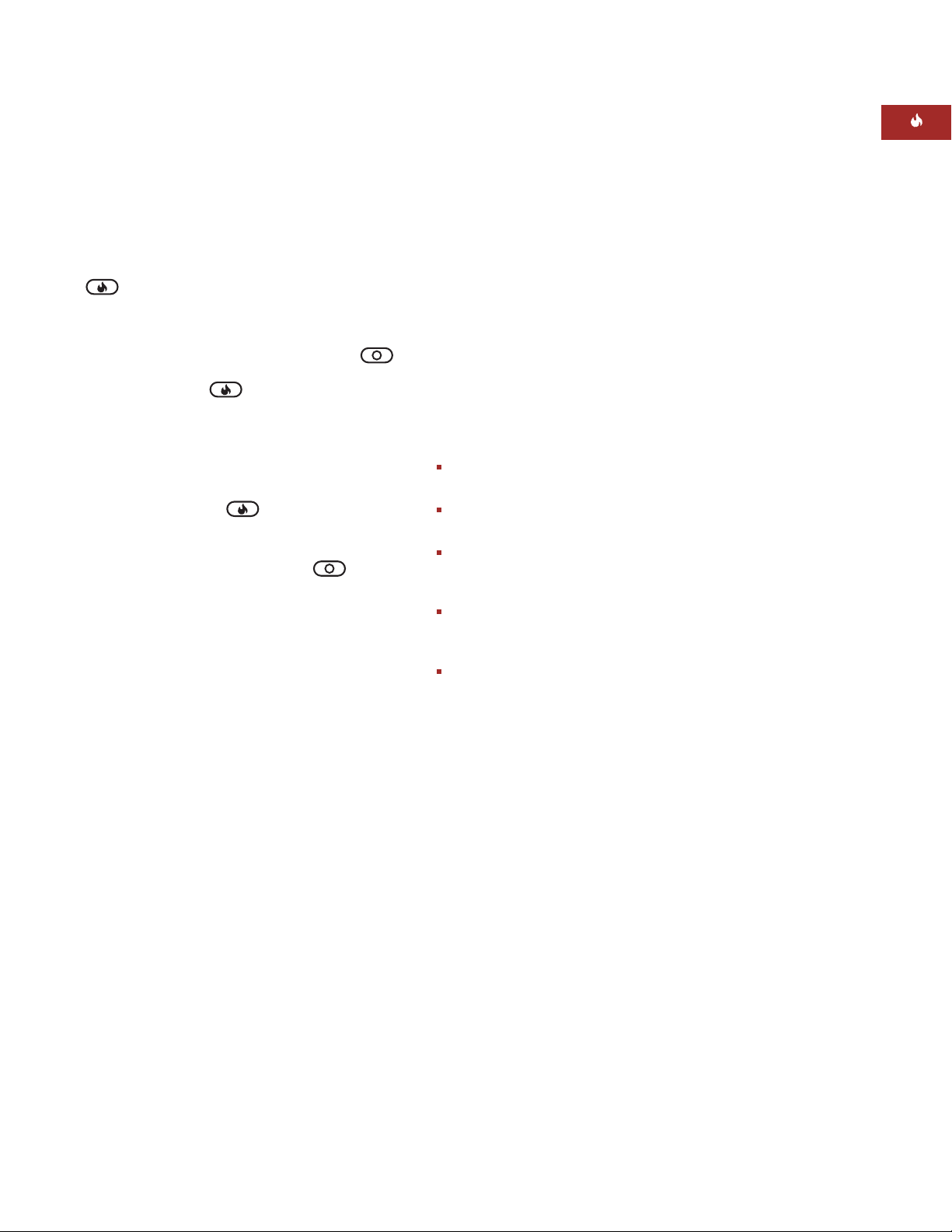

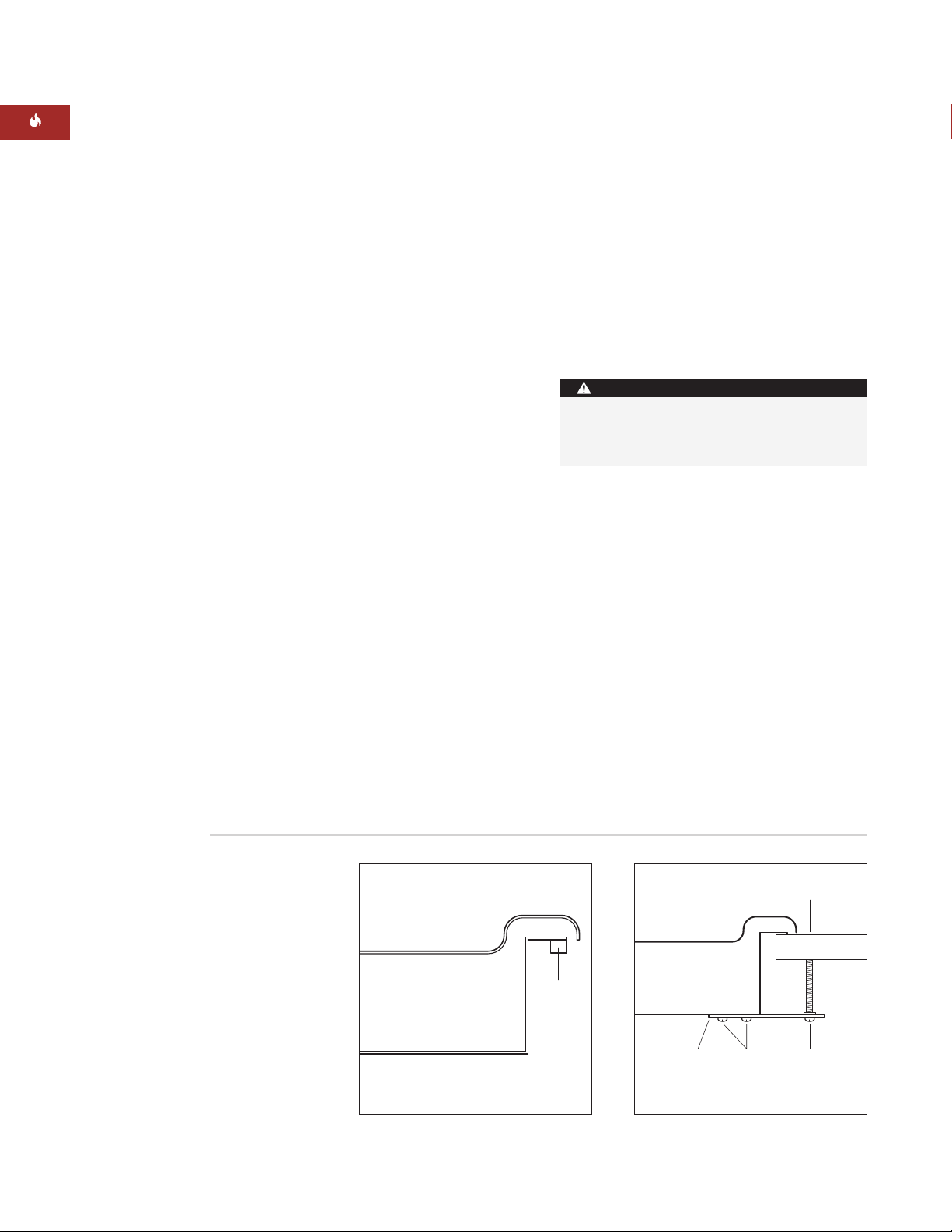

Remove the foam strip from the hardware

package. Apply the foam strip around the

bottom of the burner box flush with the edge

as shown in the illustration below.

Reinsert the cooktop into the countertop

opening. Check that the cooktop is parallel to

the front edge of the countertop. Lift the entire

cooktop to make adjustments and align the

rear edge with the pencil line.

Attach the brackets to the burner box. Insert

the 89 mm clamping screws into the brackets.

Use a screwdriver to tighten the clamping

screws against the underside of the countertop. Refer to the illustration below. Do not

overtighten screws.

GAS LEAK TESTING

Use a brush and liquid detergent to test all gas

connections for leaks. Bubbles around connections will indicate a leak. If a leak appears, shut

off gas valve controls and adjust connections.

Then check connections again. Clean all the

detergent solution from the cooktop.

Cooktop

Burner Box

Foam

Strip

Foam strip application

WOLF GAS COOKTOPS

89 mm

Clamping

Screw

Burner Box

Countertop

Bracket

Screws

Bracket

Bracket installation

Never test for a gas leak with a match or

other flame.

Page 15

15

INSTALLATION INSTRUCTIONS

SURFACE BURNERS

INITIAL LIGHTING

The surface burners use electronic igniters in

place of standing pilots. When the cooktop

control knob is pushed in and turned to the

position, the system creates a spark to

light the burner. This sparking continues until

the electronic ignition senses a flame. If the

burner fails to ignite after 10 seconds, return

the knob to the position and attempt to

ignite by turning the knob back to the

position.

Be sure to place the burner heads and caps on

each burner base and position the burner

grates over the burner bases and heads before

lighting.

To check operation of the surface burners,

push in and turn each control knob to the

position. The flame should light within four

seconds.

If the burners do not light properly, turn

control knob to the position. Check that

the burner heads and caps are in the proper

position. Check that the power supply cord is

plugged in and that the circuit breaker or

house fuse has not blown. Check operation

again, if the burners do not light properly at

this point, contact a Wolf authorized service

center.

IMPORTANT NOTE:

Initial lighting of the

surface burners may take slightly longer, as air

in the system must be purged before gas can

be supplied to the burner.

COOKTOP REMOVAL

If it is necessary to remove the cooktop for

cleaning or service, shut off the gas supply.

Disconnect the gas and electric supply.

Remove the mounting brackets on the right

and left side of the burner box and remove the

cooktop. Reinstall in the reverse order and

check the gas connection for leaks.

TROUBLESHOOTING

IMPORTANT NOTE:

If the cooktop does not

operate properly, follow these troubleshooting

steps:

Verify that power is being supplied to the

cooktop.

Check that gas valves are turned to the ON

position.

Check the gas supply and electrical

connections to ensure that the installation

has been completed correctly.

Follow troubleshooting procedures as

described in the Wolf Gas Cooktops

Use & Care Information.

If the cooktop still does not work, contact

a Wolf authorized service center. Do not

attempt to repair the cooktop yourself. Wolf

is not responsible for service required to

correct a faulty installation.

Page 16

16

CONTACT

INFORMATION

Website:

wolfappliance.com

WOLF GAS COOKTOPS

IF YOU NEED SERVICE

For service in your area, contact either your

Wolf dealer or visit the Showroom Locator

section of our website, wolfappliance.com

to find the regional distributor by country.

When calling for service, you will need the

cooktop model and serial numbers. Both

numbers are listed on the rating plate,

located on the underside of the cooktop.

Refer to the illustration on page 6 for

location of the rating plate.

The information and images in this book are the

copyright property of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. Neither this book nor any

information or images contained herein may be

copied or used in whole or in part without the

express written permission of Wolf Appliance,

Inc.,an affiliate of Sub-Zero, Inc.

©Wolf Appliance, Inc. all rights reserved.

Page 17

17

INSTALLATION INSTRUCTIONS

POWER CORD

FRONT

RIV

GAS VALVE

RED

RED

BLACK

WHITE

GRN/YEL

BLACK

REAR

BLACK

BLACK

WHITE

WHITE

Model ICBCT15G

POWER CORD

WHITE

RIGHT

FRONT

BLACK

RIV

GAS VALVE

RED

RED

RED

RED

WHITE

GRN/YEL

BLACK

RIGHT

REAR

LEFT

REAR

LEFT FRONT

BLACK

WHITE

WHITE

BLACK

LEFT FRONT

POWER CORD

RED

RIV

GAS VALVE

WHITE

BLACK

RIGHT

REAR

LEFT REAR

RIGHT

FRONT

CTR REAR

GRN/YEL

BLACK

RED

RED

RED

BLACK

WHITE

WIRING DIAGRAMS

Model ICBCT30G

Model ICBCT36G

Page 18

Cuando consulte las instrucciones que aparecen en

esta guía, encontrará símbolos de ADVERTENCIA y

PRECAUCIÓN. Esta información en recuadros es

importante para instalar el equipo de Wolf de forma

segura y eficaz. Existen dos tipos de posibles riesgos

que pueden producirse durante una instalación.

Otro tipo de anotación que es importante resaltar es

la que se incluye en NOTA IMPORTANTE: En esta

nota se resalta la información que resulta especialmente importante para que la instalación se realice

sin problemas.

PRECAUCIÓN

indica una situación en la que se pueden sufrir

heridas leves o provocar daños secundarios al

producto si no se siguen las instrucciones.

indica peligro de que se produzcan heridas

personales graves o incluso puede provocar

la muerte si no se siguen las precauciones

especificadas.

WOLF®es una marca comercial registrada de Wolf Appliance, Inc.

INFORMACIÓN

DE CONTACTO

Página Web:

www.subzero.eu.com

Page 19

19

REQUISITOS DE INSTALACIÓN

QUÉ SE DEBE HACER SI HUELE A GAS:

No encienda ningún aparato.

No toque ningún interruptor eléctrico.

No utilice ningún teléfono dentro

del edificio.

Llame inmediatamente a su proveedor

de gas desde el teléfono de un vecino.

Siga las instrucciones que le proporcione el proveedor de gas.

Si no le es posible ponerse en

contacto con el proveedor de gas,

llame a los bomberos.

PLACAS DE GAS DE WOLF

NOTA IMPORTANTE:

La instalación y el mantenimiento

deben ser realizados por un insta-lador

cualificado, por un centro de asistencia

técnica o por el proveedor de gas.

No almacene ni utilice gasolina ni otros

vapores ni líquidos infla-mables cerca

de éste o de otros aparatos.

La utilización de un aparato de cocción

de gas produce calor y vaho en la

habitación en la que está instalado.

Asegúrese que la cocina está bien ventilada; mantenga despejados los agujeros

de ventilación natural o instale un

dispositivo de ventilación mecánico

(campana extractora mecánica).

Si utiliza mucho el aparato y lo hace de

manera prolongada, es posible que

necesite ventilación adicional, por

ejemplo, puede abrir una ventana, o si

quiere que la ventilación sea más eficaz,

aumente el nivel de la ventilación

mecánica, si dispone de ella.

Este aparato debe instalarse de

acuerdo con las normativas vigentes

y sólo puede ser utilizado en un

lugar que esté bien ventilado. Lea las

instrucciones antes de instalar o

utilizar este aparato.

Page 20

20

REQUISITOS DE INSTALACIÓN

NOTA IMPORTANTE: Esta instalación debe ser

realizada por un instalador cualificado, por un

centro de asistencia técnica o por el proveedor

de gas.

NOTA IMPORTANTE:

Guarde estas instrucciones

de instalación para que el inspector local pueda

utilizarlas.

Lea las instrucciones de instalación antes de

llevar a cabo la instalación.

Instalador:

guarde estas instrucciones para que

el inspector local pueda utilizarlas como referencia y, a continuación, entréguelas el propietario

del aparato.

Propietario:

lea y guarde estas instrucciones

para que pueda utilizarlas como referencia en el

futuro y asegúrese de leer la guía de uso y

manteni-miento antes de utilizar el aparato.

NOTA IMPORTANTE:

Este aparato debe instalarse

siguiendo las normativas nacionales correspondientes. Se debe aplicar al aparato el voltaje, la

frecuencia y el amperaje adecuados desde una instalación eléctrica resistente con toma de tierra protegida por un fusible de retardo. El voltaje, la frecuencia y el amperaje se muestran en la placa de datos

del producto.

Apunte la referencia del modelo y el número de

serie antes de instalar el aparato. Esta información

se muestra en la placa de datos del producto situada

en la parte inferior de la placa. Observe la siguiente

ilustración.

ANTES DE COMENZAR

Es responsabilidad del propietario asegurarse de

que la instalación se realiza de manera correcta.

Esta placa debe ser instalada por un técnico cualificado. Debe asegurarse de que la instalación

eléctrica es la correcta y que cumple todos los

códigos y normativas nacionales.

Antes de llevar a cabo la instalación, asegúrese

de que las condiciones de distribución locales

(tipo y presión del gas) y el ajuste del aparato

son compatibles.

Debe disponer de una entrada de suministro de

gas; consulte la sección Requisitos del suministro

de gas en la página 26. También debe disponer de

una conexión eléctrica a tierra; consulte la sección

Requisitos eléctricos en la página 27.

Las condiciones de ajuste de este aparato se

especifican en la etiqueta (o en la placa de datos

del producto). La placa de datos está ubicada en

la parte inferior del aparato.

PLACAS DE GAS DE WOLF

Ubicación de la placa de datos

Ubicación de la placa

de datos debajo

de la placa

INFORMACIÓN

DE LA PLACA

DE DATOS

Referencia del

modelo

Número de serie

Page 21

21

INSTRUCCIONES DE INSTALACIÓN

REQUISITOS DE UBICACIÓN

Las ilustraciones que se incluyen en las páginas

siguientes proporcionan las medidas totales, las

medidas del corte de la encimera y las especificaciones de la instalación de las placas de gas de Wolf.

Mantenga las siguientes medidas de instalación

mínimas:

Distancia horizontal mínima desde los lados y la

parte trasera del corte de la encimera a material

combustible vertical adyacente, extendiéndose

un mínimo de 457 mm por encima de la

encimera, de la siguiente manera: 178 mm

desde los bordes laterales de la cavidad para la

placa de 381 mm; 229 mm desde los bordes

laterales de la cavidad para las placas de 762 mm

y 914 mm; 64 mm para el borde trasero de la

cavidad.

La distancia vertical mínima entre la encimera y

los materiales combustibles situados por encima

de la placa debe ser de 762 mm.

El fondo máximo de los armarios superiores

laterales situados por encima de la placa debe

ser de 330 mm con una distancia lateral mínima.

NOTA IMPORTANTE:

Cuando instale una campana

extractora, consulte los requisitos específicos de la

campana para obtener las medidas mínimas que

debe mantener respecto a la encimera.

ANTES DE COMENZAR

Inspeccione el lugar en el que va a instalar la

placa. El lugar en el que va a instalarla debe estar

alejado de áreas en las que pueda haber corrientes fuertes, por ejemplo, ventanas, puertas

y salidas de aire caliente o ventiladores. No

debe obstruir el flujo de combustión ni el aire

de ventilación.

Este aparato no está conectado a ningún dispositivo de evacuación de productos de combustión.

El aparato debe ser instalado y conectado siguiendo las normativas de instalación vigentes.

Debe prestar especial atención a los requisitos

relevantes correspondientes a la ventilación.

PREPARACIÓN DEL SITIO

DIMENSIONES DE CORTE DE

LA ENCIMERA

NOTA IMPORTANTE:

Se deben utilizar las medidas

de las cavidades de la encimera que se muestran en

la página siguiente. Las medidas que se especifican

mantienen los espacios requeridos.

Esta placa está diseñada para que se adapte a un

armario de base estándar de 610 mm de fondo con

una encimera de 635 mm de fondo. Antes de cortar

la encimera, compruebe que la placa va a quedar

separada de las paredes laterales del armario

inferior. Deberá dejar al menos una distancia de

140 mm entre la encimera y cualquier superficie

combustible que esté justo debajo de la unidad.

NOTA IMPORTANTE:

No selle la placa a la

encimera. Es posible que necesite quitarla para

realizar alguna tarea de mantenimiento.

Si no coloca la placa siguiendo las distancias

de separación correctas, es posible que se

produzca un incendio.

Esta placa está diseñada para que se utilice en

espacios interiores.

Page 22

22

ESPECIFICACIONES DE LA INSTALACIÓN

Las ilustraciones que se muestran a continuación

proporcionan las medidas totales, las medidas de

corte de la encimera y las especificaciones de instalación que corresponden al modelo ICBCT15G.

Para el modelo ICBCT15G, el servicio de gas debe

suministrarse a través del suelo si la placa no se ha

instalado encima de un horno. Consulte la ilustración

para obtener información específica sobre la colocación de la toma de gas y de electricidad.

E

102 mm

G

381 mm

381 mm

381

mm

LA UBICACIÓN DE LA TOMA

DE GAS SE PUEDE EXTENDER

127 mm EN EL SUELO DESDE

LA PARED TRASERA

178 mm* mín

CORTE A LOS

MATERIALES

COMBUSTIBLES

(AMBOS LADOS)

356 mm

ANCHURA DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

356 mm

ANCHURA DE

CORTE DE

LA SUPERFICIE

DE COCCIÓN

838 mm ANCHO DEL ARMARIO

RECOMENDADO

457 mm

NOTA: La aplicación que se muestra permite la instalación de dos módulos contiguos de 381 mm con un armario con una anchura recomendada de 838 mm.

457 mm de anchura de armario recomendada para la instalación de un solo módulo o superficie de cocción de 381 mm. *Espacio mínimo desde ambos bordes

laterales del corte de la superficie de cocción hasta la superficie inflamable situada a 457 mm por encima de la encimera. **Espacio mínimo desde el borde

trasero del corte de la superficie de cocción a la superficie inflamable situada a 457 mm sobre la encimera.

489 mm

FONDO DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

64 mm

mín

914 mm

ALTURA

ESTÁNDAR

DEL SUELO

A LA ENCIMERA

330 mm

máx

762 mm

ENCIMERA A

SUPERFICIE

INFLAMABLE SOBRE

LA SUPERFICIE

DE COCCIÓN

64**

mm

127

mm

LA UBICACIÓN DE LA TOMA

DE GAS SE PUEDE EXTENDER

127 mm EN EL SUELO DESDE

LA PARED TRASERA

PARTE DELANTERA DE LA ENCIMERA

64 mm

mín

489 mm

FONDO DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

PLACAS DE GAS DE WOLF

Medidas totales

Corte de la encimera

381 mm

ANCHURA TOTAL

533 mm

FONDO

TOTAL

102 mm

MODELO ICBCT15G

MEDIDAS

Anchura total 381 mm

Altura total 102 mm

Fondo total 533 mm

Anchura del armario

recomendada 838 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura 102 mm

Ancho del corte 356 mm

Fondo del corte 489 mm

Las dimensiones de la unidad pueden

variar ±3 mm.

ESPECIFICACIONES DE LA INSTALACIÓN – MODELO ICBCT15G

NOTA IMPORTANTE:

Cuando instale varias placas

juntas, consulte las dimensiones de corte de la

encimera en la página 25.

Page 23

23

INSTRUCCIONES DE LA INSTALACIÓN

229 mm*mín

CORTE A LOS

MATERIALES

COMBUSTIBLES

(AMBOS LADOS)

457 mm

489 mm

FONDO DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

914 mm

ALTURA

ESTÁNDAR DEL

SUELO A

LA ENCIMERA

330 mm

máx

762 mm

ENCIMERA A

SUPERFICIE

INFLAMABLE SOBRE

LA SUPERFICIE

DE COCCIÓN

610 mm mín

*Espacio mínimo desde ambos bordes laterales del corte de la superficie de cocción hasta la superficie inflamable situada a 457 mm por encima de la encimera.

**Espacio mínimo desde el borde trasero del corte de la superficie de cocción a la superficie inflamable situada a 457 mm sobre la encimera.

102 mm

254

mm

89 mm

E

95 mm

mín

G

762 mm APERTURA DEL HORNO

737 mm ANCHURA DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

737 mm

ANCHURA DE CORTE DE LA

SUPERFICIE DE COCCIÓN

PARTE DELANTERA DE LA ENCIMERA

64 mm

mín

489 mm

FONDO DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

838 mm ANCHO DEL ARMARIO

RECOMENDADO

762 mm mín

64**

mm

64 mm

mín

Medidas totales

Corte de la encimera

533 mm

FONDO

TOTAL

762 mm

ANCHURA TOTAL

102 mm

ESPECIFICACIONES DE LA INSTALACIÓN

Las ilustraciones que se muestran a continuación

proporcionan las medidas totales, las medidas de

corte de la encimera y las especificaciones de instalación que corresponden al modelo ICBCT30G.

NOTA IMPORTANTE:

Para la instalación del modelo

ICBCT30G se recomienda utilizar armarios con un

ancho de 838 mm.

Se puede instalar un horno integrable sencillo de

762 mm debajo del modelo ICBCT30G. Para esta

instalación, a menos que vaya a utilizar armarios

con un fondo superior a 610 mm, se recomienda que

la toma eléctrica y de gas se coloque en un armario

base situado a la derecha del horno. Consulte las

instrucciones de instalación que se proporcionan con

el horno integrable para obtener más información.

Si instala el modelo ICBCT30G encima de los

armarios, la colocación de la toma eléctrica y de gas

no es importante. Es necesario colocar una toma de

corriente conectada a tierra a una distancia de 1,2 m

de la parte trasera derecha de la placa.

NOTA IMPORTANTE:

Cuando instalen varias placas

juntas, consulte las dimensiones de corte de la

encimera en la página 25.

MODELO ICBCT30G

MEDIDAS

Anchura total 762 mm

Altura total 102 mm

Fondo total 533 mm

Anchura del armario

recomendada 838 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura 102 mm

Ancho del corte 737 mm

Fondo del corte 489 mm

Las dimensiones de la unidad pueden

variar ±3 mm.

ESPECIFICACIONES DE LA INSTALACIÓN – MODELO ICBCT30G

Page 24

24

PLACAS DE GAS DE WOLF

ESPECIFICACIONES DE LA INSTALACIÓN

Las ilustraciones que se muestran a continuación

proporcionan las medidas totales, las medidas de

corte de la encimera y las especificaciones de instalación que corresponden al modelo ICBCT36G.

NOTA IMPORTANTE:

Para la instalación del modelo

ICBCT36G se recomienda utilizar armarios con un

ancho de 991 mm.

Se puede instalar un horno integrable sencillo de

914 mm debajo del modelo ICBCT36G. Para esta

instalación, a menos que vaya a utilizar armarios

con un fondo superior a 610 mm, se recomienda que

la toma eléctrica y de gas se coloque en un armario

base situado a la derecha del horno. Consulte las

instrucciones de instalación que se proporcionan con

el horno integrable para obtener más información.

Si instala el modelo ICBCT36G encima de los

armarios, la colocación de la toma eléctrica y de gas

no es importante. Es necesario colocar una toma de

corriente conectada a tierra a una distancia de 1,2 m

de la parte trasera derecha de la placa.

Cuando instale un horno integrable de 914 mm

debajo de la placa modelo ICBCT36G, se recomienda

que la cavidad del horno tenga un espacio de

197 mm desde el suelo para facilitar la apertura

y cierre de la puerta del horno.

NOTA IMPORTANTE:

Cuando instalen varias placas

juntas, consulte las dimensiones de corte de la

encimera en la página 25.

229 mm*mín

CORTE A LOS

MATERIALES

COMBUSTIBLES

(AMBOS LADOS)

457 mm

489 mm

FONDO DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

914 mm

ALTURA

ESTÁNDAR

DEL SUELO A

LA ENCIMERA

330 mm

máx

762 mm

ENCIMERA A

SUPERFICIE

INFLAMABLE SOBRE

LA SUPERFICIE

DE COCCIÓN

610 mm mín

*Espacio mínimo desde ambos bordes laterales del corte de la superficie de cocción hasta la superficie inflamable situada a 457 mm por encima de la encimera.

**Espacio mínimo desde el borde trasero del corte de la superficie de cocción a la superficie inflamable situada a 457 mm sobre la encimera.

889 mm

ANCHURA DE CORTE DE LA SUPERFICIE

DE COCCIÓN

889 mm

ANCHURA DE CORTE DE LA

SUPERFICIE DE COCCIÓN

991 mm

ANCHO DEL ARMARIO RECOMENDADO

914 mm mín

102 mm

254

mm

89 mm

E

G

914 mm APERTURA DEL HORNO

95 mm

mín

64 mm

mín

PARTE DELANTERA DE LA ENCIMERA

489 mm

FONDO DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

64**

mm

64 mm

mín

Medidas totales

Corte de la encimera

533 mm

FONDO

TOTAL

914 mm

ANCHURA TOTAL

102 mm

MODELO ICBCT36G

MEDIDAS

Anchura total 914 mm

Altura total 102 mm

Fondo total 533 mm

Anchura del armario

recomendada 991 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura 102 mm

Ancho del corte 889 mm

Fondo del corte 489 mm

Las dimensiones de la unidad pueden

variar ±3 mm.

ESPECIFICACIONES DE LA INSTALACIÓN – MODELO ICBCT36G

Page 25

25

INSTRUCCIONES DE INSTALACIÓN

OPCIONES DE INSTALACIÓN

INSTALACIÓN DE VARIAS SUPERFICIES

DE COCCIÓN

Si la placa de gas se va a utilizar con otras combinaciones de módulos o unidades de cocción

adicionales con un embellecedor, el ancho del corte

se calcula sumando las medidas de corte de las

unidades correspondientes más 32 mm por cada

unidad adicional. Observe la siguiente ilustración.

NOTA IMPORTANTE:

Cuando se instalen varias

unidades juntas, cada unidad debe tener su propio

circuito eléctrico recomendado.

Cuando se instalen dos o más módulos juntos, se

recomienda utilizar un embellecedor de módulo

integrado (IFILLER/S). Póngase en contacto con su

distribuidor de Wolf para obtener información sobre

estos accesorios.

64 mm

mín

PARTE DELANTERA DE LA ENCIMERA

489 mm

FONDO

DEL CORTE

743 mm

ANCHURA DE DOS MÓDULOS

1130 mm – ANCHURA DE TRES MÓDULOS Ó

1124 mm – 762 mm SUPERFICIE DE COCCIÓN Y UN MÓDULO

1518 mm – ANCHURA DE CUATRO MÓDULOS O

1511 mm – 762 mm SUPERFICIE DE COCCIÓN Y DOS MÓDULOS Ó

1276 mm – 914 mm SUPERFICIE DE COCCIÓN Y UN MÓDULO

356 mm

ANCHURA

DEL CORTE

Dimensiones de corte de la encimera para la instalación de otras superficies

de cocción

INSTALACIONES

OPCIONALES

Las medidas pueden

variar dependiendo

de cada instalación.

Page 26

26

PLACAS DE GAS DE WOLF

NOTA IMPORTANTE:

La placa de gas debe conec-

tarse a un suministro de gas regulado.

NOTA IMPORTANTE:

Esta instalación debe cumplir

las ordenanzas y normativas nacionales.

NOTA IMPORTANTE:

La placa de gas natural está

aprobada para que se pueda utilizar en altitudes

de hasta 2438 m sin ajustes. Debe instalar un kit

de altitud para alturas que oscilen entre 2438 m y

3084 m. La placa de gas LP está aprobada para que

se utilice en altitudes de hasta 3084 m.

La placa de datos, situada en la parte inferior de la

cámara de combustión, incluye información sobre el

tipo de gas que debe utilizar. Si esta información no

coincide con el tipo de gas que tiene disponible,

póngase en contacto con su proveedor de gas.

PELIGRO DE EXPLOSIÓN—

Apriete de manera segura todas

las conexiones de gas externas.

Si no lo hace, es posible que se produzca una

explosión, un incendio o incluso la muerte.

REQUISITOS DEL SUMINISTRO DE GAS

Deberá facilitar un tubo rígido de 19 mm para la

línea de suministro de gas que llegue hasta la

ubicación de la placa. Si el tubo tiene un tamaño

inferior, es posible que el suministro de gas sea

insuficiente. Debe utilizar una pasta de recubrimiento

para tuberías que sea adecuada para que se pueda

utilizar con gas LP. Para gas LP, el tubo puede tener

un mínimo de 13 mm. Los proveedores de gas LP

normalmente determinan el tamaño y los materiales

que se utilizan en el sistema.

Si la normativa nacional lo permite, se recomienda

utilizar un conector metálico flexible para conectar

la placa al suministro de gas. Tenga cuidado de no

dañar ni doblar el conector flexible cuando mueva la

placa de gas. Deberá determinar las conexiones que

son necesarias dependiendo del tamaño de la línea

de gas, del conector flexible de metal y de la válvula

de cierre.

Si utiliza un tubo rígido como línea de suministro,

debe utilizar una combinación de empalmes de

tubos para obtener una conexión en línea con la

placa. Debe eliminar todas las deformaciones que

haya en las líneas del suministro de gas para que la

placa quede nivelada y en línea.

NOTA

IMPORTANTE:

Esta instalación debe

cumplir las ordenanzas y normativas

nacionales.

SUMINISTRO DE GAS

Salida de Potencia Tipos y

calor total Unidades eléctrica Categoría presiones

Modelo (Gas) de gas (Vatios) del aparato (mbar) País de destino

I2H G20 a 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT15G/S 6,8 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 a 20 DE, PL

I2E+ G20 a 20/25 BE, FR

ICBCT15G/S-LP 494 g/h 230 I3P G31 a 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

I2H G20 a 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT30G/S 14,7 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 a 20 DE, PL

I2E+ G20 a 20/25 BE, FR

ICBCT30G/S-LP 1069 g/h 230 I3P G31 a 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

I2H G20 a 20

AT, DK, EE, FI, GR, IE, IT, LT,

ICBCT36G/S 17,7 kW 230

NO, PT, ES, SE, SI, SK, GB, CH

I2E G20 a 20 DE, PL

I2E+ G20 a 20/25 BE, FR

ICBCT36G/S-LP 1287 g/h 230 I3P G31 a 37

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

Page 27

27

INSTRUCCIONES DE INSTALACIÓN

REQUISITOS ELÉCTRICOS

PELIGRO DE DESCARGA ELÉCTRICA—

Enchufe el aparato en un adaptador de 3

clavijas conectado a tierra.

No quite la clavija de conexión a tierra.

No utilice un adaptador.

Si no sigue estas instrucciones, existe riesgo

de que se produzca un incendio, una descarga

eléctrica o incluso la muerte.

MÉTODO DE CONEXIÓN A TIERRA

RECOMENDADO

NOTA IMPORTANTE:

Por su seguridad personal,

esta placa debe estar conectada a tierra. Esta placa

viene equipada con un enchufe de toma a tierra de

3 clavijas. Para reducir el riesgo de sufrir posibles

descargas eléctricas, el cable debe estar enchufado

a una toma de tres clavijas con conexión a tierra,

conectada a tierra de acuerdo a los códigos y normativas nacionales. Si no dispone de una toma de corriente, el cliente debe solicitar a un electricista cualificado que instale una toma de 3 clavijas que esté

conectada a tierra de manera correcta.

NOTA IMPORTANTE:

Si el producto está conectado

a una toma protegida con un GFCI (interruptor del

circuito de fallos de conexión a tierra), es posible

que se produzca un corte de luz por lo que el

aparato dejará de funcionar.

CUADRO DE CONEXIONES

En la página 31 puede consultar un cuadro de conexiones correspondiente al circuito de control del

modelo de la placa de Wolf.

NOTA IMPORTANTE:

Si las normativas lo permiten

y utiliza un cable de conexión a tierra independiente,

se recomienda que un electricista cualificado determine si la trayectoria a tierra es la adecuada.

NOTA IMPORTANTE:

Si no está seguro de si la

placa está conectada a tierra de manera correcta,

pida a un electricista que lo compruebe.

NOTA IMPORTANTE:

No conecte a tierra a una

tubería de gas.

Es necesario que la potencia eléctrica sea de 220240 V CA, 50/60 Hz con fusible. Se recomienda

utilizar un cortacircuitos o fusible. Se recomienda

disponer de un circuito independiente que preste

servicio sólo a este aparato.

Los sistemas de encendido electrónico funcionan

dentro de unos límites de voltaje amplios; sin

embargo es necesario que la conexión a tierra y la

polaridad sean los adecuados. Además de comprobar que la toma suministra una potencia de 220240 V CA y asegurarse de que está conectada a tierra

de manera correcta, un electricista cualificado debe

inspeccionar la toma para comprobar si está conectada con la polaridad correcta. La documentación

que se proporciona incluye un diagrama de

conexiones.

Este aparato, cuando esté instalado, debe estar

conectado a tierra eléctricamente siguiendo las

normativas nacionales correspondientes.

Page 28

28

INSTALACIÓN DE LA PLACA

Desembale la placa, las rejillas del quemador y los

cabezales del quemador.

Inserte la placa en la cavidad de la encimera en la

que la va a instalar. Centre la placa en la cavidad y

asegúrese de que el borde delantero de la placa se

coloca en paralelo al borde delantero de la encimera.

Compruebe que se han dejado los espacios mínimos

requeridos. Utilice un lápiz para delimitar el borde

trasero de la placa en la encimera. Retire la placa de

la cavidad de la encimera.

NOTA IMPORTANTE:

Cuando coloque de nuevo la

placa en la cavidad del corte de la encimera, levante

toda la placa para evitar que la encimera se raye.

Saque el embellecedor del paquete de accesorios.

Coloque el embellecedor alrededor de la parte

inferior de la cámara de combustión y asegúrese

de que queda bien nivelado con el borde tal y

como se muestra en la ilustración que aparece a

continuación.

Coloque la placa de nuevo en la cavidad de la

encimera. Compruebe que la placa está colocada en

paralelo al borde delantero de la encimera. Levante

toda la placa para realizar los ajustes necesarios y

alinee el borde trasero con la línea que ha dibujado

antes.

Coloque los soportes en la cámara de combustión.

Inserte los tornillos de sujeción de 89 mm en los

soportes. Utilice un destornillador para apretar

los tornillos de sujeción a la parte inferior de la

encimera. Observe la siguiente ilustración.

No apriete los tornillos demasiado.

PRUEBA DE FUGA DE GAS

Utilice un cepillo y detergente líquido para comprobar si la conexiones de gas presentan fugas. Si

aparecen burbujas alrededor de las conexiones

significa que existe una fuga. Si aparece una fuga,

apague los controles de la válvula de cierre de gas y

ajuste las conexiones. A continuación, compruebe

las conexiones de nuevo. Limpie los restos de detergente que hayan quedado en la placa.

Cámara de combustión

de la placa

Embellecedor

Colocación del embellecedor

PLACAS DE GAS DE WOLF

Tornillo de

sujeción

de 89 mm

Cámara de combustión

Encimera

Tornillos

del soporte

Soporte

Instalación de los soportes

No compruebe nunca si existe una fuga de gas

utilizando una cerilla o cualquier otro tipo de

Page 29

29

INSTRUCCIONES DE INSTALACIÓN

QUEMADORES DE SUPERFICIE

ENCENDIDO INICIAL

Los quemadores de superficie utilizan encendedores

electrónicos en lugar de pilotos permanentes.

Cuando pulse el mando de la placa y lo gire hasta

la posición , el sistema produce una chispa

que enciende el quemador. Esta chispa se mantiene

hasta que el encendido electrónico detecta

una llama. Si el quemador no se enciende en

10 segundos, coloque de nuevo el mando en

la posición e intente encenderlo girando

el mando de nuevo hasta la posición .

Asegúrese de colocar los cabezales en cada una de

las bases de los quemadores y coloque las rejillas

de los quemadores sobre las bases y los cabezales

de los quemadores antes de encenderlos.

Para comprobar que los quemadores de superficie

funcionan, presione los mandos y gírelos hasta la

posición . La llama debería prenderse en cuatro

segundos.

Si los quemadores no se encienden de manera

correcta, gire el mando hasta la posición .

Compruebe que los cabezales del quemador están

colocados de manera correcta. Compruebe que el

cable eléctrico está conectado y que el cortacircuitos

o fusible no están fundidos. Vuelva a comprobar si

los quemadores funcionan; si no se encienden de

manera correcta, póngase en contacto con un centro

de asistencia técnica autorizado de Wolf.

NOTA IMPORTANTE:

Es posible que la primera vez

que encienda los quemadores de superficie tarden

más tiempo ya que el aire del sistema debe purgarse

antes para que el gas pueda llegar al quemador.

EXTRACCIÓN DE LA PLACA

Si necesita extraer la placa para limpiarla o para

realizar alguna tarea de mantenimiento, cierre el

suministro de gas. Cierre el gas y desconecte el

suministro eléctrico. Quite los soportes de montaje

situados en los laterales derecho e izquierdo de la

cámara de combustión y extraiga la placa. Vuelva a

instalarla en orden invertido y compruebe si existe

alguna fuga en la conexión de gas.

SOLUCIÓN DE PROBLEMAS

NOTA IMPORTANTE:

Si la placa no funciona correctamente, siga estos pasos de localización y solución

de problemas:

Compruebe que la placa está conectada a la

red eléctrica.

Compruebe que las válvulas de gas están en

la posición ON.

Compruebe el suministro de gas y las conexiones eléctricas para asegurarse de que la instalación se ha llevado a cabo de manera correcta.

Realice los procedimientos de solución de problemas tal y como se describe en la guía de uso y

mantenimiento de la placa de gas de Wolf.

Si la placa sigue sin funcionar, póngase en

contacto con un centro de asistencia técnica

autorizado de Wolf. No intente realizar usted

mismo ninguna reparación en la placa. Wolf no

se hace responsable de las tareas de mantenimiento que deban realizarse para corregir una

instalación defectuosa.

Page 30

30

INFORMACIÓN

DE CONTACTO

Página Web:

www.subzero.eu.com

PLACAS DE GAS DE WOLF

SI NECESITA ASISTENCIA TÉCNICA

Para buscar el servicio técnico más cercano,

póngase en contacto con su distribuidor de Wolf

o visite la página Web, www.sub-zero.eu.com,

para buscar el distribuidor más cercano.

Cuando solicite asistencia técnica, deberá tener

localizado el número de serie y el modelo de la

placa de gas. Esta información se muestra en la

placa de datos del producto situada en la parte

inferior de la placa. Consulte la ilustración de la

página 20 para ubicar la placa de datos.

La información y las imágenes que se incluyen en esta

guía son propiedad de Wolf Appliance, Inc., una filial de

Sub-Zero, Inc. Este documento junto con la información y

las imágenes que en él se incluyen no pueden copiarse ni

utilizarse, total ni parcialmente, sin el consentimiento por

escrito de Wolf Appliance, Inc., una filial de Sub-Zero, Inc.

©Wolf Appliance, Inc. se reserva todos los derechos.

Page 31

31

INSTRUCCIONES DE INSTALACIÓN

CABLE ELÉCTRICO

DELANTERO

RIV

(REENCENDIDO

CON CONTROL

DE VÁLVULA DEL

ENCENDEDOR)

VÁLVULA DE GAS

ROJO

ROJO

NEGRO

BLANCO

VERDE/AMARILLO

NEGRO

TRASERO

NEGRO

NEGRO

BLANCO

BLANCO

Modelo ICBCT15G

CABLE ELÉCTRICO

BLANCO

DELANTERO

DERECHO

NEGRO

VÁLVULA DE GAS

ROJO

ROJO

ROJO

ROJO

BLANCO

VERDE/AMARILLO

NEGRO

TRASERO

DERECHO

TRASERO

IZQUIERDO

DELANTERO IZQUIERDO

NEGRO

BLANCO

RIV

(REENCENDIDO

CON CONTROL

DE VÁLVULA DEL

ENCENDEDOR)

BLANCO

NEGRO

DELANTERO IZQUIERDO

CABLE ELÉCTRICO

ROJO

VÁLVULA DE GAS

BLANCO

NEGRO

TRASERO

DERECHO

TRASERO IZQUIERDO

DELANTERO

DERECHO

CENTRAL TRASERO

VERDE/AMARILLO

NEGRO

ROJO

ROJO

ROJO

NEGRO

BLANCO

RIV

(REENCENDIDO

CON CONTROL

DE VÁLVULA DEL

ENCENDEDOR)

CUADRO DE CONEXIONES

Modelo ICBCT30G

Modelo ICBCT36G

Page 32

Vous remarquerez tout au long de ce manuel

d’instructions les mentions AVERTISSEMENT et

MISE EN GARDE, destinées à fournir des recommandations importantes afin d’assurer la sécurité et l’efficacité de l’installation de l’équipement Wolf. Deux

types de dangers potentiels peuvent se présenter

pendant l’installation.

De plus, la mention REMARQUE IMPORTANTE

met l’accent sur un renseignement particulièrement

important pour assurer une installation parfaite.

signale un danger qui pourrait causer une

blessure mineure ou endommager le produit

si vous ne suivez pas les instructions.

signale un danger qui pourrait causer des

blessures graves voire fatales si vous ne prenez

pas certaines précautions.

WOLF®est une marque déposée de Wolf Appliance, Inc.

CONTACT

Site Internet :

wolfappliance.com

Page 33

33

EXIGENCES RELATIVES A

L’INSTALLATION

CE QUE VOUS DEVEZ FAIRE SI VOUS

PERCEVEZ UNE ODEUR DE GAZ :

Ne mettez en marche aucun appareil

ménager.

Ne touchez à aucun interrupteur

électrique.

N’utilisez aucun téléphone de votre

immeuble.

Téléphonez immédiatement à votre

fournisseur de gaz de chez un voisin.

Suivez les instructions du fournisseur

de gaz.

Si vous ne pouvez pas joindre votre

fournisseur de gaz, contactez le service

incendie.

PLAQUES DE CUISSON AU GAZ WOLF

REMARQUE IMPORTANTE :

L’installation et l’entretien doivent être

exécutés par un poseur qualifié, une

antenne technique ou un fournisseur

de gaz.

N’entreposez pas ou n’utilisez pas

d’essence ou autres produits ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil

ménager.

L’utilisation d’un appareil de cuisson

au gaz produit de la chaleur et de

l’humidité dans la pièce où il est installé.

Assurez-vous que la cuisine est bien

ventilée ; maintenez les ouvertures de

ventilation naturelle ouvertes ou

installez un appareil de ventilation

mécanique Wolf (hotte d’extraction

mécanique).

L’utilisation intensive et prolongée de

l’appareil peut exiger une ventilation

supplémentaire, par exemple l’ouverture

d’une fenêtre, ou d’une ventilation plus

efficace, notamment l’augmentation

de la puissance de la ventilation

mécanique, le cas échéant.

Cet appareil ménager doit être

installé conformément aux règlements en vigueur et utilisé uniquement dans un endroit bien ventilé.

Lisez toutes les instructions avant

d’installer ou d’utiliser cet appareil.

Page 34

34

EXIGENCES RELATIVES A

L’INSTALLATION

REMARQUE IMPORTANTE : L’installation doit

être effectuée par un poseur qualifié, une

antenne technique ou un fournisseur de gaz.

REMARQUE IMPORTANTE :

Conservez ces instruc-

tions d’installation pour le technicien local.

Veuillez lire les instructions d’installation dans

leur intégralité avant de procéder à l’installation.

Poseur :

Veuillez conserver ces instructions afin

que le technicien puisse s’y reporter, puis laissezles au propriétaire.

Propriétaire :

Veuillez lire et garder ces instructions pour pouvoir vous y reporter ultérieurement et assurez-vous de lire le Guide d’utilisation

et d’entretien dans son intégralité avant d’utiliser

votre appareil.

REMARQUE IMPORTANTE :

Cet appareil ménager

doit être installé conformément aux codes locaux.

La tension, la fréquence et l’ampérage appropriés

doivent être fournis à cet appareil à partir d’un

circuit spécial, mis à la terre et protégé par un

disjoncteur ou un fusible à fusion temporisée adapté

à l’intensité de courant requise. La tension, la

fréquence et l’ampérage requis sont indiqués sur

la plaque des caractéristiques du produit.

Consignez les numéros de modèle et de série avant

d’installer la plaque de cuisson. Ces deux numéros

figurent sur la plaque des caractéristiques du produit

située sur le dessous de la plaque de cuisson.

Reportez-vous à l’illustration ci-après.

AVANT DE COMMENCER

L’installation correcte de votre appareil vous

incombe. Demandez à un poseur qualifié

d’installer cette plaque de cuisson. Vous devez

également vous assurer que l’installation

électrique est adéquate et conforme à tous

les codes et ordonnances locaux.

Avant l’installation, assurez-vous que l’appareil

ménager est réglé conformément aux conditions

de distribution locales (nature et pression du

gaz).

Un raccordement d’alimentation en gaz approprié doit être disponible ; reportez-vous à la

rubrique Configuration de l’alimentation en gaz,

page 40. De plus, une mise à la terre électrique

est également requise ; reportez-vous à la

rubrique Configuration électrique, page 41.

Les conditions de réglage de cet appareil

ménager sont indiquées sur l’étiquette (ou

plaque des caractéristiques). La plaque des

caractéristiques se trouve sur le dessous de

la plaque de cuisson.

PLAQUES DE CUISSON AU GAZ WOLF

Emplacement de la plaque des

caractéristiques

Emplacement de la plaque

des caractéristiques sous

la plaque de cuisson

INFORMATIONS

FIGURANT SUR

LA PLAQUE DES

CARACTERISTIQUES

Numéro de modèle

Numéro de série

Page 35

35

INSTRUCTIONS D’INSTALLATION

EXIGENCES RELATIVES A L’EMPLACEMENT

Les illustrations figurant aux pages suivantes fournissent les dimensions hors tout, ainsi que les

précisions sur les découpes du plan de travail et

sur l’installation des plaques de cuisson au gaz Wolf.

Observez les dimensions d’installation minimums

suivantes :

Dimensions du dégagement horizontal minimum

des deux côtés et de l'arrière de la découpe pour

la plaque de cuisson jusqu'à la construction

combustible verticale adjacente, qui se prolonge

d'au moins 457 mm au-dessus du plan de travail :

178 mm des bords latéraux de la découpe pour

les plaques de cuisson de 381 mm et 229 mm

pour les plaques de cuisson de 762 mm et de

914 mm; prévoir également 64 mm du bord

arrière de la découpe.

La distance verticale minimum entre le plan de

travail et les matériaux combustibles au-dessus

de la plaque de cuisson doit être de 762 mm.

La profondeur maximum des éléments de cuisine

latéraux supérieurs se trouvant directement

au-dessus, dans le dégagement latéral sera de

330 mm.

REMARQUE IMPORTANTE :

Lors de l’installation

d’une hotte de ventilation, reportez-vous aux

exigences spécifiques de la hotte pour obtenir

la distance minimum jusqu’au plan de travail.

AVANT DE COMMENCER

Vérifiez l’endroit où la plaque de cuisson sera

installée. Il devrait être à l’abri des forts courants

d’air et à l’écart des fenêtres, des portes et des

puissants tuyaux de chauffage ou ventilateurs.

N’obturez pas le passage de l’écoulement de l’air

et de la combustion.

Cet appareil n’est pas branché à un dispositif

d’évacuation de produits de combustion. L’appareil doit être installé et branché conformément

aux règlements d’installation actuellement en

vigueur. Les exigences pertinentes relatives à

la ventilation doivent être rigoureusement

observées.

PREPARATION DE L’EMPLACEMENT

DIMENSIONS DE LA DECOUPE DU PLAN

DE TRAVAIL

REMARQUE IMPORTANTE :

Vous devez utiliser les

dimensions de découpe du plan de travail fournies

dans les pages suivantes. Ces dimensions précisent

les dégagements requis.

Ces plaques de cuisson sont conçues pour s’adapter

à un élément de cuisine inférieur de profondeur

standard de 610 mm dans un plan de travail de

635 mm de profondeur. Avant d’effectuer la découpe

dans le plan de travail, assurez-vous que la plaque

de cuisson ne touchera pas les côtés de l’élément

de cuisine inférieur. Un dégagement d’au moins

140 mm devrait être prévu entre le plan de travail et

toute surface combustible située directement sous

l’appareil.

REMARQUE IMPORTANTE :

Ne scellez pas la

plaque de cuisson au plan de travail. Elle devra

pouvoir être retirée si une réparation est nécessaire.

Le non-respect des exigences de dégagement

lors de la mise en place de la plaque de

cuisson entraîne des risques d’incendie.

Cette plaque de cuisson est réservée à un

usage intérieur.

Page 36

36

SPECIFICATIONS D’INSTALLATION

Les illustrations ci-dessous fournissent les dimensions hors tout, les spécifications d’installation et

les dimensions des découpes du plan de travail

pour le modèle ICBCT15G.

Avec le modèle ICBCT15G, l’alimentation en gaz peut

être acheminée par le sol si la plaque de cuisson

n’est pas installée au-dessus d’un four. Pour plus de

précisions sur l’emplacement des raccordements de

gaz et d’électricité, reportez-vous à l’illustration.

E

102 mm

G

381 mm

381 mm

381

mm

L’EMPLACEMENT DE L’ALIMENTATION

EN GAZ PEUT AUSSI SE PROLONGER

DE 127 mm SUR LE SOL A PARTIR

DU MUR ARRIERE

178 mm*min.

DECOUPE

JUSQU’AUX

MATERIAUX

COMBUSTIBLES

(DES DEUX COTES)

356 mm

LARGEUR DE LA DECOUPE

DE LA PLAQUE

DE CUISSON

356 mm

LARGEUR DE

LA DECOUPE DE

LA PLAQUE

DE CUISSON

838 mm LARGEUR D’ELEMENT

DE CUISINE RECOMMANDEE

457 mm

REMARQUE : L’installation illustrée autorise la pose de deux dominos de 381 mm côte à côte avec une largeur d’élément de cuisine recommandée de 838 mm.

La largeur d’élément de cuisine recommandée est de 457 mm pour l’installation d’une seule plaque de cuisson ou d’un seul domino de 381 mm. *Dégagement

minimum des bords des deux côtés de la découpe de la plaque de cuisson aux matériaux combustibles : jusqu’à 457 mm au-dessus du plan de travail.

**Dégagement minimum du bord arrière de la découpe de la plaque de cuisson aux matériaux combustibles : jusqu’à 457 mm au-dessus du plan de travail.

489 mm

PROFONDEUR DE

LA DECOUPE DE LA

PLAQUE DE CUISSON

64 mm

min.

914 mm

HAUTEUR

STANDARD

DU SOL AU

PLAN DE TRAVAIL

330 mm

max.

762 mm

DU PLAN DE TRAVAIL

AUX MATERIAUX

COMBUSTIBLES

AU-DESSUS DE LA

PLAQUE DE CUISSON

64**

mm

127

mm

L’EMPLACEMENT DE

L’ALIMENTATION EN GAZ

PEUT AUSSI SE PROLONGER

DE 127 mm SUR LE SOL A

PARTIR DU MUR ARRIERE

FACADE DU PLAN DE TRAVAIL

64 mm

min.

489 mm

PROFONDEUR DE LA

DECOUPE DE LA

PLAQUE DE CUISSON

PLAQUES DE CUISSON AU GAZ WOLF

Dimensions hors-tout

Découpe dans le plan de travail

381 mm

LARGEUR

HORS TOUT

533 mm

PROFONDEUR

HORS TOUT

102 mm

MODELE ICBCT15G

DIMENSIONS

Largeur hors tout 381 mm

Hauteur hors tout 102 mm

Profondeur hors tout 533 mm

Largeur d’élément

de cuisine recommandée 838 mm

Profondeur minimum

de l’élément de cuisine 578 mm

Dégagement minimum

en hauteur 102 mm

Largeur de la découpe 356 mm

Profondeur de la découpe 489 mm

Les dimensions de l’appareil

peuvent varier de ±3 mm.

SPECIFICATIONS D’INSTALLATION MODELE ICBCT15G

REMARQUE IMPORTANTE :

Si de multiples plaques

de cuisson sont installées côte à côte, reportez-vous à

la page 39 pour obtenir les dimensions des découpes

du plan de travail.

Page 37

37

INSTRUCTIONS D’INSTALLATION

229 mm*min.

DECOUPE

JUSQU’AUX

MATERIAUX

COMBUSTIBLES

(DES DEUX COTES)

457 mm

489 mm

PROFONDEUR DE

LA DECOUPE DE

LA PLAQUE

DE CUISSON

914 mm

HAUTEUR

STANDARD DU

SOL AU PLAN

DE TRAVAIL

330 mm

max.

762 mm

DU PLAN DE TRAVAIL

AUX MATERIAUX

COMBUSTIBLES

AU-DESSUS

DE LA PLAQUE

DE CUISSON

610 mm min.

*Dégagement minimum des bords des deux côtés de la découpe de la plaque de cuisson aux matériaux combustibles : jusqu’à 457 mm au-dessus du plan de travail.

**Dégagement minimum du bord arrière de la découpe de la plaque de cuisson aux matériaux combustibles : jusqu’à 457 mm au-dessus du plan de travail.

102 mm

254

mm

89 mm

E

95 mm

min.

G

762 mm OUVERTURE DU FOUR

737 mm LARGEUR DE

LA DECOUPE DE

LA PLAQUE DE CUISSON

737 mm

LARGEUR DE LA DECOUPE

DE LA PLAQUE DE CUISSON

FACADE DU PLAN DE TRAVAIL

64 mm

min.

489 mm

PROFONDEUR DE LA

DECOUPE DE LA

PLAQUE DE CUISSON

838 mm LARGEUR D’ELEMENT

DE CUISINE RECOMMANDEE

762 mm min.

64**

mm

64 mm

min.

Dimensions hors-tout

Découpe dans le plan de travail

533 mm

PROFONDEUR

HORS TOUT

762 mm

LARGEUR HORS TOUT

102 mm

SPECIFICATIONS D’INSTALLATION

Les illustrations ci-dessous fournissent les dimensions hors tout, les spécifications d’installation et

les dimensions des découpes du plan de travail

pour le modèle ICBCT30G.

REMARQUE IMPORTANTE :

Nous vous recommandons les éléments de cuisine d’une largeur de

838 mm pour l’installation du modèle ICBCT30G.

Vous pouvez installer un four encastrable simple Wolf

de 762 mm sous le modèle ICBCT30G. Dans ce cas

d’installation, sauf si vous utilisez des éléments de

cuisine d’une profondeur supérieure à 610 mm, il est

recommandé de placer l’alimentation en électricité et

en gaz dans l’élément de cuisine inférieur, à droite du

four. Reportez-vous aux instructions d’installation

fournies avec le four encastré pour obtenir des spécifications supplémentaires.

Si le modèle ICBCT30G est installé au-dessus des

éléments de cuisine, l’emplacement des branchements du gaz et de l’électricité n’est pas crucial. Une

prise électrique mise à la terre doit être placée à une

distance maximum de 1,2 m du côté arrière droit de

la plaque de cuisson.

REMARQUE IMPORTANTE :

Si de multiples plaques

de cuisson sont installées côte à côte, reportez-vous à

la page 39 pour obtenir les dimensions des découpes

du plan de travail.

MODELE ICBCT30G

DIMENSIONS

Largeur hors tout 762 mm

Hauteur hors tout 102 mm

Profondeur hors tout 533 mm

Largeur d’élément

de cuisine recommandée 838 mm

Profondeur minimum

de l’élément de cuisine 578 mm

Dégagement minimum

en hauteur 102 mm

Largeur de la découpe 737 mm

Profondeur de la découpe 489 mm

Les dimensions de l’appareil

peuvent varier de ±3 mm.

SPECIFICATIONS D’INSTALLATION – MODELE ICBCT30G

Page 38

38

PLAQUES DE CUISSON AU GAZ WOLF

SPECIFICATIONS D’INSTALLATION

Les illustrations ci-dessous fournissent les dimensions hors tout, les spécifications d’installation et les

dimensions des découpes du plan de travail pour le

modèle ICBCT36G.

REMARQUE IMPORTANTE :

Nous vous recommandons les éléments de cuisine d’une largeur de

991 mm pour l’installation du modèle ICBCT36G.

Vous pouvez installer un four encastrable Wolf de

914 mm sous le modèle ICBCT36G. Dans ce cas

d’installation, sauf si vous utilisez des éléments de