Page 1

FIND OUT MORE

THE WEB.

ON

WILBURCURTIS.COM

WW

W

WW

ILBURILBUR

ILBUR

ILBURILBUR

C C

C

C C

URTISURTIS

URTIS

URTISURTIS

C C

C

C C

OMPOMP

OMP

OMPOMP

ANYANY

ANY

ANYANY

, I, I

, I

, I, I

NCNC

NC

NCNC

Primo Cappuccino Instructions

MODEL PC-3

References in this manual to "Primo

Cappuccino" Throughout this service

manual, the Primo Cappuccino model

PC-3 is illustrated. This will be typical.

On all other models, PC-1, PC-2, PC-4

and HC-1. parts are common except

where noted.

..

.

..

C

ISO 9001 REGISTERED

WILBUR CURTIS COMPANY

Montebello, CA 90640

Table of Contents

UNPACKING . . . . . . . . . . . . . . . .

SETUP . . . . . . . . . . . . . . . . . .

COLD DRINKS . . . . . . . . . . . . . . .

ADJUSTING BEVERAGE STRENGTH . . . .

REPLACING LAMP & STARTER . . . . . . .

CLEANING & MAINTENANCE . . . . . . .

SIDE PANEL REMOVAL . . . . . . . . . . .

TROUBLESHOOTING . . . . . . . . . . . .

ILLUSTRATED PARTS BREAKDOWN . . . .

ILLUSTRATED PARTS LIST . . . . . . . .

WIRING DIAGRAM, PC-3 . . . . . . . . . .

WARRANTY . . . . . . . . . . . . . . . .

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO

WWW.WILBURCURTIS.COM

PageDescription

1

1 - 2

3

3

3

3 - 5

5

5 - 7

8 - 9

11 - 12

13

14

Page 2

3

3

1

3

3

3

3

3

3

3

3

Unpacking

All products manufactured by the Wilbur Curtis Company are thoroughly inspected at the

factory and are warranted to be free of all defects or faulty workmanship. The Primo Cappuccino unit is packaged for maximum protection while being shipped. Make sure the shipping carton is not damaged or punctured. Unpack the carton carefully, inspecting the contents for any damage that may have occurred in transit. Report any damage immediately to

the freight company.

Setup

THIS EQUIPMENT IS TO BE INSTALLED TO COMPLY WITH THE APPLICABLE FEDERAL, STATE, OR LOCAL

PLUMBING AND ELECTRICAL CODES HAVING JURISDICTION.

The Primo Cappuccino unit should be located on a solid counter top. The counter top should

be level. Connect the water line from the water filter to the unit using ¼" copper tubing with

a flare fitting at the end. Some type of water strainer must be used to maintain a trouble-free

operation. In areas with extremely hard water, we suggest that an Everpure QC7-MH water

filter be installed.

NSF, The National Sanitation Foundation, requires the following water hookup:

1. A quick disconnect water connection or enough extra coiled tubing (at least 2x the

depth of the unit) so that the machine can be moved for cleaning underneath.

2 . An approved flow back prevention device, such as a double check valve to be installed

between the machine and the water supply.

Primo

Cappuccino

2

2

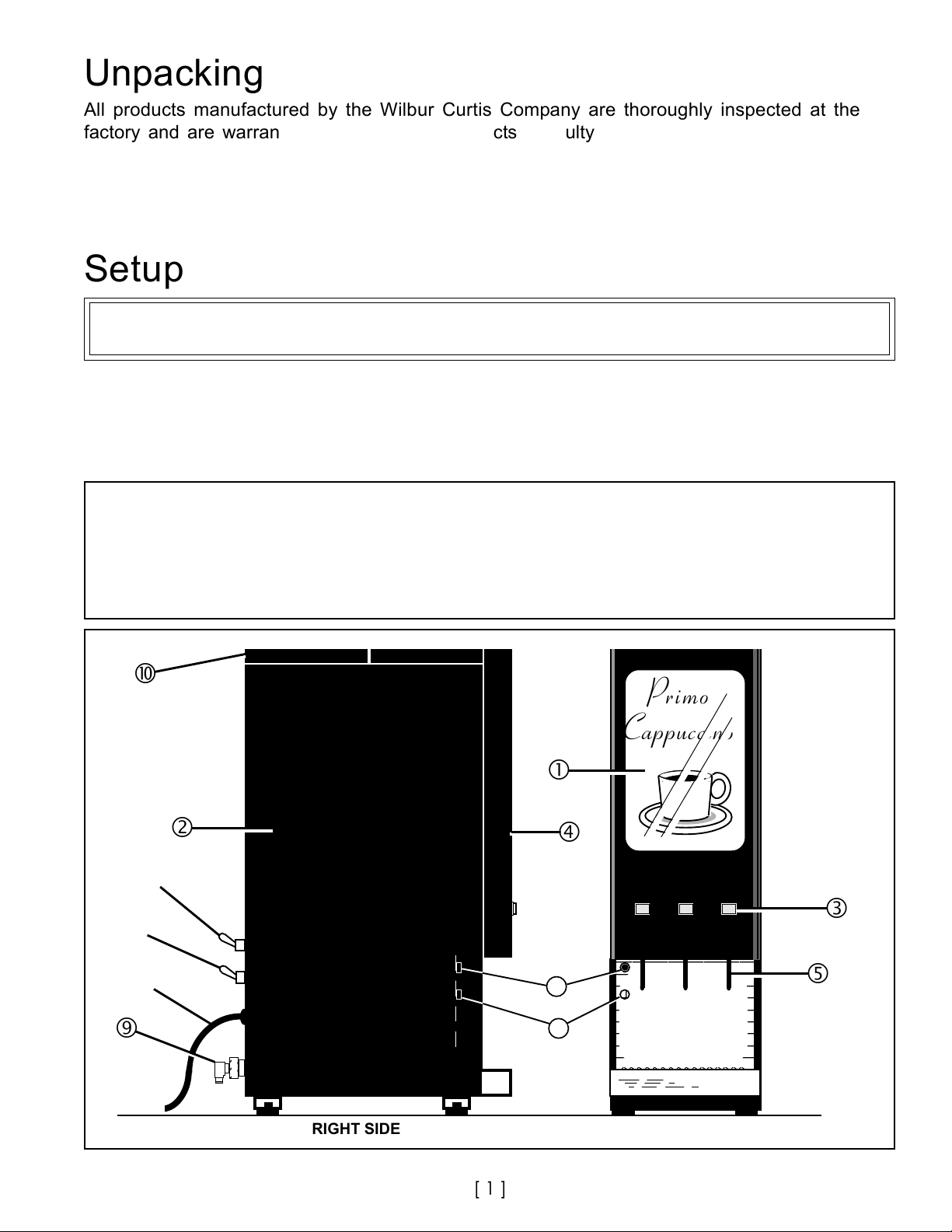

Figure 1. Location of Components on the Primo Cappuccino. PC-3 Shown, Others Similar.

RIGHT SIDE VIEW

[ 1 ]

11

12

23456789012

23456789012

23456789012

23456789012

23456789012

23456789012

23456789012

23456789012

FRONT VIEW

Page 3

Refer to figure 1. for index numbers ( ) in this section. Primo Cappuccino machines are

1

1

shipped with the power cord connected inside the machine. The power cord (8) ends with a

standard 3 pronged 120V plug. Check the serial plate on the side of the machine to make

sure of the electrical requirements for your unit.

Setup Steps

CAUTIONCAUTION

CAUTION DO NOT connect this brewer to hot water. Inlet valve not rated for hot water.

CAUTIONCAUTION

1. Connect a ¼" copper water line from your facility to the ¼" flare water inlet fitting (9)

of the valve, behind the machine. Water pressure going to the machine must be stable.

Use a water regulator to maintain constant pressure. Brewer works perfectly with

water pressures from 20 to 80 psi.

2. Make sure the thermostat is in the OFF position (turn stem all the way counterclockwise).

3. To Locate the thermostat:

A. On later PC-3 and PC-4 units the thermostat is located behind the canisters. Open the

front door (4) and pull out the canisters.The thermostat is on the right side at the back

of the canister shelf. The knob will be sticking out from behind the cover.

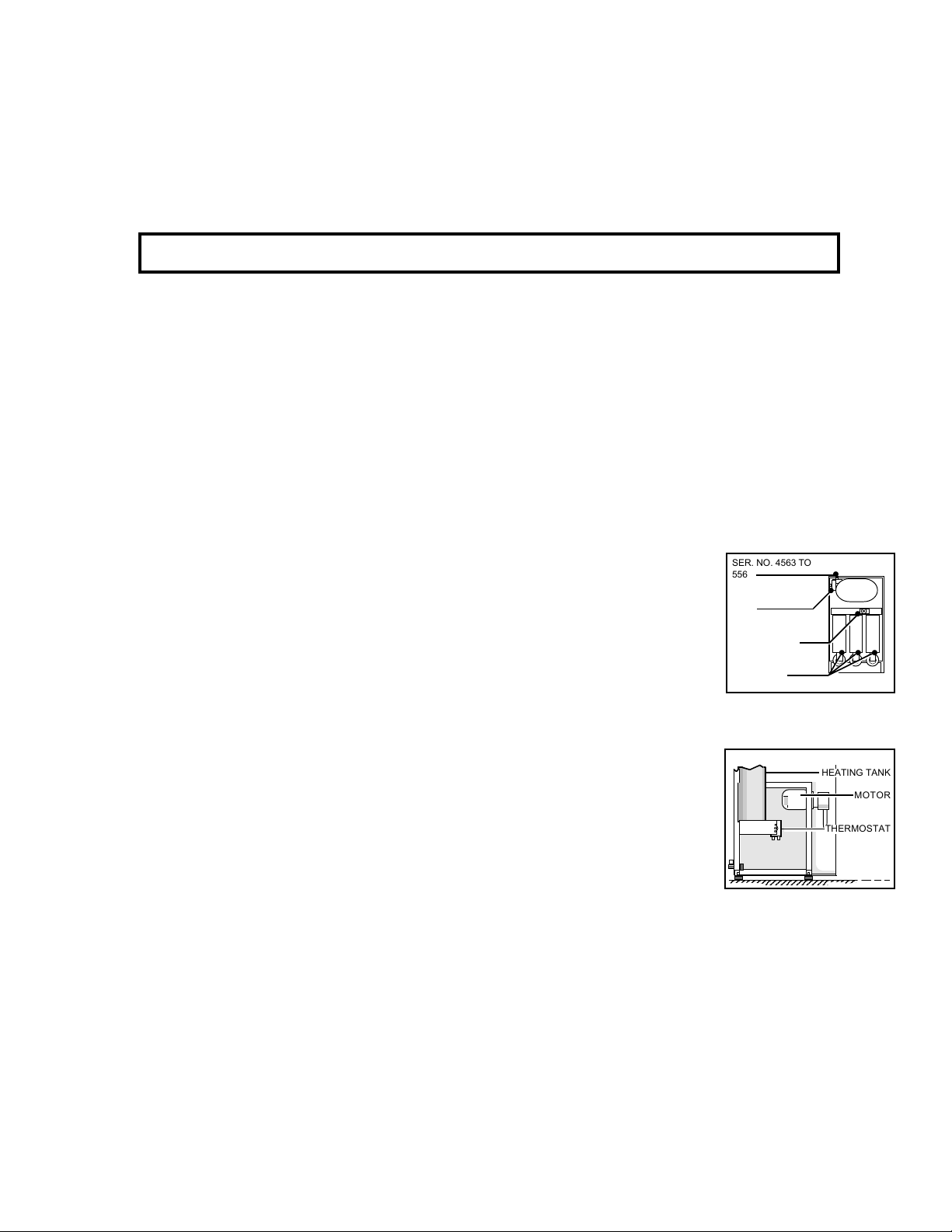

B. See Fig. 2a. for the various thermostat locations used on the PC-3.

C. On PC-1, PC-2 and HC-1, thermostat is located behind the remov-

able left side panel, Figure 2b.

Remove the screws under the front section of the top cover (10),

slide forward and remove the top cover. Loosen the screw con-

necting the spout shield and side panel (2).

Hold panel by the edges and lift up to free screw heads on the

panel from the key holes on the frame. For a more detailed de-

scription see Side Panel Removal, page 5.

SER. NO. 4563 TO

5569

SER. NO. 0100 TO

4562

THERMOSTAT

SER. NO. 5570

THRU PRESENT

CANISTERS

TOP VIEW

Figure 2a. Thermostat

Location, PC-3.

4. Turn off the heating elements, switch (6), toggle down.

5. Plug the power cord into an electrical outlet rated at 20A.

HEATING TANK

MOTOR

THERMOSTAT

6. Switch on the toggle switch (7), up, sending power to the components in the machine. The lights (display window [1] & row of

switches [3]) on the front cover will activate and the heating tank

will start to fill. At this time the READY TO BREW light will come on.

Figure 2b. HC-1 &

PC-1, Side View.

7. When the heating tank has filled, turn on the thermostat by twisting the stem clockwise

as far as it will go. Switch on the toggle switch (6) to turn on the heating elements. The

READY TO BREW light will go off.

9. The heating tank requires about 30 minutes to get up to operating temperature, 195ºF.

The READY TO BREW light will come on when the water reaches this temperature.

10.Reinstall the left side panel (2) and top cover (10) and fill the canisters with powdered

cappuccino mix.

[ 2 ]

Page 4

Cold Drinks

Primo Cappuccino units that brew hot drinks can be setup for cold iced coffee operation.

Using the optional cold water system, cold water bypasses the hot water tank when the

first switch (left) is pressed. A seperate water inlet tube and valve draws cold water from

the main water line directly into the mixing cup.

To activate this system, open the front door. Pull out the product canisters and locate the

cold water switch (#47, illustration, fig. 13.) mounted on the canister shelf. Flip this switch

to COLD. Assemble canisters on the shelf and close the door.

NOTE: Use coffee product made for cold use only.

To setup all the flavor switches to dispense cold drinks only (no hot), the heating element

must be turned off. Look behind the machine; locate the two toggle switches. The top

switch is labeled HEATING ELEMENTS. Switch this one OFF. Allow hot water in tank to cool

down before using.

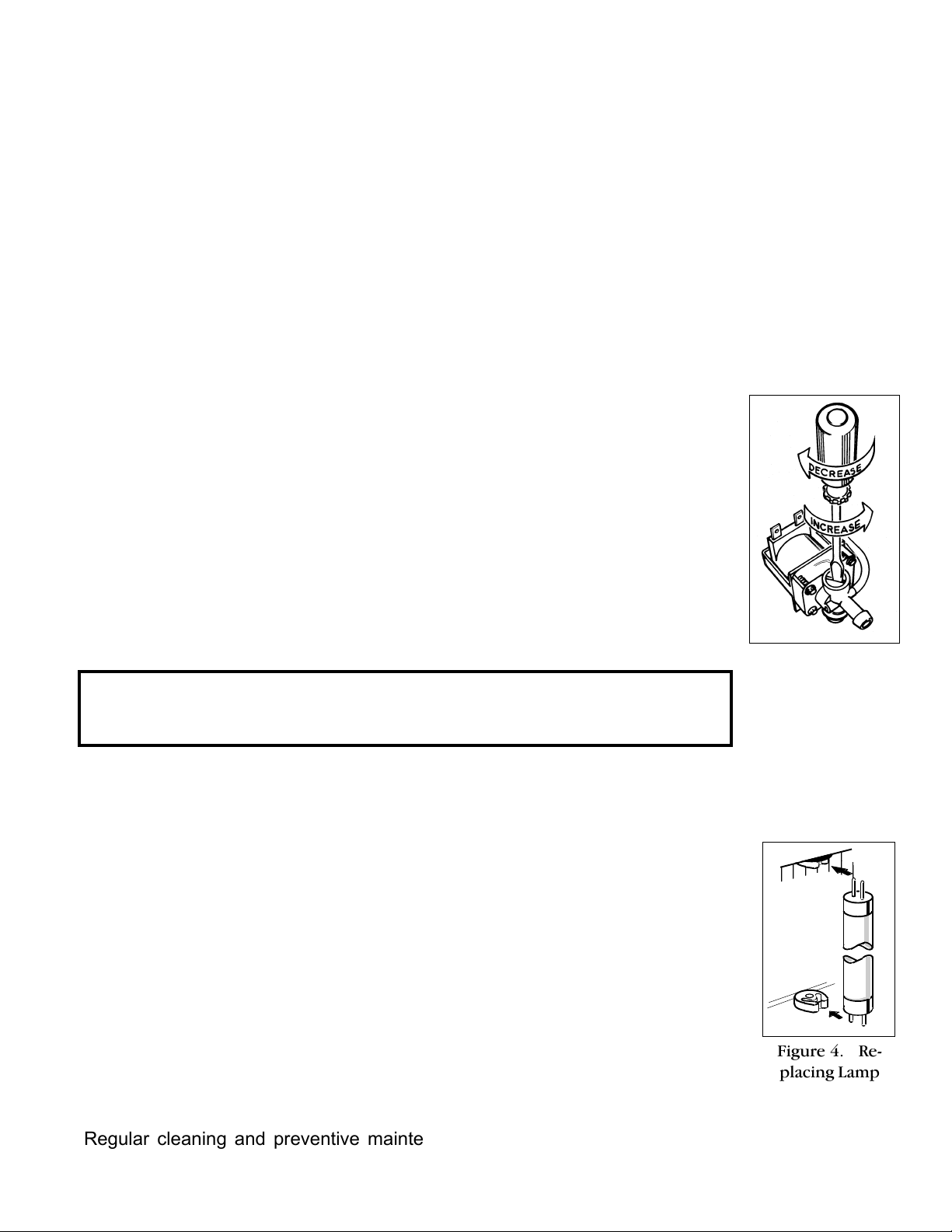

Adjusting the Beverage Strength

Adjusting the water flow rate allows you to determine the strength of

beverage you desire. Decreasing the flow rate will result in a stronger

beverage; increasing to weaken.

The dump valves are adjustable so that you can control the rate of the

water flow.

To Change the adjustment on the dump valves, use a slotted screwdriver. Turn the adjustment screw clockwise to decrease the flow rate;

counterclockwise to increase.

The dump valves are set at the factory for a flow rate of .8 ounce per

second; a higher rate will overflow the mixing cup.

Figure 3. Adjustment

NOTE The flow rate of the powder mix going to the mixing cup is fixed

by the speed of the motor and auger design. If you wish to change the

powder flow rate, various auger designs are available by special order.

Screw on Dump Valve

Replacing Lamp and Starter

Disconnect the power by unplugging the machine. To change a fluorescent

lamp, remove the panel inside the door and the light box. The fluorescent

lamp is held in its mounting with two contacts on top and two at the bottom. Take hold of the lamp and turn it slightly to free it from the socket.

Replace the lamp by aligning and inserting the lamp contacts as shown in

figure 4.. As you push the lamp into place, twist the lamp so that the other

contact seats in the socket.

To change a starter, remove by twisting slightly in the socket counterclockwise. The starter will separate from the starter base. Replace the starter by

pushing it into the base and twisting clockwise slightly.

Figure 4. Re-

placing Lamp

Cleaning & Maintenance

Regular cleaning and preventive maintenance is essential in keeping the Primo Cappuccino

coffee dispenser looking and working like new.

[ 3 ]

Page 5

CAUTION - When cleaning the unit, do not use cleansers, bleach liquids, powders or

any other substance that contains chlorine. These products promote corrosion and

will pit the stainless steel. USE OF THESE PRODUCTS WILL VOID THE WARRANTY.

DAILY CLEANING

1. Wipe off any spills, dust or debris from the exterior surfaces.

2. Wipe surfaces with a damp cloth.

3. Slide out the drip drawer and louvered cover. Wash out its contents. Dry these parts and

return them to the machine.

4. Clean around the dispensing area, wiping with a nontoxic cleaner. Dry thoroughly.

5. Flush the Whipper Chamber:

A. Turn power on.

B. Place a container under the dispensing spout to catch waste water.

C. Open the front door of the machine and locate the rinse switch (item 11, figure 1.).

D. Rinse each flavor by pushing and holding the rinse switch while at the same time

pushing the orange colored dispensing switch on the front panel. Continue until the

water runs clear.

E. Clean up any water that may have spilled.

FILL CANISTERS DAILY

1. Open the front door to access canisters. Lift the top cover.

2. Top off each of the canisters with the powdered coffee mixes. The canisters can be

removed from the unit for easier filling. Each canister holds approximately 4 pounds.

3. Reposition the canisters on the machine, aligning the auger drive with the motor shaft.

The pin on the canisters must align with the guide hole on the support shelf.

WEEKLY CLEANING

CLEANING THE CANISTERS

1. Remove the canisters from the machine.

2. To disassemble the cannister, pull off the elbow funnel from the front of the canis ter. Remove the lid from the top.

3. Wash out the canister. Wash old leftover coffee powder or dried mix from all

disassembled parts. Dry completely before reusing.

REMOVING AND CLEANING THE WHIPPER CHAMBERS*

1. Start by taking off the upper mixing cup. Pull it forward, twist to the left and lift

up to separate from the lower mixing cup.

2. Take off the lower mixing cup by pulling it up and for

ward to free it from the hot water inlet fitting.

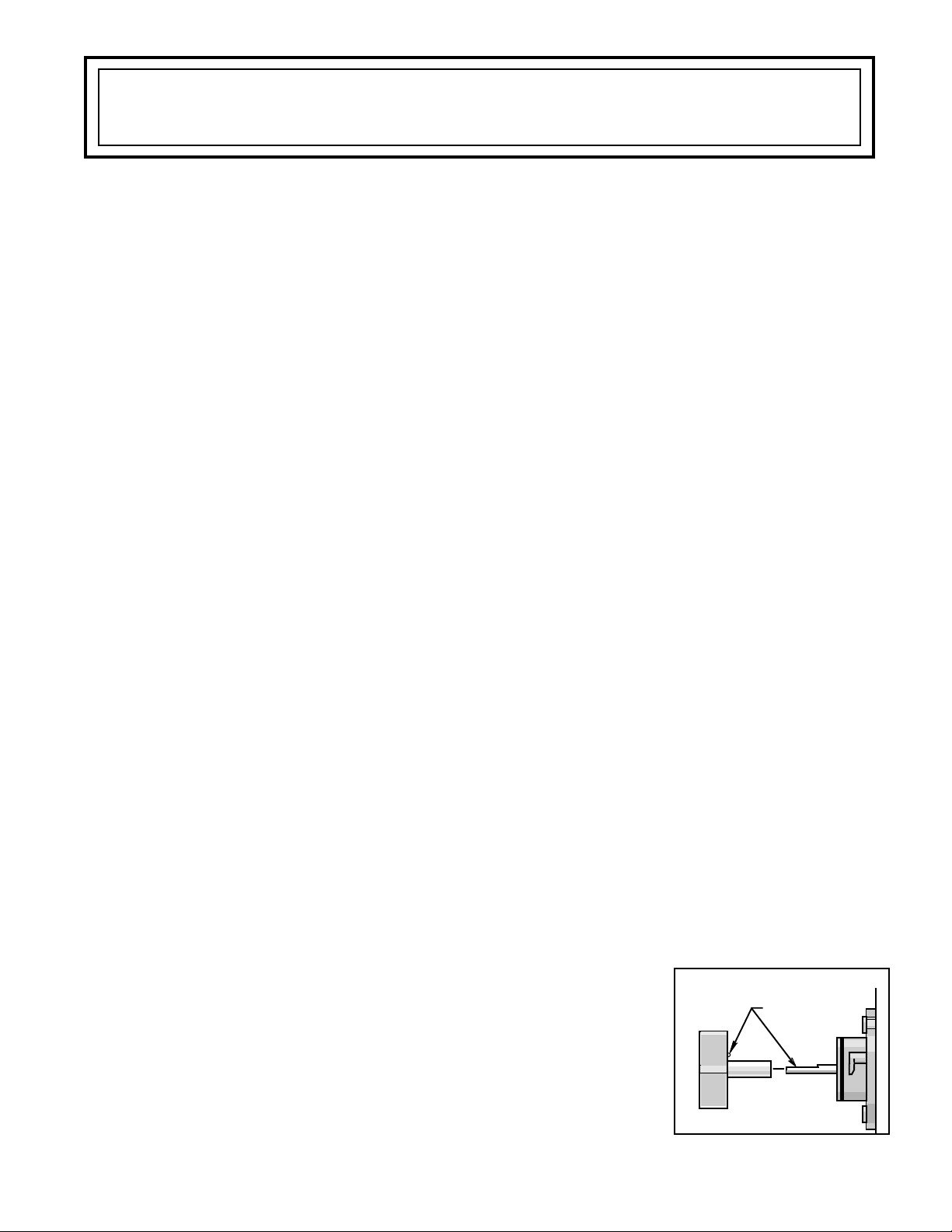

LINE UP TICK MARK

WITH FLAT ON

MOTOR SHAFT

3. Pull the dispensing nozzle from the whipper chamber.

4. Take hold of the whipper chamber and turn clockwise to

free it from the mounting plate. Remove it from the unit.

5. Pull the whipper propeller from the motor shaft. When re assembling, make sure the propeller is properly aligned

and seated on the motor shaft (fig 5.). Failure to push

Figure 5. Prop Alignment

*For easy access remove all canisters.

[ 4 ]

Page 6

Cleaning & Maintenance (Continued)

0

0

0

5

5

5

5

propeller in all the way will cause the propeller to fuse with the whipper chamber.

6. Twist the mounting plate clockwise and pull it off the motor shaft (#9, Fig. 9.).

7. Pull off the O' ring from the mounting plate (#10, Fig. 9.).

8 . Clean all the parts with a mild dishwashing liquid. Thoroughly clean inside the dis-

pensing nozzle. Rinse off the parts before re-assembling.

9. Assemble components.

EVERY SIX MONTHS

The inside of the heating tank should be de-limed periodically, more often in areas with

extremely hard water. The de-liming procedure must be performed by a qualified service

technician.

Side Panel Removal

The left side panel of Primo Cappuccino machines can be removed

easily by taking the following steps:

CAUTION Disconnect electrical power while performing

these steps.

1. Open the front door. Remove the top cover by taking out

the screws holding it to the top of the side panels. Slide the top

cover forward to remove.

On some models a screw centered in the front of the top

cover must also be loosened

2. Remove the screw holding the spout shield to inside the

left or right side panel (PC-3 only), lower arrow.

3. Take hold of the top edge of the panel, lift up and off.

NOTE If removing the right side panel, care must be taken to support

the front door. The wires that run to the controls in the door will still be

23456789

234

23456789

234

23456789

234

234

LIFTLIFT

LIFT

LIFTLIFT

UPUP

UP

UPUP

PANELPANEL

PANEL

PANELPANEL

SCREWSCREW

SCREW

SCREWSCREW

HEADHEAD

HEAD

HEADHEAD

INSIDEINSIDE

INSIDE

INSIDEINSIDE

PANELPANEL

PANEL

PANELPANEL

FRAMEFRAME

FRAME

FRAMEFRAME

KEY-KEY-

KEY-

KEY-KEYHOLEHOLE

HOLE

HOLEHOLE

ONON

ON

ONON

FRAMEFRAME

FRAME

FRAMEFRAME

Figure 6. Detail of

Fastener on Panel.

connected to the components in the frame.

Figure 7. Screw

Location.

Troubleshooting

ALL IN WARRANTY SERVICE SHOULD BE PERFORMED BY AN AUTHORIZED SERVICE TECHNICIAN

The Primo Cappuccino units are simple machines to service. This Troubleshooting guide will

cover most questions you may have about problems you can encounter with the machine. If

you find that you cannot remedy a problem on your machine, you may call our factory service department at (213) 269-8121, extension 3001.

[ 5 ]

Page 7

Troubleshooting (Continued)

WARNING As with all electrical equipment, caution must be taken to avoid electrical

shock. Be sure power cord is disconnected before removing components.

The following steps will also involve working with hot water. Scalding may occur if care

is not taken to avoid spilling hot water.

1 . PROBLEM: Water does not flow into heating tank

POSSIBLE CAUSE

Water line turned off or

filter clogged up.

Grounded probe, WC-5502.

Defective or burned out

liquid level control board,

WC-608.

SOLUTION

Disconnect the water line from the inlet valve and check the

water pressure. Reopen the water line. Replace the filter

cartridge and remove any obstruction.

Whenever the water level in the tank drops below the probe

tip, the water inlet valve should open to fill the tank. If the

water level is too low, check to see if the probe is grounded.

Pull the wire terminal off the terminal on the probe. If water

begins to flow into the tank, this indicates that the probe

has shorted. Clean up the probe thoroughly and reinstall it. If

condition persists, replace it with a new probe. Wrap probe

wire with Teflon tape if there is an indication of excessive

condensation. Leave 1/8" of the probe exposed.

If the probe is not grounded, check the operation of the

liquid level control board (L.L.C.).

Measure the voltage at the input terminals T2 and T3 of

the L.L.C.. Your voltmeter should read approximately 115

volts. It should also read 115 volts at the output terminals

T1 & T3 (this output supplies power to the valve coil).

Lacking voltage at terminals T1 & T3 will indicate that the

L.L.C. is malfunctioning. All wire connections to the board

should be tight. Make sure there is contact between the

grounding plate on the back side of the L.L.C. and its mounting bracket.

Faulty water inlet valve coil

Valve Part No. WC-826.

CAUTION Do not turn water supply off while the power is on. Damage to the coil on

the water inlet valve will result.

To check the water inlet valve, the water level must be

below the probe, the machine on and plugged in. With a

voltmeter, check for voltage to the valve coil. If there is

power to the coil and no water is flowing, the coil or valve

must be replaced.

[ 6 ]

Page 8

Troubleshooting (Continued)

2 . PROBLEM: Water level in the heating tank too high. Tank is overflowing.

POSSIBLE CAUSE

Torn diaphragm or lime build

up in the water inlet valve

Lime build up on the water

level probe

A break in the probe circuit

3 . PROBLEM: Low temperature or cold water in the heating tank.

Remove the top cover of the heating tank and check the

water level. Switch off the power using the toggle switch

behind the machine. If water continues to flow into the

tank, the valve is leaking.

Clean, rebuild or replace the valve.

Pull off the wire with terminal from the water level probe.

Touch the terminal end of the wire to the steel body of the

heating tank. If the water flow stops, this is an indication

that the probe is probably limed up or has lost its continuity

to the solid state L.L.C. board. Clean probe or look for a

break in the circuit and repair it.

When the probe is submerged in water, there should not be

voltage present at the terminals of the inlet valve. Check for

broken or loose wire connections.

SOLUTION

POSSIBLE CAUSE

Thermostat is turned off

Faulty Thermostat

Burned out heating element

SOLUTION

Check to see that the thermostat is turned on. Twist the

stem clockwise as far as it will go.

With the thermostat turned fully clockwise, turn the power

on, observe and measure the water temperature at the

instant the thermostat switches off (brew light on). If the

temperature is too low, replace the thermostat.

Read the current with a clamp ammeter on one of the two

14 gauge wires connected to the element. Turn on the

machine. The meter should read approximately 16 amperes. If you cannot get a reading, use a voltmeter to

check for voltage across the heating element terminals. If

there is ~115 volts, the element is burned out.

[ 7 ]

Page 9

AA

AA

A

DETAIL DETAIL

DETAIL DETAIL

6

7

DETAIL

Fig. 9. Whipper Motor & CanisterFig. 8. Main View, Primo Cappuccino

Illustrated Parts List

3

1

4

5

2

Illustrated Parts List

[ 8 ]

Page 10

REFREF

REFREF

REF

CC

CC

C

DETAIL DETAIL

DETAIL DETAIL

DETAIL

Fig. 11. Frame, PC-3Fig. 10. Door, PC-3

Illustrated Parts List

BB

BB

B

DETAIL DETAIL

DETAIL DETAIL

DETAIL

Illustrated Parts List

Shown.

Door, PC-1

[ 9 ]

Page 11

Illustrated Parts List

DETAIL D

Fig. 12. Heating Tank

[ 10 ]

Page 12

Parts List, PC-1, PC-2 & PC-3, PC-4 & HC-1

IndexIndex

IndexIndex

Index

IndexIndex

NN

Nº

NN

1A

1B

1C

2A

2B

2C

3A

3B

4A

4B

4C

4D

4E

5A

5B

6

7

8

9

10

11

12

13

14

15

16

17A

17B

18

19

20

21

22

23

24A

24B

24C

24D

25A

25B

26A

26B

26C

27A

27B

Part NPart N

Part Nº

Part NPart N

WC-6673

WC-6755

WC-6853

WC-6633

WC-6758

WC-6848

WC-6644

WC-6768-BLK

WC-6645

WC-6747-BLK

WC-6746-BLK

WC-6842

WC-6843

WC-6643

WC-6744-BLK

CA-1011-03

WC-43033

WC-3739

CA-1010-05

CA-1008-03

CA-1006-03

CA-1037

CA-1009-03

CA-1005-03

CA-1026-03

CA-1065

CA-1000

CA-1050

CA-1001

CA-1002

CA-1041

CA-1042

WC-37054

WC- 152

WC-6639

WC-6767

WC-6766

WC-6840

CA-1022

CA-1060

CA-1023-01

CA-1061 -01

CA-1071 -01

CA-1021

CA-1059

DescriptionDescription

Description

DescriptionDescription

Drawer, Drip,

Drawer, Drip,

Drawer, Drip,

Screen, Drip Drawer,

Screen, Drip Drawer,

Screen, Drip Drawer,

Panel, Right Side,

Panel, Right Side,

Cover, Top,

Cover, Top Front,

Cover, Top Back,

Cover, Top Front,

Cover, Top Back,

Panel, Left Side,

Panel, Left Side,

Bulkhead Water Fitting

O' Ring . . . . . . . . . . . . . . . . . . . . . . . . . . .

Kit, Motor Whipper Assy . . . . . . . . . . . . . . . . . . .

Plate, Whipper Chamber Assy W/Resin Seal . . . . . . .

Propeller, Whipper . . . . . . . . . . . . . . . . . . .

Chamber, Whipper . . . . . . . . . . . . . . . . . . .

Nozzle, Dispensing . . . . . . . . . . . . . . . . . . .

Bowl, Mixing . . . . . . . . . . . . . . . . . . . . . . .

Trap, Steam . . . . . . . . . . . . . . . . . . . . . . .

Elbow, Ingredient Chute . . . . . . . . . . . . . . .

Bushing, Discharge . . . . . . . . . . . . . . . . . .

Canister Assembly, 4 Lb.,

Canister Assembly, 6 Lb.,

Canister Only,

Lid, Canister,

Wheel, Agitation,

Auger, 6.7 cc/sec . . . . . . . . . . . . . . . . . . .

Kit, Socket Gear . . . . . . . . . . . . . . . . .

Switch, Push Button . . . . . . . . . . . . . . . .

Door, Front Only,

Door, Front Only,

Door, Front Only,

Door, Front Only

Window, Outer, Clear,

Window, Outer, Clear,

Film, Std Curtis Logo

Film Graphic, Curtis Logo,

Film Graphic, Curtis Logo,

Window, Inner, Clear,

Window, Inner, Clear,

PC-3PC-3

PC-3 . . . . . . . . . . . . . . . . .

PC-3PC-3

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . . . . . . . .

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

PC-4PC-4

PC-4 . . . . . . . . . . . . . . . . . .

PC-4PC-4

PC-3 PC-3

PC-3 . . . . . . . . . . . .

PC-3 PC-3

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . .

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

PC-4PC-4

PC-4 . . . . . . . . . . . .

PC-4PC-4

PC-3 PC-3

PC-4 PC-4

PC-3,

PC-4 . . . . . . . . .

PC-3 PC-3

PC-4 PC-4

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . . . . .

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

PC-3 PC-3

PC-3 . . . . . . . . . . . . . . . . . .

PC-3 PC-3

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . . . . .

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . . . . .

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC-4PC-4

PC-4 . . . . . . . . . . . . . . .

PC-4PC-4

PC-4PC-4

PC-4 . . . . . . . . . . . . . . .

PC-4PC-4

PC-3 PC-3

PC-4 PC-4

PC-3,

PC-4 . . . . . . . . . .

PC-3 PC-3

PC-4 PC-4

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . . . . . .

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC, CK, HCPC, CK, HC

PC, CK, HC. . . . . . . . . . .

PC, CK, HCPC, CK, HC

PC-2, PC-3, PC4PC-2, PC-3, PC4

PC-2, PC-3, PC4

PC-2, PC-3, PC4PC-2, PC-3, PC4

PC-1, HC-1 PC-1, HC-1

PC-1, HC-1 . . . .

PC-1, HC-1 PC-1, HC-1

PC-2, PC-3, PC4 PC-2, PC-3, PC4

PC-2, PC-3, PC4 . . . . . . . .

PC-2, PC-3, PC4 PC-2, PC-3, PC4

PC-2 & PC-3, PC4 PC-2 & PC-3, PC4

PC-2 & PC-3, PC4 . . . . . . .

PC-2 & PC-3, PC4 PC-2 & PC-3, PC4

PC-2, PC-3, PC4 PC-2, PC-3, PC4

PC-2, PC-3, PC4 . . . . . .

PC-2, PC-3, PC4 PC-2, PC-3, PC4

PC-3 PC-3

PC-3 . . . . . . . . . . . . . .

PC-3 PC-3

PC-2 PC-2

PC-2 . . . . . . . . . . . . . . .

PC-2 PC-2

PC-1 & HC-1 PC-1 & HC-1

PC-1 & HC-1 . . . . . . . .

PC-1 & HC-1 PC-1 & HC-1

, PC4, PC4

, PC4 . . . . . . . . . . . . . . . .

, PC4, PC4

PC-3, PC4 PC-3, PC4

PC-3, PC4 . . . . .

PC-3, PC4 PC-3, PC4

PC-1, PC-2, HC-1 . PC-1, PC-2, HC-1 .

PC-1, PC-2, HC-1 .

PC-1, PC-2, HC-1 . PC-1, PC-2, HC-1 .

PC-3, PC4 PC-3, PC4

PC-3, PC4 . . . . . . . . . . . .

PC-3, PC4 PC-3, PC4

PC-1 & PC-2 PC-1 & PC-2

PC-1 & PC-2 . .

PC-1 & PC-2 PC-1 & PC-2

HC-1 HC-1

HC-1 . . . . . . . .

HC-1 HC-1

PC-3, PC4 PC-3, PC4

PC-3, PC4 . . . . . .

PC-3, PC4 PC-3, PC4

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . .

PC-1, PC-2, HC-1 PC-1, PC-2, HC-1

[ 11 ]

Index

IndexIndex

NN

Nº

NN

28

29

30

31

32

33A

33B

34

35

36

37

38

39

40A

40B

40C

40D

41A

41B

41C

42

43

44A

44B

45

46

47

48

49

50

51

52

53

56

57

58

59

60

61A

61B

62

63

64

65

Part NPart N

Part Nº

Part NPart N

CA-1015

CA-1020

CA-1017

WC-5930

WC-4426

WC-6635

WC-6751

CA-1018

CA-1016

WC-4201

WC- 608

WC-4380

WC- 435

WC-6615

WC-6763

WC-6754

WC-6839

WC-6670

WC-6756

WC-6839

CA-1013

CA-1036

WC-6636

WC-6879

CA-1030

WC- 518

WC- 102

WC-1200

WC-1408

WC-2401

WC-4425

WC-43019

WC- 826

WC-37123

WC-3503

WC-6637

WC-4440

CA-1024-03

WC-6616

WC-6677

WC- 202

WC- 101

WC-4320

WC-4211

DescriptionDescription

Description

DescriptionDescription

Transformer . . . . . . . . . . . . . . . . . . . . . . .

Starter, Fluorecent Lamp . . . . . . . . . . . . . .

Socket, Starter Base . . . . . . . . . . . . . . . . .

Panel, Weld Assy. Door . . . . . . . . . . . . . . .

Screw, 8-32 X 3/8 Phillips . . . . . . . . . . . . .

PC-3PC-3

Box, Light,

Panel, Back,

Lamp, Fluorecent . . . . . . . . . . . . . . . . . . . .

Holder, Fluorecent Lamp . . . . . . . . . . . . . . .

Nut, Hex Kep . . . . . . . . . . . . . . . . . . . . . .

Liquid Level Control . . . . . . . . . . . . . . . . . .

Guard, Shock . . . . . . . . . . . . . . . . . . . . . .

Relay, 120V . . . . . . . . . . . . . . . . . . . . . . .

Shelf, Canister,

Shelf, Canister,

Shelf, Canister,

Shelf, Canister,

Cover, Dump Valve,

Cover, Dump Valve,

Cover, Dump Valve,

Motor, Gear . . . . . . . . . . . . . . . . . . . . . . .

Gear, Plastic Auger . . . . . . . . . . . . . . . . . .

Plenum, Exhaust,

Plenum, Exhaust,

Hose, 18", Air . . . . . . . . . . . . . . . . . . . . .

Thermostat . . . . . . . . . . . . . . . . . . . . . . . .

Switch, Toggle . . . . . . . . . . . . . . . . . . . . .

Power Cord, 120V . . . . . . . . . . . . . . . . . .

Grip, Cord . . . . . . . . . . . . . . . . . . . . . . . .

Elbow, 3/8 x 1/4 Flare . . . . . . . . . . . . . . . .

Bolt, 3/8-16 x 5/8 . . . . . . . . . . . . . . . . . . .

Washer,Split Lock . . . . . . . . . . . . . . . . . . .

Valve, S53 Water Inlet . . . . . . . . . . . . . . . .

Fan, Extract . . . . . . . . . . . . . . . . . . . . . . .

Bumper Leg . . . . . . . . . . . . . . . . . . . . . . .

Base, Bottom . . . . . . . . . . . . . . . . . . . . . .

Screw, 8-32 x ¾ L Phillip . . . . . . . . . . .

Pillar, Mounting Plate . . . . . . . . . . . . . . . . .

Shield,

, PC-4, PC-4

Shield

, PC-4 . . . . . . . . . . . . . . . . . . . . . . .

, PC-4, PC-4

Brew Light 115V . . . . . . . . . . . . . . . . . . . .

Switch, Wash Cycle . . . . . . . . . . . . . . . . . .

O' Ring,

Nut, Jam,

PC-4PC-4

PC-3,

PC-4 . . . . . . . . . . . . . . .

PC-3PC-3

PC-4PC-4

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC-1, PC-2, HC-1 . . . . . . . . .

PC-1, PC-2, HC-1PC-1, PC-2, HC-1

PC-3PC-3

PC-3 . . . . . . . . . . . . . .

PC-3PC-3

PC-2PC-2

PC-2 . . . . . . . . . . . . . .

PC-2PC-2

PC-1PC-1

PC-1 . . . . . . . . . . . . . .

PC-1PC-1

PC-4PC-4

PC-4 . . . . . . . . . . . . . . . .

PC-4PC-4

PC-3PC-3

PC-3 . . . . . . . . . . . . .

PC-3PC-3

PC-1, PC-2, HC-1 . .PC-1, PC-2, HC-1 . .

PC-1, PC-2, HC-1 . .

PC-1, PC-2, HC-1 . .PC-1, PC-2, HC-1 . .

PC-4PC-4

PC-4 . . . . . . . . . . . . .

PC-4PC-4

PC-3PC-3

PC-3 . . . . . . . . . . . . .

PC-3PC-3

PC-4PC-4

PC-4 . . . . . . . . . . . . . . .

PC-4PC-4

PC-3PC-3

PC-3 . . . . . . . . . . . . . . . . . . . . . . .

PC-3PC-3

PC-3, PC-4PC-3, PC-4

PC-3, PC-4 . . . . . . . . . . . . . . . . .

PC-3, PC-4PC-3, PC-4

PC-3, PC-4PC-3, PC-4

PC-3, PC-4 . . . . . . . . . . . . . . . .

PC-3, PC-4PC-3, PC-4

Page 13

Parts List, PC-1, PC-2 & PC-3, PC-4 & HC-1

IndexIndex

Index

IndexIndex

Index

IndexIndex

NN

Nº

NN

66A

66B

66C

66D

67

68

69

70

71

72

74

75

76

77

78

79

Part NPart N

Part Nº

Part NPart N

CA-1034

CA-1057

CA-1055

WC-54074

WC-2938

WC-5502

WC-29009

WC-4306

WC-29010

WC-4394

WC- 904

WC-4506

WC-6654

WC-3688

WC-4212

WC-29006

DescriptionDescription

Description

DescriptionDescription

Heating Tank W/Fittings Only,

Heating Tank W/Fittings Only,

Heating Tank W/Fittings Only,

Heating Tank W/Fittings Only,

Fitting, Probe . . . . . . . . . . . . . . . . . . . . . .

Probe, LLC . . . . . . . . . . . . . . . . . . . . . . . .

Fitting, Inlet . . . . . . . . . . . . . . . . . . . . . . .

Washer, 9/16 I.D. Teflon . . . . . . . . . . . . . .

Fitting, Overflow . . . . . . . . . . . . . . . . . . . .

Guard, Shock for Heating Elements . . . . . . .

Heating Element, 1600W, 120V . . . . . . . . . . .

Screw, 8-32 x 5/8, Slotted . . . . . . . . . . . . . .

Lid, Heating Tank . . . . . . . . . . . . . . . . . . . . .

Insulation, Wrap

Nut, 5/8" Jam . . . . . . . . . . . . . . . . . . . . . . .

Fitting, Dump Valve . . . . . . . . . . . . . . . . . . . .

PC-3 & PC-4PC-3 & PC-4

PC-3 & PC-4 . . . . . . . . . . . . . . . .

PC-3 & PC-4PC-3 & PC-4

PC-3 PC-3

PC-3 . . . . . .

PC-3 PC-3

PC-2PC-2

PC-2 . . . . . .

PC-2PC-2

PC-1 & HC-1PC-1 & HC-1

PC-1 & HC-1

PC-1 & HC-1PC-1 & HC-1

PC-4PC-4

PC-4 . . . . . . . .

PC-4PC-4

IndexIndex

NN

Nº

NN

80

81

82

83A

83B

83C

83D

84

89

90

91

92A

92B

92C

92D

93

Part NPart N

Part Nº

Part NPart N

CA-1039

WC- 880E

WC-43062

CA-1035

CA-1058

CA-1056

WC-54073

WC-3734

WC-4501

WC-39105

WC-39107

WC-39106

WC-39120

WC-39116

WC-39205

CA-1027

DescriptionDescription

Description

DescriptionDescription

O' Ring, Cappuccino Dump Valve . . . . . . . . . . .

Valve, Adjustable Dump . . . . . . . . . . . . . . . . .

Gasket, Silicone . . . . . . . . . . . . . . . . . . . . . . .

Heating Tank Complete,

Heating Tank Complete,

Heating Tank Complete,

Heating Tank Complete,

Kit, Rpl Deltrol Dump Valve PC . . . . . . . . . . . .

Screw, 8-32 x 1/4, Slotted . . . . . . . . . . . . . . . .

Label, Flavor, Static Cling . . . . . . . . . . . . . . . . .

Label, Flavor, Adhesive Backed . . . . . . . . . . . . .

Label, Splash Panel,

Label, Splash Panel,

Label, Splash Panel,

Label, Splash Panel,

Label, Prevent Overflow . . . . . . . . . . . . . . . . . .

PC-3PC-3

PC-3 . . . . . . . . . . . .

PC-3PC-3

PC-2 PC-2

PC-2 . . . . . . . . . . . .

PC-2 PC-2

PC-1 & HC-1PC-1 & HC-1

PC-1 & HC-1 . . . . .

PC-1 & HC-1PC-1 & HC-1

PC-4PC-4

PC-4 . . . . . . . . . . . . . .

PC-4PC-4

PC-3PC-3

PC-3 . . . . . . . . . . . . . . . . .

PC-3PC-3

PC-2PC-2

PC-2 . . . . . . . . . . . . . . . . .

PC-2PC-2

PC-1 & HC-1PC-1 & HC-1

PC-1 & HC-1 . . . . . . . . . . .

PC-1 & HC-1PC-1 & HC-1

PC-4PC-4

PC-4 . . . . . . . . . . . . . . . . .

PC-4PC-4

[ 12 ]

Page 14

[ 13 ]

Page 15

[ 14 ]

Page 16

WARRANTY

We hereby certify that the products manufactured by the Wilbur Curtis Company, Inc., are, to thebest of our knowledge,

free from all defects and faulty workmanship.

The following warranties and conditions are applicable:

1. 1 Year Parts & Labor from Date of Purchase from Factory: This warranty covers all electrical parts, fittings

and tubing.

2. 40 Months or 40, 000 Pounds of Coffee on a set of Grinding Burrs. (ADS Grinders)

3. 3 Years from Date of Purchase: This warranty covers electronic control boards and leaking or pitting of a

stainless steel body of a Brewer or Urn.

4. 90 Days from Date of Purchase: On replacement parts that have been installed on out of warranty equipment

All in-warranty service calls must have prior authorization from the manufacturer. For an RMA (Return Merchandise

Authorization) number, call the Technical Service Department at 1-800-995-0417. The Wilbur Curtis Company will allow

up to 100 miles, round trip, per in-warranty service call.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no

responsibility for substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company. Inc The Wilbur Curtis Company will not accept any responsibility if the following conditions are not

met. The warranty does not cover and is void under these circumstances:

1) Improper operation of equipment. The equipment must be used for its designed and intended

purpose and function.

2) Improper installation of equipment. This equipment must be installed by a professional,

certified technician and must comply with all local electrical, mechanical and plumbing codes.

3) Wilbur Curtis Company will not be responsible for the operation of equipment at other than the

stated voltages on the serial plate.

4) Abuse or neglect (including failure to periodically clean or remove lime accumulations).

Manufacturer is not responsible for variation in equipment operation due to excessive lime or

local water conditions.

5) Replacement of items subject to normal use and wear. This shall include, but is not limited to,

light bulbs, shear disks, “0” rings, gaskets, canister assemblies. whipper chambers and plates,

mixing bowls, agitation assemblies and whipper propellers.

6) Any faults resulting from inadequate water supply. This includes, but is not limited to, excessive or low water pressure, and inadequate or fluctuating water flow rate.

7) All repairs and/or replacements are subject to our decision that the workmanship or parts were

faulty and the defects showed up under normal use.

8) All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner.

9) Charges incurred by delays, waiting time, or operating restrictions that hinder the service

technician’s ability to perform service is the responsibility of the owner of the equipment.

This includes institutional and correctional facilities.

10) All claims under this warranty must be submitted to the Wilbur Curtis Company Technical

Service Department before return of the unit to the factory.

11) All equipment returned to us must be repackaged properly in the original carton. No units will

be accepted if they are damaged in transit due to improper packaging.

12) Damaged in transit.

13) The resetting of safety thermostats and circuit breakers, programming and temperature

adjustments are the responsibility of the equipment owner.

11.0 . ECN6052 . F-2043_revA.p65X

NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA).

RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL.

All in-warranty service calls must be performed by an authorized service center, where service is available. Call the factory

for location near you.

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150

Technical Support Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techsupport@wilburcurtis.com

Web Site: www.wilburcurtis.com

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

Fax: 323-837-2410

Printed in U.S.A. 8/03 F-2043 revA

Loading...

Loading...