Page 1

General Purpose Pressure Transmitters

Model S-10, S-11

Applications

■ Hydraulics and pneumatics

■ Test equipment

■ Pump and compressor control

■ Liquid level measurement

Special Features

■ Standard ranges available from stock

■ 4-20 mA 2-wire output signal, others available

■ Highly resistant to pressure spikes and vibration

■ Stainless steel case and wetted parts

■ Can be assembled to diaphragm seals for special

applications

Electronic

Pressure Measurement

Datasheet S-10, S-11

Description

WIKA S-10 and S-11 pressure transmitters are precision

engineered to t most industrial pressure measurement

applications. The compact, rugged design makes these

instruments suitable for applications including hydraulics and

pneumatics, vacuum, test equipment, liquid level measurement, press

control, compressor control, pump protection and

numerous other processing and control operations. A wide range

of electrical connection and process connection options are available to meet almost any requirement.

Rugged construction

The S-10 features an all-welded stainless steel measuring cell for

improved media compatibility. There are no internal soft sealing

materials that may react with the media or deteriorate over time.

The compact case is also made of stainless steel and is available

with environmental protection ratings up to NEMA 6P / IP 68.

Left: S-10 with NPT process connection

Center: S-11 with ush diaphragm process connection

Right: S-11 with ush diaphragm process connection and

integral cooling element

The S-11 transmitter features a ush diaphragm process

connection. The S-11 is specically designed for the

measurement of viscous uids or media containing solids

that may clog a NPT process connection. Flush diaphragm

pressure transmitters are available in pressure ranges

from 50 InWC to 8,000 psi. For high temperature media, an

integral cooling element is available on the S-11. This option

increases the maximum media temperature to 300

Each instrument undergoes extensive quality control testing

and calibration to achieve an accuracy of < 0.25% full scale.

The printed circuit boards use state-of-the-art surface mount

technology and are potted in silicone gel for protection

against mechanical shock, vibration and moisture. Each is

individually temperature compensated to assure accuracy

and long-term stability even when exposed to severe

ambient temperature variations.

O

F.

Datasheet S-10, S-11 1/2011

Page 1 of 4

R

Page 2

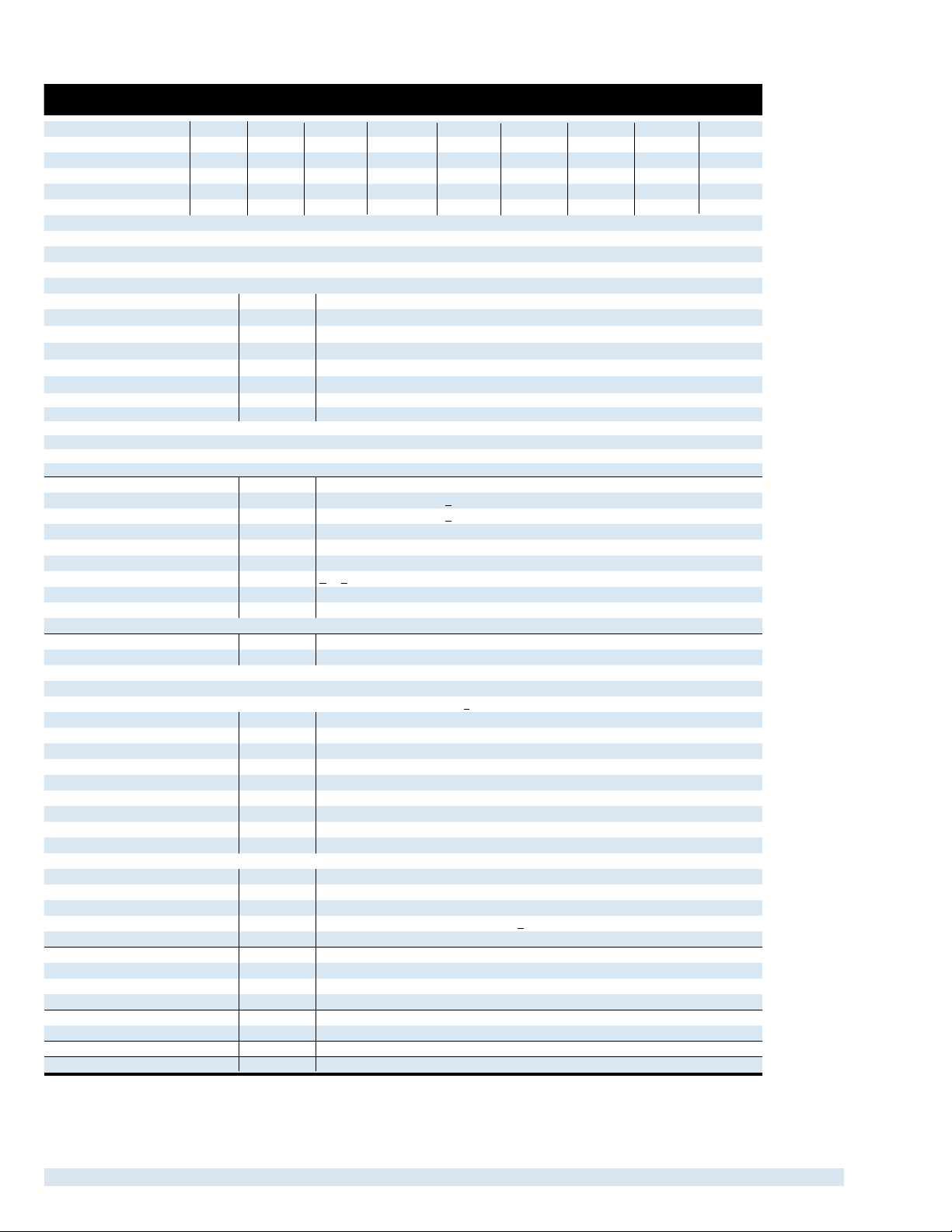

Specications Type S-10 / S-11

Pressure range 50 InWC 5 psi 10 psi 25 psi 30 psi 60 psi 100 psi 160 psi 200 psi

Maximum pressure* 14 psi 29 psi 58 psi 145 psi 145 psi 240 psi 500 psi 1,160 psi 1,160 psi

Burst pressure** 29 psi 35 psi 69 psi 170 psi 170 psi 290 psi 600 psi 1,390 psi 1,390 psi

Pressure range 300 psi 500 psi 1,000 psi 2,000 psi 3,000 psi 5,000 psi 8,000 psi 10,000 psi

Maximum pressure* 1,160 psi 1,160 psi 1,740 psi 4,600 psi 7,200 psi 11,600 psi 17,400 psi 17,400 psi 21,750 psi

Burst pressure** 1,390 psi 5,800 psi 7,970 psi 14,500 psi 17,400 psi 24,650 psi 34,800 psi 34,800 psi

{vacuum, gauge pressure, compound ranges, and absolute pressure references are available}

1)

Ranges only available with Model S-10

2)

For Model S-11 the burst pressure is limited to 21,000psi unless the pressure seal is accomplished by using the sealing ring underneath the hex.

*Pressure applied up to the maximum rating will cause no permanent change in specications but may lead to zero and span shifts

**Exceeding the burst pressure may result in destruction of the transmitter and possible loss of media

Materials

Wetted parts

Model S-10

Model S-11

Case

Internal transmission uid

Power supply U

Signal output and R

B

maximum load R

4)

3)

O-ring made of Viton or EPDM for Model S-11 with integral cooling element.

4)

Not available with Model S-10 in pressure ranges >300 psi.

5)

Media temperature for oxygen version: -4 ... +140 °F (-20....+60°C). Oxygen version is

6)

A

not available in vacuum and absolute pressure ranges or with S-11 > 500 psi

UB in DC V 10 < UB 30 (14 ... 30 with signal output 0 ... 10 V)

in Ohm 4 ... 20 mA, 2-wire RA < (UB - 10 V) / 0.02 A

A

Adjustability zero/span % ± 10 using potentiometers inside the instrument

Response time (10 ... 90 %) ms

(other materials see WIKA diaphragm seal program)

Stainless steel

Stainless steel

O-ring: NBR

Stainless steel

Synthetic oil {Halocarbon® oil for oxygen applications}

3)

{Viton® or EPDM}

5)

{Listed by FDA for food applications}}

≤

0 ... 20 mA, 3-wire RA < (UB - 3 V) / 0.02 A

{0 ... 5 V, 3-wire} R

{0 ... 10 V, 3-wire} R

> 5000

A

> 10,000 {other signal outputs available}

A

< 1 (< 10 ms at media temperatures below –22°F (-30°C) for ranges < 300 psi

or with ush diaphragm process connection)

Isolation voltage DC V 500

Accuracy

7)

6)

NEC Class 02 power supply (low voltage and low current max. 100 VA even under fault conditions)

% of span ≤ 0.25 {0.125}

% of span ≤ 0.5 {0.25}

7)

Including linearity, hysteresis and repeatability.

Limit point calibration performed in vertical mounting position with pressure connection facing down.

8)

Improved accuracy is available for pressure ranges > 100 InWC

8)

(BFSL)

8)

(limit point calibration)

Non-repeatability % of span ≤ 0.05

1-year stability % of span ≤ 0.2 (at reference conditions)

Permissible temperature of

Medium

Ambient

Storage

Compensated temperature range

9)

9)

9)

9)

Also complies with EN 50178, Tab. 7, Type C, Class 4KH Operation, 1K4 Storage, 1K3 Transport

-22 ... +212 °F {-40 ... +257 °F} -30 ... +100 °C {-40 ... +125 °C}

S-11 with cooling element: -4 ... +302 °F S-11 with cooling element: -20 ... +150 °C

-4 ... +176 °F -20 ... +80 °C

S-11 with cooling element: -4 ... +176 °F S-11 with cooling element: -20 ... +80 °C

-40 ... +212 °F -40 ... +100 °C

S-11 with cooling element: -4 ... +212°F S-11 with cooling element: -20 ... +100 °C

32 ... +176 °F 0 ... +80 °C

Temperature coecients (TC) within

compensated temp range:

Mean TC of zero

Mean TC of range

% of span ≤ 0.2 / 10 K (< 0.4 for pressure range < 100 InWC)

% of span ≤ 0.2 / 10 K

CE - conformity

Pressure equipment directive

EMC directive

97/23/EC

2004/108/EEC, EN 61 326 Emission Group (Group 1, Class B) and

Immunity )industrial locations

Shock resistance g 1000 according to IEC 60068-2-27 (mechanical shock)

Vibration resistance g 20 according to IEC 60068-2-6 (vibration under resonance)

Wiring protection Protected against reverse polarity, overvoltage and short circuit

Weight lb Approx. 0.4

1

15,000 psi

43,500 psi

1

{ } Items in curved brackets { } are optional extras for additional price.

Page 2 of 4 Datasheet S-10, S-11 · 1/2011

Page 3

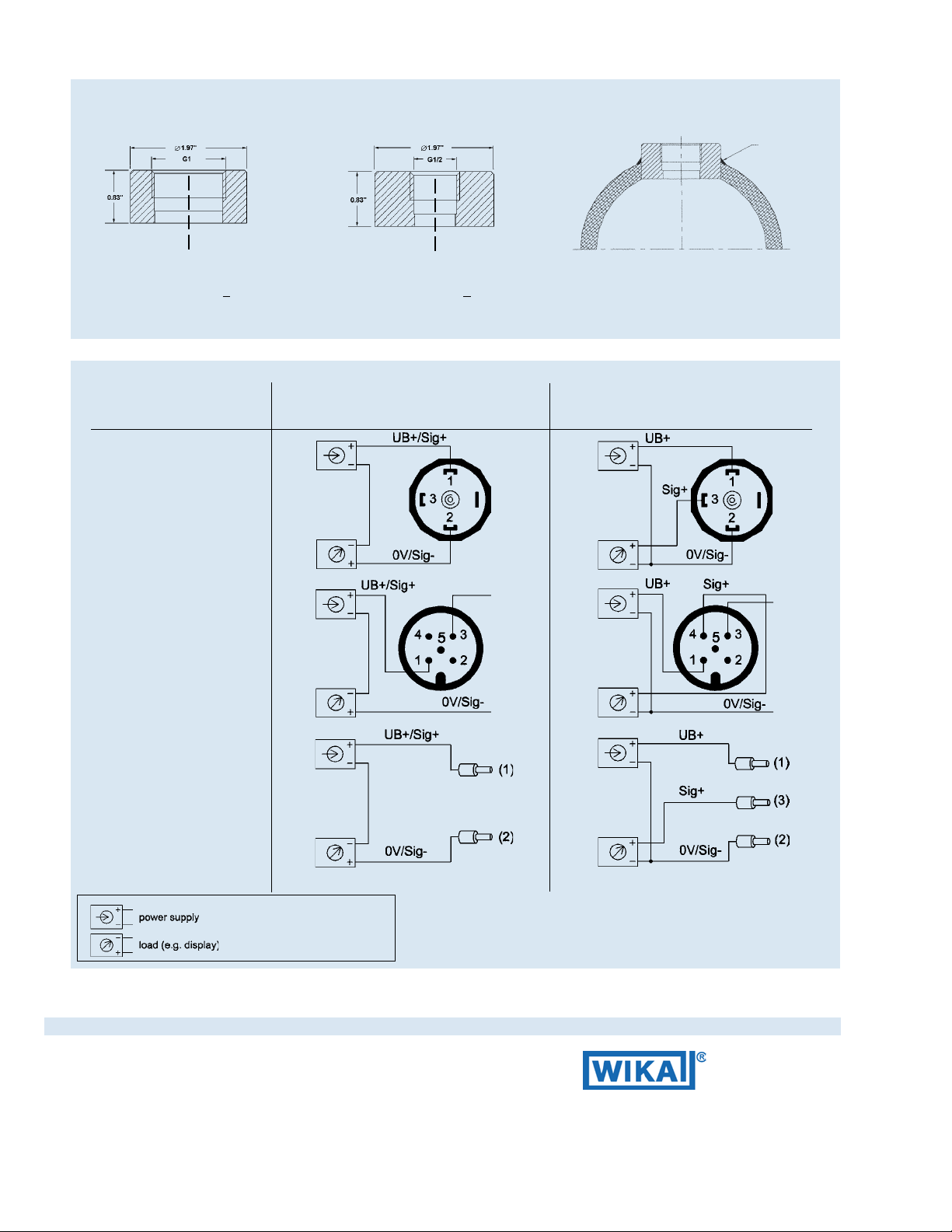

Dimensions in inches(mm)

Electrical connections

L-connector, DIN EN

175301-803, Form A

(DIN 43 650) for conductor

cross section up to max.

1.5 mm² , conductor outer

diameter 0.3“ (6-8 mm),

NEMA 5 / IP 65

Order code: A4

1.89”(48mm)

1.14”(20mm)

Circular connector

M 12x1, 5 pin,

NEMA 4 / IP 67

Order code: M5

)see note

*

1.69”(43mm)

Cable with free ends

conductor cross section up

to max. 0.5 mm² /

AWG 20 with end splices,

conductor outer diameter

6.8 mm, NEMA 4 / IP 67

Order code: DL

Cable with free ends, adjustable

zero and span

conductor cross section up to max.

0.5 mm² / AWG 20 with end splices,

conductor outer diameter 6.8 mm,

NEMA 6 P / IP 68

Order code: XM

Case

1.79”(45.5mm)

1.06”(27mm)

S-10 pressure connections (others available)

1/2 NPT male

Order code: ND

.75”

(19mm)

1.08”(27.5mm)

1/2NPT

1/4 NPT male

Order code: NB

.51”(13mm)

.85”(21.5mm)

S-11 ush diaphragm pressure connections

G 1 B

with or without cooling element

50 InWC to 25 psi

Order code: 85

G 1/2 B

with or without cooling element

30 psi to 8000 psi

Order code: 86

1.12”(28.5mm)

.79”(20mm)

0.71”(18mm)

G1/2B male

Order code: GD

.12”(3mm)

.12”(3mm)

0.91”(23mm)

1.52”(38.5mm)

1.06”(27mm)

G1/4B male

Order code: GB

.24”

(6mm)

.85”(21.5mm)

O

.08”(2mm)

.08”(2mm)

.51”(13mm)

G1B according to EHEDG

**)

ø.20”

(5mm)

ø.37”

(9.5mm)

with cooling element , up to 302°F (150°C)

100 InWC to 250 psi

Order code: 84

1.79”(45.5mm)

1.26”(31.9mm)

.39”(10mm)

.80”(20.5mm)

) Mating connector not included

*

Sealing ring

29,7x35,7x2,0

O-ring 26x2

1.79”(45.5mm)

1.22”(30.9mm)

.81”(20.5mm)

.39”(10mm)

Sealing ring

18,5x23,9x1,5

O-ring 15x2

Sealing ring

29,7x35,7x2,0

1.98”(50.5mm)

.98”(25mm)

** European Hygenic Equipment Design Group

O-ring

21,82 x 3,53

Page 3 of 4Datasheet S-10, S-11 · 1/2011

Page 4

Matching P-1 weld insert adapters for S-11 pressure transmitters

weld

P-1 G1 weld insert adapter

Part # 1206974

for pressure ranges < 30 psi

Wiring

L-Connector,

DIN EN 175301-803, Form A

(DIN 43 650)

M12x1 Circular connector

5 pin

2-wire system

P-1 G1/2 weld insert adapter

Part # 1097008

for pressure ranges > 50 psi

Cross section view of P-1

adapter installed in pipe.

3-wire system

Vented cable with free ends

Legend:

Sig+ output signal positive

UB+ power supply positive

0V power supply negative

Sig - output signal negative

brown

green

brown

white

green

Datasheet S-10, S-11 · 1/2011Page 4 of 4

WIKA Instrument Corporation

1000 Wiegand Boulevard

Lawrenceville, Georgia 30043-5868

Tel: 770-513-8200 Fax: 77-338-5118

wika.com e-mail: info@wika.com

Page 4 of 4WIKA Data Sheet PE 81.01 · 02/2004

Loading...

Loading...