Page 1

Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

Pressure transmitter, model S-10

Druckmessumformer, Typ S-10

Transmetteur de pression, type S-10

Transmisor de presión, modelo S-10

Pressure transmitter, model S-10

EN

DE

FR

ES

Page 2

EN

Operating instructions model S-10 Page 3 - 26

DE

Betriebsanleitung Typ S-10 Seite 27 - 50

FR

Mode d‘emploi type S-10 Page 51 - 74

ES

Manual de instrucciones modelo S-10 Página 75 - 99

© 2002 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 3

Contents

Contents

1. General information 4

2. Design and function 5

3. Safety 6

4. Transport, packaging and storage 8

5. Commissioning, operation 9

6. Adjustment of zero point and span 12

7. Faults 13

8. Maintenance and cleaning 15

9. Dismounting, return and disposal 16

10. Specications 18

Declarations of conformity can be found online at www.wika.com

EN

1604457.16 09/2017 EN/DE/FR/ES

3WIKA operating instructions pressure transmitter, model S-10

Page 4

1. General information

1. General information

■

EN

The instrument described in the operating instructions has been designed and manufactured using state-of-theart technology. All components are subject to stringent quality and environmental criteria during production. Our

management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that

all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range

of use.

■

The operating instructions are part of the product and must be kept in the immediate vicinity of the instrument and

readily accessible to skilled personnel at any time. Pass the operating instructions onto the next operator or owner of

the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PE 81.01

- Application consultant:

Tel.: +49 9372 132-8976

Fax: +49 9372 132-8008976

support-tronic@wika.de

4 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 5

2. Design and function

2. Design and function

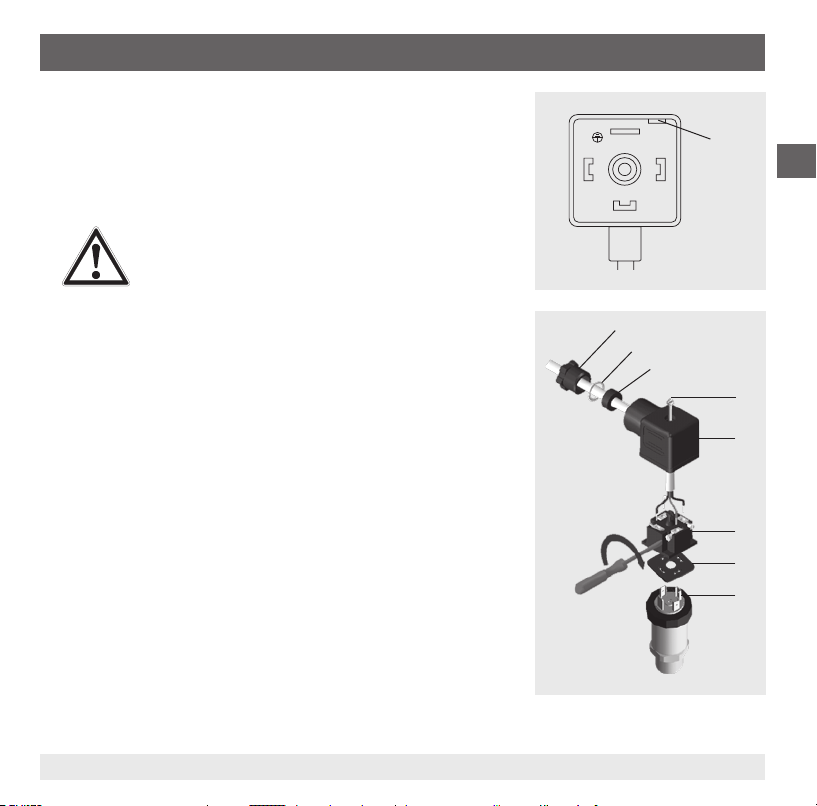

2.1 Overview

2.2 Scope of delivery

■

Pressure transmitter

■

Operating instructions

Cross-check scope of delivery with delivery note.

Electrical connection (depending on version)

Case; product label

Process connection, spanner flats

Process connection, thread

EN

1604457.16 09/2017 EN/DE/FR/ES

5WIKA operating instructions pressure transmitter, model S-10

Page 6

3. Safety

3. Safety

3.1 Explanation of symbols

EN

3.2 Intended use

The pressure transmitter is used for measuring pressure. The measured pressure is output as an electrical signal.

Only use the pressure transmitter in applications that lie within its technical performance limits (e.g. max. ambient

temperature, material compatibility, ...). The pressure transmitter is suitable for applications with pollution degree 3 and

an ambient temperature of -20 ... +80 °C.

→ For performance limits, see chapter 9 “Specications”.

The instrument has been designed and built solely for the intended use described here, and may only be used

accordingly.

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage to equipment or

the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient and trouble-free operation.

The manufacturer shall not be liable for claims of any type based on operation contrary to the intended use.

6 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 7

3. Safety

3.3 Personnelqualication

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of country-specic

regulations, current standards and directives, are capable of carrying out the work described and independently

recognising potential hazards.

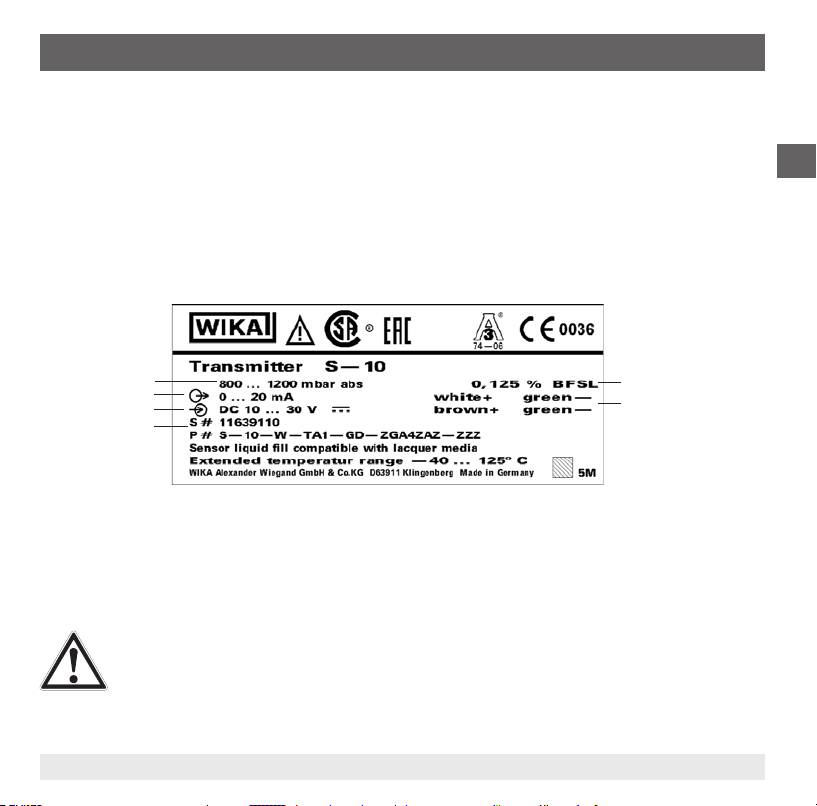

3.4 Labelling, safety marks

Product label

EN

S# Serial no., P# Model code

Power supply

Output signal

Measuring range

Symbols

Before mounting and commissioning the instrument, ensure you read the operating instructions!

1604457.16 09/2017 EN/DE/FR/ES

Accuracy

Pin assignment

7WIKA operating instructions pressure transmitter, model S-10

Page 8

4. Transport, packaging and storage

4. Transport, packaging and storage

4.1 Transport

Check the pressure transmitter for any damage that may have been caused during transportation.

EN

Obvious damage must be reported immediately.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for

repair).

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +100 °C

■

Humidity: 45 ... 75 % relative humidity (no condensation)

8 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 9

5. Commissioning, operation

5. Commissioning, operation

5.1 Mounting the instrument

Prior to commissioning, the pressure transmitter must be subjected to a visual inspection.

■

Leaking uid is indicative of damage.

■

Only use the pressure transmitter if it is in perfect condition with respect to safety.

Requirements for mounting point

The mounting point must meet the following conditions:

■

Ambience corresponds to a max. pollution degree of 3.

■

Humidity ≤ 80 % r. h. (non-condensing).

■

Protected from weather inuences.

■

Sealing faces are clean and undamaged.

■

Sucient space for a safe electrical installation.

■

For information on tapped holes and welding sockets, see Technical information IN 00.14 at www.wika.com.

■

Permissible ambient and medium temperatures remain within the performance limits. Consider possible restrictions

on the ambient temperature range caused by mating connector used.

→ For performance limits, see chapter 9 “Specications”

Sealing variants

Parallel threads

Seal the sealing face with a flat gasket, lens-type

sealing ring or WIKA profile sealing.

per EN 837

Tapered threads

Wrap threads with sealing material (e.g. PTFE

tape).

per DIN 3852-E

EN

1604457.16 09/2017 EN/DE/FR/ES

NPT, R and PT

9WIKA operating instructions pressure transmitter, model S-10

Page 10

5. Commissioning, operation

Mounting the instrument

The max. torque depends on the mounting point (e.g. material and shape). If you have any questions,

EN

1. Seal the sealing face (→ see “Sealing variants”).

.

At the mounting point, screw the pressure transmitter in hand-tight.

2

.

Tighten with a torque spanner using the spanner ats.

3

5.2 Connecting the instrument to the electric system

Requirements for voltage supply

→ For power supply, see product label

The power supply for the pressure transmitter must be made via an energy-limited electrical circuit in accordance

with section 9.4 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC 60950-1 / CSA C22.2 no. 60950-1, or class 2 in

accordance with UL1310/UL1585 (NEC or CEC). The voltage supply must be suitable for operation above 2,000 m

should the pressure transmitter be used at this altitude.

Requirements for electrical connection

■

Cable diameter matches the cable bushing of the mating connector.

■

Cable gland and seals of the mating connector are correctly seated.

■

With cable outlets, no humidity can ingress at the cable end.

Requirement for shielding and grounding

The pressure transmitter must be shielded and grounded in accordance with the grounding concept of the plant.

Connecting the instrument

1. Assemble the mating connector or cable outlet.

→ For pin assignments, see product label

.

2

Establish the plug connection.

please contact our application consultant.

→ For contact details, see chapter 1 “General information” or the back page of the operating instructions.

10 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 11

5. Commissioning, operation

5.3 Fitting a DIN 175301-803 angular connector

1. Loosen the screw (1).

2. Loosen the cable gland (2).

3. Pull the angular connector (5) + (6) away from the instrument.

4. CAUTION!

Improper mounting

The seal of the angle housing will be damaged.

▶

Do not try to push the terminal block (6) out using the

screw hole (1) or the cable gland (2).

Via the mounting hole (D), lever the terminal block (6) out of the angle

housing (5).

5. Slide the cable through the cable gland (2), the ring (3), the sealing (4) and

the angle housing (5).

6. Connect the cable ends to the terminal blocks (6) in accordance with the

connection diagram.

7. Press the angle housing (5) onto the terminal block (6).

8. Make sure that the seals are not damaged and that the cable gland and

seals are correctly seated in order to ensure ingress protection.

9. Tighten the cable gland (2) around the cable.

10. Place the at gasket (7) over the instrument's connection pins.

11. Push the angular connector (5) + (6) onto the instrument.

12. Tighten the screw (1).

(D)

EN

(2)

(3)

(4)

(1)

(5)

(6)

(7)

(8)

1604457.16 09/2017 EN/DE/FR/ES

11WIKA operating instructions pressure transmitter, model S-10

Page 12

6. Adjustment of zero point and span

6. Adjustment of zero point and span

EN

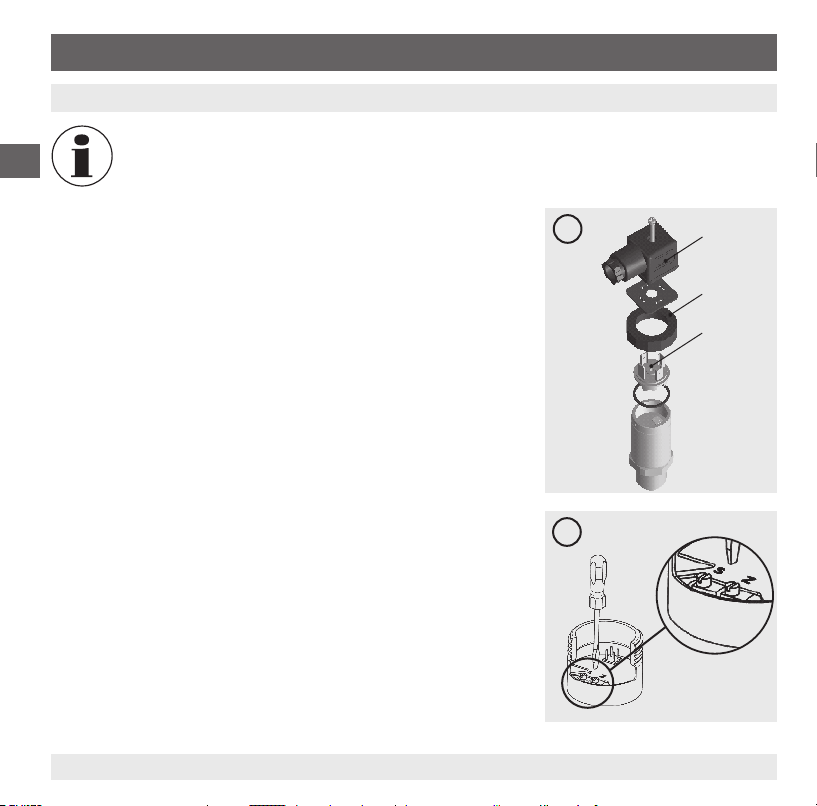

7.1Preparation(gureA)

To gain access to the potentiometers, open the instrument as follows:

■

Disconnect the electrical connection from the instrument.

■

Remove the clamping nut .

■

Carefully pull the instrument connector from the instrument.

■

Connect the instrument connector to the power supply and a display unit

(e.g. ammeter, voltmeter) according to the connection diagram.

7.2Adjustmentofzeropoint(gureB)

■

Go to the start of the measuring range.

■

Using potentiometer "Z", adjust the minimum output signal (e.g. 4 mA)

7.3Settingthespan(gureB)

■

Go to the end of the measuring range.

■

Using potentiometer "S", adjust the maximum output signal (e.g. 20 mA)

■

Check the zero point and if there is any deviation, re-adjust it.

■

Repeat the procedure until the zero point and the span are set correctly.

Only adjust the span-setting potentiometer if calibration equipment is available which has at least three

times the accuracy of the pressure transmitter.

A

B

12 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 13

7. Faults

7. Faults

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the pressure transmitter must be taken

out of operation immediately.

▶

Ensure that pressure or signal is no longer present and protect against accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 8.2 “Return”.

WARNING!

Physical injuries and damage to property and the environment caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, ammable or toxic substances), harmful

media (e.g. corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compressors, there is a danger of physical injuries and damage to property and the environment.

▶

Should a failure occur, aggressive media with extremely high temperature and under high pressure

or vacuum may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate existing codes or regulations

must also be followed.

▶

Wear the requisite protective equipment (see chapter 3.4 “Personal protective equipment”).

For contact details, see chapter 1 “General information” or the back page of the operating instructions.

In the event of any faults, rst check whether the pressure transmitter is mounted correctly, mechanically and electrically.

If complaint is unjustied, the handling costs will be charged.

EN

1604457.16 09/2017 EN/DE/FR/ES

13WIKA operating instructions pressure transmitter, model S-10

Page 14

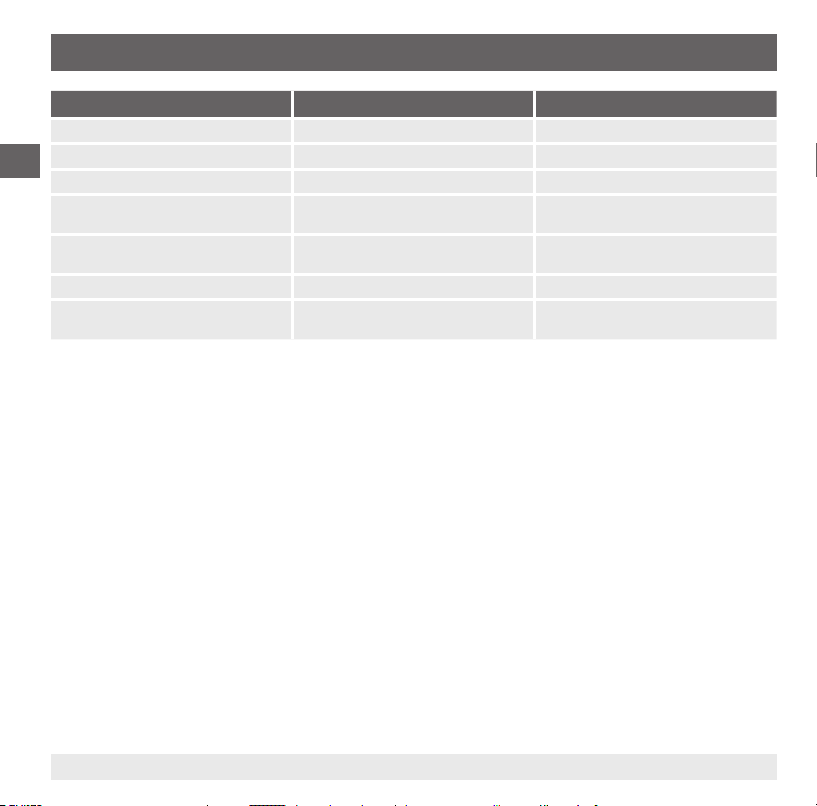

7. Faults

Faults Causes Measures

No output signal Cable break Check the continuity

Deviating zero point signal Overload safety exceeded Observe the permissible overload safety

EN

Deviating zero point signal Too high/low working temperature Observe the permissible temperatures

Constant output signal upon change in

pressure

Signal span varies EMC interference sources in the environ-

Signal span varies/inaccurate Too high/low working temperature Observe the permissible temperatures

Signal span drops/too small Mechanical overload caused by overpres-

If complaint is unjustied, we will charge you the complaint processing fees.

Mechanical overload caused by overpressure

ment; for example, frequency converter

sure

Replace instrument; if it fails repeatedly,

contact the manufacturer

Shield instrument; cable shield; remove

source of interference

Replace instrument; if it fails repeatedly,

contact the manufacturer

14 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 15

8. Maintenance and cleaning

8. Maintenance and cleaning

8.1 Maintenance

This pressure transmitter is maintenance-free.

Repairs must only be carried out by the manufacturer.

8.2 Cleaning

CAUTION!

Unsuitable cleaning agents

Cleaning with unsuitable cleaning agents may damage the instrument and the product label.

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects.

▶

Do not use any abrasive cloths or sponges.

Suitable cleaning agents

■

Water

■

Conventional dishwashing detergent

Cleaning the instrument

1. Depressurise and de-energise the pressure transmitter.

2. Wipe the instrument surface using a soft, damp cloth.

EN

1604457.16 09/2017 EN/DE/FR/ES

15WIKA operating instructions pressure transmitter, model S-10

Page 16

9. Dismounting, return and disposal

9. Dismounting, return and disposal

9.1 Dismounting

EN

Dismounting the instrument

1. Depressurise and de-energise the pressure transmitter.

.

2

Disconnect the electrical connection.

.

Unscrew the pressure transmitter with a spanner using the spanner ats.

3

9.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances (acids, bases, solutions, etc.)

and must therefore be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, ammable or toxic substances), harmful

media (e.g. corrosive, toxic, carcinogenic, radioactive), and also with refrigeration plants and compressors, there is a danger of physical injuries and damage to property and the environment.

▶

Should a failure occur, aggressive media with extremely high temperature and under high pressure

or vacuum may be present at the instrument.

▶

Wear the requisite protective equipment.

WARNING!

Physical injuries and damage to property and the environment through residual media

Residual media in the dismounted instrument can result in a risk to persons, the environment and

equipment.

▶

With hazardous substances, include the material safety data sheet for the corresponding medium.

▶

Clean the instrument, see chapter 7.2 “Cleaning”.

16 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 17

9. Dismounting, return and disposal

When returning the instrument, use the original packaging or a suitable transport packaging.

Information on returns can be found under the heading “Service” on our local website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally compatible way and in accordance

with the country-specic waste disposal regulations.

EN

1604457.16 09/2017 EN/DE/FR/ES

17WIKA operating instructions pressure transmitter, model S-10

Page 18

10.Specications

10. Specications

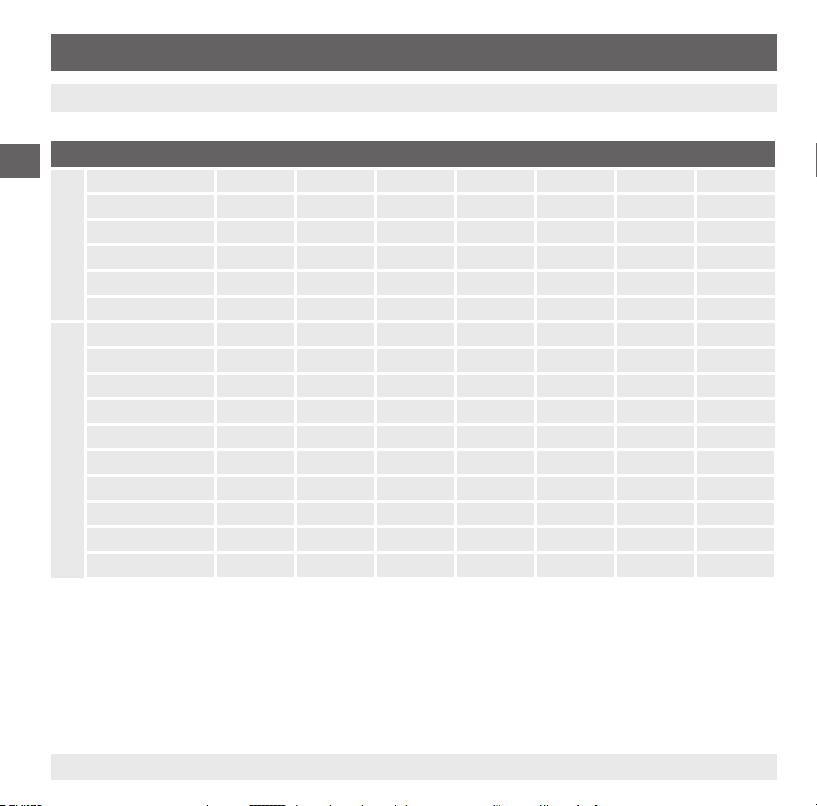

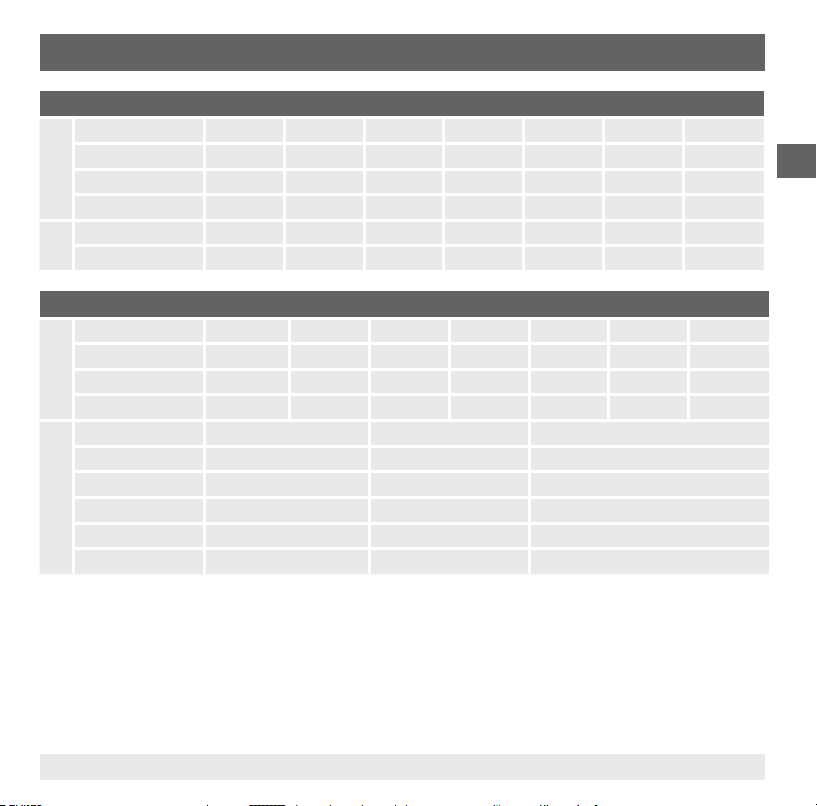

Measuringrangesandoverloadsafety(gaugepressure)

EN

bar Measuring range 0 ... 0.01 0 ... 0.16 0 ... 0.25 0 ... 0.4 0 ... 0.6 0 ... 1 0 ... 1.6

Overload safety 1 1.5 2 2 4 5 10

Measuring range 0 ... 2.5 0 ... 4 0 ... 6 0 ... 10 0 ... 16 0 ... 25 0 ... 40

Overload safety 10 17 35 35 80 50 80

Measuring range 0 ... 60 0 ... 100 0 ... 160 0 ... 250 0 ... 400 0 ... 600 0 ... 1,000

Overload safety 120 200 320 500 800 1,200 1,500

psi Measuring range 0 ... 5 0 ... 10 0 ... 15 0 ... 20 0 ... 25 0 ... 30 0 ... 50

Overload safety 29 29 72.5 145 145 145 240

Measuring range 0 ... 60 0 ... 100 0 ... 150 0 ... 160 0 ... 170 0 ... 200 0 ... 250

Overload safety 240 500 500 1,160 1,160 1,160 1,160

Measuring range 0 ... 300 0 ... 400 0 ... 500 0 ... 600 0 ... 750 0 ... 800 0 ... 1,000

Overload safety 1,160 1,160 1,160 1,160 1,740 1,740 1,740

Measuring range 0 ... 1,500 0 ... 1,600 0 ... 2,000 0 ... 3,000 0 ... 4,000 0 ... 5,000 0 ... 6,000

Overload safety 2,900 4,600 4,600 7,200 7,200 7,200 11,600

Measuring range 0 ... 7,500 0 ... 8,000 0 ... 10,000 0 ... 15,000

Overload safety 17,400 17,400 17,400 21,700

18 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 19

10.Specications

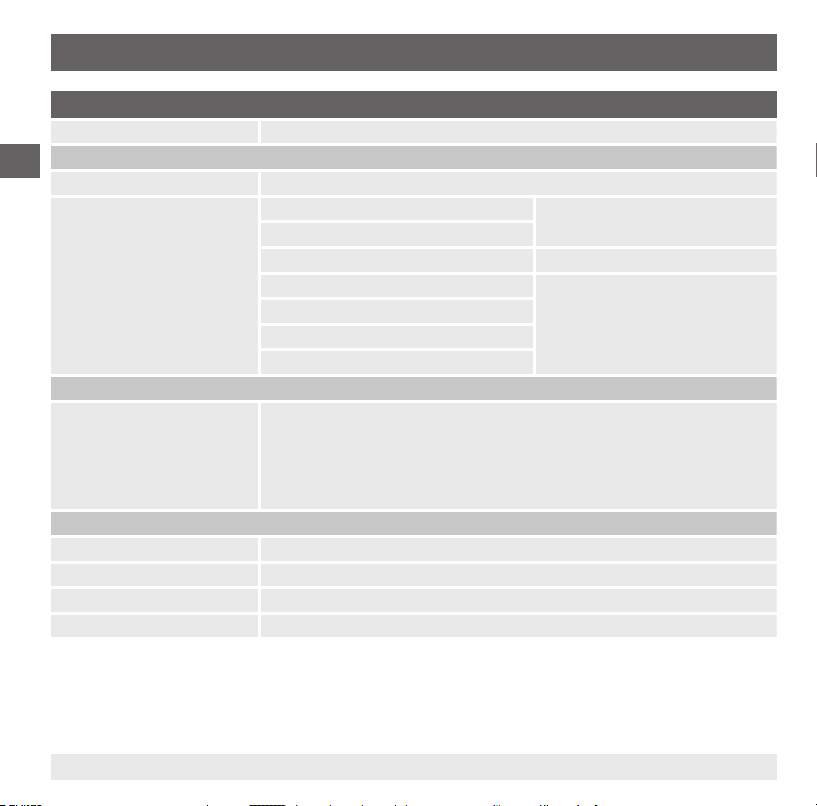

Measuringrangesandoverloadsafety(absolutepressure)

bar Measuring range 0 ... 0.25 0 ... 0.4 0 ... 0.6 0 ... 1 0 ... 1.6 0 ... 2.5 0 ... 4

Overload safety 2 2 4 5 10 10 17

Measuring range 0 ... 6 0 ... 10 0 ... 16 0 ... 25 0.8 ... 1.2

Overload safety 35 35 80 80 5

psi Measuring range 0 ... 15 0 ... 25 0 ... 50 0 ... 100 0 ... 250

Overload safety 72.5 145 240 500 1,160

Measuringrangesandoverloadsafety(vacuumand+/-measuringrange)

bar Measuring range -0.6 ... 0 -0.4 ... 0 -0.25 ... 0 -0.16 ... 0 -0.1 ... 0 -1 ... 0 -1 ... +0.6

Overload safety 4 2 2 1.5 1 5 10

Measuring range -1 ... +1.5 -1 ... +3 -1 ... +5 -1 ... +9 -1 ... +15 -1 ... +24

Overload safety 10 17 35 35 80 50

psi Measuring range -15 inHg ... 0 -30 inHg ... 0 -30 inHg ... +15

Overload safety 72.5 72.5 145

Measuring range -30 inHg ... +30 -30 inHg ... +60 -30 inHg ... +100

Overload safety 240 240 500

Measuring range -30 inHg ... +160 -30 inHg ... +200 -30 inHg ... +300

Overload safety 1,160 1,160 1,160

EN

1604457.16 09/2017 EN/DE/FR/ES

19WIKA operating instructions pressure transmitter, model S-10

Page 20

10.Specications

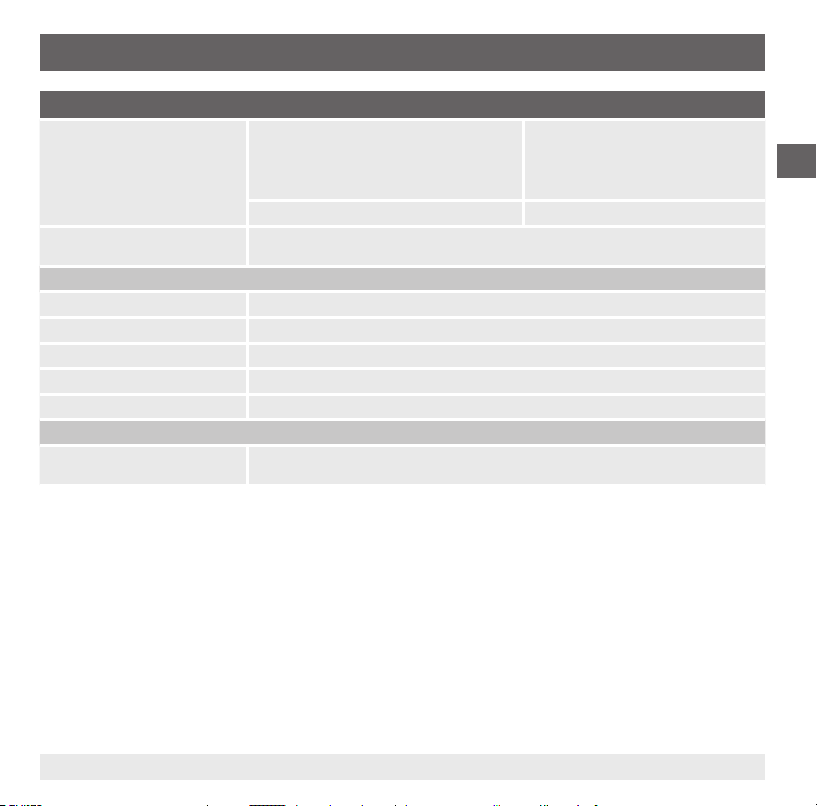

Specications

Vacuum tightness Yes

Output signal

EN

Output signal see product label

Load 4 ... 20 mA (2-wire) ≤ (power supply - 10 V) / 0.02 A

20 ... 4 mA (2-wire)

0 ... 20 mA (3-wire) ≤ (power supply - 3 V) / 0.02 A

DC 0 ... 10 V (3-wire) > max. output signal / 1 mA

DC 0 ... 5 V (3-wire)

DC 1 ... 5 V (3-wire)

DC 0.5 ... 4.5 V ratiometric (3-wire)

Voltage supply

Power supply see product label

The power supply for the pressure transmitter must be made via an energy-limited electri-

cal circuit in accordance with section 9.3 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC

60950-1, or class 2 in accordance with UL1310/UL1585 (NEC or CEC). The voltage supply

must be suitable for operation above 2,000 m should the pressure transmitter be used at this

altitude.

Accuracyspecications

Non-linearity (per IEC 61298-2) ≤ ±0.2 % of span BFSL

Non-repeatability ≤ ±0.1 % of span

Accuracy at reference conditions see product label

Adjustability of zero point and span ±5 %

20 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 21

10.Specications

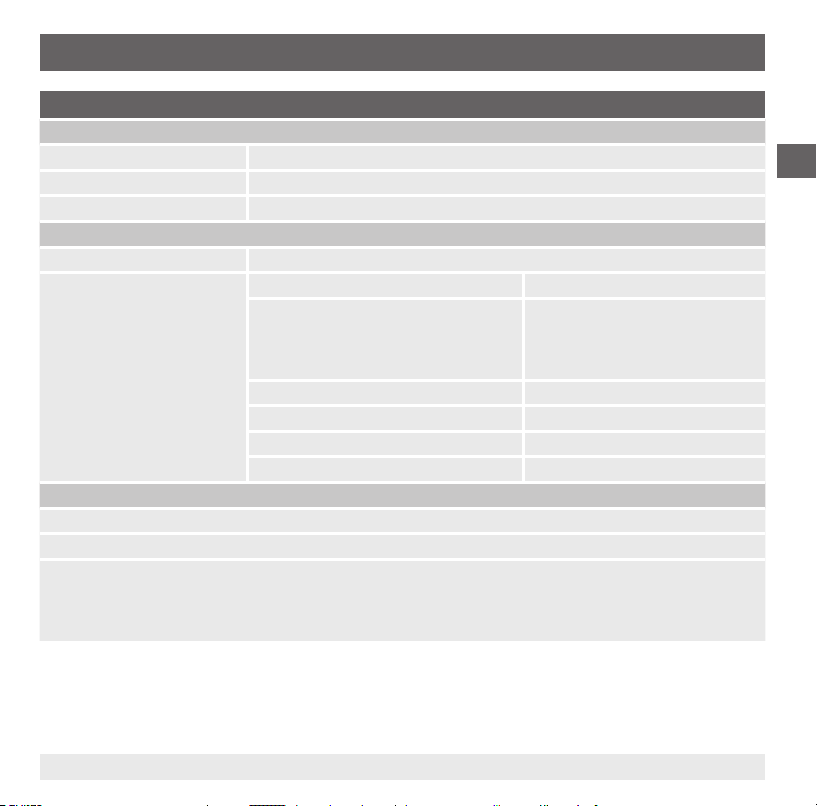

Specications

Temperature error at 0 ... 80 °C Mean temperature coecient of zero point Measuring ranges ≤ 0.25 bar:

Mean temperature coecient of span: ≤ 0.2 % of span/10 K

Long-term stability at reference

conditions

Reference conditions

Ambient temperature 15 ... 25 °C

Atmospheric pressure 860 ... 1,060 mbar

Humidity 45 ... 75 % r. h.

Power supply DC 24 V

Mounting position Calibrated in vertical mounting position with process connection facing downwards.

Time response

Settling time ≤ 1 ms

≤ ±0.2 % of span/year

≤ 2 ms for output signal DC 0.5…4.5 V ratiometric and measuring ranges < 400 mbar, 10 psi

≤ 0.4 % of span/10 K

Measuring ranges > 0.25 bar

≤ 0.2 % of span/10 K

EN

1604457.16 09/2017 EN/DE/FR/ES

21WIKA operating instructions pressure transmitter, model S-10

Page 22

10.Specications

Specications

Operating conditions

Ingress protection The stated ingress protection only applies when plugged in using mating connectors that have

EN

Shock resistance 1,000 g (IEC 60068-2-27, mechanical)

Vibration resistance 20 g (per IEC 60068-2-6)

Permissible temperature ranges Medium: -30 ... +100 °C (option: -40 ... +125 °C)

Pollution degree max. 3

Humidity ≤ 80 % r. h. (non-condensing)

the appropriate ingress protection.

Angular connector DIN 175301-803 A IP65

Angular connector DIN 175301-803 with ½ NPT IP65

Circular connector M12 x 1 (4-pin) IP67

Bayonet connector (6-pin) IP67

½ NPT conduit male, with cable outlet IP67

Cable outlet (standard) IP67

Cable outlet (not adjustable) IP68

Cable outlet (adjustable) IP68

Ambient: -20 ... +80 °C

Storage: -40 ... +100 °C

22 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 23

10.Specications

Specications

Electrical connection

Short-circuit resistance S+ vs. U-

Reverse polarity protection U

Insulation voltage DC 500 V

Materials

Wetted parts Stainless steel

Non-wetted parts Case Stainless steel

CE conformity

Pressure equipment directive

RoHS directive

EMC directive, EN 61326 emission (group 1, class B) and interference immunity (industrial application)

The existence of strong electromagnetic elds in a frequency range of < 2.7 GHz can result in increased measuring errors up to 1 %. Do

not install the instruments in the vicinity of strong electromagnetic sources of interference (e.g. transmitting devices, radio equipment),

or use sheath current lters where applicable.

vs. U-

+

Internal pressure transmission medium Synthetic oil

Instruments with a measuring range of >

25 bar relative do not contain any pressure

transmission medium (dry measuring cell).

Clamping nut PA

Angular connector PA

O-rings at the clamping nut NBR

Flat gasket VMQ

EN

For further specications see WIKA data sheet PE 81.01 and the order documentation.

1604457.16 09/2017 EN/DE/FR/ES

23WIKA operating instructions pressure transmitter, model S-10

Page 24

10.Specications

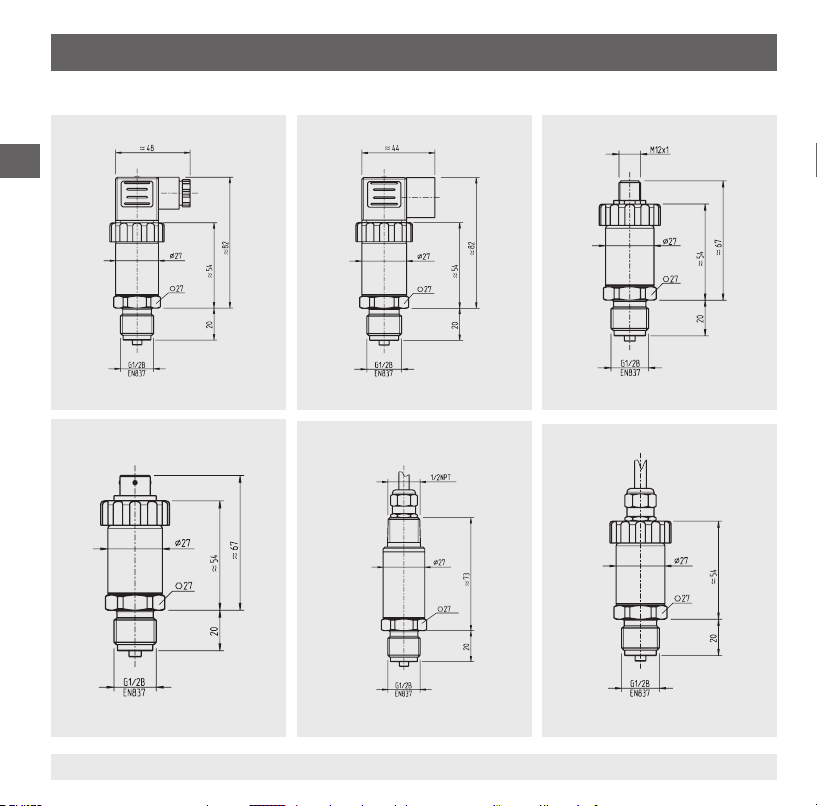

Dimensions in mm

Angular connector DIN 175301-803 A Angular connector DIN 175301-803 with

½ NPT

EN

Weight: approx. 200 g Weight: approx. 200 g Weight: approx. 200 g

Bayonet connector (6-pin)

½ NPT conduit male, with cable outlet

Circular connector M12 x 1 (4-pin)

Cable outlet, standard

Weight: approx. 200 g Weight: approx. 200 g

Weight: approx. 200 g

24 WIKA operating instructions pressure transmitter, model S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 25

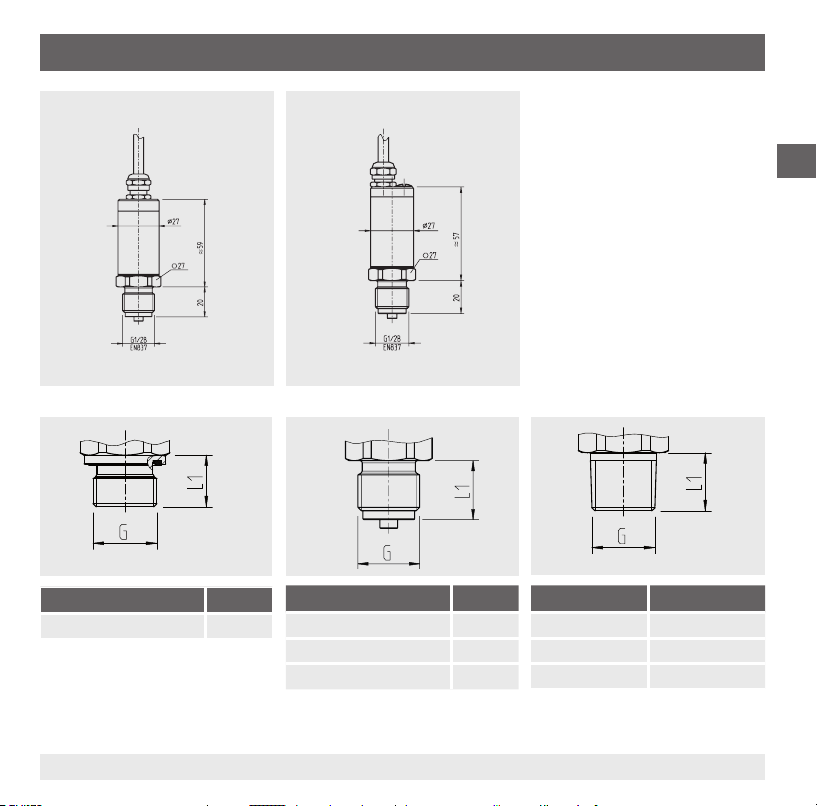

10.Specications

Cable outlet, not adjustable Cable outlet, adjustable

Weight: approx. 200 g Weight: approx. 200 g

EN

G L1

G ¼ A DIN 3852-E 14

1604457.16 09/2017 EN/DE/FR/ES

G L1

G ¼ B EN 837 13

G ½ B EN 837 20

M20 x 1.5 20

G L1

¼ NPT 13

½ NPT 19

R ¼ 13

25WIKA operating instructions pressure transmitter, model S-10

Page 26

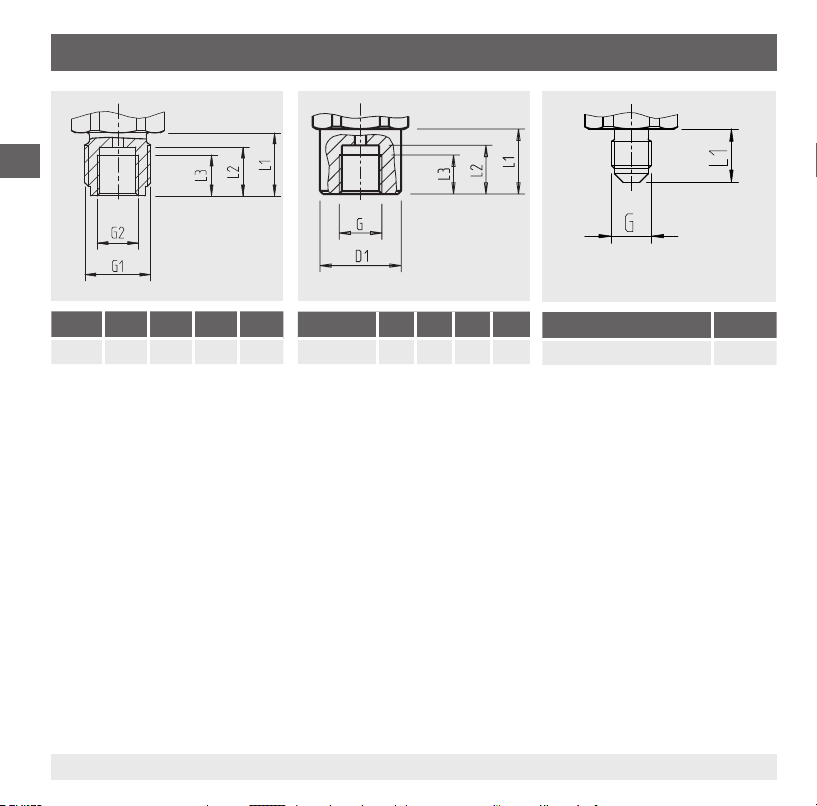

10.Specications

EN

G1 G2 L1 L2 L3

G ½ B G ¼ 20 15.5 13

For special models S-10000 or special version S-10, other technical specications apply. Please note the

specications stated on the order conrmation and the delivery note.

For further specications see WIKA data sheet PE 81.01 and the order documentation.

26 WIKA operating instructions pressure transmitter, model S-10

G D1 L1 L2 L3

G ¼ female 25 20 15 12

G L1

7/16-20 UNF with 74° taper 15

1604457.16 09/2017 EN/DE/FR/ES

Page 27

Inhalt

Inhalt

1. Allgemeines 28

2. Aufbau und Funktion 29

3. Sicherheit 30

4. Transport, Verpackung und Lagerung 32

5. Inbetriebnahme, Betrieb 33

6. Einstellung Nullpunkt und Spanne 36

7. Störungen 37

8. Wartung und Reinigung 39

9. Demontage, Rücksendung und Entsorgung 40

10. Technische Daten 42

Konformitätserklärungen finden Sie online unter www.wika.de

DE

1604457.16 09/2017 EN/DE/FR/ES

27WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 28

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach dem aktuellen Stand der Technik konstruiert und

gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere

DE

Managementsysteme sind nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist

die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für das Fachpersonal

jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes

weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden

haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Zugehöriges Datenblatt: PE 81.01

- Anwendungsberater:

Tel.: +49 9372 132-8976

Fax: +49 9372 132-8008976

support-tronic@wika.de

28 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 29

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Überblick

2.2 Lieferumfang

■

Druckmessumformer

■

Betriebsanleitung

Lieferumfang mit dem Lieferschein abgleichen.

Elektrischer Anschluss (je nach Ausführung)

Gehäuse; Typenschild

Prozessanschluss, Schlüsselfläche

Prozessanschluss, Gewinde

DE

1604457.16 09/2017 EN/DE/FR/ES

29WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 30

3. Sicherheit

3. Sicherheit

3.1 Symbolerklärung

WARNUNG!

DE

3.2 Bestimmungsgemäße Verwendung

Der Druckmessumformer dient der Messung von Druck. Der gemessene Druck wird als elektrisches Signal

ausgegeben.

Den Druckmessumformer nur in Anwendungen verwenden, die innerhalb seiner technischen Leistungsgrenzen liegen

(z. B. max. Umgebungstemperatur, Materialverträglichkeit, ...). Der Druckmessumformer eignet sich für Anwendungen

mit Verschmutzungsgrad 3 und einer Umgebungstemperatur von -20 ... +80 °C.

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und

konstruiert und darf nur dementsprechend verwendet werden.

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder zu schweren Verletzungen

führen kann, wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten

Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen ezienten und störungsfreien

Betrieb hervor.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind ausgeschlossen.

30 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 31

3. Sicherheit

3.3 Personalqualikation

Fachpersonal

Das vom Betreiber autorisierte Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der

Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften, geltenden

Normen und Richtlinien in der Lage, die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu

erkennen.

3.4 Beschilderung, Sicherheitskennzeichnungen

Typenschild

DE

S# Serien-Nr., P# Typcode

Hilfsenergie

Ausgangssignal

Messbereich

Symbole

Vor Montage und Inbetriebnahme des Gerätes unbedingt die Betriebsanleitung lesen!

1604457.16 09/2017 EN/DE/FR/ES

Genauigkeit

Anschlussbelegung

31WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 32

4. Transport, Verpackung und Lagerung

4. Transport, Verpackung und Lagerung

4.1 Transport

Druckmessumformer auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

DE

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen Schutz (z. B. wechselnder

Einbauort, Reparatursendung).

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -40 ... +100 °C

■

Feuchtigkeit: 45 ... 75 % relative Feuchte (keine Betauung)

32 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 33

5. Inbetriebnahme, Betrieb

5. Inbetriebnahme, Betrieb

5.1 Gerät montieren

Vor der Inbetriebnahme den Druckmessumformer optisch prüfen.

■

Auslaufende Flüssigkeit weist auf eine Beschädigung hin.

■

Den Druckmessumformer nur in sicherheitstechnisch einwandfreiem Zustand einsetzen.

Anforderungen an Montagestelle

Die Montagestelle muss folgende Bedingungen erfüllen:

■

Umgebung entspricht einem max. Verschmutzungsgrad 3.

■

Luftfeuchte ≤ 80 % r. F. (nicht-kondensierend).

■

Geschützt vor Wettereinüssen.

■

Dichtächen sind sauber und unbeschädigt.

■

Ausreichend Platz für eine sichere elektrische Installation.

■

Angaben zu Einschraublöchern und Einschweißstutzen siehe Technische Information IN 00.14 unter www.wika.de.

■

Zulässige Umgebungs- und Messstotemperaturen bleiben innerhalb der Leistungsgrenzen. Mögliche Einschränkungen des Umgebungstemperaturbereichs durch verwendeten Gegenstecker berücksichtigen.

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“

Abdichtungsvarianten

Zylindrische Gewinde

Dichtfläche mit Flachdichtung, Dichtlinse oder

WIKA-Profildichtung abdichten.

nach EN 837

Kegelige Gewinde

Gewinde mit Dichtwerksto umwickeln

(z. B. PTFE-Band).

nach DIN 3852-E

DE

1604457.16 09/2017 EN/DE/FR/ES

NPT, R und PT

33WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 34

5. Inbetriebnahme, Betrieb

Gerät montieren

Der max. Drehmoment ist abhängig von der Montagestelle (z. B. Werksto und Form). Bei Fragen

wenden Sie sich an unseren Anwendungsberater.

→ Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der Betriebsanleitung.

DE

1. Dichtäche abdichten (→ siehe „Abdichtungsvarianten“).

.

Druckmessumformer handfest in Montagestelle einschrauben.

2

.

Mit Drehmomentschlüssel über Schlüsseläche anziehen.

3

5.2 Gerät elektrisch anschließen

Anforderungen an Spannungsversorgung

→ Hilfsenergie siehe Typenschild

Die Versorgung des Druckmessumformers muss durch einen energiebegrenzten Stromkreis gemäß 9.4 der

UL/EN/IEC 61010-1 oder LPS gemäß UL/EN/IEC 60950-1 / CSA C22.2 No.60950-1 oder Class 2 gemäß UL1310/

UL1585 (NEC oder CEC) erfolgen. Die Spannungsversorgung muss für den Betrieb oberhalb 2.000 m geeignet sein,

falls der Druckmessumformer ab dieser Höhe verwendet wird.

Anforderungen an elektrische Verbindung

■

Kabeldurchmesser passt zur Kabeldurchführung des Gegensteckers.

■

Kabelverschraubung und Dichtungendes Gegensteckers sitzen korrekt.

■

Bei Kabelausgängen kann keine Feuchtigkeit am Kabelende eindringen.

Anforderung an Schirmung und Erdung

Der Druckmessumformer muss entsprechend dem Erdungskonzept der Anlage geschirmt und geerdet werden.

Gerät anschließen

1. Gegenstecker oder Kabelausgang konfektionieren.

→ Anschlussbelegungen siehe Typenschild

.

2

Steckverbindung herstellen.

34 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 35

5. Inbetriebnahme, Betrieb

5.3 Montage Winkelstecker DIN 175301-803

1. Schraube (1) lösen.

2. Kabelverschraubung (2) lösen.

3. Winkelstecker (5) + (6) vom Gerät abziehen.

4. VORSICHT!

Unsachgemäße Montage

Dichtung des Winkelgehäuses wird beschädigt.

▶

Klemmblock (6) nicht durch Schraubenöffnung (1) oder

Kabelverschraubung (2) herausdrücken.

Über Montageönung (D) den Klemmblock (6) aus dem Winkelgehäuse

(5) hebeln.

5. Kabel durch Kabelverschraubung (2), Ring (3), Dichtung (4) und Winkelgehäuse (5) schieben.

6. Kabelenden gemäß Anschlussschema am Klemmblocks (6) anschließen.

7. Winkelgehäuse (5) auf Klemmblock (6) drücken.

8. Darauf achten, dass die Dichtungen unbeschädigt sind und Kabelverschraubung und Dichtungen korrekt sitzen, um die Schutzart zu gewährleisten.

9. Kabel über Kabelverschraubung (2) verschrauben.

10. Flachdichtung (7) über Anschlusspins des Gerätes legen.

11. Winkelstecker (5) + (6) auf Gerät stecken.

12. Schraube (1) festziehen.

(D)

DE

(2)

(3)

(4)

(1)

(5)

(6)

(7)

(8)

1604457.16 09/2017 EN/DE/FR/ES

35WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 36

6. Einstellung Nullpunkt und Spanne

6. Einstellung Nullpunkt und Spanne

Das Potentiometer zur Spanneeinstellung nur verstellen, wenn eine Kalibrierausstattung vorhanden ist,

die mindestens die dreifache Genauigkeit des Druckmessumformers aufweist.

DE

7.1Vorbereitung(AbbildungA)

Um Zugang zu den Potentiometern zu erhalten, das Gerät wie folgt önen:

■

Den elektrischen Anschluss vom Gerät trennen.

■

Den Griring lösen.

■

Den Gerätestecker vorsichtig aus dem Gerät ziehen.

■

Den Gerätestecker gemäß Anschlussschema mit der Hilfsenergie

und einer Anzeigeeinheit (z. B. Strommessgerät, Spannungsmessgerät)

verbinden.

7.2EinstellungNullpunkt(AbbildungB)

■

Den Messbereichsanfang anfahren.

■

Über das Potentiometer „Z“ das minimale Ausgangssignal justieren (z. B. 4

mA)

7.3EinstellungSpanne(AbbildungB)

■

Den Messbereichsendwert anfahren.

■

Über das Potentiometer „S“ das maximale Ausgangssignal justieren (z. B.

20 mA).

■

Den Nullpunkt überprüfen und bei Abweichung erneut justieren.

■

Den Vorgang solange wiederholen bis Nullpunkt und Spanne korrekt

eingestellt sind.

A

B

36 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 37

7. Störungen

7. Störungen

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Können Störungen mit Hilfe der aufgeführten Maßnahmen nicht beseitigt werden, Druckmessumformer

unverzüglich außer Betrieb setzen.

▶

Sicherstellen, dass kein Druck bzw. Signal mehr anliegt und gegen versehentliche Inbetriebnahme

schützen.

▶

Kontakt mit dem Hersteller aufnehmen.

▶

Bei notwendiger Rücksendung die Hinweise unter Kapitel 8.2 „Rücksendung“ beachten.

WARNUNG!

Körperverletzungen,Sach-undUmweltschädendurchgefährlicheMessstoe

Bei Kontakt mit gefährlichen Messstoen (z. B. Sauersto, Acetylen, brennbaren oder giftigen Stoen),

gesundheitsgefährdenden Messstoen (z. B. ätzend, giftig, krebserregend, radioaktiv) sowie bei Kälteanlagen, Kompressoren besteht die Gefahr von Körperverletzungen, Sach- und Umweltschäden.

▶

Am Gerät können im Fehlerfall aggressive Messstoffe mit extremer Temperatur und unter hohem

Druck oder Vakuum anliegen.

▶

Bei diesen Messstoffen müssen über die gesamten allgemeinen Regeln hinaus die einschlägigen

Vorschriften beachtet werden.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.4 „Persönliche Schutzausrüstung“).

Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der Betriebsanleitung.

Bei Störungen zuerst überprüfen, ob der Druckmessumformer mechanisch und elektrisch korrekt montiert ist.

Im unberechtigten Reklamationsfall werden Bearbeitungskosten berechnet.

DE

1604457.16 09/2017 EN/DE/FR/ES

37WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 38

7. Störungen

Störungen Ursachen Maßnahmen

Kein Ausgangssignal Leitungsbruch Durchgang überprüfen

Abweichendes Nullpunkt-Signal Überlastsicherheit überschritten Zulässige Überlastsicherheit einhalten

Abweichendes Nullpunkt-Signal Zu hohe/niedrige Einsatztemperatur Zulässige Temperaturen einhalten

DE

Gleichbleibendes Ausgangssignal bei

Druckänderung

Signalspanne schwankend EMV-Störquellen in Umgebung,

Signalspanne schwankend/ungenau Zu hohe/niedrige Einsatztemperatur Zulässige Temperaturen einhalten

Signalspanne fällt ab/zu klein Mechanische Überlastung durch

Im unberechtigten Reklamationsfall berechnen wir die Reklamationsbearbeitungskosten.

Mechanische Überlastung durch

Überdruck

z. B. Frequenzumrichter

Überdruck

Gerät austauschen; bei wiederholtem

Ausfall Rücksprache mit Hersteller

Gerät abschirmen; Leitungsabschirmung;

Störquelle entfernen

Gerät austauschen; bei wiederholtem

Ausfall Rücksprache mit Hersteller

38 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 39

8. Wartung und Reinigung

8. Wartung und Reinigung

8.1 Wartung

Dieser Druckmessumformer ist wartungsfrei.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

8.2 Reinigung

VORSICHT!

Ungeeignete Reinigungsmittel

Eine Reinigung mit ungeeigneten Reinigungsmitteln kann Gerät und Typenschild beschädigen.

▶

Keine aggressiven Reinigungsmittel verwenden.

▶

Keine harten oder spitzen Gegenstände verwenden.

▶

Keine scheuernden Tücher oder Schwämme verwenden.

Geeignete Reinigungsmittel

■

Wasser

■

Handelsüblicher Geschirrreiniger

Gerät reinigen

1. Druckmessumformer druck- und stromlos schalten.

2. Geräteoberäche mit weichem, feuchten Tuch abwischen.

DE

1604457.16 09/2017 EN/DE/FR/ES

39WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 40

9. Demontage, Rücksendung und Entsorgung

9. Demontage, Rücksendung und Entsorgung

9.1 Demontage

WARNUNG!

DE

Gerät demontieren

1. Druckmessumformer druck- und stromlos schalten.

.

2

Elektrische Verbindung trennen.

.

Druckmessumformer mit Schraubenschlüssel über Schlüsseläche ausschrauben.

3

9.2 Rücksendung

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren, Laugen, Lösungen, etc.) sein und sind daher

vor der Rücksendung zu reinigen.

Körperverletzungen,Sach-undUmweltschädendurchgefährlicheMessstoe

Bei Kontakt mit gefährlichen Messstoen (z. B. Sauersto, Acetylen, brennbaren oder giftigen Stoen),

gesundheitsgefährdenden Messstoen (z. B. ätzend, giftig, krebserregend, radioaktiv) sowie bei Kälteanlagen, Kompressoren besteht die Gefahr von Körperverletzungen, Sach- und Umweltschäden.

▶

Am Gerät können im Fehlerfall aggressive Messstoffe mit extremer Temperatur und unter hohem

Druck oder Vakuum anliegen.

▶

Notwendige Schutzausrüstung tragen.

WARNUNG!

Körperverletzungen,Sach-undUmweltschädendurchMessstoreste

Messstoreste im ausgebauten Gerät können zur Gefährdung von Personen, Umwelt und Einrichtung

führen.

▶

Bei Gefahrenstoffen das Sicherheitsdatenblatt für den entsprechenden Messstoff beilegen.

▶

Gerät reinigen, siehe Kapitel 7.2 „Reinigung“.

40 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 41

9. Demontage, Rücksendung und Entsorgung

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung verwenden.

Hinweise zur Rücksendung benden sich in der Rubrik „Service“ auf unserer lokalen Internetseite.

9.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen Abfallbehandlungs- und

Entsorgungsvorschriften umweltgerecht entsorgen.

1604457.16 09/2017 EN/DE/FR/ES

DE

41WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 42

10. Technische Daten

10. Technische Daten

MessbereicheundÜberlastsicherheiten(Relativdruck)

bar Messbereich 0 ... 0,01 0 ... 0,16 0 ... 0,25 0 ... 0,4 0 ... 0,6 0 ... 1 0 ... 1,6

DE

Überlastsicherheit 1 1,5 2 2 4 5 10

Messbereich 0 ... 2,5 0 ... 4 0 ... 6 0 ... 10 0 ... 16 0 ... 25 0 ... 40

Überlastsicherheit 10 17 35 35 80 50 80

Messbereich 0 ... 60 0 ... 100 0 ... 160 0 ... 250 0 ... 400 0 ... 600 0 ... 1.000

Überlastsicherheit 120 200 320 500 800 1.200 1.500

psi Messbereich 0 ... 5 0 ... 10 0 ... 15 0 ... 20 0 ... 25 0 ... 30 0 ... 50

Überlastsicherheit 29 29 72,5 145 145 145 240

Messbereich 0 ... 60 0 ... 100 0 ... 150 0 ... 160 0 ... 170 0 ... 200 0 ... 250

Überlastsicherheit 240 500 500 1.160 1.160 1.160 1.160

Messbereich 0 ... 300 0 ... 400 0 ... 500 0 ... 600 0 ... 750 0 ... 800 0 ... 1.000

Überlastsicherheit 1.160 1.160 1.160 1.160 1.740 1.740 1.740

Messbereich 0 ... 1.500 0 ... 1.600 0 ... 2.000 0 ... 3.000 0 ... 4.000 0 ... 5.000 0 ... 6.000

Überlastsicherheit 2.900 4.600 4.600 7.200 7.200 7.200 11.600

Messbereich 0 ... 7.500 0 ... 8.000 0 ... 10.000 0 ... 15.000

Überlastsicherheit 17.400 17.400 17.400 21.700

42 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 43

10. Technische Daten

MessbereicheundÜberlastsicherheiten(Absolutdruck)

bar Messbereich 0 ... 0,25 0 ... 0,4 0 ... 0,6 0 ... 1 0 ... 1,6 0 ... 2,5 0 ... 4

Überlastsicherheit 2 2 4 5 10 10 17

Messbereich 0 ... 6 0 ... 10 0 ... 16 0 ... 25 0,8 ... 1,2

Überlastsicherheit 35 35 80 80 5

psi Messbereich 0 ... 15 0 ... 25 0 ... 50 0 ... 100 0 ... 250

Überlastsicherheit 72,5 145 240 500 1.160

MessbereicheundÜberlastsicherheiten(Vakuum-und+/-Messbereich)

bar Messbereich -0,6 ... 0 -0,4 ... 0 -0,25 ... 0 -0,16 ... 0 -0,1 ... 0 -1 ... 0 -1 ... +0,6

Überlastsicherheit 4 2 2 1,5 1 5 10

Messbereich -1 ... +1,5 -1 ... +3 -1 ... +5 -1 ... +9 -1 ... +15 -1 ... +24

Überlastsicherheit 10 17 35 35 80 50

psi Messbereich -15 inHg ... 0 -30 inHg ... 0 -30 inHg ... +15

Überlastsicherheit 72,5 72,5 145

Messbereich -30 inHg ... +30 -30 inHg ... +60 -30 inHg ... +100

Überlastsicherheit 240 240 500

Messbereich -30 inHg ... +160 -30 inHg ... +200 -30 inHg ... +300

Überlastsicherheit 1.160 1.160 1.160

DE

1604457.16 09/2017 EN/DE/FR/ES

43WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 44

10. Technische Daten

Technische Daten

Vakuumfestigkeit Ja

Ausgangssignal

Ausgangssignal siehe Typenschild

DE

Bürde 4 ... 20 mA (2-Leiter) ≤ (Hilfsenergie - 10 V) / 0,02 A

20 ... 4 mA (2-Leiter)

0 ... 20 mA (3-Leiter) ≤ (Hilfsenergie - 3 V) / 0,02 A

DC 0 ... 10 V (3-Leiter) > max. Ausgangssignal / 1 mA

DC 0 ... 5 V (3-Leiter)

DC 1 ... 5 V (3-Leiter)

DC 0,5 ... 4,5 V ratiometrisch (3-Leiter)

Spannungsversorgung

Hilfsenergie siehe Typenschild

Die Versorgung des Druckmessumformers muss durch einen energiebegrenzten Stromkreis

gemäß 9.3 der UL/EN/IEC 61010-1 oder LPS gemäß UL/EN/IEC 60950-1 oder Class 2 gemäß

UL1310/UL1585 (NEC oder CEC) erfolgen. Die Spannungsversorgung muss für den Betrieb

oberhalb 2.000 m geeignet sein, falls der Druckmessumformer ab dieser Höhe verwendet wird.

Genauigkeitsangaben

Nichtlinearität (nach IEC 61298-2) ≤ ±0,2 % der Spanne BFSL

Nichtwiederholbarkeit ≤ ±0,1 % der Spanne

Genauigkeit bei

Referenzbedingungen

Einstellbarkeit Nullpunkt und

Spanne

siehe Typenschild

±5 %

44 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 45

10. Technische Daten

Technische Daten

Temperaturfehler bei 0 ... 80 °C Mittlerer Temperaturkoezient des

Langzeitstabilität bei

Referenzbedingungen

Referenzbedingungen

Umgebungstemperatur 15 ... 25 °C

Luftdruck 860 ... 1.060 mbar

Luftfeuchte 45 ... 75 % r. F.

Hilfsenergie DC 24 V

Einbaulage Kalibriert bei senkrechter Einbaulage mit dem Prozessanschluss nach unten

Zeitverhalten

Einschwingzeit ≤ 1 ms

Nullpunktes

Mittlerer Temperaturkoezient der Spanne: ≤ 0,2 % der Spanne/10 K

≤ ±0,2 % der Spanne/Jahr

≤ 2 ms für Ausgangssignal DC 0,5…4,5 V ratiometrisch und Messbereiche < 400 mbar, 10 psi

Messbereiche ≤ 0,25 bar:

≤ 0,4 % der Spanne/10 K

Messbereiche > 0,25 bar

≤ 0,2 % der Spanne/10 K

DE

1604457.16 09/2017 EN/DE/FR/ES

45WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 46

10. Technische Daten

Technische Daten

Einsatzbedingungen

Schutzart Die angegebenen Schutzarten gelten nur im gesteckten Zustand mit Gegensteckern

DE

Schockfestigkeit 1.000 g (IEC 60068-2-27, mechanisch)

Vibrationsbeständigkeit 20 g (nach IEC 60068-2-6)

Zulässige Temperaturbereiche Messsto: -30 ... +100 °C (Option: -40 ... +125 °C)

Verschmutzungsgrad max. 3

Luftfeuchte ≤ 80 % r. F. (nicht-kondensierend)

Elektrischer Anschluss

Kurzschlussfestigkeit S+ gegen U-

Verpolungsschutz U

Isolationsspannung DC 500 V

entsprechender Schutzart.

Winkelstecker DIN 175301-803 A IP65

Winkelstecker DIN 175301-803 mit ½ NPT IP65

Rundstecker M12 x 1 (4-polig) IP67

Bajonettstecker (6-polig) IP67

½ NPT Conduit außen, mit Kabelausgang IP67

Kabelausgang (Standard) IP67

Kabelausgang (nicht abgleichbar) IP68

Kabelausgang (abgleichbar) IP68

Umgebung: -20 ... +80 °C

Lagerung: -40 ... +100 °C

gegen U-

+

46 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 47

10. Technische Daten

Technische Daten

Werkstoe

Messstoberührte Teile CrNi-Stahl

Nicht messstoberührte Teile Gehäuse CrNi-Stahl

Internes Druckübertragungsmedium Synthtisches Öl

Geräte mit Messbereich > 25 bar relativ

enthalten kein Druckübertragungsmedium

(trockene Messzelle).

Griring PA

Winkelstecker PA

O-Ringe am Griring NBR

Flachdichtung VMQ

CE-Konformität

Druckgeräterichtlinie

RoHS-Richtlinie

EMV-Richtlinie, EN 61326 Emission (Gruppe 1, Klasse B) und Störfestigkeit (industrieller Bereich)

Bei Vorhandensein von starken elektromagnetischen Feldern im Frequenzbereich < 2,7 GHz, kann es zu erhöhten Messfehlern bis zu

1 % kommen. Die Geräte nicht in der Nähe von starken elektromagnetischen Störquellen installieren (z. B. Sendegeräte, Funkanlagen)

oder ggf. Mantelstromlter einsetzen.

Weitere technische Daten siehe WIKA-Datenblatt PE 81.01 und Bestellunterlagen.

DE

1604457.16 09/2017 EN/DE/FR/ES

47WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 48

10. Technische Daten

Abmessungen in mm

Winkelstecker DIN 175301-803 A Winkelstecker DIN 175301-803 mit

½ NPT

DE

Gewicht: ca. 200 g Gewicht: ca. 200 g Gewicht: ca. 200 g

Rundstecker M12 x 1 (4-polig)

Bajonettstecker (6-polig)

Gewicht: ca. 200 g Gewicht: ca. 200 g

½ NPT Conduit außen, mit

Kabelausgang

Kabelausgang, Standard

Gewicht: ca. 200 g

48 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 49

10. Technische Daten

Kabelausgang, nicht abgleichbar Kabelausgang, abgleichbar

Gewicht: ca. 200 g Gewicht: ca. 200 g

DE

G L1

G ¼ A DIN 3852-E 14

1604457.16 09/2017 EN/DE/FR/ES

G L1

G ¼ B EN 837 13

G ½ B EN 837 20

M20 x 1,5 20

G L1

¼ NPT 13

½ NPT 19

R ¼ 13

49WIKA Betriebsanleitung Druckmessumformer, Typ S-10

Page 50

10. Technische Daten

DE

G1 G2 L1 L2 L3

G ½ B G ¼ 20 15,5 13

Bei Sondertypen S-10000 oder S-10 Special Version gelten abweichende technische Spezikationen. Spezikationen

gemäß Auftragsbestätigung und Lieferschein beachten.

Weitere technische Daten siehe WIKA Datenblatt PE 81.01 und Bestellunterlagen.

G D1 L1 L2 L3

G ¼ innen 25 20 15 12

G L1

7/16-20 UNF mit 74° Konus 15

50 WIKA Betriebsanleitung Druckmessumformer, Typ S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 51

Sommaire

Sommaire

1. Généralités 52

2. Conception et fonction 53

3. Sécurité 54

4. Transport, emballage et stockage 56

5. Mise en service, utilisation 57

6. Réglage du point zéro et étendue 60

7. Dysfonctionnements 61

8. Entretien et nettoyage 63

9. Démontage, retour et mise au rebut 64

10. Spécications 66

Déclarations de conformité disponibles en ligne sur www.wika.com

FR

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 51

Page 52

1. Généralités

1. Généralités

■

L'instrument décrit dans le mode d'emploi est conçu et fabriqué selon les dernières technologies en vigueur. Tous

les composants sont soumis à des exigences environnementales et de qualité strictes durant la fabrication. Nos

systèmes de gestion sont certiés selon ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation de l'instrument. Il est possible de

FR

travailler en toute sécurité avec ce produit en respectant toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les prescriptions générales de sécurité en

vigueur pour le domaine d'application de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité immédiate de l'instrument et accessible

à tout moment pour le personnel qualié. Transmettre le mode d'emploi à l'utilisateur ou propriétaire ultérieur de

l'instrument.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneusement et compris le mode

d'emploi.

■

Les conditions générales de vente mentionnées dans les documents de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : PE 81.01

- Conseiller applications :

Tél.: +33 1 343084-84

Fax : +33 1 343084-94

info@wika.fr

52 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 53

2. Conception et fonction

2. Conception et fonction

2.1 Vue générale

Raccordement électrique (en fonction de la version)

Boîtier; plaque signalétique

Raccord process, surfaces de clé

Raccord process, filetage

2.2 Détail de la livraison

■

Transmetteur de pression

■

Mode d'emploi

Comparer le détail de la livraison avec le bordereau de livraison.

FR

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 53

Page 54

3. Sécurité

3. Sécurité

3.1 Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou des blessures

graves si elle n'est pas évitée.

FR

3.2 Utilisation conforme à l'usage prévu

Le transmetteur de pression est utilisé pour mesurer la pression. La pression mesurée est émise sous forme de signal

électrique.

Utiliser le transmetteur de pression uniquement dans des applications qui se trouvent dans les limites de ses performances techniques (par exemple température ambiante maximale, compatibilité de matériaux, ...). Le transmetteur de

pression convient pour des applications avec une pollution de degré 3 et une température ambiante de -20 ... +80 °C.

→ Pour limites de performance, voir chapitre 9 “Spécications”

L'instrument est conçu et construit exclusivement pour une utilisation conforme à l'usage prévu décrit ici et ne doit être

utilisé qu'en conséquence.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage prévu.

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de provoquer de légères blessures

ou des dommages matériels et pour l'environnement si elle n'est pas évitée.

Information

... met en exergue les conseils et recommandations utiles de même que les informations permettant

d'assurer un fonctionnement ecace et normal.

54 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 55

3. Sécurité

3.3 Qualicationdupersonnel

Personnelqualié

Le personnel qualié, autorisé par l'opérateur, est, en raison de sa formation spécialisée, de ses connaissances dans

le domaine de l'instrumentation de mesure et de régulation et de son expérience, de même que de sa connaissance

des réglementations nationales et des normes en vigueur, en mesure d'eectuer les travaux décrits et d'identier de

façon autonome les dangers potentiels.

3.4 Etiquetage, marquages de sécurité

Plaque signalétique

S# N° de série, P# Code articlePrécision

Alimentation

Signal de sortie

Etendue de mesure

Symboles

Lire impérativement le mode d’emploi avant le montage et la mise en service de l’instrument !

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 55

Configuration du raccordement

FR

Page 56

4. Transport, emballage et stockage

4. Transport, emballage et stockage

4.1 Transport

Vérier s'il existe des dégâts sur le transmetteur de pression liés au transport.

Communiquer immédiatement les dégâts constatés.

4.2 Emballage et stockage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci ore, lors d'un transport, une protection optimale (par ex. changement de lieu d'utilisa-

FR

tion, renvoi pour réparation).

Conditions admissibles sur le lieu de stockage :

■

Température de stockage : -40 ... +100 °C

■

Humidité : 45 ... 75 % d'humidité relative (sans condensation)

56 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 57

5. Mise en service, utilisation

5. Mise en service, utilisation

5.1 Montage de l'instrument

Avant la mise en service, le transmetteur de pression doit être soumis à un contrôle visuel.

■

Une fuite de liquide indique un dommage.

■

Le transmetteur de pression ne doit être utilisé qu'en parfait état de sécurité technique.

Exigences concernant le lieu d'installation

Le lieu d'installation doit remplir les conditions suivantes :

■

L'environnement correspond à un degré de pollution maximal de 3.

■

Humidité ≤ 80 % h. r. (sans condensation).

■

Protégé contre les inuences des intempéries.

■

Les surfaces d'étanchéité sont propres et intactes.

■

Un espace susant pour une installation électrique en toute sécurité.

■

Pour obtenir des informations concernant les trous taraudés et les embases à souder, voir les Informations

techniques IN 00.14 sur www.wika.fr.

■

Les températures ambiantes et du uide admissibles restent dans les limites de leurs performances. Considérer les

restrictions possibles sur la plage de température ambiante causée par le contre-connecteur utilisé.

→ Pour limites de performance, voir chapitre 9 “Spécications”

Variantes de joints d'étanchéité

Filetage parallèle

Sceller la surface d'étanchéité avec un joint d'étanchéité plat, une bague d'étanchéité de type lentille ou

un joint d'étanchéité profilé WIKA .

selon EN 837

Filetages coniques

Envelopper les letages avec du matériau d'étanchéité (par exemple du ruban PTFE).

selon DIN 3852-E

FR

NPT, R et PT

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 57

Page 58

5. Mise en service, utilisation

Montage de l'instrument

la couple maximum dépend du point d'installation (par exemple matériau et forme). Si vous avez des

questions, veuillez contacter notre conseiller applications.

→ Pour le détail des contacts, voir le chapitre 1 “Généralités” ou au dos du mode d'emploi.

1. Sceller la surface d'étanchéité (→ voir “Variantes de joints d'étanchéité”).

.

Au point d'installation, visser le transmetteur de pression en serrant à la main.

2

FR

.

Serrer avec une clé dynamométrique en utilisant des surfaces de clé.

3

5.2 Connexion de l'instrument au système électrique

Exigences concernant la tension d'alimentation

→ Pour l'alimentation électrique, voir la plaque signalétique

L'alimentation d'un transmetteur de pression doit être faite par un circuit électrique limité en énergie en accord avec

la Section 9.4 de UL / EN / CEI 61010-1, ou un LPS à UL / EN / CEI 60950-1 / CSA C22.2 no. 60950-1, ou Class 2 en

accord avec UL1310/UL1585 (NEC ou CEC). La tension d'alimentation doit être capable de fonctionner au-dessus de

2.000 m dans le cas où le transmetteur de pression serait utilisé à cette altitude.

Exigences concernant le raccordement électrique

■

Le diamètre du câble correspond au passe-câble du contre-connecteur.

■

Le presse-étoupe et les joints d'étanchéité du contre-connecteur sont posés correctement.

■

Avec les sorties câble, aucune humidité ne peut pénétrer à l'extrémité du câble.

Exigences concernant le blindage et la mise à la terre

Le transmetteur de pression doit être blindé et mis à la terre en conformité avec le concept de mise à la terre de

l'installation.

Connexion de l'instrument

1. Assembler le contre-connecteur ou la sortie câble.

→ Pour la conguration du raccordement, voir la plaque signalétique

.

Etablir la connexion.

2

58 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 59

5. Mise en service, utilisation

5.3 Pose d'un connecteur coudé DIN 175301-803

1. Dévisser la vis (1).

2. Desserrer le passe-câble (2).

3. Retirer soigneusement le connecteur coudé (5) + (6) de l'instrument.

4. ATTENTION !

Montage inapproprié

Le joint d'étanchéité du connecteur sera endommagé.

▶

Ne pas essayer de pousser le bloc terminal (6) vers

l'extérieur en utilisant le trou de vis (1) ou le passecâble (2).

Par le trou de montage (D), hisser le bloc terminal (6) hors du boîtier

d'angle (5).

5. Glissez le câble à travers le passe-câble (2), le joint (3), l'étanchéité (4) et

le boîtier d'angle (5).

6. Connecter les extrémités de câble aux platines de raccordement (6) en

accord avec le diagramme de connection.

7. Presser le boîtier d'angle (5) sur le bloc terminal (6).

8. S'assurer que les joints d'étanchéité ne sont pas endommagés et que le

presse-étoupe et les joints d'étanchéité sont correctement positionnés an

d'assurer l'indice de protection.

9. Serrer le passe-câble (2) autour du câble.

10. Placer le joint plat (7) sur les ches de connexion de l'instrument.

11. Pousser le connecteur coudé (5) + (6) sur l'instrument.

12. Serrer la vis (1).

(D)

FR

(2)

(3)

(4)

(1)

(5)

(6)

(7)

(8)

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 59

Page 60

6. Réglage du point zéro et étendue

6. Réglage du point zéro et étendue

N'ajuster le potentiomètre qui règle l'échelle que si on dispose d'un équipement d'étalonnage ayant au

moins trois fois la précision du transmetteur de pression.

7.1Préparation(IllustrationA)

D'accéder au potentiomètre, ouvrir l'instrument comme suit:

■

FR

Déconnecter l'alimentation électrique d'instrument.

■

Éliminer l'écrou de serrage .

■

´Sortez soigneusement la prise d'instrument .

■

Raccorder la prise d'instrument à l'alimentation électrique et une unité

d'achage (par exemple, ampèremètre, voltmètre) suivant le diagramme de

connexion.

7.2Réglagedupointzéro(illustrationB)

■

Aller sur le démarrage de l'étendue de mesure.

■

Au moyen du potentiomètre "Z", régler le signal de sortie minimum

(par exemple 4 mA)

7.3Réglagedel'échelle(illustrationB)

■

Aller sur le n de l'étendue de mesure.

■

Au moyen du potentiomètre "S", régler le signal de sortie maximum

(par exemple 20 mA)

■

Vériez le point zéro et s'il y a un écart, corrigez-le.

■

Répéter la procédure jusqu'à ce que le point zéro et l'échelle soient réglés

correctement.

A

B

60 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 61

7. Dysfonctionnements

7. Dysfonctionnements

ATTENTION !

Blessures physiques, dommages aux équipements et à l'environnement

Si les défauts ne peuvent pas être éliminés au moyen des mesures listées, le transmetteur de pression

doit être mis hors service immédiatement.

▶

S'assurer que la pression ou le signal n'est plus présent et protéger contre une mise en service

accidentelle.

▶

Contacter le fabricant.

▶

S'il est nécessaire de retourner l'instrument au fabricant, respecter les indications mentionnées au

chapitre 8.2 “Retour”.

AVERTISSEMENT !

Blessuresphysiquesetdommagesauxéquipementsetàl'environnementcausésparunuide

dangereux

Lors du contact avec un uide dangereux (par ex. oxygène, acétylène, substances inammables ou

toxiques), un uide nocif (par ex. corrosif, toxique, cancérigène, radioactif), et également avec des

installations de réfrigération et des compresseurs, il y a un danger de blessures physiques et de

dommages aux équipements et à l'environnement.

▶

En cas d'erreur, des fluides agressifs peuvent être présents à une température extrême et sous une

pression élevée ou sous vide au niveau de l'instrument.

▶

Pour ces fluides, les codes et directives appropriés existants doivent être observés en plus des

régulations standard.

▶

Porter les équipements de protection requis (voir chapitre 3.4 “Equipement de protection individuelle”).

Pour le détail des contacts, voir le chapitre 1 “Généralités” ou au dos du mode d'emploi.

FR

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 61

Page 62

7. Dysfonctionnements

Dans le cas de pannes, vérier d'abord si le transmetteur de pression est monté correctement, mécaniquement et

électriquement.

Si la réclamation n'est pas justiée, nous vous facturerons les frais de traitement de la réclamation.

Dysfonctionnements Raisons Mesures

Pas de signal de sortie Câble sectionné Vérier la continuité

Déviation du signal de point zéro Limite de surpression dépassée Respectez la limite de surpression

FR

Déviation du signal de point zéro Température de fonctionnement trop

Signal de sortie constant après une variation de pression

Le signal de sortie varie Sources d'interférence CEM dans

Plage de signaux varie/n'est pas précis Température de fonctionnement trop

Plage de signaux tombe/trop petite Surcharge mécanique causé par une

haute/trop basse

Surcharge mécanique causé par une

surpression

l'environnement ; par ex. convertisseur de

fréquence

haute/trop basse

surpression

Si la réclamation n'est pas justiée, nous vous facturerons les frais de traitement de la réclamation

admissible

Respectez les températures admissibles

Remplacer l'instrument ; s'il tombe en

panne de manière répétée, contacter le

fabricant

Utiliser un blindage pour l'instrument;

câble blindé; Se débarrasser de la source

d'interférences.

Respectez les températures admissibles

Remplacer l'instrument ; s'il tombe en

panne de manière répétée, contacter le

fabricant

62 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 63

8. Entretien et nettoyage

8. Entretien et nettoyage

8.1 Entretien

Ce transmetteur de pression ne nécessite aucun entretien.

Les réparations ne doivent être eectuées que par le fabricant.

8.2 Nettoyage

ATTENTION !

Agents de nettoyage inappropriés peuvent endommager l'instrument

Un nettoyage avec des agents de nettoyage inappropriés peut endommager l'instrument et la plaque

signalétique.

▶

Ne pas utiliser de détergents agressifs.

▶

Ne pas utiliser d'objets durs ou pointus.

▶

Ne pas utiliser de chions abrasifs ou d'éponges abrasives.

Agents de nettoyage appropriés

■

Eau

■

Liquide vaisselle conventionnel

Nettoyage de l'instrument

1. Dépressuriser et mettre hors tension le transmetteur de pression.

2. Essuyer la surface de l'instrument avec un chion doux et humide.

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 63

FR

Page 64

9. Démontage, retour et mise au rebut

9. Démontage, retour et mise au rebut

9.1 Démontage

AVERTISSEMENT !

Blessuresphysiquesetdommagesauxéquipementsetàl'environnementcausésparunuide

dangereux

Lors du contact avec un uide dangereux (par ex. oxygène, acétylène, substances inammables ou

FR

Démontage de l'instrument

1. Dépressuriser et mettre hors tension le transmetteur de pression.

.

2

Déconnecter l'alimentation électrique.

.

Dévisser le transmetteur de pression avec une clé en utilisant des surfaces de clé.

3

9.2 Retour

En cas d'envoi de l'instrument, il faut respecter impérativement ceci :

Tous les instruments livrés à WIKA doivent être exempts de substances dangereuses (acides, bases, solutions, etc.) et

doivent donc être nettoyés avant d'être retournés.

toxiques), un uide nocif (par ex. corrosif, toxique, cancérigène, radioactif), et également avec des

installations de réfrigération et des compresseurs, il y a un danger de blessures physiques et de

dommages aux équipements et à l'environnement.

▶

En cas d'erreur, des fluides agressifs peuvent être présents à une température extrême et sous une

pression élevée ou sous vide au niveau de l'instrument.

▶

Porter l'équipement de protection requis.

AVERTISSEMENT !

Blessures physiques et dommages aux équipements et à l'environnement liés aux résidus de

uides

Les restes de uides se trouvant dans les instruments démontés peuvent mettre en danger les

personnes, l'environnement ainsi que l'installation.

▶

Avec les substances dangereuses, inclure la fiche technique de sécurité de matériau pour le fluide

correspondant.

▶

Nettoyer l'instrument, voir chapitre 7.2 “Nettoyage”.

64 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 65

9. Démontage, retour et mise au rebut

Pour retourner l'instrument, utiliser l'emballage original ou un emballage adapté pour le transport.

Des informations relatives à la procédure de retour sont disponibles sur notre site Internet à la rubrique

“Services”.

9.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour l'environnement.

Eliminer les composants des instruments et les matériaux d'emballage conformément aux prescriptions nationales

pour le traitement et l'élimination des déchets et aux lois de protection de l'environnement en vigueur.

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 65

FR

Page 66

10.Spécications

10. Spécications

Etenduesdemesureetlimitesdesurpression(pressionrelative)

bar Etendue de mesure 0 ... 0,01 0 ... 0,16 0 ... 0,25 0 ... 0,4 0 ... 0,6 0 ... 1 0 ... 1,6

Limite de surpression 1 1,5 2 2 4 5 10

FR

Etendue de mesure 0 ... 2,5 0 ... 4 0 ... 6 0 ... 10 0 ... 16 0 ... 25 0 ... 40

Limite de surpression 10 17 35 35 80 50 80

Etendue de mesure 0 ... 60 0 ... 100 0 ... 160 0 ... 250 0 ... 400 0 ... 600 0 ... 1.000

Limite de surpression 120 200 320 500 800 1.200 1.500

psi Etendue de mesure 0 ... 5 0 ... 10 0 ... 15 0 ... 20 0 ... 25 0 ... 30 0 ... 50

Limite de surpression 29 29 72,5 145 145 145 240

Etendue de mesure 0 ... 60 0 ... 100 0 ... 150 0 ... 160 0 ... 170 0 ... 200 0 ... 250

Limite de surpression 240 500 500 1.160 1.160 1.160 1.160

Etendue de mesure 0 ... 300 0 ... 400 0 ... 500 0 ... 600 0 ... 750 0 ... 800 0 ... 1.000

Limite de surpression 1.160 1.160 1.160 1.160 1.740 1.740 1.740

Etendue de mesure 0 ... 1.500 0 ... 1.600 0 ... 2.000 0 ... 3.000 0 ... 4.000 0 ... 5.000 0 ... 6.000

Limite de surpression 2.900 4.600 4.600 7.200 7.200 7.200 11.600

Etendue de mesure 0 ... 7.500 0 ... 8.000 0 ... 10.000 0 ... 15.000

Limite de surpression 17.400 17.400 17.400 21.700

66 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 67

10.Spécications

Etenduesdemesureetlimitesdesurpression(pressionabsolue)

bar Etendue de mesure 0 ... 0,25 0 ... 0,4 0 ... 0,6 0 ... 1 0 ... 1,6 0 ... 2,5 0 ... 4

Limite de surpression 2 2 4 5 10 10 17

Etendue de mesure 0 ... 6 0 ... 10 0 ... 16 0 ... 25 0,8 ... 1,2

Limite de surpression 35 35 80 80 5

psi Etendue de mesure 0 ... 15 0 ... 25 0 ... 50 0 ... 100 0 ... 250

Limite de surpression 72,5 145 240 500 1.160

Etenduesdemesureetlimitesdesurpression(videetétenduesdemesure+/-)

bar Etendue de mesure -0,6 ... 0 -0,4 ... 0 -0,25 ... 0 -0,16 ... 0 -0,1 ... 0 -1 ... 0 -1 ... +0,6

Limite de surpression 4 2 2 1,5 1 5 10

Etendue de mesure -1 ... +1,5 -1 ... +3 -1 ... +5 -1 ... +9 -1 ... +15 -1 ... +24

Limite de surpression 10 17 35 35 80 50

psi Etendue de mesure -15 inHg ... 0 -30 inHg ... 0 -30 inHg ... +15

Limite de surpression 72,5 72,5 145

Etendue de mesure -30 inHg ... +30 -30 inHg ... +60 -30 inHg ... +100

Limite de surpression 240 240 500

Etendue de mesure -30 inHg ... +160 -30 inHg ... +200 -30 inHg ... +300

Limite de surpression 1.160 1.160 1.160

FR

1604457.16 09/2017 EN/DE/FR/ES

WIKA Mode d‘emploi transmetteur de pression, type S-10 67

Page 68

10.Spécications

Spécications

Etanchéité au vide Oui

Signal de sortie

Signal de sortie voir plaque signalétique

Charge 4 ... 20 mA (2 ls) ≤ (alimentation - 10 V) / 0,02 A

FR

Tension d'alimentation

Alimentation voir plaque signalétique

Caractéristiques de précision

Non-linéarité (CEI 61298-2) ≤ ±0,2 % de l'échelle BFSL

Non-répétabilité ≤ ±0,1 % de l'échelle

Précision aux conditions de

référence

Possibilité de réglage du point zéro

et étendue

20 ... 4 mA (2 ls)

0 ... 20 mA (3 ls) ≤ (alimentation - 3 V) / 0,02 A

0 ... 10 VDC (3 ls) > signal de sortie maximum / 1 mA

0 ... 5 VDC (3 ls)

1 ... 5 VDC (3 ls)

0,5 ... 4,5 VDC ratiométrique (3 ls)

L'alimentation d'un transmetteur de pression doit être faite par un circuit électrique limité en

énergie en accord avec la Section 9.3 de UL / EN / CEI 61010-1, ou un LPS à UL / EN / CEI

60950-1, ou Class 2 en accord avec UL1310/UL1585 (NEC ou CEC). La tension d'alimenta-

tion doit être capable de fonctionner au-dessus de 2.000 m dans le cas où le transmetteur de

pression serait utilisé à cette altitude.

voir plaque signalétique

±5 %

68 WIKA Mode d‘emploi transmetteur de pression, type S-10

1604457.16 09/2017 EN/DE/FR/ES

Page 69

10.Spécications

Spécications

Erreur de température sur la plage

de 0 ... 80 °C

Stabilité à long terme aux conditions

de référence