White Rodgers 1F92W-51 User Manual

INSTALLATION &

OPERATION GUIDE

Multi-stage/Heat Pump Electronic

Digital Thermostat

WHITE-RODGERS

Operator: Save this booklet for future use!

1F92W-51

About Your New Thermostat . . .

Your new White-Rodgers Digital Multi-stage/Heat Pump Thermostat uses the technology of a solid-state

microcomputer to provide precise time/temperature control. This thermostat offers you the flexibility to

design heating and cooling programs that fit your needs.

Please read this manual thoroughly before operating or programming your thermostat. If you have

questions, contact us at the address shown on the back cover of this manual.

2

In This Guide . . .

YOUR NEW THERMOSTAT’S

FEATURES .................................................. 4

PRECAUTIONS ................................................. 5

THE THERMOSTAT’S SPECIFICATIONS ....... 6

INSTALLING YOUR THERMOSTAT ................ 7

NEW INSTALLATION

Select Thermostat Location

Route Wires to Location

REPLACEMENT INSTALLATION

Remove Old Thermostat

Attach Subbase to Wall

SYSTEM CONFIGURATON

Set Option Switches

CHECK THERMOSTAT OPERATION

Fan Operation

Heating System Operation

Cooling System Operation

LOCKOUT BYPASS OPTION

Compressor Long Term Cycle Protection

Compressor Short Term Cycle Protection

OPERATING YOUR THERMOSTAT ............... 22

PARTS OF THE THERMOSTAT

The Back Of the Thermostat Body

The Display

The Thermostat Buttons

OPERATING FEATURES

PROGRAMMING YOUR

THERMOSTAT........................................... 34

PLANNING FOR YOUR NEEDS

ENTERING YOUR PROGRAM

Set Current Time and Day

Enter Heating Program

Enter Cooling Program

CHECK YOUR PROGRAMMING

QUESTIONS AND ANSWERS........................ 44

3

YOUR NEW THERMOSTAT’S FEATURES

• Five-day/two-day programming capability

• Simultaneous heat and cool program storage

• Four separate time and temperature settings

per 24-hour period

• Up to 2 stages of heat and up to 1 stage of cool

• Computed Energy Management Recovery

(EMR)

• Automatic changeover (operator selectable)

• Two hour temperature override

• Manual program override (HOLD temperature)

• “Advance Program” button

• Armchair programming capability

• LCD displays continuous setpoint, time, and

room temperature

4

• Adjustable cycle times

• 9 volt Energizer® alkaline battery backup

• Compressor long term cycle protection

• Compressor short cycle protection

• Blower delay in the cooling cycle

• Preprogrammed temperature control

• Visual prompting during operation

• Programmable blower control

• Temperature range 40° to 99°F

• °F/°C convertibility

• Electric Heat (installer-selectable)

PRECAUTIONS

If in doubt about whether your wiring is millivolt, line,

or low voltage, have it inspected by a qualified

heating and air conditioning contractor, electrician,

or someone familiar with basic electricity and wiring.

Do not exceed the specification ratings.

All wiring must conform to local and national electri-

cal codes and ordinances.

This control is a precision instrument, and should be

handled carefully. Rough handling or distorting components could cause the control to malfunction.

CAUTION

!

To prevent electrical shock and/or equipment damage, disconnect electric power to

system, at main fuse or circuit breaker box,

until installation is complete.

WARNING

!

Do not use on circuits exceeding specified

voltage. Higher voltage will damage control

and could cause shock or fire hazard.

Do not short out terminals on gas valve or

primary control to test. Short or incorrect

wiring will burn out thermostat and could

cause personal injury and/or property

damage.

5

THE THERMOSTAT’S SPECIFICATIONS

THIS CONTROL IS DESIGNED FOR USE WHERE BOTH SIDES OF THE TRANSFORMER ARE

PRESENT AT THE THERMOSTAT (both the hot and common sides of the 24 VAC end of the

transformer.)

ELECTRICAL DATA

Electrical Rating:

20 to 30 VAC 50/60 Hz.

0.01 to 1.5 Amps (Load per terminal)

2.5 Amps Maximum Total Load (All terminals

combined)

Anticipation:

Heating 4 to 40

Cooling 4 to 40

Auxiliary 4 to 40

STAGING DATA

Up to 3 heating stages

Up to 1 cooling stage

6

THERMAL DATA

Setpoint Temperature Range:

40°F to 99°F (4°C to 37°C)

Operating Ambient Temperature Range:

32°F to 105°F

Operating Humidity Range:

0 to 90% RH (non-condensing)

Shipping Temperature Range:

-40°F to 150°F

ACCESSORIES

Thermostat Guard:

W. R. Part No. F29-0198 (clear)

or F29-0238 (opaque)

INSTALLING YOUR THERMOSTAT

NEW INSTALLATION

WE RECOMMEND THAT YOU PROGRAM THE

THERMOSTAT WITH BATTERY INSTALLED BEFORE ATTACHING ON SUBBASE. SEE OPERATION SECTION FOR PROGRAMMING INSTRUCTIONS.

SELECT THERMOSTAT LOCATION

Proper location insures that the thermostat will

provide a comfortable building temperature. Observe the following general rules when selecting

a location:

1. Locate thermostat about 5 ft. above the floor.

2. Install thermostat on a partitioning wall, not on an

outside wall.

3. Never expose thermostat to direct light from

lamps, sun, fireplaces or any temperature radiating equipment.

4. Avoid locations close to windows, adjoining outside walls, or doors that lead outside.

5. Avoid locations close to air registers or in the

direct path of air from them.

6. Make sure there are no pipes or duct work in that

part of the wall chosen for the thermostat location.

7. Never locate thermostat in a room that normally

warmer or cooler than the rest of the building.

8. Avoid locations with poor air circulation, such as

behind doors or in alcoves.

ROUTE WIRES TO LOCATION

NOTE

All wiring must conform with local and national

electrical codes and ordinances.

7

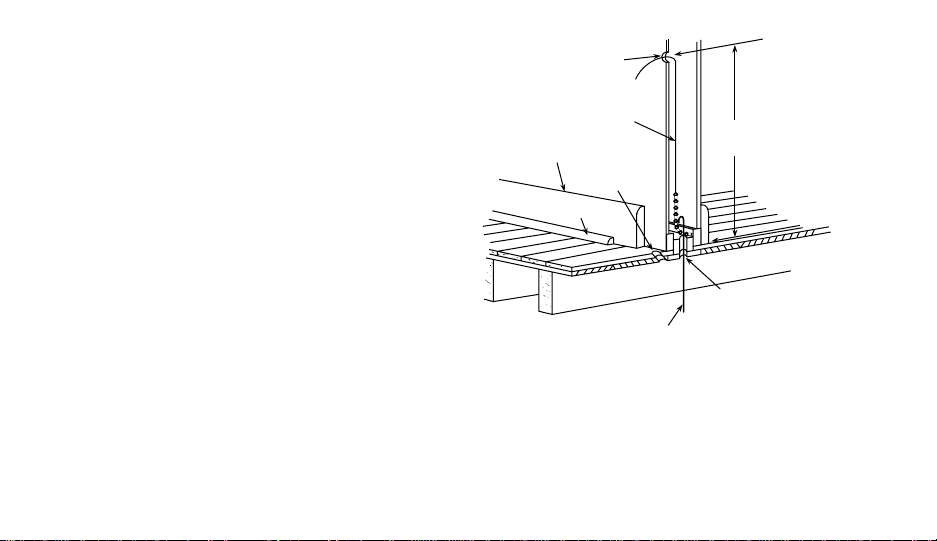

1. Probe for obstructions in partition before drilling

1

⁄2” hole in wall at selected location. Take up

quarter round and drill a small guide hole for

sighting (see fig. 1). From basement, drill 3⁄4” hole

in partition floor next to guide hole. In buildings

without basements, drill 1⁄2” hole through ceiling

and into partition from above (see fig. 1).

2. Through this hole drop a light chain, or 6” chain

attached to a strong cord. Snag cord in basement

with hooked wire. In buildings without basements, drop cord through hole in ceiling and

down partitioning; snag cord at the thermostat

location.

3. Attach thermostat wires to cord and pull wires

through hole in wall so that 6” of wire comes out

of the wall.

8

1

⁄2” hole for

thermostat wire

Stout cord with 6”

chain attached

Baseboard

strip moulding

Quarter round

removed

1

⁄4” guide hole

for sighting

Hooked wire for snagging chain

Approximately

5 feet from floor

3

⁄4” hole in floor of partition

Figure 1. Routing thermostat wires

REPLACEMENT INSTALLATION

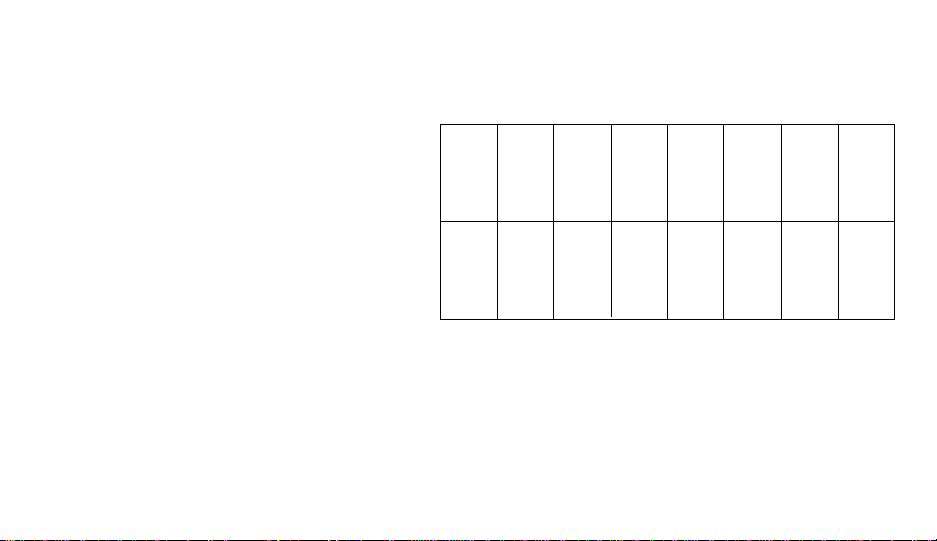

TABLE 1. WIRE IDENTIFICATION LABELS

1

G

G

1

9

Y1

Y1

9

2

C

C

2

3

L

L

3

4

R

R

4

5

O

O

5

6

B

B

6

7

E1

E1

7

8

E2

E2

8

10

Y2

Y2

10

11

W1

W1

11

12

W2

W2

12

13

W3

W3

13

14

S1

S1

14

15

S2

S2

15

16

S3

S3

16

REMOVE OLD THERMOSTAT

1. Shut off electricity at the main fuse box until

installation is complete. Verify power is off

with a voltmeter.

2. Remove the front cover of the old thermostat. With wires still attached, remove

wall plate from the wall.

3. If the old thermostat has a wall mounting

plate, remove the thermostat and the wall

mounting plate as an assembly.

4. Use the Cross Reference Guide to find the

thermostat type you are replacing.

5. Identify each wire attached to the old thermo-

stat using the labels enclosed with the new

thermostat (see Table 1). Record the identification of the wire on the corresponding blank

in Table 2.

6. Disconnect the wires from old thermostat one at

a time. Pull at least 6 inches of wire out of the

wall. DO NOT LET WIRES FALL BACK INTO

THE WALL.

7. Install new thermostat using the following procedures.

9

LABEL

NUMBER

10

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

TABLE 2. TERMINAL REFERENCE

NEW THERMOSTAT

TERMINAL

DESIGNATION FUNCTION

G

C

L

R

O

B

E1

Fan Output

Transformer 24 VAC Common

(this terminal not used)

Transformer 24 VAC Hot

Changeover Output (Cooling)

Changeover Output (Heating)

Emergency Heat Relay (cycles on

1st stage in Emergency Mode)

E2

Emergency Heat Relay (continually

energized in Emergency Mode)

Y1

Y2

W1

W2

W3

Stage 1 Cool

(this terminal not used)

Stage 1 Heat (Compressor)

Stage 2 Heat (Auxiliary)

(this terminal not used)

OLD THERMOSTAT

TERMINAL

DESIGNATION

ATTACH SUBBASE TO WALL

1. Remove the packing material from the thermostat. Place the fingers of one hand on the center

top and bottom portion of the thermostat. Grasp

the subbase in the other hand on the top and

bottom center, and gently pull straight out (see

fig. 2). The thermostat has pin and socket connectors. Forcing or prying on the thermostat will

cause damage to the unit.

2. Connect wires beneath terminal screws on subbase using wiring schematic for your particular

application (see figs. 3 through 6).

3. Place subbase over hole in wall and mark

mounting hole locations on wall using subbase

as a template.

4. Move subbase out of the way. Drill mounting

holes.

5. Fasten subbase loosely to wall, as shown in fig.

3, using two mounting screws. Place a level

against bottom of subbase, adjust until level, and

then tighten screws. (Leveling is for appearance

only and will not affect thermostat operation.) If

you are using existing mounting holes, or if holes

drilled are too large and do not allow you to

tighten subbase snugly, use plastic expansion

plugs to secure subbase.

6. Push excess wire into wall and plug hole with a

fire-resistant material (such as fiberglass insulation) to prevent drafts from affecting thermostat

operation.

(Instructions continue on page 16).

11

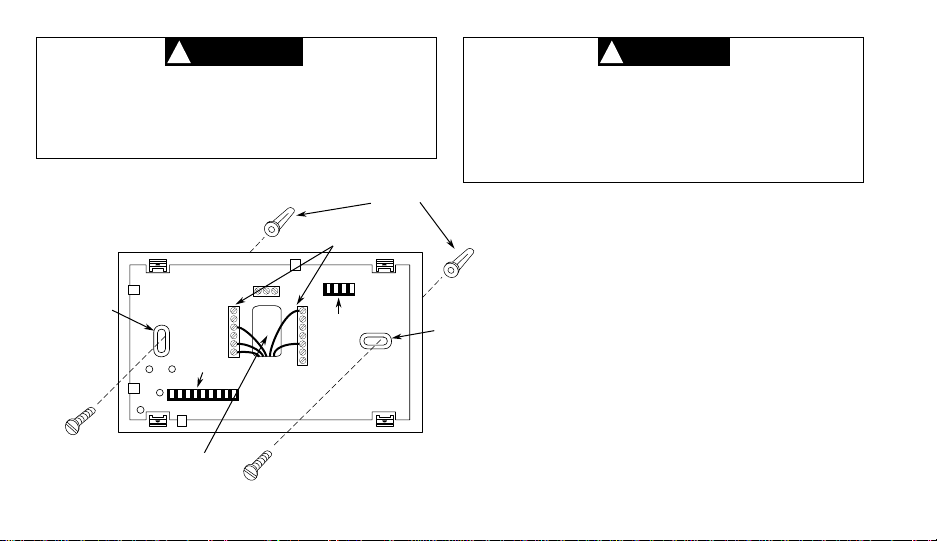

CAUTION

!

WARNING

!

DO NOT EXCEED MAXIMUM VOLTAGE OR

CURRENT RATINGS. FIRE, PERSONAL INJURY, AND/OR EQUIPMENT DAMAGE

COULD RESULT.

Connect wires under

terminal screws

S3

S2

Mounting

hole

9-pin connector

Pull wires through

this opening

S1

O

W1

E1

B

Y1

Y2

C

G

4-pin connector

E2

L

R

W2

W3

Figure 3. Subbase

12

Expansion

plugs

To prevent electrical shock and/or equipment damage, disconnect electrical power

at the main fuse box until installation is

complete. Verify power is off with a voltmeter.

Mounting

hole

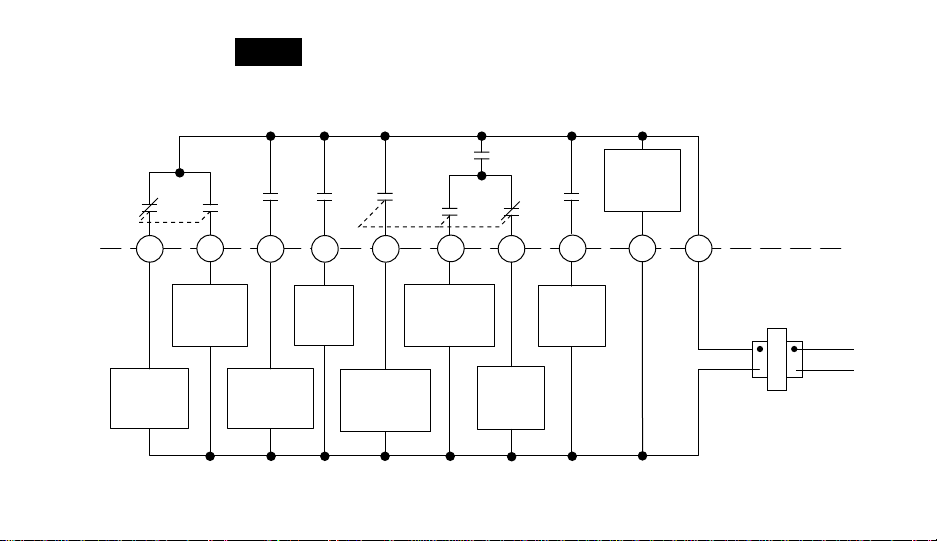

NOTE

The following wiring diagrams show typical terminal identification and wiring. For proper installation, refer to the

original manufacturers' instructions.

Thermostat

Control

Circuit

O

Changeover

Energized

In Cool

B

Changeover

Energized

In Heat

G

Y1 W1

Fan

Relay

Compressor

Contactor

Stage 1

E2

Emergency

Relay

Constant

Output

E1

Emergency

Relay

Switched

Output

W2

Heat

Relay

Stage 2

Heat

Relay

Stage 1

C R

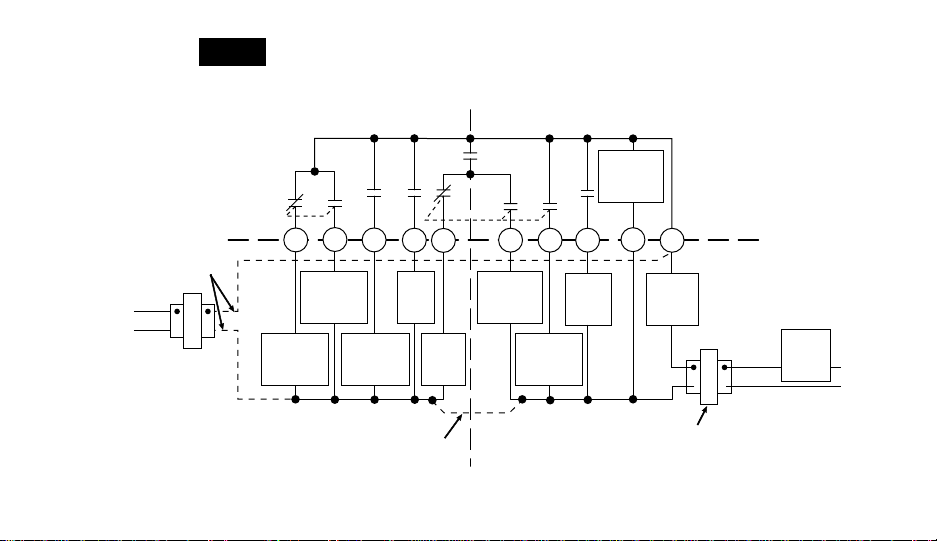

Figure 4. Typical wiring diagram for single transformer systems

THERMOSTAT

SYSTEM

Hot

24 VAC 120 VAC

Neutral

TRANSFORMER

13

NOTE

IF SAFETY CIRCUITS ARE IN ONLY ONE OF THE

SYSTEMS, REMOVE THE TRANSFORMER OF THE

SYSTEM WITH NO SAFETY CIRCUITS.

Thermostat

Control

Circuit

14

CUT AND

TAPE OFF!

Hot

Neutral

TRANSFORMER

24 VAC120 VAC

B

O

Changeover

Changeover

Energized

In Cool

HEAT PUMP SYSTEM AUXILIARY HEATING SYSTEM

TWO COMMONS MUST

BE JUMPERED TOGETHER!

Energized

In Heat

Compressor

Y1

Contactor

Stage 1

G

Fan

Relay

W1

Heat

Relay

Stage 1

Emergency

Relay

Switched

Output

Emergency

E2

W2E1

Heat

Relay

Stage 2

Relay

Constant

Output

DEPENDING ON SYSTEM REQUIRE-

75VA TRANSFORMER, IF NEEDED

C

MENTS, REPLACE WITH A

R

Limit or

Safety

Switches

24 VAC

THERMOSTAT

SYSTEM

TRANSFORMER

Hot

120 VAC

Neutral

Limit or

Safety

Switches

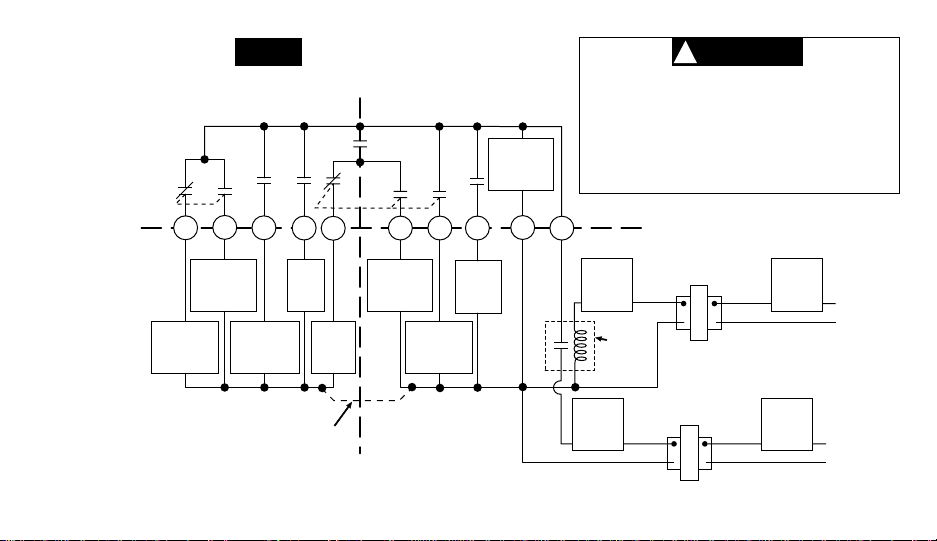

Figure 5. Typical wiring diagram for two transformer systems with NO safety circuits

Relay contacts shown are thermostatically operated. The

CAUTION

!

NOTE

accessory relay scheme is required when safety circuits

exist in both systems.

Thermostat

Control

Circuit

Polarity must be observed. If the HOT

side of the second transformer is

jumpered to the COMMON side of the

first transformer a short will be made.

Damage to equipment will occur when

power is restored.

B

O

Changeover

Changeover

Energized

In Cool

HEAT PUMP SYSTEM AUXILIARY

TWO COMMONS MUST

BE JUMPERED TOGETHER!

Energized

In Heat

Compressor

Y1

Contactor

Stage 1

G

Fan

Relay

W1

Heat

Relay

Stage 1

Emergency

Relay

Switched

Output

E2

W2E1

Heat

Relay

Stage 2

Emergency

Relay

Constant

Output

HEATING SYSTEM

C

THERMOSTAT

R

SYSTEM

Limit or

Safety

Switches

Accessory

Relay N.O.

Limit or

Safety

Switches

24 VAC

24 VAC

Contact

24 VAC

AUXILIARY

HEATING

TRANSFORMER

HEAT PUMP

TRANSFORMER

Hot

Neutral

Hot

120 VAC

Neutral

120 VAC

Limit or

Safety

Switches

Limit or

Safety

Switches

Figure 6. Typical wiring diagram for two transformer systems with safety circuits in BOTH systems

15

ATTACH THERMOSTAT TO SUBBASE

WE RECOMMEND THAT YOU SET OPTION

SWITCHES TO DESIRED POSITION BEFORE ATTACHING ON SUBBASE (see OPERATION). WE

ALSO RECOMMEND THAT YOU PROGRAM THE

THERMOSTAT WITH BATTERY INSTALLED BEFORE ATTACHING ON SUBBASE (see OPERATION section for programming instructions).

SYSTEM

USE

HEAT-OFF-COOL-AUTO

TO TURN THERMOSTAT OFF BE-

FORE ATTACHING TO WALL. FAILURE TO TURN

OFF THERMOSTAT BEFORE ATTACHING TO

WALL MAY CAUSE EQUIPMENT DAMAGE DUE

TO RAPID COMPRESSOR CYCLING.

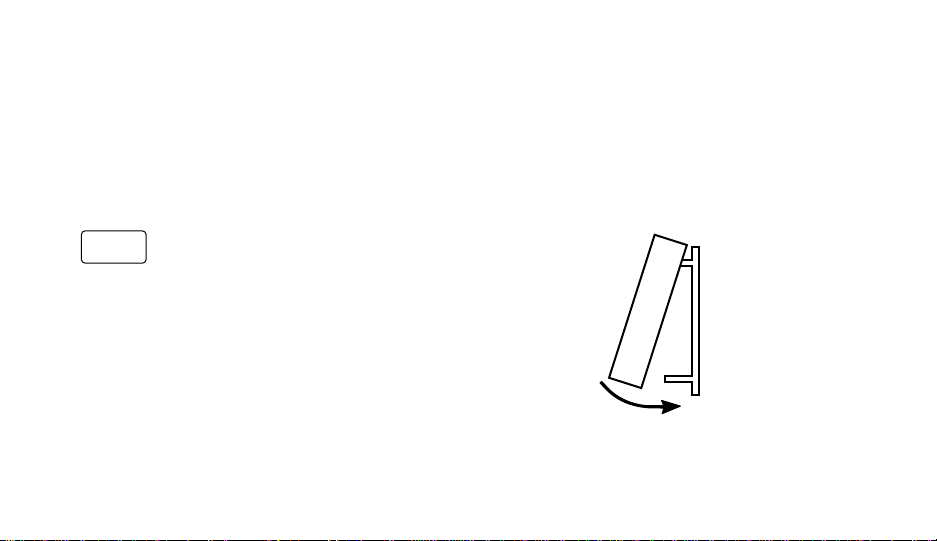

To attach thermostat to subbase, line up the plastic

snap guides at the top of the thermostat and the 4

connector pins on the thermostat with the connectors near the top right section of the subbase (when

viewed from the front). Gently pivot the thermostat

down until the 9-pin connectors and the plastic

16

snaps lock into place (see fig. 7). Be gentle when

attaching thermostat. If the thermostat does not

seem to be attaching to the subbase easily, make

sure that the connector pins and plastic snaps are

properly aligned, and that excess wire is pushed into

the wall. Damage to the thermostat may occur if

force is used.

ENGAGE TWO UPPER GUIDES; PIVOT DOWN

Figure 7. Attaching thermostat to subbase

Loading...

Loading...