Whirlpool Energy Smart 188412, Energy Smart EE2H40RD045V, Energy Smart 188413, Energy Smart 188414, EnergySmart Installation And Use Manual

...

®

®

VACATION

STANDARD

ENERGY

GRID

SMART

ENABLED

F

°F/°C

Residential Electric

Water Heater

Installation

Instructions and

Use & Care Guide

To obstain technical, warranty, or service assistance during or after the

installation of this water heater, visit our website at:

http://www.whirlpoolwaterheatersupport.com

or call tool free

1-877-817-6750

When calling for assistance, please have the following information ready:

1. Model Number 4. Date of Installation

2. 7 Digit Product Number 5. Place of Purchase

3. Serial Number

Table Of Contents PAGE

Water Heater Safety ............................................................................ 2

Installing Your Electric Water Heater ................................................... 3-9

Unpacking Instructions ................................................................... 3

Location Requirements .................................................................. 4

Water System Piping ................................................................... 5

Electrical Requirements ................................................................. 7

Installation Checklist ...................................................................... 9

Operating Your Water Heater ............................................................. 10-12

Water Heater Start-Up ................................................................... 10

Water Temperature Regulation ...................................................... 10

Energy Smart

Electronic Thermostat .................................................................... 12

Smart Grid Technology .................................................................. 13

Operational Conditions ................................................................... 14

Maintenance of Your Water Heater .................................................... 15-23

Diagnostic Code (ESM)..................................................................17-18

Diagnostic Code (ET).................................................................... 19-20

Trouble Shooting Chart .....................................................................21

Repair Parts illustration ................................................................... 22

Thermostat Wiring Diagram ............................................................ 23

PRINTED IN THE U.S.A 0411 PART NO. 318686-000

®

Module/Operational Modes ................................... 11

1

LOW LEAD

COMPLIANT

WATER HEATER SAFETY

Your safety and the safety or others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all

safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or

“WARNING”. These words mean:

DANGER: indicates an imminently hazardous situation

which, if not avoided, will result in death or injury.

WARNING: indicates a potentially hazardous situation

which, if not avoided, could result in death or injury.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

IMPORTANT: Hydrogen gas is produced in a hot water system served by this heater that has not been used for a long

period of time (2 weeks or more). Hydrogen is extremely fl ammable. To reduce the risk of injury under these

conditions, it is recommended that the hot water faucet be opened for several minutes at the kitchen sink before using

any electrical appliance connected to the hot water system. When hydrogen is present, there will probably be an unusal

sound such as air escaping through the pipe as the water begins to fl ow. There should be no smoking or open fl ame

near the faucet at the time it is open.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of

substances known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires

businesses to warn of potential exposure to such substances.

• WARNING: This product contains a chemical known to the State of California to cause cancer, birth defects, or other

reproductive harm.

• This appliance can cause low-level exposure to some of the substances listed in the Act.

Important Safety Instructions

2

INSTALLING YOUR WATER HEATER

Consumer Information

This water heater should be installed in accordance

with the local code authority having jurisdiction, the

power company or electric utility, and this installation

manual. In the absence of local code requirements,

follow the regulations set forth in the latest edition of the

National Electric Code, NFPA70. This is available from

the following:

National Fire Protection Agency

1 Batterymarch Park

Quincy, MA 02269

American National Standards Institute

1430 Broadway

New York, NY 10018

Check your phone listings for the local authorities

having jurisdiction over your installation.

Consumer Responsibilities

This manual has been prepared to acquaint you with

the installation, operation, and maintenance of your electric water heater and provide important safety information

in these areas.

We urge you to read all of the instructions thoroughly before attempting the installation or operation of this water

heater. This manual should be kept for future reference.

The manufacturer of this water heater will not be liable for

any damages caused by failure to comply with the installation and operating instructions outlined in this manual.

If you lack the necessary skills required to properly

install this water heater or you have difficulty following

the directions, you should not proceed but have a

qualified person perform the installation of this water

heater.

Examples of a qualified personnel include:

licensed plumbers, authorized electric company personnel, and authorized service person.

Massachusetts code requires this water heater to be

installed in accordance with Massachusetts Plumbing

and Fuel Code 248-CMR 2.00: State Plumbing Code and

248-CMR 5.00.

A data plate identifying your water heater can be found

adjacent to the energy smart module. When referring to

your water heater always have the information listed on

the data plate readily available, to include the model and

serial number.

Retain your original receipt as proof of purchase.

Insulation Blankets

The use of an insulation blanket on this water heater is

not needed nor recommended. The purpose of an insulation blanket is to reduce the standby heat loss encountered with storage tank heaters. Your water heater meets

or exceeds the National Appliance Energy Conservation

Act standards with respect to insulation and standby loss

requirements, making an insulation blanket unnecessary.

Unpacking the Water Heater

Removing Packaging Materials

Use two or more people to move and install

water heater.

Failure to do can result in back or

other injury.

IMPORTANT: Do not remove any permanent instructions,

labels, or the data label from outside of the water heater or

on the inside of panels.

• Remove exterior packaging and place installation

components aside.

• Do not remove the envelope bag containing the

water heater literature from the side of the water

heater.

• Inspect all parts for damage prior to installation and

start-up.

• Completely read and understand all instructions

before attempting to assemble and install this product.

• Replace this manual inside the envelope bag when

installation is complete.

• After installation, dispose of packaging material in

the proper manner.

WARNING

Excessive Weight Hazard

3

Location Requirements

Site location

Select a location near the center of the water piping

system. It must be installed indoors and in a vertical

position on a level surface, in an area where water

leakage will not cause consequential damage.

NOTE: Local codes and requirements in your area may

require the water heater to be installed such that the

bottom element is elevated from the floor at least 18

inches.

The water heater should be located in an area not

subject to freezing temperatures. Water heaters located

in unconditioned spaces (i.e., attics, garages, basements, etc.) may require the water piping and drain

piping to be insulated to protect against freezing. The

drain and controls must be easily accessible for operation and service.

Keep combustibles such as boxes, magazines, clothes,

etc., away from the water heater area.

Do not use this water heater in conjunction with a spa or

hot tub.

IMPORTANT: The water heater should be located in

an area where leakage of the tank or connections will

not result in damage to the area adjacent to the water

heater or to lower floors of the structure. Due to the

normal corrosive action of the water, the tank will

eventually leak after an extended period of time.

Also, any external plumbing leak, including those

from improper installation, may cause early

failure of the water tank due to corrosion if not

repaired. If the homeowner is uncomfortable with

making the repair, a qualified person should be

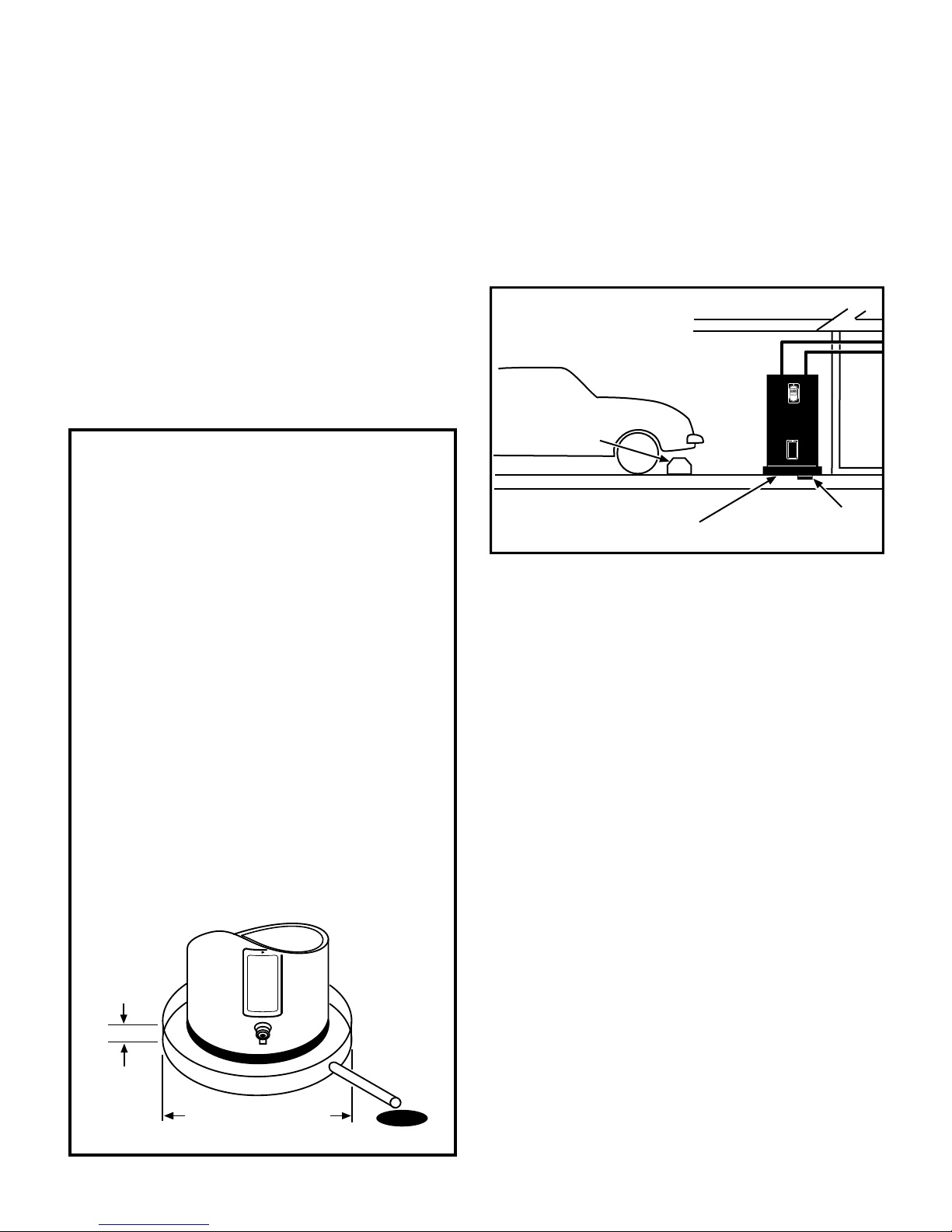

contacted. A suitable metal drain pan should be

installed under the water heater as shown below. This

metal drain pan is to protect the property from damage

which may occur from normal condensate formation

on the tank or leaks in the tank and pipe connections.

The metal drain pan must limit the water level to a

maximum depth of 2-1/2 inches and be two inches

wider than the heater and piped to an adequate drain.

Locate the water heater near a

suitable indoor drain. Outdoor drains are subject to

freezing temperatures which can obstruct the drain

line. The piping should be at least 3/4”ID and pitched

for proper drainage.

Under no circumstance will the manufacturer or

seller of this water heater be held liable for any

water damage that is caused by your failure to

follow these instructions.

NOTE: The water heater shall be located so it is not

subject to physical damage by moving vehicles or area

flooding.

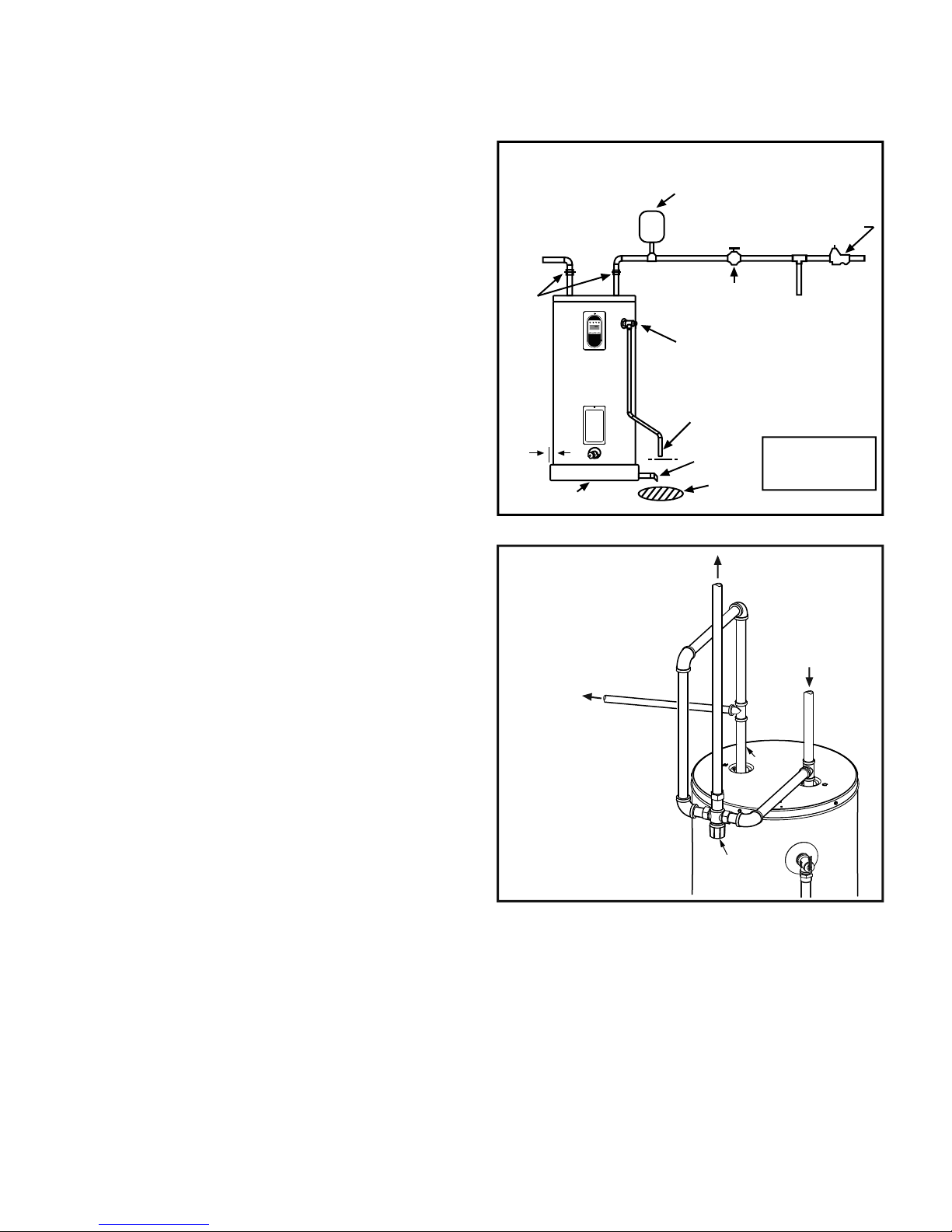

Figure 2

Residential Garage

Installation

VACATION

STANDARD

ENERGY

GRID

SMART

EMABLED

F

°F/°C

Vehicle

Stop

Metal Drain Pan

Drain

State of California

NOTE: The water heater must be braced, anchored, or

strapped to avoid moving during an earthquake. Contact

local utilities for code requirements in your area or call

1-877-817-6750 and request instructions.

2 1/2” Max

At least 2” inches greater than

the diameter of the water

Figure 1

heater.

Pipe to

adequate

drain

4

Water System Piping

Piping Installation

Piping, fi ttings, and valves should be installed according

to the installation drawing (Figure 3). If the indoor installation area is subject to freezing temperatures, the

water piping must be protected by insulation.

Water supply pressure should be around 50 to 60 psi

and should not exceed 80 psi. If this occurs, a pressure

reducing valve should be installed in the cold water inlet

line. This should be placed on the supply to the entire

house in order to maintain equal hot and cold water

pressures.

IMPORTANT: Heat cannot be applied to the water fi ttings

on the heater as they may contain nonmetallic parts.

If solder connections are used, solder the pipe to the

adapter before attaching the adapter to the hot and cold

water fi ttings.

IMPORTANT: Always use a good grade of joint com-

pound and be certain that all fi ttings are drawn up tight.

1. Install the water piping and fitting as shown in

Figure 3. Connect the cold water supply (3/4” NPT)

to the fitting marked “Cold”. Connect the hot water

supply (3/4” NPT) to the fitting marked “Hot”.

IMPORTANT: Some models may contain energy saving

heat traps to prevent the circulation of hot water within

the pipes. Do not remove these inserts.

2. The Installation of dielectric unions in both the hot

and cold water supply lines is recommended for

ease of removing the water heater for service or

replacement.

3. Some local codes may require, and the manufac turer of this water heater recommends,

installing a mixing valve in the domestic hot water

line as shown in Figure 4. These valves reduce the

point-of-use temperature of the hot water by mixing

cold and hot water and are readily available.

Contact a licensed plumber or the local plumbing

authority.

4. If installing the water heater in a closed water

system, install a relief valve or expansion tank in

the cold water line as specified under “Closed

System/Thermal Expansion”.

5. Install a shut-off valve in the cold water inlet line. It

should be located close to the water heater and be

easily accessible. Know the location of this valve

and how to shut off the water to the heater.

6. Install a discharge line from the temperature and

pressure relief valve in the opening marked “T & P

RELIEF VALVE”. Install as specified under

“Temperature and Pressure Relief Valve”.

7. After piping has been properly connected to the

water heater, open the nearest hot water faucet.

Then open the cold water shut off valve and

allow the tank to completely fill with water. To purge

the lines of any excess air and sediment, keep the

hot water faucet open for 3 minutes after a constant

flow of water is obtained. Close the faucet and

check all connections for leaks.

Figure 3

Water Piping Installation

Hot Water

Outlet

Union

VACATION

STANDARD

ENERGY

GRID

SMART

ENABLED

F

°F/°C

1”

Min.

Metal Drain Pan

2-1/2” depth max.

Figure 4

Mixing Valve

Top Water Connections

Unmixed

Hot Water

Follow The Mixing Valve

Manufacturer’s Instructions

In a Closed System use a

Thermal Expansion Tank.

Cold Water

Inlet Valve

Temperature and

Pressure Relief Valve

Discharge line 6” maximum

above drain

Drain line

3/4” ID

minimum

Drain

Mixed Water

To Fixtures

Mixing Valve

(Set To 120 F)

Pressure Reducing

Valve With Bypass

Cold Water

Supply to

Fixtures

Massachusetts:

Install vacuum relief

in cold water line per

section 19 MGL 142.

Cold Water

Hot

Water

Outlet

0

Inlet

Main

Water

Supply

5

Please note the following:

DO NOT install this water heater with iron piping.

The system should be installed only with piping that

is suitable for potable (drinkable) water such as

copper, CPVC, or polyethylene (PEX).

DO NOT use PVC water piping.

DO NOT use any pumps, valves, or fi ttings that are

not compatible with potable water.

DO NOT use valves that may cause excessive

restriction to water fl ow. Use full-fl ow ball or gate

valves only.

DO NOT use tin-lead solder in potable water lines.

Use 95/5 tin antimony or other equivalent material.

DO NOT tamper with the energy smart module,

electronic thermostat, temperature sensors, heat ing elements, electrical connections, or temperature

and pressure relief valve. Tampering voids all war ranties. Only qualifi ed person should service these

components.

DO NOT use with piping that has been treated with

chromate’s, boiler seal, or other chemicals.

DO NOT add any chemicals to the system piping

which will contaminate the potable water supply.

Closed System/Thermal Expansion

Typically, a closed system includes a pressure reducing

valve (PRV) on the cold water inlet (supply line). As water

is heated, it expands (thermal expansion). In a closed system, the volume of water will grow. As the volume of water

grows, there will be a corresponding increase in water

pressure due to thermal expansion. Thermal expansion

can cause premature tank failure (leakage). This type of

failure is not covered under the limited warranty. Thermal

expansion can also cause intermittent temperaturepressure relief valve operation: water discharged from the

valve due to excessive pressure build up. The temperature-pressure relief valve is not intended for the constant

relief of thermal expansion. This condition is not covered

under the limited warranty.

A properly-sized thermal expansion tank should be installed on all closed systems to control the harmful effects

of thermal expansion. Contact a plumbing service agency

or your retail supplier regarding the installation of a thermal expansion tank.

Expansion Tank Sizing Chart

Inlet Water Heater Capacity (Gallons)

Water

Pressure 30 40 50 66 82

Expansion 40psi 2 2 2 5 5

Tan k 50psi 2 2 2 5 5

Capacity 60psi 2 2 5 5 5

Needed 70psi 2 2 5 5 5

80psi 2 5 5 5 5

A thermal expansion tank can help prevent damage to the

water heater and other appliances (i.e.: washing machine,

ice maker, dishwasher, etc.).

IMPORTANT: Do not plug or remove the temperature and

pressure relief valve (T&P valve).

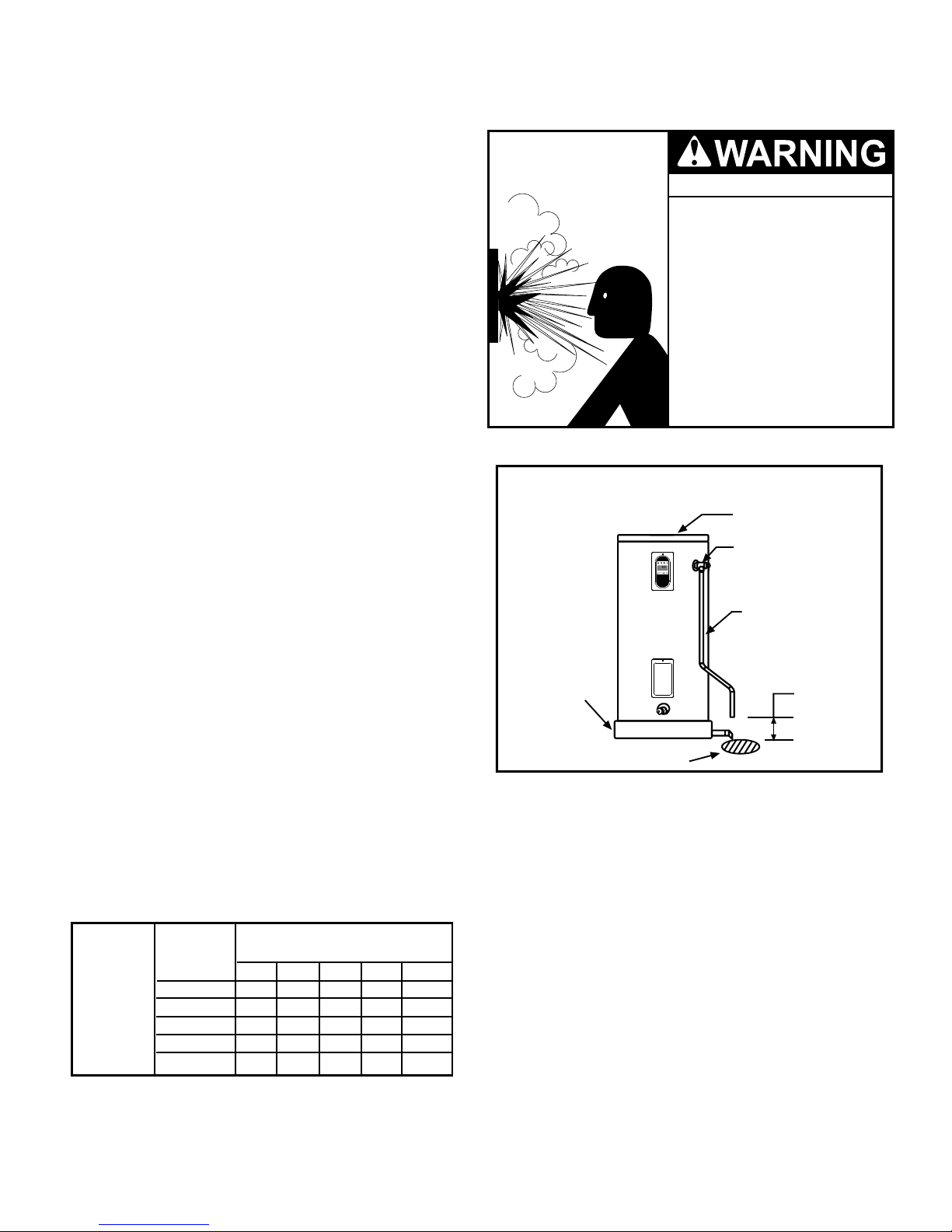

Temperature and Pressure

Relief Valve

Explosion Hazard

• Temperature-pressure relief

valve must comply with ANSI

Z21.22-CSA 4.4 and ASME

code.

• Properly sized temperaturepressure relief valve must be

installed in opening provided.

• Can result in overheating

and excessive tank pressure.

• Can cause serious injury or

death.

Figure 5

Temperature and Pressure

Relief Valve Installation

VACATION

STANDARD

ENERGY

GRID

SMART

ENABLED

F

°F/°C

Drain Pan

Drain

For protection against excessive pressures and

temperatures, a temperature and pressure relief valve

must be installed in the opening marked “T&P RELIEF

VALVE” (See Figure 5). This valve must be design certifi ed by a nationally recognized testing laboratory that

maintains periodic inspection of the production of listed

equipment or materials as meeting the requirements

for Relief Valves for Hot Water Supply Systems, ANSI

Z21.22. The function of the temperature and pressure

relief valve is to discharge water in large quantities in the

event of excessive temperature or pressure developing in the water heater. The valve’s relief pressure must

not exceed the working pressure of the water heater as

stated on the rating plate.

IMPORTANT: Only a new temperature and pressure

relief valve should be used with your water heater. Do

not use an old or existing valve as it may be damaged or

not adequate for the working pressure of the new water

heater. Do not place any valve between the relief valve

and the tank.

6

Optional location some

models only

Temperature and

Pressure Relief Valve

Discharge Line

3/4 inch min.

Do not cap or plug.

6 inch

maximum

The Temperature & Pressure Relief Valve:

• Must be connected to an adequate discharge line.

• Must not be in contact with any electrical part.

• Must not be rated higher than the working pressure

shown on the data plate of the water heater.

The Discharge Line:

• Must not be smaller than the pipe size of the relief

valve or have any reducing coupling installed in the

discharge line.

• Must not be capped, blocked, plugged, or contain

any valve between the relief valve and the end of

the discharge line.

• Must terminate a maximum of six inches above a

fl oor drain or external to the building. In cold climates,

it is recommended that the discharge pipe be termi nated at an adequate drain inside the building.

• Must be capable of withstanding 250° F (121°

without distortion.

• Must be installed to allow complete drainage of

both the valve and discharge line.

C)

T&P Relief Valve and Pipe Insulation:

6. Spread the slit open and slip the insulation over

the cold water (inlet) pipe. Apply gentle pressure

along the length of the insulation to ensure it is fully

seated around the pipe. Also ensure that the base of

insulation is flush with the water heater. Once seated,

secure the insulation with duct tape, electrical tape, or

equivalent.

7. Repeat steps 5 through 6 for the hot water (outlet)

pipe.

8. Add additional sections of pipe insulation as needed.

Solar Installation

If this water heater is used as a solar storage heater or

as a backup for the solar system, the water supply

temperatures to the water heater tank may be in excess

of 120° F (48.8° C). A mixing valve or other temperature

limiting valve must be installed in the water supply line to

limit the supply temperature to 120° F (48.8° C).

Note: Solar water heating systems can often supply water

with temperatures exceeding 180° F (82.2° C) and may

result in water heater malfunction.

1. Locate the temperature and pressure relief valve on

the water heater (also known as a T&P Relief Valve,

(Figure 6).

2. Locate the slit running the length of the insulation.

3 Spread this slit open and slip it up under the T&P

Relief Valve (See Figure 6). Apply gentle pressure to

the insulation to ensure it is fully seated on the T&P

Relief Valve. Once sealed, secure the insulation with

a section of duct tape, electrical tape, or equivalent.

IMPORTANT: The insulation or tape must not block

the discharge opening or hinder access to the manual

relief lever. Ensure a discharge pipe is installed into

the T&P valve discharge opening per the instructions

manual.

4. Locate the hot water (outlet) & cold water (inlet) pipes

to the water heater.

5. Locate the slit running the length of a section of pipe

insulation.

Figure 6

Temperature and Pressure

Relief Valve Installation

Manual Relief Lever

T&P Relief Valve

T&P Relief Valve

Drain Line

T&P Relief Valve Insulation

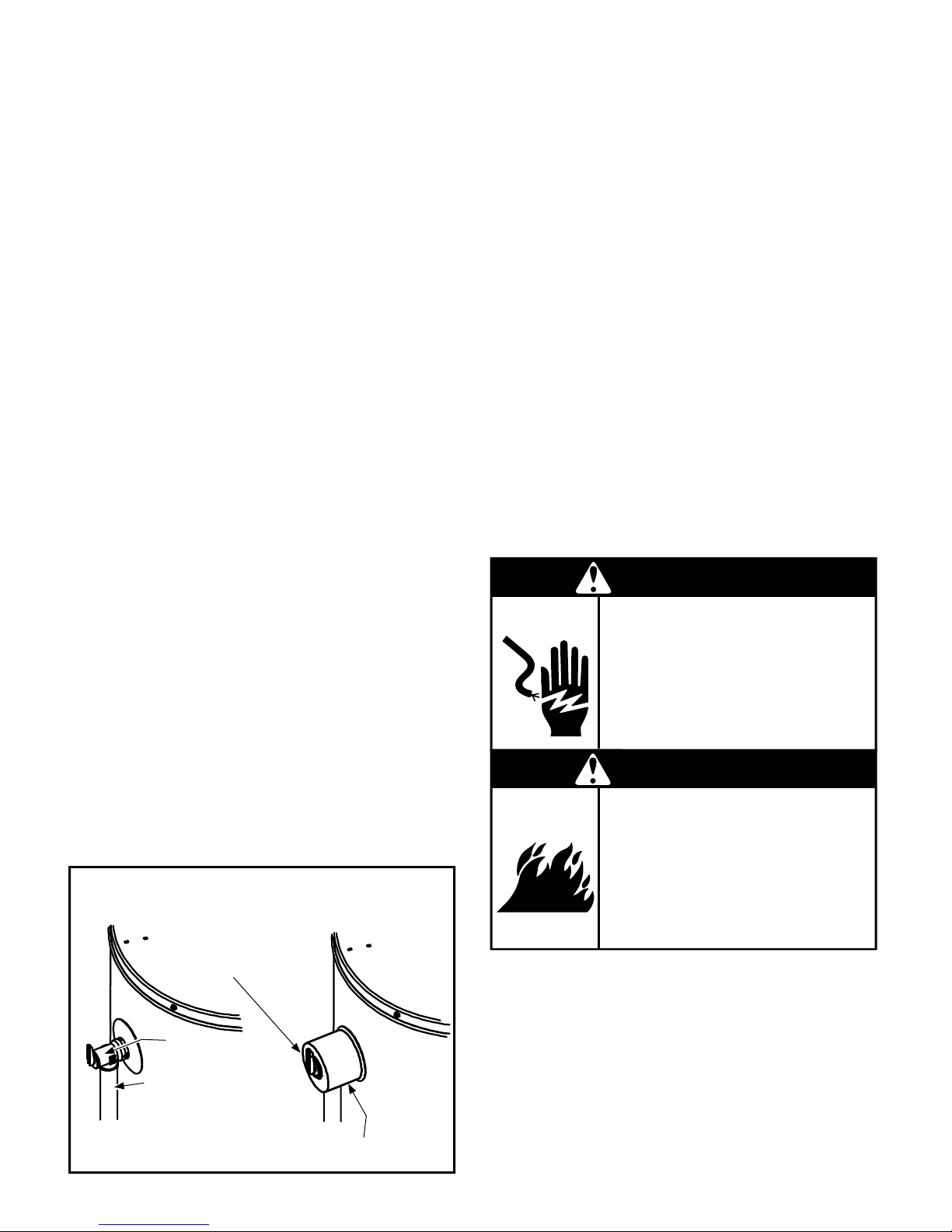

Electrical Requirements

WARNING

Electric Shock Hazard

Disconnect power before

servicing.

Replace all parts and panels

before operating.

Failure to do so can result in

death or electric shock.

WARNING

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Connect ground wire to green

ground screw.

Failure to do so can result in

death, fire, or electrical shock.

If you lack the necessary skills required to properly

install the electrical wiring to this water heater, do not

proceed, but have a qualifi ed electrician perform the

installation.

When making the electrical connections, always make

sure:

• The electrical supply has the proper overload fuse

or circuit breaker protection.

• Wire sizes and connections comply with all

applicable codes.

7

• Wiring is enclosed in approved conduit (if required

by local codes).

• The water heater and electrical supply are properly

grounded.

Always reference the wiring diagram for the correct electrical connection. The complete wiring diagram can also be

found on the top of the water heater near the junction box

cover.

When installing the electrical wiring to the water heater

• Although this water heater is equipped with “Dry-fi re”

protection, be sure the tank is completely fi lled with

water, and all air is purged from the tank before

making any electrical connections (See Figure 7).

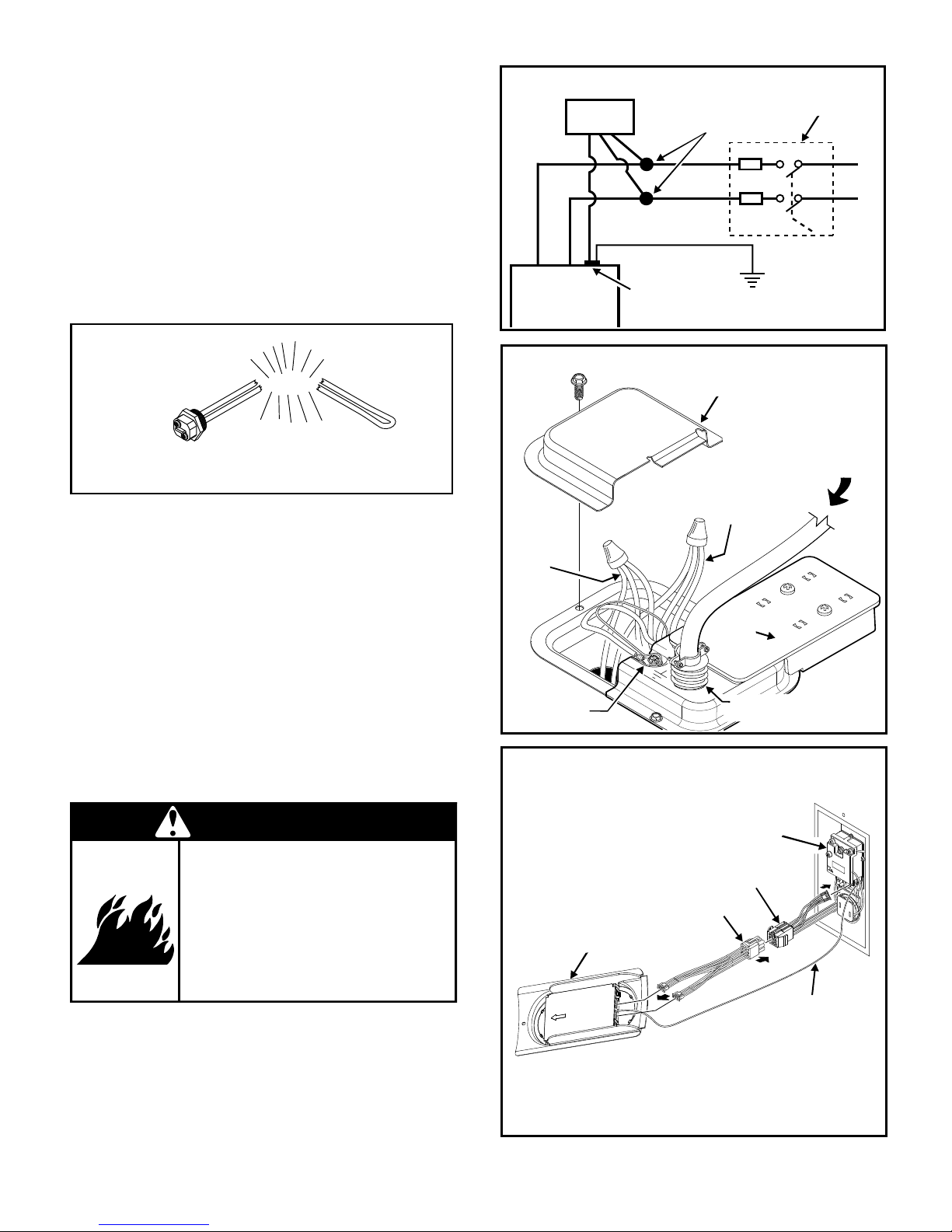

Figure 7

Heating Element

Bang

Figure 8

Wiring Diagram

Black

Water Heater

Figure 8A

Junction Box

Smart Grid

Wire Harness

Red

Green

Black

Red

Ring Terminal

at Ground

Screw

Approved

Connectors

Junction Box Cover

Electrical

Service ground

Circuit

Breaker

L1

L2

To 240v

1 Phase

Power

supply

NOTE: Applying electrical power to elements that are not submerged

in water will destroy them. The manufacturer will not warranty any

elements damaged in this manner.

1. Check and turn off power to the electrical wiring of the

water heater before making any electrical connections

to the water heater.

2. Remove the junction box cover that is secured by one

screw (Figure 8A). Place the cover and screw aside

and view the wiring diagram. Locate the four power

wires inside the junction box (there will be TWO red

wires and TWO black wires).

3. Connect the electrical supply to the water heater in

accordance with the local utility requirements and

codes. A standard 1/2 inch opening has been made

in the junction box for the conduit connections (Fig ure 8A). NOTE: Use only 10 gauge solid copper wire

for the electrical connections and an appropriate size

double pole circuit breaker.

WARNING

Fire Hazard

Use 10 gauge solid copper wire.

Use a UL approved strain relief.

Connect ground wire to green

ground screw.

Failure to do so can result in

death, fire, or electrical shock.

4. Ground the water heater by connecting the bare cop per ground wire from the home’s electrical service to

the green ground screw (located on the electrical jun-

ction box on top of the water heater). See Figures 8

and 8A.

5. There are TWO black wires and TWO red wires in the

water heater. The smaller red and black wires are

used by the Smart Grid connector.

Black Wires

(3)

Ground Wires

Figure 8B

Electronic Thermostat (ET)

Energy Smart®

Module (ESM)

Red Wires

(3)

Electronic

Thermostat (ET)

Wiring Harness

( Junction Box )

Wiring Harness

( ET to ESM )

From Home

Electrical Service

Smart Grid

Cover

1/2” Conduit

Connection

( Attached To T-Stat Bracket Screw )

Ground Wire

8

Loading...

Loading...