Whirlpool AKR 009/IX, AKR 009/WH, AKR 001/IX, AKR 013/IX, AKR 002/IX INSTRUCTION FOR USE

...

N C

INTRODUCTION

BEFORE USING THE COOKTOP

1. Clean the cooktop.

2. Light the burners to remove fumes and smells from the protective greases.

FOR EVERYDAY USE

1. Turn the control knob to the “large flame” position

2. Operate the electric ignition (see the model specifications)

3. In the models with safety valves keep the knob pressed for 10 seconds after the burner has lit.

4. To turn off turn the knob to “

Read the Instructions For Use carefully so that you become familiar with your cooktop.

26

M Y

26

x”.

N C

TABLE OF CONTENTS GB

FEATURES page 28-29-30

BEFORE USING THE COOKTOP page 31

TIPS FOR SAFEGUARDING THE ENVIRONMENT page 31

WARNINGS FOR THE USE OF ELECTRICAL APPLIANCES page 32

PRECAUTIONS AND GENERAL SUGGESTIONS page 32

GAS COOKTOP page 33

USING THE COOKTOP page 35

CLEANING AND MAINTENANCE page 36

TROUBLE-SHOOTING GUIDE page 37

AFTER-SALES SERVICE page 37

INSTALLATION page 38

27

M Y

27

N C

FEATURES

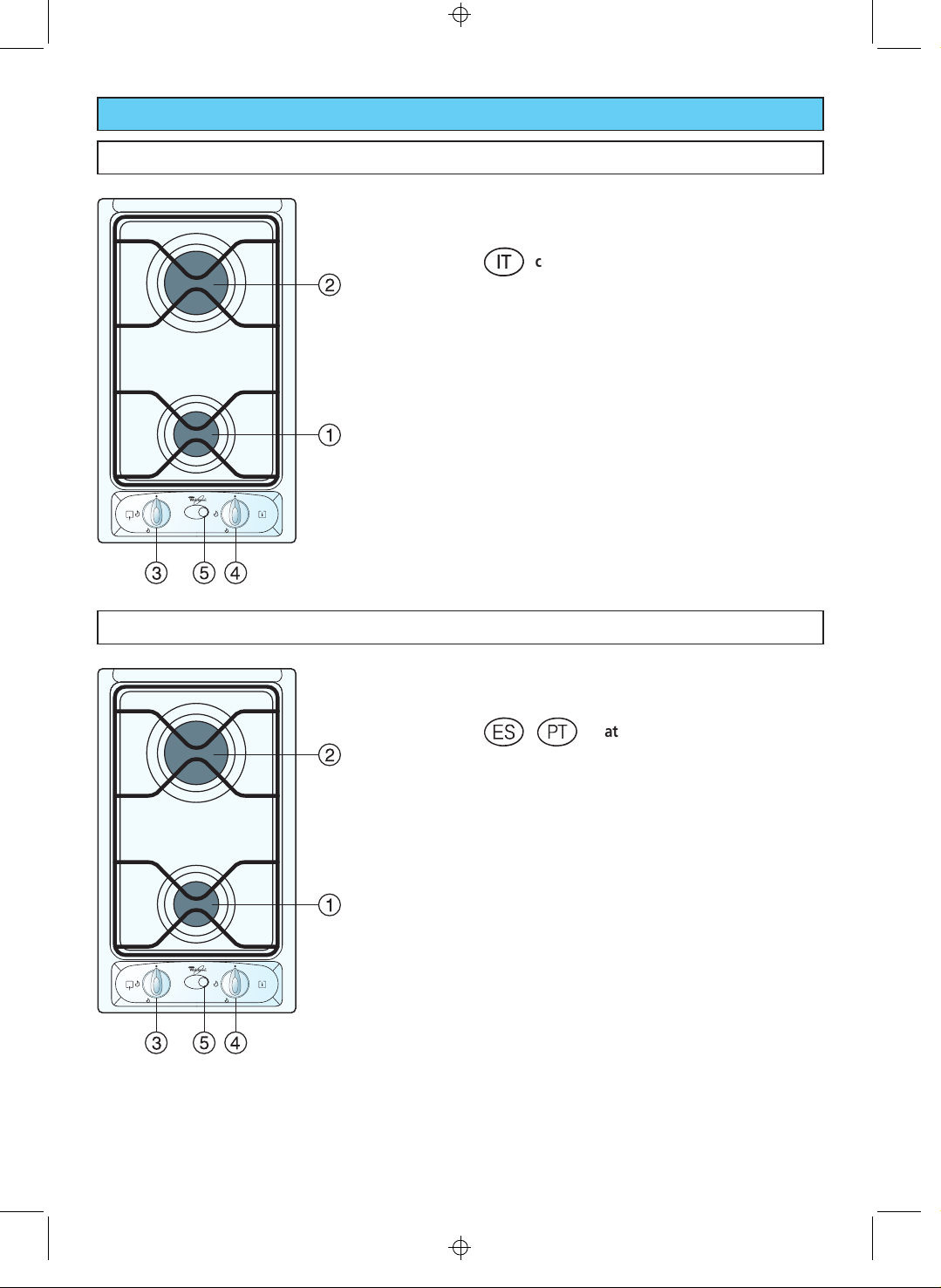

AKR 001

2 GAS COOKTOP

- This appliance is Class 3.

cat. III 1a2H3+.

o

GAS BURNERS

1. Medium-power burner - 1.65 kW

2. High-power burner - 3.00 kW

CONTROL PANEL

3. Front burner control knob (1)

4. Rear burner control knob (2)

5. Electric ignition push-button

Note:

The appliance is fitted with a safety valve on each

burner which shuts off the gas supply if the gas goes

out accidentally.

AKR 002

2 GAS COOKTOP

- This appliance is Class 3.

kv

GAS BURNERS

1. Medium-power burner - 1.65 kW

2. High-power burner - 3.00 kW

CONTROL PANEL

3. Front burner control knob (1)

4. Rear burner control knob (2)

5. Electric ignition push-button

cat. II 2H 3+.

28

M Y

28

N C

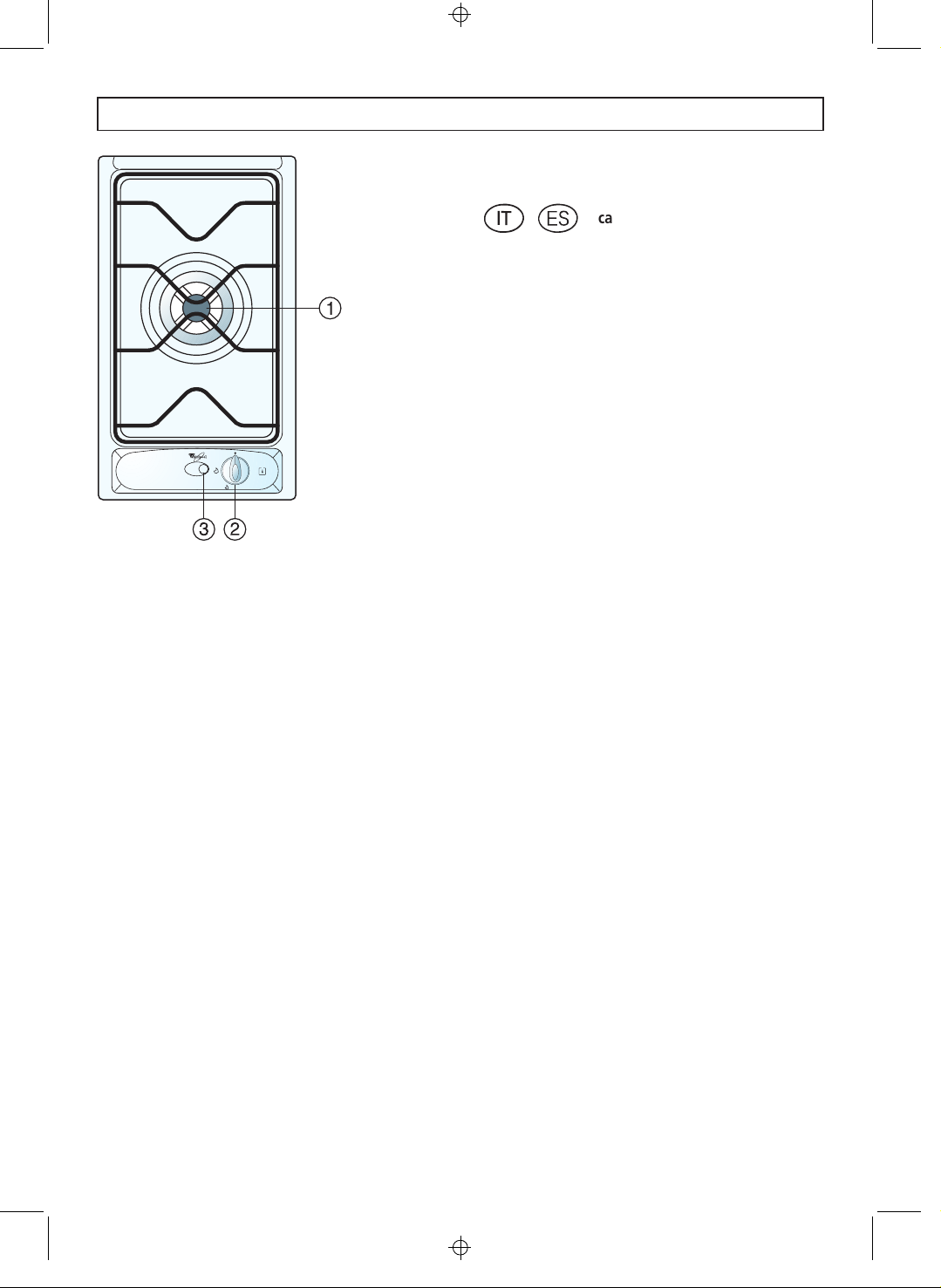

AKR 009

2 GAS COOKTOP

- This appliance is Class 3.

cat. II 2E+ 3+.

l

GAS BURNERS

1. Medium-power burner - 1.65 kW

2. High-power burner - 3.00 kW

CONTROL PANEL

3. Front burner control knob (1)

4. Rear burner control knob (2)

5. Electric ignition push-button

AKR 013

2 GAS COOKTOP

- This appliance is Class 3.

m

GAS BURNERS

1. Medium-power burner - 1.65 kW

2. High-power burner - 3.00 kW

CONTROL PANEL

3. Front burner control knob (1)

4. Rear burner control knob (2)

5. Electric ignition push-button

Note:

The appliance is fitted with a safety valve on each

burner which shuts off the gas supply if the gas goes

out accidentally.

cat. II 2ELL 3B/P.

29

M Y

29

N C

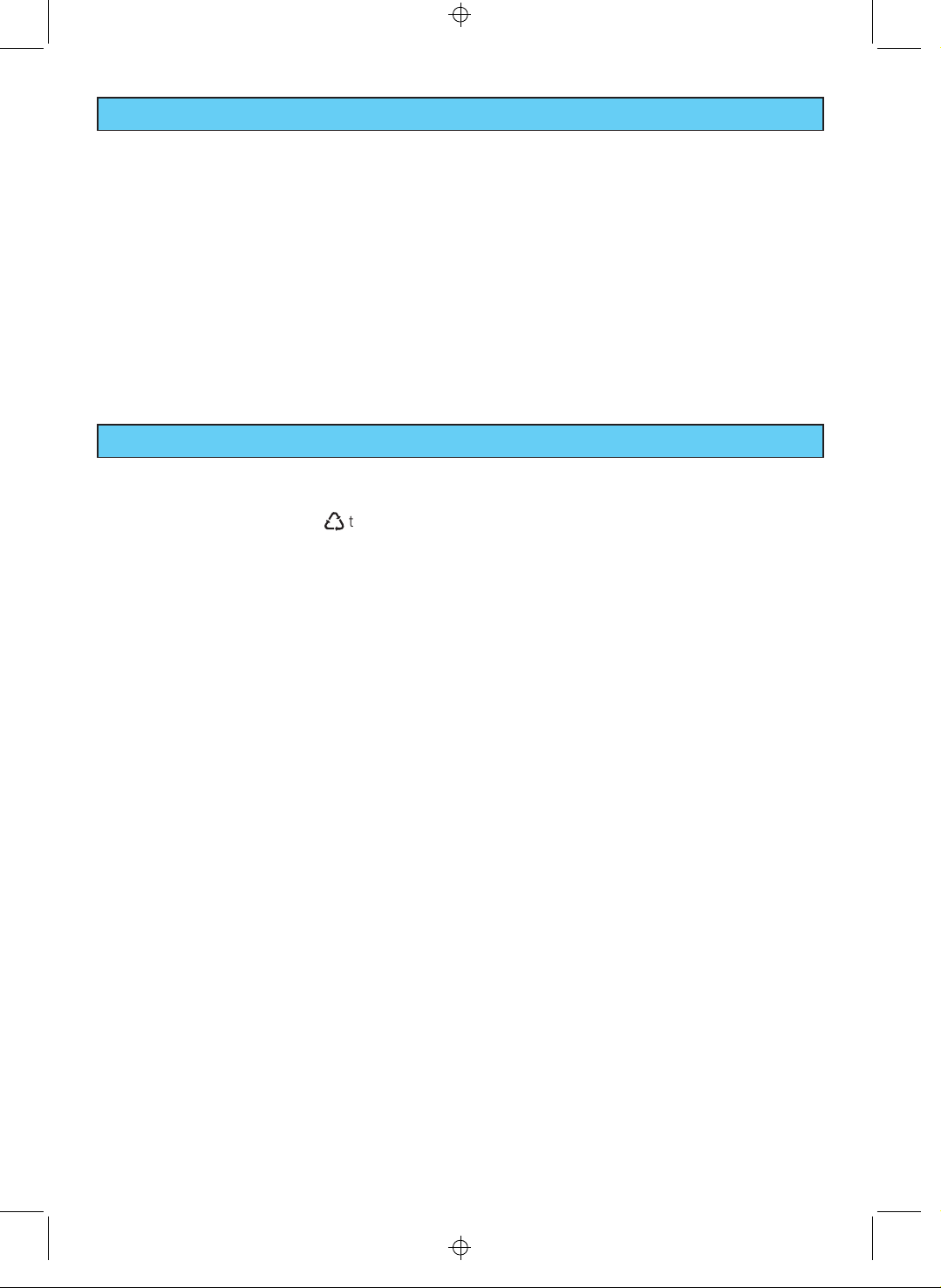

AKR 003

DOUBLE CROWN GAS COOKTOP

- This appliance is Class 3.

ok

cat II 2H3+.

GAS BURNERS

1. Double-crown burner - 3.30 kW

CONTROL PANEL

2 Double crown burner control knob

3. Ignition push-button

Note:

The appliance is fitted with a safety valve on each

burner which shuts off the gas supply if the gas goes

out accidentally.

30

M Y

30

N C

BEFORE USING THE COOKTOP

x

For best use of your cooktop, read the

Instructions For Use carefully and keep them in

asafeplace.

x

This appliance must only be used for the

purpose for which it was designed, i.e. for

cooking foods.

Any other use should be considered incorrect

and therefore dangerous.

x

The manufacturer declines all responsibility for

damage caused by unreasonable, incorrect or

contrary to these instructions.

x

Do not try to alter the technical features of

the appliance, because this could be very

dangerous.

x

Packaging materials (plastic bags, polystyrene pieces,

etc...) must be stored out of the reach of children as

they are potentially dangerous.

x

Check that the cooktop has not been damaged

during transport. If in doubt, consult a specialised

engineer.

x

Please make sure that the installation and

electrical connections are made by a qualified

electrician following the manufacturer’s

instructions and in compliance with the local

regulations in force.

TIPS FOR SAFEGUARDING THE ENVIRONMENT

1. Packaging

The packaging material is 100% recyclable and is

marked with the recycling symbol

type of material which must be taken to the local

collection centres.

to identify the

Ù

2. Product

The cooktop has been manufactured with recyclable

material. Dispose of it following the local regulations

for the disposal of waste.

Before disposing of it make it unusable by cutting

off the supply cable.

31

M Y

31

N C

WARNINGS FOR THE USE OF ELECTRICAL APPLIANCES

When using electrical appliances some

important rules must always be followed. In

particular:

x

Never touch the appliance with wet or damp hands

or feet

x

Never use the appliance with bare feet

x

Keep children away from the hob when it is in use.

x

Before any cleaning or maintenance, switch off the

electricity to the cooktop.

PRECAUTIONS AND GENERAL SUGGESTIONS

x

Risk of fire!

Do not leave inflammable material on the cooktop.

x

Make sure that the electrical cables of other

appliances installed near the cooktop do not come

into contact with it.

x

During and immediately after operation some parts

of the cooktop reach very high temperatures. Do

not touch them.

x

Keep children away from the appliance, especially

when it is being used.

x

After using the cooktop make sure that the knobs

are switched off.

x

When not using the cooktop it is a good idea to

switch off the gas line supply tap.

EU Declaration of conformity

x

This cooktop is intended to come into contact with

food products and conforms with European

Directive 89/109/EEC.

x

This cooktop has been designed, constructed and

put on to the market in conformity with:

- Safety requirements of the “Gas” Directive 90/

396/EEC and amendments;

- Safety requirements of the “Low Voltage”

Directive 73/23/EEC and amendments;

- Protection requirements of the “EMC” Directive

89/336/EEC and amendments;

- Requirements of Directive 93/68/EEC.

n

If the cooktop is fitted with a glass cover:

x

Do not close the glass cover when the hotplates are

still hot. If there is an oven under the cooktop, do

not close the cover when the oven is switched on

or still hot.

x

Do not put pans or heavy objects on the cover.

x

Dry off any liquid which may have spilt on the cover

before opening it.

32

M Y

32

N C

GAS COOKTOP

AKR 001 – AKR 003 – AKR 013

GAS BURNERS

The flow of gas to the burners is adjusted by the

knobs which control the taps with safety valves.

Match the mark on the knob with the symbols printed

on the panel:

-fulldisc

- symbol

- symbol

x

=tapoff

= max. opening or max. flow

æ

æ

= min. opening or min. flow

To light one of the burners:

1. Press and turn the gas tap knob anticlockwise to the

maximum flow position, press it down and keep it

pressed.

2. Press the electric ignition push-button. If there is a

power cut use a flame.

3. Wait for ten seconds after lighting the burner before

releasing the knob (valve triggering time).

4. Set the gas tap to the position required.

If particular characteristics of the locally supplied gas

make lighting the burner with the knob in the

maximum flow position difficult, repeat the operation

with the knob in the minimum flow position.

If the burner flame should go out for any reason, the

safety valve will automatically shut off the gas supply.

To light the gas again, turn the knob to the

and then repeat the lighting operations.

The maximum flow is used to bring liquids to the boil

quickly, while the low flow is used to heat food slowly

or for simmering.

All the operating positions must be chosen between

the maximum and the minimum and never between

the maximum and the OFF.

x

position

33

M Y

33

N C

GAS COOKTOP

AKR 002 – AKR 009

GAS BURNERS

The flow of gas to the burners is adjusted by the

knobs which control the safety-closing taps.

Match the mark on the knob with the symbols printed

on the panel:

-fulldisc

x

=tapoff

- symbol

- symbol

To light one of the burners:

1. Press and turn the corresponding knob to the

maximum flow position (large flame).

2. Press the electric ignition push-button until the gas

has lit. If there is a power cut use a flame.

3. Set the gas tap to the position required.

If particular characteristics of the locally supplied gas

make lighting the burner with the knob in the

maximum flow position difficult, repeat the operation

with the knob in the minimum flow position.

The maximum flow is used to bring liquids to the boil

quickly, while the low flow is used to heat food slowly

or for simmering.

All the operating positions must be chosen between

the maximum and the minimum and never between

the maximum and the OFF.

= max. opening or max. flow

æ

æ

= min. opening or min. flow

34

M Y

34

N C

USING THE COOKTOP

SPECIAL GRIDS FOR WOKS

optional (only model AKR 003)

This special grid for woks rests on the grid of the

double-crown burner.

WARNING:

− Using woks without this special grid could seriously

damage the burner.

− Donotusethisgridwithflatbottomedpans.

ENERGY SAVING HINTS

x

Use pans with base of the same diameter or slightly

larger than that of the cooking zone.

x

Use only flat-bottomed pans.

The use of pans with concave or convex bottoms is

not recommended.

x

The pans must not interfere with the control panel.

x

If possible, put covers on pans.

x

Boil vegetables, potatoes, etc. with just a little water

to save energy.

x

Pressure cookers help to save energy and are

quicker than traditional pans.

PAN DIAMETER

Burners minimum maximum

Medium-power 16 cm 22 cm

High-power 24 cm 26 cm

Doublecrown 24cm 28cm

WOKdiametermax.36cm

Warning: During use the cooktop cooking

zones become very hot. Keep children away.

35

M Y

35

N C

CLEANING AND MAINTENANCE

CLEANING THE COOKTOP AND

CONTROL PANEL

x

Before cleaning the cooktop switch it off and wait

forittocooldown.

x

Cleanwithaclothwettedwithhotwaterandsoap

or water and liquid detergent.

x

Do not use products which are abrasive, corrosive or

chlorine based, or steel pads.

x

Do not leave acid or alkaline substances (vinegar,

salt, lemon juice etc.) on the cooktop.

ENAMEL COOKTOP

x

Enamelled parts must be washed using a sponge,

with soapy water or other non-abrasive products.

Drywithasoftcloth.Ifacidsubstancessuchas

lemon juice, tomato conserve, vinegar etc. are left

on the enamel for a long time they will etch it,

making it opaque.

STAINLESS STEEL COOKTOP

x

Stainless steel parts must be rinsed with water and

dried with a soft and clean cloth or with a chamois

leather.

x

For difficult dirt, use a specific non-abrasive product

available commercially or a little hot vinegar.

x

Note: regular use could cause discolouring around

the burners, because of the high temperature.

CLEANING THE BURNERS AND THE

GRIDS

x

These pieces can be removed and washed with

suitable products.

x

After cleaning, the burners and spreaders must be

dried carefully and put back into their housing

correctly.

x

It is very important to check the correct position of

the burner spreader because if it moves out of place

serious problems could occur.

x

In models which have safety valves, make sure that

the sensor, near to each burner, remains clean so

that the safety valves can work properly.

x

In appliances with electric ignition make sure that

the electrode remains clean so that the sparks can

strike properly. The spark plugs must be cleaned

very carefully.

N.B.: To avoid damage to the electric ignition, do

not use it when the burners are not in place.

GAS TAPS

The gas taps should be cleaned regularly and only by

specialised engineers.

If the gas taps are not working correctly, call the AfterSales Service.

36

M Y

36

N C

TROUBLE-SHOOTING GUIDE

1. The burner does not light:

x

Is the gas supply tap switched on?

x

Has the gas supply (methane) been cut off?

x

Is the cylinder empty? (Liquid gas).

x

Are the burner openings clogged?

x

Have the cap or burner been repositioned correctly

after cleaning?

AFTER-SALES SERVICE

Before contacting the After-Sales Service:

1. Check whether you can deal with the problem

yourself (See “Trouble Shooting Guide”).

2. Switch on the appliance again to check whether the

problem has been solved.

3. If it is still not working properly, call the After-Sales

Service.

Give:

x

The type of fault

x

The model

x

The Service number (the number after the word

SERVICE on the rating plate underneath the cooktop,

on the guarantee and on this instruction manual).

x

Your complete address including Post Code

x

Your telephone number

x

When you can be contacted.

2. The burner does not stay lit:

x

Repeat the lighting operation turning the knob to

the symbol representing the small flame

3. The electric ignition does not work:

x

Is there a power failure?

l

æ

.

37

M Y

37

N C

INSTALLATION

x

The installation, adjustment and modification of the

appliance for the use of other gases must be

performed by a trained installer. Failure to observe

this rule will lead to cancellation of the guarantee.

x

The appliance must be installed correctly and in

conformity with the local regulations in force.

x

Any operation must be performed with the

appliance switched off.

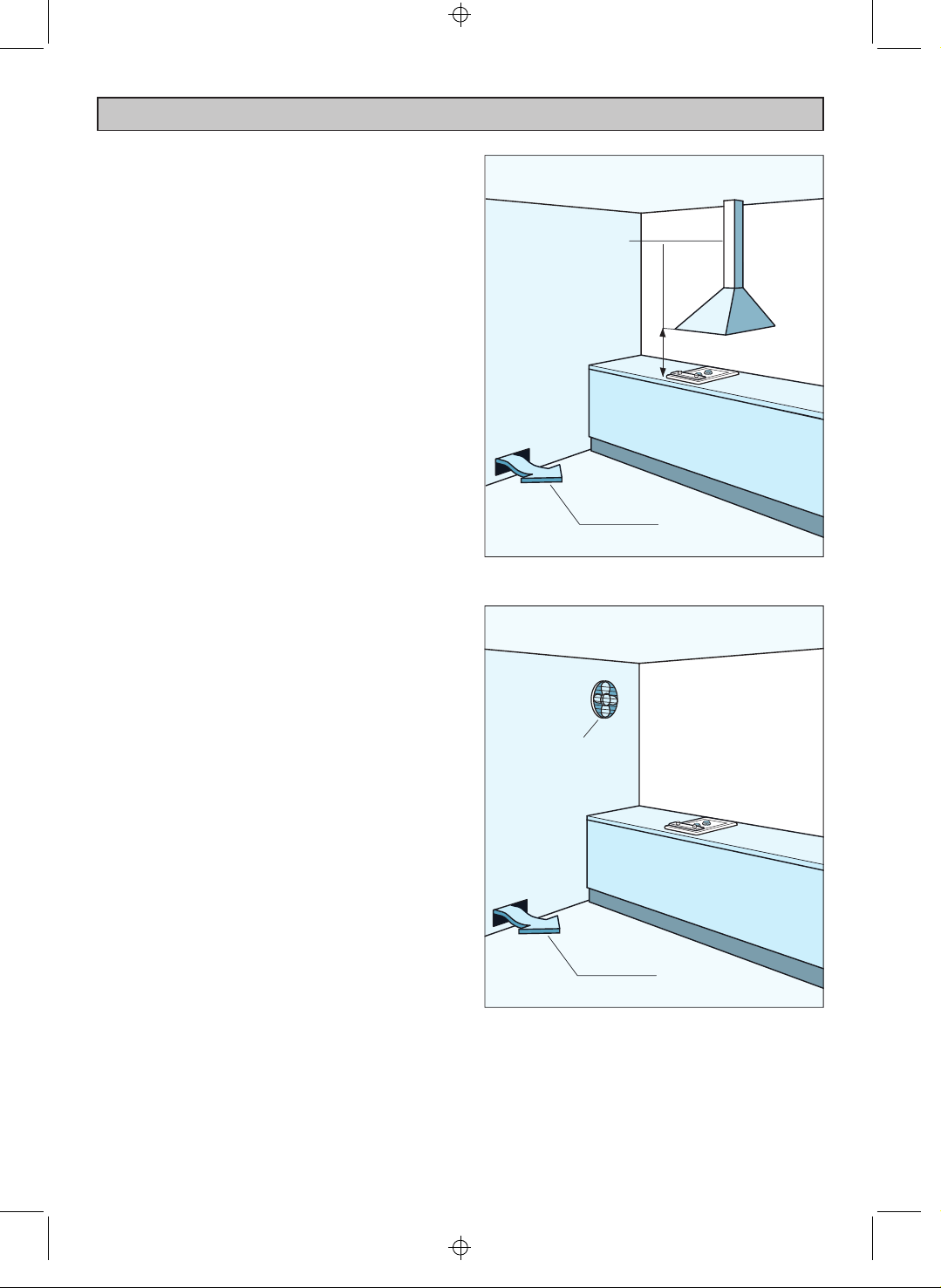

Combustion product

extractor hood

INSTALLATION ROOM

x

In the room where the cooktop is installed there

must be enough air for correct gas combustion (2

3

/h x kW).

m

The installer must refer to the national

standards in force concerning ventilation and

removal of combustion products.

x

The natural flow of air must occur through one or

more suitable openings which must be:

- Permanent and made in the outside walls of the

room to be ventilated, in an area away from

sources of pollution.

- So made that the opening outlets, both inside and

outside the wall, cannot be blocked, even

accidentally.

- Protected with grids, metal net etc. so as not to

reduce the useful section indicated above.

- Situated at roughly floor level and such as not to

cause disturbance to the correct operation of the

combustion product removal devices.

When these openings cannot be made, the necessary

airmustcomefromanadjacentroom,ventilatedas

required, as long as it is not a bedroom or a dangerous

room. In this case the kitchen door must allow the

passage of air.

DISCHARGE OF THE COMBUSTION

PRODUCTS

The combustion products of gas appliances must be

discharged through hoods connected directly to the

outside.

When this is not possible an electric fan can be used,

attached to the outside wall or to the window, having

a capacity such as to allow an hourly exchange of air of

3–5timesthevolumeofthekitchen.

The fan can only be installed if there are suitable

openings for the inlet of air.

H min 650 mm

Opening for

air inlet

Electric fan to

remove combustion

products

Opening for

air inlet

38

M Y

38

N C

INSTALLATION

Technical information for the installer

The appliance must be installed by a qualified engineer

following the manufacturer’s instructions and in

compliance with local regulations in force.

To fit the cooktop into the unit remember that:

− inside the unit there must be a space of at least

30 mm between the bottom of the cooktop and

the top of an appliance or bracket.

− any wall to the side and above the cooktop must

be at least 100 mm away.

− the wall behind the cooktop must be at least 50

mm away.

− when there is a wall unit or hood above the

cooktop there must be at least 650 mm between

the cooktop and the unit or hood.

− the coatings of the walls of the unit or appliances

nearthecooktopmustbeheatresistant(“Y”

protection against heating in compliance with

standards EN 60335-2 6).

Do not install the cooktop near inflammable

materials (e.g. curtains).

39

M Y

39

N C

INSTALLATION

Before installing the cooktop, remove the protective

film.

This cooktop can be built into a working surface 20 to

40 mm thick and 600 mm deep.

To fit the cooktop into the unit make a hole of the

dimensions given in the figures below and respect the

indications given in the previous section “Technical

information for the installer”.

AKR 003 AKR 009 - AKR 013

AKR 001 - AKR 002

40

M Y

40

N C

INSTALLATION

INSTALLING SEVERAL DOMINO

COOKTOPS SIDE-BY-SIDE

Several DOMINO cooktops can be installed side-by-side

using the special junction piece (code No. AMH 719)

available from the After-Sales Service.

For this type of installation openings must be made in

the unit as indicated in the figure, remembering that:

− all the provisions described for the single installation

must be observed

− a 5 mm space must be left between the cooktops

to insert the junction piece

− for installations with more than 3 cooktop side-byside calculate the hole needed referring to the

measurements given in the figures.

− each cooktop must have its own gas/electrical

supply

2 DOMINO side-by-side

3 DOMINO side-by-side

AMH 719

850

41

M Y

41

N C

INSTALLATION

INSTALLATION ON UNITS WITH DOOR

The unit must be so constructed that when the door is

opened or closed, even violently, the pressure or

depressure caused by this does not cause the burners

to go out, whether set to minimum or maximum.

Leave a depressure space of 30 mm between the

bottom of the cooktop and the top of the unit

underneath.

30 mm

FASTENING THE COOKTOP

Eachcooktopissuppliedwithasetoftabsandscrews

to fasten it on units with a working surface from 2 to 4

cm deep.

The kit includes 4 tabs “A” and 4 self-threading

screws “B”.

- Cut the unit.

- Stretch gasket “C” over the edge of the hole made,

being careful to overlay the junction edges.

Depressure space

Door

Space for connections

- Turn the cooktop over and put tabs “A” into the

mountings; only tighten screws “B” a few turns.

Make sure that the tabs are mounted correctly as

showninthefigure.

- Put the cooktop into the hole cut into the unit and

position it correctly.

- Put tabs “A” into place and tighten screws “B” until

the cooktop is completely secured.

C

B

A

20 mm min.

40 mm max

42

M Y

42

N C

INSTALLATION

GAS SUPPLY CONNECTION

Thecooktopissetupandcalibratedtoworkwiththe

gas indicated on the rating plate affixed to the

appliance.

The gas supply system must conform to the local

regulations in force.

To connect the cooktop to the gas mains or cylinder

use a flexible stainless steel hose with continuous wall

conforming to local regulations. Use gasket F for the

cylindrical elbow connection.

The flexible metal tubes must be at most 2 m long.

Attention: If a flexible stainless steel hose is used,

it must be so installed that it cannot come into

contact with a movable part of the unit and is

not obstructed and so that its whole length can

be inspected.

The cooktop connection is made up as follows:

− 1 nipple or 1 nut “A”

−1bicone“B”

− union elbow “C”:

- cylindrical – for Italy, France, Spain and Portugal

- conical – for Germany

IMPORTANT:

− Never turn union C forcibly without first

slackening nipple or nut A. In versions with

bicone “A”, use 2 spanners for this operation.

Never leave it in the horizontal or vertical

position.

− Gasket F and bicone B are the elements which

guarantee the gas connection seal.

Replace them when they are even slightly

deformed or imperfect.

− After the connection check the connection seal

with a soapy solution, never with a flame.

conical

cylindrical

43

M Y

43

N C

INSTALLATION

ADAPTATION TO DIFFERENT TYPES

OF GAS

If a gas different from that indicated on the label is

used, adapt the cooktop to this new function.

Each cooktop comes with a set of injectors for the

various types of gas.

Injectors not supplied can be obtained from the AfterSales Service.

Proceed as follows:

1. Replace the injectors with the correct ones.

2. Connect the cooktop to the on-off tap with a tube

which is suitable for the gas to be used according

to the regulations in force.

3. Adjust the gas burner minima.

Replacing gas burner injectors

Choose the injectors to be replaced according to the

tables of Page 45.

The injector diameter, expressed in hundredths of a

millimetre, is marked on the injector bodies.

To replace the injectors proceed as follows:

− Remove the grids and extract the burner bodies

− With a spanner replace nozzles “J” with nozzles

suitable for the gas to be used.

The burners are so designed that there is no

need to adjust the primary air.

44

M Y

44

N C

INSTALLATION

INJECTOR TABLES

o

G30/G31 G20 G110

BURNERS

Medium-power 1,650 0,35 65 94 185

High-power 3,000 0,60 85 128 290

Rated output Low output

[kW] [kW] Ø injector Ø injector Ø injector

28-30/37 mbar 20 mbar 8 mbar

[1/100 mm] [1/100 mm] [1/100 mm]

kvo

G30/G31 G20

BURNERS

Medium-power 1,650 0,35 65 94

High-power 3,000 0,60 85 128

Double-crown 3,300 1,50 92 139

Rated output Low output

[kW] [kW] Ø injector Ø injector

28-30/37 mbar 20 mbar

[1/100 mm] [1/100 mm]

l

G30/G31 G20/G25

BURNERS

Medium-power 1,650 0,35 65 94

High-power 3,000 0,60 85 128

Rated output Low output

[kW] [kW] Ø injector Ø injector

28-30/37 mbar 20/25 mbar

[1/100 mm] [1/100 mm]

cat. III 1a2H3+

cat. II 2H3+

cat. II 2E+ 3+

m

BURNERS

Medium-power 1,650 0,52 58

High-power 3,000 0,85 79

BURNERS

Medium-power 1,650 0,35 94 106

High-power 3,000 0,60 128 138

M Y

Rated output Low output

[kW] [kW] Ø injector

G20 G25

Rated output Low output

[kW] [kW] Ø injector Ø injector

20 mbar 20 mbar

[1/100 mm] [1/100 mm]

cat. II 2ELL 3B/P

G30/G31

50/50 mbar

[1/100 mm]

45

45

N C

INSTALLATION

Adjusting the gas burner minimum

For taps with adjusting screw inside the shaft:

− with a screwdriver, max. diameter 3 mm, turn the

screw inside the tap shaft until adjustment is correct.

− perform the adjustment with the tap in the

minimum position (small flame

For taps with adjusting screw on the body:

− with a screwdriver turn screw “A” until adjustment is

correct.

− in the models with ignition incorporated in the knob

access to screw “A” is through a hole in the

microswitch.

− perform the adjustment with the tap in the

minimum position (small flame

For gas G30/G31 tighten the adjusting screw

completely.

æ

æ

).

).

GAS TAP LUBRICATION

If a gas tap is difficult to turn, disassemble it, clean it

carefully with petrol and spread a little special hightemperature resistant grease on it.

These operations should be performed by a specialised

engineer.

A

46

M Y

46

N C

INSTALLATION

ELECTRICAL PART

IMPORTANT: Install the cooktop following the

manufacturer’s instructions.

Incorrect installation can cause damage to

people, animals or things, for which the

manufacturer cannot be held responsible.

− The appliance must be connected to the mains by a

trained electrician and according to the regulations

in force.

− The appliance must be connected to the mains

checking first of all that the voltage corresponds to

the value given on the rating plate and that the

section of the electrical cables can take the load

indicated on the rating plate.

− The plug must be put into a socket connected to

the earth system in compliance with safety rules.

− If the appliance is supplied without a plug fit a

standard plug which is suitable for the power

absorbed by the appliance.

− The connection can be made directly to the mains

by putting an all-pole switch with minimum opening

between the contacts of 3 mm between the

appliance and the mains.

− The supply cable must not touch hot parts and must

be so positioned that it does not exceed the

temperature of 75

− When the appliance is installed the switch or socket

must always be accessible.

− The appliance must have its own supply; any other

appliances installed near it must be supplied

separately.

o

C at any point.

N.B. For connection to the mains do not use adapters,

reductions or shunts because these can cause

overheating or burning.

If the installation requires modifications to the domestic

electrical system or if the socket and the appliance plug

are not compatible, contact a professional electrician.

He must, in particular, also make sure that the crosssection of the socket cables is suitable for the power

absorbed by the appliance.

The appliance must be connected to the earth.

The manufacturer declines all responsibility for

any problem caused by failure to observe this

rule.

47

M Y

47

N C

INSTALLATION

REPAIRS

Replacing the supply cable

− The supply cable must be replaced by a cable of the

same sort as that fitted to the appliance.

− The supply cable must be connected to the terminal

board following the diagram shown below.

Section of the supply cables

type H05V2V2-F

230 V

4

o

Ù

N

3 x 0,75 mm

2

resistanttoatemperatureof90

230 V

Ù

L

48

M Y

48

Loading...

Loading...