Whirlpool 50 User Manual

Installation Instructions

ICE MAKER

Model 50

jve Ovens, Compactors, Room Air Conditioners, Dehumidifiers, Automatic Washers, Clothes Dryers, Freezers, Refrigerator-Freezers, Ice Makers,Dishwas

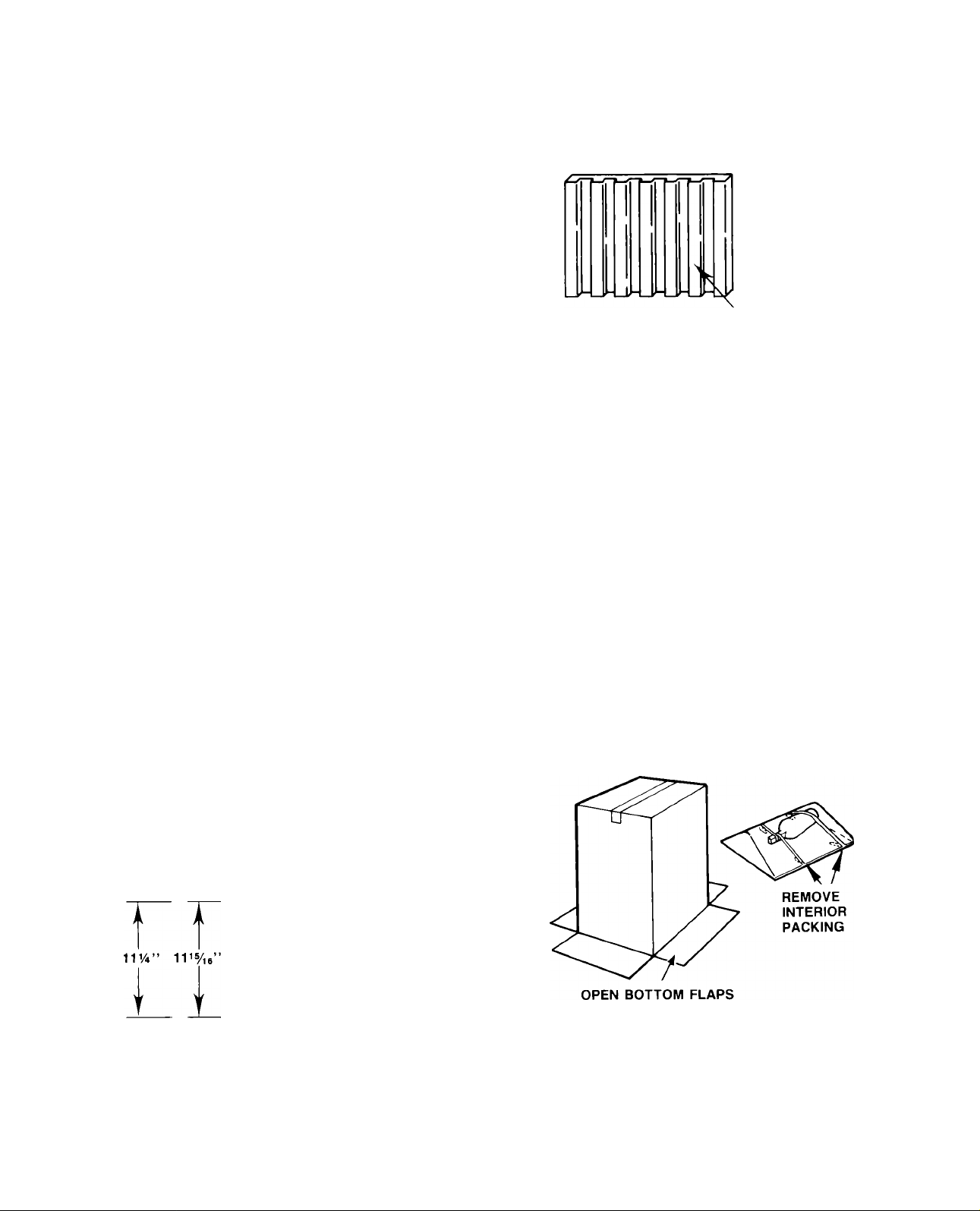

Changing the bin door

and lower panel

The storage bin door is designed to accept an optional

decorative wood panel of your choice.

The wood panel should be no more than 'A inch (6 mm)

thick. Cut it to the same size as the production metal

panel. See Figure 1.

To change the bin door panel:

1. Open the bin door.

2. Remove the two screws on top of the door which

hold the handle.

3. Remove the handle.

4. Slide the metal panel out.

5. Break off the ribs on the door insulation to allow for

the wood thickness. See Figure 2.

6. Slide the wood panel into the door frame.

7. Replace handle and screws.

To change the lower panel:

1. Remove the two screws at the bottom that hold the

lower panel assembly to the ice maker.

2. Remove the two screws on the top of the panel

assembly.

3. Slide the metal panels and spacers out.

4. Slide the wood panel into the door frame.

REMOVE ALL DOOR INSULATION

RIBS TO ACCEPT WOOD PANEL

THICKNESS

FIGURE 2

Thermostat calibrations

If ice maker is installed above two thousand feet of

altitude, the bin and evaporator thermostats must be

adjusted to a warmer setting. Disconnect electricity,

remove thermostat and follow the directions for turn

ing the altitude adjustment screw as shown in the label

on each thermostat.

Shipboard operation

When this ice cube maker is installed aboard a ship,

it will be necessary to purchase and install a water

deflector. This deflector hangs between the lower edge

of the evaporator and the cutter grid. It keeps the water

flowing over the evaporator from spilling into the

storage bin area. Order the necessary parts from your

local ice maker dealer.

General information

Unpack

5. Replace the top of the panel assembly.

NOTE: Make sure the galvanized panel is replaced in

back of the panel assembly.

DOOR LOWER

BIN PANEL

WOOD

PANEL

DIMENSIONS

17”-

FIGURE 1

FIGURE 3

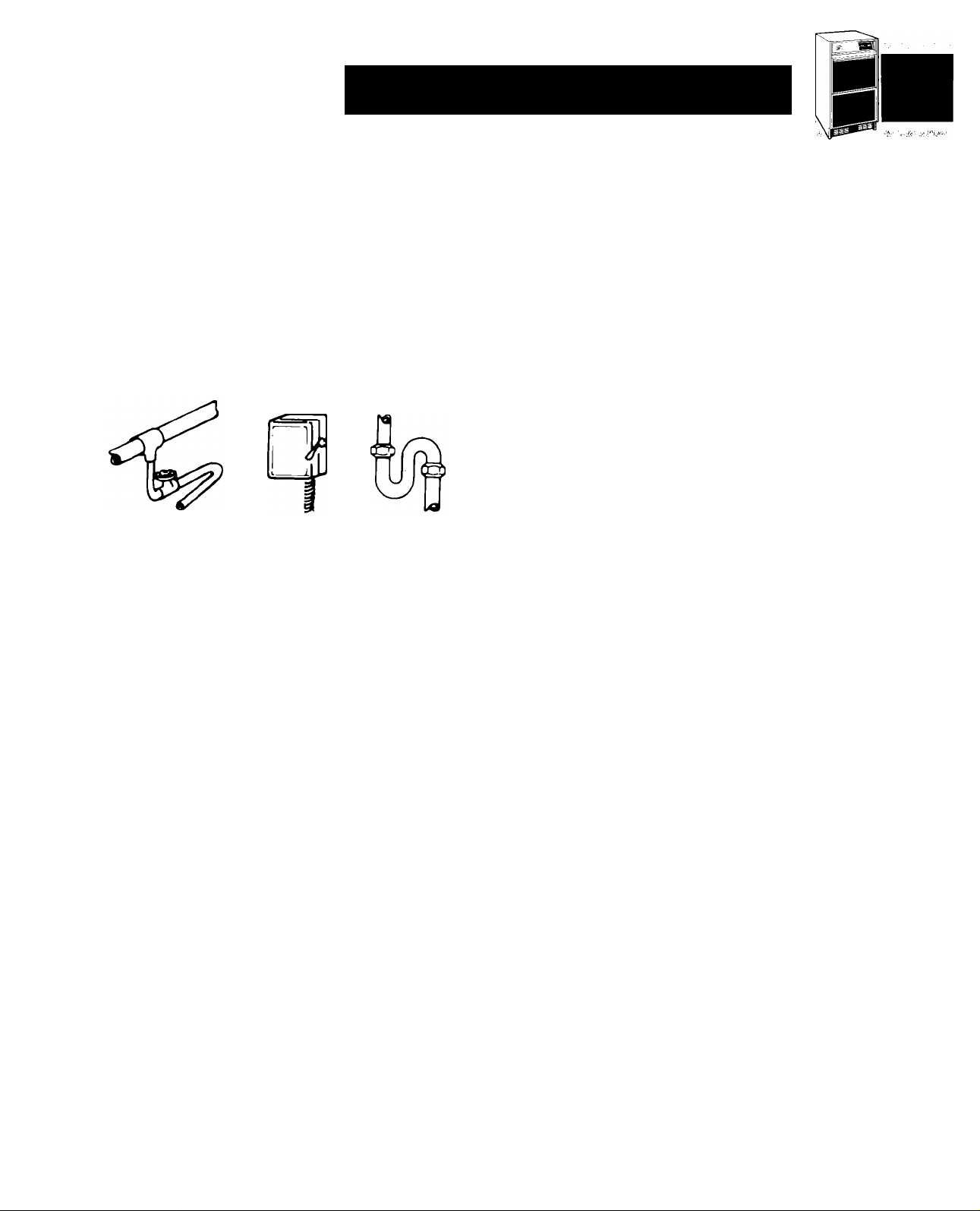

1. Lay carton on rear face and break open bottom flap.

2. Set carton upright with all four flaps outward. See

Figure 3.

3. Lift carton up and off of machine.

FIGURE 4

Installation Instructions

4. Remove all tape and packaging material from the

outside and inside of the cabinet. See Figure 4.

5. Remove the front grill; take out the screws securing

the grill at the bottom and lift it free of cabinet.

6. Turn the fan by hand to make certain it moves freely.

7. Loosen thumb screws holding cutter grid and water

pan to “thumb tight.”

Utilities

WATER

OBSERVE LOCAL CODES

Each installation is unique but will require:

1. A cold water inlet of Va” OD soft copper tubing and

a shut-off valve.

2. Either a gravity drain system or a sump pump to lift

the water to an existing drain.

3. An electrical branch circuit of 115 Volt, 60 Hz. 1

phase, with a 15 Amp delayed action fuse or circuit

breaker.

ELECTRICITY

DRAIN

Locate unit

2. Area should be well ventilated with temperature

above 55° F and below 110°F. Best results are ob

tained between 70°F and 90°F.

3. Provision for electricity, water and drain connections

should be determined.

4. The unit may be closed in on the top and three sides,

but the front MUST BE unobstructed for air circula

tion and proper operation. Installation should be

such that the cabinet can be moved forward for ser

vicing, if necessary.

Level unit

1. After placing unit in position, check to make certain

the unit is level side to side and front to back.

2. Accurate leveling is essential for proper operation.

3. Unit should be shimmed so that it is solid as well

as level. The shims should be of hard permanent

type material such as masonite.

4. Compliance with National Sanitation Foundation

standards require that this type of product be sealed

to the floor at the bottom rail in order to prevent con

tamination from spills or the entrance of vermin.

Therefore, we recommend that when installing this

product you seal it to the floor in accordance with

those standards. A silicone-type sealer is recom

mended.

For the plumber

Connect to water

(Observe local codes)

1. Use Va” OD soft copper tubing for the cold water

supply.

2. Provide a convenient manual shut-off valve in the

water line.

THIS UNIT MUST BE

INSTALLED IN AN

AREA PROTECTED FROM

THE ELEMENTS, SUCH

AS WIND, RAIN, WATER

SPRAY OR DRIP.

1. Place unit so the front side will be completely

unobstructed to provide proper air flow.

90“ F

70“ F

BEST

RANGE

3. Position the tubing so it can enter the access hole

located in the right-hand rear of the cabinet. The tub

ing shoud extend beyond the cabinet front when the

cabinet is pushed back into position. See Figure 5.

NOTE:

Always purge the water line before making the final con

nection to the inlet of the water valve to prevent possi

ble water valve malfunction.

After the cabinet is in place, bend the tubing to meet

the connection at the water valve. The garden hose

threaded compression fitting is found in the parts bag.

This joint provides a convenient disconnect for service.

Be sure the tubing is clear of compressor, to prevent

rattle.

Loading...

Loading...