Whirlpool 4GWED5500, 4GMEDX500 Installation Instructions

ELECTRIC DRYER

INSTALLATION INSTRUCTIONS

INSTRUCTIONS POUR L’INSTALLATION DU

SECHE-LINGE ELECTRIQUE

INSTRUCCIONES DE INSTALACIÓN DE LA

SECADORA ELÉCTRICA

Table of Contents

DRYER SAFETY .........................................................................2

INSTALLATION REQUIREMENTS ............................................. 3

Tools and Parts ...................................................................... 3

Location Requirements ......................................................... 4

Electrical Requirements ........................................................ 6

Install Leveling Legs .............................................................. 6

VENTING REQUIREMENTS ...................................................... 7

Table des matières

SECURITE DU SECHE-LINGE ................................................ 15

EXIGENCES D’INSTALLATION ............................................... 17

Outillage et pièces ............................................................... 17

Exigences d’emplacement .................................................. 17

Spécications électriques................................................... 19

Installation des pieds de nivellement ................................. 20

EXIGENCES CONCCERNANT L’ÉVACUATION .....................20

SEGURIDAD DE LA SECADORA ............................................ 29

REQUISITOS DE INSTALACIÓN ............................................. 30

Herramientas y piezas ......................................................... 30

Requisitos de ubicación ...................................................... 31

Requisitos eléctricos ........................................................... 33

Instalación de las patas niveladoras .................................. 34

REQUISITOS DE VENTILACIÓN ............................................. 34

Plan Vent System ...................................................................8

Install Vent System ................................................................9

Connect Vent .......................................................................... 9

LEVEL DRYER .......................................................................... 10

COMPLETE INSTALLATION CHECKLIST .............................. 10

REVERSE DOOR SWING (OPTIONAL) ................................... 11

TROUBLESHOOTING .............................................................. 14

Planication du système d’évacuation .............................. 21

Installation du circuit d’évacuation .................................... 22

Raccordment du conduit d’évacuation .............................23

REGLAGE DE L’APLOMB DU SECHE-LINGE ........................ 23

ACHEVER L’INSTALLATION – LISTE DE VERIFICATION ...... 24

INVERSION DE LA PORTE (FACULTATIF) .............................. 24

DEPANNAGE ............................................................................28

Índice

Planicación del sistema de ventilación ........................... 35

Instalación del sistema de ventilación................................ 36

Conexión del conducto de escape ..................................... 37

NIVELACIÓN DE LA SECADORA............................................37

LISTA DE CONTROL DE LA INSTALACIÓN TERMINADA .... 38

CAMBIO DEL SENTIDO DE ABERTURA DE LA

PUERTA (OPCIONAL) .............................................................. 38

SOLUCIÓN DE PROBLEMAS .................................................. 42

W10461694C

4GWED5500

4GMEDX500

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

2

INSTALLATION REQUIREMENTS

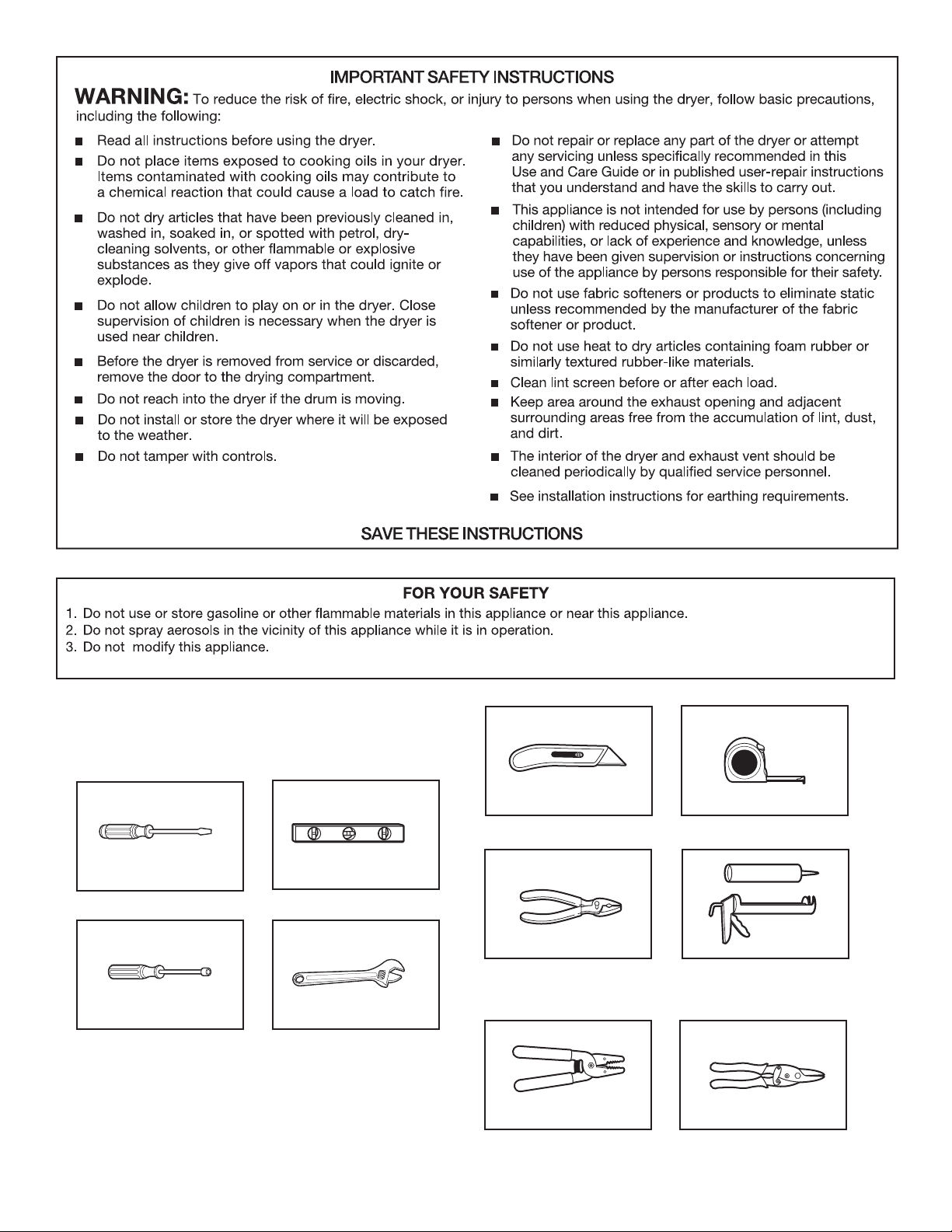

Tools and Parts:

Gather required tools and parts before starting installation.

Flat-blade screwdriver

6,2 mm (1/4") nut driver

Level

Adjustable wrench that

opens to 25 mm (1") or a

hex-head socket

Utility knife

Pliers

Wire stripper

(direct wire installations)

Tape measure

Caulking gun and

compound (for installing

new exhaust vent)

Tin snips

(new vent installations)

3

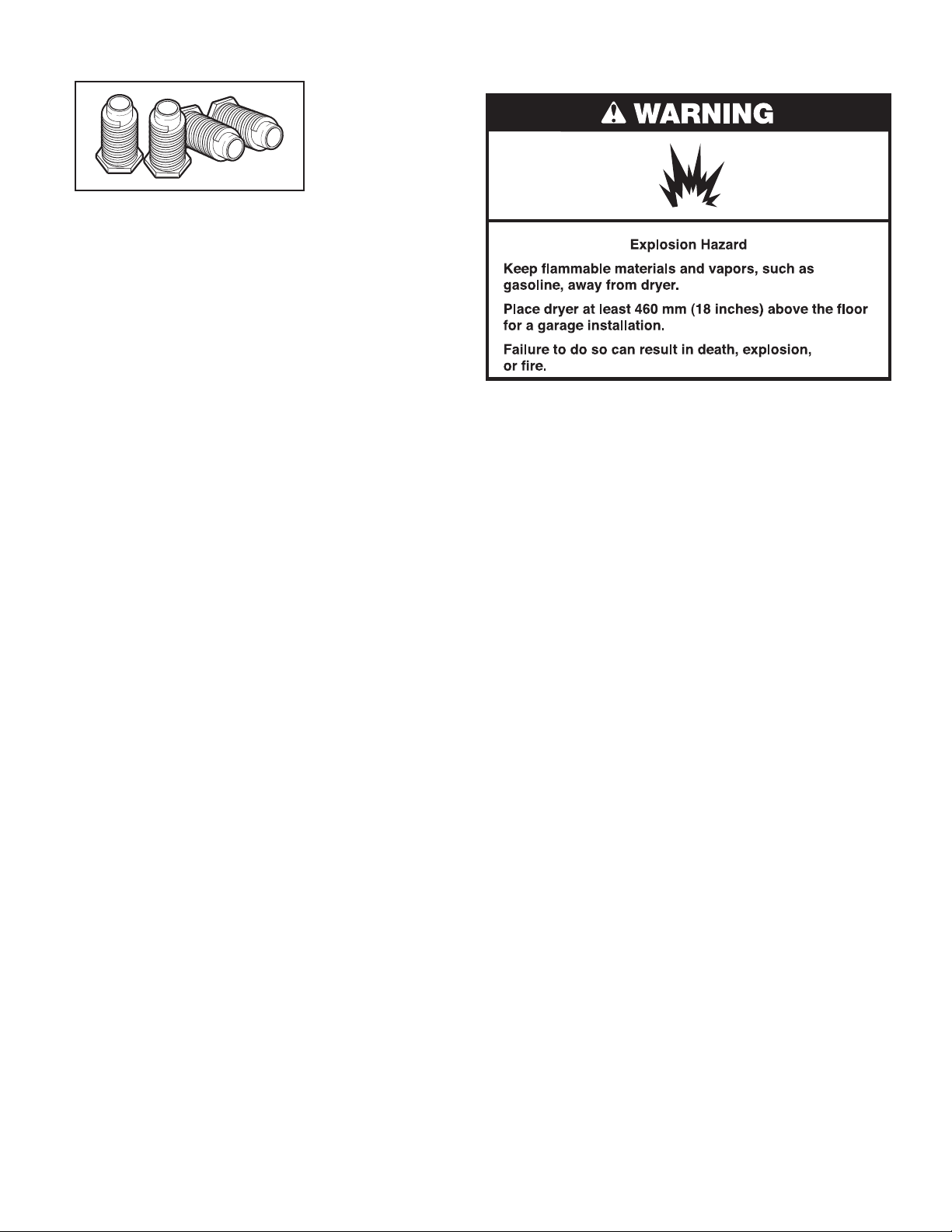

Parts supplied (all models):

Leveling legs (4)

Parts package is located in dryer drum. Check that all parts

are included.

Parts needed: (not supplied with dryer)

■ Electric Cord and Plug

■ Vent clamps

■ Vent elbows and ductwork

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with dryers.

The kit should contain:

■ A UL listed 30-amp power supply cord, rated 240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

■ A UL listed strain relief.

Additional parts may be required, depending on your installation.

Check local codes. Check existing electrical supply and venting.

Read “Electrical Requirements” and “Venting Requirements”

before purchasing parts.

LOCATION REQUIREMENTS

Select proper location for your dryer to improve performance

and minimize noise. Check code requirements. Some codes limit,

or do not permit, installation of the dryer in garages, closets,

mobile homes, or sleeping quarters. Contact your local building

inspector.

You will need:

■ A location that allows for proper exhaust installation. The

dryer must be exhausted to the outdoors. See “Venting

Requirements.”

■ A oor that will support the dryer and a total weight (dryer

and load) of 90,7 kg (200 lbs). The combined weight of a

companion appliance should also be considered.

■ A level oor with maximum slope of 25 mm (1") under entire

dryer. If slope is greater than 25 mm (1"), install Extended

Dryer Feet Kit. Clothes may not tumble properly and models

with automatic sensor cycles may not operate correctly if

dryer is not level.

■ It is important to make sure the room has an adequate air

supply for drying operation. The operation of this appliance

may affect the operation of other appliances which take their

air supply for safe combustion from the same room.

■ Adequate ventilation must be provided to avoid a backow

of gases into the room from appliances burning other

fuels, including open res. If in doubt consult the appliance

manufacturers.

IMPORTANT: The dryer must not be installed or stored in an

area where it will be exposed to water and/or weather. Do not

operate your dryer at temperatures below 7°C (45°F). At lower

temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

Proper installation is your responsibility.

4

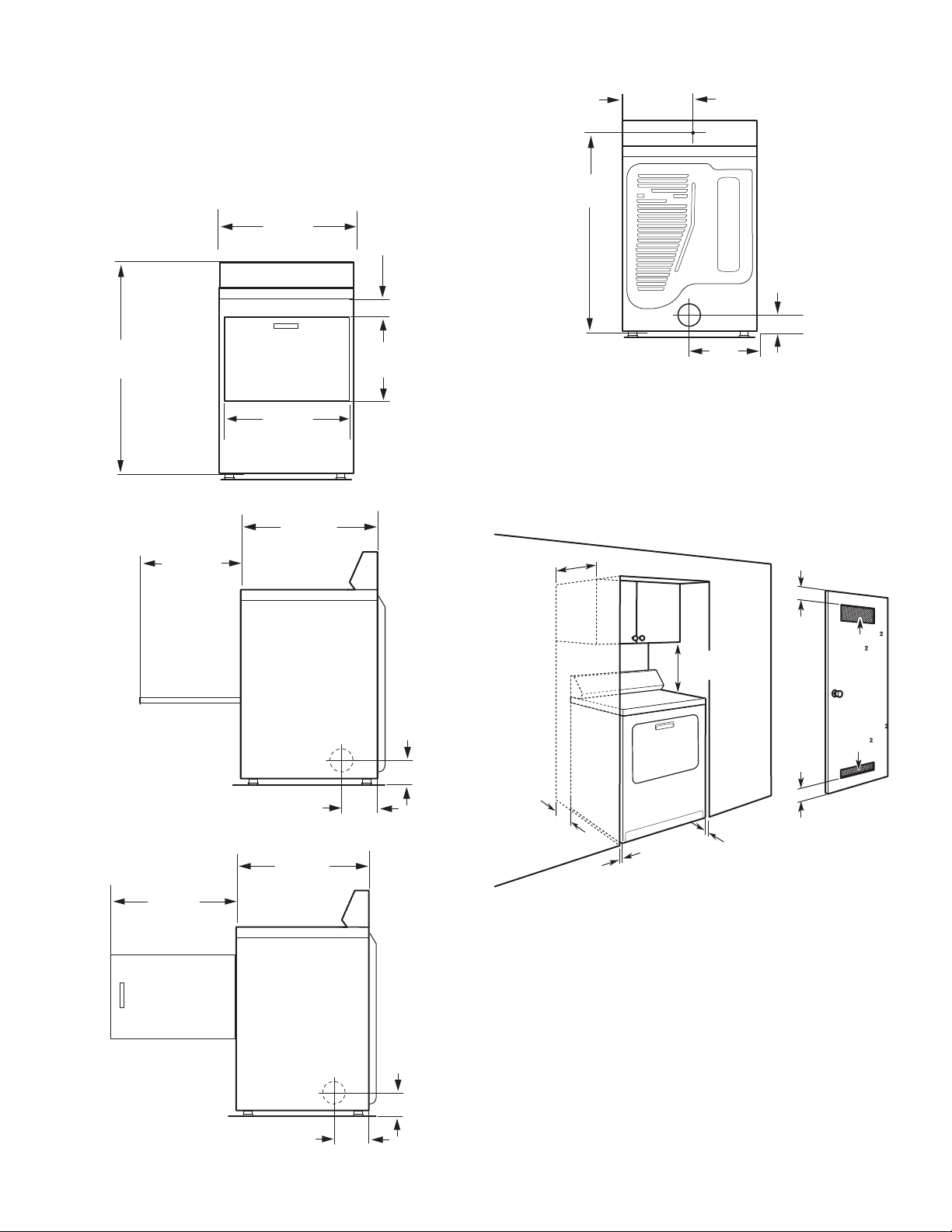

Installation clearances:

279 mm

For each arrangement, consider allowing more space for ease of

installation and servicing; spacing for companion appliances and

clearances for walls, doors, and oor moldings. Space must be

large enough to allow door to fully open. Add spacing on all sides

of dryer to reduce noise transfer. If a closet door or louvered door

is installed, top and bottom air openings in door are required.

Dryer Dimensions

Front View:

686 mm

(27")

98 mm

7

.5

(3

/8

")

Back View:

972 mm

1

.5

")

(38

/

4

(11")

100 mm

(4")

1095 mm

1

.5

")

(43

/8

Side View:

356 mm

(14")

Side View of Side Swing Door:

578 mm

3

(22

.5

")

/4

578 mm

3

.5

(22

/4

743 mm

(29

260 mm

1

(10

.5

/4

743 mm

(29

.5 ")

260 mm

1

(10

.5

/4

")

1

1

.5

")

/4

")

489 mm

1

.5

(19

/8

")

359 mm

1

.5

(14

/8

")

Recessed Area and Closet Installation

This dryer may be installed in a recessed area or closet. If

a closet door or louvered door is installed, the minimum

unobstructed air openings in the top and bottom of the door are

required. For recessed area and closet installations, minimum

clearances can be found on the serial tag on the dryer.

")

/4

356 mm

(14") max.

76 mm

(3")

310 mm

(48" )

155 mm

(24" )

108 mm

1

(4

.5

")

/4

108 mm

1

(4

.5

")

/4

457 mm

(18")

76 mm

(3")

102 mm

(4")

25 mm

(1")

■ Dimensions shown are minimum spacings required. Consider

25 mm

(1")

allowing more space for ease of installation, servicing, and

compliance with local codes and ordinances.

■ Additional spacing for companion appliances and clearances

for walls, doors, and oor moldings should also be

considered. Add spacing of 25 mm (1") on all sides of dryer

to reduce noise transfer.

■ This dryer must not be installed behind a lockable door,

a sliding door or a door with a hinge on the opposite side

to that of the dryer.

■ The dryer must be exhausted outdoors.

■ No other fuel-burning appliance may be installed in the same

closet as the dryer.

5

ELECTRICAL REQUIREMENTS

This dryer is supplied without an electric cord and plug.

It is your responsibility:

■ To contact a qualied electrical installer.

■ To be sure that the electrical connection is adequate and in

conformance with all local codes and ordinances.

■ To supply the required single phase, 240 volt, 60 Hz, AC

only electrical supply on a separate 30-amp circuit fused on

both sides of the line. A time-delay fuse or circuit breaker is

recommended. Connect to an individual branch circuit. Do

not have a fuse in the neutral or grounding circuit.

■ Do not use an extension cord.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate.

Electrical Connection

To properly install your dryer, you must determine the type of

electrical connection you will be using and follow the instructions

provided for it here.

If using a power supply cord:

Use a UL listed power supply cord kit marked for use with

clothes dryers. The kit should contain:

■ A UL listed 30-amp power supply cord, rated 240 volt

minimum. The cord should be type SRD or SRDT and be at

least 4 ft (1.22 m) long. The wires that connect to the dryer

must end in ring terminals or spade terminals with upturned

ends.

■ A UL listed strain relief.

Connecting by direct wire:

Power supply cable must match power supply and be:

■ Flexible armored cable or nonmetallic sheathed copper cable

(with ground wire), covered with exible metallic conduit. All

current-carrying wires must be insulated.

■ 10-gauge solid copper wire (do not use aluminum).

■ At least 5 ft (1.52 m) long.

Recommended Grounding Method

■ It is your responsibility to contact a qualied electrical installer

to ensure that the electrical installation is adequate and in

conformance with all local codes and ordinances.

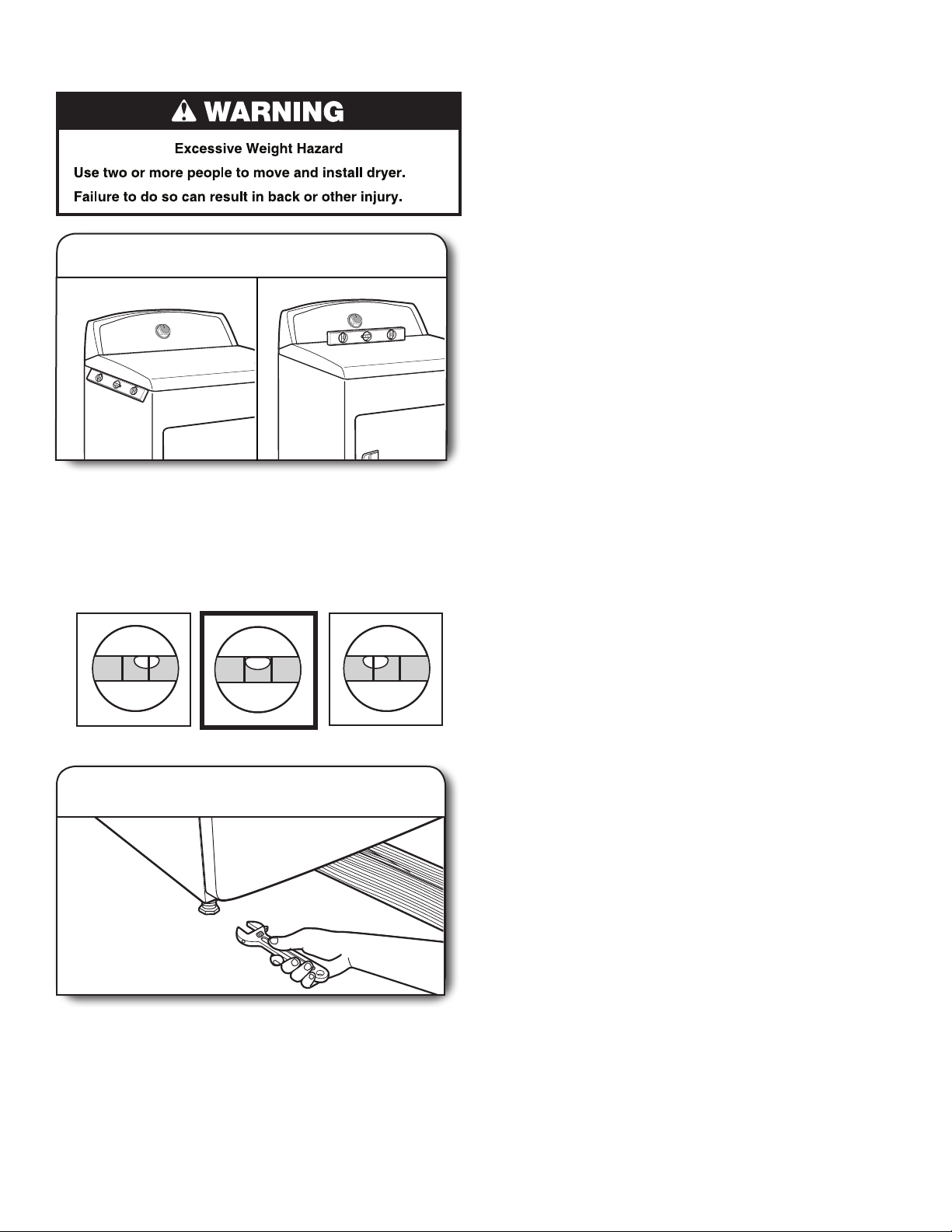

INSTALL LEVELING LEGS

1.

Prepare dryer for leveling legs

To avoid damaging oor, use a large at piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

6

2.

Screw in leveling legs

diamond

marking

■ Do not install in enclosed walls, ceilings, or oors.

■ The total length should not exceed 2.4 m (7¾ ft.).

NOTE: If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not

plugged with lint. Replace plastic or metal foil vents with rigid

metal or exible metal vents. Review “Vent System Chart” and

if necessary, modify existing vent system to achieve best drying

performance.

Exhaust hoods:

■ Must be at least 305 mm (12") from ground or any object that

may obstruct exhaust (such as owers, rocks, bushes, or

snow).

Examine leveling legs, nd diamond marking. Screw legs into

leg holes by hand, use a wrench to nish turning legs until

diamond marking is no longer visible.

Now stand the dryer on its feet. Slide the dryer until it is

close to its nal location. Leave enough room for electrical

connection and to connect the exhaust vent.

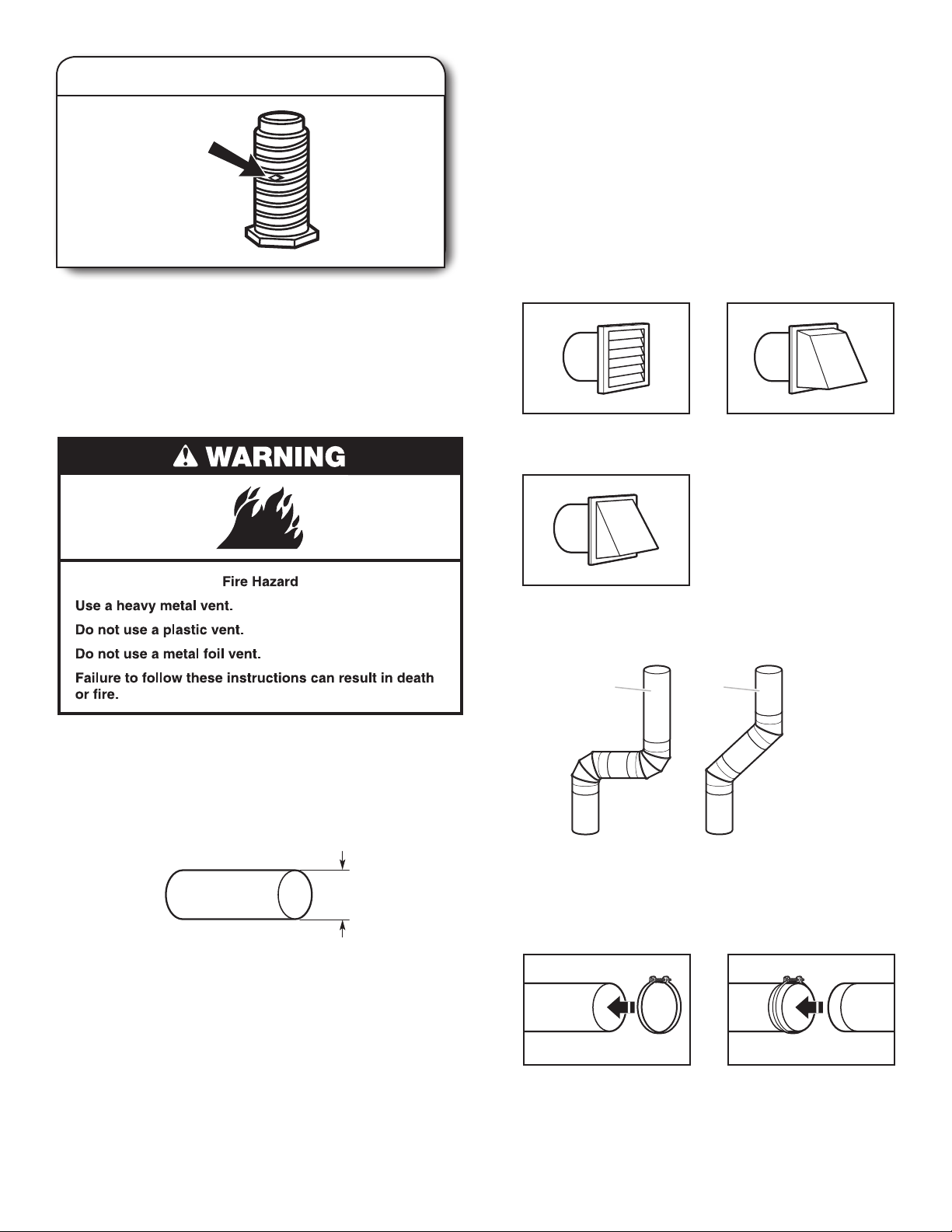

VENTING REQUIREMENTS

Recommended Styles:

Louvered Hood

Box Hood

Acceptable Style:

Angled Hood

Elbows:

■ 45° elbows provide better airow than 90° elbows.

Good Better

WARNING: To reduce the risk of re, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or exible metal vent shall be used for

exhausting.

102 mm

(

4"

)

■ Only a 102 mm (4") heavy metal exhaust vent and clamps

may be used. Do not install metal vent that is smaller than

102 mm (4") in diameter.

■ Do not use plastic, non-metal, or metal foil vent.

Rigid metal vent

■ Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

■ Must be fully extended and supported in nal dryer location.

■ Remove excess exible metal vent to avoid sagging

and kinking that may result in reduced airow and poor

performance.

Clamps:

■ Use clamps to seal all joints.

■ Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

Vent products can be purchased from your dealer. For more

information, see “Assistance or Service” section in your “Use

and Care Guide.”

7

Improper venting can cause moisture and lint to collect

indoors, which may result in:

Moisture damage to woodwork, furniture, paint,

wallpaper, carpets, etc.

Housecleaning problems and health problems.

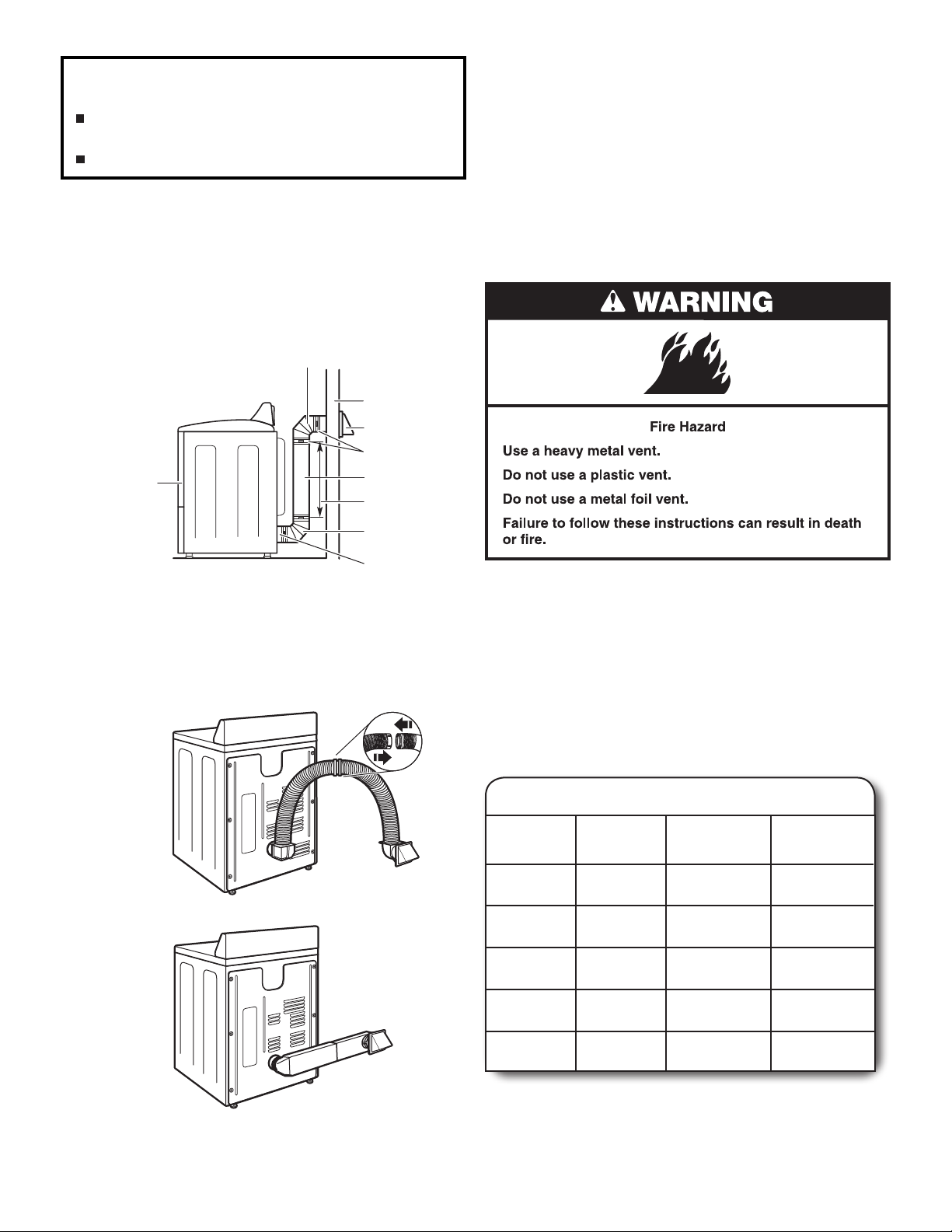

PLAN VENT SYSTEM

The design of the ue system should ensure that any condensate

formed when operating the appliance from cold, is either retained

and subsequently evaporated or discharged. Following these

installation instructions should adequately meet this requirement.

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

C

D

E

If you prefer, dryer may be converted to exhaust out right side,

left side, or through bottom. You must contact your local dealer

to have dryer converted.

Determine vent path:

■ Select route that will provide straightest and most direct

path outdoors.

■ Plan installation to use fewest number of elbows and turns.

■ When using elbows or making turns, allow as much room

as possible.

■ Bend vent gradually to avoid kinking.

■ Use as few 90° turns as possible.

F

G

B

H

A. Dryer

B. Elbow

C. Wall

D. Exhaust hood

A

E. Clamps

F. Rigid metal or exible metal vent

G. Vent length necessary to connect elbows

H. Exhaust outlet

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer’s instructions.

Over-The-Top installation (also available with one offset elbow)

Determine vent length and elbows needed for best

drying performance:

■ Use following Vent System Chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specied

in Vent System Chart. Exhaust systems longer than those

specied will:

■ Shorten life of dryer.

■ Reduce performance, resulting in longer drying times

and increased energy usage.

Vent System Chart

Number of

90° turns

or elbows

0

1

Type

of vent

Rigid metal

Rigid metal

Box/louvered

hoods

15,8 m (52 ft.)

13,4 m (44 ft.)

Angled

hoods

13,4 m (44 ft.)

11,0 m (36 ft.)

2

3

4

Rigid metal

Rigid metal

Rigid metal

11,0 m (36 ft.)

8,2 m (27 ft.)

6,1 m (20 ft.)

18,5 m (28 ft.)

6,4 m (21 ft.)

4,3 m (14 ft.

The Vent System Chart provides venting requirements that

will help achieve best drying performance.

Periscope installation

NOTE: Side and bottom exhaust installations have a 90° turn

inside the dryer. To determine maximum exhaust length, add

one 90° turn to the chart.

8

305 mm

(

12" mín.

)

305 mm

(

12" mín.

)

The maximum length using a 51 mm x 152 mm (2"x 6")

rectangular vent with 2 elbows and a 64 mm (2-1/2") exhaust

hood is 2,4 m (8 ft).

For exhaust systems not covered by the Vent System Chart (such

as multiple unit hookups, plenums, and power-assist fans), see

Service Manual. (To purchase the Service Manual, contact your

local authorized service dealer.)

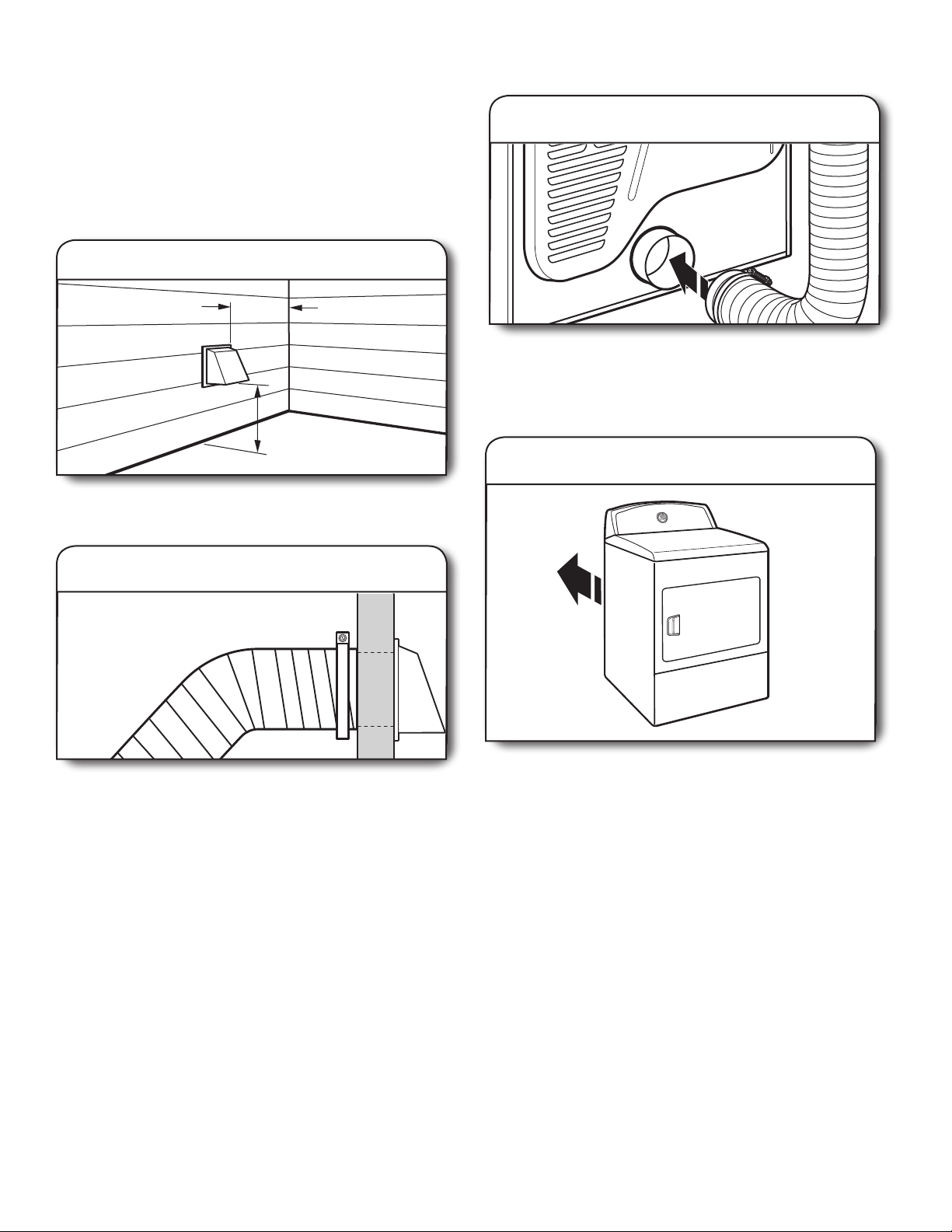

INSTALL VENT SYSTEM

1.

Install exhaust hood

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

CONNECT VENT

1.

Connect vent to exhaust outlet

Using a 102 mm (4") clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must t over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 102 mm (4") clamp.

2.

Move dryer to nal location

2.

Connect vent to exhaust hood

Vent must t over the exhaust hood. Secure vent to exhaust

hood with 102 mm (4") clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

Move dryer to nal location. Avoid crushing or kinking vent.

After dryer is in place, remove corner posts and cardboard

from under the dryer.

9

LEVEL DRYER

1.

Level Dryer

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level to reduce noise and assure

proper performance.

If legs are not long enough to level dryer, order Extended Dryer

Feet kit (sold two legs per kit), from your dealer.

Not Level LEVEL Not Level

Tighten and adjust leveling legs

2.

COMPLETE INSTALLATION

CHECKLIST

Check that all parts are now installed. If there is an extra

q

part, go back through steps to see what was skipped.

Check that you have all of your tools.

q

Dispose of/recycle all packaging materials.

q

Check dryer’s nal location. Be sure vent is not crushed

q

or kinked.

For power supply cord installation, plug into an outlet.

q

For direct wire installation, turn on power.

Check that dryer is level. See “Level Dryer”.

q

Remove lm on console and any tape remaining on dryer.

q

Wipe dryer drum interior thoroughly with a damp cloth

q

to remove any dust.

Read “Dryer Use” in your Use and Care Guide.

q

Set the dryer on a full heat cycle (not an air cycle) for

q

20 minutes and start the dryer.

If the dryer will not start, check the following:

■ Controls are set in a running or “On” position.

■ Start button has been pushed rmly.

■ Dryer is plugged into an outlet and/or electrical supply

is on.

■ Household fuse is intact and tight, or circuit breaker has

not tripped.

■ Dryer door is closed.

When the dryer has been running for 5 minutes, open the

q

dryer door and feel for heat. If you feel heat, cancel cycle and

close the door.

If you do not feel heat, turn off dryer, and check the

following:

■ There may be 2 household fuses or circuit breakers for

the dryer. Check that both fuses are intact and tight,

or that both circuit breakers have not tripped. If there

is still no heat, contact a qualied technician.

NOTE: You may notice an odor when the dryer is rst heated.

This odor is common when the heating element is rst used.

The odor will go away.

If dryer is not level, prop up using a wood block, use wrench

to adjust legs up or down, and check again for levelness.

Once legs are level, make sure all four legs are snug against

the ground.

10

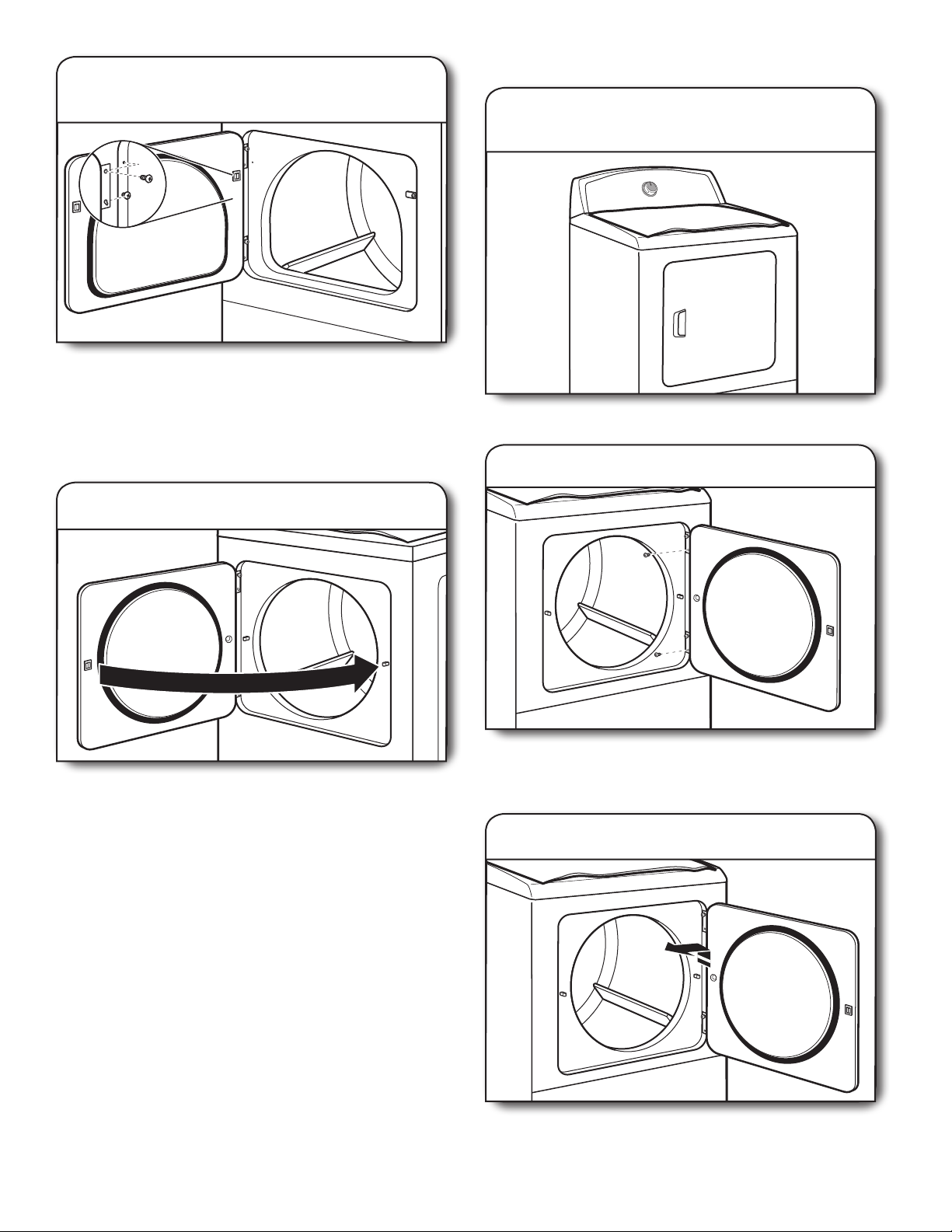

REVERSE DOOR SWING (OPTIONAL)

(MODELS WITH SIDE SWINGS DOORS ONLY)

If your door is the 29" Large Side-Swing Door,

follow steps 1-6.

If your door is the 29" Super Wide Side-Swing Door,

follow steps 1-13.

NOTE: Magnetized screw driver is helpful.

Remove bottom screws

2.

Open dryer door. Remove bottom screws from dryer cabinet

side of hinges. Loosen (do not remove) top screws from dryer

cabinet side of hinges.

3.

Lift door off top screws

Large Side-Swing Door

1.

Place towel on dryer

Place towel on top of dryer to avoid damaging the surface.

Lift door until top screws in cabinet are in large part of hinge

slot. Pull door forward off screws. Set door on top of dryer.

Remove top screws from dryer cabinet.

4.

Remove and transfer hinge

hole plugs

Use a small, at-blade screwdriver to gently remove 4 hinge

hole plugs on left side of dryer cabinet. Insert plugs into hinge

holes on opposite side of dryer cabinet.

11

Insert screws in hinge holes on

5.

dryer cabinet

NOTE: Two people maybe needed to reinstall door.

Insert screws into bottom holes on left side of dryer cabinet.

Tighten screws halfway. Position door so large end of door

hinge slot is over screws. Slide door up so screws are in

bottom of slots. Tighten screws. Insert and tighten top

screws in hinges.

6.

Check door strike alignment

Super Wide Side-Swing Door

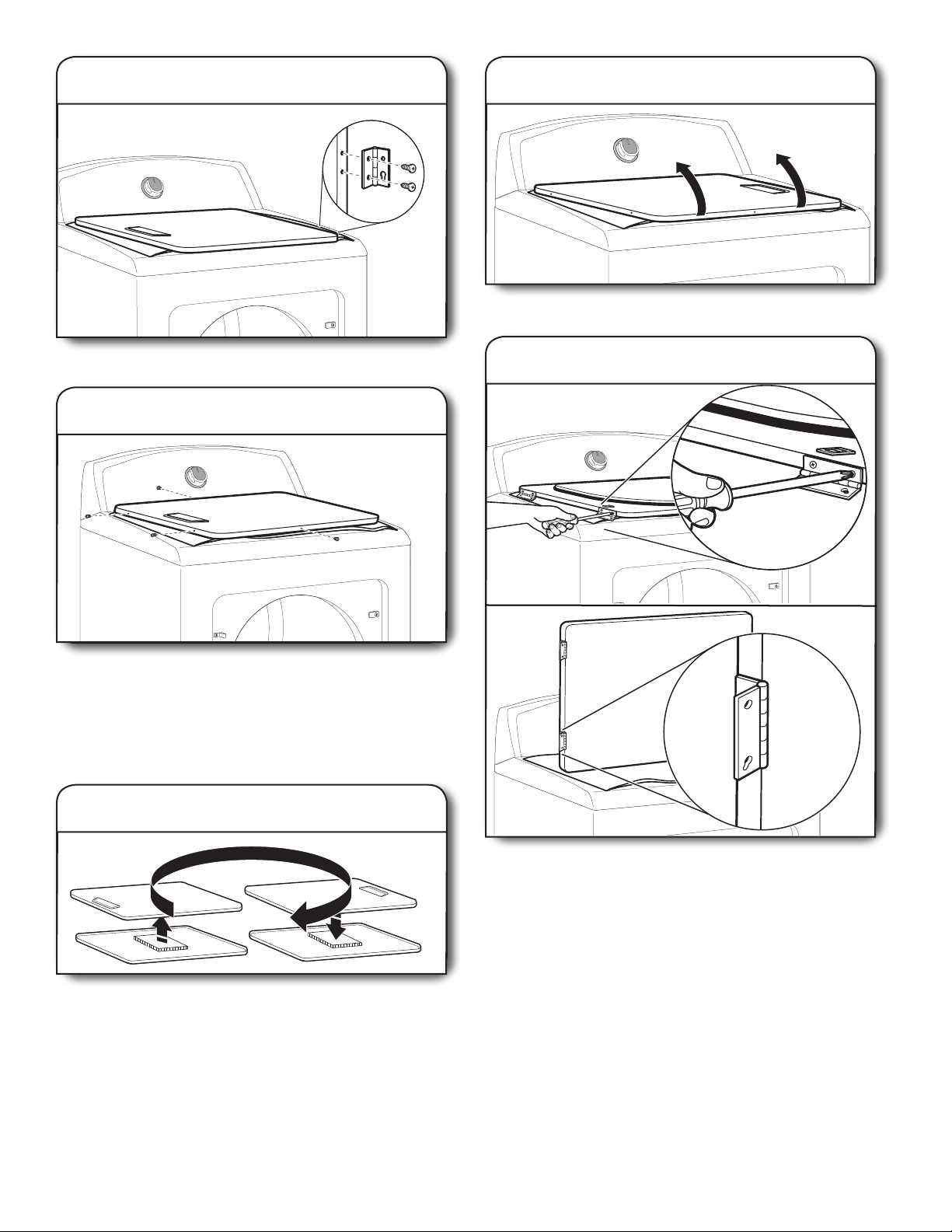

1.

Place towel on dryer

Place towel on top of dryer to avoid damaging the surface.

2.

Remove bottom screws

Close door and check that door strike aligns with door

catch. If needed, slide door catch left or right within slot

to adjust alignment.

12

Open dryer door. Remove bottom screws from dryer cabinet

side of hinges. Loosen (do not remove) top screws from

dryer cabinet side of hinges.

3.

Lift door off top screws

Lift door until top screws in dryer cabinet are in large part of

hinge slot. Pull door forward off screws. Set door (handle side

up) on top of dryer. Remove top screws from dryer cabinet.

Remove screws from hinges

4.

7.

Flip door over

Flip door over so handle side is down.

Remove screws attaching hinges to door.

Remove screws from door

5.

Remove screws at top, bottom, and side of door

(4 screws). Keep door screws separate from hinge screws

as they are different sizes. Holding door over towel on dryer,

grasp sides of outer door and lift to separate it from inner

door.

NOTE: Do not pry apart with putty knife or screwdriver.

Do not pull on door seal or plastic door catches.

Rotate outer door

6.

8.

Attach door hinges

Take outer door and rotate in 180º and set it back down on

inner door. Be certain to keep cardboard spacer centered

between doors. Reattach outer door panel to inner door

panel so handle is on the side where hinges were just

removed. Insert 4 door screws.

Reattach door hinges to dryer door so that the larger hole is

at the bottom of the hinge.

13

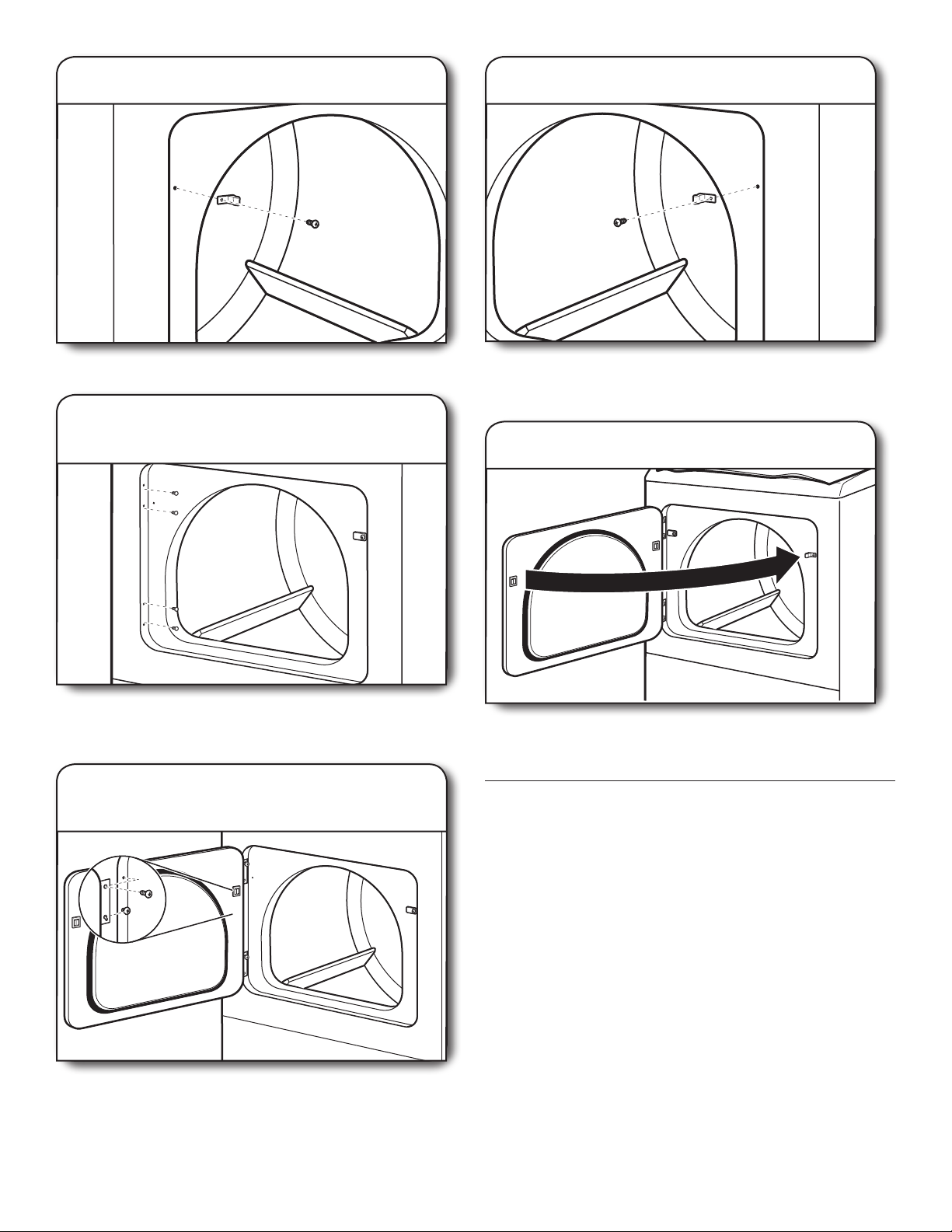

9.

Remove door strike

12.

Remove door strike plug

Remove door strike from dryer cabinet and set aside.

10.

Remove and transfer

hinge hole plugs

Use a small, at-blade screwdriver to gently remove 4 hinge

hole plugs on left side of dryer cabinet. Transfer plugs into

hinge holes on opposite side of dryer cabinet.

11.

Insert screws in hinge holes on

dryer cabinet

Remove door strike plug. Insert the door strike removed in

Step 9 into hole and secure with screw. Insert door strike

plug into original door strike hole and secure with screw.

13.

Close door and check that door strike aligns with door

catch. If it is needed, slide door catch left or right within slot

to adjust alignment.

Check door strike alignment

TROUBLESHOOTING

See the “Use and Care Guide” to possibly avoid the cost of a

service call.

NOTE: Two people maybe needed to reinstall door.

Insert screws into the bottom holes on left side of dryer

cabinet. Tighten screws halfway. Position door so large end

of door hinge slot is over screws. Slide door up so screws

are in bottom of slots. Tighten screws. Insert and tighten top

screws in hinges.

14

SECURITE DU SECHE-LINGE

15

16

EXIGENCES D’INSTALLATION

Outillage et Pièces

Rassembler les outils et piéces nécessaires avant de commencer

l’installation.

Tournevis à lame plate

Clé à douille ou tourneécrou de 6,2 mm (1/4")

Niveau

Clé à molette avec ouverture

jusqu’à 25 mm (1") ou clé à

douille hexagonale

Pièces nécessaires : (non fournies avec le sèche-linge)

■ Cordon d’alimentation

■ Clapets d’évacuation

■ Coudes et les conduits de ventilation

En cas d’utilisation d’un câble d’alimentation

électrique :

Utiliser un ensemble de câble d’alimentation électrique

homologué UL marqué pour utilisation avec les sèche-linge.

L’ensemble doit contenir :

■ Un câble d’alimentation électrique homologué UL de

30 ampères, 240 volts minimum. Le câble doit être de type

SRD ou SRDT et mesurer au moins 4 pi (1,22 m) de long.

Les ls raccordés au sèche-linge doivent se terminer par des

cosses rondes ou à fourche à pointes relevées.

■ Un serre-câble (homologation UL).

Des pièces supplémentaires seront peut-être nécessaires,

selon l’installation. Consulter les codes locaux. Vérier

l’alimentation électrique et le circuit d’évacuation existants.

Consulter “Spécications électriques” et “Exigences concernant

l’évacuation” avant d’acheter les pièces.

EXIGENCES D’EMPLACEMENT

Couteau universel

Pince

Pince à dénuder

(installations avec

raccordement par

câblage direct)

Mètre à ruban

Pistolet à calfeutrage et

composé de calfeutrage

(pour l’installation

d’un nouveau conduit

d’évacuation)

Cisaille de ferblantier

(pour l’installation

d’un nouveau conduit

d’évacuation)

Pièces fournies (pour tous les modèles) :

Pieds de nivellement (4)

Retirer le sac de pièces du tambour du sèche-linge. Vérier

la présence de toutes les pièces.

Choisir un emplacement approprié pour le sèche-linge an

d’en améliorer la performance et de réduire au maximum le

bruit qu’il produit. Vérier les spécications des codes. Certains

codes limitent ou interdisent l’installation des sèche-linge dans

un garage, un placard, une maison mobile ou une chambre à

coucher. Contacter l’inspecteur en bâtiments local.

Il vous faudra :

■ Un emplacement permettant une évacuation appropriée.

L’évacuation du sèche-linge doit se faire à l’extérieur. Voir

“Exigences concernant l’évacuation”.

■ Le plancher doit pouvoir soutenir le poids du sèche-linge

de 90,7 kg (200 lb). Tenir également compte du poids des

appareils voisins.

■ Un plancher de niveau avec une pente maximale de

1" (25 mm) sous l’ensemble du sèche-linge. Si l’inclinaison

est supérieure à 25 mm (1"), installer l’ensemble de pieds

d’extension. Si le sèche-linge n’est pas d’aplomb, il est

possible que le linge ne culbute pas convenablement et que

les programmes commandés par détecteurs automatiques ne

fonctionnent pas correctement.

■ Il est important de s’assurer que la pièce dans laquelle se

trouve l’appareil possède un approvisionnement d’air sufsant

pour permettre son bon fonctionnement. L’utilisation de cet

appareil peut affecter celle d’autres appareils dont la source

d’approvisionnement en air se fait dans la même pièce pour

une combustion sans danger.

17

Loading...

Loading...