Whirlpool 3LCHW9100WQ Installation Instructions

®

A

INSTALLATION INSTRUCTIONS

SEMI-PRO FRONT-LOAD WASHER

INSTRUCTIONS D’INSTALLATION

LAVE-LINGE SEMI-PRO A CHARGEMENT FRONTAL

INSTRUCCIONES DE INSTALACIÓN

LAVADORA SEMIPROFESIONAL DE CARGA FRONTAL

ISTRUZIONI D’INSTALLAZIONE

LAVATRICE SEMI-PRO A CARICAMENTO FRONTALE

Table of Contents/Table des matières/Índice/Sommario....................................................2

Model/Modèle/Modelo/Modello

3LCHW9100WQ

W10299462

TABLE OF CONTENTS

ÍNDICE

WASHER SAFETY ..........................................................................3

WASHER DISPOSAL......................................................................4

INSTALLATION REQUIREMENTS ................................................4

Tools and Parts ............................................................................ 4

Options.........................................................................................5

Location Requirements................................................................5

Drain System................................................................................6

Electrical Requirements ............................................................... 6

INSTALLATION INSTRUCTIONS ..................................................7

Remove Transport System ..........................................................7

Power Cord Installation................................................................7

Connect the Inlet Hoses...............................................................7

Route the Drain Hose...................................................................8

Secure the Drain Hose.................................................................9

Level the Washer..........................................................................9

Complete Installation ...................................................................9

CONTROL SET-UP INSTRUCTIONS..........................................10

General Information....................................................................10

Control Set-up Procedures........................................................10

Set-up Codes.............................................................................10

Washer Diagnostic Mode...........................................................11

WASHER CARE ............................................................................12

Cleaning Your Washer ...............................................................12

Water Inlet Hoses.......................................................................13

ASSISTANCE OR SERVICE.........................................................13

SEGURIDAD DE LA LAVADORA.................................................26

ELIMINACIÓN DE LA LAVADORA..............................................27

REQUISITOS DE INSTALACIÓN.................................................27

Herramientas y piezas................................................................27

Opciones ....................................................................................28

Requisitos de ubicación.............................................................28

Sistema de desagüe...................................................................29

Requisitos eléctricos ..................................................................29

INSTRUCCIONES DE INSTALACIÓN.........................................30

Eliminación del sistema protector de transporte.......................30

Instalación del cable de suministro de energía .........................31

Conexión de las mangueras de entrada....................................31

Tendido de la manguera de desagüe ........................................32

Fijación de la manguera de desagüe.........................................32

Nivelación de la lavadora ...........................................................32

Complete la instalación..............................................................33

INSTRUCCIONES DE PROGRAMACIÓN DEL CONTROL .......33

Información general....................................................................33

Procedimientos de programación del control ...........................33

Códigos de programación .........................................................34

Modo de diagnóstico de la lavadora .........................................35

CUIDADO DE LA LAVADORA .....................................................36

Cómo limpiar su lavadora ..........................................................36

Mangueras de entrada de agua.................................................37

AYUDA O SERVICIO TÉCNICO...................................................37

TABLE DES MATIERES

SECURITE DU LAVE-LINGE........................................................14

MISE AU REBUT DU LAVE-LINGE .............................................15

EXIGENCES D’INSTALLATION...................................................15

Outillage et pièces......................................................................15

Options.......................................................................................16

Exigences d’emplacement.........................................................16

Système de vidange...................................................................17

Spécifications électriques..........................................................17

INSTRUCTIONS D’INSTALLATION ............................................18

Dépose du système de transport ..............................................18

Installation du cordon d’alimentation ........................................18

Raccordement des tuyaux d’arrivée d’eau................................19

Acheminement du tuyau de vidange.........................................20

Immobilisation du tuyau de vidange..........................................20

Réglage de l’aplomb du lave-linge ............................................20

Achever l’installation ..................................................................21

INSTRUCTIONS DE PARAMÉTRAGE DU MODULE

DE COMMANDE...........................................................................21

Informations générales...............................................................21

Procédures de réglage des systèmes de commande...............21

Codes de paramétrage ..............................................................22

Mode de diagnostic du lave-linge .............................................23

ENTRETIEN DU LAVE-LINGE .....................................................24

Nettoyage du lave-linge .............................................................24

Tuyaux d’arrivée d’eau...............................................................25

ASSISTANCE OU SERVICE.........................................................25

SOMMARIO

SICUREZZA DELLA LAVATRICE................................................38

SMALTIMENTO DELLA LAVATRICE..........................................39

REQUISITI D’INSTALLAZIONE ...................................................39

Attrezzi e componenti ................................................................39

Opzioni........................................................................................40

Requisiti di posizionamento.......................................................40

Sistema di scarico......................................................................41

Requisiti elettrici .........................................................................41

ISTRUZIONI D’INSTALLAZIONE.................................................42

Rimozione del sistema di trasporto ...........................................42

Installazione del cavo di alimentazione......................................42

Collegamento dei tubi ................................................................42

Instradamento del tubo di scarico .............................................43

Fissaggio del tubo di scarico .....................................................44

Livellamento della lavatrice ........................................................44

Installazione completa................................................................44

ISTRUZIONI PER L’UTENTE E DI CONFIGURAZIONE ............45

Informazioni di carattere generale..............................................45

Procedure di configurazione dei comandi.................................45

Codici di configurazione.............................................................45

Modalità diagnostica della lavatrice...........................................46

MANUTENZIONE DELLA LAVATRICE .......................................47

Pulizia della lavatrice ..................................................................47

Tubi di ingresso dell’acqua ........................................................48

ASSISTENZA O MANUTENZIONE..............................................48

2

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

can be killed or seriously injured if you don't

You

instructions.

follow

3

WASHER DISPOSAL

INSTALLATION REQUIREMENTS

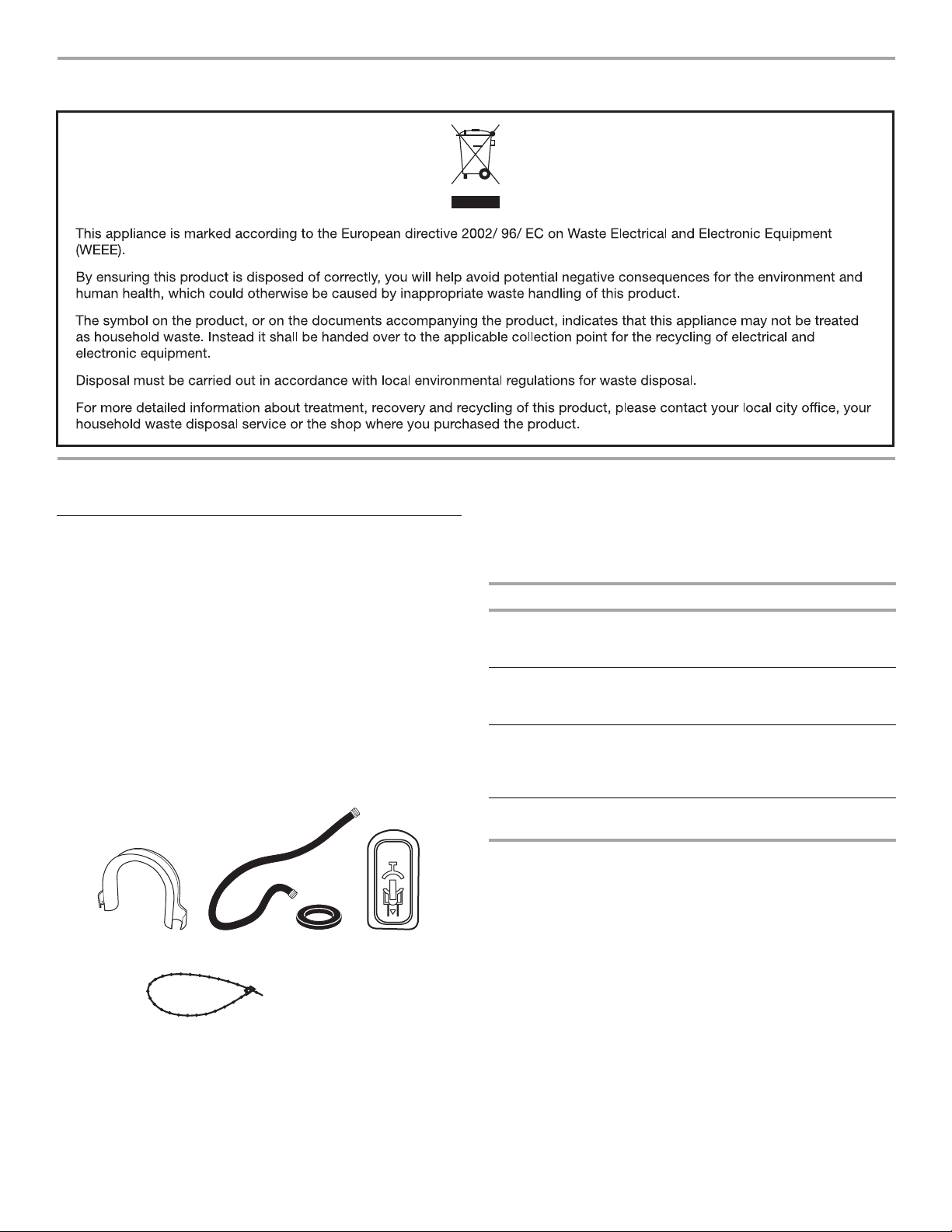

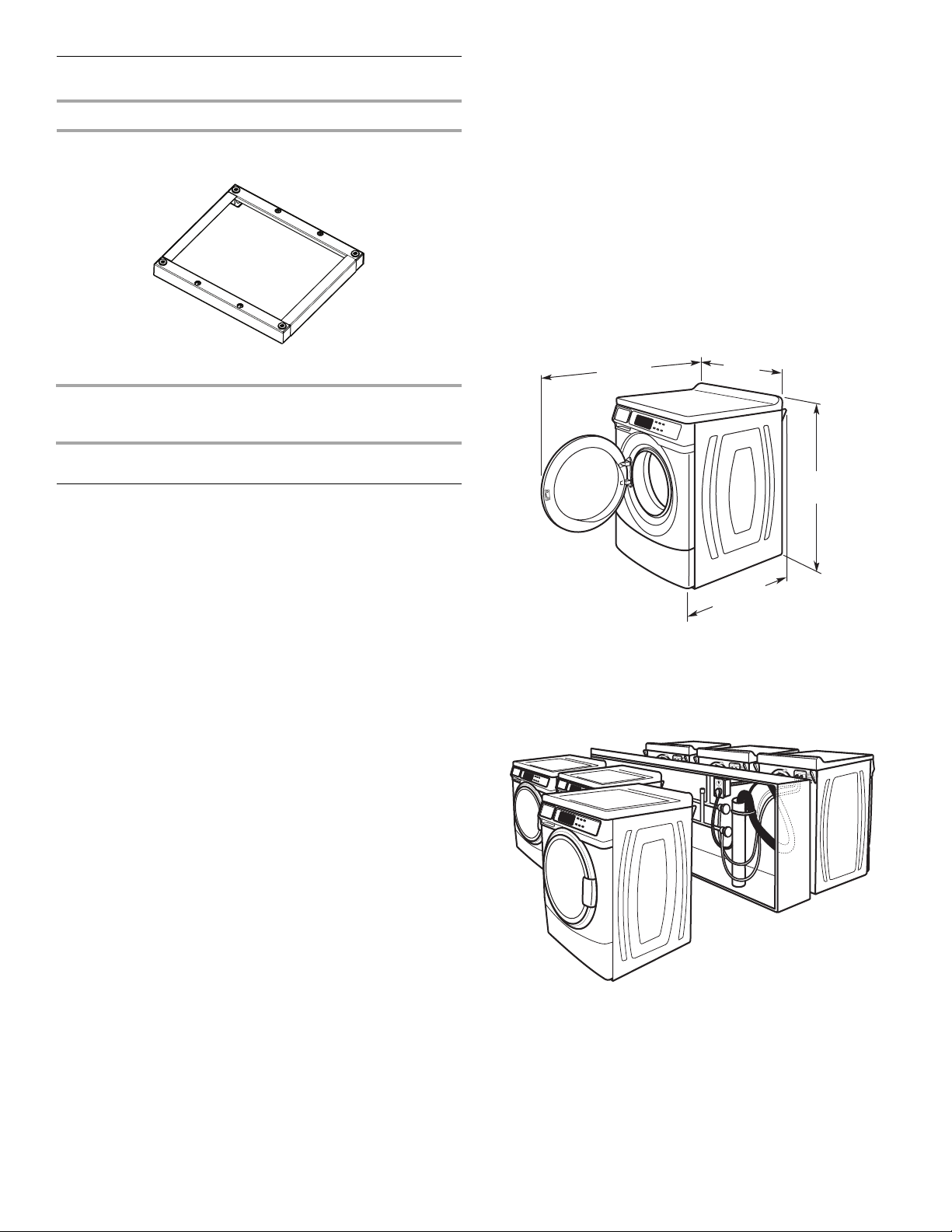

Tools and Parts

Gather the required tools and parts before starting installation.

The parts supplied are in the washer drum.

Tools needed for connecting the water inlet hoses

■ Pliers (that open to

39.5 mm [1

9

/16"])

Tools needed for installation

■ Open end wrenches

1/2" and 9/16"

■ To rx

■ 1/4" nut driver

Parts supplied

®†

T-20 Security

screwdriver

■ Flashlight (optional)

■ Level

■ Wood block

■ Ruler or measuring tape

Alternate Parts

Your installation may require additional parts. If you are interested

in purchasing one of the items listed here, contact your

authorized Whirlpool distributor.

If You Have You Will Need to Buy

Laundry tub or

standpipe taller

than 2.4 m (96")

Overhead sewer Standard 76 L (20 gal. ), 762 mm (30") tall

Floor drain Siphon break, Part Number 285320;

Drain hose

too short

Sump pump system (if not already

available)

rain tub or utility sink and sump pump

d

(available from local plumbing suppliers)

additional drain

Part Number 8318155; and Floor drain

ki

t, Part Number 280129

1.2 m (4 ft.) drain hose extension kit,

Part Number 285834

hose,

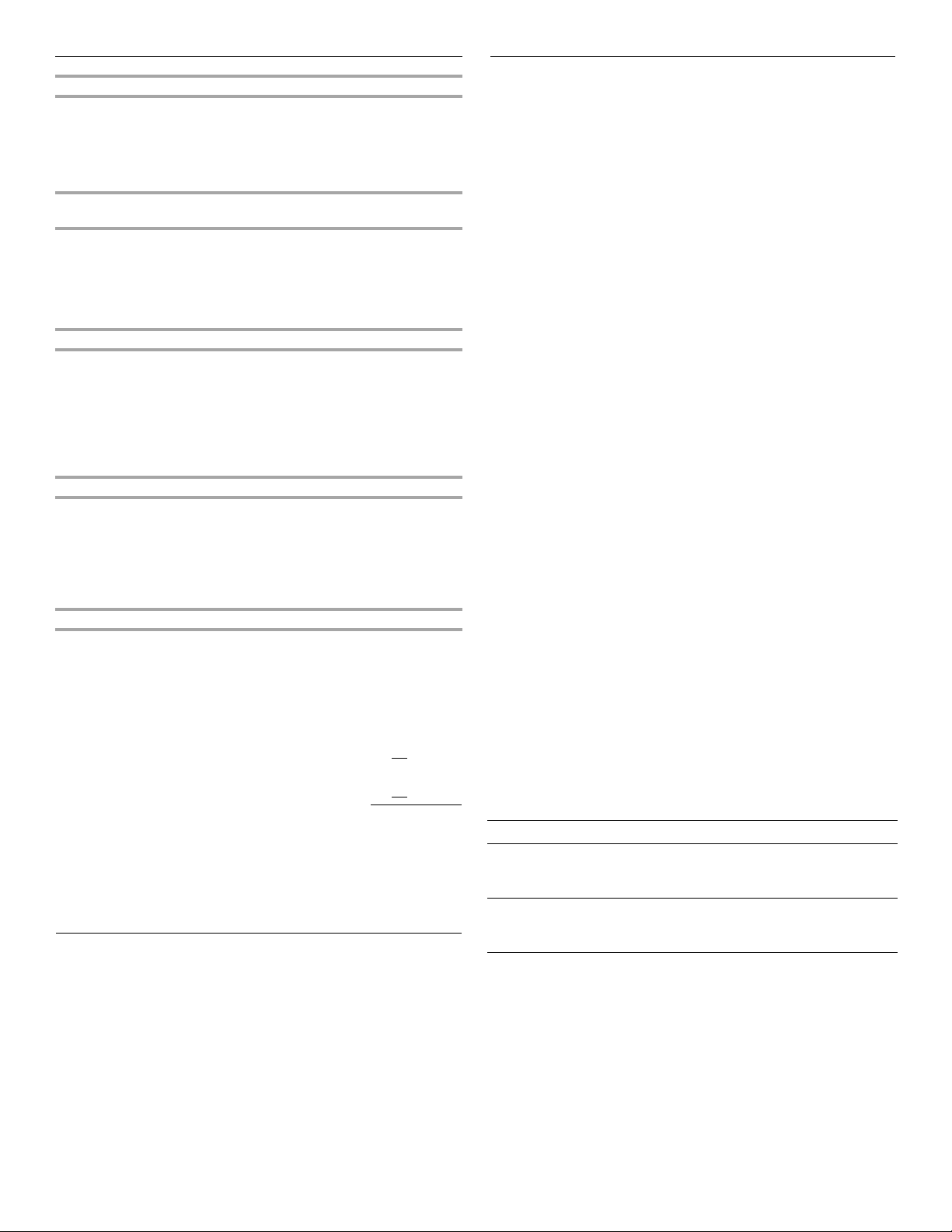

A BC

E

A. U-shaped hose form

B. Water inlet hoses (2)

C. Inlet hose washers (4)

D. Transit bolt hole plug (4)

E. Beaded tie strap

†® TORX is a registered trademark of Acument Intellectual Properties, LLC.

D

4

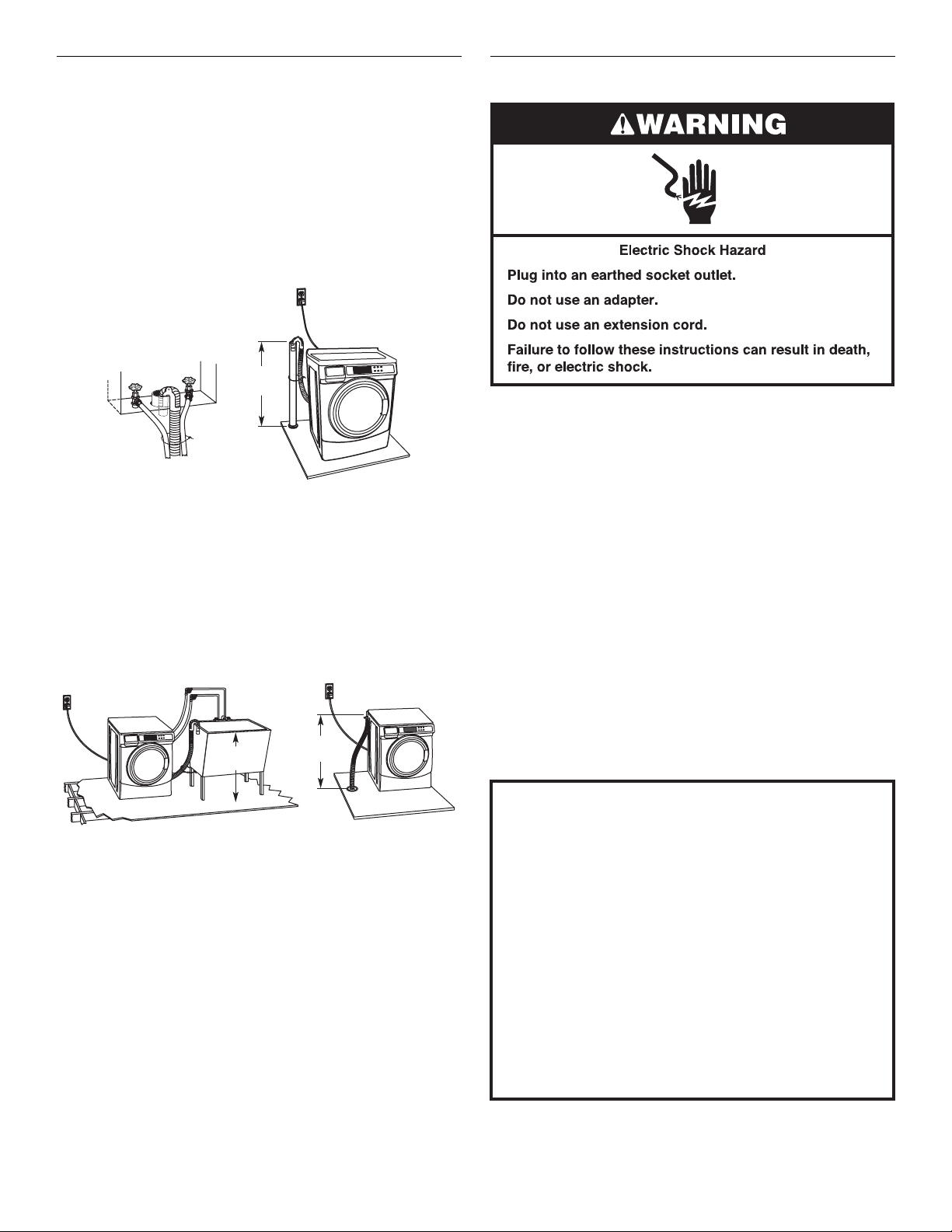

Options

Pedestal

You have the option of purchasing pedestals separately for this

washer. The pedestal will add to the total height of the washer.

Installation clearances

■ The location must be large enough to allow the washer door

to be fully opened.

■ Additional spacing should be considered for ease of

installation and servicing. The door opens more than 90°

and it is not reversible.

■ Additional clearances might be required for wall, door, and

floor moldings.

■ Additional spacing of 25 mm (1") on all sides of the washer

is recommended to reduce noise transfer.

■ Companion appliance spacing should also be considered.

■ When installed, the plug should be accessible for washer

disconnection from the mains supply.

Optional pedestal

Pedestal

Height

Approximate

ight

he

Color Part Number

with washer

(73 mm) 2

7

/8" (1207 mm) 47.5" White WHP0400VW

Location Requirements

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed under a custom counter, or in a

basement,

Companion appliance location requirements should also be

considered. Proper installation is your responsibility.

You will need

■ A water heater set to deliver 60°C (140°F) water to the

■ An earthed electrical outlet located within 1.8 m (6 ft.) of

■ Hot and cold water taps located within 1.2 m (4 ft.)

■ A level floor with a maximum slope of 25 mm (1") under entire

■ A sturdy and solid floor to support the washer with a total

Do not operate your washer in temperatures below 0°C (32°F).

Some water can r

in low temperatures.

laundry room, or recessed area. See “Drain System.”

washer.

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

of the hot and cold water fill va

lves, and water pressure

of 137.9-689.6 kPa (20-100 psi).

washer. Installing the washer on soft floor surfaces, such as

carpets or surfaces with foam backing, is not recommended.

weight (water and load) of 180 kg (400 lbs).

emain in the washer and can cause damage

Washer Dimensions

1282 mm

1

(50

/2")

Door is not reversible.

686 mm

(27")

732 mm

13

/16")

(28

961 mm

5

(37

/6")

A floor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water

inlet lines, and drain facilities should be used only where

local codes permit.

5

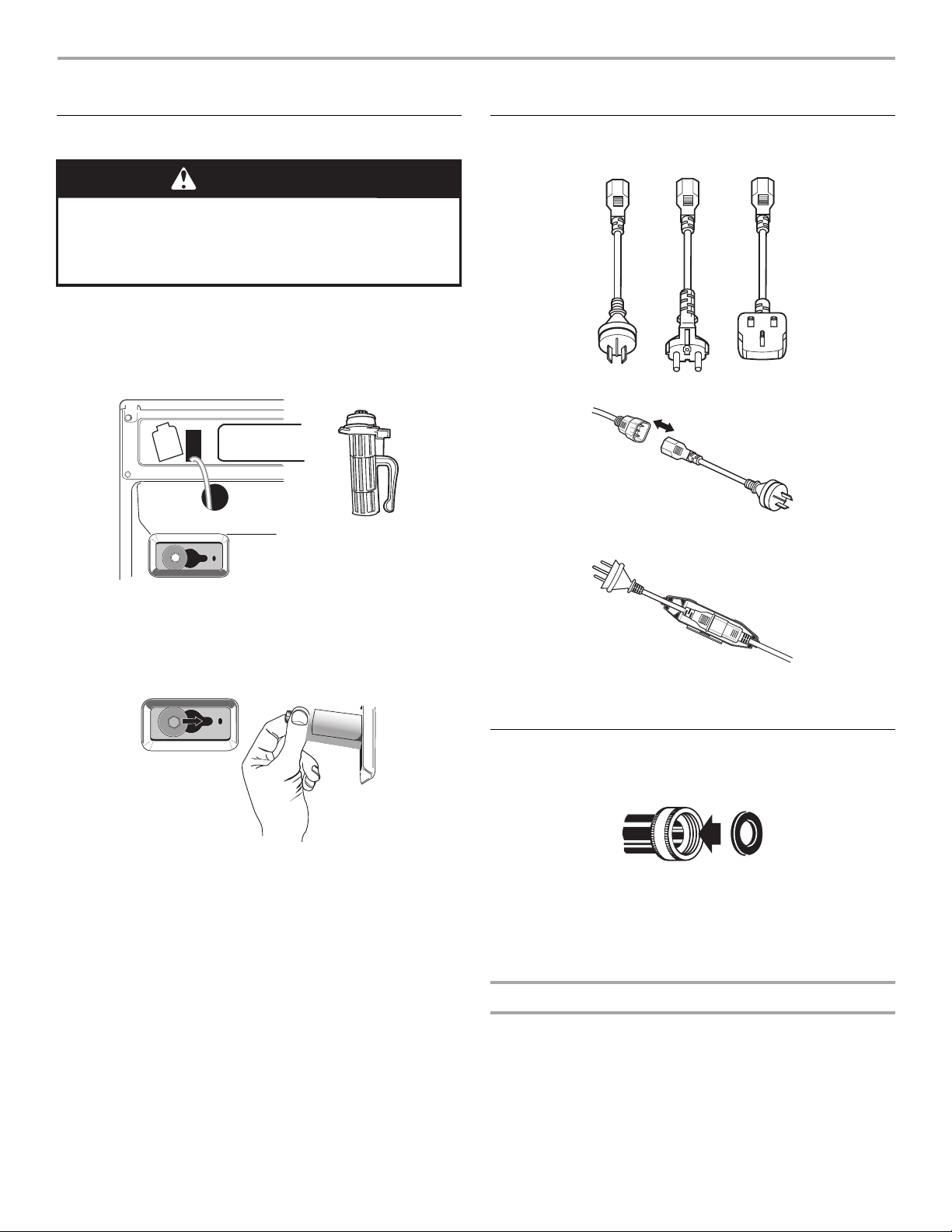

Drain System

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need.

See “Tools and Parts.”

Standpipe drain system - wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe of

50 mm (2"). The minimum carry-away

than 45.5 L (12 gal.) per minute.

The top of the standpipe must be at least 762 mm (30") high and

higher than 2.4 m (96") from the bottom of the washer.

no

762 mm

(30" min.)

A B

Laundry tub drain system (view C)

The laundry tub needs a minimum 76 L (20 gal.) capacity. The top

of the laundry tub must be at least 762 mm (30") above the floor.

Floor drain system (view D)

The floor drain system requires a siphon break that may be

purchased separately. See “Tools and Parts.”

The siphon break must be a minimum of 710 mm (28") from the

bottom of the washer. Additional hoses might be needed.

762 mm

(30" min.)

capacity can be no less

710 mm

(28" min.)

Electrical Requirements

■ A 220-240V, 50 Hz., fused electrical supply is required. A

time-delay 10-16A fuse or circuit breaker is recommended.

■ This washer is equipped with a power supply cord having an

earthed plug.

■ To minimize possible shock hazard, the cord must be

plugged into an earthed socket outlet, earthed in accordance

with local codes and ordinances. If a mating outlet is not

available, it is the personal responsibility and obligation of the

customer to have the properly earthed outlet installed by a

qualified electrician.

■ If codes permit and a separate earth wire is used, it is

recommended that a qualified electrician determine that the

earth path is adequate.

■ If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent, or a qualified person to avoid

a hazard.

■ Do not earth to a gas pipe.

■ Check with a qualified electrician if you are not sure the

washer is properly earthed.

■ Do not have a fuse in the neutral or earth circuit.

EARTHING INSTRUCTIONS

This washer must be earthed. In the event of a malfunction

C D

6

or breakdown, earthing will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-earthing conductor and an earthing plug. The

plug must be plugged into an appropriate outlet that is

properly installed and earthed in accordance with all local

codes and ordinances.

WARNING:

Improper connection of the equipmentearthing conductor can result in a risk of electric shock.

Check with a qualied electrician or serviceman if you are in

doubt as to whether the appliance is properly earthed.

Do not modify the plug provided with the appliance – if it

will not t the outlet, have a proper outlet installed by a

qualied electrician.

INSTALLATION INSTRUCTIONS

Remove Transport System

WARNING

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

IMPORTANT: Position the washer so that the rear of the washer

is within approximately 900 mm (3 ft.) of its final location.

There are 4 shipping bolts in the rear panel of the washer that

support the suspension system during transportation. These

bolts also retain the power cord inside the washer until the bolts

are removed.

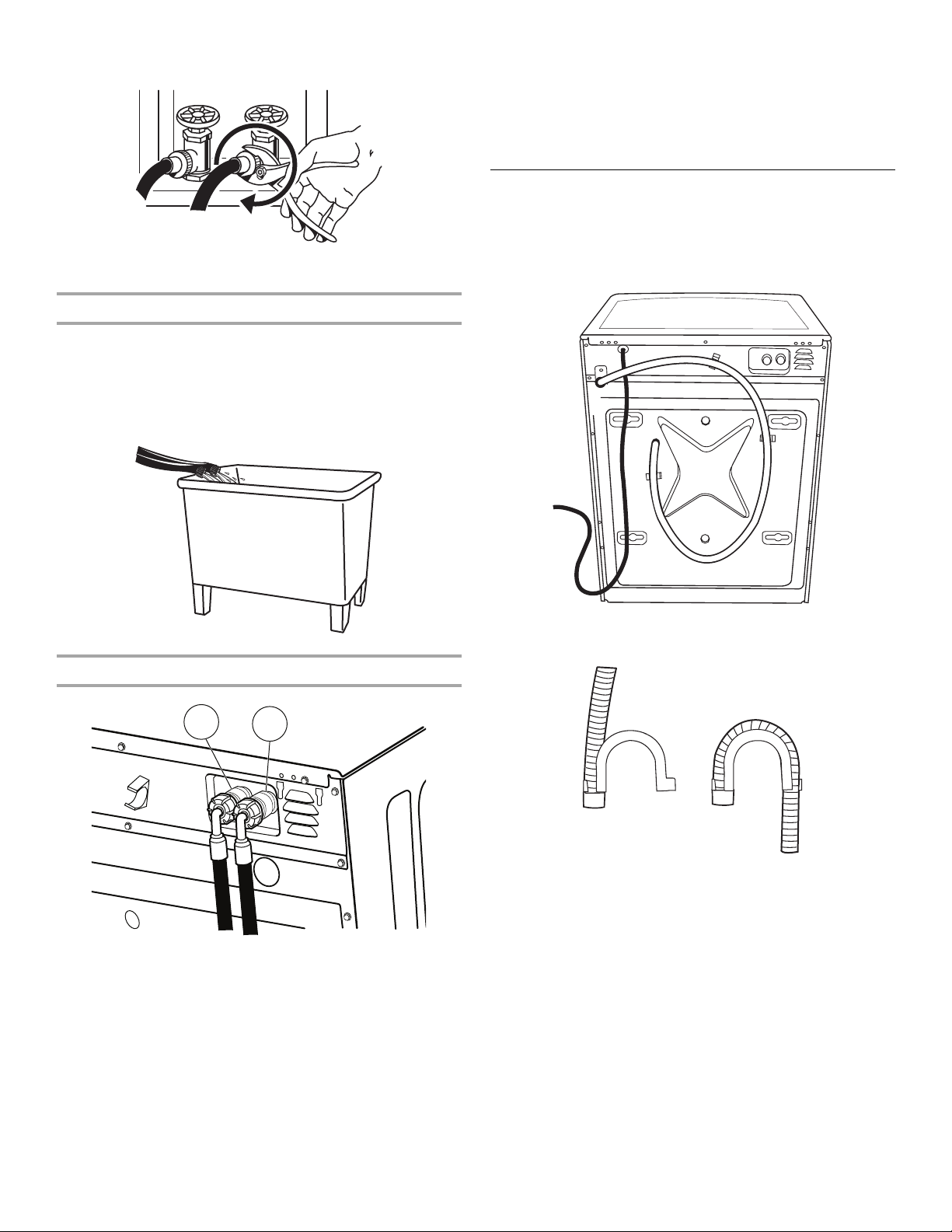

Power Cord Installation

1. Select the plug that fits with the electric receptacle.

2. Assemble the plug into the end of the power cord.

3. Secure the power cord by seating the connection on the cord

lock.

1. Keep the washer in the upright position while removing the

shipping bolts.

2. Using a 1/2

3. Once

completely pull out the bolt, including the plastic spacer

covering the bolt.

4. Once all 4 bolts are removed, discard the bolts and spacers.

Then push the power cord plug into the opening on the right

side of the rear panel and pull the power cord through the

opening on the left side of the rear panel and close holes with

the attached cap. Do not pull plug end of power cord through

the right side hole.

5. Close the bolt holes with the 4 transport bolt hole plugs. NOTE: If the wash

product distributor or installer. To avoid suspension and structural

damage, your washer must be properly set up for relocation by a

trained professional.

" wrench, loosen each of the bolts.

the bolt is loose, move it to the center of the hole and

er is to be transported at a later date, call your

4. Place the cord lock cover and push until it snaps.

ke sure the power cord connection is seated on the cord

5. Ma

lock and that the cord lock clamps correctly.

Connect the Inlet Hoses

Insert new flat washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

A B

A. Coupling

B. Washer

■ Use the new inlet hoses supplied with washer. Do not re-use

old inlet hoses.

Connect the inlet hoses to the water taps

Make sure the washer drum is empty.

1. Attach

2. Attach

a hose to the hot water tap. Screw on coupling

by hand until it is seated on the washer.

a hose to the cold water tap. Screw on coupling

by hand until it is seated on the washer.

7

3. Using pliers, tighten the couplings with an additional

two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the tap.

Damage to the inlet hoses can result.

Clear water lines

■ Run water through both taps and inlet hoses, into a laundry

tub, drainpipe, or bucket, to get rid of particles in the water

lines that might clog the inlet valve screens.

■ Check the temperature of the water to make sure that the hot

water hose is connected to the hot water tap and that the

cold water hose is connected to the cold water tap.

4. T

urn on the water taps completely and check for leaks.

NOTE: Replace inlet hoses after 5 years of use to reduce the

risk of hose failure. Record hose installation or replacement

dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

w

ear, or leaks are found.

Route the Drain Hose

Proper routing of the drain hose protects your floor from damage

due to water leakage. Read and follow these instructions.

Remove drain hose from the washer

Gently pull the corrugated drain hose from the shipping clips.

Connect the inlet hoses to the check valves on washer

H

H. Hot water inlet

C. Cold water inlet

1. Attach the hot water hose to the check valve on washer’s hot

(H) water inlet valve. Screw on coupling by hand until it is

seated on the check valve.

2. Attach th

cold (C) water inlet valve. Screw on coupling by hand until it is

seated on the check valve.

3. Using pliers, tigh

thirds turn.

NOTE: Do n

result.

e cold water hose to the check valve on washer’s

ten the couplings with an additional two-

ot overtighten. Damage to the coupling can

C

Laundry tub drain or standpipe drain

Connect the drain hose form to the corrugated d

A B

A. Snap either end of the drain hose for

at the point where the corrugation begins.

B. Bend drain hose over drain hose for

To keep drain water from going back into the washer:

■ Do not straighten the drain hose, do not force excess drain

hose into standpipe. Hose should be secure, but loose

enough to provide a gap for air.

■ Do not lay excess hose on the bottom of the laundry tub.

m to the drain hose

m and snap into place.

rain hose.

Floor drain

You may need additional parts. See Floor drain under “Tools

and Parts.”

8

Secure the Drain Hose

1. Drape the power cord over the washer top.

2. Move the washer to its final location.

ce the drain hose in the laundry tub or standpipe as

3. Pla

shown. See illustrations A and B.

4. Sec

5. If the washer taps and the drain standpipe are recessed, put

NOTES:

■ Do not force excess drain hose back into the rear of the

■ To avoid siphoning, do not seal the drain hose into the

ure the drain hose using the supplied beaded tie strap.

A B C

the hooked end of the drain hose in the standpipe as shown.

See illustration C.

washer.

standpipe.

2. Ma

ke sure all four feet are stable and resting on the floor.

Check that the washer is level (use a level).

er the washer is level, use a 9/16" open-end wrench to turn

3. Aft

the nuts on the feet tightly against the washer cabinet.

IMPORTANT: All four fe

not tight against the washer cabinet, the washer may vibrate.

4. The washer should not move front to back, side to side, or

diagonally when pushed on its top edges.

5. Slid

6. Conf

e the washer to its final location.

irm the levelness of the washer.

et must be tightened. If the nuts are

Complete Installation

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended earthing

method. See “Electrical Requirements.”

eck that all parts are now installed. If there is an extra part,

2. Ch

go back through the steps to see which step was skipped.

heck that you have all of your tools.

3. C

spose of/recycle all packaging materials.

4. Di

5. Check that the water taps are on.

6. Che

ck for leaks around taps and inlet hoses.

Level the Washer

Properly leveling your washer avoids excessive noise and

vibration.

1. Check

the levelness of the washer by placing a level on the

top edge of the washer, first side to side, then front to back.

If the washer is against a wall, move the washer out slightly

before tipping back. If the washer is not level, first prop the

front with a wood block and adjust the feet as necessary;

then prop the back and adjust feet as necessary. Repeat this

step until washer is level.

7. Plug into an earthed socket outlet.

8. To test and to clean your washer, measure 1/2 the detergent

manufacturer’s recommended amount for a medium-size

load. Pour the detergent into the detergent dispenser. Select

any cycle and allow the washer to complete one whole cycle.

9

CONTROL SET-UP INSTRUCTIONS

1. Door must be closed before cycle selection is made.

2. Press fabric setting key pad for the wash cycle desired. After

the cycle is started, the time will display and count down.

General Information

Scrolling ‘out of order’ showing in display, followed by a

failure code

This condition indicates the washer is inoperative.

“0 Minutes” showing in display

This condition indicates the washer cannot be operated. If a door

ch fails, it must be replaced before normal operation can be

swit

restored.

Cold Start (initial first use)

Washer is programmed at the factory as follows:

■ 9-minute wash period

■ 3 rinses (extra rinse not enabled)

Warm Start (after power failure)

A few seconds after power is restored, if a cycle was in progress

at th

e time of the power failure, “RESELECT CYCLE” will flash in

the display, indicating the need for a key press to restart washer.

Control Set-up Procedures

IMPORTANT: Read all instructions before operating.

Set-up procedures can be entered by

Code (see service Access Code section).

IMPORTANT: Unplug wa

opening the console. To access connector AA1:

Unplug

Open con

Plu

The washer is now in the set-up mod

key pads and the digital display are used to set up the controls.

The display can contain 4 numbers and/or letters and a decimal

point. These are used to indicate the set-up codes and related

code values available for use in programming the washer.

washer or disconnect power.

g in washer or reconnect power.

sher or disconnect power before

sole, disconnect plug on AA1, close console.

How to use the key pads to program controls

1. The PERM PRESS key pad is used to adjust the

values associated with set-up codes. Pr

will change the value by increments. Rapid adjustment

is possible by holding the key pad down.

2. The WOOLENS

codes. Pressing this key pad will advance you to the next

available set-up code. Holding the key pad down will

automatically advance through the set-up codes at a rate

of 1 per second.

key pad advances you through the set-up

using the Service Access

e. The lower fabric setting

essing this key pad

3. T

he DELICATES/KNITS key pad is used to select or deselect

options.

Start Operating Set-up

Before proceeding, it is worth noting that, despite all of the

options available, an owner can simply choose to un-crate a new

semi-pro washer, hook it up, plug it in, and have a washer that

operates. Washers are preset at the factory for a 9-minute wash

period and 3 rinses (no extra rinse).

Set-up Codes

■ The WOOLENS key pad will advance you from code to code.

■ The PERM PRESS key pad will change the code value.

■ The DELICATES/KNITS key pad will select or deselect

options.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two or

three right-hand characters.

CODE EXPLANATION

7 9 WASH LENGTH

7 9

8 00 ADDITIONAL RINSE OPTION

8800

9 00 CYCLE COUNTER OPTION

9900

This is the number of minutes for WASH. Washer

c

omes from the factory preset with 9 minutes.

Choose fr

PRESS key

Press the WOOLENS key pad once to advance

to next code.

This option is either SELECTED “ON” or

NOT SELECTED “OFF.”

Not Selected “OFF.”

Ar

Selected “ON.” Cannot be combined with the

Super Cycle rinse option.

Press the DELICATES/KNITS key pad once for this

selection.

Press the WOOLENS key pad once to advance

to next code.

This option is either SELECTED “ON” or

NOT SELECTED “OFF.”

Not Selected “OFF.”

0C

Selected “ON” and not able to be deselected.

Press the DELICATES/KNITS key pad

3 consecutive times to select “ON.” Once selected

“ON” it cannot

Press the WOOLENS key pad once to advance

to next code.

om 9-17 minutes by pressing the PERM

pad.

be deselected.

10

CODE EXPLANATION

5. 00 TIME-OF-DAY CLOCK, MINUTES

5. 00

6. 00 TIME-OF-DAY CLOCK, HOURS

6. 00

r. 800 TOP SPIN SPEED RPM

r. 800

A1. 00 PREWASH LENGTH

A1. 00

A2. 03 FINAL SPIN LENGTH

A2. 03

If cycle counter (9 0C) is selected, the

1 00 Number of cycles in

2 00 Number of cycles in ONES. 2

This is “VIEW ONLY” and cannot be cleared.

Pr

next code.

EXIT FROM SET-UP MODE

Remove power, open console, reinsert plug into AA1, close console,

apply power.

and

This is the TIME-OF-DAY CLOCK, minute setting;

select 0-59 minutes by pressing the PERM PRESS

key pad.

Press the WOOLENS key pad once to advance

to next code.

NOTE: Use

This is the TIME-OF-DAY CLOCK, hour setting;

select 0-23 hours by pressing the PERM PRESS

key pad.

Press the WOOLENS key pad once to advance

to next code.

This can be selected from the following spin

speeds: 600 rpm, 750 rpm, 800 rpm, 1000

(displa

ess the WOOLENS button once to advance to

essing the PERM PRESS key pad. Factory pre-

pr

set for 800 rpm.

Press the WOOLENS key pad once to advance

to next code.

This is the number of minutes of PREWASH.

C

hoose 0 to disable the prewash or

2 and 7 minutes by pressing the PERM PRESS key

pad.

Press the WOOLENS key pad once to advance

to next code.

This is the number of minutes of final high speed

spin.

P

ERM PRESS key pad.

Press the WOOLENS key pad once to advance

to next code.

HU

s the 24 hr. clock

ys as 999) rpm. Step between speeds by

select between

Choose from 3-8 minutes by pressing the

following is true:

1 02 = 200

NDREDS.

TOTAL CYCLES = 225 cycles

25 = 25

Washer Diagnostic Mode

To enter the “Washer Diagnostic Mode,” first enter “Start

Operating Set-up.” Then press and hold the DELICATES/KNITS

key pad for 1 second while in set-up code 6, anytime a

diagnostic code is present.

On entry to diagnostic mode the

cycle in process is canceled, money in escrow is cleared, and

dia

gnostic codes are cleared. If a diagnostic code persists,

it must be corrected before the following cycle options

are permitted.

There are five possible ways to initiate cycle activity from

diagnostic mode as follows:

asher Cleanout cycle - With the entire display flashing, this

1. W

cycle is started by pressing the BRIGHTS key pad.

Use the Washer Cleanout cycle once a month to keep the

in

side of your washer fresh and clean. This cycle uses a

higher water level. Use with liquid chlorine bleach to

thoroughly clean the inside of the washer. This cycle should

not be interrupted.

IMPORTANT: Do not place garments or

washer during the Washer Cleanout cycle. Use this cycle with

an empty wash drum.

2. Manual Overview T

cycle is started by pressing the WHITES key pad. This cycle

provides more typical full length fills, tumbles, drains, and

actuator dispenser movement, allowing for a more thorough

analysis of the washer operation, including pressure switch

behavior.

3. Quick

4. Quick Overview Test - With the entire display flashing, this

Pressing the DELICATES/KNITS key pad will exit diagnostic

mode and cancel a diagnostic

Spin Cycle - With the entire display flashing, this cycle

is started by pressing the COLORS key pad. This cycle

provides a method to quickly drain and spin (remove water

from the washer) if desired.

cycle is started by pressing the WOOLENS key pad. This

cycle provides a quick verification that the cold and hot water

valves, dispensers, and pump motor are working, as well as

actuator dispenser movement. It also includes door lock,

drain, and spin operations.

est - With the entire display flashing, this

DIAGNOSTIC CODES

If one of the following has occurred, the appropriate diagnostic

code will be in the display.

d9 Low voltage detected for 8 seconds.

F20 Slow Fill. The washer will not detect water input for

4 min. Pressure switch failure or no water inlet. This

cod

e is reported as d8 on d7.

F22 The door is not able to lock. Door lock error or

someon

door switch with their finger.

(For any other display consult service personnel)

e trying to start the washer, by pressing the

entire display will flash, a

other items in the

cycle in process.

11

SERVICE ACCESS CODE

This code can be entered to access service mode without

removing the console. It only functions on washers set up for 0

vend price without any Special Pricing set-up, and the Coin/Debit

Option must be set to “J._d”. If the washer is not in failure mode,

the door must be opened to proceed. Service Access Code

contains 6 steps and some are timed. Using only the three bottom

buttons (numbered 1, 2, and 3 from left to right):

ress 2 for longer than 2 seconds but less than 10 seconds.

1. P

2. Press 1 & 3 together for 2 seconds, then release. Displays S 3.

3. Press 1 & 2 together, then release. Displays S 4.

ess 2 & 3 together, then release. Displays S 5.

4. Pr

5. Press 2, then release. Display shows “codE”.

6. Wait at least 2 seconds, but not more than 15 seconds, then

press in succession: 3, 2, 1, 3.

NOTE: If

properly, as noted above, there is a 15 second delay before it can

be attempted again.

When the Service Access Code is used, there are 3 options

to exit.

1. Fr

2. Wait 2 minutes without touching any keypads (without

the Service Access Code procedure is not completed

om Set-up Code 8, press key #1 for 4 seconds.

diagnostic modes running).

WASHER CARE

3. Power down the washer, then reapply power.

WASHER HELP MODE

This mode is entered by pressing the PERM PRESS key pad

while in Set-up option code 2.XX.

In help mode, other display symb

to reflect the state of various inputs a

Display Symbol Description

Wash Water sensed at wash level.

*

° (Circle above digit) Door closed.

DOOR LOCKED Door sensed locked.

COLD Cold water relay on.

HOT Hot water relay on.

OR Door unlock.

AVAILABLE Drain pump ON.

ols and elements are mapped

nd outputs as follows:

Low voltage present (below about

90 VAC).

Cleaning Your Washer

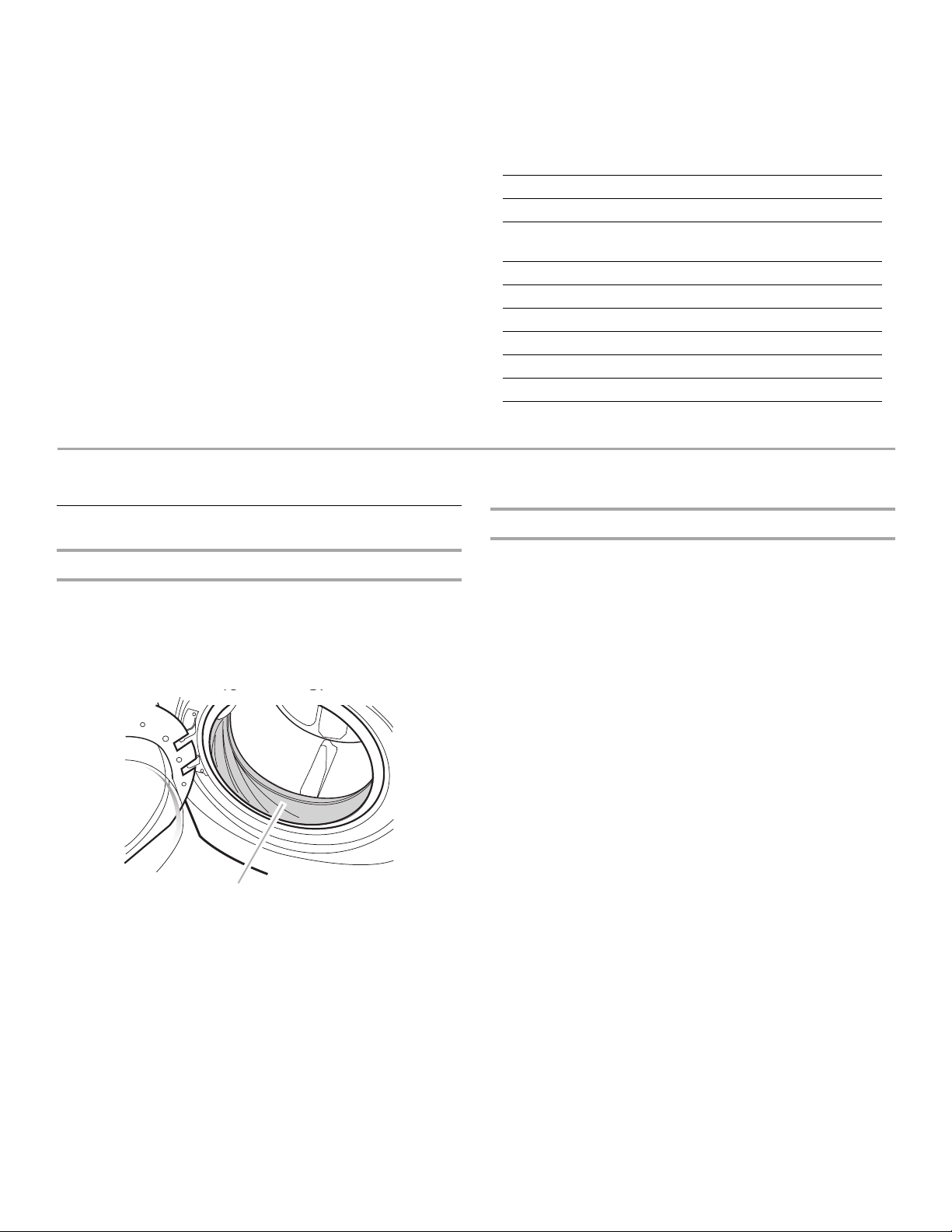

Cleaning the Door Seal/Bellow

1. Open the washer door and remove any clothing or items from

the washer.

2. Inspect

3. If stained areas are found, wipe down these areas of the

IMPORTANT:

■ Wear rubber gloves when cleaning for prolonged periods.

■ Refer to the bleach manufacturer’s instructions for proper

the colored seal/bellow between the door opening

and the drum for stained areas. Pull back the seal/bellow to

inspect all areas under the seal/bellow and to check for

foreign objects.

A

A. Seal/Bellow

seal/bellow, using the procedure that follows.

a) Mi

x a dilute solution, using 177 mL (3/4 cup) of liquid

chlorine bleach, and 3.8 L (1 gal.) of warm tap water.

b) Wipe the

using a damp cloth.

c) Let stand 5 minutes.

d) Wipe down area thoroughly with a dry cloth and let the

washer interior air dry with door open.

use.

seal/bellow area with the dilute solution,

Washer Maintenance Procedure

This washer has a special cycle that uses higher water volumes in

combination with liquid chlorine bleach to thoroughly clean the

inside of the washer.

NOTES:

■ Read these instructions completely before beginning the

cleaning process.

■ If necessary, the cleaning cycle may be interrupted by

pressing the DELICATES/KNITS button twice. However, this

will not immediately stop the cycle. The washer will continue

with several rinse and drain steps to ensure that all remaining

bleach is rinsed from the washer.

Begin procedure

1. Open the washer door and remove any clothing or items from

the washer.

2. Use liquid chlorine bleach:

Open the dispenser drawer and immediately

160 mL (2/3 cup) of liquid chlorine bleach to the bleach

compartm

NOTE: Do

than 160 mL (2/3 cup) of bleach will cause pr

over time.

3. Close

4. To start the Clean Washer cycle, first enter “Start Operating

Set-up.” Then press and hold DELICATES/KNITS for

1 second. With the entire displa

NOTE: Th

again, and then the cycle will continue.

■ The washer will not fill, but the drum will rotate while the

ent.

not add any detergent to this cycle. Use of more

the washer door and the dispenser drawer.

y flashing, press BRIGHTS.

e drum will rotate, then the door will unlock, lock

washer runs a short sensing cycle. This will take

approximately 3 minutes.

add

oduct damage

12

5. The cycle will determine whether clothing or other items are

in the washer.

If no items are detected in the washer, it will proceed

a)

to Step 7.

b) If any items are detected in the washer, “rL” or “F-34”

will be displayed. Then

■ Press DELICATES/KNITS to cancel the failure code.

Then repeat steps 1, 3, and 4 to start the cycle again.

6. Once

7. Afte

the cycle has begun, allow the cycle to complete.

r the cycle is complete, leave the door open slightly,

to allow for better ventilation and drying of washer i

the door will unlock.

nterior.

Cleaning the dispenser drawer

The dispenser drawer is removable for easy cleaning.

1. Unlock the

Remove the drawer.

2. Remove the

compartments).

3. W

ash the parts under running water.

NOTE: D

eplace the inserts and return the dispenser to the drawer.

4. R

dispenser drawer by pressing the Release Lever.

inserts (the siphon from the softener and bleach

o not wash components in the dishwasher.

Always do the following to maintain washer freshness

■ Use only detergent for automatic washer.

■ Leave the door slightly open after each cycle to allow for

better ventilation and drying of washer interior.

■ Clean the washer monthly using the Washer Maintenance

Procedure, 160 mL (2/3 cup) of liquid chlorine bleach.

■ If the procedure does not sufficiently improve the washer

freshness, please evaluate your installation and usage

conditions for other causes.

Cleaning the exterior

Use a soft damp cloth or sponge to wipe up any spills.

Occasionally wipe the outside of your washer to keep it looking

new. Use mild soap and water. Do not use abrasive products.

Water Inlet Hoses

Replace inlet hoses after 5 years of use to reduce the risk of hose

failure. Periodically inspect and replace inlet hoses if bulges,

kinks, cuts, wear, or leaks are found.

When replacing your inlet hoses, record the date of replacement.

ASSISTANCE OR SERVICE

If you need further assistance, you can contact the dealer/distributor

where the washer was purchased.

When you call, you will need the washer model number

number. Both numbers can be found on the serial-rating plate

located on your washer.

For Warranty Terms and Conditions contact the dealer/distributor.

and serial

13

SECURITE DU LAVE-LINGE

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les dangers potentiels de décès et de blessures graves à vous

et à d’autres.

Tous les messages de sécurité suivront le symbole d’alerte de sécurité et le mot “DANGER” ou

“AVERTISSEMENT”. Ces mots signient :

Risque possible de décès ou de blessure grave si vous ne

DANGER

AVERTISSEMENT

Tous les messages de sécurité vous diront quel est le danger potentiel et vous disent comment réduire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

suivez pas immédiatement les instructions.

Risque possible de décès ou de blessure grave si vous

ne suivez pas les instructions.

14

MISE AU REBUT DU LAVE-LINGE

EXIGENCES D’INSTALLATION

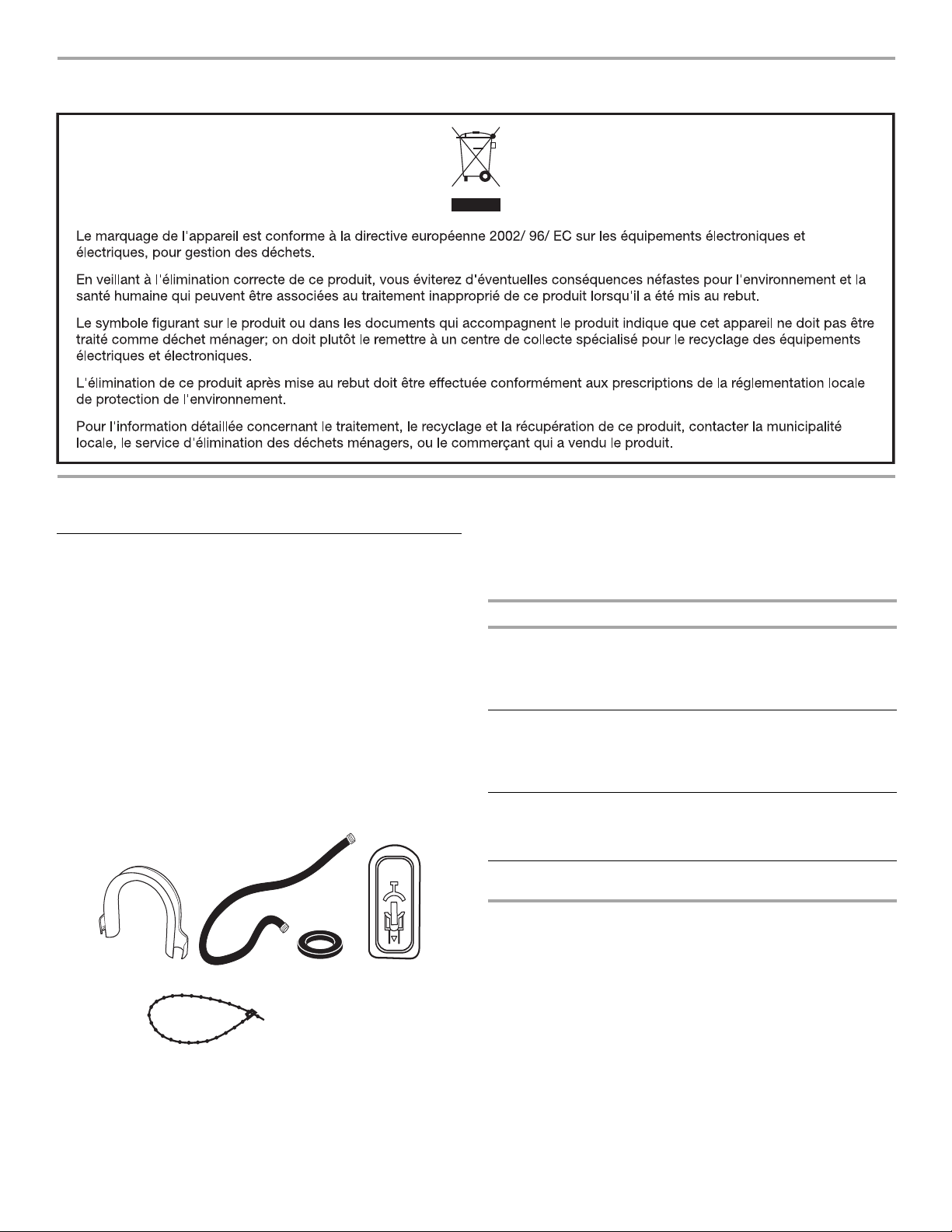

Outillage et pièces

Rassembler les outils et pièces nécessaires avant de commencer

l'installation. Les pièces fournies se trouvent dans le tambour du

lave-linge.

Outils nécessaires au raccordement des tuyaux d'arrivée d'eau

■ Pince (ouverture jusqu'à

39,5 mm [1

9

/16"])

Outils nécessaires à l'installation

■ Clés plates de 1/2" et 9/16"

■ Tournevis de sécurité

■ Tourne-écrou de 1/4"

Pièces fournies

To rx

®†

T-20

■ Lampe de poche

(facultative)

■ Niveau

■ Cale en bois

■ Règle ou mètre ruban

Autres pièces

Il se peut que l'installation nécessite des pièces supplémentaires.

Pour acheter l'un des articles indiqués ici, contacter votre

concessionnaire Whirlpool agréé.

Si vous avez Vous devrez acheter

Evier de buanderie

ou tuyau rigide de

rejet à l'égout plus

haut que 2,4 m

(96")

Egout surélevé Evier de vidange standard de 76 L

Egout au plancher Brise-siphon, pièce n° 285320; tuyau de

Tuyau de vidange

op court

tr

Système de pompe de puisard (si non

déjà disponible)

(20 gal.) de 762 mm (30") de hauteur ou

évier utilitair

(disponibles chez votre fournisseur local

d'articles de plomberie)

vidange

ensemble de système de vidange au

plancher, pièce n° 280129

Trousse de rallonge du tuyau de vidange

de 1,2 m (4 pi), pièce n° 285834

e et pompe de puisard

additionnel, pièce n° 8318155; et

A BC

D

E

A. Bride de retenue pour tuyau de vidange (en forme de U)

B. Tuyaux d'arrivée d'eau (2)

C. Rondelles pour tuyau d'arrivée d'eau (4)

D. Bouchons d'obturation des boulons de trans

E. Courroie perlée

port (4)

†® TORX est une marque déposée de Acument Intellectual Properties, LLC.

15

Loading...

Loading...