wheelock SCSP-8RP, SCSP-15SP, SCSP-4RP INSTALLATION INSTRUCTIONS

RV9

Q2

Q1

RV8

TB 3

RV7

RV6

Installation, Testing, Operation,

RV5

RV4

RV3

RV2

TB 2

RV1

TB 1

P83412 REV ( )

U17

C50

R72

RV10

R71

R73

R69

J3

+

C10D2

R64R63 D11

J2

C46

D12

C48

R70

R66

R67

D13

R68

U13

SAFEPATH

R65

C44

D10

J6

R62

C41

R60

R59

C40

R58

R57

C39

R56

R55

C38

R54

R53

C36

R52

and Maintenance Manual

R43

R51

C35

K1

F1

C9

D1

R50

R49

C34

R48

R47

C33

R46

R45

+

C27

GND

EA RTH

E1

K2

R21

R22

D3

C17

+

U1

+

C7

C8R9

R35

R34

D4

C20

R26

R20

C31

R42

R44

U9

Single Circuit

D9

U7

C25

L2

D8

C21

+

L1

R32

C19

R25

C14

R17

R19

R18

R16

C15

C16

U4

U3

R8

R4C3C1

R6 C6

R5 R7R1C4

C5

REV: SN:

U16

C49 C47

U15

S15

C45

U14

S14

C43

U12

S12

C42

R61

J5

U11

C37

R41

R40

C32

R38

U10

C30

C29

C28

R39

SAFEPATH P83167 REV B

T1

U3

FOR

R36

R37

U8

S8

C26

C24

J4

C22

C23

R33

R14

C12

C11 R15

C13

R3

R2

C2

D7

SCSP-4RP (108951)

D6

D5

J1

SCSP-8RP (108952)

SCSP-15SP (108969)

R31

R29

R27

U6

U5

R30

R28

CH1 VOL

R24

R23

C18

R13

J1

R10

R12

R11

U2

SAFEPATH

C16

P1

D1

D2

AMBER GREEN

K1

K2

SW1 SW2 SW3

K3

U1

U2

U4

X2

X1

U5

®

Systems

U6

R53

GROUND

FAULT

ADJUST

U8

U10

F1

®

TB1

F2

TB2

TB3

SW4

SW5

U9

TB5

MICROPHONE

4

2 3

1

ON

4

2 3

1

ON

+

TRB AUD

-

TRB COM

TRB NO

TRB NC

ALARM COM

ALARM NO

ALARM NC

+

DV POWER

-

+

DV STATUS

-

+

CH PLAY

-

+

LINE OUT

-

+

LINE IN

-

+

RM AUDIO

-

RM TXD

RM RXD

+

RM POWER

-

TONE SEL

3

2

1

CND FLT ENB

RM ENABLE

SYNC

DV ENABLE

LAMP TEST

E1

+

ALL CALL

-

+

24V

-

+

SPK AMP

-

+

STROBE

-

+

AUDIO

-

J2

273 Branchport Avenue, Long Branch, NJ 07740-6899 Ph: (732) 222-6880 Fax: (732) 222-2588

Toll Free 800-631-2148 Web Site: www.wheelockinc.com

E-Mail: info@wheelockinc.com

A83637 Revision B

Intentionally Blank

Typographical Notation Conventions

Thank you for using our products. Use this product according to this instruction manual. Please keep

this instruction manual for future reference.

ANY MATERIAL EXTRAPOLATED FROM THIS DOCUMENT OR FROM WHEELOCK MANUALS OR

OTHER DOCUMENTS DESCRIBING THE PRODUCT FOR USE IN PROMOTIONAL OR

ADVERTISING CLAIMS, OR FOR ANY OTHER USE, INCLUDING DESCRIPTION OF THE

PRODUCT'S APPLICATION, OPERATION, INSTALLATION AND TESTING IS USED AT THE SOLE

RISK OF THE USER AND WHEELOCK WILL NOT HAVE ANY LIABILITY FOR SUCH USE.

Certain information contained in this manual has been extracted from the NFPA 72 Manual (1999 Edition)

and the Life Safety Code 101™ Manual (2000 Edition).

Notation Conventions

This manual uses the following notation conventions:

WARNING: INDICATES A POTENTIALLY HAZARDOUS SITUATION THAT, IF NOT AVOIDED,

COULD RESULT IN PROPERTY DAMAGE AND SERIOUS PERSONAL INJURY

OR DEATH TO YOU AND OR OTHERS.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

P83636

Rev. G March 2003

Copyright 2003 Wheelock, Inc. All rights reserved.

iii

Intentionally Blank

iv

TABLE OF CONTENTS

Typographical Notation Conventions…………………………………………………………… iii

Table of Contents…………………………………………………………………………………. v

Table of Figures…………………………………………………………………………………… vii

Table of Tables……………………………………………………………………………………. ix

Chapter 1 – Safety Precautions…………………………………………………………………. 1-1

Section 1-1 – Read This Manual…………………………………………………………. 1-1

Section 1-2 – Operational Safety………………………………………………………… 1-1

Section 1-3 – Compliance with Applicable Codes, Regulations, Laws, Standards,

And Guidelines……………………………………………………………. 1-2

Section 1-4 – Property Insurance Recommendation………………………………….. 1-2

Section 1-5 – Audio Output Considerations……………………………………………. 1-3

Section 1-6 – RF Interference…………………………………………………………… 1-3

Section 1-7 – General…………………………………………………………………….. 1-3

Chapter 2 – Overview and Features……………………………………………………………. 2-1

Section 2-1 - Description…………………………………………………………………. 2-1

Section 2-2 – Enclosure and Configuration…………………………………………….. 2-2

Section 2-3 – Nominal Electrical Data………………………………………………….. 2-2

Section 2-4 – Module Configurations…………………………………………………… 2-3

Section 2-5 – Single Circuit SAFEPATH

Section 2-6 – Remote Microphone Station (RMS-2) (Optional)……………………… 2-3

Section 2-7 – Operation Modes…………………………………………………………. 2-4

Section 2-8 – Glossary of Terms……………………………………………………….. 2-4

®

Panel Basic Configuration…….…………. 2-3

Chapter 3 – Installation and Setup……………………………………………………………… 3-1

Section 3-1 – Introduction………………………………………………………………… 3-1

Section 3-2 – Fire Alarm Control Panel Interface Wiring Applications………………. 3-1

Section 3-3 – General Installation Instructions………………………………………… 3-2

Section 3-4 – Prepare a System Wiring Diagram……………………………………… 3-4

Section 3-5 – Mounting…………………………………………………………………… 3-13

Section 3-6 - System Checkout…………………………………………………………. 3-15

Section 3-7 – Ground Fault Detection Sensitivity Adjustment……………………….. 3-18

Section 3-8 – Battery Care and Backup Battery Calculations………………………... 3-19

Chapter 4 – Operation…………………………………………………………………………… 4-1

Section 4-1 – Introduction……………………………………………………………….. 4-1

Section 4-2 – Operator’s Console………………………………………………………. 4-1

Section 4-3 – Supervision……………………………………………………………….. 4-1

Section 4-4 – Actions That Initiate Alarms…………………………………………….. 4-2

Chapter 5 – Operational Procedures………………………………………………………….. 5-1

Section 5-1 – Operator Instructions……………………………………………………… 5-1

v

Section 5-2 – To Make Live Announcements………………………………………….. 5-1

Section 5-3 – To Sound Evacuation Tone……………………………………………… 5-1

Section 5-4 – To Reset Visual Appliances……………………………………………… 5-2

Section 5-5 – To Acknowledge a Trouble Condition………………………………….. 5-2

Chapter 6 – Periodic Testing and Maintenance………………………………………………. 6-1

Section 6-1 – Periodic Testing…………………………………………………………… 6-1

Section 6-2 – Qualified Personnel..……………………………………………………… 6-1

Section 6-3 – Miscellaneous Hardware Testing ………………………………………. 6-1

Chapter 7 – Troubleshooting……………………………………………………………………. 7-1

Section 7-1 – Troubleshooting…………………………………………………………… 7-1

Section 7-2 - SAFEPATH

Section 7-3 – Single Circuit SAFEPATH

®

Module Replacement Procedure……………………….. 7-11

®

Module Wiring Diagram…………..…….. 7-12

Chapter 8 – Technical Data…………………………………………………………………….. 8-1

Section 8-1 – Mechanical……………………………………………………………….. 8-1

Section 8-2 – Environmental……………………………………………………………. 8-1

Section 8-3 – Electrical………………………………………………………………….. 8-1

Chapter 9 – Module Descriptions……………………………………………………………… 9-1

Section 9-1 – Introduction………………………………………………………………. 9-1

Section 9-2 Single Circuit SAFEPATH

®

Motherboard (SCMB)………….…………. 9-3

Section 9-3 Digital Voice Module (MDX-2)……………..………………….…………. 9-6

Section 9-4 Power Supply/Battery Charger (DCPS)…….…..………………….…… 9-8

Section 9-5 Supervised Audio System Amplifier/Signal Circuit Module, 40 Watts

(SAA-40S)…………………………………….……………………………. 9-9

Section 9-6 Supervised Audio System Amplifier/Signal Circuit Module, 80 Watts

(SAA-80S/SE)………….…………………………………………………… 9-11

Section 9-7 Supervised Audio Line Level Module (SALL-15S)…………..…………. 9-13

Section 9-8 Notification Appliance Circuit Interface Module (NACIM)………….…… 9-15

Section 9-9 4-Zone Splitter Module (SC-SPL)…………………..……………………. 9-16

Section 9-10 Auxiliary Input Module (AIM-3)……………………………….…………. 9-17

Section 9-11 Remote Microphone Station (RMS-2R)…………………………..……. 9-19

Chapter 10 – MEA and Warranty……………………………………………..……………….. 10-1

Battery Backup Calculation Sheet…………………………………………..………………… 1

vi

List of Figures

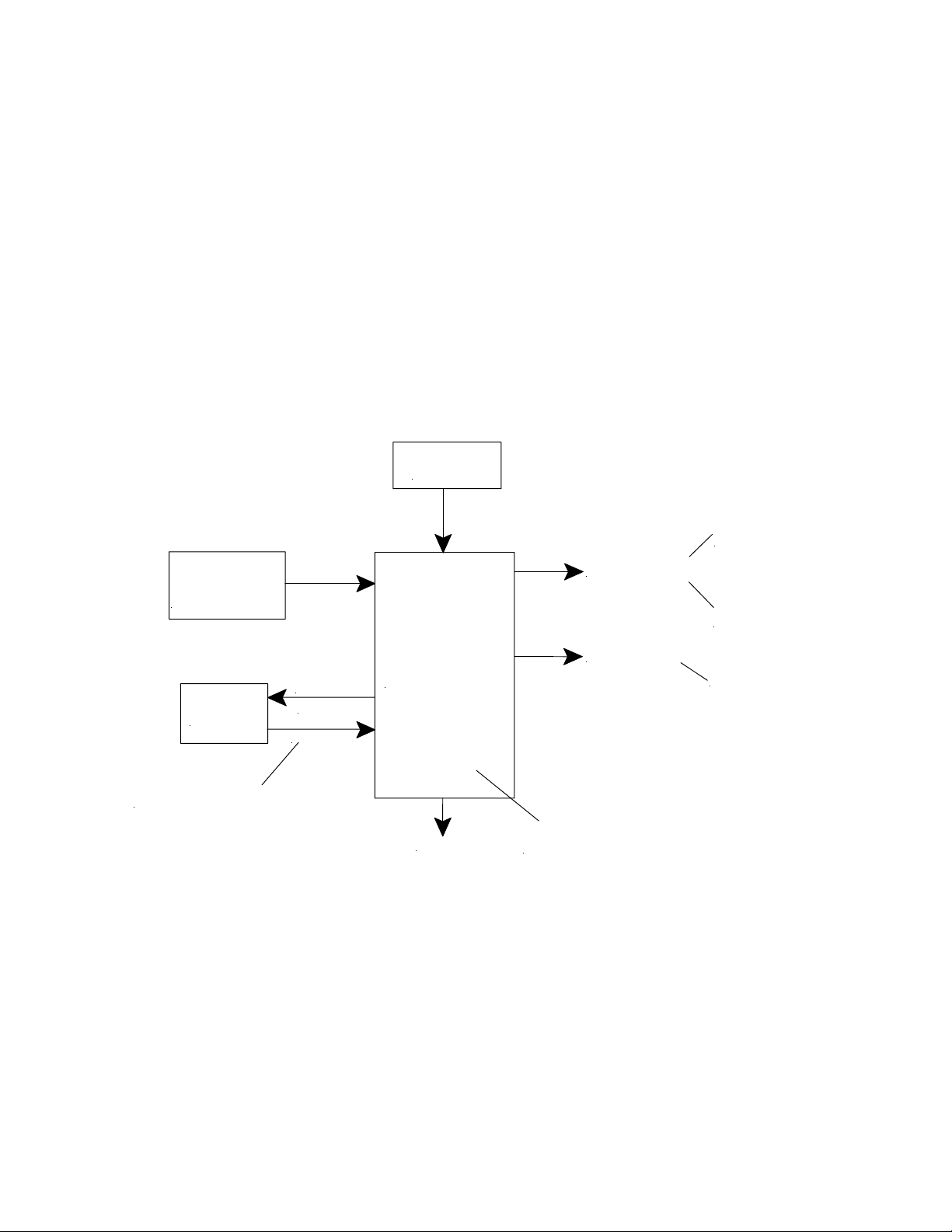

Figure 2-1 Basic Capabilities of the Single Circuit SAFEPATH

®

Panel………………………... 2-2

Figure 2-2 Module Layout of a Typical Single Circuit SAFEPATH® Panel………………… 2-5

Figure 3-1 Location of Plug-in Modules and Wire Connections……………………………… 3-2

Figure 3-2 Strobe and Audio Output Connections……………………………………………. 3-3

Figure 3-3 Wiring Diagram for Visual Notification Appliance Output………………………… 3-5

Figure 3-4 Wiring Diagram for Combination Audio/Visual Notification Appliances in

Central Amplifier Applications………………………………………………………. 3-6

Figure 3-5 Wiring Diagram for Combination Audio/Visual Notification Appliances in

Central Amplifier Applications………………………………………………………. 3-6

Figure 3-6 Wiring Diagram for Audio Notification Appliance Output………………………… 3-7

Figure 3-7 Wiring Diagram for Combination Audio/Visual Notification Appliances in

Central Amplifier Applications………………………………………………………. 3-7

Figure 3-8 Wiring Diagram for Audio Notification Appliances in Amplified Speaker

Applications…………………………………………………………………………… 3-8

Figure 3-9 Wiring Diagram for Combination Audio/Visual Notification Appliances in

Amplified Speaker Applications…………………………………………………….. 3-8

Figure 3-10 Wiring Connection Locations……………………………………………………… 3-9

Figure 3-11 Dry Contact Input Connections……………………………………………………. 3-10

Figure 3-12 Alarm and Trouble Status Output Connections…………………………………. 3-10

Figure 3-13 Alarm Relay Contacts……………………………………………………………… 3-11

Figure 3-14 Trouble Status Relay Contacts……………………………………………………. 3-11

Figure 3-15 Trouble Audible Connection………………………………………………………. 3-12

Figure 3-16 Input Power and Battery Connection Locations………………………………… 3-13

Figure 3-17 Single Circuit SAFEPATH

®

Panel Mounting……………………………………. 3-14

Figure 3-18 Configuration DIP Switch Location on SCMB Module………………………….. 3-16

Figure 5-1 Single Circuit SAFEPATH

®

Panel Operator Console…………………………… 5-3

Figure 7-1 Trouble LED Locations……………………………………………………………… 7-2

Figure 7-2 Basic Troubleshooting Flowchart………………………………………………….. 7-4

Figure 7-3 Digital Voice Module (MDX-2) Troubleshooting Flowchart……………………… 7-6

Figure 7-4 Single Circuit SAFEPATH

®

Module Wiring Diagram.………………………….. 7-13

Figure 9-1 Location of Plug-in Modules………………………………………………………… 9-2

Figure 9-2 Single Circuit SAFEPATH

®

Motherboard (SCMB)………………………………. 9-5

Figure 9-3 Digital Voice Module (MDX-2)……………..………………………………………. 9-7

Figure 9-4 Power Supply/Battery Charger (DCPS)………..………………………………… 9-8

Figure 9-5 Supervised Audio System Amplifier/Signal Circuit Module, 40 Watts

(SAA-40S)……………………………………………………………………………. 9-10

vii

Figure 9-6 Supervised Audio System Amplifier/Signal Circuit Module, 80 Watts

(SAA-80S/SE)………………………………………………………………………… 9-12

Figure 9-7 Supervised Audio Line Level Module (SALL-15S)………………………………. 9-14

Figure 9-8 Notification Appliance Circuit Interface Module (NACIM)………………………… 9-15

Figure 9-9 4-Zone Splitter Module (SC-SPL)…………………………………………………. 9-16

Figure 9-10 Auxiliary Input Module (AIM-3)……………………………………………………. 9-18

Figure 9-11 Remote Microphone Station (RMS-2)……………………………………………. 9-19

viii

LIST OF TABLES

Table 3-1 SCMB DIP Switch Setting Description……………………………………………… 3-17

Table 3-2 DIP Switch Settings for Available Tone Sounds…………………………………… 3-17

Table 3-3 Standby Current for Single Circuit SAFEPATH

Table 3-4 Standby and Alarm Current for Single Circuit SAFEPATH

Table 3-5 Standby Current for Single Circuit SAFEPATH

®

Panel………………………….. 3-20

®

Modules………….. 3-21

®

Amplifier Modules……………. 3-21

Table 3-6 Calculations for Amplifier Alarm Current………………………………..…………. 3-22

Table 3-7 Average Current Output Measured by Wheelock, Inc……………….…………… 3-22

Table 4-1 Alarm Conditions and Results……………………………………………………….. 4-3

Table 6-1 Miscellaneous Hardware Tests………………………………………..……………. 6-1

Table 7-1 Module Trouble Procedure Cross Reference……………………………………… 7-3

Table 7-2 MDX-2 Trouble Procedure Cross Reference………………………………………. 7-3

Table 8-1 Outputs…………………………………………………………………………………. 8-2

ix

Intentionally Blank

x

Chapter 1 - Safety Precautions

Section 1-1 - Read This Manual

Personnel properly qualified in the application and use of life safety equipment ("qualified personnel")

shall read this manual carefully before performing any actions to specify, apply, install, maintain and

operationally test SAFEPATH

This manual shall be kept with the SAFEPATH

manual shall be made available to all qualified personnel who operate, test, maintain, or service

SAFEPATH

®

Panel products. It is strongly recommend that such personnel read and understand the

entire manual.

Section 1-2 - Operational Safety

®

Panel products in accordance with the instructions in this manual.

®

Panel for reference during the life of the system. This

WARNING: IF SAFETY PRECAUTIONS, INSTALLATION AND TESTING INSTRUCTIONS ARE

NOT PERFORMED PROPERLY, THE

SAFEPATH

®

PANEL MAY NOT OPERATE IN

AN EMERGENCY SITUATION WHICH COULD RESULT IN PROPERTY DAMAGE

AND SERIOUS INJURY OR DEATH TO YOU AND/OR OTHERS.

WARNING: IF THE TROUBLE CONDITION PROTECTIVE SIGNALING SYSTEM SOUNDS

AND/OR FLASHES, IT IS A WARNING OF A POSSIBLE SERIOUS SITUATION AND

REQUIRES IMMEDIATE ATTENTION.

CAUTION: The SAFEPATH

delicate components mounted on a board. Discharge any static electricity from your

body by touching a grounded object, such as a metal screw, which is connected to

earth ground. Handle the board by its edges and be careful not to twist or flex it. The

SAFEPATH

attach grounded wrist straps before touching any static sensitive areas. After handling

SAFEPATH

Section 3-5 “System Checkout” of this manual to verify that the printed circuit board is

functioning properly.

®

printed circuit boards are sensitive to static electricity and have

Panel is to be installed in a static free area, and the installer is to properly

®

printed circuit boards, the panel should be tested in accordance with

This SAFEPATH® Panel will not work without power.

or 220VAC. 24VDC re-chargeable batteries provide back-up power. If both sources of power are cut off

for any reason, the SAFEPATH

®

Panel will not operate.

The SAFEPATH

DO NOT assume any installation, operation and testing details not shown in this manual.

The SAFEPATH

®

Panel shall only be operated with the dead front panel properly in place.

®

Panel is powered by 120VAC

WARNING: FOR PROPER OPERATION, THE

SAFEPATH

®

PANEL SHALL BE CONNECTED TO

A LISTED COMPATIBLE AND PROPERLY OPERATING CONTROL PANEL, WHICH

CONTROLS ITS ACTIVATION. ALL EQUIPMENT SHALL BE PROPERLY

INTERCONNECTED AND OPERATING. THE INSTALLER SHALL CHECK

COMPATIBILITY OF ALL EQUIPMENT PRIOR TO INSTALLATION, OTHERWISE

THE SAFEPATH

®

PANEL AND/OR THE CONTROL PANEL MAY BE DAMAGED

AND/OR FAIL TO OPERATE IN AN EMERGENCY SITUATION.

1-1

®

Notification equipment cannot last forever. Even though SAFEPATH

years, any of its parts or components could fail before then. Therefore testing of the entire protective

signaling system, including the SAFEPATH

®

Panel, all notification equipment, as well as all messages

Panel is expected to last up to ten

and their output channel, and priority assignment, shall be conducted at least twice each year, or more

often as required by local, state and federal codes, regulations and laws, by qualified personnel. If the

notification equipment is not working properly, immediately contact the installer and have all/any problems

corrected immediately. Malfunctioning components should be replaced immediately. Do not attempt to

repair malfunctioning components. Malfunctioning components should be returned for factory repair or

replacement. In the event you cannot contact the installer, contact the manufacturer.

WARNING: CERTAIN HARDWARE FUNCTIONS ON THE SAFEPATH PANEL ARE NOT

SUPERVISED. IF ANY SUCH HARDWARE FUNCTIONS FAIL, THE SAFEPATH

PANEL MAY NOT PROVIDE THE INTENDED WARNING AND/OR NOT INDICATE A

TROUBLE CONDITION. THE FOLLOWING ARE NOT SUPERVISED:

1. THE "SHORT CIRCUIT" DETECTION CIRCUITRY FOR ANYONE OR ALL OF

THE EIGHT CONTACT INPUTS.

THE FOLLOWING HARDWARE FAILURES WOULD PREVENT THE

SAFEPATH

PANEL FROM INDICATING A TROUBLE CONDITION:

1. THE "OPEN CIRCUIT" DETECTION CIRCUITRY FOR ANY ONE OR ALL OF THE

EIGHT CONTACT INPUTS.

2. THE AUDIO SUPERVISION CIRCUITRY FOR EACH OF THE TWO OUTPUT

CHANNELS.

3.

THE STATUS CONTACT.

THESE HARDWARE FUNCTIONS SHALL BE PERIODICALLY CHECKED FOR

PROPER OPERATION.

®

Section 1-3 - Compliance with Applicable Codes, Regulations, Laws,

Standards, and Guidelines

COMPLY WITH ALL OF THE LATEST APPLICABLE CODES, REGULATIONS, LAWS, STANDARDS,

AND GUIDELINES.

WARNING: FOR EMERGENCY, HAZARDOUS, SECURITY, LIFE SAFETY, AND FIRE

PROTECTIVE SIGNALING SYSTEM APPLICATIONS USING THE SAFEPATH

PANEL INSTALLATION, TESTING AND MAINTENANCE SHALL BE PERFORMED

BY QUALIFIED PERSONNEL IN ACCORDANCE WITH ALL THE LATEST

NATIONAL FIRE PROTECTION ASSOCIATION (NFPA), UNDERWRITER’S

LABORATORY (UL), NATIONAL ELECTRIC CODE (NEC), OCCUPATIONAL

SAFETY AND HEALTH ADMINISTRATION (OSHA), STATE, COUNTY, LOCAL,

PROVINCE, DISTRICT, FEDERAL, AND OTHER APPLICABLE BUILDING AND

FIRE STANDARDS, GUIDELINES, REGULATIONS, LAWS, AND CODES

INCLUDING, BUT NOT LIMITED TO, ALL APPENDICES AND AMENDMENTS AND

REQUIREMENTS OF THE LOCAL AUTHORITY HAVING JURISDICTION (AHJ).

It is recommended that the local AHJ inspect and approve the proposed placement of all the notification

appliances.

Section 1-4 - Property Insurance Recommendation

The SAFEPATH® Panel is not a substitute for insurance. All users should have adequate levels of life and

property insurance

.

1-2

Section 1-5 - Audio Output Considerations

WARNING: AUDIBLE SIGNALS MAY MASK MEDICAL EQUIPMENT MONITORING ALARMS.

WHERE MEDICAL EQUIPMENT MONITORING ALARMS ARE IN USE, DO NOT

USE AUDIBLE SIGNALS; PROVIDE VISUAL NOTIFICATION APPLIANCES IN

HIGHLY VISIBLE LOCATIONS.

CAUTION: The output of the audio system may not be heard in all cases. Sound can be blocked

or reduced by walls, doors, carpeting, wall coverings, furniture, insulation, bed

coverings, and other obstacles that may temporarily or permanently impede the output

of the audio system. Sound is also reduced by distance and masked by background

noise. The output of the audio system may not be sufficient to alert all occupants,

especially those who are asleep, those who are hearing-impaired, those who are

wearing devices that plug or cover the ears, and those who have recently used drugs

or alcohol. The output of the audio system may not be heard by an alert person if the

output device is placed in an area which is isolated by a closed door, or is located on a

different floor from the person in a hazardous situation or is placed too far away to be

heard over ambient noise such as, but not limited to, running water, traffic, air

If live microphone announcements, audible tones and/or voice messages cannot be readily heard and

understood clearly within the protected areas as intended, it will be necessary to increase the number

and/or sound output intensity of speakers within those areas so that they are heard and understood

clearly when activated

conditioners, machinery or musical appliances

.

.

Section 1-6 - RF Interference

The SAFEPATH® Panel has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at owners expense.

Section 1-7 - General

Each manufacturer's fire alarm control panel, and notification appliances operate differently and have

different features. Before specifying, installing, operating, testing, maintaining or servicing a system,

carefully read the installation, operation and testing manual for each piece of equipment and applicable

codes.

Additional copies of this manual may be obtained from:

Wheelock, Inc.

273 Branchport Ave.

Long Branch, N.J. 07740

Tel: (732) 222- 6880

Fax: (732) 222- 2588

Email: infoatwheelockinc.com

1-3

Intentionally Blank

1-4

Chapter 2 - Overview and Features

Section 2-1- Description

General

The Single Circuit SAFEPATH® Panel is a stand alone, single channel, supervised audio fire and

emergency evacuation system. Figure 2-1 on Page 2-2 illustrates the basic capabilities of the Single

Circuit SAFEPATH

The control panel that activates the Single Circuit SAFEPATH

buttons to a sophisticated computer based control panel providing dry contact closures.

The SAFEPATH

of a system that does sense such conditions. The SAFEPATH

recorded tone and/or voice message(s) to notification appliances. When used as part of a protective

signaling system, the SAFEPATH

has been approved by a nationally recognized testing laboratory ("LISTED") and to LISTED compatible

notification appliances for proper operation.

THE

SAFEPATH

TO A COMPATIBLE FIRE ALARM CONTROL PANEL TO FUNCTION IN A VOICE EVACUATION

SYSTEM.

WHEELOCK EXPRESSLY DISCLAIMS ALL LIABILITY FOR THE CONTENT, CLARITY AND

LANGUAGES OF, AND OUTPUT CHANNEL AND PRIORITY LEVEL ASSIGNED TO, ANY AND ALL

MESSAGES. IT IS ESSENTIAL THAT YOU HAVE MESSAGE CONTENT AND LANGUAGE,

SEQUENCE, OUTPUT CHANNEL AND PRIORITY ASSIGNMENTS REVIEWED AND APPROVED BY

QUALIFIED LEGAL AND SAFETY ADVISORS, QUALIFIED REPRESENTATIVE(S) OF OWNER(S)

AND USER(S), AND AUTHORITIES HAVING JURISDICTION.

Panel.

Panel can range from simple push

Panel does

PANEL MUST BE PROPERLY INSTALLED, PROGRAMMED, AND CONNECTED

not

sense an emergency condition or hazards such as fire; it is only a part

Panel must be properly connected to a compatible control panel that

Panel, when activated, provides a pre-

Standard Features

• One zone of audio and strobe NAC outputs.

• Multiple contact closure inputs

• A hand held, push-to-talk microphone (PTT) for live, emergency voice announcements and

instructions. The microphone overrides (mutes) any voice message or tones in progress.

• A multi-tone tone generator with 8 field selectable sounds for an optional evacuation signal.

• Visual NAC circuit of up to 2 amps at 24VDC. The visual NAC circuit may be selected to be

compatible with Wheelock, Inc. synchronized or non-synchronized visual notification appliances.

• Supervised Audio Amplifier module (SAA-40S, or 80S/SE) power 25, 70.7 or 100-volt speakers, or

Line Level Audio Amplifier (SALL-15S) to drive external power amplifiers and/or self-amplified

speakers.

• Digital Voice Module (MDX-2) with a Standard Message Kit (SMK) containing 8 standard messages

• Full supervision with on-board diagnostics and trouble reporting circuits for:

• Audio NAC circuit wiring open and short conditions

• Ground Fault detection

• Strobe NAC circuit wiring open and short conditions

• Self Amplified power output circuit wiring open and short conditions

• Microphone open condition

• Amplifier operation

• Selected evacuation signal

2-1

• Optional remote microphone station

• Digital Voice Module (MDX-2)

• Alarm input activation wiring

• Input voltage/low battery

• Built-in audible alert indicates any supervision loss

• Auxiliary trouble output for trouble signal connection

• Remote reporting via output contacts for system trouble or alarm activation.

• An internal 6-amp power supply/ 40Ah battery charger.

Optional Features

• Remote Microphone Station (RMS-2) for live, emergency announcements.

• Programmed Message Kit (PMK) for up to two minutes of messages tailored to customer’s needs.

• Four Zone Audio Splitter (SC-SPL).

• Auxiliary Input Module (AIM-3) used to connect three Remote Microphone Stations or two Remote

Microphone Stations and a telephone page input.

BATTERY

STANDBY

CENTRAL AMPLIFIED

(40 OR 80 WATT, SELECTABLE

25V, 70.7V, or 100V)

REMOTE

MICROPHONE

(RMS-2)

CONTROL

SYSTEM

UP TO 8 CONTACT ACTIVATIONS.

SPEAKER CIRCUIT

STROBE CIRCUIT

TROUBLE

RELAY

INPUTS

SAFEPATH

PANEL

120 VAC

8 STANDARD MESSAGES ON THE SMK OR

UP TO 2 MINUTES OF AUDIO STORAGE FOR

PERSONALIZED MESSAGES ON THE MDV-PMK.

Figure 2-1

Basic Capabilities of the Single Circuit SAFEPATH

®

Panel

AMPLIFIED SPEAKER

(15 Ohms @ 0.5 VOLT AUDIO

24 VDC @ 2A MAX.)

24 vdc AT 2A Max.

Section 2-2 - Enclosure and Configuration

See Chapter 8 for Technical Specifications data.

Section 2-3 - Nominal Electrical Data

See Chapter 8 for Technical Specifications data.

2-2

Section 2-4 - Module Configurations

The Single Circuit SAFEPATH® Panel is equipped with a combination of the following modules:

There are ten modules in the Single Circuit SAFEPATH

Panel product line.

The ten modules are:

SCMB (Single Circuit Motherboard)

DCPS (Power Supply/Battery Charger)

SAA-40S (40 Watt, Supervised Audio Amplifier Module with 2 Amps of strobe current)

SAA-80S/SE* (80 Watt, Supervised Audio Amplifier Module with 2 Amps of strobe current)

SALL-15S (Line Level, Supervised Audio Amplifier Module with 2 Amps of strobe current)

SC-SPL (Single Circuit Splitter - 4 Zone)

NACIM (Notification Appliance Circuit Interface Module)

MDX-2 (Digital Voice Module)

RMS-2 (Single Circuit Remote Microphone Station)

AIM-3 (Auxiliary Input Module)

* 100 Volt for Export Installations

Section 2-5 - Single Circuit SAFEPATH® Panel Basic Configuration

Each Single Circuit SAFEPATH

SCMB (Single Circuit Motherboard)

MDX-2 (Digital Voice Module)

SMK (Standard Message Kit) or optional PMK (Programmed Message Kit)

One amplifier module

DCPS (Power Supply/Battery Charger)

Optional Modules:

One SC-SPL (Single Circuit Splitter-4 Zone)

Up to eight NACIM (Notification Appliance Circuit Interface Module)

Up to three RMS-2 (Remote Microphone Station)

One AIM-3 (Auxiliary Input Module)

The module layout of the Single Circuit SAFEPATH

Panel is configured with:

®

Panel is shown in Figure 2-2 on Page 2-5.

Section 2-6 - Remote Microphone Station (RMS-2) (Optional)

The Remote Microphone Station (RMS-2) is a 4 gang switch-plate consisting of a push-to-talk (PTT),

hand-held microphone, pre-amplifier and associated LED’s and activation switches which provides a

remote live voice input. Additional Information is found in the Installation Manual.

2-3

Section 2-7 - Operation Modes

The SAFEPATH® Panel has two operation modes:

1. Standby

2. Alarm

Standby Mode

Standby is the normal mode. The SAFEPATH® Panel supervises the connections and internal

components to maintain proper operation. All strobes and speaker appliances are off.

Alarm Mode

Alarm mode occurs when an emergency signal is initiated manually, or by the FACP or control

equipment.

Section 2-8 – Glossary of Terms

AHJ – Authority Having Jurisdiction

EOLR – End of Line Resistor

FACP – Fire Alarm Control Panel

NAC – Notification Appliance Circuit

NEC – National Electric Code (NFPA-70)

NFPA – National Fire Protection Association

PTT – Push to Talk (Microphone)

PCB - Printed Circuit Board

UL - Underwriters Laboratory

2-4

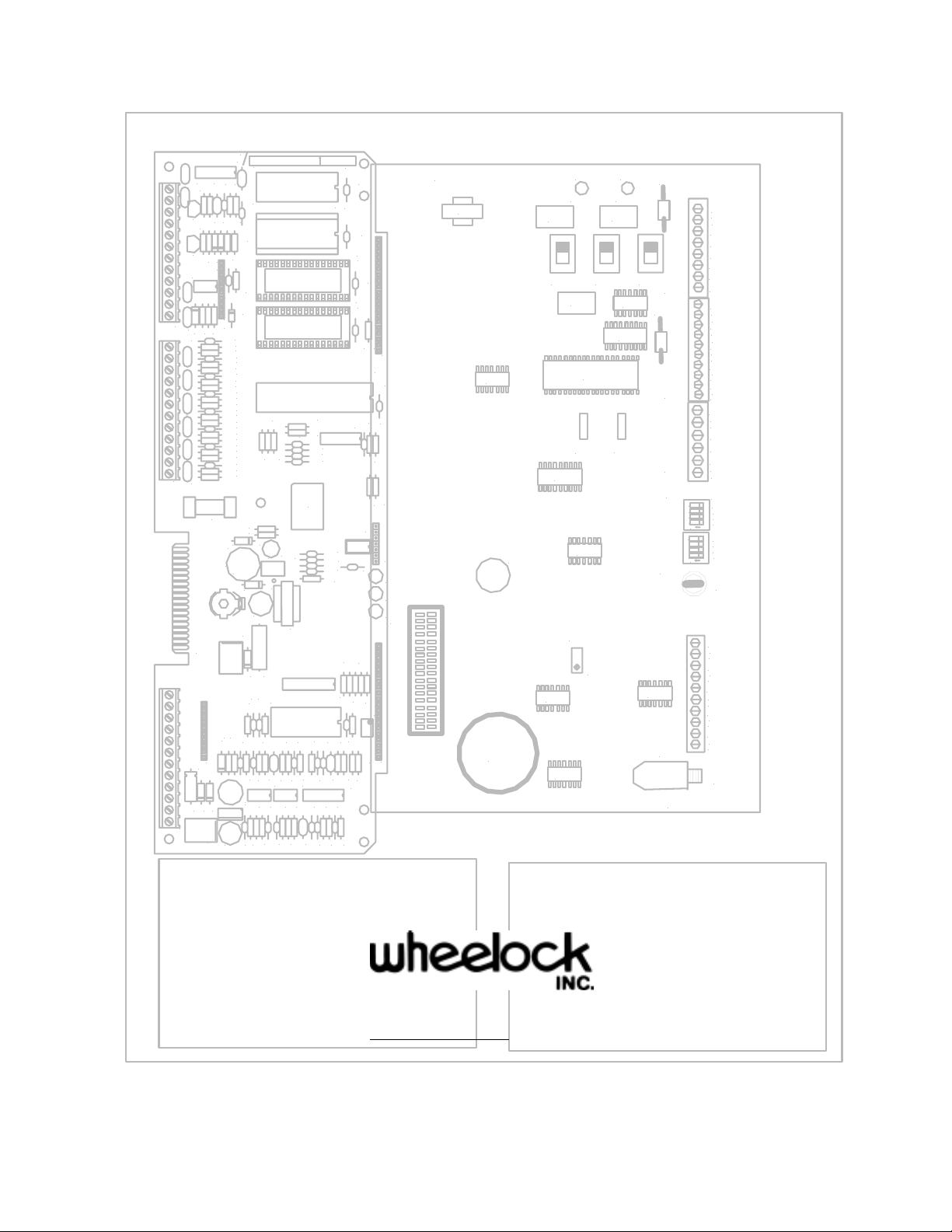

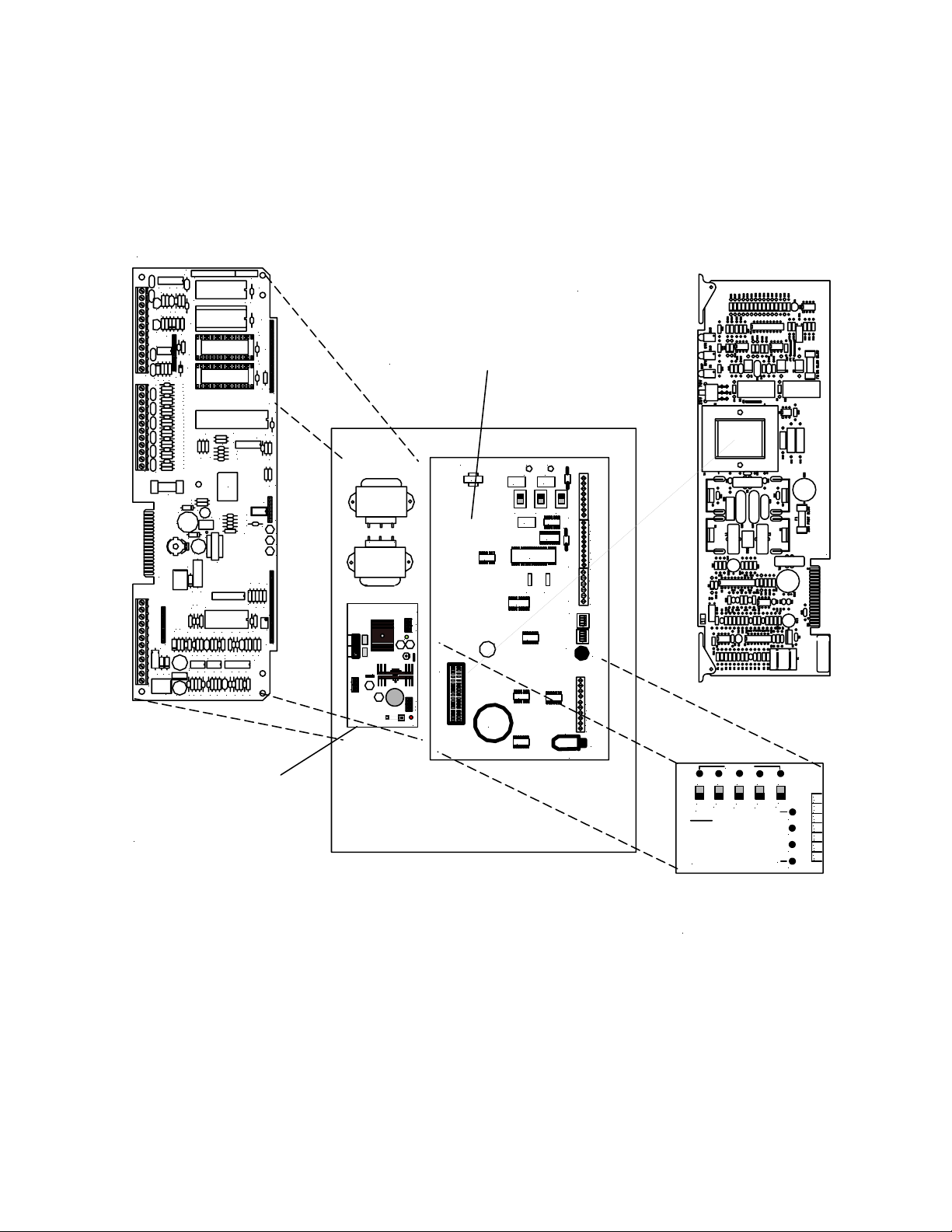

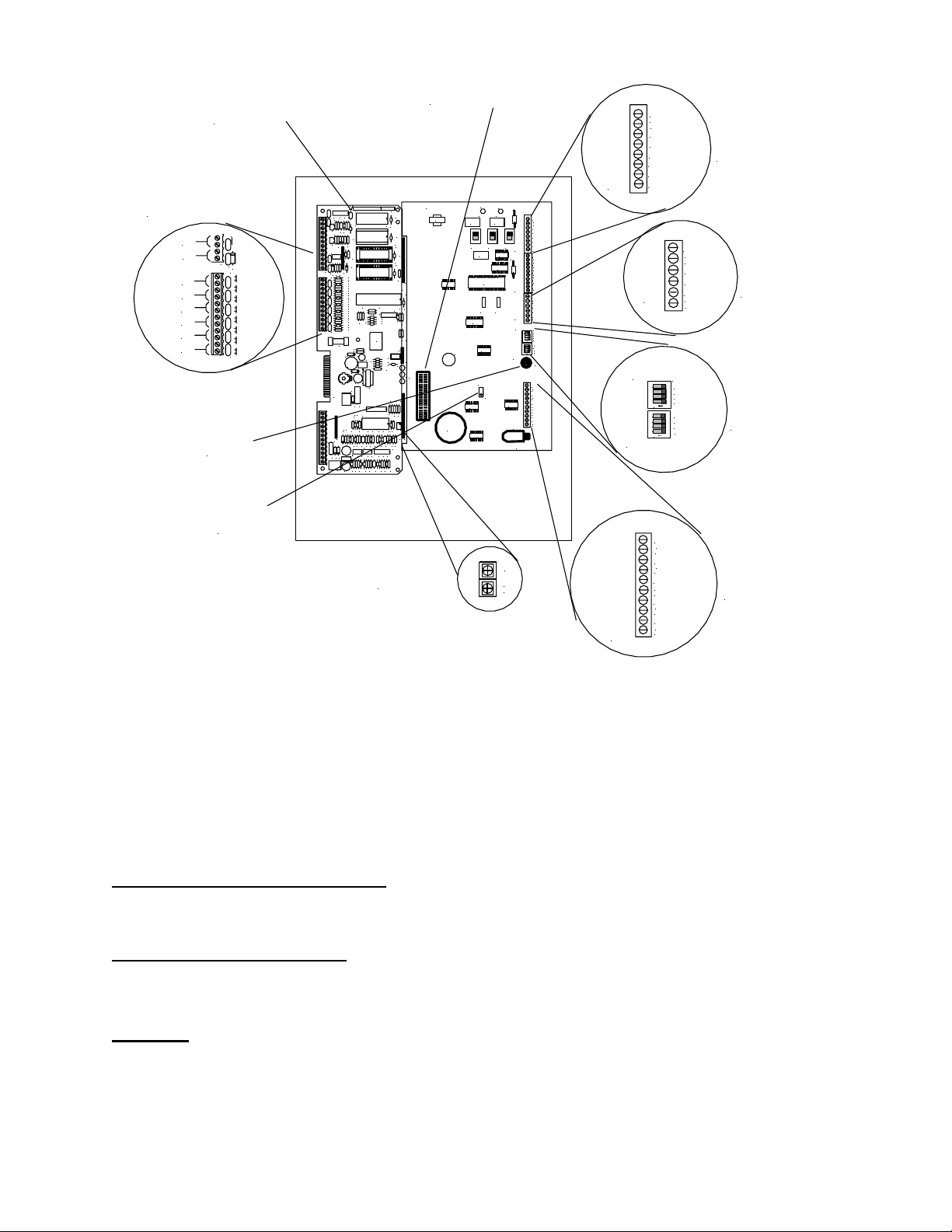

Digital Voice

Module MDX-2

P83412 REV ( )

U17

C50

R72

RV10

R71

R73

C46

RV9

Q2

D12

C48

R70

R69

R66

Q1

R67

D13

R68

U13

RV8

R65

C44

D10

J6

TB 3

R62

RV7

R64R63 D11

C41

RV6

R60

R59

C40

R58

R57

C39

R56

R55

RV5

C38

R54

R53

C36

RV4

R52

R43

R51

C35

R50

RV3

R49

C34

R48

R47

RV2

TB 2

TB 1

R44

C33

R46

R45

RV1

F1

R35

R34

D9

+

C27

L2

GND

EAR TH

D8

E1

C21

+

K2

J3

R32

D4

C20

C19

R25

R26

R21

R22

D3

R19

C17

J2

+

R20

R18

C16

C9

+

R8U1R6 C6

C10D2

D1

+

K1

C8

R9

R42

U7

L1

R17

R16

C15

R5 R7R1C4

C5

R41

R40

C31

C30

C29

C28

U9

C25

R14

C14

C13

U3 U4

R3

R4C3C1

C2 C7

REV: SN:

U16

C49 C47

U15

S15

C45

U14

S14

C43

U12

S12

C42

R61

J5

U11

C37

C32

R38

U10

R39

R36

R37

U8

S8

C26

C24

J4

C22

C23

R33

D7

D6

D5

R31

R29

R27

U6

U5

R30

R28

CH1 VOL

R24

R23

C18

R13

C12

J1

R10

C11 R15

R12

R11

U2

R2

Power Supply/

Battery Charger

(DCPS)

MOTHER BOARD

(SCMB)

SAFEPATH P83167 REV B

T1

10 6

10 6

U3

SMP7PM

AC

AC

AC FAIL

C NC NO

BAT FAIL

NO NC C

-

DC

+

AC

SW1

SW2

J1

-

BAT

+

DC

P1

C16

D1

D2

AMBER GREEN

K2

K1

SW1 SW2 SW3

K3

U1

U2

U4

X2

X1

U5

U6

U8

U10

Amplifier

SAA-40S, 80S, 80SE

SALL-15S

F1

TB1

+

F2

-

+

-

+

-

+

TB2

-

+

-

+

TB3

-

SW4

2 3 4

1

ON

4

2 3

1

ON

SW5

E1

U9

+

-

+

-

+

-

TB5

J2

MICROPHONE

ZONE SELECT LED'S

ON

ON

OFF OFF

OFF

ZONE 1

ALL

CALL

OPERATION:

Use zone switches to select zones

for live announcements.

Use all-call to select all zones.

Zone select LED's indicate the

selected zones.

Zone active LED's indicate the

active zones.

ZONE 2

P83236 SAA-40/ 80

ON

ON

ON

TB1

+

ALL

_

OFF

OFF

ZONE 3

+

ZONE 4

PWR

_

Z

O

+

ZONE 1

AUD

N

_

E

+

Z1

A

_

C

ZONE 2

+

T

Z2

I

_

V

+

E

Z3

_

ZONE 3

L

+

E

Z4

D

_

S

ZONE 4

4 Way Splitter

(SC-SPL)

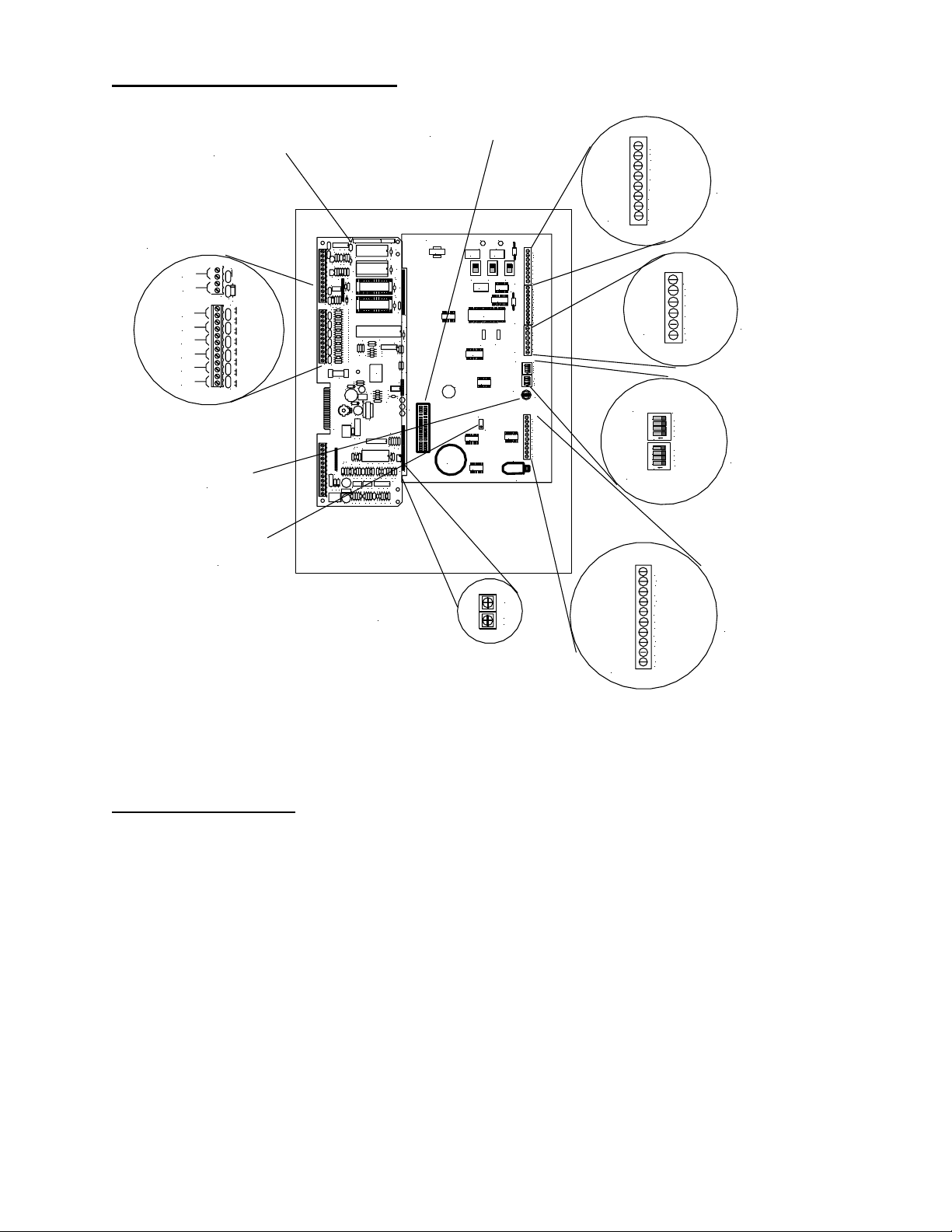

Figure 2-2.

Module Layout of a Typical Single Circuit SAFEPATH

®

Panel

2-5

Intentionally Blank

2-6

Chapter 3 - Installation and Setup

Section 3-1 - Introduction

The lives of people depend upon the safe and proper installation of the SAFEPATH® Panel. Please read,

understand and carefully follow the specific installation instructions set forth below to avoid damage to the

SAFEPATH

procedures in this manual should conduct installation.

WARNING: SHUT OFF ALL POWER BEFORE STARTING THE INSTALLATION. ELECTRICAL

WARNING: DO NOT CONNECT AC POWER OR BATTERY BACKUP POWER UNTIL SYSTEM

CAUTION: The SAFEPATH

®

Panel and equipment connected to it. Only qualified personnel in accordance with the

SHOCK CAN CAUSE DEATH OR SERIOUS INJURY.

WIRING HAS BEEN CONNECTED, MODULES HAVE BEEN INSTALLED, AND

FIELD WIRING HAS BEEN INSPECTED.

®

printed circuit boards are sensitive to static electricity and have

delicate components mounted on them. Before handling either a board or any

component on a board, discharge any static electricity from your body by touching

a grounded object such as a metal screw, which is connected to earth, ground.

Handle the board by its edges, and be careful not to twist or flex it. The

SAFEPATH

attach grounded wrist straps before touching any static sensitive areas. After

handling SAFEPATH

®

Panel is to be installed in a static free area and the user is to properly

®

printed circuit boards, verify that the printed circuit boards

are undamaged and functioning properly.

The installer, prior to installation should consult with the authorities having jurisdiction

(AHJ).

Section 3-2 - Fire Alarm Control Panel Interface Wiring Applications

The SAFEPATH® Panel can be connected to either the FACP alarm output dry contact or to the

FACP Notification Appliance Circuit (NAC). If it is connected to the NAC, then the Notification

Appliance Circuit Interface Module (NACIM) shall be used. Follow the NACIM instruction sheet

(P83478) for proper mounting and wiring.

The SAFEPATH

appliance circuit depending upon system requirements. When the SAFEPATH

a “silenceable” NAC circuit on the FACP, activating the FACP’s alarm silence switch will silence it.

The Strobe NAC circuit on the SAFEPATH

remain in alarm when the audible is silenced, the Strobe NAC circuit must be connected to a “nonsilenceable” NAC circuit on the FACP.

A SAFEPATH

FACP.

“TROUBLE”, Form C relay terminals are available for monitoring the condition of the SAFEPATH

Panel at the FACP.

®

Panel may be connected to either a “silenceable” or “non-silenceable” notification

®

Panel will also be silenced. In order for the strobes to

®

Panel connected to a “non-silenceable” NAC circuit cannot be silenced from the

®

Panel is connected to

®

3-1

Digital Voice

Module MDX-2

SECTION 1

INPUT

CONNECTIONS

IN8

IN7

IN6

IN5

IN4

IN3

IN2

IN1

EARTH

GROUND

RV8

TB 3

RV7

D11

RV6

RV5

RV4

RV3

RV2

TB 2

RV1

GROUND

FAULT

ADJUST

RV10

R73

RV9

Q2

R69

Q1

R68

RV8

TB3

RV7

R64R63 D11

RV6

RV5

RV4

RV3

RV2

TB2

RV1

J3

J2

+

C10D2

TB1

K1

P83412 REV ( )

U17

C50

R72

R71

C46

D12

C48

R70

R66

R67

D13

U13

R65

C44

D10

J6

R62

C41

R60

R59

C40

R58

R57

C39

R56

R55

C38

R54

R53

C36

R52

R43

R51

C35

R50

R49

C34

R48

R47

R42

R44

C33

R46

R45

F1

R35

R34

D9

+

C27

U7

L2

GND

EARTH

D8

E1

C21

+

K2

R32

D4

C20

C19

R25

R26

R21

R22

D3

R19

C17

R20

R18

C15

C16

C9

+

R8U1R6 C6

D1

+

C5

C8R9R2

REV: SN:

U16

C49 C47

U15

S15

C45

U14

S14

C43

U12

S12

C42

R61

J5

U11

C37

R41

C32

R38

U10

R40

C31

C30

C29

C28

R39

R36

R37

U9

U8

S8

C26

C25

C24

J4

C22

C23

R33

D7

D6

J1

D5

L1

R31

R29

R27

U6

U5

R30

R28

CH1 VOL

R24

R23

C18

R14

R13

C14

R17

C12

J1

R10

C11 R15

R12

R16

R11

C13

U3 U4

U2

R3

R4C3C1

R5 R7R1C4

C2 C7

BATTERY

CONNECTION

Amplifier Connector

D1

C16

AMBER GREEN

K2

K1

SW1 SW2 SW3

K3

U4

X2

X1

U5

U6

R53

GROUND

FAULT

ADJUST

U8

U10

D2

U1

F2

U2

U9

SAFEPATH P83167 REV B

T1

U3

P1

-

BAT

+

F1

TB1

TB2

TB3

SW4

SW5

TB5

MICROPHONE

+

TRB AUD

-

TRB COM

TRB NO

TRB NC

ALARM COM

ALARM NO

ALARM NC

TB1

+

TRB AUD

-

TRB COM

TRB NO

TRB NC

ALARM COM

ALARM NO

ALARM NC

+

DV POWER

-

+

DV STATUS

-

+

CH PLAY

-

+

LINE OUT

-

+

LINE IN

-

+

RM AUDIO

-

RM TXD

RM RXD

+

RM POWER

-

TONE SEL

4

3

2

1

1 23

CND FLT ENB

ON

4

RM ENABLE

SYNC

DV ENABLE

1 23

LAMP TEST

ON

E1

+

ALL CALL

-

+

24V

-

+

SPK AMP

-

+

STROBE

-

+

AUDIO

-

J2

TB5

SW4

SW5

TB3

4

2 3

1

ON

4

2 3

1

ON

+

ALL CALL

-

+

24V

-

+

SPK AMP

-

+

STROBE

-

+

AUDIO

-

SECTION 2

STATUS AND TROUBLE

CONNECTIONS

+

RM AUDIO

-

RM TXD

RM RXD

+

RM POWER

-

TONE SEL

3

2

1

CND FLT ENB

RM ENABLE

SYNC

DV ENABLE

LAMP TEST

SECTION 4

CONFIGURATION

DIP SWITCHES

SECTION 5

STROBE AND AUDIO

OUTPUT CONNECTIONS

SECTION 3

REMOTE MICROPHONE

STATION AND AIM-3

CONNECTIONS

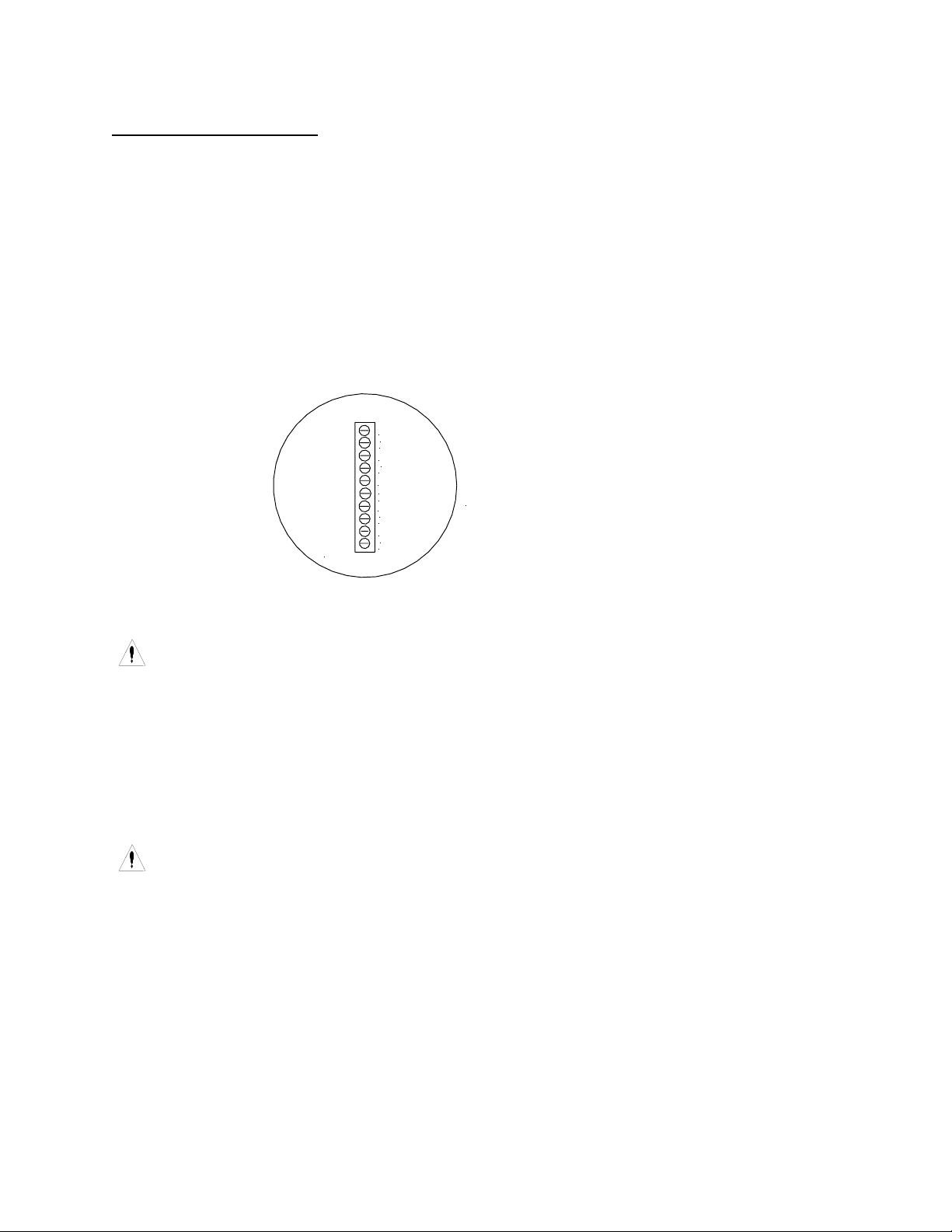

Figure 3-1

Location of Plug-in Modules and Wire Connections

Section 3-3 - General Installation Instructions

Refer to Figure 3-1, which shows the location of modules and wiring connections used in the

installation of the SAFEPATH

Prepare a System Wiring Diagram

1. Using Section 3-4, prepare a complete system-wiring diagram. Keep a copy of the system-wiring

diagram with the SAFEPATH

Unpack and Check Inventory

2. Carefully unpack the SAFEPATH® Panel and make sure each item described on the packing slip

is present and undamaged.

Mounting

3. Mount the SAFEPATH® Panel and optional expansion modules in the desired locations as

described in Section 3-5.

4. Mount any additional wiring boxes or junction boxes needed to interconnect field wiring.

®

Panel.

®

Panel manual as a permanent record of the system wiring.

3-2

Connect conduit fittings or bushings as needed through the knockouts provided on the top and

5.

bottom of the SAFEPATH

®

Panel.

Field Wiring Connections

6.

Install field wiring in conduit when required, following the most current National Electrical Code

(NFPA-70) and local codes for the type of system being installed. Make all necessary

connections at any additional wiring or junction boxes.

Wire all ancillary equipment, power connections, and Fire Alarm Control Panel correctly and

7.

prepare all wires for hookup to the SAFEPATH

NAC speaker and strobe appliance wiring to the SAFEPATH

starting with Step 13 of this procedure.

Connect supplied 10K Ohm, ¼ Watt test resistors to Strobe and Audio NAC Circuit output

8.

connections on Motherboard. (If SALL-15S amplifier module is being used, connect a 10K Ohm

¼ Watt test resistor to the SPK AMP terminals also. See Figure 3-1 on Page 3-2 for location.

Figure 3-2 is an enlarged picture of the referred area.

+

ALL CALL

-

+

24V

-

+

SPK AMP

-

+

STROBE

-

+

AUDIO

TB5

-

®

Panel. Do not connect Ancillary equipment or

Panel. This will be done

SECTION 5

STROBE AND AUDIO

OUTPUT CONNECTIONS

Figure 3-2

Strobe and Audio Output Connections

CAUTION: Provide proper strain relief for all wiring not in conduit

1. Connect the SAFEPATH Panel to earth ground, following the National Electrical Code and local

codes for the type of system being installed.

Wire gauge selection of the earth ground wiring should involve consideration of all factors, including

maximum allowable wire resistance and length. The panel is tied to earth ground by connecting the

ground terminals to an earth ground. The location of the ground terminals within the panel is shown

in Figure 3-17 on Page 3-15.

CAUTION: Do not connect input voltage to any equipment until the field wiring has been tested,

inspected and approved.

1. Check the integrity of all field wiring. Confirm that the specified cable is installed, and that there is

continuity between required points (no open circuits), with no unwanted shorts to other conductors,

chassis, or earth ground.

a. Verify that the field wiring complies with the instructions of this manual and the detailed wiring

diagram prepared for this installation.

.

b. Ensure that no unwanted voltages are present on circuit conductors and ground.

c. Test all ungrounded connectors for electrical isolation from ground.

Measure and record the resistance of each NAC circuit. Conduct this test under reverse polarity

conditions.

1. Install Amplifier Module(s) (SAA-40S, 80S/SE or SALL-15S) if removed.

3-3

Initial Checkout

WARNING: TWO DIFFERENT SOURCES OF POWER MAY BE CONNECTED TO THE

SAFEPATH

®

PANEL. DISCONNECT BOTH SOURCES OF POWER BEFORE

SERVICING. FAILURE TO DO SO COULD RESULT IN PROPERTY DAMAGE,

SERIOUS INJURY, OR DEATH TO YOU AND/OR OTHERS.

CAUTION: Connect the AC power source before connecting the battery backup power. Disconnect

the battery backup power before disconnecting the AC power source.

1. Conduct the Initial Checkout procedures as described in Section 3-6 System Checkout.

Final Checkout

2. Remove all EOLRs on Audio and Visual NAC Circuits.

3. Connect all Strobe and Speaker NAC Circuits to the proper connections on the SAFEPATH

Motherboard (SCMB). See Figure 3-2 on Page 3-3.

4. Connect all Optional Equipment to the SAFEPATH

®

Panel in accordance with each Installation

Sheet.

5. If the Strobe NAC Circuit is not being used connect a Wheelock, Inc. LISTED 10K Ohm, 1W EOLR to

the terminals on the Mother Board.

6. If Ground Fault Detection is required, connect and align according to Section 3-7 Ground Fault

Detection Sensitivity Adjustment.

7. Perform Final Checkout Procedures as described in Section 3-6 System Checkout.

®

8. Calculate and Install properly sized backup batteries. (Section 3-8)

Section 3-4 – Prepare a System Wiring Diagram

Wiring Guidelines

Although the SAFEPATH Panel products incorporate signal verification and noise filtering circuitry on

their inputs, induced voltages or noise on the input wiring can cause improper operation. Therefore, use

shielded twisted pair wire for all dry contact input wiring.

The shield of each cable should be connected only at one end. Each shield of each cable that

connects to the SAFEPATH

knockout locations on the chassis (see Figure 3-17 on Page 3-15).

The National Electrical Code (NFPA-70) defines two types of circuits for protective signaling systems:

power limited circuits and non-power limited circuits. The SAFEPATH

limited.

WARNING: ALL SAFEPATH

SHOULD BE ROUTED AWAY FROM ANY HIGH VOLYAGE OR HIGH CURRENT

WIRING (SUCH AS AC OR DC POWER WIRING, AUDIO POWER WIRING, AND

MOTOR OR RELAY ACTUATION WIRING). DRY CONTACT INPUT WIRING SHALL

BE INSTALLED IN SEPARATE CONDUIT. FAILURE TO DO SO MAY CAUSE

ELECTRICAL SHOCK RESULTING IN PROPERTY DAMAGE AND SERIOUS

INJURY OR DEATH TO YOU AND/OR OTHERS.

Panel is to be connected to the grounding points provided near the

®

Panel circuits are non-power

®

PANEL DRY CONTACT INPUT WIRING AND AUDIO WIRING

3-4

CAUTION: The National Electric Code limits the maximum number of conductors that can be

installed in conduit and wiring boxes depending on the size of the conduit, the volume

of the boxes, and the gauge of the wire used. Make sure that wiring used for

SAFEPATH

®

Panel installation complies with the latest NEC, NFPA, Local, State,

County or Province requirements.

Field Wiring Connections

®

All SAFEPATH

Panel wiring terminals are designed to accept #12 AWG through #22 AWG wiring (one

wire per terminal). Proper wire gage considerations for the NAC Circuit must take into account current

requirements versus length of run.

Prepare System Wiring Diagram

.

1. Prepare a system-wiring diagram to include all Notification Appliances, ancillary equipment, and

internal connections and power sources as required.

Visual Notification Appliance Output Wiring

Available alarm strobe current is a maximum of 2 Amps at 24VDC. Table 3-1 shows available strobe

current using the standard calculation for a Temporal Code 3 signal. The SAFEPATH

®

Panel does

not include any optional modules. Complete calculation information for other configurations is located

in Section 3-8 Backup Battery Calculations.

Wire gauge may vary for each visual notification appliance output circuit on the panel. Wire gauge

selection should involve consideration of all factors including, wire loop length, maximum current draw of

each appliance, number of appliances, and maximum voltage drop allowable.

• Strobe NAC has a 24VDC, 2.0 amps maximum output

• Strobe NAC meets Class B supervision requirements for notification appliance circuits.

• Each output circuit shall have a UL LISTED, 10K Ohm, 1W, EOLR installed across the last visual

notification appliance. If the output is unused, a UL LISTED, 10K Ohm, 1W, EOLR shall be

placed across the output terminals. Each amplifier module contains the required number for the

supervised outputs. If more are needed, recommend using Wheelock, Inc. End of Line Resistor

Kit (Model Number EOLK, Part# 5076), which contains Eight (8) UL LISTED 10K Ohm 1W

resistors.

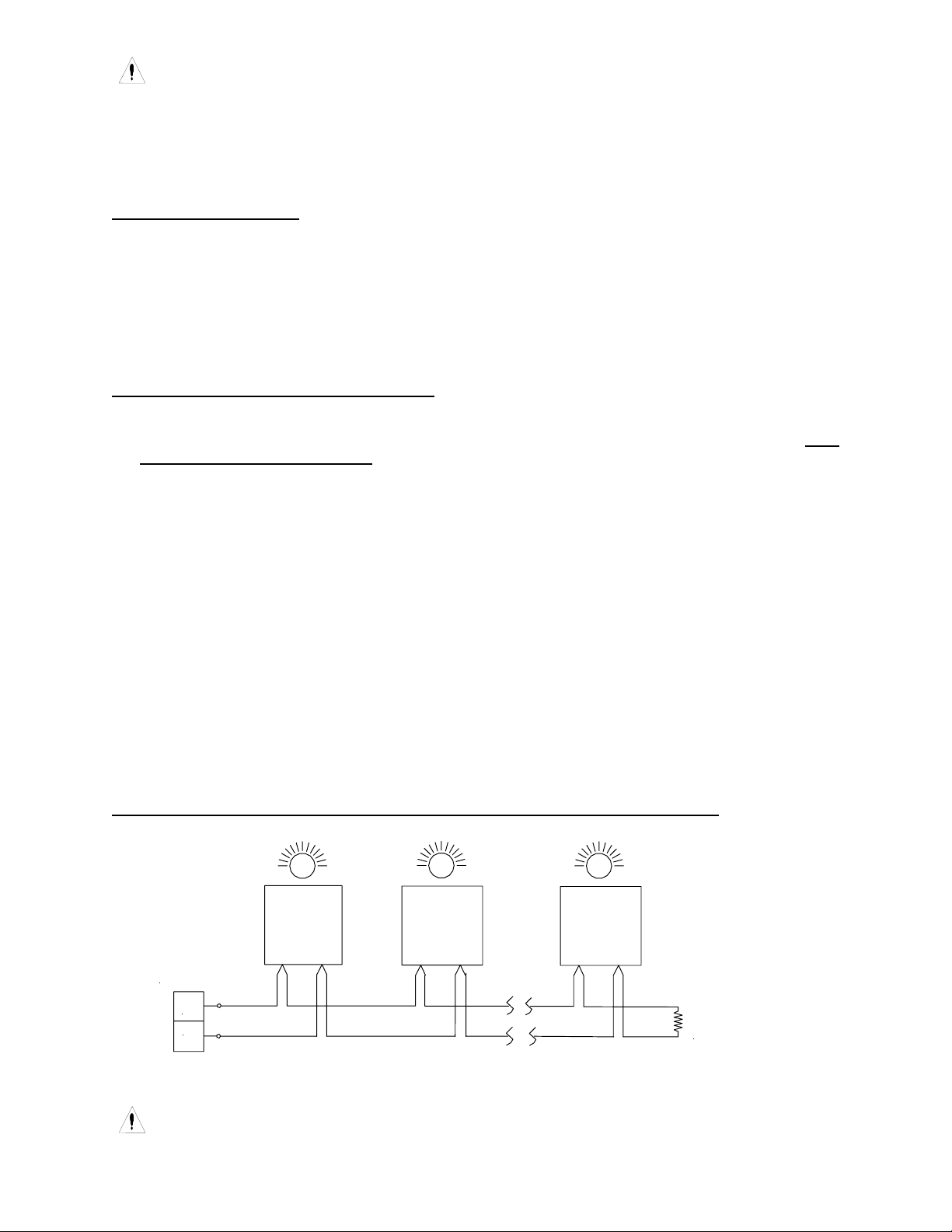

Wiring Diagrams for Visual Portion of Audio/Visual Notification Appliances

STROBE

+

_

Figure 3-3

Wiring Diagram for Visual Notification Appliance Output

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of

connection.

UL LISTED 10K Ohm

1W EOLR

3-5

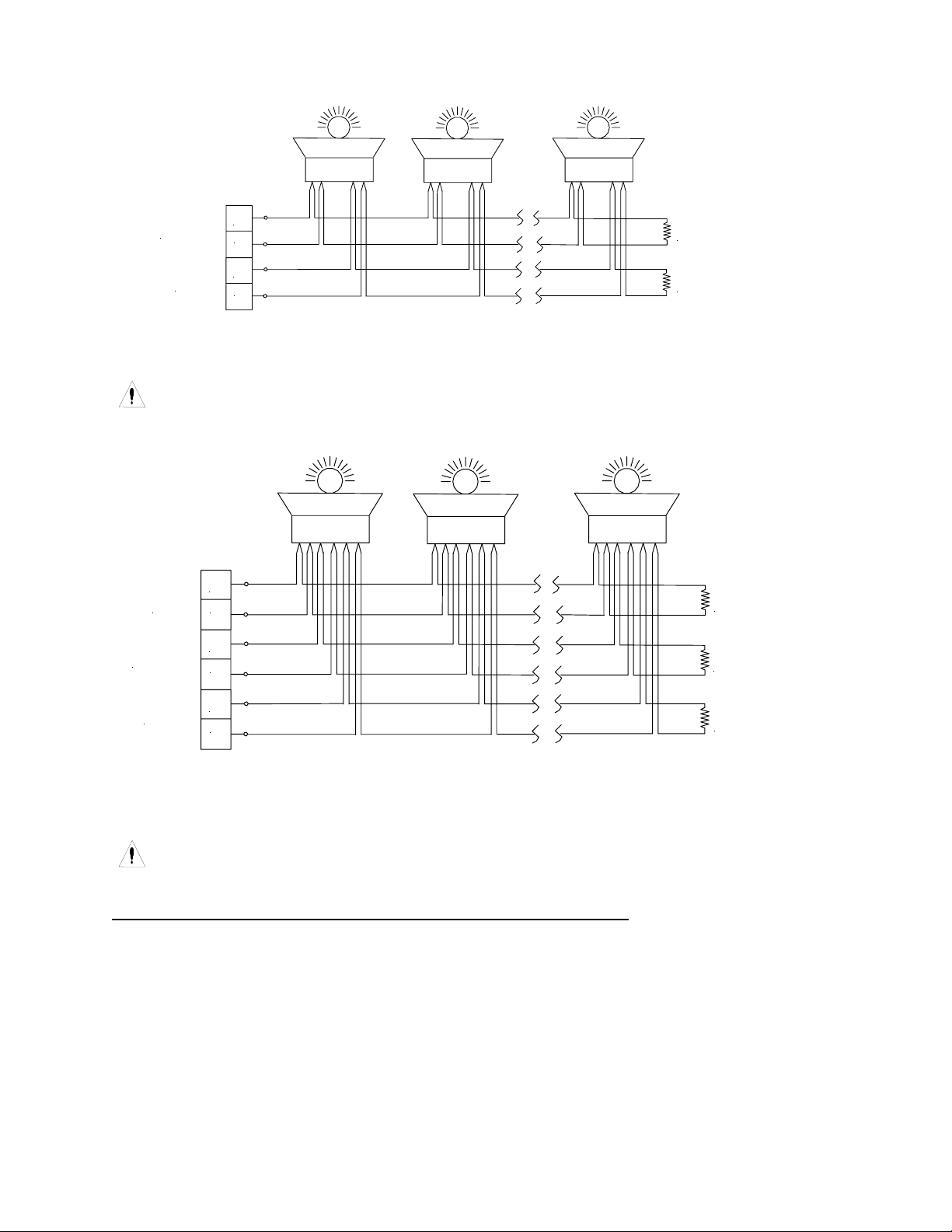

STROBE

_

+

+

AUDIO

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of

connection.

SPKR

AMP

_

Figure 3-4

Wiring Diagram for Combination Audio/Visual Notification

Appliances in Central Amplifier Applications

+

_

+

STROBE

_

UL LISTED 10K Ohm

1W EOLR

UL LISTED 10K Ohm

1W EOLR

UL LISTED 10K Ohm

1W EOLR

UL LISTED 10K Ohm

1W EOLR

AUDIO

+

_

UL LISTED 10K Ohm

1W EOLR

Figure 3-5

Wiring Diagram for Combination Audio/Visual Notification

Appliances in Amplified Speaker Applications

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of

connection.

Central Amplified Speaker Notification Appliance Output Wiring

The audio alarm current of the amplifier module depends on the number of speakers on the circuit, length

and gauge of wire of the audio circuit, and the audio mode in use.

When laying out each NAC circuit for the speakers, calculate the total wattage required. A good

engineering practice is to not exceed 85% of the amplifier rating that you plan to use. If your calculations

exceed this, an amplifier having increased power capacity is required or replacing the entire SAFEPATH

Panel with greater capacity.

Wire gauge may vary for each audio appliance output on the panel. When:

• Speaker (with transformer) appliances are used with supervised audio amplifier module

(central amplified outputs). Wire gauge selection should involve consideration of all

factors including, wire length, appliance power ratings, and the number of appliances.

®

3-6

• The central amplified output is either a selectable 25, 70.7 or a 100 volt audio output,

rated for 40, or 80 watts maximum, depending upon the amplifier and its configuration.

• The output meets Class B supervision requirements for notification appliance circuits.

• Each output circuit shall have a UL LISTED, 10K Ohm, 1W EOLR installed across the

last audio notification appliance. If the output is unused, it shall have a UL LISTED, 10K

Ohm, 1W EOLR across the output terminals. Each amplifier module contains the required

number for the supervised outputs. If more are needed, recommend using Wheelock, Inc.

End of Line Resistor Kit (Model Number EOLK, Part# 5076), which contains Eight (8) UL

LISTED 10K Ohm 1W resistors.

Wiring Diagrams for the Audio Portion of Audio/Visual Notification Appliances

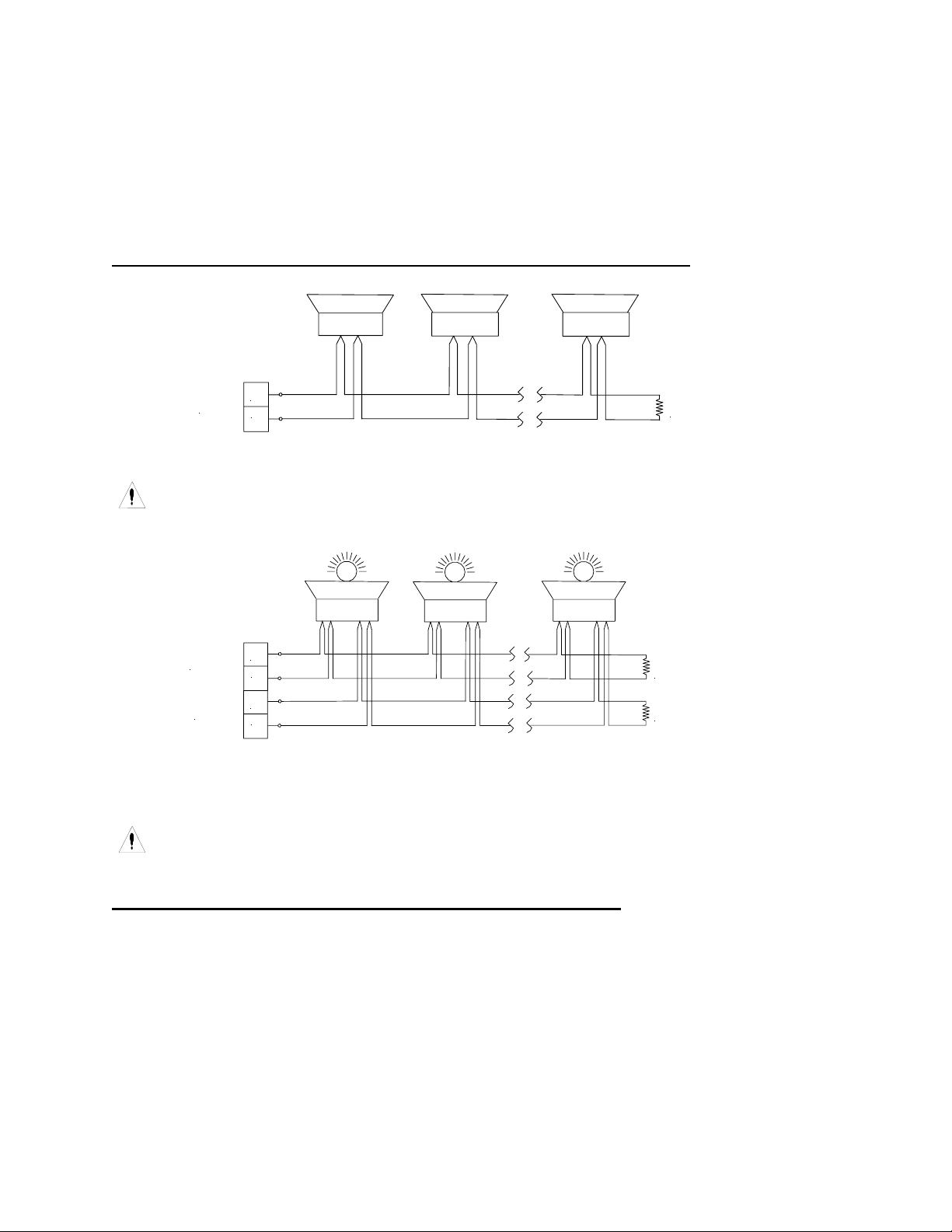

AUDIO

+

_

UL LISTED 10K Ohm

1W EOLR

Figure 3-6

Wiring Diagram for Audio Notification Appliance Output

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of

connection.

STROBE

AUDIO

+

_

+

_

Figure 3-7

Wiring Diagram for Combination Audio/Visual Notification Appliances

in Central Amplifier Applications

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of

connection.

UL LISTED 10K Ohm

1W EOLR

UL LISTED 10K Ohm

1W EOLR

Amplified Speaker Notification Appliance Power Output Wiring

Wire gauge selection for the amplified speaker notification appliance power output should involve

consideration of all factors including wire loop length, maximum current draw of each appliance,

number of appliances, and maximum voltage drop allowable.

• The Speaker Amp (SPK AMP) output is rated for 24VDC, 2.0 amps maximum.

• The output meets Class B supervision requirements for notification appliance circuits.

• The amplified speaker output is 15 Ohms, -5dBm maximum.

• Each output circuit shall have a UL LISTED, 10K Ohm, 1W EOLR installed across

the last appliance. All unused outputs shall have a UL LISTED, 10K Ohm, 1W EOLR

across the output terminals. Each amplifier module contains the required number for

the supervised outputs. If more are needed, recommend using Wheelock, Inc. End of

Line Resistor Kit (Model Number EOLK, Part# 5076), which contains Eight (8) UL

LISTED 10K Ohm 1W resistors.

3-7

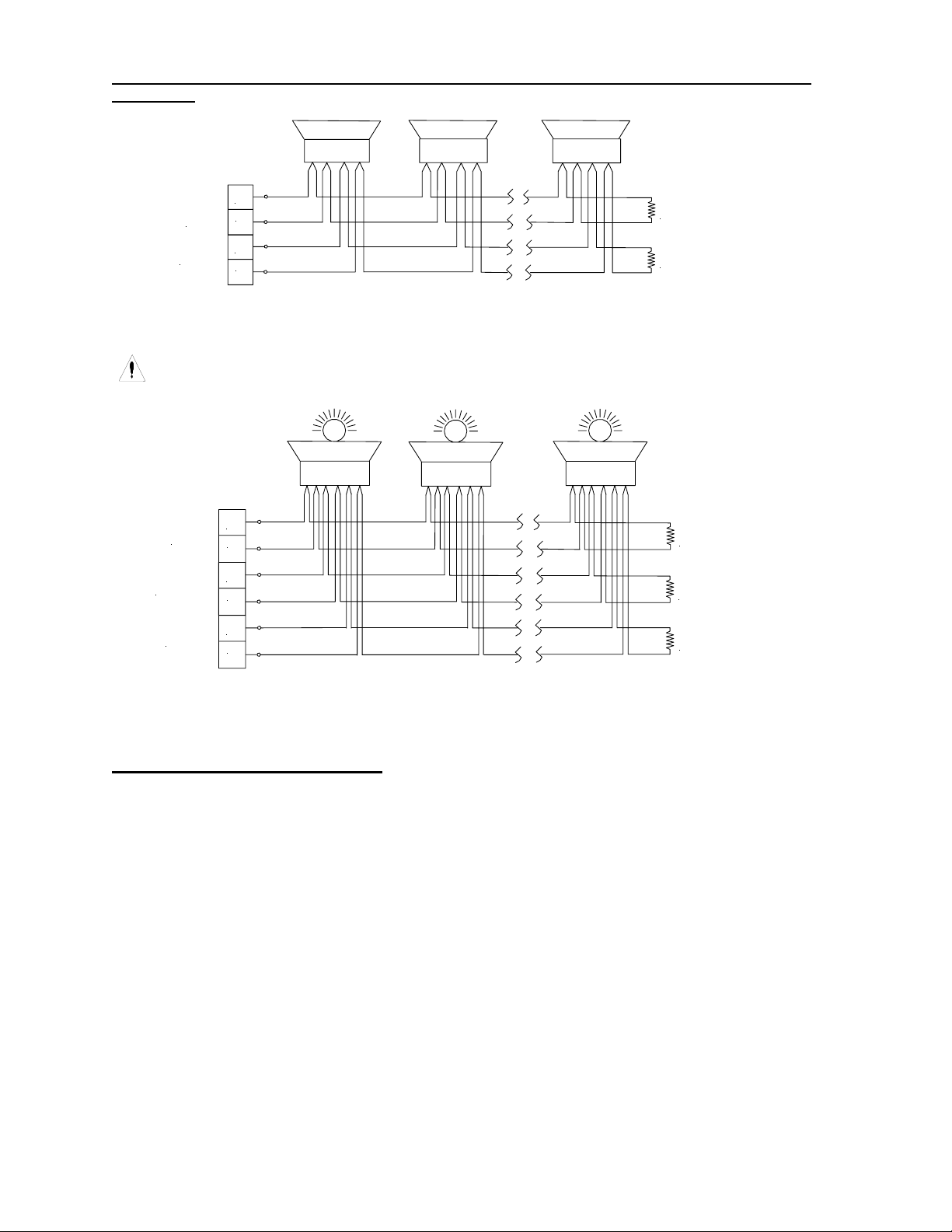

Wiring Diagrams for Audio and SPK AMP Portions of Self-Amplified Audio/Visual Notification

Appliances

SPKR

AMP

AUDIO

+

_

+

_

UL LISTED 10K Ohm

1W EOLR

UL LISTED 10K Ohm

1W EOLR

Figure 3-8

Wiring Diagram for Audio Notification Appliances

in Amplified Speaker Applications

CAUTION: Do not loop wire under terminals. Break wire run to provide supervision of

SPKR

AMP

connection

+

_

+

STROBE

AUDIO

_

+

_

Figure 3-9

Wiring Diagram for Combination Audio/Visual Notification Appliances

in Amplified Speaker Applications

UL LISTED 10K Ohm

1W EOLR

UL LISTED 10K Ohm

1W EOLR

UL LISTED 10K Ohm

1W EOLR

Optional Equipment Connections

Remote Microphone Station (RMS-2)

See the Remote Microphone Station instruction sheet P83270 for additional information.

Notification Appliance Circuit Interface Module (NACIM)

See the Notification Appliance Circuit Interface Module instruction sheet P83487 for additional

information.

4 Zone Splitter (SC-SPL)

See the Four Zone Splitter instruction sheet P83439 for additional information.

Auxiliary Interface Module (AIM-3)

See the Auxiliary Interface Module instruction sheet P83667 for additional information.

3-8

INTERNAL WIRING CONNECTIONS

Digital Voice

Module MDX-2

SECTION 1

INPUT

CONNECTIONS

IN8

IN7

IN6

IN5

IN4

IN3

IN2

IN1

EARTH

GROUND

RV8

TB 3

RV7

D11

RV6

RV5

RV4

RV3

RV2

TB 2

RV1

GROUND

FAULT

ADJUST

RV10

R73

RV9

Q2

R69

Q1

R68

RV8

TB3

RV7

R64R63 D11

RV6

RV5

RV4

RV3

RV2

TB2

RV1

J3

J2

+

C10D2

TB1

K1

P83412 REV ( )

U17

C50

R72

R71

C46

D12

C48

R70

R66

R67

D13

U13

R65

C44

D10

J6

R62

C41

R60

R59

C40

R58

R57

C39

R56

R55

C38

R54

R53

C36

R52

R43

R51

C35

R50

R49

C34

R48

R47

R42

R44

C33

R46

R45

F1

R35

R34

D9

+

C27

U7

L2

GND

EARTH

D8

E1

C21

+

K2

R32

D4

C20

C19

R25

R26

R21

R22

D3

R19

C17

R20

R18

C15

C16

C9

+

R8U1R6 C6

D1

+

C5

C8R9R2

REV: SN:

U16

C49 C47

U15

S15

C45

U14

S14

C43

U12

S12

C42

R61

J5

U11

C37

R41

C32

R38

U10

R40

C31

C30

C29

C28

R39

R36

R37

U9

U8

S8

C26

C25

C24

J4

C22

C23

R33

D7

D6

J1

D5

L1

R31

R29

R27

U6

U5

R30

R28

CH1 VOL

R24

R23

C18

R14

R13

C14

R17

C12

J1

R10

C11 R15

R12

R16

R11

C13

U3 U4

U2

R3

R4C3C1

R5 R7R1C4

C2 C7

BATTERY

CONNECTION

Amplifier Connector

D1

C16

AMBER GREEN

K2

K1

SW1 SW2 SW3

K3

U4

X2

X1

U5

U6

R53

GROUND

FAULT

ADJUST

U8

U10

D2

U1

F2

U2

U9

SAFEPATH P83167 REV B

T1

U3

P1

-

BAT

+

F1

TB1

TB2

TB3

SW4

SW5

TB5

MICROPHONE

+

TRB AUD

-

TRB COM

TRB NO

TRB NC

ALARM COM

ALARM NO

ALARM NC

TB1

+

TRB AUD

-

TRB COM

TRB NO

TRB NC

ALARM COM

ALARM NO

ALARM NC

+

DV POWER

-

+

DV STATUS

-

+

CH PLAY

-

+

LINE OUT

-

+

LINE IN

-

+

RM AUDIO

-

RM TXD

RM RXD

+

RM POWER

-

TONE SEL

4

3

2

1

1 23

CND FLT ENB

ON

4

RM ENABLE

SYNC

DV ENABLE

1 23

LAMP TEST

ON

E1

+

ALL CALL

-

+

24V

-

+

SPK AMP

-

+

STROBE

-

+

AUDIO

-

J2

TB5

SW4

SW5

TB3

4

2 3

1

ON

4

2 3

1

ON

+

ALL CALL

-

+

24V

-

+

SPK AMP

-

+

STROBE

-

+

AUDIO

-

SECTION 2

STATUS AND TROUBLE

CONNECTIONS

+

RM AUDIO

-

RM TXD

RM RXD

+

RM POWER

-

TONE SEL

3

2

1

CND FLT ENB

RM ENABLE

SYNC

DV ENABLE

LAMP TEST

SECTION 4

CONFIGURATION

DIP SWITCHES

SECTION 5

STROBE AND AUDIO

OUTPUT CONNECTIONS

SECTION 3

REMOTE MICROPHONE

STATION AND AIM-3

CONNECTIONS

Figure 3-10

Wiring Connection Locations

Dry Contact Input Wiring

The dry contact inputs shall be dry contacts or open collector of a transistor. The locations of the dry

contact inputs are shown in Figure 3-10 Section 1. A magnified view of this area on the Motherboard

(SCMB) is shown in Figure 3-11 on Page 3-11.

• The dry contact input meets the requirements for non-power limited fire protective signaling

circuits as defined in the National Electrical Code. The dry contact inputs are unsupervised.

• The field wiring for the dry contact input shall not exceed 100 Ohms of resistance or 0.050 µF of

capacitance.

• IN1 through IN8 are the contact closure inputs for as many as 8 separate messages. As shown in

Figure 3-11.

3-9

Loading...

Loading...