Western Digital H4102-J User Manual

User Guide

Ultrastar Data102

Regulatory Model: H4102-J

December 2020

Rev. 1.18

1ET1094

User Guide Table of Contents

Table of Contents

Revision History.................................................................................................................................... vi

Notices....................................................................................................................................................x

Points of Contact.................................................................................................................................. xi

Product Label Information..............................................................................................................xi

Chapter 1. Overview.........................................................................................................1

Ultrastar Data102 Description..............................................................................................................2

System Architecture Overview........................................................................................................... 2

System Level Block Diagram...............................................................................................................3

Environmental Specifications...............................................................................................................3

Electrical Specifications....................................................................................................................... 4

Mechanical Specifications....................................................................................................................4

Performance Specifications................................................................................................................. 5

Ultrastar Data102 Layout......................................................................................................................5

List of Customer Replaceable Units (CRUs).......................................................................................7

Supported Operating Systems........................................................................................................... 8

LEDs.......................................................................................................................................................9

Front and Rear IO LEDs................................................................................................................9

IOM LEDs.......................................................................................................................................11

IOM Fan LED................................................................................................................................. 11

PSU LED........................................................................................................................................12

Rear Fan LED................................................................................................................................13

Drive Assembly LED.................................................................................................................... 14

Ultrastar Data102 Rack Requirements............................................................................................... 15

Compatible Rack Hardware Configuration................................................................................17

Power Requirements.......................................................................................................................... 19

ESD....................................................................................................................................................... 19

Enclosure Cooling...............................................................................................................................19

i

User Guide Table of Contents

SAS Cabling........................................................................................................................................20

Supported SKUs................................................................................................................................. 22

List of Compatible Drives..................................................................................................................22

Chapter 2. Components................................................................................................34

Chassis.................................................................................................................................................35

Chassis Specifications................................................................................................................ 35

Chassis Layout.............................................................................................................................36

IOM...................................................................................................................................................... 38

IOM Specifications...................................................................................................................... 38

IOM Layout.................................................................................................................................. 39

IOM Blank.....................................................................................................................................39

PSU...................................................................................................................................................... 40

PSU Specifications...................................................................................................................... 40

PSU Layout................................................................................................................................... 41

Rear Fan.............................................................................................................................................. 42

Rear Fan Specifications.............................................................................................................. 42

Rear Fan Layout.......................................................................................................................... 43

IOM Fan............................................................................................................................................... 44

IOM Fan Specifications............................................................................................................... 44

IOM Fan Layout........................................................................................................................... 45

Rails......................................................................................................................................................46

Rails Specifications..................................................................................................................... 46

Rails Layout..................................................................................................................................47

Rear Cover Alignment Bracket.................................................................................................. 48

CMA..................................................................................................................................................... 49

CMA Specifications..................................................................................................................... 49

CMA Layout.................................................................................................................................50

CMA Cable Tray...........................................................................................................................51

CMA Lite............................................................................................................................................. 52

ii

User Guide Table of Contents

CMA Lite Specifications............................................................................................................. 52

CMA Lite Layout..........................................................................................................................53

3.5in HDD Assembly.......................................................................................................................... 54

3.5in HDD Assembly Specifications.......................................................................................... 54

3.5in HDD Assembly Layout...................................................................................................... 55

3.5in Drive Blank......................................................................................................................... 56

2.5in SSD Assembly............................................................................................................................57

Operating the 2.5" Drive Carrier............................................................................................... 57

Chapter 3. Support........................................................................................................60

Part Replacement Service Window.................................................................................................. 61

IOM Replacement............................................................................................................................... 61

PSU Replacement...............................................................................................................................64

Rear Fan Replacement.......................................................................................................................68

IOM Fan Replacement........................................................................................................................ 71

3.5in HDD Assembly Replacement................................................................................................... 73

CMA Replacement..............................................................................................................................77

Rails Replacement............................................................................................................................ 100

Chassis Replacement........................................................................................................................132

Special Considerations for Cable Routing.......................................................................................171

Cabling for CMA Standard and CMA Lite....................................................................................... 173

Before You Begin....................................................................................................................... 173

Cabling CMA Standard..............................................................................................................174

Cable Configuration for CMA Lite............................................................................................175

Chapter 4. Management.............................................................................................. 177

Management Overview.................................................................................................................... 178

Firmware Features Overview.......................................................................................................... 178

Firmware Upgrade............................................................................................................................ 179

Downloading Firmware from the Support Portal....................................................................179

iii

User Guide Table of Contents

Linux Upgrade Preparation........................................................................................................181

Linux Upgrade to New Firmware.............................................................................................183

Non-Automatic Firmware Activation in Linux.......................................................................... 185

Windows Firmware Upgrade Preparation...............................................................................187

Windows Upgrade to New Firmware..................................................................................... 188

Non-Automatic Firmware Activation in Windows................................................................... 191

OOBM Management Overview........................................................................................................ 194

Configuring OOBM Network Settings Using SES....................................................................194

Upgrading Firmware with OOBM.............................................................................................196

SES Page 02...................................................................................................................................... 198

Zoning................................................................................................................................................198

Before Zoning............................................................................................................................ 198

Predefined Zoning Configurations........................................................................................... 198

sg_senddiag Command...........................................................................................................205

Enabling Zoning using Linux....................................................................................................205

Disabling Zoning using Linux...................................................................................................209

Enabling Zoning using Windows.............................................................................................212

Disabling Zoning using Windows............................................................................................215

File-Based Zoning......................................................................................................................219

Subenclosure Nickname.................................................................................................................. 229

Setting the Subenclosure Nickname....................................................................................... 229

Partially Populated Enclosures.........................................................................................................231

Partial Population Configurations............................................................................................. 231

Installing Drives......................................................................................................................... 234

Daisy Chaining.................................................................................................................................. 238

Daisy Chaining Configurations.................................................................................................238

One Host Cable Configurations.............................................................................................. 239

Two Host Cable Configurations.............................................................................................. 245

iv

User Guide Table of Contents

Cabling for Daisy Chaining...................................................................................................... 250

Chapter 5. Safety.........................................................................................................257

Safety Warnings and Cautions........................................................................................................258

Electrostatic Discharge....................................................................................................................258

Optimizing Location.........................................................................................................................258

Power Connections..........................................................................................................................259

Power Cords.....................................................................................................................................259

Rackmountable Systems..................................................................................................................259

Safety and Service........................................................................................................................... 260

Chapter 6. Disclaimers.................................................................................................261

Restricted Access Location.............................................................................................................262

Safety Compliance........................................................................................................................... 262

Electromagnetic Compatibility (EMC) Class A Compliance......................................................... 262

Country Certifications...................................................................................................................... 263

Chapter 7. Regulatory Statements............................................................................264

Europe (CE Declaration of Conformity)..........................................................................................265

FCC Class A Notice......................................................................................................................... 265

ICES-003 Class A Notice—Avis NMB-003, Classe A..................................................................... 265

Japanese Compliance Statement, Class A ITE.............................................................................. 265

Taiwan Warning Label Statement, Class A ITE.............................................................................. 266

v

User Guide Revision History

Revision History

Date Revision Comment

November 2017 1.0 Initial release

November 2017 1.1

December 2017 1.2

January 2018 1.2.1 Updated the product name

January 2018 1.3

• The crossbar on the CMA was changed. See CMA (page 49).

• Removed Lowline power specs from Power Requirements (page

19).

• Changed required rack depth, see Mechanical Specifications (page

4).

• Changed typical power consumption, see Electrical Specifications

(page 4).

• Updated LED Flash Patterns, see LEDs (page 9).

• Added active cable support

• Added firmware upgrade section. See Firmware Upgrade (page

179).

• Updated the Non-Op altitude specification. See Environmental

Specifications (page 3).

• Updated information on the 2.5" drive carrier option. See 2.5in SSD

Assembly (page 57).

• Added torque requirements for all screws used in the enclosure.

• Updated the IOM replacement section to account for the possibility

of a firmware mismatch. See IOM Replacement (page 61).

• Updated the drive assembly installation instructions to clarify

the orientation of the drive assemblies. 3.5in HDD Assembly

Replacement (page 73).

April 2018 1.4

May 2018 1.5 Added the Part Replacement Service Window. See: Part Replacement

June 2018 1.6

• Updated Compatible Drives List. See List of Compatible Drives

(page 22).

• Updated the Rack Requirements. See Ultrastar Data102 Rack

Requirements (page 15).

• Updated the Firmware Upgrades. See: Firmware Upgrade (page

179)

Service Window (page 61)

• Updated Compatible Drives List. See List of Compatible Drives

(page 22)

• Updated the Firmware Upgrade section. See Firmware Upgrade

(page 179)

vi

User Guide Revision History

Date Revision Comment

• Updated the Firmware Download section. See Downloading

Firmware from the Support Portal (page 179)

• Updated the System Architecture Overview section. See System

Architecture Overview (page 2)

• Updated the Daisy Chaining section. See Daisy Chaining (page

238)

• Added the Rear Cover Alignment Bracket Description. See Rear

Cover Alignment Bracket (page 48)

November 2018 1.7

May 2019 1.8

May 2019 1.9

June 2019 1.10

• Updated the images in the Daisy Chaining section. See Daisy

Chaining (page 238)

• Updated List of CRUs. See List of Customer Replaceable Units

(CRUs) (page 7)

• Updated Compatible Drives List. See List of Compatible Drives

(page 22)

• Updated the Host Connectivity section. See: SAS Cabling (page

20)

• Changed senddiag commands from images to codeblocks. See

sg_senddiag Command (page 205).

• Updated daisy-chaining tables to match diagrams. See Two Host

Cable Configurations (page 245).

• Corrected OOBM zoning configuration instructions. See Predefined

Zoning Configurations (page 198).

• Added Configuring OOBM Network Settings Using SES (page

194).

• Corrected explanation of SATA configuration in Firmware Upgrade

(page 179) section.

• Updated the Host Connectivity section. See: SAS Cabling (page

20)

• Added Windows syntax examples and reorganized the Upgrading

Firmware with OOBM section

June 2019 1.11 Updated the Host Connectivity section. See: SAS Cabling (page 20)

July 2019 1.12

Moved the following topics to the Ultrastar Data102 Description (page

2) section:

• Ultrastar Data102 Rack Requirements (page 15)

• Power Requirements (page 19)

• ESD (page 19)

• Enclosure Cooling (page 19)

• SAS Cabling (page 20)

vii

User Guide Revision History

Date Revision Comment

Moved the Supported Operating Systems (page 8) topic to the

Management (page 177) section.

Corrected LED identification tables for IOMs, PSUs, and drives in the

LEDs (page 9) section.

Updated servicing image to correct length values and rail servicing

extension in Ultrastar Data102 Rack Requirements (page 15) section.

Updated the following for CMA Lite:

• Added CMA Lite Component Overview (page 52) section,

including description, specs, and layout.

• Updated CMA Replacement (page 77) section to combine CMA

Standard and CMA Lite content where applicable.

• Updated Maximum HD Mini-SAS Configuration (page 175) section.

Added a note about OOBM ports configured for DHCP by default to the

OOBM Management Overview (page 194) section.

September 2019 1.13

November 2019 1.14

April 2020 1.15

• Replaced references to He12 drives with Ultrastrar DC HC520 in List

of Compatible Drives (page 22)

• Changed device references from OS-specific (/dev/sgX for Linux

and SCSIX:X,X,X for Windows) to generic (<dev>) throughout.

• Updated table for Approved SAS Cables in SAS Cabling (page

20)

• Added Subenclosure Nickname (page 229) section

• Updated Supported Operating Systems (page 8)

• Updated images of captive chassis-cover screws throughout

• Updated table for Approved SAS Cables in SAS Cabling (page

20)

• Updated the Daisy Chaining configurations in Daisy Chaining (page

238)

• Added note about using non-automatic firmware activation for RAID

adpaters in Firmware Upgrade (page 179)

• Added note about performing zoning offline in Zoning (page 198)

• Added note and step for configuring zoning on an IOM after

replacement in IOM Replacement (page 61)

• Added RHEL 8.0 to Supported Operating Systems (page 8)

• Added note about LED behavior during proper drive insertion in

Drive Assembly LED (page 14)

• Added note about minimum time between removing and

reapplying power in Power Connections (page 259)

August 2020 1.16

• Updated Supported Operating Systems (page 8)

• Updated SAS Cabling (page 20)

viii

User Guide Revision History

Date Revision Comment

• Updated List of Compatible Drives (page 22)

• Added File-Based Zoning (page 219) section

• Updated note in IOM Replacement (page 61) about standard vs.

file-based zoning configuration after IOM replacement

October 2020 1.17

December 2020 1.18

• Fixed typo in Rails Layout (page 47)

• Updated text and color-coded images in Predefined Zoning

Configurations (page 198)

• Updated images in LEDs (page 9) and Components (page

34)

• Added note about not unzipping tar.gz file prior to firmware

upgrade in Downloading Firmware from the Support Portal

(page 179), Linux Upgrade to New Firmware (page 183), Non-

Automatic Firmware Activation in Linux (page 185), Windows

Upgrade to New Firmware (page 188), and Non-Automatic

Firmware Activation in Windows (page 191)

• Added Ubuntu 20.04 to Supported Operating Systems (page 8)

• Updated table of approved SAS cables in SAS Cabling (page 20)

• Updated FW activation step in Upgrading Firmware with OOBM

(page 196)

• Added UK Import Representation Contact

• Removed Formerica cables from SAS Cabling (page 20)

ix

User Guide Notices

Notices

Western Digital Technologies, Inc. or its affiliates' (collectively “Western Digital”) general policy does not

recommend the use of its products in life support applications wherein a failure or malfunction of the product

may directly threaten life or injury. Per Western Digital Terms and Conditions of Sale, the user of Western

Digital products in life support applications assumes all risk of such use and indemnifies Western Digital

against all damages.

This document is for information use only and is subject to change without prior notice. Western Digital

assumes no responsibility for any errors that may appear in this document, nor for incidental or consequential

damages resulting from the furnishing, performance or use of this material.

Absent a written agreement signed by Western Digital or its authorized representative to the contrary,

Western Digital explicitly disclaims any express and implied warranties and indemnities of any kind that may,

or could, be associated with this document and related material, and any user of this document or related

material agrees to such disclaimer as a precondition to receipt and usage hereof.

Each user of this document or any product referred to herein expressly waives all guaranties and warranties

of any kind associated with this document any related materials or such product, whether expressed or

implied, including without limitation, any implied warranty of merchantability or fitness for a particular

purpose or non-infringement. Each user of this document or any product referred to herein also expressly

agrees Western Digital shall not be liable for any incidental, punitive, indirect, special, or consequential

damages, including without limitation physical injury or death, property damage, lost data, loss of profits or

costs of procurement of substitute goods, technology, or services, arising out of or related to this document,

any related materials or any product referred to herein, regardless of whether such damages are based on

tort, warranty, contract, or any other legal theory, even if advised of the possibility of such damages.

This document and its contents, including diagrams, schematics, methodology, work product, and

intellectual property rights described in, associated with, or implied by this document, are the sole and

exclusive property of Western Digital. No intellectual property license, express or implied, is granted by

Western Digital associated with the document recipient's receipt, access and/or use of this document or the

products referred to herein; Western Digital retains all rights hereto.

Western Digital, the Western Digital logo, and Ultrastar are registered trademarks or trademarks of Western

Digital Corporation or its affiliates in the US and/or other countries. Linux® is the registered trademark of

Linus Torvalds in the U.S. and other countries. All other marks are the property of their respective owners.

Product specifications subject to change without notice. Pictures shown may vary from actual products. Not

all products are available in all regions of the world.

Western Digital

5601 Great Oaks Parkway

San Jose, CA 95119

© 2020 Western Digital Corporation or its affiliates. All Rights Reserved.

x

User Guide Points of Contact

Points of Contact

For further assistance with a Western Digital product, contact Western Digital Datacenter Platforms technical

support. Please be prepared to provide the following information: part number (P/N), serial number (S/N),

product name and/or model number, and a brief description of the issue.

Email:

support@wdc.com

Website:

https://portal.wdc.com/Support/s/

UK Import Representation Contact

Western Digital UK Limited Hamilton House, Regent Park, Kingston Road Leatherhead, Surrey KT22 7PL, GB,

United Kingdom

Telephone: +44 1372 366000

1.1 Product Label Information

The following product information is required for technical support requests:

• Part Number (P/N)

• Serial Number (S/N)

• Product Name and/or Model Number (MODEL)

This information may be found on the product label, which is affixed to an exterior, non-removable surface of

the chassis. The following is an example label with the applicable information fields highlighted:

xi

Western Digital

Overview

This section provides a high level overview of the features of the

Ultrastar Data102 .

In This Chapter:

- System Architecture Overview.....................2

- System Level Block Diagram.........................2

- Environmental Specifications........................3

- Electrical Specifications................................ 3

- Mechanical Specifications............................. 4

- Performance Specifications...........................4

- Ultrastar Data102 Layout............................... 5

- List of Customer Replaceable Units

(CRUs)............................................................... 5

- Supported Operating Systems......................7

- LEDs................................................................. 8

- Ultrastar Data102 Rack Requirements..........9

- Power Requirements.................................... 15

- ESD..................................................................19

- Enclosure Cooling.........................................19

- SAS Cabling................................................... 19

- Supported SKUs........................................... 20

- List of Compatible Drives............................22

1

User Guide

1.1 Ultrastar Data102 Description

Figure 2: Ultrastar Data102

1. Overview

1.1 Ultrastar Data102 Description

The Ultrastar Data102 is a 4U form factor, high availability, high density, rack-mounted storage enclosure

that is capable of hosting up to 102 SAS or SATA drives. The maximum data storage capacity of the Ultrastar

Data102 is 1.428 PB using 14TB HGST Ultrastar® HC530 drives . (For a full list of compatible drives and total

storage capacities, see the List of Compatible Drives (page 22).) The enclosure runs on an input voltage

of 200 - 240 VAC and consumes ~1300W of power under typical conditions. It requires a maximum of

~1600W at full load.

It is designed to fit within a 4U rack space and requires 1181-1197 mm (46.5in. - 47.13in.) of usable rack space,

frame to frame. A fully loaded system will add 118.8 kg / 262 lbs. of static load when fully loaded with drives.

• 4U Storage Enclosure

• Supports up to 102 Drives

• Can support 3.5” drives and 2.5” SSD drives (2.5" requires an adapter) in the 102 available drive bays.

• Up to 12W per drive slot for the 102 data storage drives (Cannot exceed 85A on the 5V rail)

• House and control four (4) N+1 redundant 80mm rear fans

• House and control a dual rotor 40mm internal IOM Fan

• Controlled by two (2) redundant I/O Modules

• Powered by two (2) redundant 1600W PSUs

• Supports High Line (220-240 VAC) Input Power

• Full high availability with independent dual paths to all HDDs

• Toolless replacement of all Customer Replaceable Units (CRUs)

• Fits within a standard EIA-310 rack including all necessary cable management (see Compatible Rack

Hardware Configuration (page 17))

• Supports up to 3m passive SAS cables (limited to 3m or less) or active cables (any length) (see SAS

Cabling (page 20))

1

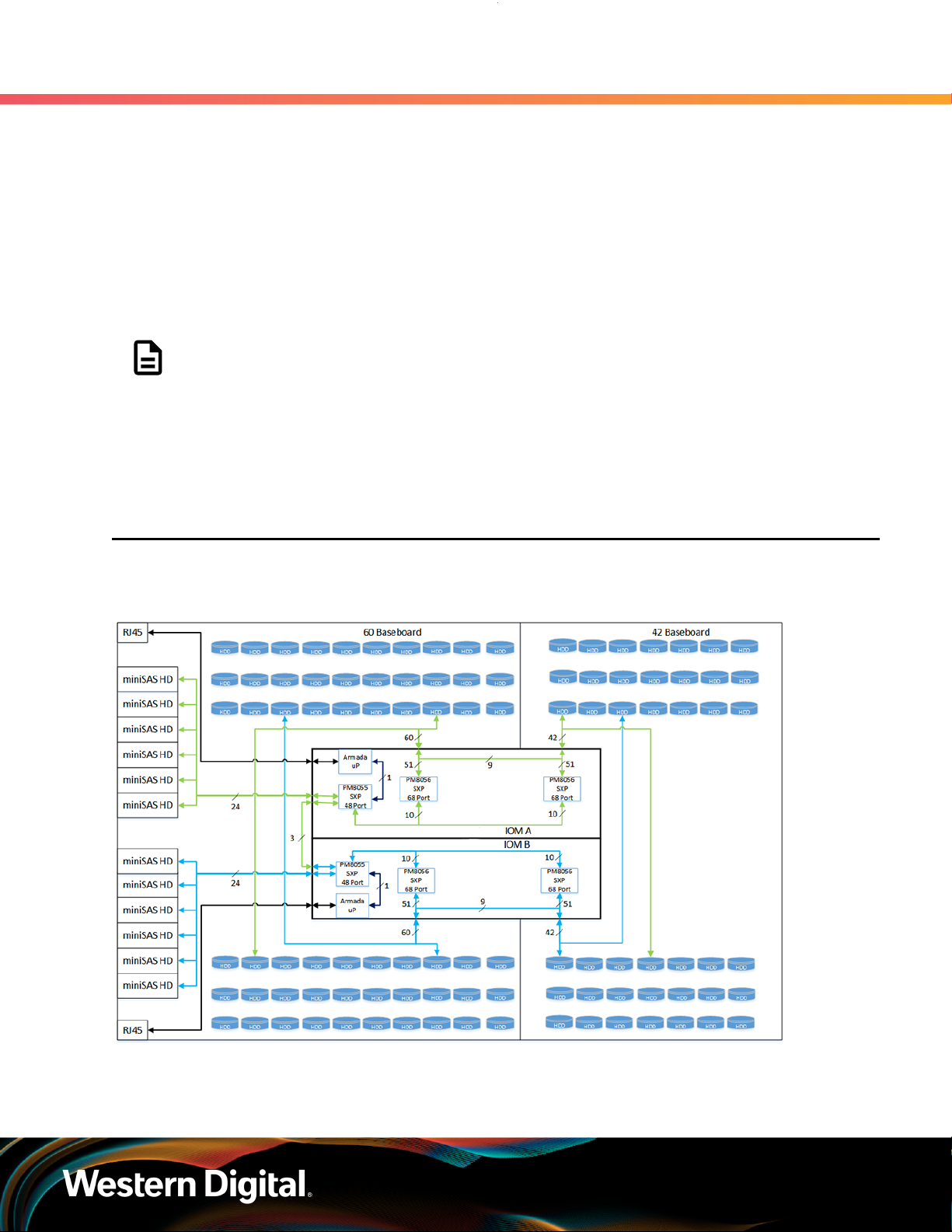

1.2 System Architecture Overview

1. SATA based models will only include 1 IOM

2

User Guide

The Ultrastar Data102 IOM uses a cascaded expander design to allow for connection to all 102 drives.

A 48-port primary expander connects with the six host ports, has a x3 link to the other IOM for IOM-IOM

communication and syncing, and also has a x10 SAS link to each secondary expander. Each secondary

expander then connects with fifty-one (51) drives.

The out-of-band management microprocessor provides an Ethernet connection using a Redfish/RESTful

API to access the various enclosure services. All the SES enclosure information can be obtained through the

out-of-band management port. Major use cases for this feature include obtaining storage subsystem health

information, locating enclosure components using the IDENT LEDs, and updating firmware.

The system FPGAs control and report the states of the system fans, enclosure LEDs, connector LEDs, drive

LEDs, and T10 drive power disable signals on the 102 data storage drives.

The I2C architecture is designed to support only one single master on any given bus. The primary expander

will be the master on each I2C bus. There are eight I2C buses used in the Ultrastar Data102 enclosure.

The number of devices on each bus are balanced to allow communication to peripheral devices and not

overload any one bus. The devices connected on the I2C buses include the enclosure VPDs, temp sensors,

baseboard FPGAs, and SAS connectors among others.

1. Overview

1.3 System Level Block Diagram

Note: To use T10 power disable, the drives installed must also support this feature.

1.3 System Level Block Diagram

The following image shows the system block diagram for the Ultrastar Data102 .

Figure 3: System Block Diagram

3

User Guide

1.4 Environmental Specifications

Table 1: Environmental Specification

Specification Non-Operational Operational

Temperature -40°C to 70°C 5°C to 35°C

Temperature Gradient 30°C per hour max 20°C per hour max

Temperature De-rating 1°C per 300m above 3000m 1°C per 300m above 900m

Relative Humidity 8-90% Non-Condensing 8-90% Non-Condensing

Relative Humidity Gradient 30% per hour maximum 30% per hour maximum

1. Overview

1.4 Environmental Specifications

Altitude -300m to 12,000m /

-984 ft. to 39,370 ft

1.5 Electrical Specifications

Table 2: Electrical Specifications

Specification Value

Max Power Consumption ~1600W

Typical Power Consumption

Input Voltage 200 - 240 VAC

PSU Connector Type C14

PSU Efficiency 80 PLUS Platinum

Inrush Current Maximum (per

Caution: The Ultrastar Data102 can only be plugged into high line (200 - 240 VAC) power. If

the unit is plugged into low line (110-127 VAC), the PSU will report a "Critical" state when status

pages are queried using SES. In this case, the enclosure will power up, but the drives will not.

The enclosure will remain in low-power mode.

2

AC line inrush current shall not exceed 40A peak, for up to

PSU)

should be no more than the specified maximum input current.

-300m to 3048m /

-984 ft. to 10,000 ft.

~1300W

one-quarter of the AC cycle after which, the input current

1.6 Mechanical Specifications

2. Max and typical power consumption values represent the output power to the system. Input power will vary depending

on the PSU efficiency and load sharing between PSUs.

4

User Guide

Table 3: Mechanical Specifications

1.7 Performance Specifications

Specification Non-Operational Operational

Shock 10G, 0 - peak,11ms half sine;

3 positive and 3 negative

pulses in each axis Shock

5G, 0 - peak, 11ms half sine; 3 positive

and 3 negative pulses in each axis-

minimum 6 seconds between shocks

to allow for write/read recovery

1. Overview

Vibration 0.75G, 0 - peak swept sine;

5 -500Hz; 1 complete sweep

@ 1/2 octave per minute

Weight 118.8 kg / 262 lbs.

Enclosure Dimensions W: 447mm x L: 1048.5 mm x H: 175mm / W: 17.6in. x L: 41.28in. x H: 6.89in.

CMA

Required Rack Width 450mm with (17.72in.) with 465mm (18.31in.) ± 1.5mm

nominal hole spacing. See EIA-310 Rack Standard

Required Rack Depth 1181-1197 mm (46.5in. - 47.13in.) of usable rack space, frame to frame

Rack Units (U) 4U

Vertical Rack Rail

Spacing

1.7 Performance Specifications

Table 4: Performance Specifications

0.10G,0 - peak swept sine; 5

-500Hz; 1 complete sweep

@ 1/2octave per minute

CMA Standard: 1183mm / 46.57in.Length of Enclosure w/

CMA Lite: 1148mm / 45.19in.

812.8mm - 914.4mm / 32 in. - 36 in.

Specification Value

Number of Drive Slots 102

Data Transfer Rates 12GBps SAS / 6Gbps SATA

Max Raw Data Storage Capacity 1.428 PB using 14TB HGST Ultrastar® HC530 drives

SAS Ports 12 x Mini-SAS HD (6 per IOM)

1.8 Ultrastar Data102 Layout

2 x 10/100/1G Ethernet

5

User Guide

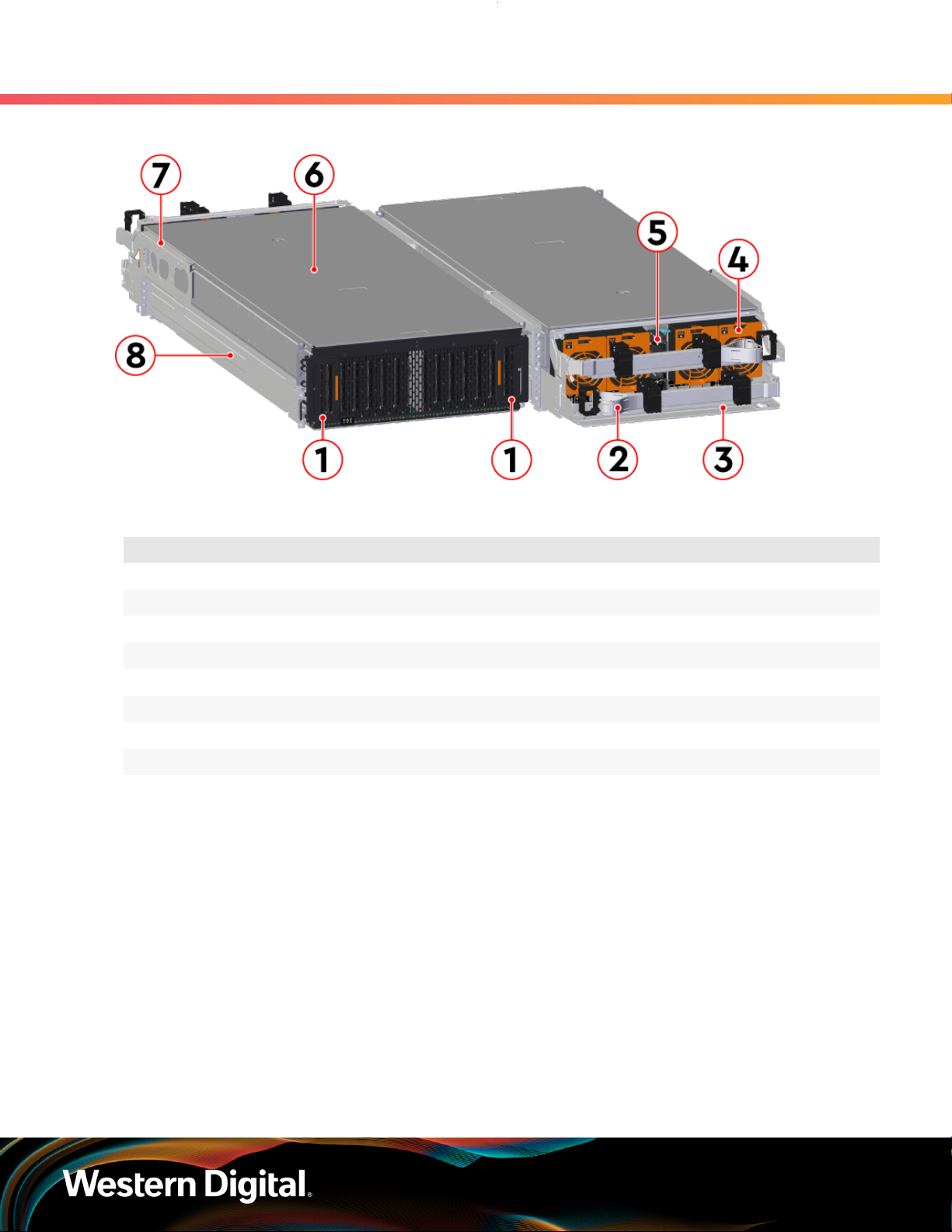

Figure 4: Front and Rear Product Layout

1. Overview

1.8 Ultrastar Data102 Layout

Table 5: Front and Rear Component Identification

Number Component

1 Enclosure Handles

2 CMAs

3 CMA Tray

4 Rear Fans

5 PSUs

6 Chassis Cover

7 Rear Cover Alignment Brackets

8 Rails

The following is an image of the layout of the major system components inside the Ultrastar Data102 .

6

User Guide

Figure 5: Component Layout

1. Overview

1.9 List of Customer Replaceable Units (CRUs)

1.9 List of Customer Replaceable Units (CRUs)

The following table lists the replaceable components and their part numbers.

Table 6: List of Replaceable Components

Component Part Number

Ultrastar Data102 Chassis with a single IOM and PSUs 1EX0440

Ultrastar Data102 Chassis with IOMs and PSUs 1EX0441

IOM 1EX2201

IOM Blank 1EX0431

PSU 1600W 1EX0434

Rear Fan 1EX0433

IOM Fan 1EX0432

Rails (CMA Standard) 1EX0435

Rails (CMA Lite) 1EX1601

Rear Cover Alignment Bracket 1EX2288

CMA Standard Arms 1EX0437

CMA Lite Kit (w/ rails, spacer brackets, and CMA) 1EX1825

CMA Lite Arm 1EX1834

CMA Lite Cable Tray 1EX1603

7

User Guide

Component Part Number

CMA Cable Tray 1EX1119

3.5 in. Drive Carrier, Qty=1 1EX0438

3.5 in. to 2.5 in. conversion Drive Carrier, Qty=1 1EX0439

3.5 in. Drive Blank, Qty=1 1EX0429

Power Cable for PDU, C13-C14, 18AWG, 3m, Qty=1 1EX1158

HD Mini-SAS to HD Mini-SAS, 3m, Qty=2 1EX1533

1.10 Supported Operating Systems

Table 7: Compatible Operating Systems

OS Support

Microsoft® Windows

1. Overview

1.10 Supported Operating Systems

2012 R2 x64 Server

2016 R1 x64 Server

CentOS/RedHat® Enterprise Linux (RHEL)

Ubuntu® Server

2019 R1 x64 Server

7.2 (x86_64) Kernel: 3.10.0-327

7.3 (x86_64) Kernel: 3.10.0-514

7.4 (x86_64) Kernel: 3.10.0-693

7.6 (x86_64) Kernel: 3.10.0-957

8.0 (x86_64) Kernel: 4.18.0-80

8.2 (x86_64) Kernel: 4.18.0-193

14.04 Kernel: 3.13

16.04 Kernel: 4.4

18.04 Kernel: 4.15

20.04

8.10 Kernel: 3.16Debian GNU/Linux

9.6 Kernel: 4.9

12 SP3SUSE® Linux Enterprise Server (SLES)

15 SP1

8

User Guide

1.11 LEDs

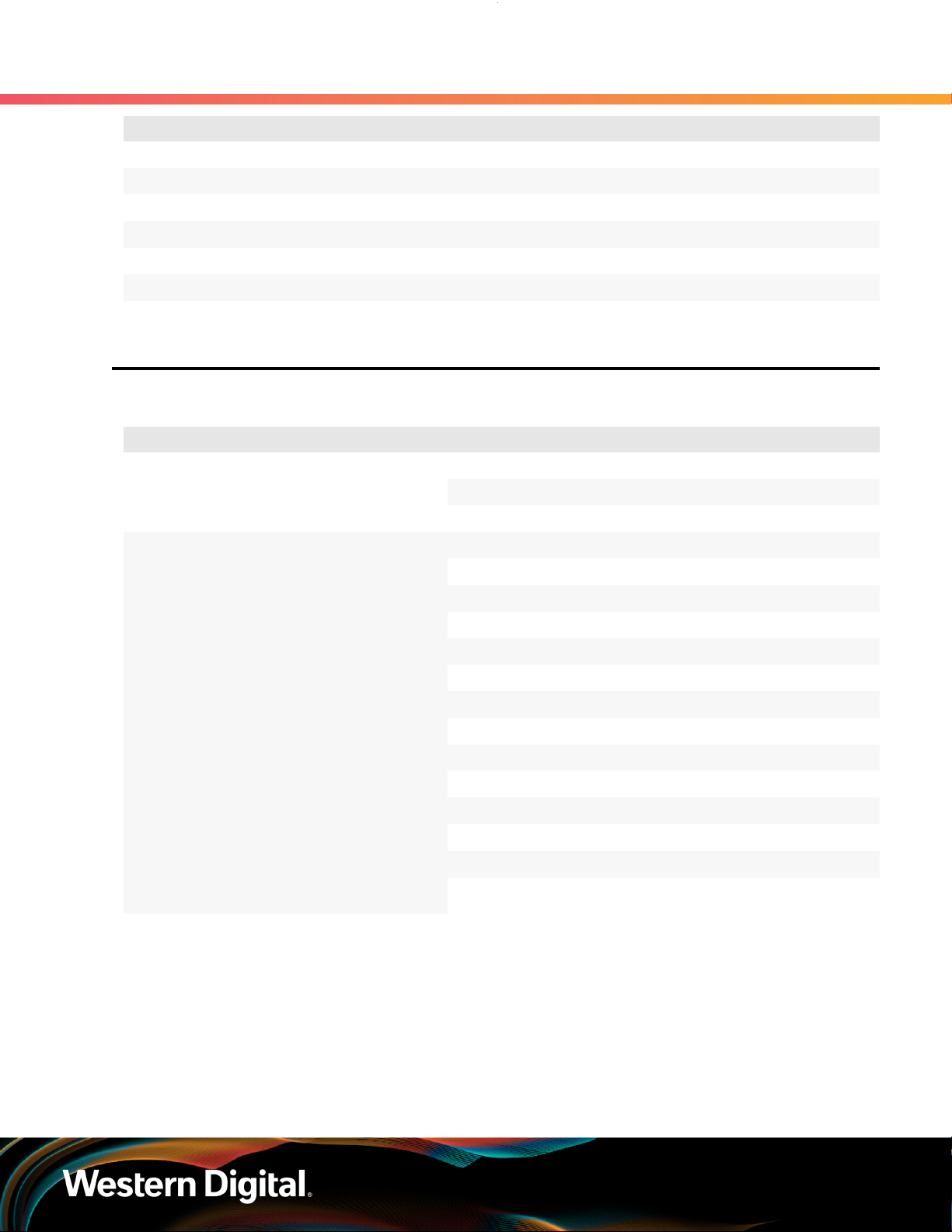

1.11.1 Front and Rear IO LEDs

The Ultrastar Data102 has a number of LEDs on the exterior of the enclosure that display various system

statuses. The three LEDs on the front mirror three on the rear, allowing the general status of the enclosure

to be determined from either side of the rack.

Figure 6: Front LEDs Location

1. Overview

1.11 LEDs

Table 8: Front LEDs Identification

Number LED Name Color Behavior

1 Identify Blue Blink @ 1 Hz (50% duty cycle) – Blinks only when Identification

has been activated. Will blink when any component is

identified.

2 Fault Amber Blink @ 1 Hz (50% duty cycle) – Enclosure has a fault

Off – Enclosure has no fault

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

3 Power Green Solid – Powered On

In addition to the three enclosure status LEDs, the rear provides LEDs for the Ethernet and SAS ports.

9

User Guide

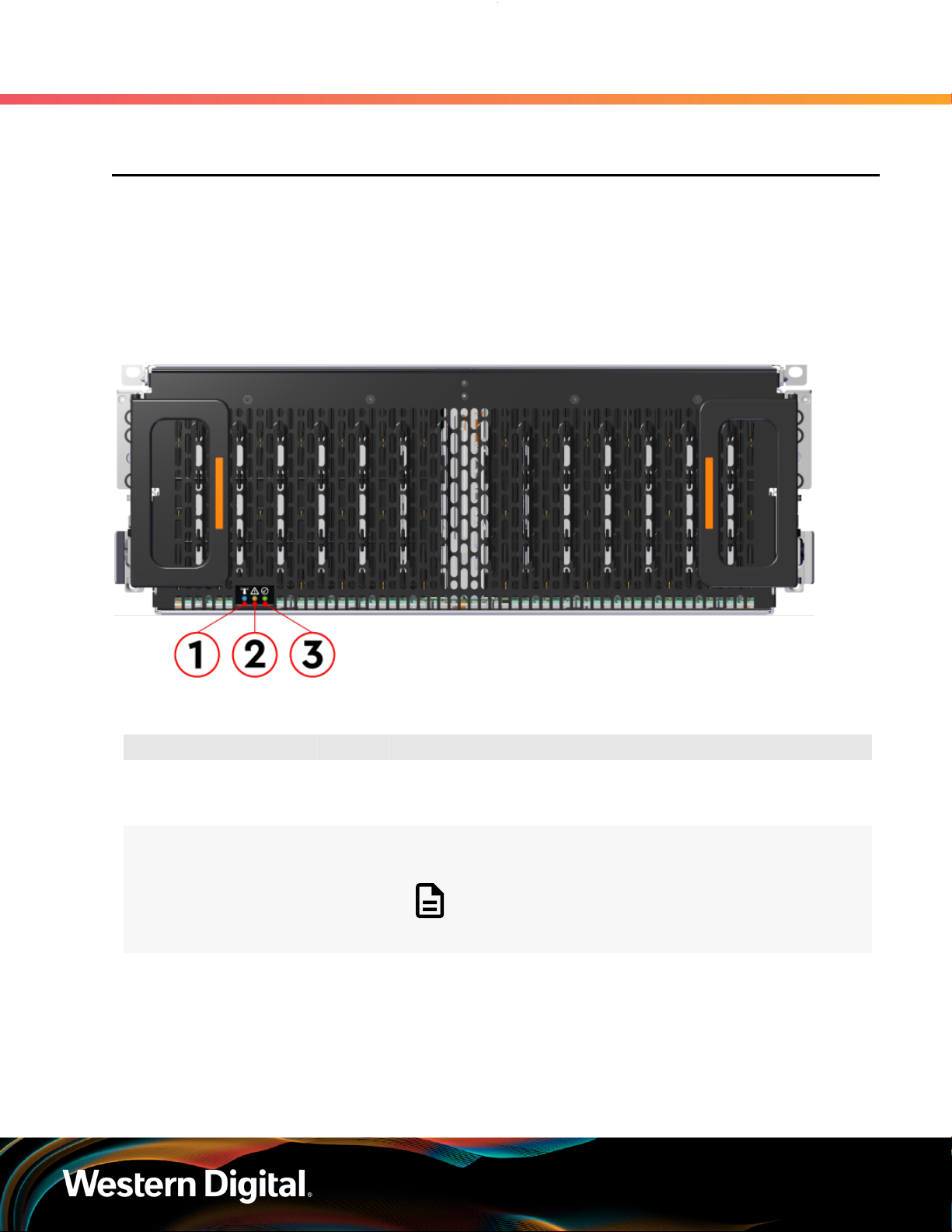

Figure 7: Rear LEDs Location

1. Overview

1.11 LEDs

Table 9: Rear LEDs Identification

Number LED Name Color Behavior

1 SAS Link Status Green Solid – SAS cable connected

Off – SAS cable not connected

2 SAS Fault

Status

3 Identification Blue Blink @ 1 Hz (50% duty cycle) – Blinks only when Identification

4 Fault Amber Blink @ 1 Hz (50% duty cycle) – Enclosure has a fault

5 Power Green Solid – Powered On

Amber Blink @ 1 Hz (50% duty cycle) – SAS connection fault

Off – No SAS connection fault

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

has been activated. Will blink when any component is

identified.

Off – Enclosure has no fault

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

10

User Guide

Number LED Name Color Behavior

6 Ethernet

Connector

Speed

Green/

Amber

1. Overview

1.11 LEDs

Off – Operating at 10 Mbps

Green Solid – Operating at 100 Mbps

Amber Solid – Operating at 1Gpbs

7 Ethernet

Connectors

Link/Activity

Green Off – No Connection

Solid – Connected

Blink – Activity

1.11.2 IOM LEDs

The IOM has three LEDs, one each for power, fault, and identification.

Figure 8: IOM LEDs Location

Table 10: IOM LEDs Identification

Number LED Name Color Behavior

1 IOM Identification Blue Blink @ 0.5 Hz (75% duty cycle) – Blinks only when IOM

Identification has been activated

Off - Not being identified

2 IOM Fault Amber Blink @ 0.5 Hz (75% duty cycle) – IOM has Fault

Off - IOM is functioning normally

3 IOM Power Green Solid – IOM is on

Off – IOM is off

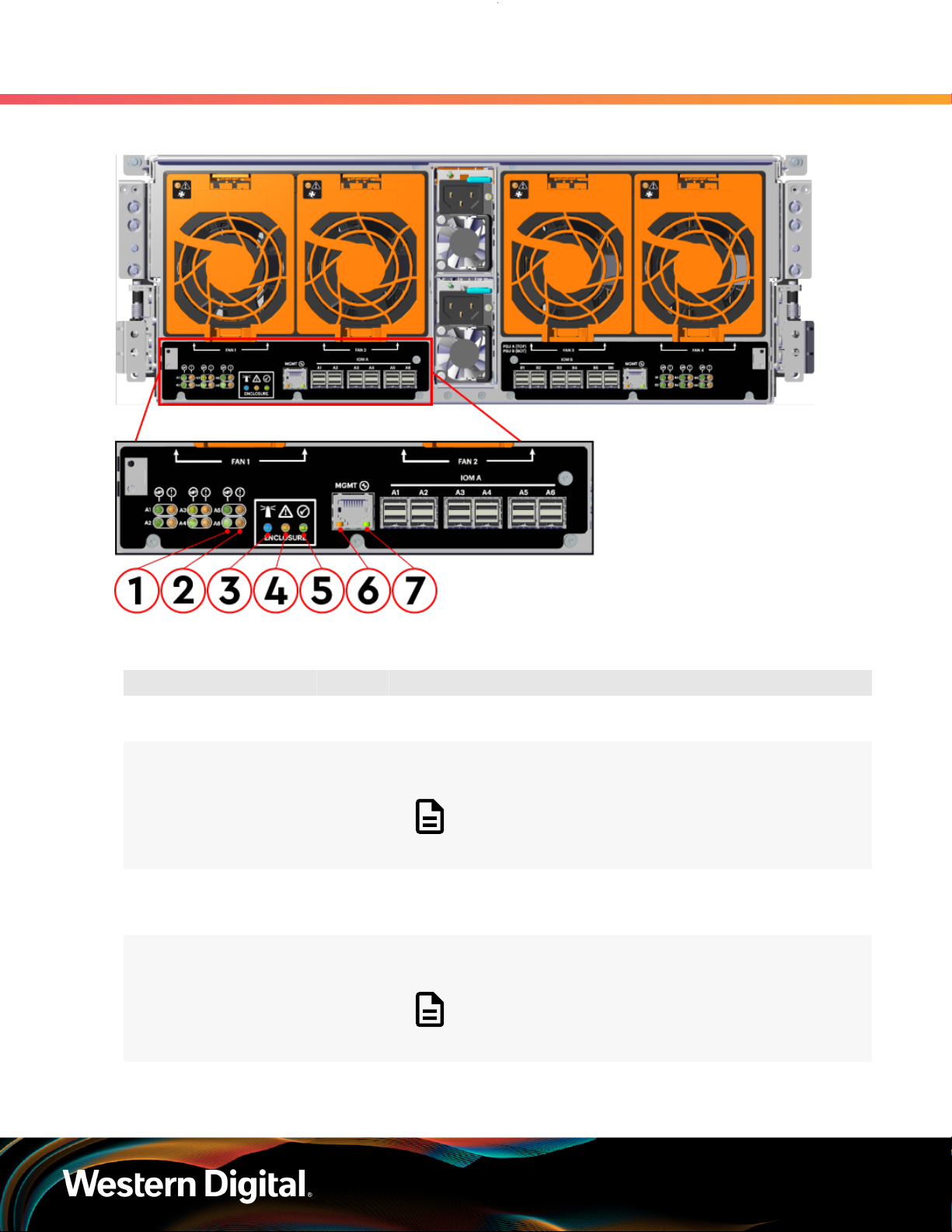

1.11.3 IOM Fan LED

The IOM Fan has a single LED with three distinct states for fault condition, identification, and power off.

11

User Guide

Figure 9: IOM Fan LED Location

1. Overview

1.11 LEDs

Table 11: IOM Fan LED Identification

Number LED Name Color Behavior

1 IOM Fan LED Amber Blink @ 2 Hz (50% duty cycle) – IOM Fan is being identified

Blink @ 1 Hz (50% duty cycle) – IOM Fan is reporting faults

Off – IOM Fan is on and reporting no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

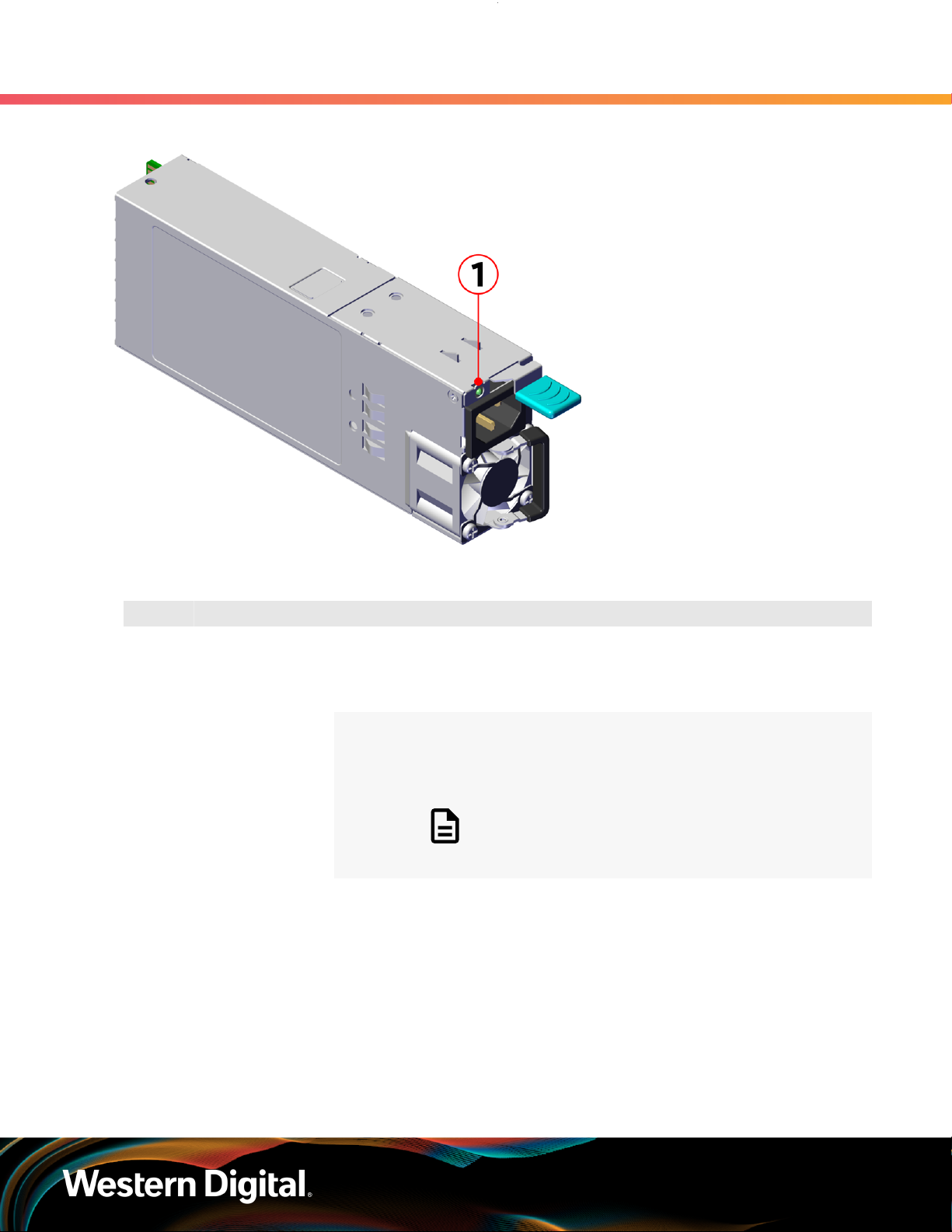

1.11.4 PSU LED

The PSU has a single, multi-function LED. See the table below for a detailed functional description.

12

User Guide

Figure 10: PSU LEDs Location

1. Overview

1.11 LEDs

Table 12: PSU LEDs Identification

Number LED Name Color Behavior

1 PSU Multi-

Function LED

Green Solid – PSU is on and reporting no faults

Blink @ 2Hz (50% duty cycle) – PSU in firmware update mode

Off – PSU is disconnected from power

Amber Solid – PSU is disconnected from power or critical fault

causing a shutdown failure

Blink @ 0.5Hz (50% duty cycle) – PSU reporting warnings

Off – PSU is reporting no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

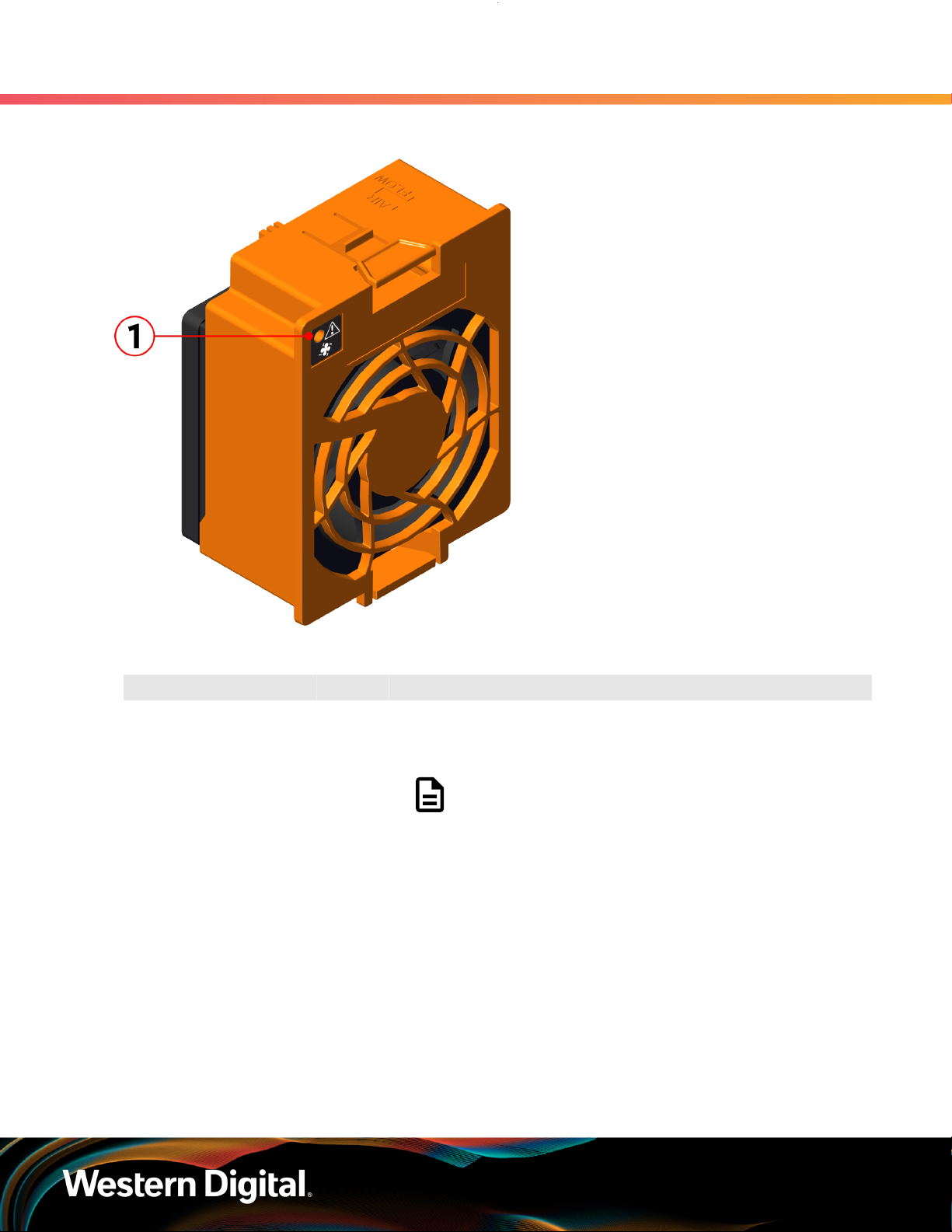

1.11.5 Rear Fan LED

The Rear Fan has a single LED with three distinct states for indicating a fault condition, identification, or

normal operation.

13

User Guide

Figure 11: Fan LED Location

1. Overview

1.11 LEDs

Table 13: Fan LED Identification

Number LED Name Color Behavior

1 Fan LED Amber Blink @ 1 Hz (50% duty cycle) – Fan is reporting faults

Blink @ 2 Hz (50% duty cycle) – Fan is being identified

Off – Fan is on and reporting no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

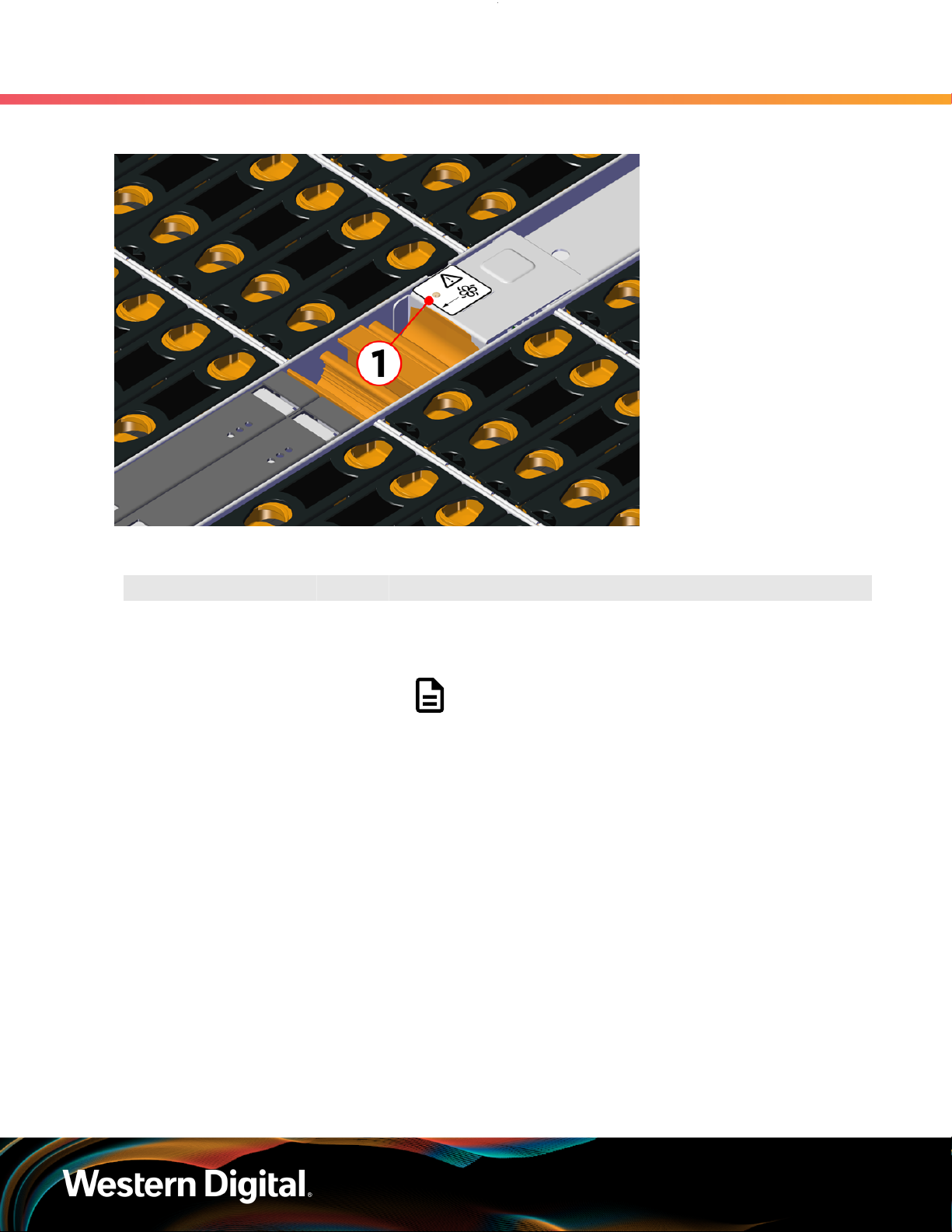

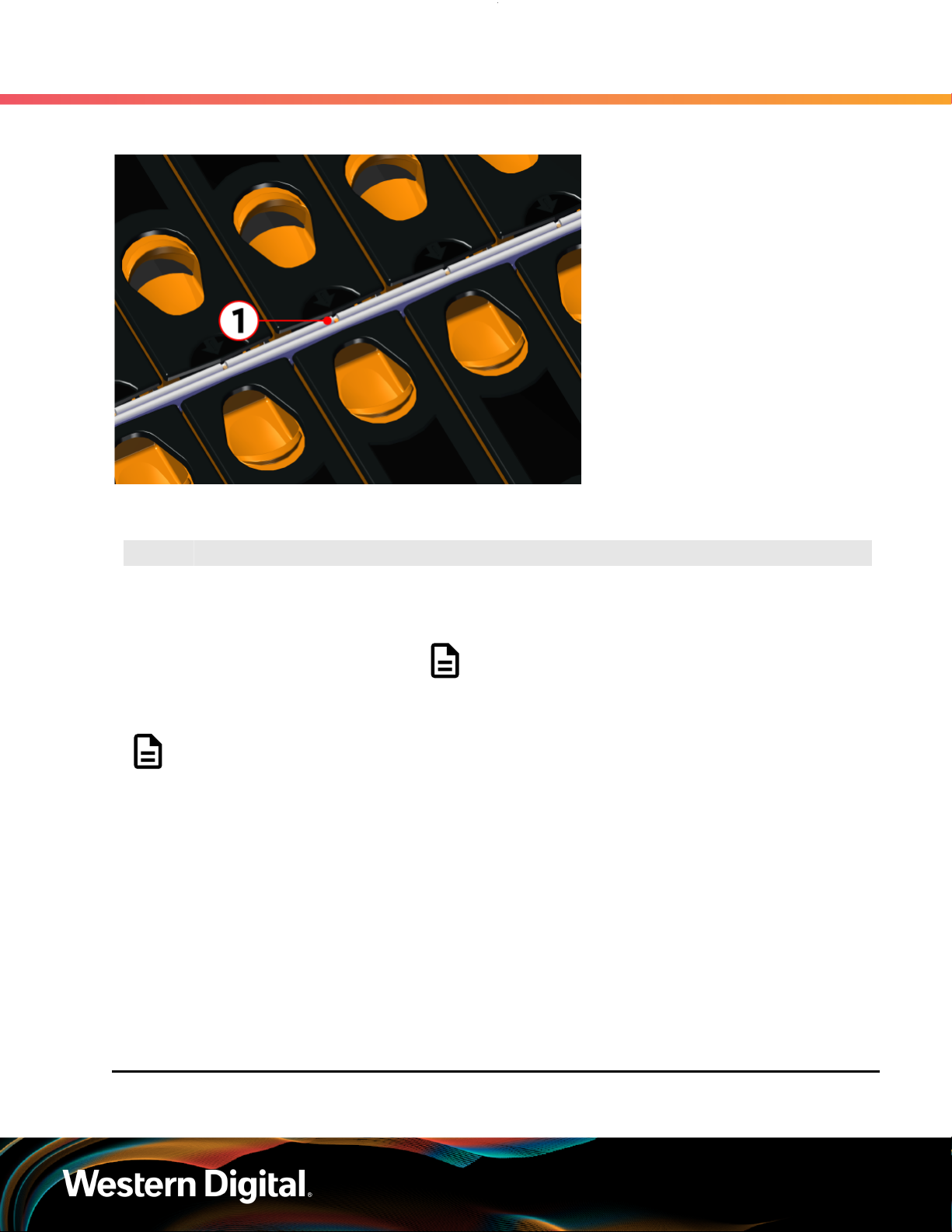

1.11.6 Drive Assembly LED

The HDD drive assembly itself does not contain an LED, but it contains a light-pipe that displays the

multi-function LED located on the drive slot. This amber LED has three distinct states for indicating a fault

condition, identification, or normal operation.

14

User Guide

Figure 12: HDD Assembly LED Location

1. Overview

1.12 Ultrastar Data102 Rack Requirements

Table 14: HDD Assembly LED Identification

Number LED Name Color Behavior

1 HDD Drive Multi-

Function LED

Note: During service events—when a drive is hot plugged or replaced and the drive installed

properly—the LED state of that drive slot will change to solid ON. This is to provide the user

with visual feedback that the drive has been successfully connected and has been discovered

by the expander. Once the enclosure has been slid back into the rack and the OPEN bit on the

door sensor element is 0, the LED will return to the previously set state (Ident, Fault, or Off).

For example: A drive in slot 0 needs to be replaced. The fault bit on Array Slot descriptor

0 is set to indicate to the service technician which drive slot to replace. This will cause the

LED to blink at 1Hz (50% duty cycle). When the service technician pulls out the enclosure,

inserts a new drive, and successfully installs the drive, the slot LED state will change to solid

ON to indicate that the drive was properly installed. When the service technician pushes the

enclosure back into the rack and the OPEN bit of the door sensor element changes from 1

to 0, the LED state of drive slot 0 will change back to the fault indication blink rate (1 Hz 50%

duty cycle).

Amber Blink @ 2 Hz (50% duty cycle) – Drive identify

Blink @ 1 Hz (50% duty cycle) – Drive fault

Off – Drive has no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

1.12 Ultrastar Data102 Rack Requirements

15

User Guide

The Ultrastar Data102 is designed to be installed into a rack that meets the EIA-310 standard at a minimum

1181-1197 mm (46.5in. - 47.13in.) of usable rack space, frame to frame. The vertical rack rails must be set

between 812.8mm - 914.4mm / 32 in. - 36 in. to support the enclosure. It requires 4U of rack space, and it

should be installed into the rack at the lowest possible U height to keep the load on the rack balanced.

Table 15: Required Rack Specifications

1. Overview

1.12 Ultrastar Data102 Rack Requirements

Parameter Requirement

Rack Depth 1181-1197 mm (46.5in. - 47.13in.) of usable rack space, frame to frame

Rack Width

Rack Units (U) 4U

Vertical Rack Rail Spacing 812.8mm - 914.4mm / 32 in. - 36 in.

Static Load Rating 1360.7 kg. / 3000 lbs.

Dynamic Load Rating 1020.5 kg. / 2250 lbs.

Warning: When extended out of the rack on the rail system, the Ultrastar Data102 will be

~950 mm / 37.4in. extended outward. This may be a potential tipping hazard depending on

the configuration of the rack. Ensure that leveling feet, anti-tilt, and any other safety features

recommended by the specific rack manufacturers have been deployed before servicing.

The following section provides specific information necessary to install, service, and remove the Ultrastar

Data102 . The installation of the Ultrastar Data102 requires two people and a space of 1524mm / 60in.

in front of the installation space. The servicing of the enclosure requires one person and a minimum of

1219.2mm / 48in. of space in front of the installation space. The removal of the enclosure requires two

people, 1371mm / 54in. of space in front of the installation space, and 24in. on either side of the enclosure

for two people to remove the enclosure.

Warning: The handles on the front of the chassis are not intended to be used to support the

weight of the Ultrastar Data102 . Lifting the unit by the chassis handles or trying to support the

unit on the handles can cause them to fail. This can cause serious damage to the unit or serious

bodily harm to those handling the unit. Always team lift the chassis by gripping the underside

of the unit, and never try to lift a chassis that is filled with drives.

450mm with (17.72in.) with 465mm (18.31in.) ± 1.5mm

nominal hole spacing. See EIA-310 Rack Standard

16

User Guide

Figure 13: Installation, Servicing, and Removal

1. Overview

1.12 Ultrastar Data102 Rack Requirements

Attention: Do not install or remove the enclosure while it is populated with drives. The fully

populated enclosure exceeds the amount of weight that a team of two should lift.

1.12.1 Compatible Rack Hardware Configuration

The following table(s) list the approved rack hardware configurations for the Ultrastar Data102 :

Table 16: Compatible Hardware Configuration 1

Parameter Rack PDU (Vertical)

Vendor CRENLO/EMCOR Server Technology Server Technology Various

AS-160099-03

(Drawing

Number EMCOR

Part

Number

Quantity 1 2 2 Varies

526121 Rev 5)

412-0761-11_STV-4501

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

KIT-MBVPT-1B

(one kit per PDU)

Additional Mounting

Bracket Hardware

4 x M6 x 16 Hex

Cap Screws

8 x M6 Fender

Washers

4 x M6 Hex Nut

with Nylon Lock

Table 17: Compatible Hardware Configuration 2

Parameter Rack PDU (Vertical)

Vendor AFCO/Legrand Server Technology Server Technology Various

Part

Number

Options:

412-0761-11_STV-4501

PDU Mounting

Bracket

KIT-MB-40 None

Additional Mounting

Bracket Hardware

17

User Guide

1. Overview

1.12 Ultrastar Data102 Rack Requirements

Parameter Rack PDU (Vertical)

42RU –

WEDIT605

45RU –

WEDIT604

48RU –

WEDIT603

51RU –

WEDIT606

Quantity 1 rack 2 1 N/A

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

Additional Mounting

Bracket Hardware

Table 18: Compatible Hardware Configuration 3

Parameter Rack PDU (Vertical)

Vendor TRIPP LITE Server Technology Server Technology Various

Options:

SR42UBDP (Rack)

412-0761-11_STV-4501

412-0761-20_STV-4502

PDU Mounting

Bracket

KIT-MBVPT-1B None

Additional Mounting

Bracket Hardware

SREXTENDER

25U (Rack

Part

Number

Quantity 1 rack 2 1 N/A

Extension)

SREXTENDER

42U (Rack

Extension)

SREXTENDER

48U (Rack

Extension)

412-0761-23_STV-4503

Table 19: Compatible Hardware Configuration 4

Parameter Rack PDU (Vertical)

Vendor APC/Schneider Server Technology Server Technology Various

AR3300W

Part

Number

412-0761-11_STV-4501

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

KIT-MBVPT-1B

(one kit per PDU)

Additional Mounting

Bracket Hardware

4 x M6 x 16 Hex

8 x M6 Fender

Cap Screws

Washers

4 x M6 Hex Nut

with Nylon Lock

18

Loading...

Loading...