Page 1

Installation Guide

Ultrastar Data102

Regulatory Model: H4102-J

December 2020

Rev. 1.15

1ET1098

Page 2

Installation Guide Table of Contents

Table of Contents

Revision History.....................................................................................................................................iii

Notices....................................................................................................................................................v

Points of Contact.................................................................................................................................. vi

Product Label Information............................................................................................................. vi

Chapter 1. Overview.........................................................................................................1

Ultrastar Data102 Description..............................................................................................................2

Ultrastar Data102 Layout......................................................................................................................2

Environmental Specifications...............................................................................................................4

Electrical Specifications....................................................................................................................... 4

Mechanical Specifications....................................................................................................................5

Performance Specifications................................................................................................................. 5

Ultrastar Data102 Rack Requirements.................................................................................................6

Compatible Rack Hardware Configuration................................................................................. 7

List of Compatible Drives....................................................................................................................9

Chapter 2. Disclaimers...................................................................................................21

Restricted Access Location...............................................................................................................22

Safety Compliance............................................................................................................................. 22

Electromagnetic Compatibility (EMC) Class A Compliance........................................................... 22

Country Certifications........................................................................................................................ 23

Chapter 3. Safety...........................................................................................................24

Safety Warnings and Cautions..........................................................................................................25

Electrostatic Discharge......................................................................................................................25

Optimizing Location...........................................................................................................................25

Power Connections............................................................................................................................26

Power Cords.......................................................................................................................................26

Rackmountable Systems....................................................................................................................26

i

Page 3

Installation Guide Table of Contents

Safety and Service............................................................................................................................. 27

Chapter 4. Packaging....................................................................................................28

Ultrastar Data102 Packaging Overview.............................................................................................29

Ultrastar Data102 Unpacking Procedure...........................................................................................32

Chapter 5. Installation...................................................................................................35

Ultrastar Data102 Installation Overview............................................................................................36

Ultrastar Data102 Installation Procedure........................................................................................... 37

Operating the 2.5" Drive Carrier............................................................................................... 65

SAS Cabling........................................................................................................................................ 66

Special Considerations for Cable Routing....................................................................................... 68

Cabling for CMA Standard and CMA Lite........................................................................................ 70

Before You Begin........................................................................................................................ 70

Cabling CMA Standard................................................................................................................71

Cable Configuration for CMA Lite..............................................................................................71

ii

Page 4

Installation Guide Revision History

Revision History

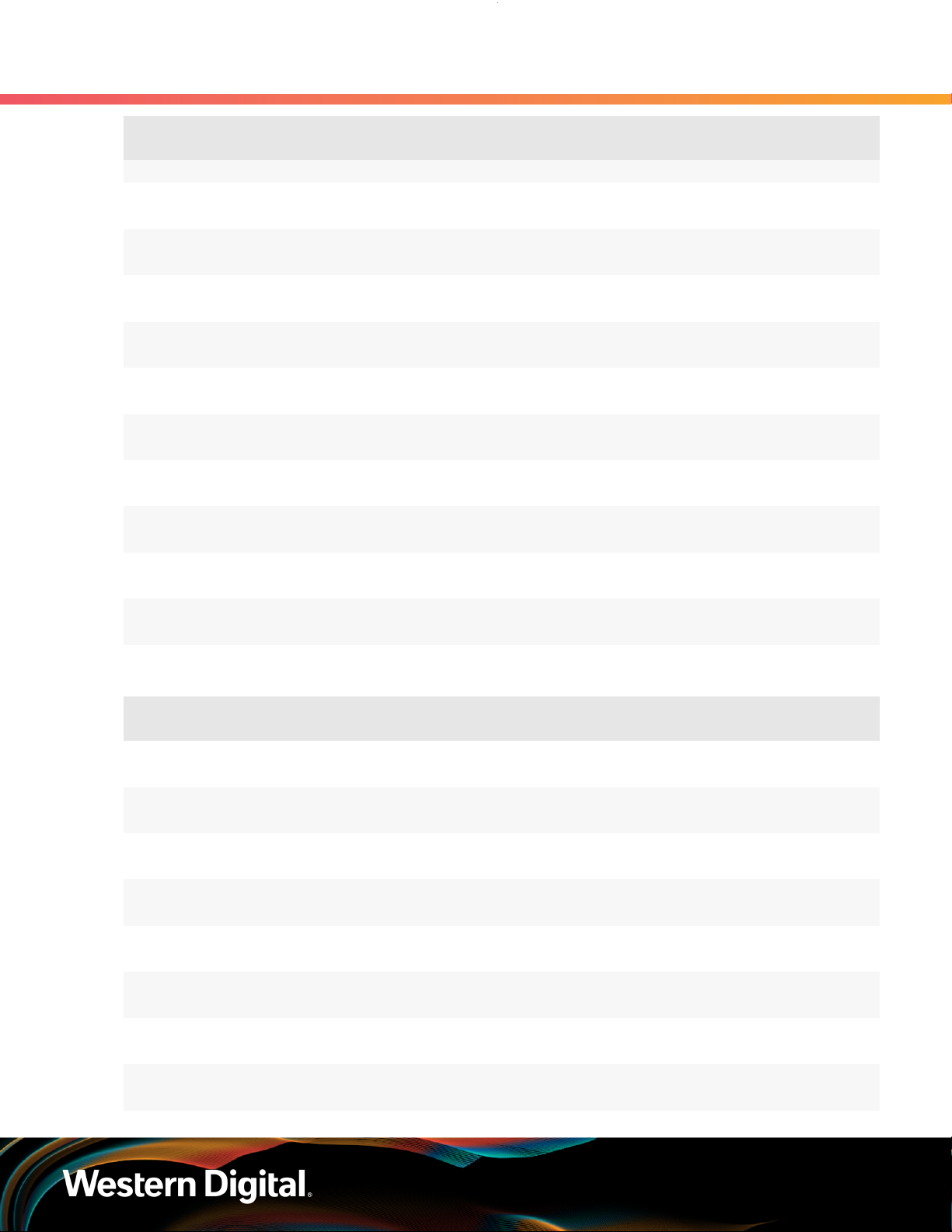

Date Revision Comment

November 2017 1.0 Initial release

November 2017 1.1

December 2017 1.2

January 2018 1.2.1 Updated the product name

January 2018 1.2.2 Added an image for cage nut positioning in the installation procedure.

January 2018 1.3

• The crossbar on the CMA was changed. See the installation

instructions for details.

• Changed required rack depth, see Required Rack Depth (page

5).

• Changed typical power consumption, see Typical Power

Consumption (page 4).

• Added active cable support

• Added a note regarding single IOMs in SATA TLAs. See Ultrastar

Data102 Description (page 2)

• Updated the Non-Op altitude specification. See Non-Operational

Altitude (page 4).

• Correct the packaging images to show the two CMA boxes that

come in the accessory tray. See Packaging Layout (page 29).

• Updated information on the 2.5" drive carrier option. (topic

removed)

• Added torque requirements for all screws used in the enclosure.

• Updated the IOM replacement section to account for the possibility

of a firmware mismatch. (topic removed)

• Updated the drive assembly installation instructions to clarify the

orientation of the drive assemblies. See Ultrastar Data102 Installation

Procedure (page 37).

April 2018 1.4

June 2018 1.5

December 2018 1.6

March 2019 1.7 Updated the Ultrastar Data102 Installation Procedure (page 37)

May 2019 1.8 Updated the Ultrastar Data102 Installation Procedure (page 37)

• Updated Compatible Drives List. See List of Compatible Drives

(page 9).

• Updated the Rack Requirements. See Ultrastar Data102 Rack

Requirements (page 6).

• Updated the Compatible Drives List. See List of Compatible Drives

(page 9)

• Updated Compatible Drives List. See List of Compatible Drives

(page 9)

iii

Page 5

Installation Guide Revision History

Date Revision Comment

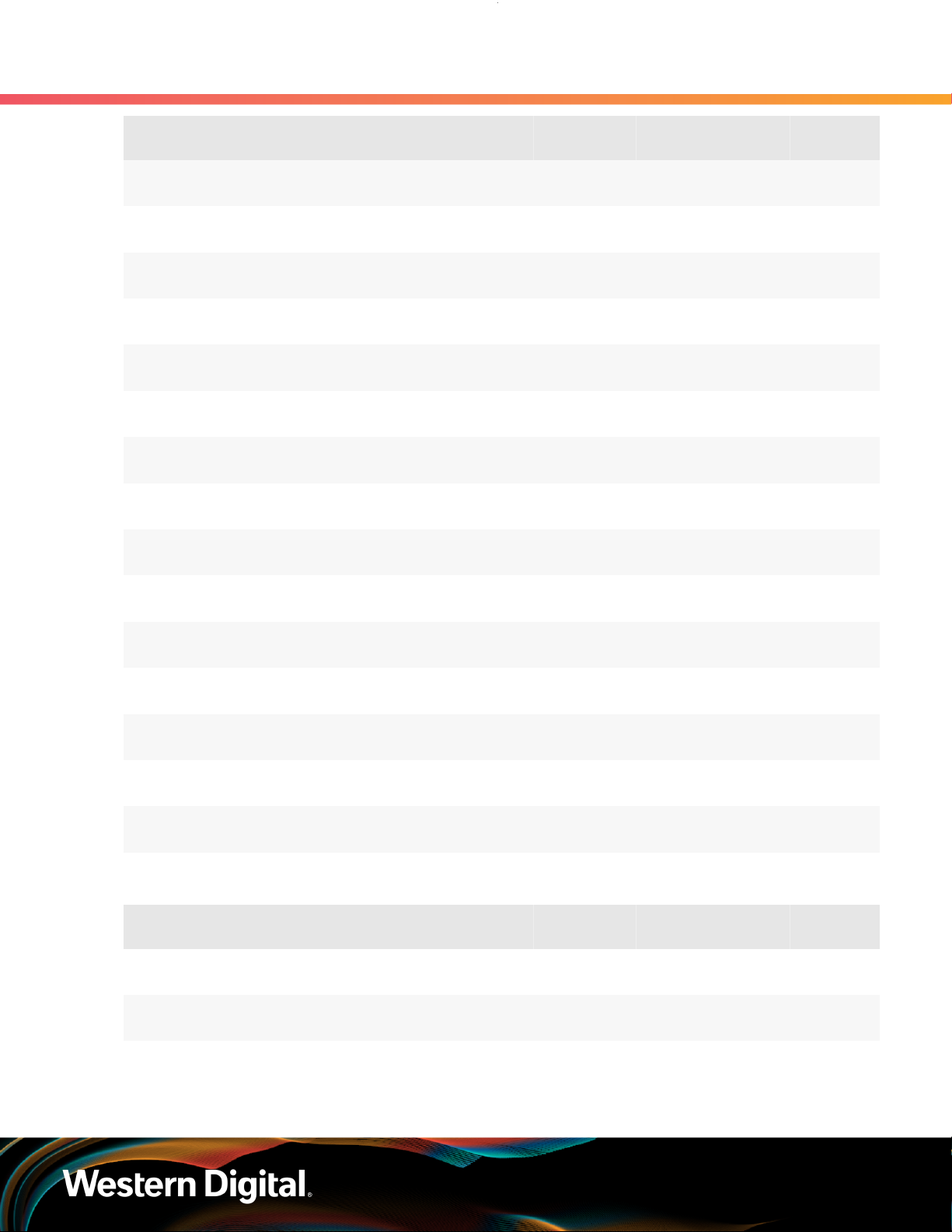

July 2019 1.9

• Updated servicing image to correct length values and rail servicing

extension in Ultrastar Data102 Rack Requirements (page 6)

section.

• Updated Ultrastar Data102 Installation Overview (page 36)

section to include options for cable management.

• Updated Ultrastar Data102 Installation Procedure (page 37)

section to combine CMA Standard and CMA Lite instructions where

applicable.

• Updated Cable Configuration for CMA Lite (page 71)section to

correct instructions.

• Updated revision history to remove broken links to topics no longer

in this document.

November 2019 1.10

December 2019 1.11

April 2020 1.12

August 2020 1.13 Updated SAS Cabling (page 66)

October 2020 1.14

• Replaced references to He12 drives with Ultrastrar DC HC520 in List

of Compatible Drives (page 9)

• Updated images of chassis cover screws throughout

• Rebranded document to WD design

• Updated the List of Compatible Drives (page 9)

• Updated drive installation order in the Ultrastar Data102 Installation

Procedure (page 37)

• Added SAS Cabling (page 66)

• Added note about minimum time between removing and

reapplying power in Power Connections (page 26)

• Updated images and text in Ultrastar Data102 Packaging Overview

(page 29) and Ultrastar Data102 Unpacking Procedure (page

32)

•

Added the following to Ultrastar Data102 Installation Procedure

(page 37):

◦ Note about input voltage at plug-in step

◦ Reference to User Guide after installation instructions

◦ Note about installation of 2.5in SSD Assembly

December 2020 1.15

• Added Operating the 2.5" Drive Carrier (page 65)

• Updated table of approved SAS cables in SAS Cabling (page 66)

• Reordered cabling topics in Installation (page 35) section

• Added UK Import Representation Contact

• Removed Formerica cables from SAS Cabling (page 66)

iv

Page 6

Installation Guide Notices

Notices

Western Digital Technologies, Inc. or its affiliates' (collectively “Western Digital”) general policy does not

recommend the use of its products in life support applications wherein a failure or malfunction of the product

may directly threaten life or injury. Per Western Digital Terms and Conditions of Sale, the user of Western

Digital products in life support applications assumes all risk of such use and indemnifies Western Digital

against all damages.

This document is for information use only and is subject to change without prior notice. Western Digital

assumes no responsibility for any errors that may appear in this document, nor for incidental or consequential

damages resulting from the furnishing, performance or use of this material.

Absent a written agreement signed by Western Digital or its authorized representative to the contrary,

Western Digital explicitly disclaims any express and implied warranties and indemnities of any kind that may,

or could, be associated with this document and related material, and any user of this document or related

material agrees to such disclaimer as a precondition to receipt and usage hereof.

Each user of this document or any product referred to herein expressly waives all guaranties and warranties

of any kind associated with this document any related materials or such product, whether expressed or

implied, including without limitation, any implied warranty of merchantability or fitness for a particular

purpose or non-infringement. Each user of this document or any product referred to herein also expressly

agrees Western Digital shall not be liable for any incidental, punitive, indirect, special, or consequential

damages, including without limitation physical injury or death, property damage, lost data, loss of profits or

costs of procurement of substitute goods, technology, or services, arising out of or related to this document,

any related materials or any product referred to herein, regardless of whether such damages are based on

tort, warranty, contract, or any other legal theory, even if advised of the possibility of such damages.

This document and its contents, including diagrams, schematics, methodology, work product, and

intellectual property rights described in, associated with, or implied by this document, are the sole and

exclusive property of Western Digital. No intellectual property license, express or implied, is granted by

Western Digital associated with the document recipient's receipt, access and/or use of this document or the

products referred to herein; Western Digital retains all rights hereto.

Western Digital, the Western Digital logo, and Ultrastar are registered trademarks or trademarks of Western

Digital Corporation or its affiliates in the US and/or other countries. Linux® is the registered trademark of

Linus Torvalds in the U.S. and other countries. All other marks are the property of their respective owners.

Product specifications subject to change without notice. Pictures shown may vary from actual products. Not

all products are available in all regions of the world.

Western Digital

5601 Great Oaks Parkway

San Jose, CA 95119

© 2020 Western Digital Corporation or its affiliates. All Rights Reserved.

v

Page 7

Installation Guide Points of Contact

Points of Contact

For further assistance with a Western Digital product, contact Western Digital Datacenter Platforms technical

support. Please be prepared to provide the following information: part number (P/N), serial number (S/N),

product name and/or model number, and a brief description of the issue.

Email:

support@wdc.com

Website:

https://portal.wdc.com/Support/s/

UK Import Representation Contact

Western Digital UK Limited Hamilton House, Regent Park, Kingston Road Leatherhead, Surrey KT22 7PL, GB,

United Kingdom

Telephone: +44 1372 366000

1.1 Product Label Information

The following product information is required for technical support requests:

• Part Number (P/N)

• Serial Number (S/N)

• Product Name and/or Model Number (MODEL)

This information may be found on the product label, which is affixed to an exterior, non-removable surface of

the chassis. The following is an example label with the applicable information fields highlighted:

vi

Page 8

Western Digital

Overview

This section provides a high level overview of the features of the

Ultrastar Data102 .

In This Chapter:

- Ultrastar Data102 Layout............................... 2

- Environmental Specifications........................2

- Electrical Specifications................................ 4

- Mechanical Specifications............................. 4

- Performance Specifications...........................5

- Ultrastar Data102 Rack Requirements..........5

- List of Compatible Drives..............................6

1

Page 9

Installation Guide

1.1 Ultrastar Data102 Description

Figure 2: Ultrastar Data102

1. Overview

1.1 Ultrastar Data102 Description

The Ultrastar Data102 is a 4U form factor, high availability, high density, rack-mounted storage enclosure

that is capable of hosting up to 102 SAS or SATA drives. The maximum data storage capacity of the Ultrastar

Data102 is 1.428 PB using 14TB HGST Ultrastar® HC530 drives . (For a full list of compatible drives and total

storage capacities, see the List of Compatible Drives (page 9).) The enclosure runs on an input voltage

of 200 - 240 VAC and consumes ~1300W of power under typical conditions. It requires a maximum of

~1600W at full load.

It is designed to fit within a 4U rack space and requires 1181-1197 mm (46.5in. - 47.13in.) of usable rack space,

frame to frame. A fully loaded system will add 118.8 kg / 262 lbs. of static load when fully loaded with drives.

• 4U Storage Enclosure

• Supports up to 102 Drives

• Can support 3.5” drives and 2.5” SSD drives (2.5" requires an adapter) in the 102 available drive bays.

• Up to 12W per drive slot for the 102 data storage drives (Cannot exceed 85A on the 5V rail)

• House and control four (4) N+1 redundant 80mm rear fans

• House and control a dual rotor 40mm internal IOM Fan

• Controlled by two (2) redundant I/O Modules

• Powered by two (2) redundant 1600W PSUs

• Supports High Line (220-240 VAC) Input Power

• Full high availability with independent dual paths to all HDDs

• Toolless replacement of all Customer Replaceable Units (CRUs)

• Fits within a standard EIA-310 rack including all necessary cable management (see Compatible Rack

Hardware Configuration (page 7))

• Supports up to 3m passive SAS cables (limited to 3m or less) or active cables (any length) (see SAS

Cabling (page 66))

1

1.2 Ultrastar Data102 Layout

1. SATA based models will only include 1 IOM

2

Page 10

Installation Guide

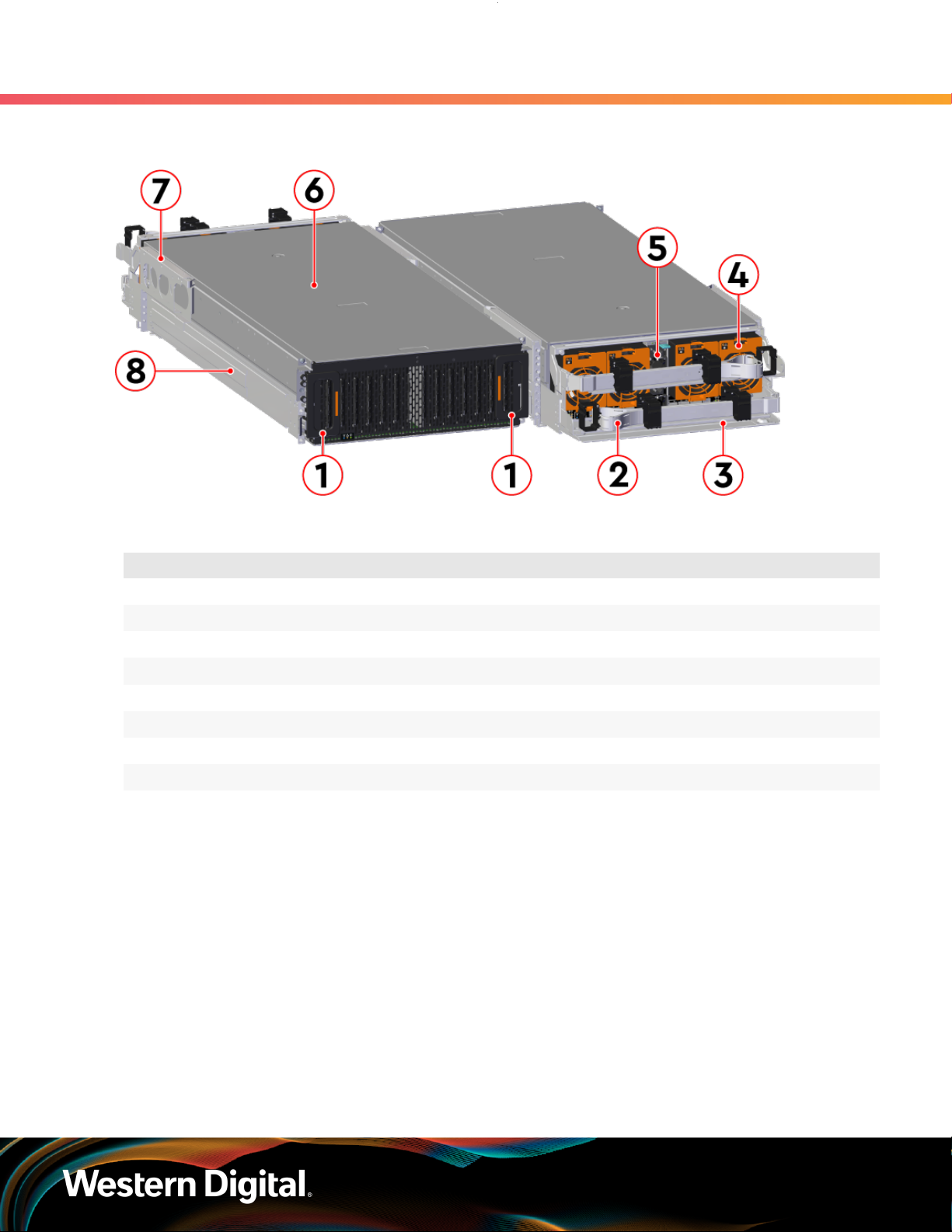

Figure 3: Front and Rear Product Layout

1. Overview

1.2 Ultrastar Data102 Layout

Table 1: Front and Rear Component Identification

Number Component

1 Enclosure Handles

2 CMAs

3 CMA Tray

4 Rear Fans

5 PSUs

6 Chassis Cover

7 Rear Cover Alignment Brackets

8 Rails

The following is an image of the layout of the major system components inside the Ultrastar Data102 .

3

Page 11

Installation Guide

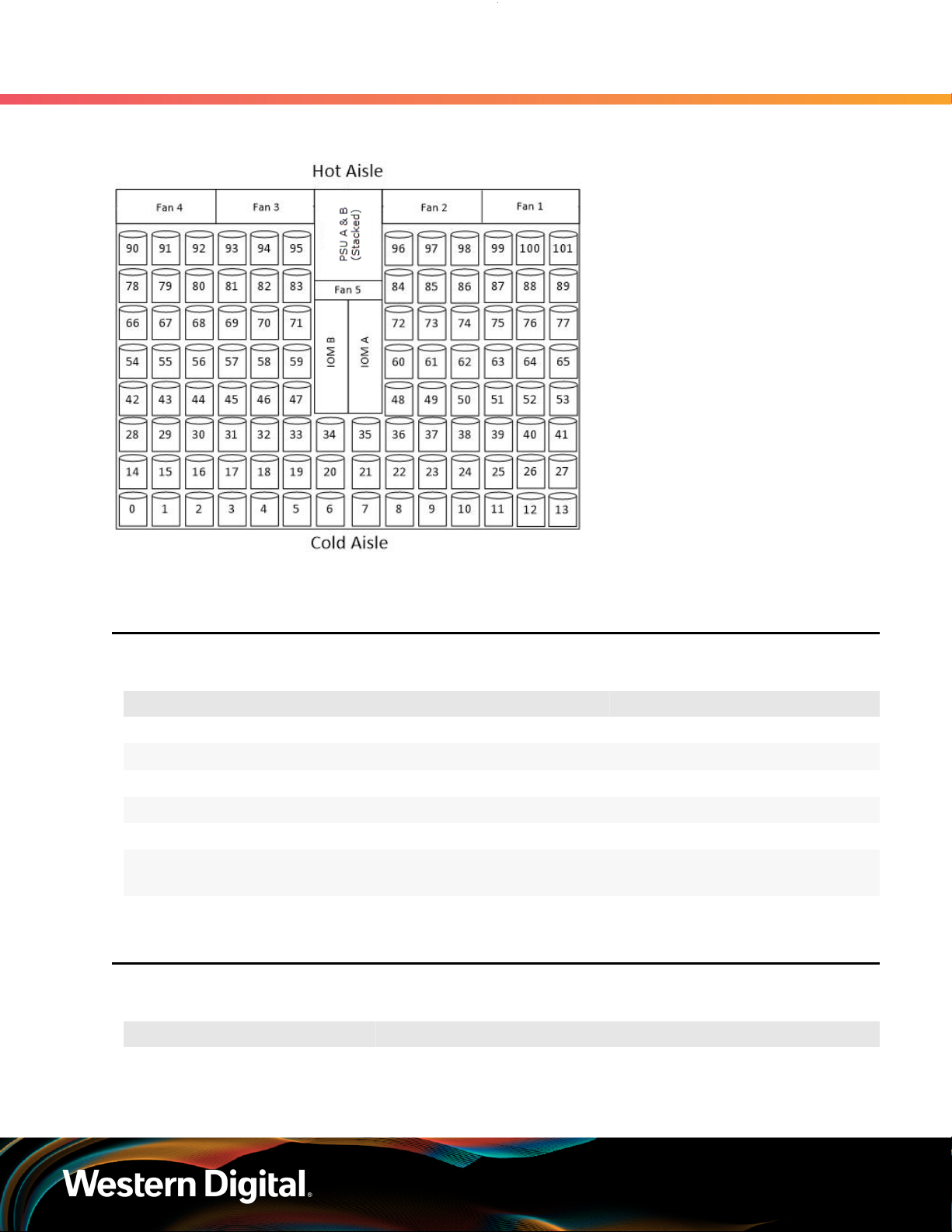

Figure 4: Component Layout

1. Overview

1.3 Environmental Specifications

1.3 Environmental Specifications

Table 2: Environmental Specification

Specification Non-Operational Operational

Temperature -40°C to 70°C 5°C to 35°C

Temperature Gradient 30°C per hour max 20°C per hour max

Temperature De-rating 1°C per 300m above 3000m 1°C per 300m above 900m

Relative Humidity 8-90% Non-Condensing 8-90% Non-Condensing

Relative Humidity Gradient 30% per hour maximum 30% per hour maximum

Altitude -300m to 12,000m /

-984 ft. to 39,370 ft

1.4 Electrical Specifications

Table 3: Electrical Specifications

Specification Value

Max Power Consumption ~1600W

-300m to 3048m /

-984 ft. to 10,000 ft.

4

Page 12

Installation Guide

Typical Power Consumption

Specification Value

2

Input Voltage 200 - 240 VAC

PSU Connector Type C14

PSU Efficiency 80 PLUS Platinum

~1300W

1. Overview

1.5 Mechanical Specifications

Inrush Current Maximum (per

PSU)

Caution: The Ultrastar Data102 can only be plugged into high line (200 - 240 VAC) power. If

the unit is plugged into low line (110-127 VAC), the PSU will report a "Critical" state when status

pages are queried using SES. In this case, the enclosure will power up, but the drives will not.

The enclosure will remain in low-power mode.

AC line inrush current shall not exceed 40A peak, for up to

one-quarter of the AC cycle after which, the input current

should be no more than the specified maximum input current.

1.5 Mechanical Specifications

Table 4: Mechanical Specifications

Specification Non-Operational Operational

Shock 10G, 0 - peak,11ms half sine;

3 positive and 3 negative

pulses in each axis Shock

Vibration 0.75G, 0 - peak swept sine;

5 -500Hz; 1 complete sweep

@ 1/2 octave per minute

5G, 0 - peak, 11ms half sine; 3 positive

and 3 negative pulses in each axis-

minimum 6 seconds between shocks

to allow for write/read recovery

0.10G,0 - peak swept sine; 5

-500Hz; 1 complete sweep

@ 1/2octave per minute

Weight 118.8 kg / 262 lbs.

Enclosure Dimensions W: 447mm x L: 1048.5 mm x H: 175mm / W: 17.6in. x L: 41.28in. x H: 6.89in.

CMA Standard: 1183mm / 46.57in.Length of Enclosure w/

CMA

Required Rack Width 450mm with (17.72in.) with 465mm (18.31in.) ± 1.5mm

nominal hole spacing. See EIA-310 Rack Standard

Required Rack Depth 1181-1197 mm (46.5in. - 47.13in.) of usable rack space, frame to frame

Rack Units (U) 4U

Vertical Rack Rail

Spacing

2. Max and typical power consumption values represent the output power to the system. Input power will vary depending

on the PSU efficiency and load sharing between PSUs.

CMA Lite: 1148mm / 45.19in.

812.8mm - 914.4mm / 32 in. - 36 in.

5

Page 13

Installation Guide

1.6 Performance Specifications

Table 5: Performance Specifications

Specification Value

Number of Drive Slots 102

Data Transfer Rates 12GBps SAS / 6Gbps SATA

Max Raw Data Storage Capacity 1.428 PB using 14TB HGST Ultrastar® HC530 drives

SAS Ports 12 x Mini-SAS HD (6 per IOM)

2 x 10/100/1G Ethernet

1.7 Ultrastar Data102 Rack Requirements

The Ultrastar Data102 is designed to be installed into a rack that meets the EIA-310 standard at a minimum

1181-1197 mm (46.5in. - 47.13in.) of usable rack space, frame to frame. The vertical rack rails must be set

between 812.8mm - 914.4mm / 32 in. - 36 in. to support the enclosure. It requires 4U of rack space, and it

should be installed into the rack at the lowest possible U height to keep the load on the rack balanced.

1. Overview

1.6 Performance Specifications

Table 6: Required Rack Specifications

Parameter Requirement

Rack Depth 1181-1197 mm (46.5in. - 47.13in.) of usable rack space, frame to frame

Rack Width

Rack Units (U) 4U

Vertical Rack Rail Spacing 812.8mm - 914.4mm / 32 in. - 36 in.

Static Load Rating 1360.7 kg. / 3000 lbs.

Dynamic Load Rating 1020.5 kg. / 2250 lbs.

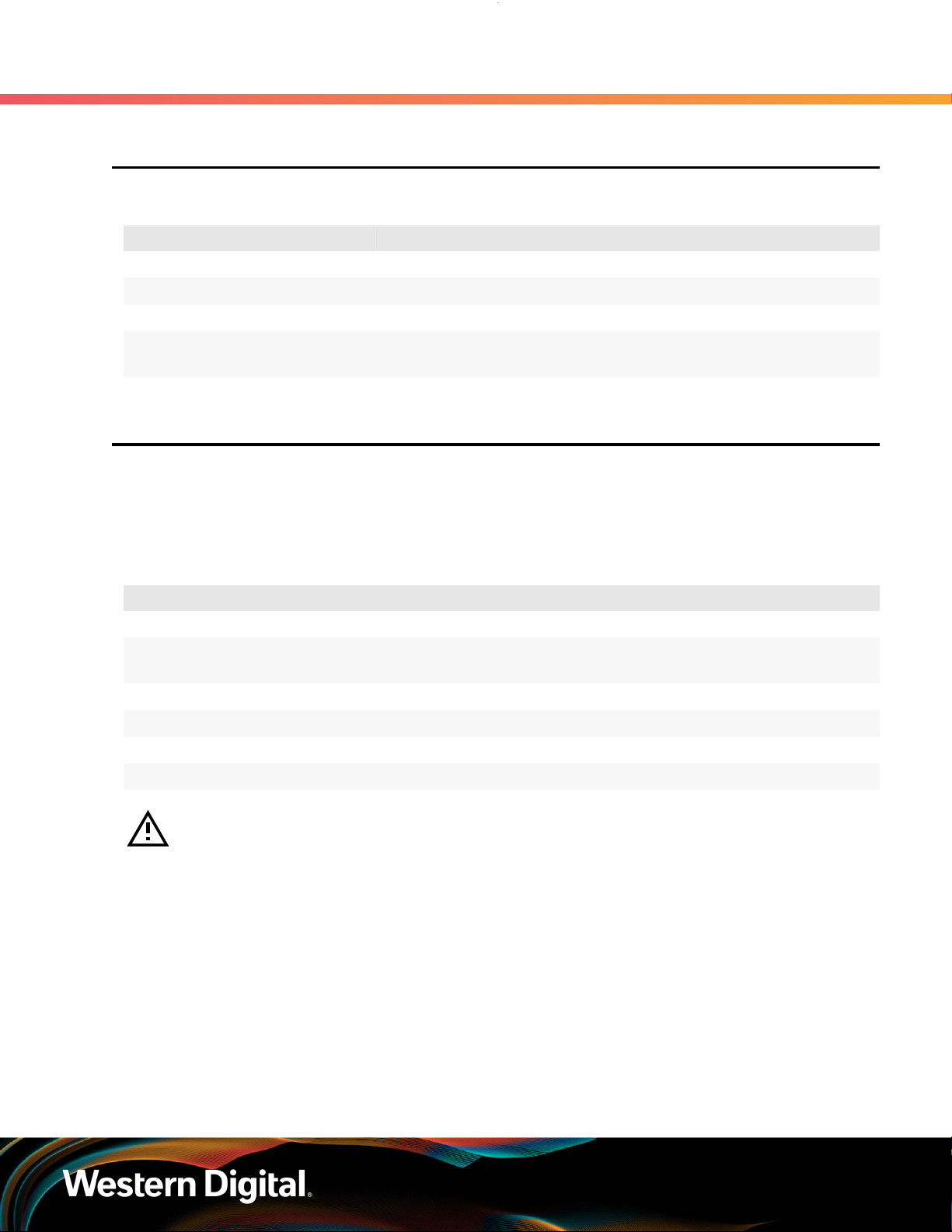

Warning: When extended out of the rack on the rail system, the Ultrastar Data102 will be

~950 mm / 37.4in. extended outward. This may be a potential tipping hazard depending on

the configuration of the rack. Ensure that leveling feet, anti-tilt, and any other safety features

recommended by the specific rack manufacturers have been deployed before servicing.

The following section provides specific information necessary to install, service, and remove the Ultrastar

Data102 . The installation of the Ultrastar Data102 requires two people and a space of 1524mm / 60in.

in front of the installation space. The servicing of the enclosure requires one person and a minimum of

1219.2mm / 48in. of space in front of the installation space. The removal of the enclosure requires two

people, 1371mm / 54in. of space in front of the installation space, and 24in. on either side of the enclosure

for two people to remove the enclosure.

450mm with (17.72in.) with 465mm (18.31in.) ± 1.5mm

nominal hole spacing. See EIA-310 Rack Standard

6

Page 14

Installation Guide

Warning: The handles on the front of the chassis are not intended to be used to support the

weight of the Ultrastar Data102 . Lifting the unit by the chassis handles or trying to support the

unit on the handles can cause them to fail. This can cause serious damage to the unit or serious

bodily harm to those handling the unit. Always team lift the chassis by gripping the underside

of the unit, and never try to lift a chassis that is filled with drives.

Figure 5: Installation, Servicing, and Removal

1. Overview

1.7 Ultrastar Data102 Rack Requirements

Attention: Do not install or remove the enclosure while it is populated with drives. The fully

populated enclosure exceeds the amount of weight that a team of two should lift.

1.7.1 Compatible Rack Hardware Configuration

The following table(s) list the approved rack hardware configurations for the Ultrastar Data102 :

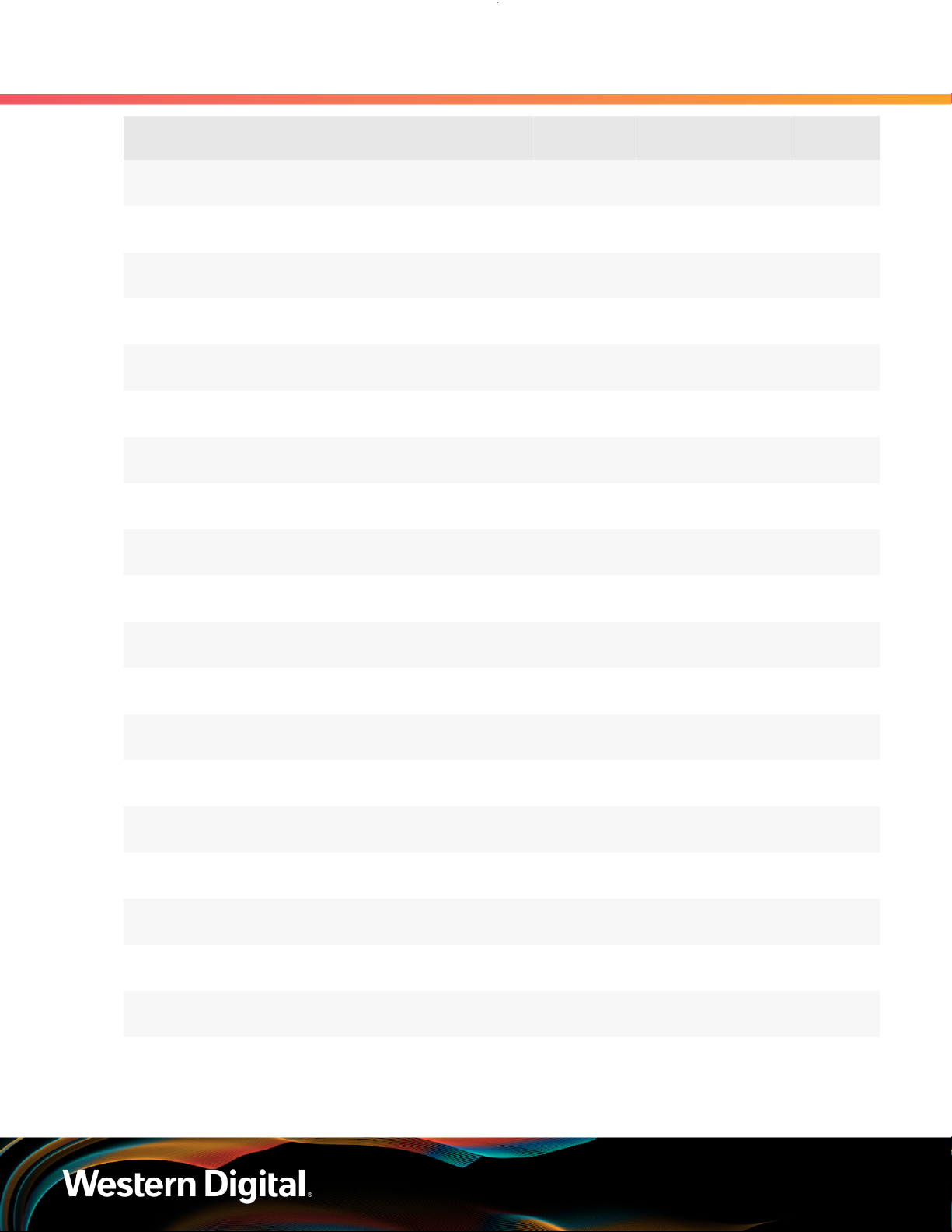

Table 7: Compatible Hardware Configuration 1

Parameter Rack PDU (Vertical)

Vendor CRENLO/EMCOR Server Technology Server Technology Various

AS-160099-03

(Drawing

Number EMCOR

Part

Number

Quantity 1 2 2 Varies

526121 Rev 5)

412-0761-11_STV-4501

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

KIT-MBVPT-1B

(one kit per PDU)

Additional Mounting

Bracket Hardware

4 x M6 x 16 Hex

Cap Screws

8 x M6 Fender

Washers

4 x M6 Hex Nut

with Nylon Lock

7

Page 15

Installation Guide

Table 8: Compatible Hardware Configuration 2

1. Overview

1.7 Ultrastar Data102 Rack Requirements

Parameter Rack PDU (Vertical)

Vendor AFCO/Legrand Server Technology Server Technology Various

Options:

42RU –

WEDIT605

Part

Number

Quantity 1 rack 2 1 N/A

45RU –

WEDIT604

48RU –

WEDIT603

51RU –

WEDIT606

412-0761-11_STV-4501

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

KIT-MB-40 None

Additional Mounting

Bracket Hardware

Table 9: Compatible Hardware Configuration 3

Parameter Rack PDU (Vertical)

Vendor TRIPP LITE Server Technology Server Technology Various

PDU Mounting

Bracket

Additional Mounting

Bracket Hardware

Options:

SR42UBDP (Rack)

SREXTENDER

25U (Rack

Part

Number

Quantity 1 rack 2 1 N/A

Extension)

SREXTENDER

42U (Rack

Extension)

SREXTENDER

48U (Rack

Extension)

412-0761-11_STV-4501

412-0761-20_STV-4502

412-0761-23_STV-4503

KIT-MBVPT-1B None

Table 10: Compatible Hardware Configuration 4

Parameter Rack PDU (Vertical)

Vendor APC/Schneider Server Technology Server Technology Various

Part

Number

AR3300W

412-0761-11_STV-4501

412-0761-20_STV-4502

PDU Mounting

Bracket

KIT-MBVPT-1B

(one kit per PDU)

Additional Mounting

Bracket Hardware

4 x M6 x 16 Hex

Cap Screws

8

Page 16

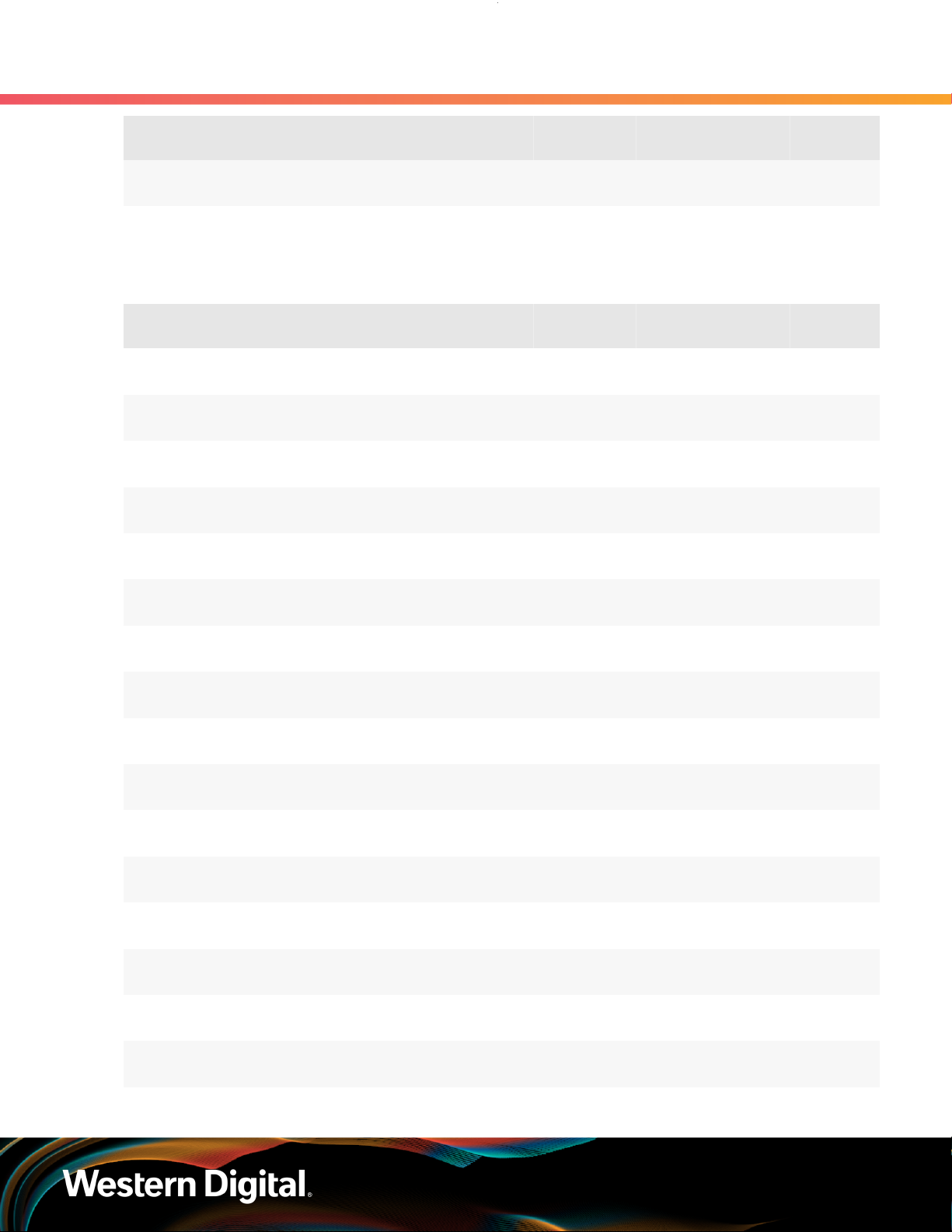

Installation Guide

1. Overview

1.8 List of Compatible Drives

Parameter Rack PDU (Vertical)

412-0761-23_STV-4503 8 x M6 Fender

Quantity 1 rack 2 2 Varies

1.8 List of Compatible Drives

HDD with 3.5-inch Drive Carrier

Table 11: Western Digital Ultrastar DC HC310

Drive Type Interface

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 6TB 1EX1189

HDD SATA 6Gb/s 512e TCG 6TB 1EX1188

PDU Mounting

Sector

Size

Additional Mounting

Bracket

Encryption Volume Part Number

Bracket Hardware

Washers

4 x M6 Hex Nut

with Nylon Lock

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 4Kn SE 6TB 1EX1187

HDD SATA 6Gb/s 4Kn TCG 6TB 1EX1186

HDD SAS 12Gb/s 512e SE 6TB 1EX1185

HDD SAS 12Gb/s 512e TCG 6TB 1EX1184

HDD SAS 12Gb/s 512e TCG-FIPS 6TB 1EX1853

HDD SAS 12Gb/s 4Kn SE 6TB 1EX1183

HDD SAS 12Gb/s 4Kn TCG 6TB 1EX1182

HDD SAS 12Gb/s 4Kn TCG-FIPS 6TB 1EX1852

Table 12: Western Digital Ultrastar DC HC320

Drive Type Interface

Ultrastar DC HC320

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 8TB 1EX1227

Sector

Size

Encryption Volume Part Number

9

Page 17

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Sector

Size

HDD SATA 6Gb/s 512e SED 8TB 1EX1226

HDD SATA 6Gb/s 4Kn SE 8TB 1EX1225

HDD SATA 6Gb/s 4Kn TCG 8TB 1EX1224

HDD SAS 12Gb/s 512e SE 8TB 1EX1223

HDD SAS 12Gb/s 512e TCG 8TB 1EX1222

HDD SAS 12Gb/s 512e TCG-FIPS 8TB 1EX1343

HDD SAS 12Gb/s 4Kn SE 8TB 1EX1221

HDD SAS 12Gb/s 4Kn TCG 8TB 1EX1220

HDD SAS 12Gb/s 4Kn TCG-FIPS 8TB 1EX1342

Encryption Volume Part Number

Table 13: Western Digital Ultrastar DC HC330

Drive Type Interface

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 10TB 1EX2440

HDD SATA 6Gb/s 512e SED 10TB 1EX2441

HDD SATA 6Gb/s 4Kn SE 10TB 1EX2438

HDD SATA 6Gb/s 4Kn SED 10TB 1EX2439

HDD SAS 12Gb/s 512e SE 10TB 1EX2435

HDD SAS 12Gb/s 512e TCG 10TB 1EX2436

HDD SAS 12Gb/s 512e TCG-FIPS 10TB 1EX2437

HDD SAS 12Gb/s 4Kn TCG 10TB 1EX2433

HDD SAS 12Gb/s 4Kn TCG-FIPS 10TB 1EX2434

Sector

Size

Encryption Volume Part Number

10

Page 18

Installation Guide

Table 14: Western Digital Ultrastar DC HC510

1. Overview

1.8 List of Compatible Drives

Drive Type Interface

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Sector

Size

HDD SATA 6Gb/s 512e SE 10TB 1EX0499

HDD SATA 6Gb/s 512e ISE 10TB 1EX0497

HDD SATA 6Gb/s 512e SED 10TB 1EX0498

HDD SATA 6Gb/s 4Kn SE 10TB 1EX0496

HDD SATA 6Gb/s 4Kn ISE 10TB 1EX0494

HDD SATA 6Gb/s 4Kn SED 10TB 1EX0495

HDD SAS 12Gb/s 512e SE 10TB 1EX0487

HDD SAS 12Gb/s 512e ISE 10TB 1EX0485

HDD SAS 12Gb/s 512e TCG 10TB 1EX0486

Encryption Volume Part Number

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 512e TCG-FIPS 10TB 1EX1341

HDD SAS 12Gb/s 4Kn SE 10TB 1EX0484

HDD SAS 12Gb/s 4Kn ISE 10TB 1EX0482

HDD SAS 12Gb/s 4Kn TCG 10TB 1EX0483

HDD SAS 12Gb/s 4Kn TCG-FIPS 10TB 1EX1340

Table 15: Western Digital Ultrastar DC HC520

Drive Type Interface

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 12TB 1EX1015

HDD SATA 6Gb/s 512e ISE 12TB 1EX1013

HDD SATA 6Gb/s 512e SED 12TB 1EX1014

Sector

Size

Encryption Volume Part Number

Ultrastar DC HC520 HDD SATA 6Gb/s 4Kn SE 12TB 1EX1012

11

Page 19

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Sector

Size

HDD SATA 6Gb/s 4Kn ISE 12TB 1EX1010

HDD SATA 6Gb/s 4Kn SED 12TB 1EX1011

HDD SAS 12Gb/s 512e SE 12TB 1EX1009

HDD SAS 12Gb/s 512e ISE 12TB 1EX1007

HDD SAS 12Gb/s 512e TCG 12TB 1EX1008

HDD SAS 12Gb/s 512e TCG-FIPS 12TB 1EX1338

HDD SAS 12Gb/s 4Kn SE 12TB 1EX1006

HDD SAS 12Gb/s 4Kn ISE 12TB 1EX1004

HDD SAS 12Gb/s 4Kn TCG 12TB 1EX1005

Encryption Volume Part Number

Ultrastar DC HC520

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 4Kn TCG-FIPS 12TB 1EX1339

Table 16: Western Digital Ultrastar DC HC530

Drive Type Interface

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 14TB 1EX1793

HDD SATA 6Gb/s 512e SED 14TB 1EX1794

HDD SATA 6Gb/s 4Kn SE 14TB 1EX1790

HDD SAS 12Gb/s 512e SE 14TB 1EX1791

HDD SAS 12Gb/s 512e ISE 14TB 1EX1583

HDD SAS 12Gb/s 512e TCG 14TB 1EX1792

HDD SAS 12Gb/s 512e TCG-FIPS 14TB 1EX1855

Sector

Size

Encryption Volume Part Number

Ultrastar DC HC530

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 4Kn SE 14TB 1EX1788

12

Page 20

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 4Kn TCG 14TB 1EX1789

HDD SAS 12Gb/s 4Kn TCG-FIPS 14TB 1EX1854

Table 17: Western Digital Ultrastar DC HC550

Drive Type Interface

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 16TB 1EX2476

HDD SATA 6Gb/s 512e SED 16TB 1EX2477

HDD SAS 12Gb/s 512e SE 16TB 1EX2473

HDD SAS 12Gb/s 512e TCG 16TB 1EX2474

HDD SAS 12Gb/s 512e TCG-FIPS 16TB 1EX2475

Sector

Size

Sector

Size

Encryption Volume Part Number

Encryption Volume Part Number

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 18TB 1EX2481

HDD SATA 6Gb/s 512e SED 18TB 1EX2482

HDD SAS 12Gb/s 512e SE 18TB 1EX2478

HDD SAS 12Gb/s 512e TCG 18TB 1EX2479

HDD SAS 12Gb/s 512e TCG-FIPS 18TB 1EX2480

SSD with 2.5-inch Drive Carrier

Table 18: Western Digital Ultrastar SS300

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 400GB

SSD SAS 12Gb/s RI-3DW/D ISE 400GB

Part

Number

No longer

available

No longer

available

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D TCG 400GB

No longer

available

13

Page 21

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s ME-10DW/D SE 400GB

SSD SAS 12Gb/s ME-10DW/D ISE 400GB

SSD SAS 12Gb/s ME-10DW/D TCG 400GB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s RI-3DW/D SE 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 800GB

SSD SAS 12Gb/s RI-3DW/D TCG 800GB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 800GB

Part

Number

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D SE 800GB

SSD SAS 12Gb/s ME-10DW/D ISE 800GB

SSD SAS 12Gb/s ME-10DW/D TCG 800GB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 1.6TB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 1.6TB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 1.6TB

SSD with 3.5-inch to 2.5-inch Drive Carrier

Table 19: Western Digital Ultrastar SS200

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 400GB

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Part

Number

No longer

available

14

Page 22

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D ISE 400GB

SSD SAS 12Gb/s RI-3DW/D TCG 400GB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s RI-1DW/D TCG 480GB

SSD SAS 12Gb/s RI-3DW/D SE 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 800GB

SSD SAS 12Gb/s RI-3DW/D TCG 800GB

SSD SAS 12Gb/s RI-1DW/D TCG 960GB

SSD SAS 12Gb/s RI-3DW/D SE 1.6TB

Part

Number

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D ISE 1.6TB

SSD SAS 12Gb/s RI-3DW/D TCG 1.6TB

SSD SAS 12Gb/s RI-1DW/D TCG 1.92TB

SSD SAS 12Gb/s RI-3DW/D ISE 3.2TB

SSD SAS 12Gb/s RI-1DW/D ISE 3.84TB

SSD SAS 12Gb/s RI-1DW/D SE 7.68TB

Table 20: Western Digital Ultrastar SS300

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 400GB

SSD SAS 12Gb/s RI-3DW/D ISE 400GB

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Part

Number

No longer

available

No longer

available

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D TCG 400GB

No longer

available

15

Page 23

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D SE 400GB

SSD SAS 12Gb/s ME-10DW/D ISE 400GB

SSD SAS 12Gb/s ME-10DW/D TCG 400GB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s RI-3DW/D SE 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 800GB

SSD SAS 12Gb/s RI-3DW/D TCG 800GB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 800GB

SSD SAS 12Gb/s ME-10DW/D SE 800GB

Part

Number

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D ISE 800GB

SSD SAS 12Gb/s ME-10DW/D TCG 800GB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 800GB

SSD SAS 12Gb/s RI-3DW/D SE 1.6TB

SSD SAS 12Gb/s RI-3DW/D ISE 1.6TB

SSD SAS 12Gb/s RI-3DW/D TCG 1.6TB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 1.6TB

SSD SAS 12Gb/s RI-10DW/D SE 1.6TB

SSD SAS 12Gb/s RI-10DW/D ISE 1.6TB

SSD SAS 12Gb/s RI-10DW/D TCG 1.6TB

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 1.6TB

No longer

available

16

Page 24

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 3.2TB

SSD SAS 12Gb/s RI-3DW/D ISE 3.2TB

Table 21: Western Digital Ultrastar SS530

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 400GB 1EX2020

SSD SAS 12Gb/s RI-3DW/D ISE 400GB 1EX2021

SSD SAS 12Gb/s RI-3DW/D TCG 400GB 1EX2087

SSD SAS 12Gb/s ME-10DW/D SE 400GB 1EX2012

SSD SAS 12Gb/s ME-10DW/D ISE 400GB 1EX2013

Part

Number

No longer

available

No longer

available

Part

Number

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D TCG 400GB 1EX2083

SSD SAS 12Gb/s RI-1DW/D SE 480GB 1EX2030

SSD SAS 12Gb/s RI-1DW/D ISE 480GB 1EX2031

SSD SAS 12Gb/s RI-1DW/D TCG 480GB 1EX2092

SSD SAS 12Gb/s RI-3DW/D SE 800GB 1EX2022

SSD SAS 12Gb/s RI-3DW/D ISE 800GB 1EX2023

SSD SAS 12Gb/s RI-3DW/D TCG 800GB 1EX2088

SSD SAS 12Gb/s ME-10DW/D SE 800GB 1EX2014

SSD SAS 12Gb/s ME-10DW/D ISE 800GB 1EX2015

SSD SAS 12Gb/s ME-10DW/D TCG 800GB 1EX2084

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530 SSD SAS 12Gb/s RI-1DW/D ISE 960GB 1EX2033

SSD SAS 12Gb/s RI-1DW/D SE 960GB 1EX2032

17

Page 25

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Part

Number

SSD SAS 12Gb/s RI-1DW/D TCG 960GB 1EX2093

SSD SAS 12Gb/s RI-3DW/D SE 1.6TB 1EX2024

SSD SAS 12Gb/s RI-3DW/D ISE 1.6TB 1EX2025

SSD SAS 12Gb/s RI-3DW/D TCG 1.6TB 1EX2089

SSD SAS 12Gb/s ME-10DW/D SE 1.6TB 1EX2016

SSD SAS 12Gb/s ME-10DW/D ISE 1.6TB 1EX2017

SSD SAS 12Gb/s ME-10DW/D TCG 1.6TB 1EX2085

SSD SAS 12Gb/s RI-1DW/D SE 1.92TB 1EX2034

SSD SAS 12Gb/s RI-1DW/D ISE 1.92TB 1EX2035

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-1DW/D TCG 1.92TB 1EX2094

SSD SAS 12Gb/s RI-3DW/D SE 3.2TB 1EX2026

SSD SAS 12Gb/s RI-3DW/D ISE 3.2TB 1EX2027

SSD SAS 12Gb/s RI-3DW/D TCG 3.2TB 1EX2090

SSD SAS 12Gb/s ME-10DW/D SE 3.2TB 1EX2018

SSD SAS 12Gb/s ME-10DW/D ISE 3.2TB 1EX2019

SSD SAS 12Gb/s ME-10DW/D TCG 3.2TB 1EX2086

SSD SAS 12Gb/s RI-1DW/D SE 3.84TB 1EX2036

SSD SAS 12Gb/s RI-1DW/D ISE 3.84TB 1EX2037

SSD SAS 12Gb/s RI-1DW/D TCG 3.84TB 1EX2095

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 6.4TB 1EX2028

18

Page 26

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS530

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D ISE 6.4TB 1EX2029

SSD SAS 12Gb/s RI-3DW/D TCG 6.4TB 1EX2091

SSD SAS 12Gb/s RI-1DW/D SE 7.68TB 1EX2038

SSD SAS 12Gb/s RI-1DW/D ISE 7.68TB 1EX2039

SSD SAS 12Gb/s RI-1DW/D TCG 7.68TB 1EX2096

SSD SAS 12Gb/s RI-1DW/D SE 15.36TB 1EX2040

SSD SAS 12Gb/s RI-1DW/D ISE 15.36TB 1EX2041

SSD SAS 12Gb/s RI-1DW/D TCG 15.36TB 1EX2097

Table 22: Western Digital Ultrastar SA620

Part

Number

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

SSD SATA 6Gb/s RI-1.8DW/D SE 400GB

SSD SATA 6Gb/s RI-1.8DW/D ISE 400GB

SSD SATA 6Gb/s RI-0.6DW/D SE 480GB

SSD SATA 6Gb/s RI-0.6DW/D ISE 480GB

SSD SATA 6Gb/s RI-1.8DW/D SE 800GB

SSD SATA 6Gb/s RI-1.8DW/D ISE 800GB

SSD SATA 6Gb/s RI-0.6DW/D SE 960GB

SSD SATA 6Gb/s RI-0.6DW/D ISE 960GB

SSD SATA 6Gb/s RI-1.8DW/D SE 1.6TB

Part

Number

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

SSD SATA 6Gb/s RI-1.8DW/D ISE 1.6TB

No longer

available

19

Page 27

Installation Guide

1. Overview

1.8 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SA620

w/ 3.5 in. to 2.5 in. drive carrier

SSD SATA 6Gb/s RI-0.6DW/D SE 1.92TB

SSD SATA 6Gb/s RI-0.6DW/D ISE 1.92TB

Part

Number

No longer

available

No longer

available

20

Page 28

Western Digital

Disclaimers

Learn about the Regulatory, Safety, and Electromagnetic

standards for which this product is compliant.

The following chapter describes the Regulatory Statement

of Compliance, Safety Compliance, and Electromagnetic

Compatibility Agency Requirements for the Ultrastar Data102 .

In This Chapter:

- Restricted Access Location.........................22

- Safety Compliance.......................................22

- Electromagnetic Compatibility (EMC) Class

A Compliance.................................................22

- Country Certifications................................. 23

21

Page 29

Installation Guide

2.1 Restricted Access Location

The Ultrastar Data102 is intended for installation in a server room or computer room where at least one of

the following conditions apply:

• access can only be gained by service persons or by users who have been instructed about the

restrictions applied to the location and about any precautions that shall be taken and/or

• access is through the use of a tool or lock and key, or other means of security, and is controlled by the

authority responsible for the location.

2.2 Safety Compliance

Product Name: Ultrastar Data102

Regulatory Model: H4102-J

Electromagnetic Compatibility Emissions: Class A

This product has been tested and evaluated as Information Technology Equipment (ITE) at accredited thirdparty laboratories for all safety, emissions and immunity testing required for the countries and regions where

the product is marketed and sold. The product has been verified as compliant with the latest applicable

standards, regulations and directives for those regions/countries. The suitability of this product for other

product categories other than ITE may require further evaluation.

The product is labeled with a unique regulatory model that is printed on the label and affixed to every unit.

The label will provide traceability to the regulatory approvals listed in this document. The document applies

to any product that bears the regulatory model and type names including marketing names other than

those listed in this document.

2. Disclaimers

2.1 Restricted Access Location

2.3 Electromagnetic Compatibility (EMC) Class A Compliance

The H4102-J complies with and conforms to the latest international standards as applicable:

Emissions

• FCC CFR 47 Part 15, Subpart B

• ICES-003

• EN 55032

• CISPR 32

• CE – EMC Directive 2014/30/EU

• VCCI V-3

• BSMI CNS14338

• KN32

• AS/NZS CISPR 32

• TR CU 020/2011

Immunity

• EN 61000-3-2 Harmonic Current Emissions

• EN 61000-3-3 Voltage Fluctuations and Flicker

• EN 55024

• KN35

• EN 61000-4-2 ESD

22

Page 30

Installation Guide

• EN 61000-4-3 Radiated Immunity

• EN 61000-4-4 EFT

• EN 61000-4-5 Surge

• EN 61000-4-6 RF Common Mode

• EN 61000-4-8 Power Frequency Magnetic Field

• EN 61000-4-11 Voltage Dips and Interruptions

2.4 Country Certifications

Table 23: Country Certifications

Country/Region Authority or Mark

North America (Canada, USA) Nemko

European Union CE

Japan VCCI

Korea MSIP

2. Disclaimers

2.4 Country Certifications

Taiwan BSMI

Australia/New Zealand RCM

Russia, Kazakhstan, Belarus, Armenia CU EAC

Ukraine Ukrsepro

Mexico NOM

Israel SII

South Africa SABS

India BIS

23

Page 31

Western Digital

Safety

The following chapter provides safety and regulatory

information for the Ultrastar Data102 .

In This Chapter:

- Safety Warnings and Cautions....................25

- Electrostatic Discharge............................... 25

- Optimizing Location.................................... 25

- Power Connections......................................26

- Power Cords................................................. 26

- Rackmountable Systems............................. 26

- Safety and Service....................................... 27

24

Page 32

Installation Guide

3.1 Safety Warnings and Cautions

To avoid personal injury or property damage, before you begin installing the product, read, observe, and

adhere to all of the following safety instructions and information. The following safety symbols may be used

throughout the documentation and may be marked on the product and/or the product packaging.

CAUTION Indicates the presence of a hazard that may cause minor personal injury or property damage if

the CAUTION is ignored.

WARNING Indicates the presence of a hazard that may result in serious personal injury if the WARNING is

ignored.

Indicates potential hazard if indicated information is ignored.

Indicates shock hazards that result in serious injury or death if safety instructions are not followed.

3. Safety

3.1 Safety Warnings and Cautions

Indicates do not touch fan blades, may result in injury.

Indicates disconnect all power sources before servicing.

3.2 Electrostatic Discharge

CAUTION

Electrostatic discharge can harm delicate components inside Western Digital products.

Electrostatic discharge (ESD) is a discharge of stored static electricity that can damage equipment and

impair electrical circuitry. It occurs when electronic components are improperly handled and can result in

complete or intermittent failures.

Wear an ESD wrist strap for installation, service and maintenance to prevent damage to components in the

product. Ensure the antistatic wrist strap is attached to a chassis ground (any unpainted metal surface). If

possible, keep one hand on the frame when you install or remove an ESD-sensitive part.

Before moving ESD-sensitive parts place them in ESD static-protective bags until you are ready to install the

part.

3.3 Optimizing Location

Failure to recognize the importance of optimally locating your product and failure to protect against

electrostatic discharge (ESD) when handling your product can result in lowered system performance or

system failure.

Do not position the unit in an environment that has extreme high temperatures or extreme low

temperatures. Be aware of the proximity of the unit to heaters, radiators, and air conditioners.

25

Page 33

Installation Guide

Position the unit so that there is adequate space around it for proper cooling and ventilation. Consult the

product documentation for spacing information.

Keep the unit away from direct strong magnetic fields, excessive dust, and electronic/electrical equipment

that generate electrical noise.

3.4 Power Connections

Be aware of the ampere limit on any power supply or extension cables being used. The total ampere rating

being pulled on a circuit by all devices combined should not exceed 80% of the maximum limit for the

circuit.

CAUTION The power outlet must be easily accessible close to the unit.

Always use properly grounded, unmodified electrical outlets and cables. Ensure all outlets and

cables are rated to supply the proper voltage and current.

This unit has more than one power supply connection; both power cords must be removed from the

power supplies to completely remove power from the unit. There is no switch or other disconnect device.

When power cycling the unit, wait 10 seconds before re-applying power. Failure to do so may cause the

enclosure to boot up in an inaccessible state. If this is encountered, remove power, wait 10 seconds, and

then reapply power.

3. Safety

3.4 Power Connections

3.5 Power Cords

Use only tested and approved power cords to connect to properly grounded power outlets or

insulated sockets of the rack's internal power supply.

If an AC power cord was not provided with your product, purchase one that is approved for use in your

country or region.

CAUTION To avoid electrical shock or fire, check the power cord(s) that will be used with the product as

follows:

• The power cord must have an electrical rating that is greater than that of the electrical current rating

marked on the product.

• Do not attempt to modify or use the AC power cord(s) if they are not the exact type required to fit into

the grounded electrical outlets.

• The power supply cord(s) must be plugged into socket-outlet(s) that is / are provided with a suitable

earth ground.

• The power supply cord(s) is / are the main disconnect device to AC power. The socket outlet(s) must

be near the equipment and readily accessible for disconnection.

3.6 Rackmountable Systems

CAUTION

26

Page 34

Installation Guide

Always install rack rails and storage enclosure according to Ultrastar Data102 product documentation.

Follow all cautions, warnings, labels, and instructions provided within the rackmount instructions.

Reliable grounding of rack-mounted equipment should be maintained.

If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient. Therefore, consideration should be given to installing the

equipment in an environment compatible with the maximum ambient temperature (Tma) specified by the

manufacturer.

Observe the maximum rated ambient temperature, which is specified in the product documentation.

For safe operation of the equipment, installation of the equipment in a rack should be such that the

amount of air flow is not impeded so that the safe operation of the equipment is not compromised.

3.7 Safety and Service

All maintenance and service actions appropriate to the end-users are described in the product

documentation. All other servicing should be referred to a Western Digital-authorized service technician.

3. Safety

3.7 Safety and Service

To avoid shock hazard, turn off power to the unit by unplugging both power cords before

servicing the unit. Use extreme caution around the chassis because potentially harmful voltages are present.

When replacing a hot-plug power supply, unplug the power cord to the power supply being

replaced before removing it from the Ultrastar Data102 .

The power supply in this product contains no user-serviceable parts. Do not open the power supply.

Hazardous voltage, current and energy levels are present inside the power supply. Return to manufacturer

for servicing.

Use caution when accessing part of the product that are labeled as potential shock

hazards, hazardous access to moving parts such as fan blades.

27

Page 35

Western Digital

Packaging

The following chapter provides information about how the

Ultrastar Data102 is packaged and instructions for unpacking it.

In This Chapter:

- Ultrastar Data102 Packaging Overview......29

- Ultrastar Data102 Unpacking

Procedure....................................................... 32

28

Page 36

Installation Guide

4.1 Ultrastar Data102 Packaging Overview

4.1 Ultrastar Data102 Packaging Overview

Figure 6: Outer Packaging

4. Packaging

The Ultrastar Data102 is shipped in protective outer

packaging that consists of cardboard caps on the

top and bottom and an outer sleeve surrounding

the sides. Edge protectors reinforce the top cap,

while plastic banding surrounds the packaging and

secures it all to the shipping pallet.

The inner contents of the Ultrastar Data102

packaging consists of three layers: the accessory

tray (top), the chassis box (middle), and the drive

boxes (bottom). The contents of each layer are

detailed in the following sections.

29

Page 37

Installation Guide

Accessory Tray

The accessory tray contains boxes for the CMA arms, the Rails, and the Top Cover Alignment Brackets, as

well as plastic bags containing the cables and necessary hardware.

4. Packaging

4.1 Ultrastar Data102 Packaging Overview

Figure 7: Accessory Tray Contents

Table 24: Accessory Tray Contents

Container Contents

CMA Box 2 CMA arms (1 upper, 1 lower)

Rails Box

Brackets

Box

Accessory

Tray

• 2 Rails (each containing 1 innerrail & 1 outer-rail)

• Cross-bar

2 Top Cover Alignment Brackets

• 2 Rack Latch Brackets (1 left, 1

right)

• Screws & Nuts

◦ 10 M5 cagenuts

◦ 30 M5 x 12, T15 Torx

screws

◦ 2 M5 x 12 Philips panhead

screws (for cover

retention)

◦ 16 custom round washers

◦ 6 custom low-profile M4

xcrews (packaged with

the rail kit)

• Cables

◦ 2 C13 to C14 power cables

(3m)

◦ 2 MiniSAS HD cables (3m)

30

Page 38

Installation Guide

Chassis Box

The Chassis is boxed in the middle layer and protected by foam padding. It comes with pre-installed Rear

Fans, PSUs, IOM Fan, and IOMs.

4. Packaging

4.1 Ultrastar Data102 Packaging Overview

Figure 8: Chassis Box Contents

Drive Boxes

On the bottom layer are seven drive boxes holding fourteen HDD assemblies each, and one box holding

four HDD assemblies.

Figure 9: Drive Box Contents

Table 25: Chassis Box Contents

Container Contents

Chassis box 1 Chassis w/ all internal

components pre-installed (except

HDDs):

• 2 PSUs

• 2 IOM s

• 1 IOM Fan

• 4 Rear Fans

Table 26: Drive Box Contents

Container Contents

7 boxes:

1 box:

(total of 8

boxes)

14 HDD assemblies each

4 HDD assemblies

(total of 102 HDD assemblies)

31

Page 39

Installation Guide

4.2 Ultrastar Data102 Unpacking Procedure

4.2 Ultrastar Data102 Unpacking Procedure

Step 1 : Make sure that all of the necessary parts and equipment are available, including any equipment

necessary to support the enclosure during installation. To verify the list of necessary parts, see

Ultrastar Data102 Packaging Overview (page 29).

Step 2 :

Step 3 : Remove and discard the top cap and the outer sleeve.

Using a box cutter, cut the straps that secure the packaging to the pallet.

Figure 10: Top Cap and Sleeve Removal

4. Packaging

Step 4 : From the accessory tray, open the boxes for the rails, CMA arms, and top cover alignment

brackets. Remove these parts and set them aside.

32

Page 40

Installation Guide

Figure 11: Unpack Accessory Tray Contents

4. Packaging

4.2 Ultrastar Data102 Unpacking Procedure

Step 5 : Open the chassis box and remove the top cushions from the front and rear of the chassis.

Figure 12: Unpack Chassis Box Contents

Step 6 : With assistance, and without using the system handles, remove the chassis from the chassis box

and set it aside.

33

Page 41

Installation Guide

Step 7 : Open the drive boxes and verify their contents. Depending on the version of the Ultrastar

Data102 being unpacked, seven boxes should contain fourteen drive assemblies (in the form of

HDDs, SSDs, or blanks), and one box should contain four drive assemblies. Once the contents are

verified, leave them in the boxes. This will protect them from damage until they are installed in

the enclosure.

Figure 13: Verify Drives and Drive Blanks

4. Packaging

4.2 Ultrastar Data102 Unpacking Procedure

Warning: The chassis weight without drives is 32.34 kg / 71.3 lbs. To avoid injury,

the chassis should be team lifted.

Caution: Do not lift the chassis by the system handles. The handles are designed

only for sliding the enclosure out of the rack on its rails.

34

Page 42

Western Digital

Installation

In This Chapter:

- Ultrastar Data102 Installation Overview.....36

- Ultrastar Data102 Installation

Procedure........................................................37

- SAS Cabling.................................................. 66

- Special Considerations for Cable

Routing........................................................... 68

- Cabling for CMA Standard and CMA

Lite...................................................................70

35

Page 43

Installation Guide

5.1 Ultrastar Data102 Installation Overview

5.1 Ultrastar Data102 Installation Overview

Procedure Info

5. Installation

Required Tools Required Parts

• Long T15 Torx Screwdriver

• # 2 Philips Screwdriver

• Long T10 Torx Screwdriver

• Cable Ties (for configurations

with greater than 10 total

cables)

• Tape Measure

• Level

Torque Specifications for Screws

• M5 x 12mm T15 Flat Head Torx

screws

• M5 x 12mm Phillips Pan Head

screws (to secure top cover)

• Included Washers

• Low-Profile M4 x 3.2mm Philips

screws (included with rail

assembly)

• M3 x 8mm T10 Torx screws

• 10 M5 cage nuts

• CMA Crossbar

• Cable Tray (optional)

• Optional (if using CMA Tray):

M3 x 8mm T10 Torx screws

• Zip Tie (from CMA box)

# of People

Required

3 Total (2 for

Team Lifting

Purposes and

1 to Guide and

Spot)

Time

Required

45 min.

Screw Type Torque Value

M5 x 12mm T15 Flat Head Torx

screws

M5 x 12mm Phillips Pan Head screws 3.38-3.61 Nm / 30-32 in-lbf

Low-Profile M4 x 3.2mm Philips

screws

M3 x 8mm T10 Torx screws .33-.56 Nm / 3-5 in-lbf

Captive M5 Torx chassis cover thumb

screws

3.38-3.61 Nm / 30-32 in-lbf

.90-1.12 Nm / 8-10 in-lbf

3.38-3.61 Nm / 30-32 in-lbf

36

Page 44

Installation Guide

Cable Management

There are two different options for cable management in Ultrastar Data102 : CMA Standard and CMA

Lite. Each of these options has a different installation, configuration, and purpose. The standard CMA

configuration manages and protects the full cable load during normal operation of the Ultrastar Data102 . If a

fully-configured Ultrastar Data102 is not necessary, CMA Lite provides a better management and protection

solution for a lighter cable load, with a more compact hardware footprint. Utilizing front spacer brackets

that shift the enclosure forward, and narrower basket clips for tighter cable management, CMA Lite allows

the enclosure to fit within shallower racks and/or those with front and rear doors. The following information

provides a list of the features of each cable management option:

CMA Standard:

• Enables use of all I/O connections

• Manages and protects full set of cables during installation, operation, and servicing

• Easy cable routing with the open-top cable baskets

• Toolless installation

CMA Lite:

• Smaller rack footprint for shallower racks and/or racks with doors

• Manages and protects a lighter cable load (with only one CMA arm) during installation, operation, and

servicing

• Easy cable routing with the open-top cable baskets

• Toolless installation

5. Installation

5.2 Ultrastar Data102 Installation Procedure

CMA and CMA Lite in the Installation Procedure

The installation procedure for the Ultrastar Data102 includes instructions for both CMA Standard and CMA

Lite. These instructions are labeled, in-line, to notify the user when a step or part of a step is used for one

option or the other. These options occur during the steps for rail installation, CMA installation, cabling,

and securing the enclosure to the rack.

Attention: The CMA Lite replacement package includes a CMA arm and spacer brackets.

Replacing the CMA arm can be done with the enclosure in place in the rack. To replace the

spacer brackets, the enclosure must be removed from the rack.

5.2 Ultrastar Data102 Installation Procedure

Warning: The handles on the front of the chassis are not intended to be used to support the

weight of the Ultrastar Data102 . Lifting the unit by the chassis handles or trying to support the

unit on the handles can cause them to fail. This can cause serious damage to the unit or serious

bodily harm to those handling the unit. Always team lift the chassis by gripping the underside

of the unit, and never try to lift a chassis that is filled with drives.

Attention: This procedure utilizes "Right" and "Left" as to inform the user on actions related to

the installation. "Right" and "Left" will be in reference to where the user is positioned, whether

at the front or the rear of the installation space.

37

Page 45

Installation Guide

Note: For CMA Lite Installation only: Ensure that the chosen rack has about 2.5in. of extra

space in front of the vertical rack rails. The intent of CMA Lite is to reposition the enclosure

closer to the front of the rack to create a more centered enclosure.

Step 1 : Remove the inner rail that is nested inside the rack rails.

a. Start by sliding the inner rail out of the outer/rack rail until the safety latch engages and the

b. Press on the safety latch release spring located on the side of the rail and slide the inner rail

Figure 14: Rail Safety Latch

5. Installation

5.2 Ultrastar Data102 Installation Procedure

Note: There are Right and Left rails and they must be installed as a set. Each inner

rail will read "R" for the right or "L" for the left embossed on the inside. Each outer

rail will read "R-Front" for the right or "L-Front" for the left. Right and Left refer to

when you are facing the front of the rack.

inner rail will not extend further. It will only slide one way.

out the rest of the way.

Step 2 : Install the inner rail onto the chassis making sure they are installed on the correct side. Each inner

rail will read "R" for the right or "L" for the left embossed on the side that faces away from the

chassis. Right and Left are with reference to looking at the front of the enclosure.

a. Orient the inner rails so that the flat side is facing the enclosure and the side with the

grooves is facing away from the enclosure.

Align the keyholes on the inner rail to the mounting pegs on the side of the enclosure and

b.

press the inner rail flush against the chassis. If the keyholes don't line up with the pegs, flip

the rail length-wise to see if this will align them.

38

Page 46

Installation Guide

5. Installation

5.2 Ultrastar Data102 Installation Procedure

Figure 15: Inner Rail Attachment

c.

Slide the inner rail toward the rear of the chassis to lock it in place. There will be an audible

click and the mounting pegs will cover the front part of the keyhole.

Figure 16: Slide Inner Rail

d.

Install the three special low-profile M4 x 3.2mm Philips screws provided to secure the inner

rail to the chassis.

e. Follow these steps for the second inner rail on the opposite side of the enclosure.

Caution: When installing the inner rail onto the chassis, make sure to only use

the special Low-Profile M4 x 3.2mm Philips screws provided in the accessory

kit with the CMA. These screws should be tightened to .90-1.12 Nm / 8-10 inlbf using a # 2 Philips Screwdriver. These screws are specially designed for this

purpose. Using unapproved screws could cause damage to the slides inside

the rail.

Step 3 : Attach a cable tie mount to the cable tray.

a. Clean the surface of the cable tray, under the mounting area, with isopropyl alcohol and

allow to dry.

Adhere a cable tie mount in the approximate location shown in the following diagram:

b.

39

Page 47

Installation Guide

5. Installation

5.2 Ultrastar Data102 Installation Procedure

Figure 17: Cable Tie Mount Location

Step 4 : Secure the Cable Tray onto the enclosure using the included M3 x 8mm T10 Torx screws and the

Long T10 Torx Screwdriver. These screws should be tightened to .33-.56 Nm / 3-5 in-lbf using a

Long T10 Torx Screwdriver.

Figure 18: Installing the Cable Tray

Step 5 : Set the vertical rack rail depth to between 32" and 36".

Note: Ensure that all of the vertical rails are set to the same depth using a tape

measure.

40

Page 48

Installation Guide

Step 6 : Install the outer rails into the rack. Pay special attention to which side is being installed. The

embossed R is for the right side and L is for the left side. Right and Left refer to when you are

facing the front of the rack.

a. Move to the rear of the rack.

b.

5. Installation

5.2 Ultrastar Data102 Installation Procedure

Orient the rail so that the word "REAR" that is embossed into the metal of the rail is at the