User Guide

Ultrastar Data60

Regulatory Model: H4060-J

December 2020

Rev. 1.18

1ET1101

User Guide Table of Contents

Table of Contents

Revision History.................................................................................................................................... vi

Notices....................................................................................................................................................x

Points of Contact.................................................................................................................................. xi

Product Label Information..............................................................................................................xi

Chapter 1. Overview.........................................................................................................1

Ultrastar Data60 Description............................................................................................................... 2

System Architecture Overview........................................................................................................... 2

System Level Block Diagram...............................................................................................................3

Environmental Specifications...............................................................................................................4

Electrical Specifications....................................................................................................................... 4

Mechanical Specifications....................................................................................................................5

Performance Specifications................................................................................................................. 6

Ultrastar Data60 Layout....................................................................................................................... 6

List of Customer Replaceable Units (CRUs).......................................................................................7

Supported Operating Systems........................................................................................................... 8

LEDs.......................................................................................................................................................9

Front and Rear IO LEDs................................................................................................................9

IOM LEDs.......................................................................................................................................11

IOM Fan LED................................................................................................................................. 11

PSU LED........................................................................................................................................12

Rear Fan LED................................................................................................................................13

Drive Assembly LED.................................................................................................................... 14

Ultrastar Data60 Rack Requirements.................................................................................................15

Compatible Rack Hardware Configuration................................................................................17

Power Requirements.......................................................................................................................... 19

ESD....................................................................................................................................................... 19

Enclosure Cooling...............................................................................................................................19

i

User Guide Table of Contents

SAS Cabling........................................................................................................................................20

Supported SKUs................................................................................................................................. 22

List of Compatible Drives..................................................................................................................22

Chapter 2. Components................................................................................................34

Chassis.................................................................................................................................................35

Chassis Specifications................................................................................................................ 35

Chassis Layout.............................................................................................................................36

IOM...................................................................................................................................................... 38

IOM Specifications...................................................................................................................... 38

IOM Layout.................................................................................................................................. 39

IOM Blank.....................................................................................................................................39

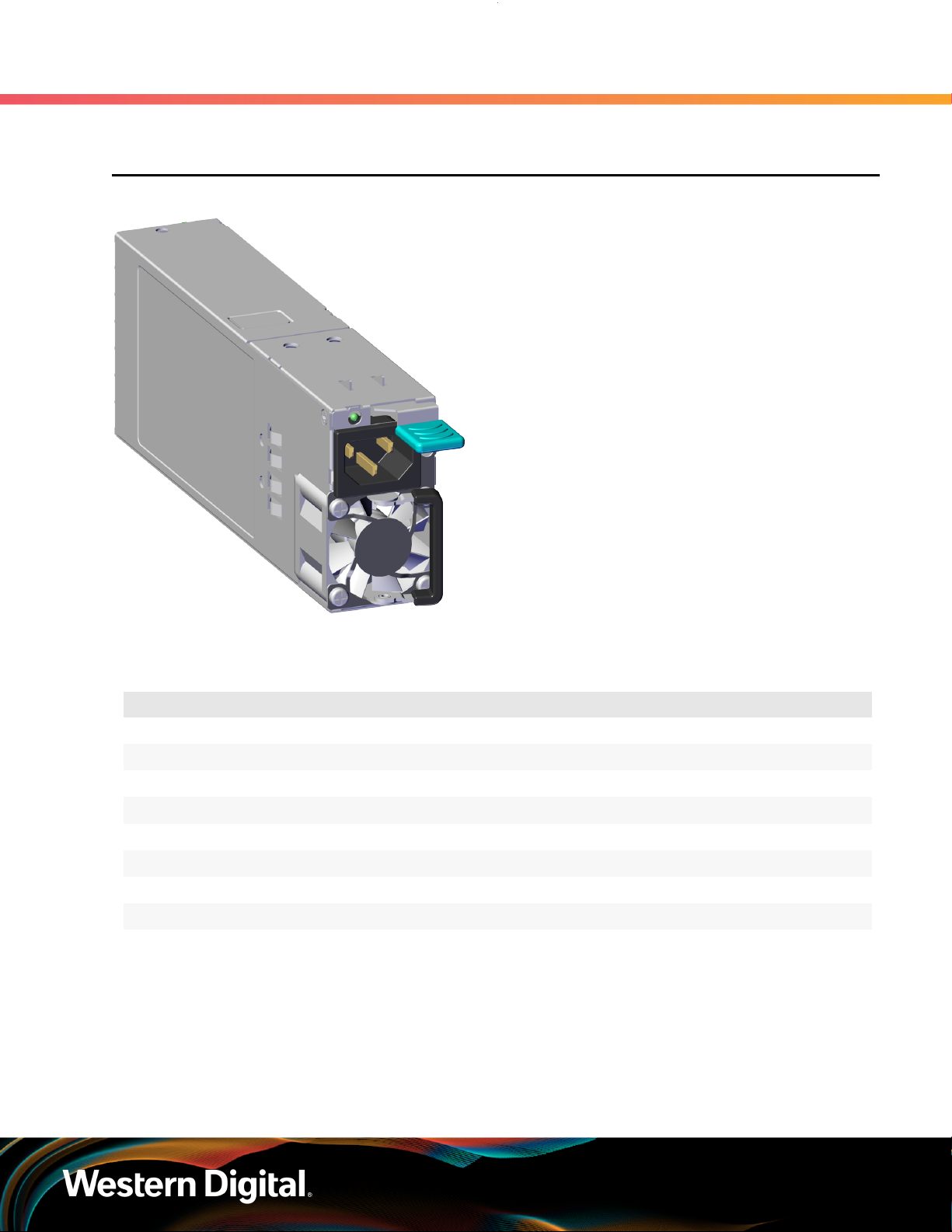

PSU...................................................................................................................................................... 40

PSU Specifications...................................................................................................................... 40

PSU Layout................................................................................................................................... 41

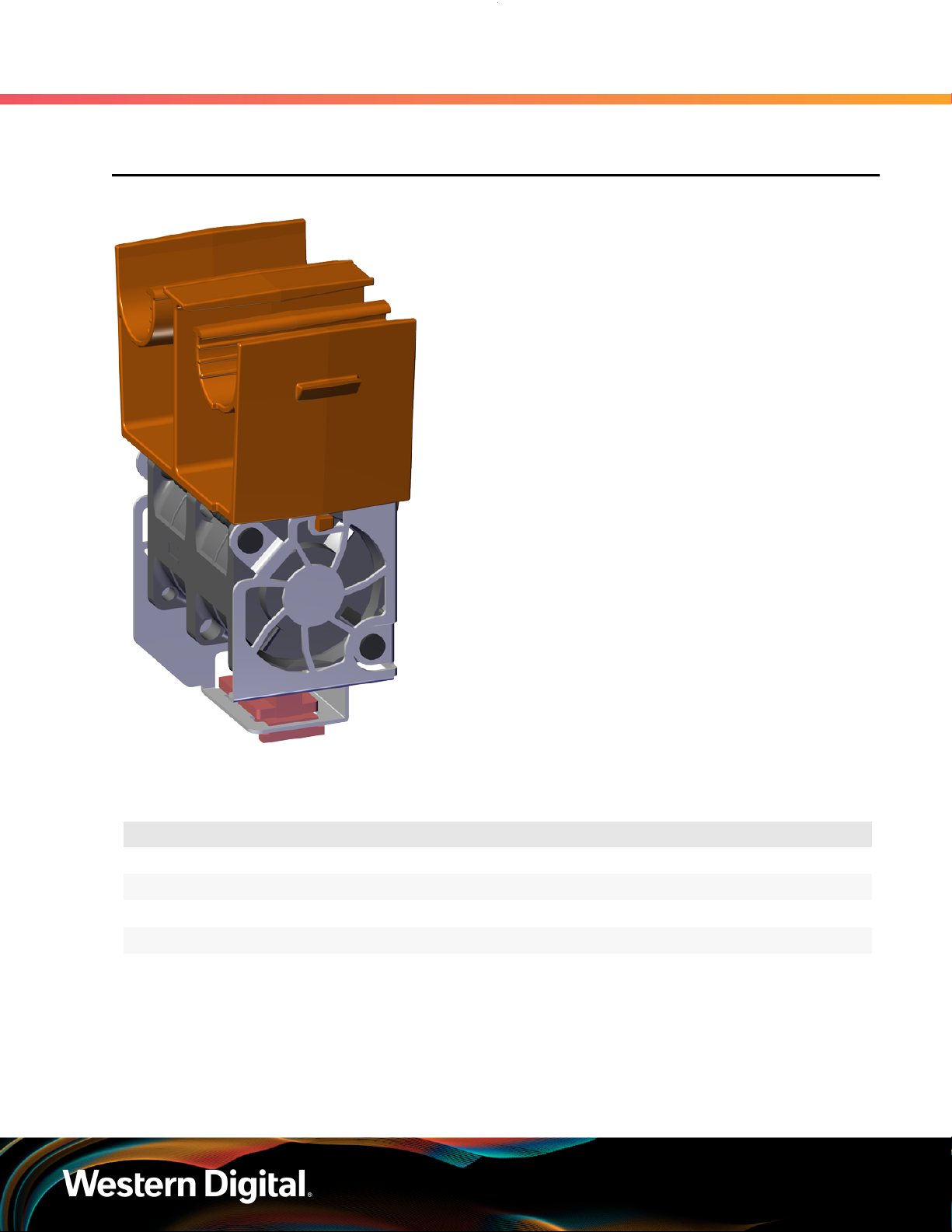

Rear Fan.............................................................................................................................................. 42

Rear Fan Specifications.............................................................................................................. 42

Rear Fan Layout.......................................................................................................................... 43

IOM Fan............................................................................................................................................... 44

IOM Fan Specifications............................................................................................................... 44

IOM Fan Layout........................................................................................................................... 45

Rails......................................................................................................................................................46

Rails Specifications..................................................................................................................... 46

Rails Layout..................................................................................................................................47

Rear Cover Alignment Bracket.................................................................................................. 48

CMA..................................................................................................................................................... 49

CMA Specifications..................................................................................................................... 49

CMA Layout.................................................................................................................................50

CMA Cable Tray...........................................................................................................................51

3.5in HDD Assembly.......................................................................................................................... 52

ii

User Guide Table of Contents

3.5in HDD Assembly Specifications.......................................................................................... 52

3.5in HDD Assembly Layout...................................................................................................... 53

3.5in Drive Blank......................................................................................................................... 54

2.5in SSD Assembly........................................................................................................................... 55

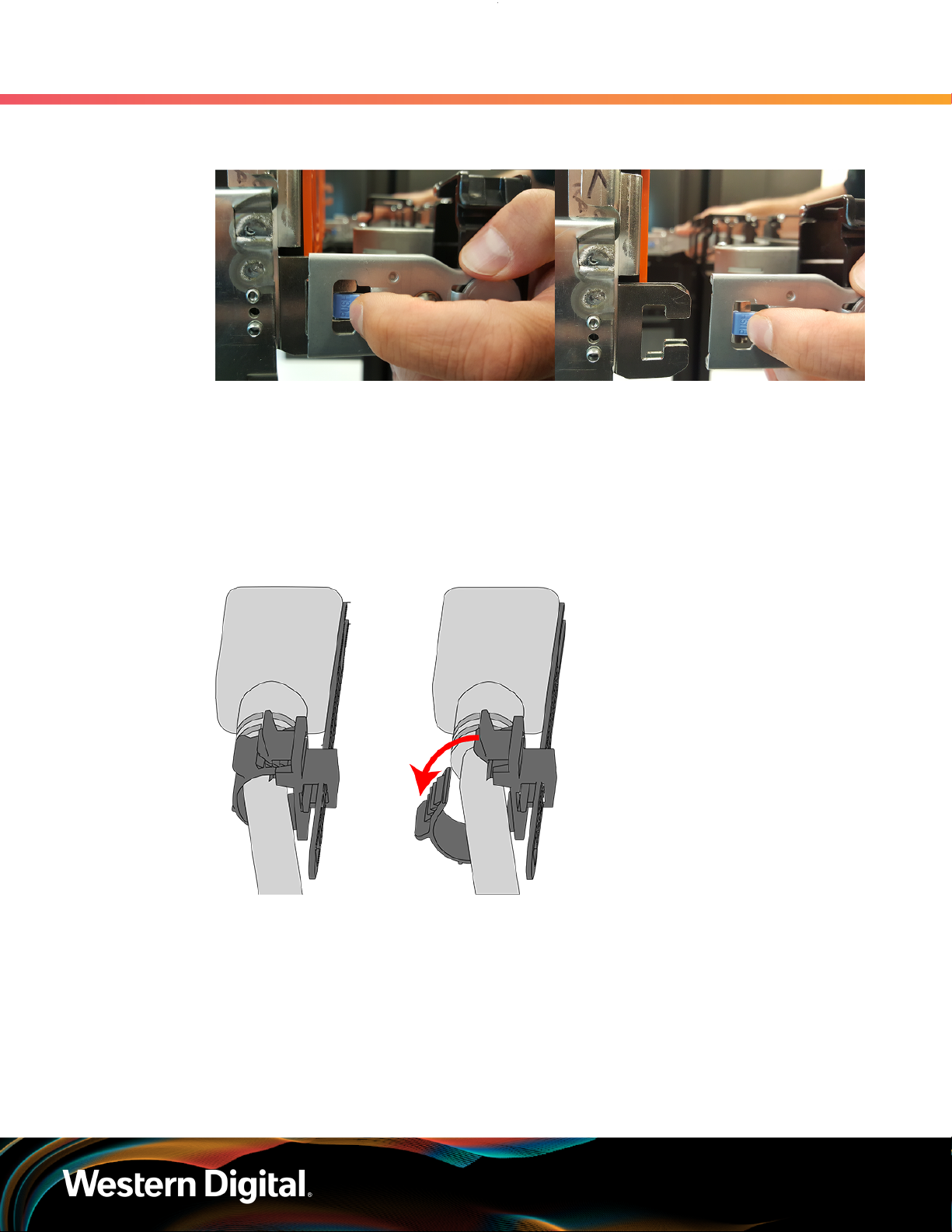

Operating the 2.5" Drive Carrier............................................................................................... 55

Chapter 3. Support........................................................................................................58

Part Replacement Service Window................................................................................................. 59

IOM Replacement...............................................................................................................................59

PSU Replacement...............................................................................................................................62

Rear Fan Replacement.......................................................................................................................66

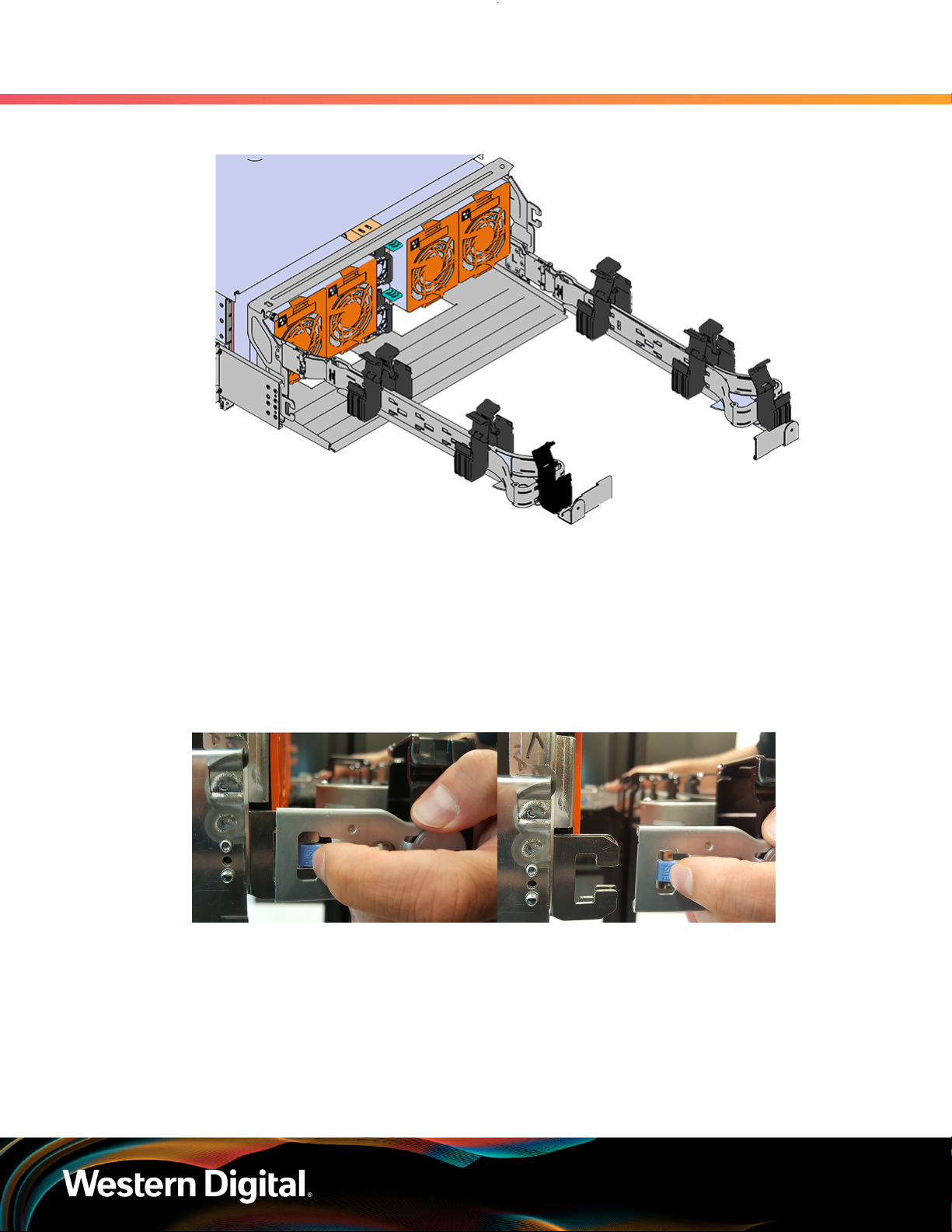

IOM Fan Replacement........................................................................................................................69

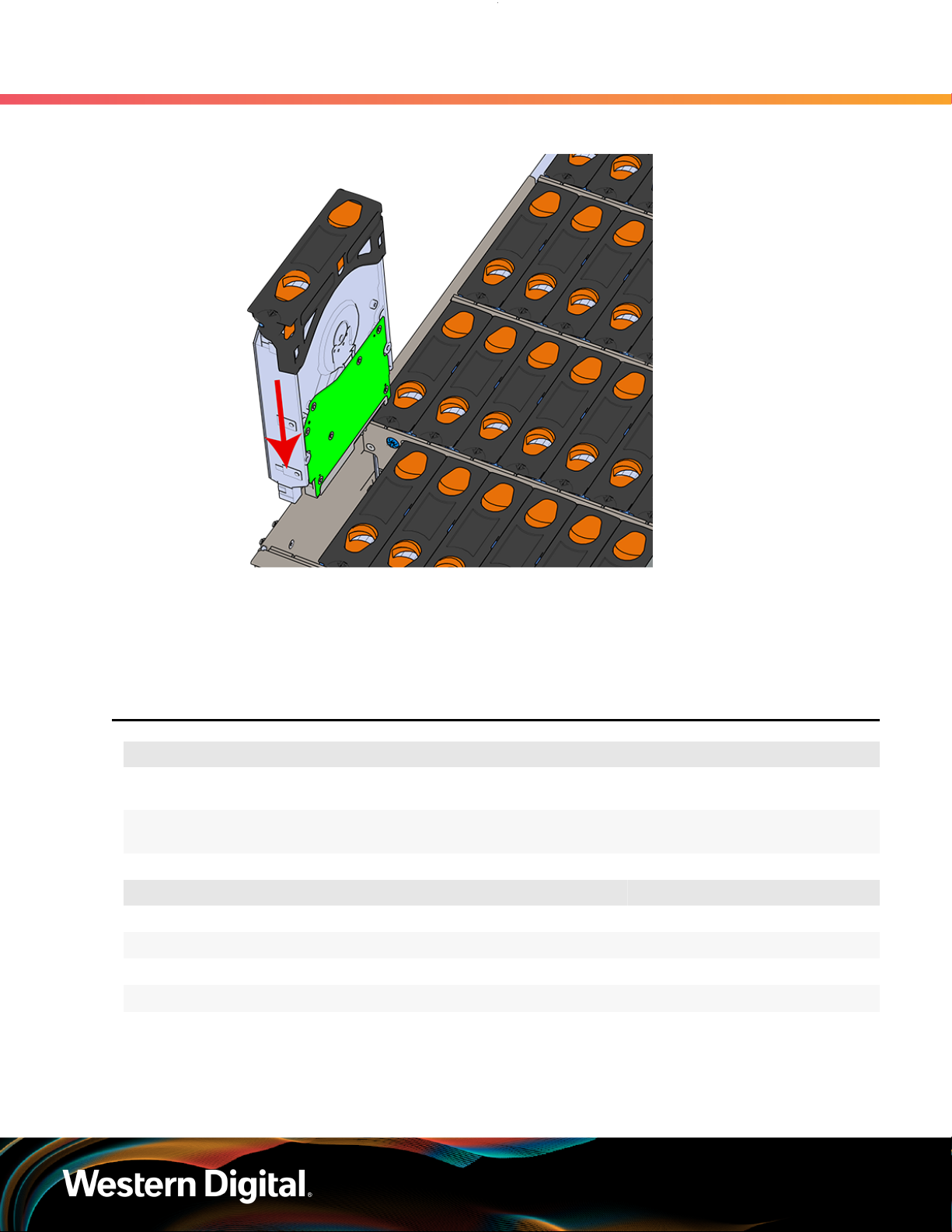

3.5in HDD Assembly Replacement....................................................................................................71

CMA Replacement..............................................................................................................................75

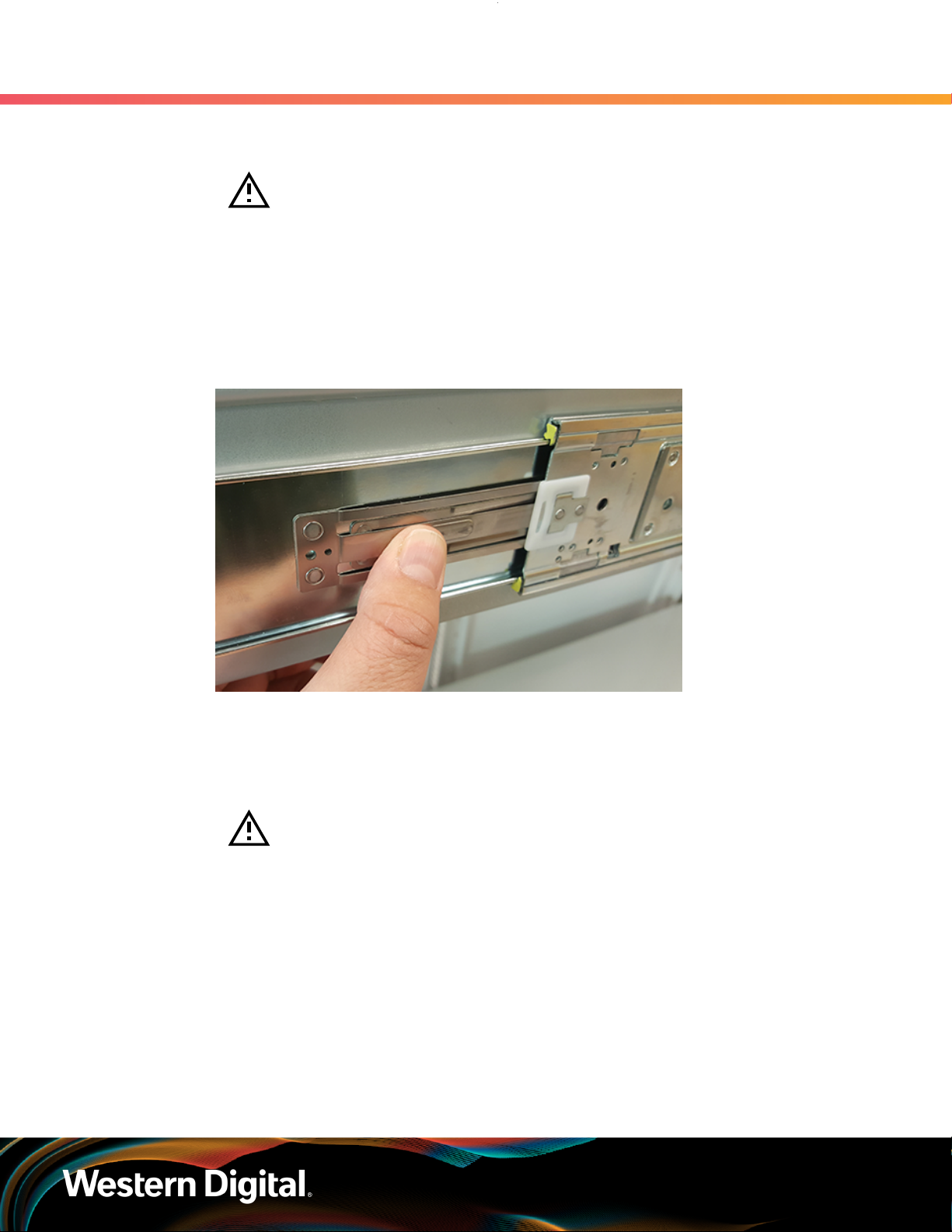

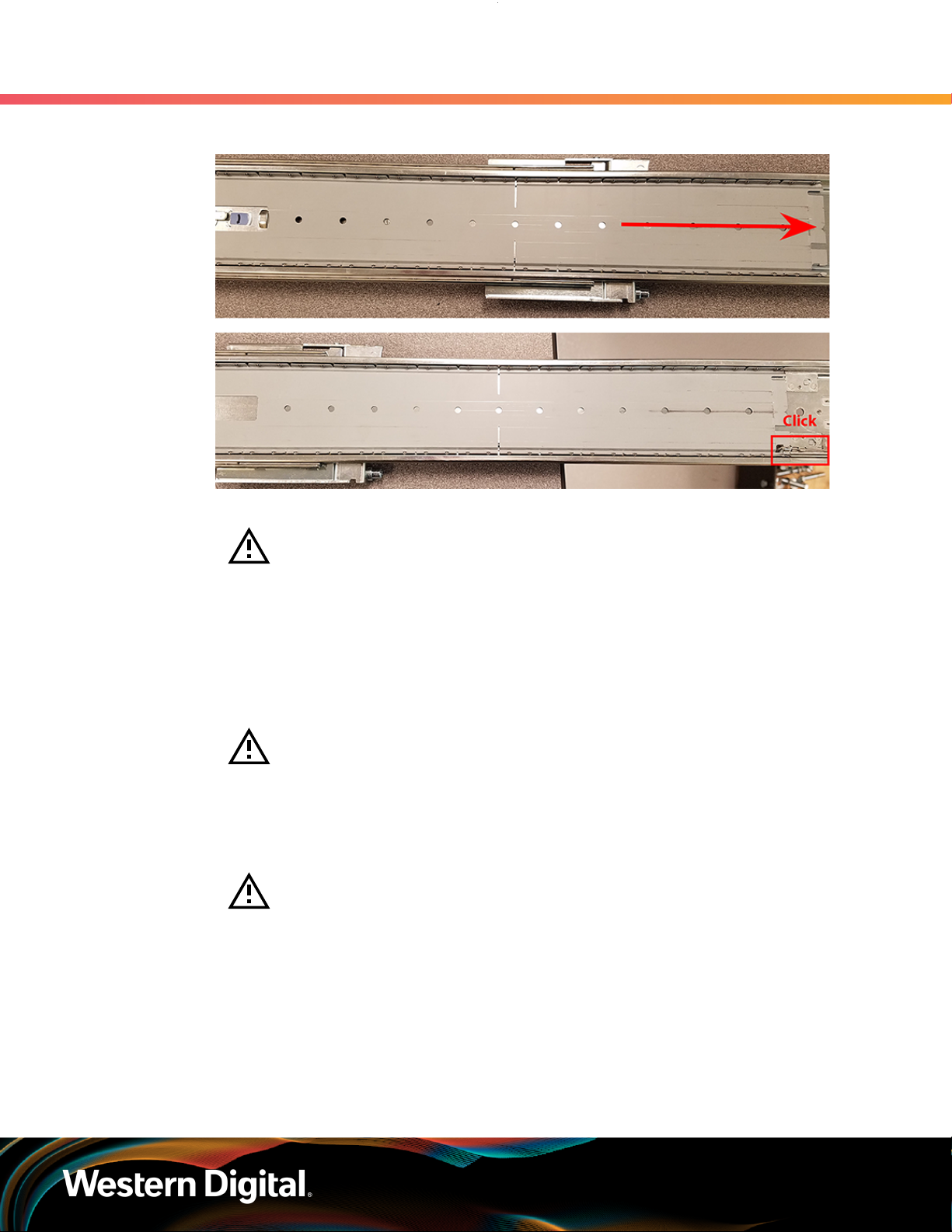

Rails Replacement..............................................................................................................................90

Chassis Replacement........................................................................................................................ 119

Special Considerations for Cable Routing......................................................................................154

Cabling for CMA............................................................................................................................... 156

Before You Begin.......................................................................................................................156

Cabling CMA.............................................................................................................................. 157

Chapter 4. Management.............................................................................................. 159

Management Overview.................................................................................................................... 160

Firmware Features Overview..........................................................................................................160

Firmware Upgrade.............................................................................................................................161

Downloading Firmware from the Support Portal.................................................................... 161

Linux Upgrade Preparation....................................................................................................... 163

Linux Upgrade to New Firmware.............................................................................................165

Non-Automatic Firmware Activation in Linux.......................................................................... 167

Windows Firmware Upgrade Preparation...............................................................................169

iii

User Guide Table of Contents

Windows Upgrade to New Firmware..................................................................................... 170

Non-Automatic Firmware Activation in Windows...................................................................173

OOBM Management Overview........................................................................................................ 176

Configuring OOBM Network Settings Using SES.................................................................... 176

Upgrading Firmware with OOBM.............................................................................................178

SES Page 02......................................................................................................................................180

Zoning................................................................................................................................................180

Before Zoning............................................................................................................................180

Predefined Zoning Configurations...........................................................................................180

sg_senddiag Command............................................................................................................188

Enabling Zoning using Linux.................................................................................................... 188

Disabling Zoning using Linux....................................................................................................192

Enabling Zoning using Windows.............................................................................................195

Disabling Zoning using Windows............................................................................................198

File-Based Zoning..................................................................................................................... 202

Subenclosure Nickname................................................................................................................... 212

Setting the Subenclosure Nickname........................................................................................212

Partially Populated Enclosures.........................................................................................................214

Partial Population Configurations............................................................................................. 214

Installing Drives.......................................................................................................................... 217

Daisy Chaining..................................................................................................................................220

Daisy Chaining Configurations................................................................................................. 221

One Host Cable Configurations.............................................................................................. 222

Two Host Cable Configurations.............................................................................................. 227

Cabling for Daisy Chaining...................................................................................................... 232

Chapter 5. Safety.........................................................................................................239

Safety Warnings and Cautions........................................................................................................240

Electrostatic Discharge....................................................................................................................240

iv

User Guide Table of Contents

Optimizing Location.........................................................................................................................240

Power Connections.......................................................................................................................... 241

Power Cords......................................................................................................................................241

Rackmountable Systems...................................................................................................................241

Safety and Service........................................................................................................................... 242

Chapter 6. Disclaimers................................................................................................ 243

Restricted Access Location.............................................................................................................244

Safety Compliance........................................................................................................................... 244

Electromagnetic Compatibility (EMC) Class A Compliance..........................................................244

Country Certifications...................................................................................................................... 245

Chapter 7. Regulatory Statements............................................................................246

Europe (CE Declaration of Conformity).......................................................................................... 247

FCC Class A Notice..........................................................................................................................247

ICES-003 Class A Notice—Avis NMB-003, Classe A......................................................................247

Japanese Compliance Statement, Class A ITE...............................................................................247

Taiwan Warning Label Statement, Class A ITE.............................................................................. 248

v

User Guide Revision History

Revision History

Date Revision Comment

November 2017 1.0 Initial release

November 2017 1.1

December 2017 1.2

January 2018 1.2.1 Updated the product name

January 2018 1.3

• The crossbar on the CMA was changed. See CMA (page 49).

• Removed Lowline power specs from Power Requirements (page

19).

• Changed required rack depth, see Mechanical Specifications (page

5).

• Changed typical power consumption, see Electrical Specifications

(page 4).

• Updated LED Flash Patterns, see LEDs (page 9).

• Added active cable support

• Added firmware upgrade section. See Firmware Upgrade (page

161).

• Updated the Non-Op altitude specification. See Environmental

Specifications (page 4).

• Updated information on the 2.5" drive carrier option. See 2.5in SSD

Assembly (page 55).

• Added torque requirements for all screws used in the enclosure.

• Updated the IOM replacement section to account for the possibility

of a firmware mismatch. See IOM Replacement (page 59).

• Updated the drive assembly installation instructions to clarify

the orientation of the drive assemblies. 3.5in HDD Assembly

Replacement (page 71).

April 2018 1.4

May 2018 1.5 Added the Part Replacement Service Window. See: Part Replacement

June 2018 1.6

• Updated Compatible Drives List. See List of Compatible Drives

(page 22).

• Updated the Rack Requirements. See Ultrastar Data60 Rack

Requirements (page 15).

• Updated the Firmware Upgrades. See: Firmware Upgrade (page

161)

Service Window (page 59)

• Updated Compatible Drives List. See List of Compatible Drives

(page 22)

• Updated the Firmware Upgrade section. See Firmware Upgrade

(page 161)

vi

User Guide Revision History

Date Revision Comment

• Updated the Firmware Download section. See Downloading

Firmware from the Support Portal (page 161)

• Updated the System Architecture Overview section. See System

Architecture Overview (page 2)

• Updated the Daisy Chaining section. See Daisy Chaining (page

220)

• Added the Rear Cover Alignment Bracket Description. See Rear

Cover Alignment Bracket (page 48)

November 2018 1.7

May 2019 1.8

May 2019 1.9

• Updated the images in the Daisy Chaining section. See Daisy

Chaining (page 220)

• Updated List of CRUs. See List of Customer Replaceable Units

(CRUs) (page 7)

• Updated Compatible Drives List. See List of Compatible Drives

(page 22)

• Updated the Host Connectivity section. See: SAS Cabling (page

20)

• Changed senddiag commands from images to codeblocks. See

sg_senddiag Command (page 188).

• Updated daisy-chaining tables to match diagrams. See Two Host

Cable Configurations (page 227).

• Corrected OOBM zoning configuration instructions. See Predefined

Zoning Configurations (page 180).

• Added Configuring OOBM Network Settings Using SES (page

176).

• Corrected the system architecture overview. See System

Architecture Overview (page 2).

• Corrected explanation of SATA configuration in Firmware Upgrade

(page 161) section.

June 2019 1.10

June 2019 1.11 Updated the Host Connectivity section. See: SAS Cabling (page 20)

July 2019 1.12

• Updated the Host Connectivity section. See: SAS Cabling (page

20)

• Added Windows syntax examples and reorganized the Upgrading

Firmware with OOBM section

Moved the following topics to the Ultrastar Data60 Description (page

2) section:

• Ultrastar Data60 Rack Requirements (page 15)

• Power Requirements (page 19)

• ESD (page 19)

• Enclosure Cooling (page 19)

vii

User Guide Revision History

Date Revision Comment

• SAS Cabling (page 20)

Moved the Supported Operating Systems (page 8) topic to the

Management (page 159) section.

Corrected LED identification tables for IOMs, PSUs, and drives in the

LEDs (page 9) section.

Updated servicing image to correct length values and rail servicing

extension in Ultrastar Data60 Rack Requirements (page 15) section.

Added a note about OOBM ports configured for DHCP by default to the

OOBM Management Overview (page 176) section.

September 2019 1.13

November 2019 1.14

April 2020 1.15

• Replaced references to He12 drives with Ultrastrar DC HC520 in List

of Compatible Drives (page 22)

• Changed device references from OS-specific (/dev/sgX for Linux

and SCSIX:X,X,X for Windows) to generic (<dev>) throughout.

• Updated table for Approved SAS Cables in SAS Cabling (page

20)

• Added Subenclosure Nickname (page 212) section

• Updated Supported Operating Systems (page 8)

• Added drive assembly LED pointer orientation image in 3.5in HDD

Assembly Replacement (page 71) section

• Updated images of captive chassis-cover screws throughout

• Updated table for Approved SAS Cables in SAS Cabling (page

20)

• Updated the Daisy Chaining configurations in Daisy Chaining (page

220)

• Corrected explanation of expanders in System Architecture

Overview (page 2)

• Added note about using non-automatic firmware activation for RAID

adpaters in Firmware Upgrade (page 161)

• Added note about performing zoning offline in Zoning (page 180)

• Added note and step for configuring zoning on an IOM after

replacement in IOM Replacement (page 59)

• Added RHEL 8.0 to Supported Operating Systems (page 8)

• Added note about LED behavior during proper drive insertion in

Drive Assembly LED (page 14)

• Corrected part number for rail kit in List of Customer Replaceable

Units (CRUs) (page 7) and Rails Specifications (page 46)

• Added note about minimum time between removing and

reapplying power in Power Connections (page 241)

August 2020 1.16

• Updated Supported Operating Systems (page 8)

• Updated SAS Cabling (page 20)

viii

User Guide Revision History

Date Revision Comment

• Updated List of Compatible Drives (page 22)

• Added File-Based Zoning (page 202) section

• Updated note in IOM Replacement (page 59) about standard vs.

file-based zoning configuration after IOM replacement

October 2020 1.17

December 2020 1.18

• Fixed typo in Rails Layout (page 47)

• Updated text and color-coded images in Predefined Zoning

Configurations (page 180)

• Updated images in LEDs (page 9) and Components (page

34)

• Added note about not unzipping tar.gz file prior to firmware

upgrade in Downloading Firmware from the Support Portal

(page 161), Linux Upgrade to New Firmware (page 165), Non-

Automatic Firmware Activation in Linux (page 167), Windows

Upgrade to New Firmware (page 170), and Non-Automatic

Firmware Activation in Windows (page 173)

• Added Ubuntu 20.04 to Supported Operating Systems (page 8)

• Updated table of approved SAS cables in SAS Cabling (page 20)

• Updated FW activation step in Upgrading Firmware with OOBM

(page 178)

• Added UK Import Representation Contact

• Removed Formerica cables from SAS Cabling (page 20)

ix

User Guide Notices

Notices

Western Digital Technologies, Inc. or its affiliates' (collectively “Western Digital”) general policy does not

recommend the use of its products in life support applications wherein a failure or malfunction of the product

may directly threaten life or injury. Per Western Digital Terms and Conditions of Sale, the user of Western

Digital products in life support applications assumes all risk of such use and indemnifies Western Digital

against all damages.

This document is for information use only and is subject to change without prior notice. Western Digital

assumes no responsibility for any errors that may appear in this document, nor for incidental or consequential

damages resulting from the furnishing, performance or use of this material.

Absent a written agreement signed by Western Digital or its authorized representative to the contrary,

Western Digital explicitly disclaims any express and implied warranties and indemnities of any kind that may,

or could, be associated with this document and related material, and any user of this document or related

material agrees to such disclaimer as a precondition to receipt and usage hereof.

Each user of this document or any product referred to herein expressly waives all guaranties and warranties

of any kind associated with this document any related materials or such product, whether expressed or

implied, including without limitation, any implied warranty of merchantability or fitness for a particular

purpose or non-infringement. Each user of this document or any product referred to herein also expressly

agrees Western Digital shall not be liable for any incidental, punitive, indirect, special, or consequential

damages, including without limitation physical injury or death, property damage, lost data, loss of profits or

costs of procurement of substitute goods, technology, or services, arising out of or related to this document,

any related materials or any product referred to herein, regardless of whether such damages are based on

tort, warranty, contract, or any other legal theory, even if advised of the possibility of such damages.

This document and its contents, including diagrams, schematics, methodology, work product, and

intellectual property rights described in, associated with, or implied by this document, are the sole and

exclusive property of Western Digital. No intellectual property license, express or implied, is granted by

Western Digital associated with the document recipient's receipt, access and/or use of this document or the

products referred to herein; Western Digital retains all rights hereto.

Western Digital, the Western Digital logo, and Ultrastar are registered trademarks or trademarks of Western

Digital Corporation or its affiliates in the US and/or other countries. Linux® is the registered trademark of

Linus Torvalds in the U.S. and other countries. All other marks are the property of their respective owners.

Product specifications subject to change without notice. Pictures shown may vary from actual products. Not

all products are available in all regions of the world.

Western Digital

5601 Great Oaks Parkway

San Jose, CA 95119

© 2020 Western Digital Corporation or its affiliates. All Rights Reserved.

x

User Guide Points of Contact

Points of Contact

For further assistance with a Western Digital product, contact Western Digital Datacenter Platforms technical

support. Please be prepared to provide the following information: part number (P/N), serial number (S/N),

product name and/or model number, and a brief description of the issue.

Email:

support@wdc.com

Website:

https://portal.wdc.com/Support/s/

UK Import Representation Contact

Western Digital UK Limited Hamilton House, Regent Park, Kingston Road Leatherhead, Surrey KT22 7PL, GB,

United Kingdom

Telephone: +44 1372 366000

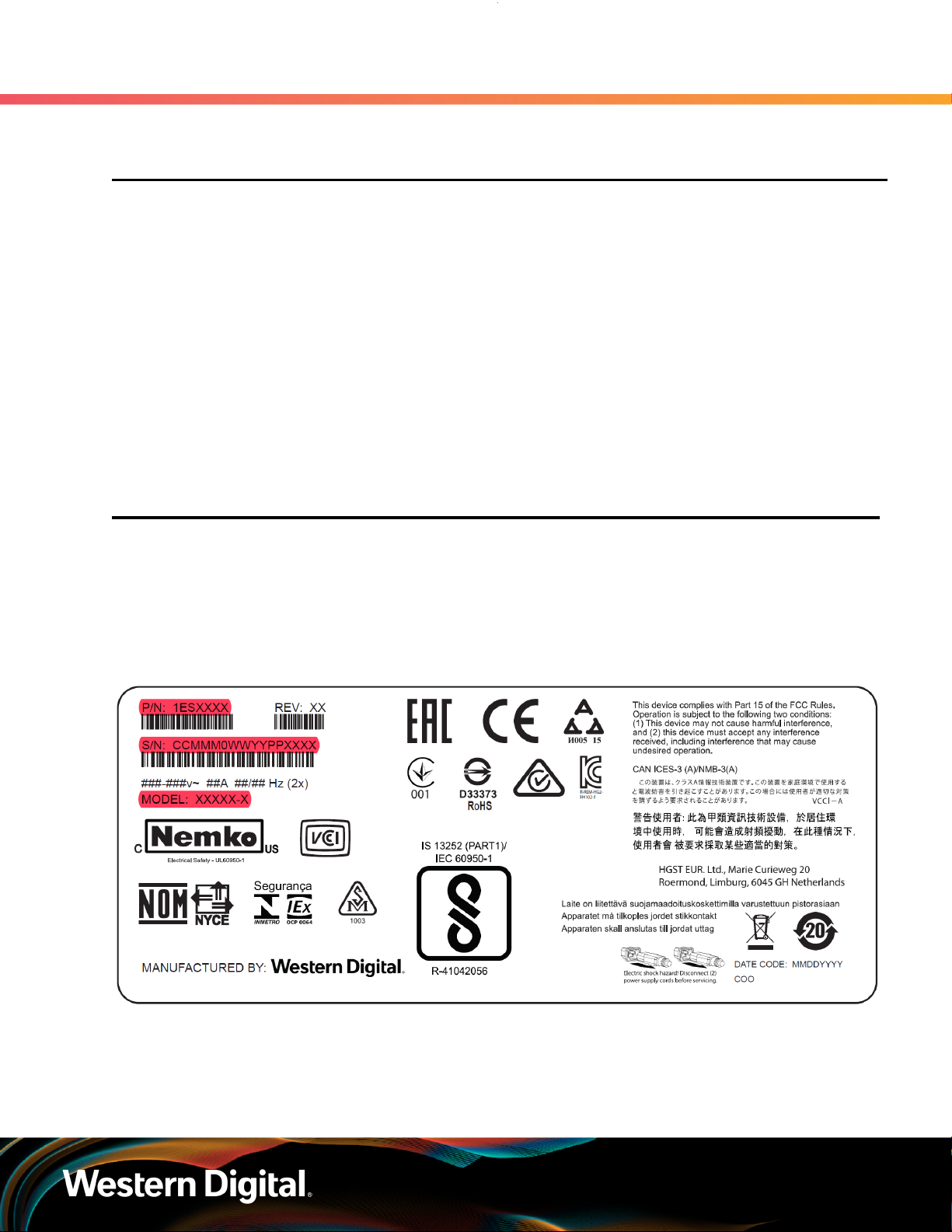

1.1 Product Label Information

The following product information is required for technical support requests:

• Part Number (P/N)

• Serial Number (S/N)

• Product Name and/or Model Number (MODEL)

This information may be found on the product label, which is affixed to an exterior, non-removable surface of

the chassis. The following is an example label with the applicable information fields highlighted:

xi

Western Digital

Overview

This section provides a high level overview of the features of the

Ultrastar Data60 .

In This Chapter:

- System Architecture Overview.....................2

- System Level Block Diagram.........................2

- Environmental Specifications........................3

- Electrical Specifications................................ 4

- Mechanical Specifications............................. 4

- Performance Specifications...........................5

- Ultrastar Data60 Layout................................ 6

- List of Customer Replaceable Units

(CRUs)............................................................... 6

- Supported Operating Systems......................7

- LEDs................................................................. 8

- Ultrastar Data60 Rack Requirements........... 9

- Power Requirements.................................... 15

- ESD..................................................................19

- Enclosure Cooling.........................................19

- SAS Cabling................................................... 19

- Supported SKUs........................................... 20

- List of Compatible Drives............................22

1

User Guide

1.1 Ultrastar Data60 Description

Figure 2: Ultrastar Data60

1. Overview

1.1 Ultrastar Data60 Description

The Ultrastar Data60 is a 4U form factor, high availability, high density, rack-mounted storage enclosure

that is capable of hosting up to 60 SAS or SATA drives. The maximum data storage capacity of the Ultrastar

Data60 is 840 TB using 14TB HGST Ultrastar® HC530 drives . (For a full list of compatible drives and total

storage capacities, see the List of Compatible Drives (page 22).) The enclosure runs on an input voltage

of 200 - 240 VAC and consumes ~1000W of power under typical conditions. It requires a maximum of

~1250W at full load.

It is designed to fit within a 4U rack space and requires 900mm (35.43in.) usable rack space, frame to frame.

A fully loaded system will add 79.4 kg. / 175 lbs. of static load when fully loaded with drives.

• 4U Storage Enclosure

• Supports up to 60 Drives

• Can support 3.5” drives and 2.5” SSD drives (2.5" requires an adapter) in the 60 available drive bays.

• Up to 12W per drive slot for the 60 data storage drives (Cannot exceed 85A on the 5V rail)

• House and control four (4) N+1 redundant 80mm rear fans

• House and control a dual rotor 40mm internal IOM Fan

• Controlled by two (2) redundant I/O Modules

• Powered by two (2) redundant 1600W PSUs

• Supports High Line (220-240 VAC) Input Power

• Full high availability with independent dual paths to all HDDs

• Toolless replacement of all Customer Replaceable Units (CRUs)

• Fits within a standard EIA-310 rack including all necessary cable management (see Compatible Rack

Hardware Configuration (page 17))

• Supports up to 3m passive SAS cables (limited to 3m or less) or active cables (any length) (see SAS

Cabling (page 20))

1

1.2 System Architecture Overview

1. SATA based models will only include 1 IOM

2

User Guide

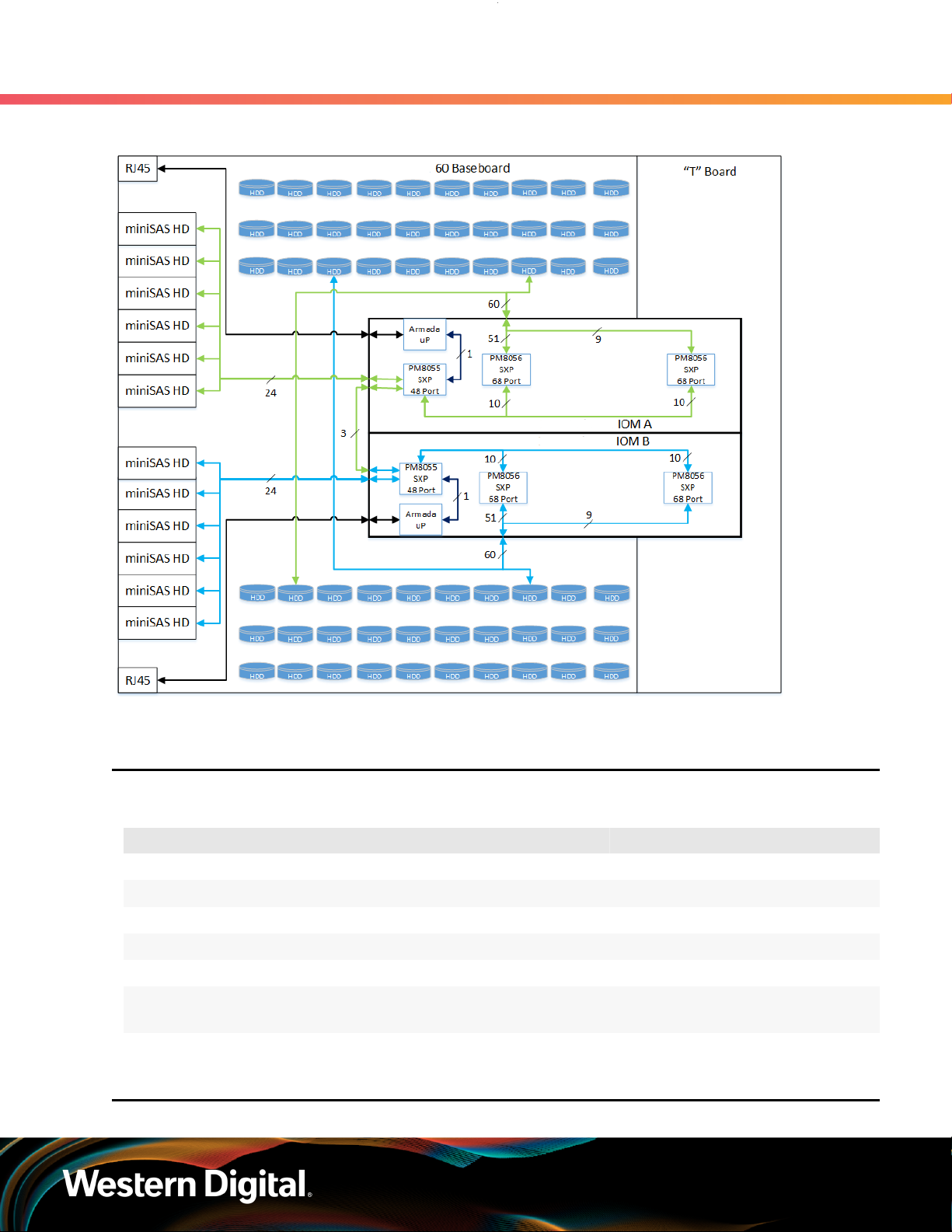

The Ultrastar Data60 IOM uses a cascaded expander design to allow for connection to all 60 drives. A

48-port primary expander connects with the six host ports, has a x3 link to the other IOM for IOM-IOM

communication and syncing, and also has a x10 SAS link to each secondary expander. One secondary

expander then connects with fifty-one (51) drives, while the other connects with nine (9) drives.

The out-of-band management microprocessor provides an Ethernet connection using a Redfish/RESTful

API to access the various enclosure services. All the SES enclosure information can be obtained through the

out-of-band management port. Major use cases for this feature include obtaining storage subsystem health

information, locating enclosure components using the IDENT LEDs, and updating firmware.

The system FPGAs control and report the states of the system fans, enclosure LEDs, connector LEDs, drive

LEDs, and T10 drive power disable signals on the 60 data storage drives.

The I2C architecture is designed to support only one single master on any given bus. The primary expander

will be the master on each I2C bus. There are eight I2C buses used in the Ultrastar Data60 enclosure.

The number of devices on each bus are balanced to allow communication to peripheral devices and not

overload any one bus. The devices connected on the I2C buses include the enclosure VPDs, temp sensors,

baseboard FPGAs, and SAS connectors among others.

1. Overview

1.3 System Level Block Diagram

Note: To use T10 power disable, the drives installed must also support this feature.

1.3 System Level Block Diagram

The following image shows the system block diagram for the Ultrastar Data60 .

3

User Guide

Figure 3: System Block Diagram

1. Overview

1.4 Environmental Specifications

1.4 Environmental Specifications

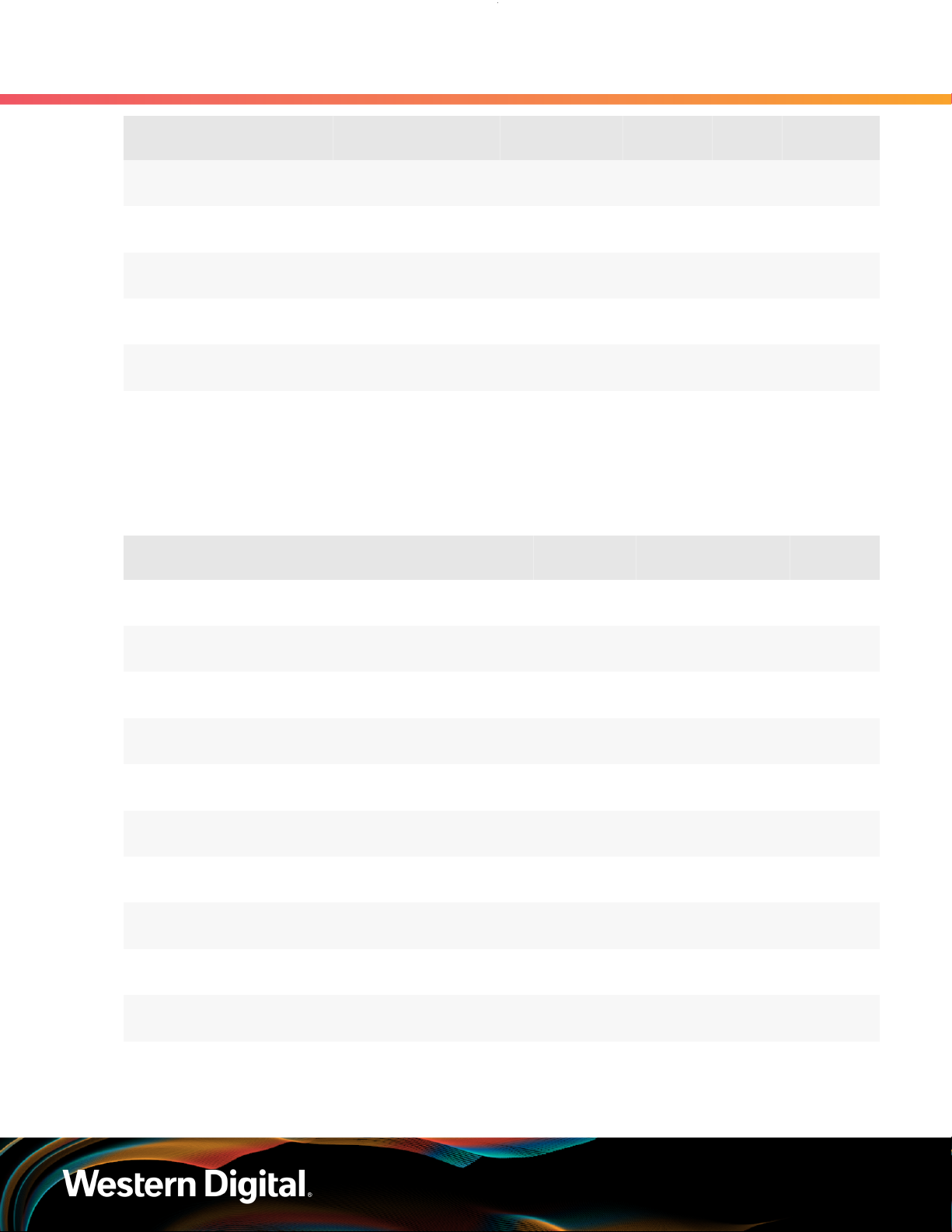

Table 1: Environmental Specification Summary

Specification Non-Operational Operational

Temperature -40°C to 70°C 5°C to 35°C

Temperature Gradient 30°C / Hr 20°C per hour maximum

Temperature De-rating 1°C per 300m above 3000m 1°C per 300m above 900m

Relative Humidity 8-90% Non-Condensing 8-90% Non-Condensing

Relative Humidity Gradient 30% per hour maximum 30% per hour maximum

Altitude -300m to 12,000m /

-984 ft. to 39,370 ft

1.5 Electrical Specifications

-300m to 3048m /

-984 ft. to 10,000 ft.

4

User Guide

Table 2: Electrical Specifications

Specification Value

Max Power Consumption ~1250W

Typical Power Consumption

Input Voltage 200 - 240 VAC

PSU Connector Type C14

PSU Efficiency 80 PLUS Platinum

2

1. Overview

1.6 Mechanical Specifications

~1000W

Inrush Current Maximum (per

PSU)

Caution: The Ultrastar Data60 can only be plugged into high line (200 - 240 VAC) power. If

the unit is plugged into low line (110-127 VAC), the PSU will report a "Critical" state when status

pages are queried using SES. In this case, the enclosure will power up, but the drives will not.

The enclosure will remain in low-power mode.

AC line inrush current shall not exceed 40A peak, for up to

one-quarter of the AC cycle after which, the input current

should be no more than the specified maximum input current.

1.6 Mechanical Specifications

Table 3: Mechanical Specifications

Specification Non-Operational Operational

Shock 10G, 0 - peak,11ms half sine;

3 positive and 3 negative

pulses in each axis Shock

Vibration 0.75G, 0 - peak swept sine;

5 -500Hz; 1 complete sweep

@ 1/2 octave per minute

5G, 0 - peak, 11ms half sine; 3 positive

and 3 negative pulses in each axis-

minimum 6 seconds between shocks

to allow for write/read recovery

0.10G,0 - peak swept sine; 5

-500Hz; 1 complete sweep

@ 1/2octave per minute

Weight 79.4 kg. / 175 lbs.

Dimensions 447mm x 890mm x 175mm / 17.67in. x 35.04in. x 6.89in.

Length without CMA 712 mm / 28.03in.

Required Rack Width 450mm (17.72in.) with 465mm (18.31in.) ± 1.5mm

nominal hole spacing. See EIA-310 Rack Standard

Required Rack Depth 900mm (35.43in.) usable rack space, frame to frame

Rack Units (U) 4U

2. Max and typical power consumption values represent the output power to the system. Input power will vary depending

on the PSU efficiency and load sharing between PSUs.

5

User Guide

Specification Non-Operational Operational

Vertical Rack Rail

Spacing

1.7 Performance Specifications

Table 4: Performance Specifications

Specification Value

Number of Drive Slots 60

Data Transfer Rates 12Gbps SAS / 6Gbps SATA

Max Raw Data Storage Capacity 840 TB using 14TB HGST Ultrastar® HC530 drives

SAS Ports 12 x Mini-SAS HD ( 6 per IOM)

1. Overview

1.7 Performance Specifications

24 in. - 32 in.

2 x 10/100/1G Ethernet

1.8 Ultrastar Data60 Layout

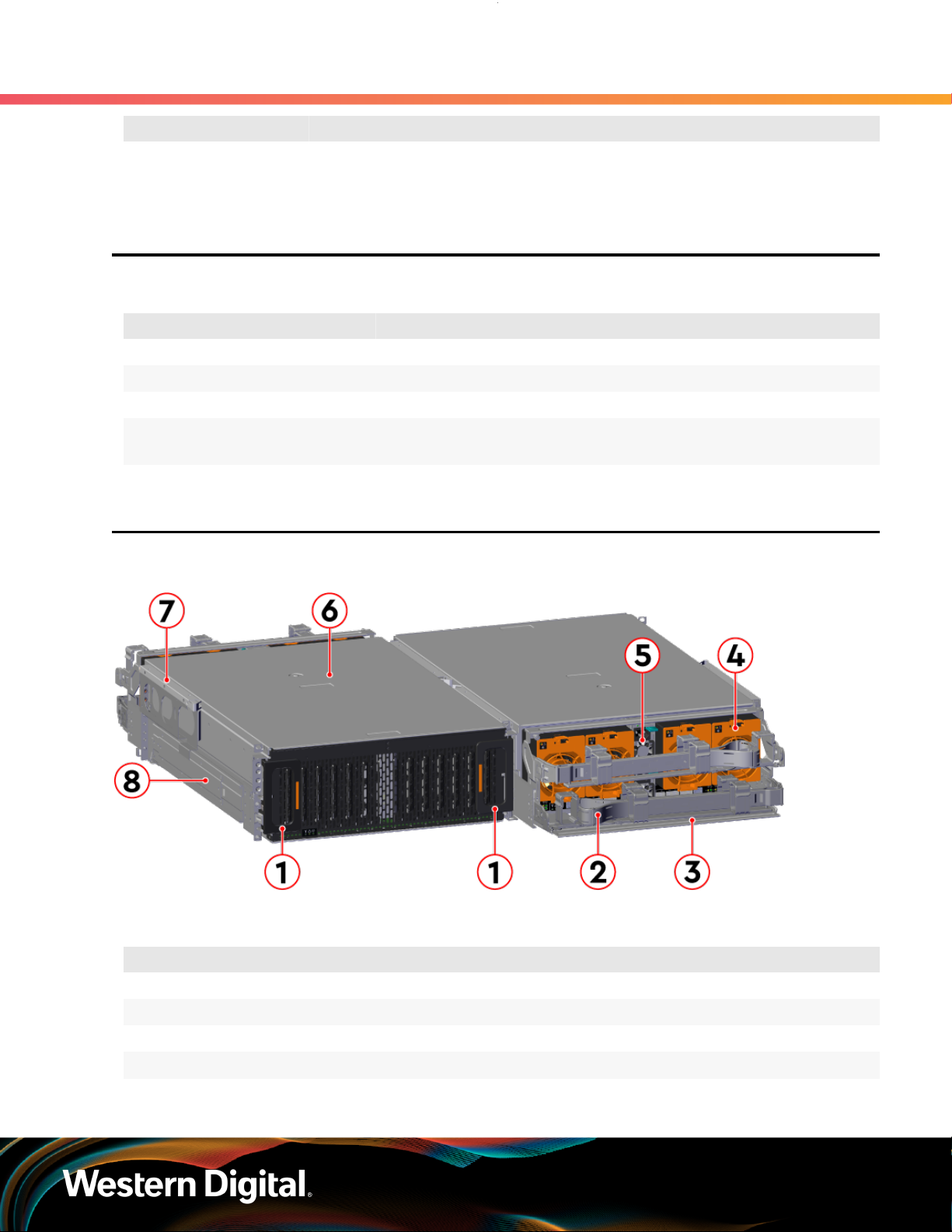

Figure 4: Front and Rear Product Layout

Table 5: Front and Rear Component Identification

Number Component

1 Enclosure Handles

2 CMAs

3 CMA Tray

4 Rear Fans

5 PSUs

6

User Guide

The following is an image of the layout of the major system components inside the Ultrastar Data60 .

Figure 5: Component Layout

1. Overview

1.9 List of Customer Replaceable Units (CRUs)

Number Component

6 Chassis Cover

7 Rear Cover Alignment Brackets

8 Rails

1.9 List of Customer Replaceable Units (CRUs)

The following table lists the replaceable components and their part numbers.

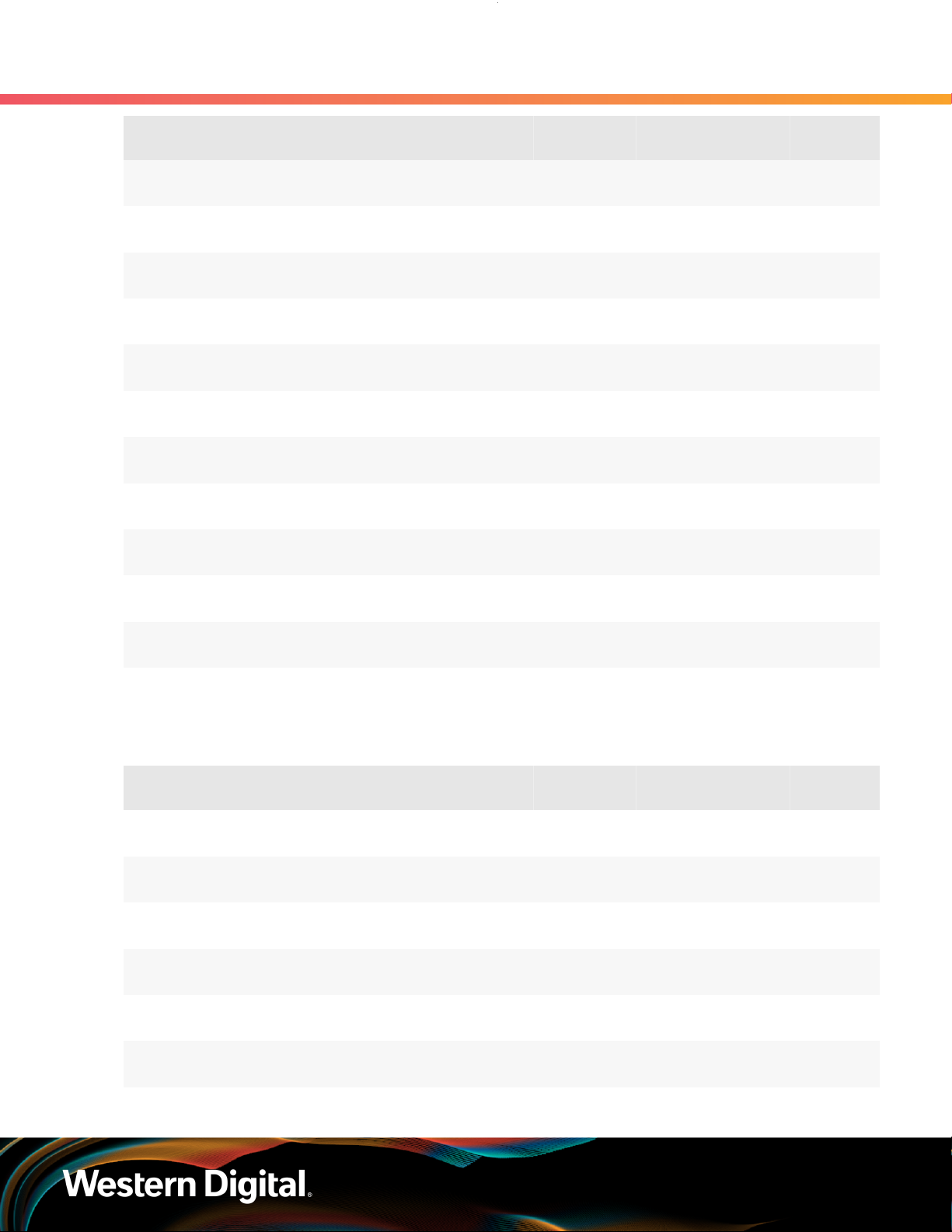

Table 6: List of Replaceable Components

Component Part Number

Ultrastar Data60 Chassis with a single IOM and PSUs 1EX0442

Ultrastar Data60 Chassis with IOMs and PSUs 1EX0443

IOM 1EX2201

IOM Blank 1EX0431

PSU 1600W 1EX0434

Rear Fan 1EX0433

IOM Fan 1EX0432

Rails (CMA Standard) 1EX0436

Rear Cover Alignment Bracket 1EX2288

CMA Standard Arms 1EX0437

CMA Cable Tray 1EX1119

3.5 in. Drive Carrier, Qty=1 1EX0438

7

User Guide

Component Part Number

3.5 in. to 2.5 in. conversion Drive Carrier, Qty=1 1EX0439

3.5 in. Drive Blank, Qty=1 1EX0429

Power Cable for PDU, C13-C14, 18AWG, 3m, Qty=1 1EX1158

HD Mini-SAS to HD Mini-SAS, 3m, Qty=2 1EX1533

1.10 Supported Operating Systems

Table 7: Compatible Operating Systems

OS Support

Microsoft® Windows

1. Overview

1.10 Supported Operating Systems

2012 R2 x64 Server

2016 R1 x64 Server

2019 R1 x64 Server

CentOS/RedHat® Enterprise Linux (RHEL)

Ubuntu® Server

7.2 (x86_64) Kernel: 3.10.0-327

7.3 (x86_64) Kernel: 3.10.0-514

7.4 (x86_64) Kernel: 3.10.0-693

7.6 (x86_64) Kernel: 3.10.0-957

8.0 (x86_64) Kernel: 4.18.0-80

8.2 (x86_64) Kernel: 4.18.0-193

14.04 Kernel: 3.13

16.04 Kernel: 4.4

18.04 Kernel: 4.15

20.04

8.10 Kernel: 3.16Debian GNU/Linux

9.6 Kernel: 4.9

12 SP3SUSE® Linux Enterprise Server (SLES)

15 SP1

8

User Guide

1.11 LEDs

1.11.1 Front and Rear IO LEDs

The Ultrastar Data60 has a number of LEDs on the exterior of the enclosure that display various system

statuses. The three LEDs on the front mirror three on the rear, allowing the general status of the enclosure

to be determined from either side of the rack.

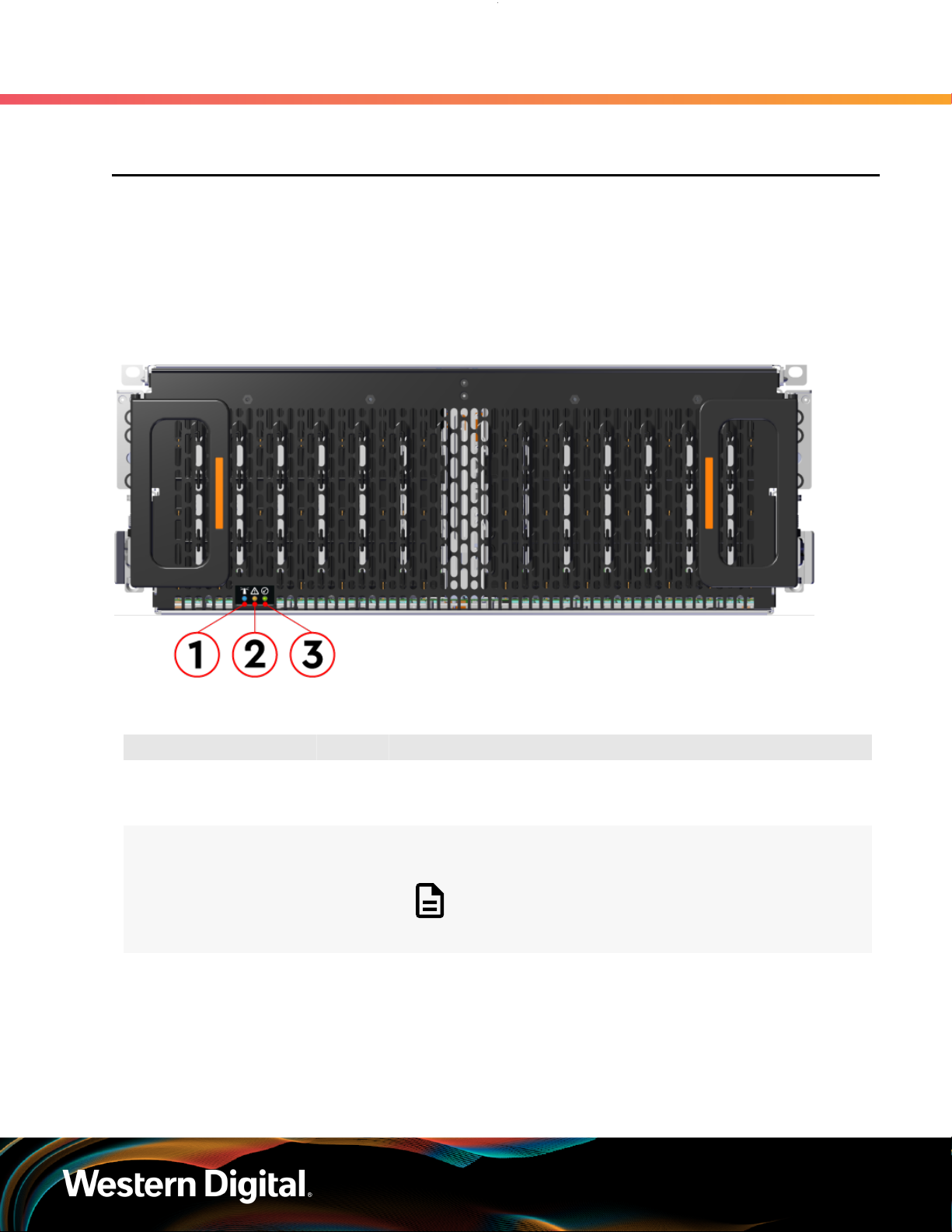

Figure 6: Front LEDs Location

1. Overview

1.11 LEDs

Table 8: Front LEDs Identification

Number LED Name Color Behavior

1 Identify Blue Blink @ 1 Hz (50% duty cycle) – Blinks only when Identification

has been activated. Will blink when any component is

identified.

2 Fault Amber Blink @ 1 Hz (50% duty cycle) – Enclosure has a fault

Off – Enclosure has no fault

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

3 Power Green Solid – Powered On

In addition to the three enclosure status LEDs, the rear provides LEDs for the Ethernet and SAS ports.

9

User Guide

Figure 7: Rear LEDs Location

1. Overview

1.11 LEDs

Table 9: Rear LEDs Identification

Number LED Name Color Behavior

1 SAS Link Status Green Solid – SAS cable connected

Off – SAS cable not connected

2 SAS Fault

Status

3 Identification Blue Blink @ 1 Hz (50% duty cycle) – Blinks only when Identification

4 Fault Amber Blink @ 1 Hz (50% duty cycle) – Enclosure has a fault

5 Power Green Solid – Powered On

Amber Blink @ 1 Hz (50% duty cycle) – SAS connection fault

Off – No SAS connection fault

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

has been activated. Will blink when any component is

identified.

Off – Enclosure has no fault

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

10

User Guide

Number LED Name Color Behavior

6 Ethernet

Connector

Speed

Green/

Amber

1. Overview

1.11 LEDs

Off – Operating at 10 Mbps

Green Solid – Operating at 100 Mbps

Amber Solid – Operating at 1Gpbs

7 Ethernet

Connectors

Link/Activity

Green Off – No Connection

Solid – Connected

Blink – Activity

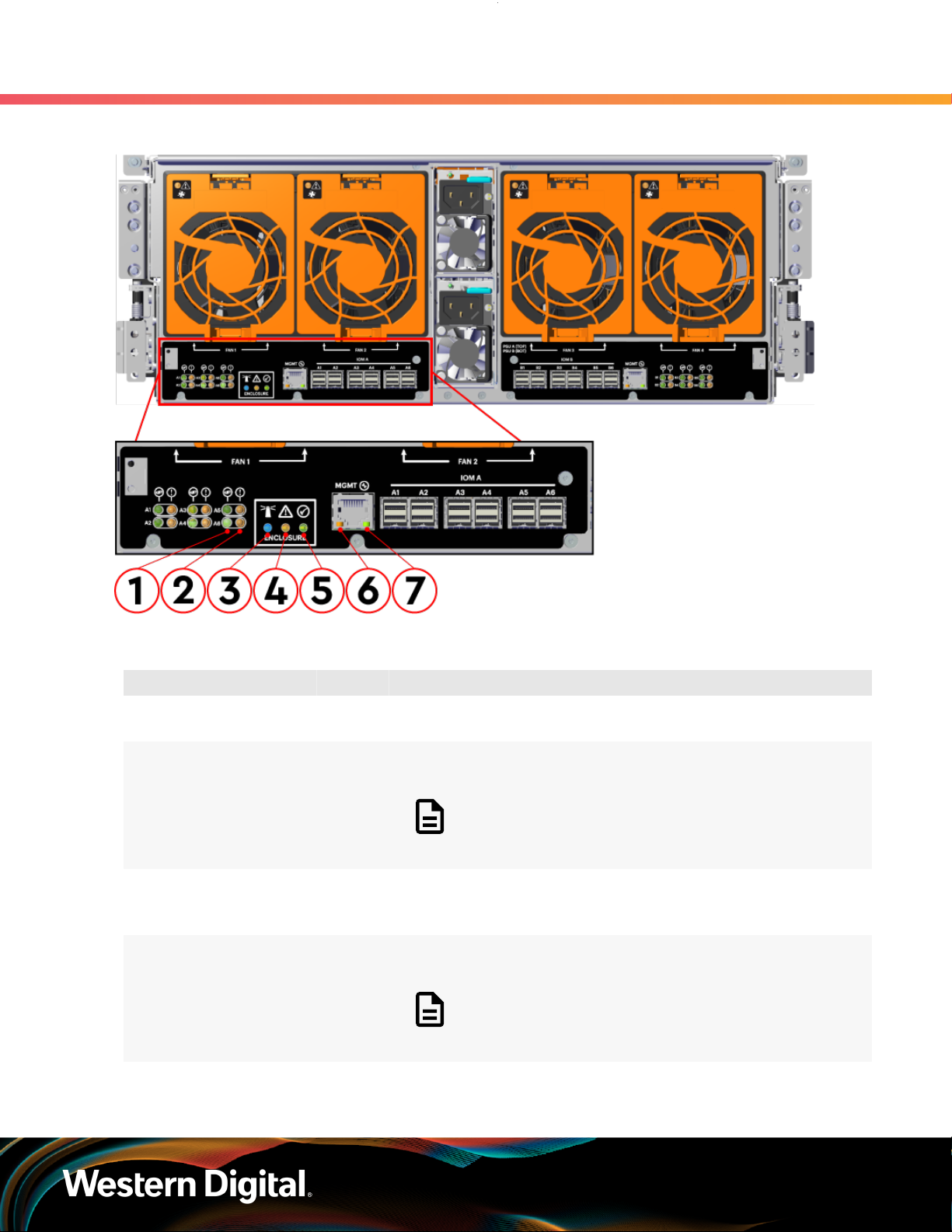

1.11.2 IOM LEDs

The IOM has three LEDs, one each for power, fault, and identification.

Figure 8: IOM LEDs Location

Table 10: IOM LEDs Identification

Number LED Name Color Behavior

1 IOM Identification Blue Blink @ 0.5 Hz (75% duty cycle) – Blinks only when IOM

Identification has been activated

Off - Not being identified

2 IOM Fault Amber Blink @ 0.5 Hz (75% duty cycle) – IOM has Fault

Off - IOM is functioning normally

3 IOM Power Green Solid – IOM is on

Off – IOM is off

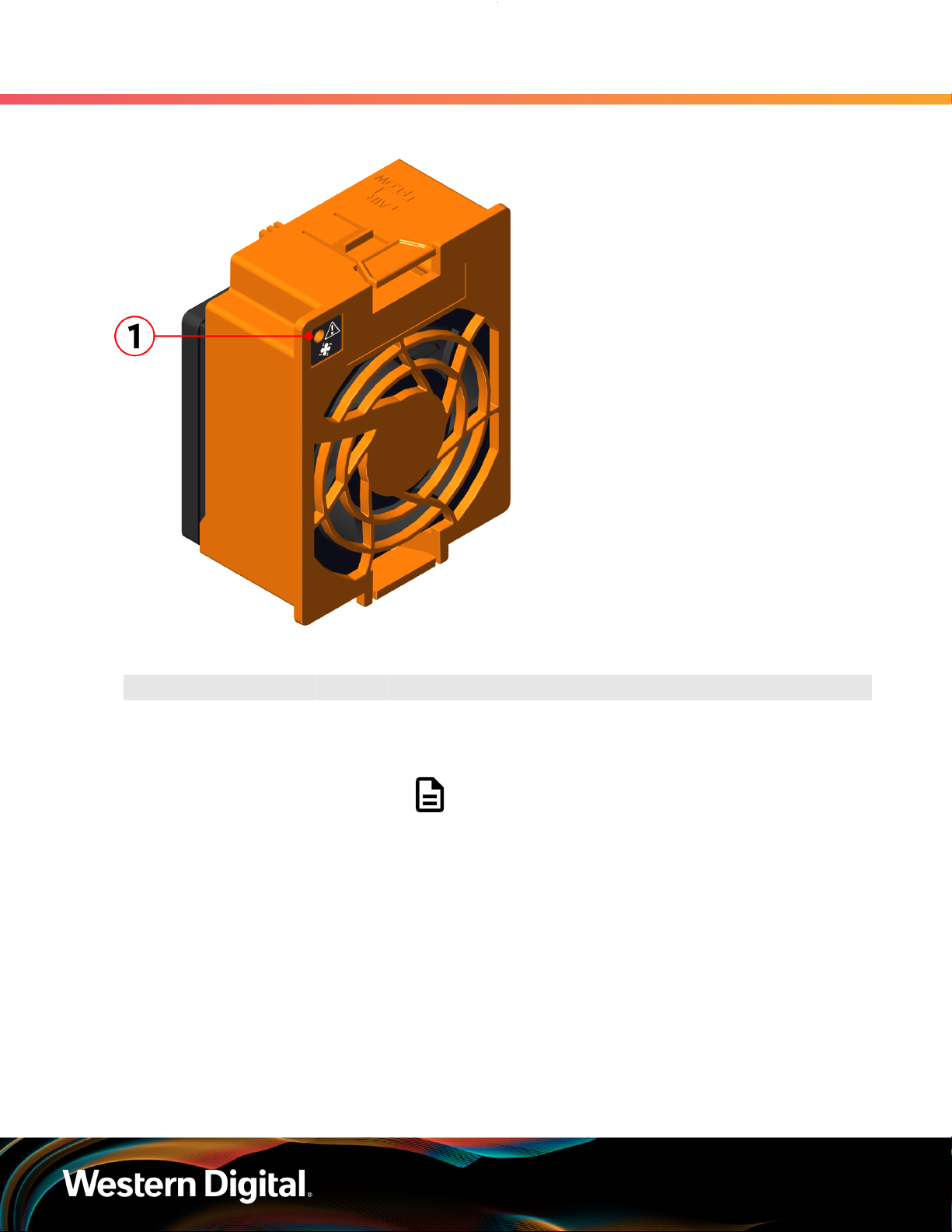

1.11.3 IOM Fan LED

The IOM Fan has a single LED with three distinct states for fault condition, identification, and power off.

11

User Guide

Figure 9: IOM Fan LED Location

1. Overview

1.11 LEDs

Table 11: IOM Fan LED Identification

Number LED Name Color Behavior

1 IOM Fan LED Amber Blink @ 2 Hz (50% duty cycle) – IOM Fan is being identified

Blink @ 1 Hz (50% duty cycle) – IOM Fan is reporting faults

Off – IOM Fan is on and reporting no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

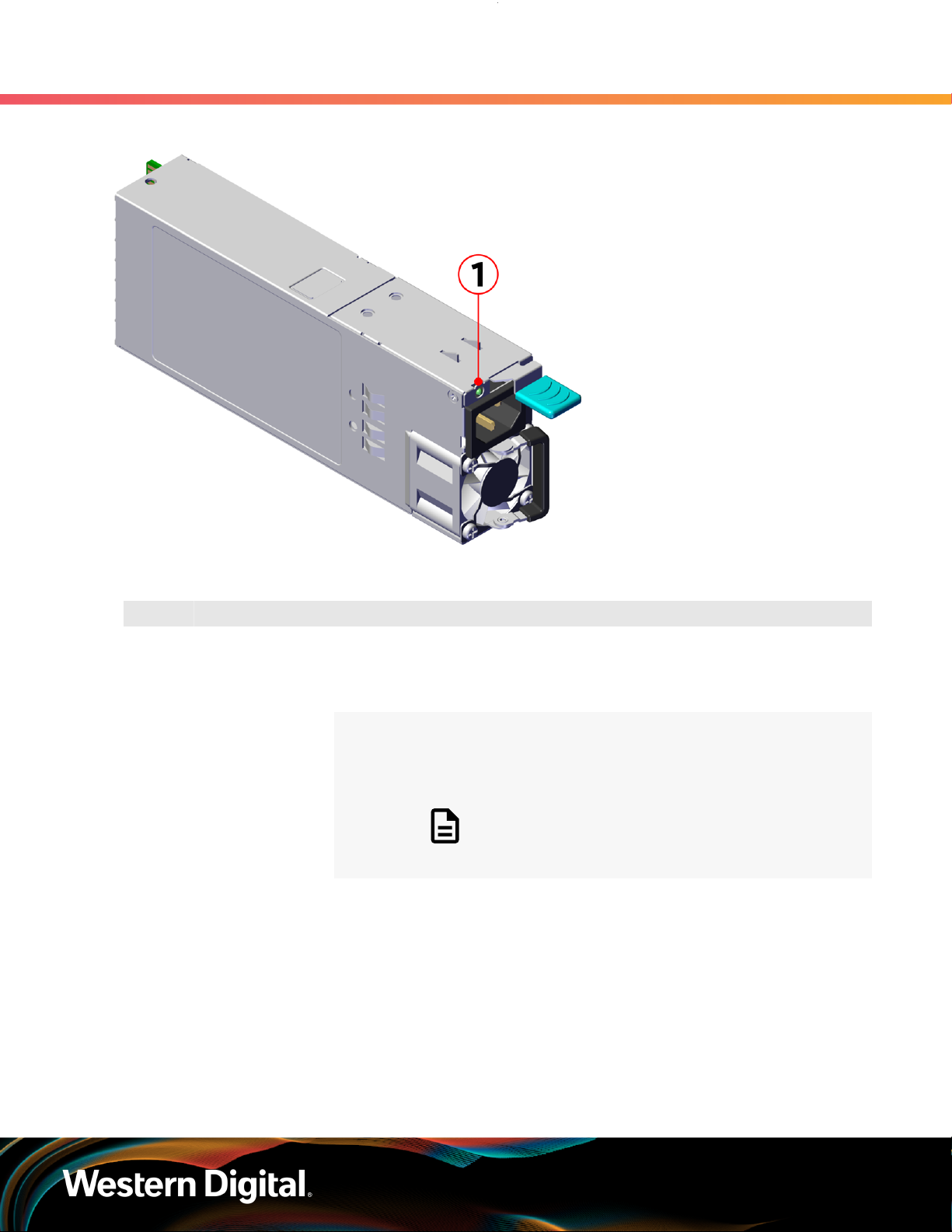

1.11.4 PSU LED

The PSU has a single, multi-function LED. See the table below for a detailed functional description.

12

User Guide

Figure 10: PSU LEDs Location

1. Overview

1.11 LEDs

Table 12: PSU LEDs Identification

Number LED Name Color Behavior

1 PSU Multi-

Function LED

Green Solid – PSU is on and reporting no faults

Blink @ 2Hz (50% duty cycle) – PSU in firmware update mode

Off – PSU is disconnected from power

Amber Solid – PSU is disconnected from power or critical fault

causing a shutdown failure

Blink @ 0.5Hz (50% duty cycle) – PSU reporting warnings

Off – PSU is reporting no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

1.11.5 Rear Fan LED

The Rear Fan has a single LED with three distinct states for indicating a fault condition, identification, or

normal operation.

13

User Guide

Figure 11: Fan LED Location

1. Overview

1.11 LEDs

Table 13: Fan LED Identification

Number LED Name Color Behavior

1 Fan LED Amber Blink @ 1 Hz (50% duty cycle) – Fan is reporting faults

Blink @ 2 Hz (50% duty cycle) – Fan is being identified

Off – Fan is on and reporting no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

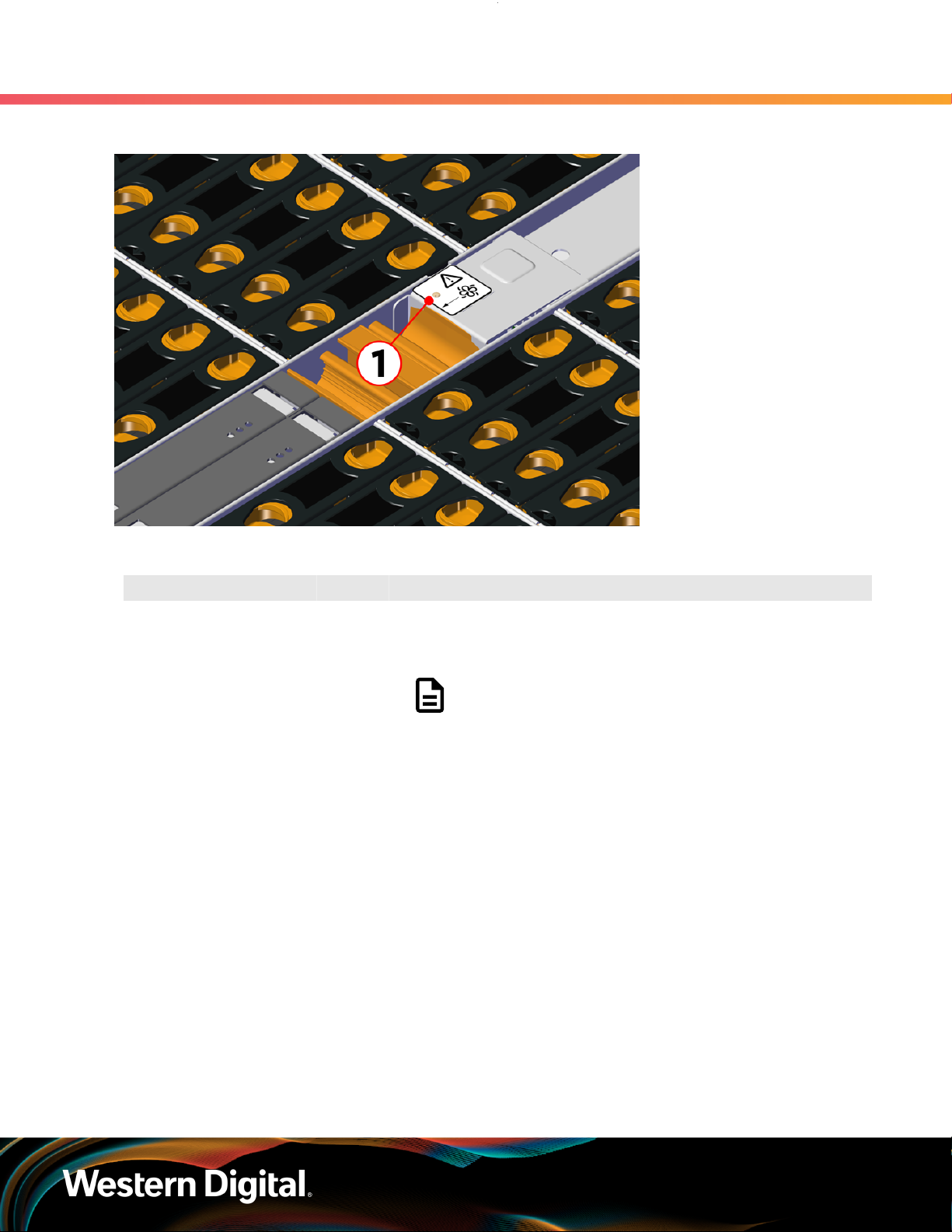

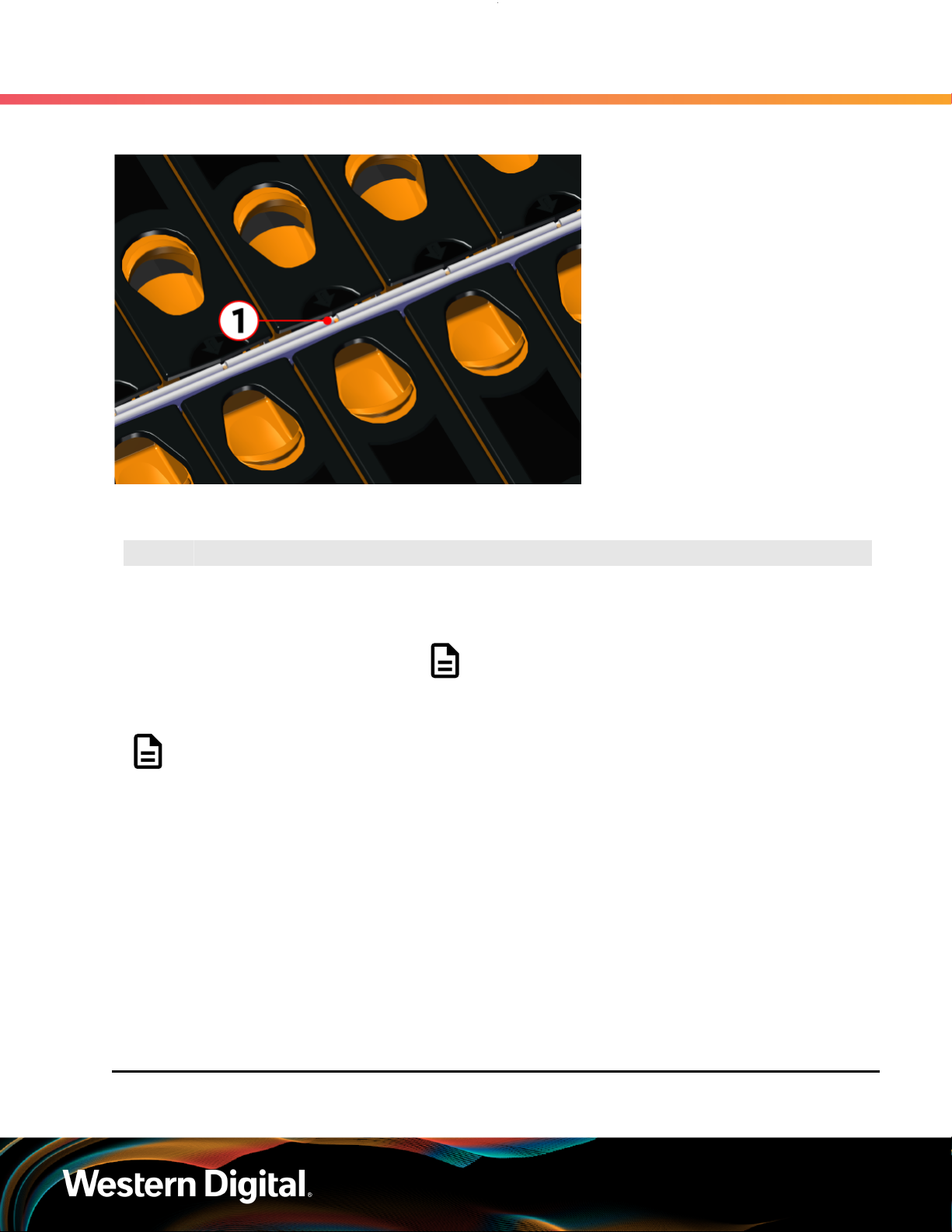

1.11.6 Drive Assembly LED

The HDD drive assembly itself does not contain an LED, but it contains a light-pipe that displays the

multi-function LED located on the drive slot. This amber LED has three distinct states for indicating a fault

condition, identification, or normal operation.

14

User Guide

Figure 12: HDD Assembly LED Location

1. Overview

1.12 Ultrastar Data60 Rack Requirements

Table 14: HDD Assembly LED Identification

Number LED Name Color Behavior

1 HDD Drive Multi-

Function LED

Note: During service events—when a drive is hot plugged or replaced and the drive installed

properly—the LED state of that drive slot will change to solid ON. This is to provide the user

with visual feedback that the drive has been successfully connected and has been discovered

by the expander. Once the enclosure has been slid back into the rack and the OPEN bit on the

door sensor element is 0, the LED will return to the previously set state (Ident, Fault, or Off).

For example: A drive in slot 0 needs to be replaced. The fault bit on Array Slot descriptor

0 is set to indicate to the service technician which drive slot to replace. This will cause the

LED to blink at 1Hz (50% duty cycle). When the service technician pulls out the enclosure,

inserts a new drive, and successfully installs the drive, the slot LED state will change to solid

ON to indicate that the drive was properly installed. When the service technician pushes the

enclosure back into the rack and the OPEN bit of the door sensor element changes from 1

to 0, the LED state of drive slot 0 will change back to the fault indication blink rate (1 Hz 50%

duty cycle).

Amber Blink @ 2 Hz (50% duty cycle) – Drive identify

Blink @ 1 Hz (50% duty cycle) – Drive fault

Off – Drive has no faults

Note: LEDs have a 50% duty cycle (On for 2

seconds, off for less than a second).

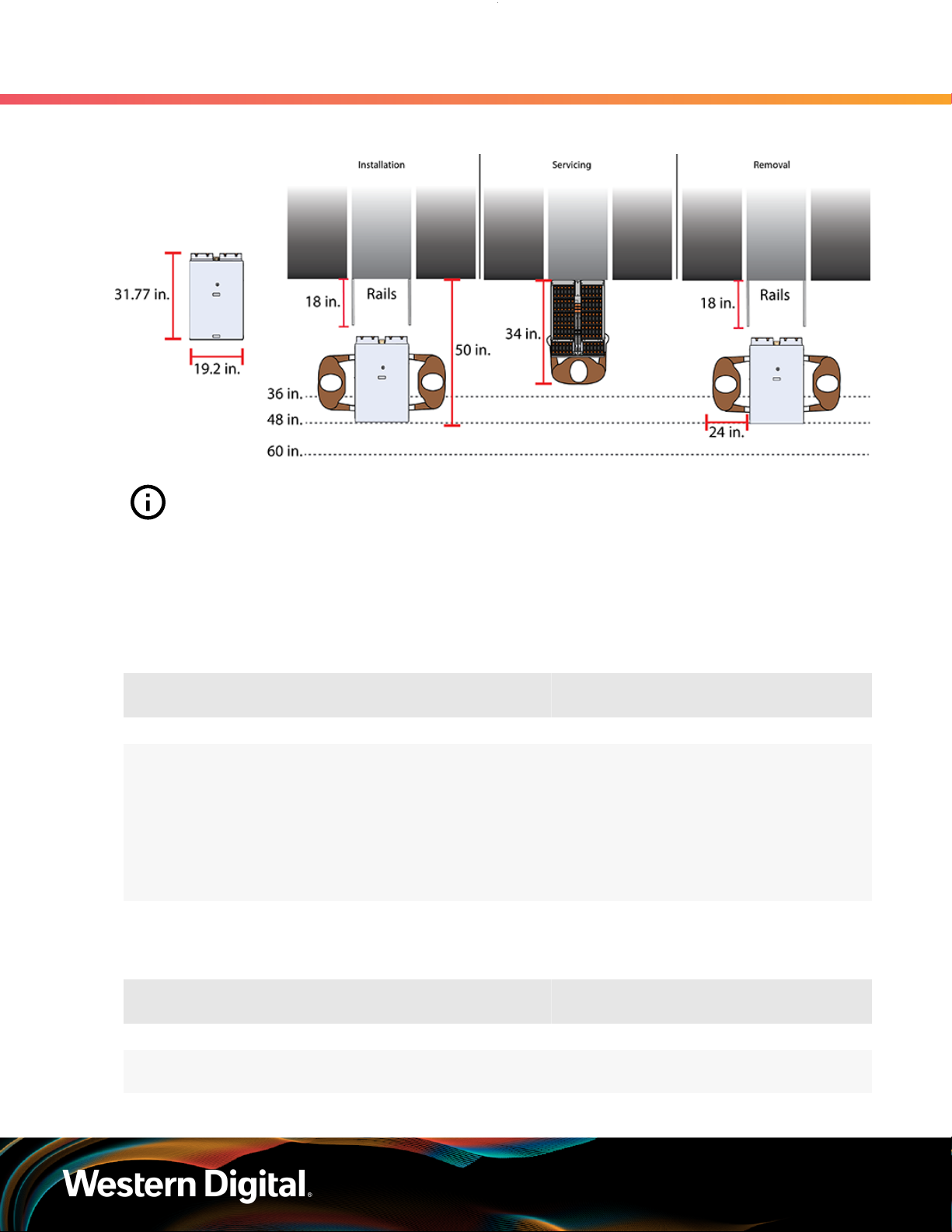

1.12 Ultrastar Data60 Rack Requirements

15

User Guide

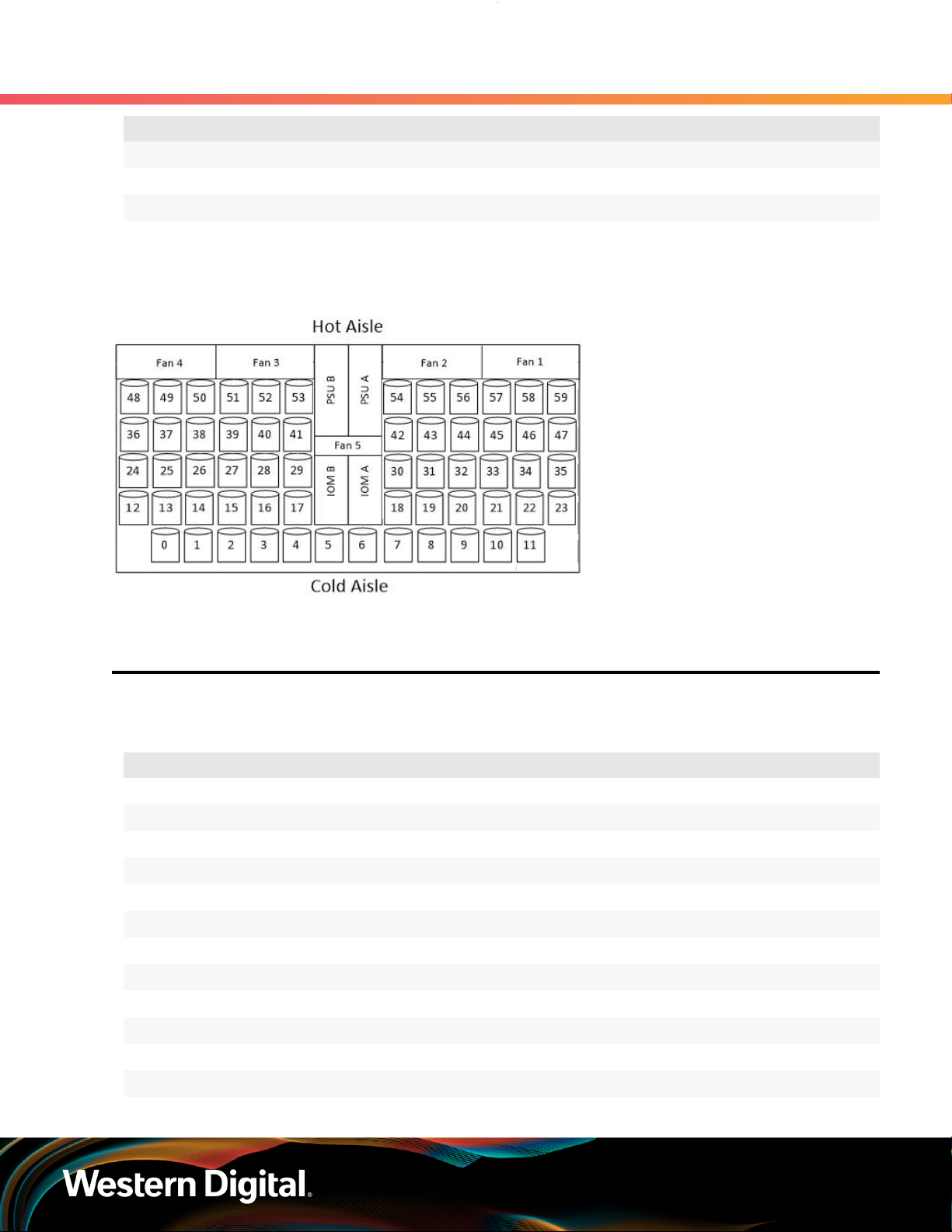

The Ultrastar Data60 is designed to be installed into a rack that meets the EIA-310 standard at a minimum

900mm (35.43in.) usable rack space, frame to frame. The vertical rack rails must be set between 24 in. 32 in. to support the enclosure. It requires 4U of rack space, and it should be installed into the rack at the

lowest possible U height to keep the load on the rack balanced.

Table 15: Required Rack Specifications

1. Overview

1.12 Ultrastar Data60 Rack Requirements

Parameter Requirement

Rack Depth 900mm (35.43in.) usable rack space, frame to frame

Rack Width

Rack Units (U) 4U

Vertical Rack Rail Spacing 24 in. - 32 in.

Static Load Rating 1360.7 kg. / 3000 lbs.

Dynamic Load Rating 1020.5 kg. / 2250 lbs.

Warning: When extended out of the rack on the rail system, the Ultrastar Data60 will be

~630mm / 24.8in. extended outward. This may be a potential tipping hazard depending on

the configuration of the rack. Ensure that leveling feet, anti-tilt, and any other safety features

recommended by the specific rack manufacturers have been deployed before servicing.

The following section provides specific information necessary to install, service, and remove the Ultrastar

Data60 . The installation of the Ultrastar Data60 requires two people and a space of 1270mm / 50in.

in front of the installation space. The servicing of the enclosure requires one person and a minimum of

863.6mm / 34in. of space in front of the installation space. The removal of the enclosure requires two

people, 914.4mm / 36in. of space in front of the installation space, and 24in. on either side of the enclosure

for two people to remove the enclosure.

Warning: The handles on the front of the chassis are not intended to be used to support the

weight of the Ultrastar Data60 . Lifting the unit by the chassis handles or trying to support the

unit on the handles can cause them to fail. This can cause serious damage to the unit or serious

bodily harm to those handling the unit. Always team lift the chassis by gripping the underside

of the unit, and never try to lift a chassis that is filled with drives.

450mm (17.72in.) with 465mm (18.31in.) ± 1.5mm

nominal hole spacing. See EIA-310 Rack Standard

16

User Guide

Figure 13: Installation, Servicing, and Removal

1. Overview

1.12 Ultrastar Data60 Rack Requirements

Attention: Do not install or remove the enclosure while it is populated with drives. The fully

populated enclosure exceeds the amount of weight that a team of two should lift.

1.12.1 Compatible Rack Hardware Configuration

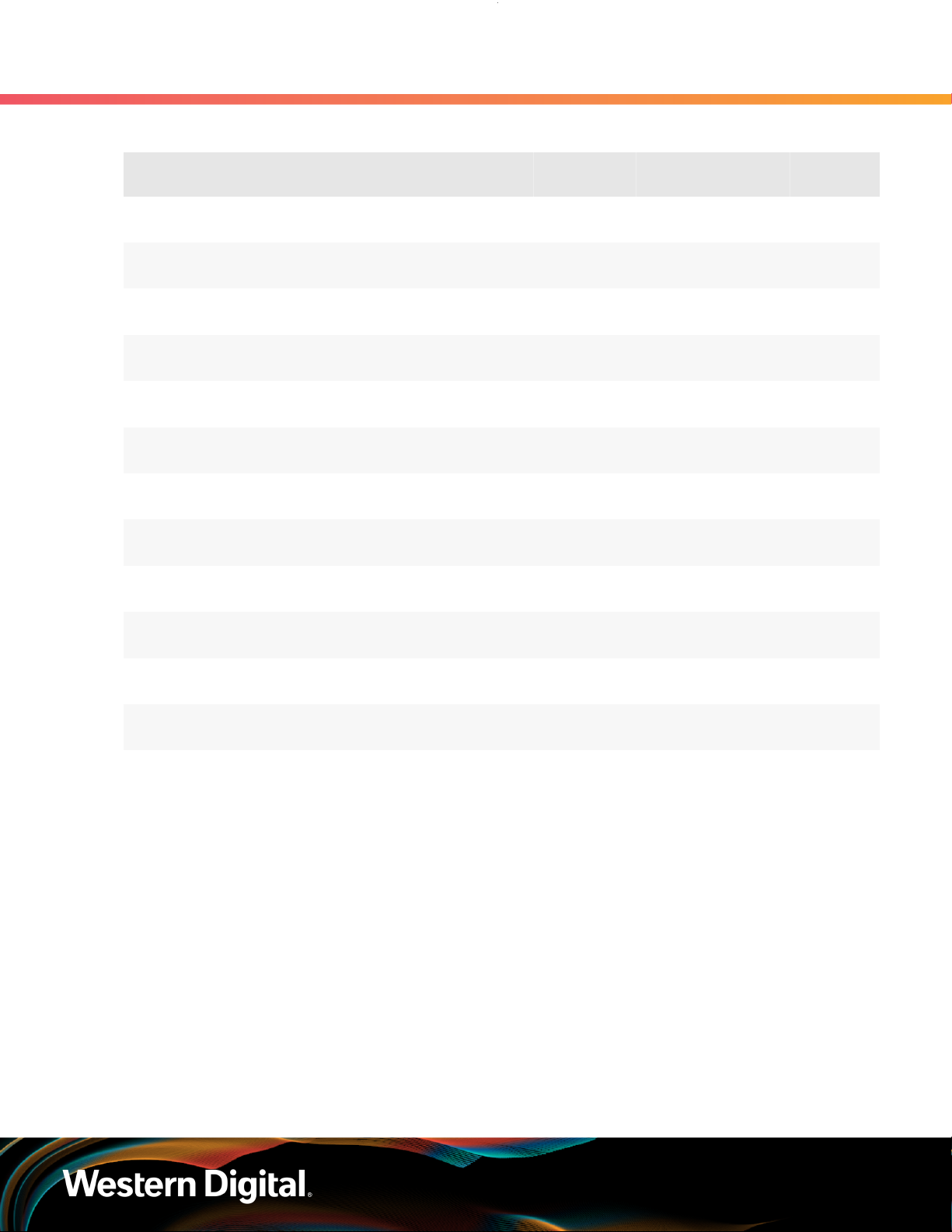

The following table(s) list the approved rack hardware configurations for the Ultrastar Data60 :

Table 16: Compatible Hardware Configuration 1

Parameter Rack PDU (Vertical)

Vendor CRENLO/EMCOR Server Technology Server Technology Various

AS-160099-03

(Drawing

Number EMCOR

Part

Number

Quantity 1 2 2 Varies

526121 Rev 5)

412-0761-11_STV-4501

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

KIT-MBVPT-1B

(one kit per PDU)

Additional Mounting

Bracket Hardware

4 x M6 x 16 Hex

Cap Screws

8 x M6 Fender

4 x M6 Hex Nut

with Nylon Lock

Washers

Table 17: Compatible Hardware Configuration 2

Parameter Rack PDU (Vertical)

Vendor AFCO/Legrand Server Technology Server Technology Various

Part

Number

Options:

412-0761-11_STV-4501

PDU Mounting

Bracket

KIT-MB-40 None

Additional Mounting

Bracket Hardware

17

User Guide

1. Overview

1.12 Ultrastar Data60 Rack Requirements

Parameter Rack PDU (Vertical)

42RU –

WEDIT605

45RU –

WEDIT604

48RU –

WEDIT603

51RU –

WEDIT606

Quantity 1 rack 2 1 N/A

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

Additional Mounting

Bracket Hardware

Table 18: Compatible Hardware Configuration 3

Parameter Rack PDU (Vertical)

Vendor TRIPP LITE Server Technology Server Technology Various

Options:

SR42UBDP (Rack)

412-0761-11_STV-4501

412-0761-20_STV-4502

PDU Mounting

Bracket

KIT-MBVPT-1B None

Additional Mounting

Bracket Hardware

SREXTENDER

25U (Rack

Part

Number

Quantity 1 rack 2 1 N/A

Extension)

SREXTENDER

42U (Rack

Extension)

SREXTENDER

48U (Rack

Extension)

412-0761-23_STV-4503

Table 19: Compatible Hardware Configuration 4

Parameter Rack PDU (Vertical)

Vendor APC/Schneider Server Technology Server Technology Various

AR3300W

Part

Number

412-0761-11_STV-4501

412-0761-20_STV-4502

412-0761-23_STV-4503

PDU Mounting

Bracket

KIT-MBVPT-1B

(one kit per PDU)

Additional Mounting

Bracket Hardware

4 x M6 x 16 Hex

8 x M6 Fender

Cap Screws

Washers

4 x M6 Hex Nut

with Nylon Lock

18

User Guide

1. Overview

1.13 Power Requirements

Parameter Rack PDU (Vertical)

Quantity 1 rack 2 2 Varies

1.13 Power Requirements

The following table describes the A/C input power specification for the Ultrastar Data60 .

Table 20: AC Power Specifications

Alternating Current (AC) Power Supply (2 per enclosure)

Wattage (per power supply)

Voltage (per power supply) 200 - 240 VAC, auto-ranging, 50/60 Hz

Maximum inrush current (per power

supply)

PDU Mounting

Bracket

Power

3

Supply Rating: 80 PLUS Platinum rated

Max Power Consumption: ~1250W

Typical Power Consumption: ~1000W

AC line inrush current shall not exceed 40A

peak, for up to one-quarter of the AC cycle

after which, the input current should be no

more than the specified maximum input current.

Additional Mounting

Bracket Hardware

Caution: The Ultrastar Data60 can only be plugged into high line (220-240 VAC). If the unit is

plugged into low line (110-127 VAC), the PSU will report a "Critical" state when status pages

are queried using SES. In this case, the enclosure will power up, but the drives will not. The

enclosure will remain in low-power mode.

1.14 ESD

The enclosure is designed to dissipate all electrostatic discharge (ESD) to the chassis base. Ensure that

there is sufficient electrical and mechanical connection from the chassis base to the rack rails, and that the

rack itself is tied to earth ground. Precautions must be taken to ensure that the system is not exposed to

ESD while handling components or servicing the unit.

The unit must be grounded in accordance with all local/regional and national electrical codes.

1.15 Enclosure Cooling

3. Max and typical power consumption values represent the output power to the system. Input power will vary depending

on the PSU efficiency and load sharing between PSUs.

19

User Guide

The Ultrastar Data60 has an advanced thermal algorithm running within the logical enclosure services

process called the SEP that monitors all of the temperature sensors in the enclosure. The SEP makes

adjustments to the fan speeds based upon the thermal sensors. The fan algorithm takes into account the

component and the warning and critical threshold limits defaulted and managed by the SEP controller. If

any temperature sensor exceeds the temperature threshold configured in the SES pages, the fan speed

will increase to cool the enclosure. If the enclosure encounters low temperatures, the enclosure will reduce

fan speed in an attempt to conserve power and not over-cool the enclosure. This algorithm is agnostic

to effects of altitude and humidity. The algorithm works based on temperatures within the enclosure with

emphasis on reducing power consumption.

The rack that the Ultrastar Data60 is installed in must not restrict airflow to the enclosure. Racks with doors

should be tested to ensure they do not constrict airflow to the enclosure. If the enclosure reaches critical

temperature, it will go into low-power mode to avoid damage to the enclosure.

When the Ultrastar Data60 is extended out of the rack, the cover of the enclosure remains inside the

rack which exposes the drives. This feature allows for easier access to drives and simplifies maintenance

tasks related to internal components. However, there is a limit to the amount of time the enclosure can be

extended out of the rack before the enclosure will begin to overheat.

1. Overview

1.16 SAS Cabling

Attention: Limit the amount of time that the enclosure is extended out of the rack to only

what is necessary to exchange a component or perform regular maintenance and should be

limited to a maximum of 5 minutes total. Never extend the enclosure out for longer than 5

minutes to prevent overheating. Only extend the enclosure out of the rack as far as necessary

to service components. The enclosure is equipped with a sensor that will be tripped when

the enclosure's top cover has been opened resulting in the rear fans increasing to max speed.

In the event that a fan has failed, it must be replaced before any other CRUs and should be

removed from the enclosure within 30 seconds of removing the enclosure cover.

1.16 SAS Cabling

The Ultrastar Data60 can use passive cables up to 3m in length, or active cables up to 10m, for SAS

connections to the host. Active cables must be used for Ultrastar Data60 to Ultrastar Data60 daisy-chaining

connections. All approved passive and active SAS cables are listed in the following table.

Note: MegaRAID adapters do not support the use of active SAS cables. If your configuration

requires the use of MegaRAID adapters, passive cables must be used.

Table 21: Approved SAS Cables

Type Length Manufacturer Vendor Part Number

Active Optical

HD Mini-SAS to HD Mini-SAS

5. Listed FOHHB23P00xxx cables are compatible, beginning with FW 2052-003.

4. Active cables can be used for both direct (host-to-enclosure) and daisy-chain (enclosure-to-enclosure) connections.

4

3m

4m Amphenol ICC (FCI) FOHHB23P00004

Amphenol ICC (FCI) FOHHB23P00003

Molex 106415-2103

5

20

User Guide

1. Overview

1.16 SAS Cabling

Type Length Manufacturer Vendor Part Number

Amphenol ICC (FCI) FOHHB23P000055m

Molex 106415-2105

6m Amphenol ICC (FCI) FOHHB23P00006

10m Molex 106415-2110

Passive

HD Mini-SAS to HD Mini-SAS

Active Cables

When daisy-chaining multiple Ultrastar Data60 enclosures together, active cables must be used between

enclosures for improved signal integrity.

Passive Cabling

As a best practice, Western Digital requires connecting the cables to every other SAS connector port when

connecting more than one host per IOM. Please refer to Table 22: Recommended IOM Port Connection

Order (page 21) for port connection ordering required for IOMA and IOMB:

6

1m Amphenol ICC (FCI) 10112041-2010LF

2m

3m

Amphenol ICC (FCI) 601760006

CS Electronics 12G-HD-4444/2M

Data Storage Cables (DSC) C5555-2M

The Mate Company (TMC) C5555-2M

10112041-2020LFAmphenol ICC (FCI)

10117949-2020LF

Molex 1110751002

Amphenol ICC (FCI) 601760008

CS Electronics 12G-HD-4444/3M

10112041-2030LFAmphenol ICC (FCI)

10117949-4030LF

Molex 1110751003

6. Passive cables should only be used for direct (host-to-enclosure) connections.

21

User Guide

Table 22: Recommended IOM Port Connection Order

IOM 1st Host 2nd Host 3rd Host 4th Host 5th Host 6th Host

A A6 A4 A2 A5 A3 A1

B B1 B3 B5 B2 B4 B6

Edge Buffering

Edge buffering is an enclosure feature that increases the overall performance when a 6Gb/s target is

connected. With edge buffering disabled, primitives that can be deleted from the initiator are added to

slow the effective logical rate to the slowest target device connected between the initiator and the target

device. With edge buffering enabled, the expanders buffer data from slower 6Gb/s targets to utilize the

12Gb/s link from the expander to the initiator in a more efficient manner.

1.17 Supported SKUs

The following table lists the versions of this HGST product that are supported by this document.

Table 23: List of Supported SKUs

1. Overview

1.17 Supported SKUs

1ES1157 1ES1158 1ES1159 1ES1160 1ES1161 1ES1162

1ES1163 1ES1164 1ES1234 1ES1235 1ES1236 1ES1237

1ES1238 1ES1239 1ES1240 1ES1241 1ES0347 1ES0348

1ES0349 1ES0350 1ES0351 1ES0352 1ES0353 1ES0354

1ES0355 1ES0356 1ES0357 1ES0358 1ES0359 1ES0360

1ES0361 1ES0362 1ES0363 1ES0364 1ES0365 1ES0366

1ES0367 1ES0368 1ES0369 1ES0370 1ES1461 1ES1462

1ES1463 1ES1464 1ES1465 1ES1466 1ES1467

1.18 List of Compatible Drives

HDD with 3.5-inch Drive Carrier

Table 24: Western Digital Ultrastar DC HC310

Drive Type Interface

Ultrastar DC HC310

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 6TB 1EX1189

SKUs

Sector

Size

Encryption Volume Part Number

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310 HDD SATA 6Gb/s 4Kn TCG 6TB 1EX1186

HDD SATA 6Gb/s 512e TCG 6TB 1EX1188

HDD SATA 6Gb/s 4Kn SE 6TB 1EX1187

22

User Guide

1. Overview

1.18 List of Compatible Drives

Drive Type Interface

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

Ultrastar DC HC310

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 512e SE 6TB 1EX1185

HDD SAS 12Gb/s 512e TCG 6TB 1EX1184

HDD SAS 12Gb/s 512e TCG-FIPS 6TB 1EX1853

HDD SAS 12Gb/s 4Kn SE 6TB 1EX1183

HDD SAS 12Gb/s 4Kn TCG 6TB 1EX1182

HDD SAS 12Gb/s 4Kn TCG-FIPS 6TB 1EX1852

Table 25: Western Digital Ultrastar DC HC320

Drive Type Interface

Ultrastar DC HC320

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 8TB 1EX1227

Sector

Size

Sector

Size

Encryption Volume Part Number

Encryption Volume Part Number

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

Ultrastar DC HC320

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SED 8TB 1EX1226

HDD SATA 6Gb/s 4Kn SE 8TB 1EX1225

HDD SATA 6Gb/s 4Kn TCG 8TB 1EX1224

HDD SAS 12Gb/s 512e SE 8TB 1EX1223

HDD SAS 12Gb/s 512e TCG 8TB 1EX1222

HDD SAS 12Gb/s 512e TCG-FIPS 8TB 1EX1343

HDD SAS 12Gb/s 4Kn SE 8TB 1EX1221

HDD SAS 12Gb/s 4Kn TCG 8TB 1EX1220

HDD SAS 12Gb/s 4Kn TCG-FIPS 8TB 1EX1342

23

User Guide

Table 26: Western Digital Ultrastar DC HC330

1. Overview

1.18 List of Compatible Drives

Drive Type Interface

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Ultrastar DC HC330

w/ 3.5 in. drive carrier

Sector

Size

HDD SATA 6Gb/s 512e SE 10TB 1EX2440

HDD SATA 6Gb/s 512e SED 10TB 1EX2441

HDD SATA 6Gb/s 4Kn SE 10TB 1EX2438

HDD SATA 6Gb/s 4Kn SED 10TB 1EX2439

HDD SAS 12Gb/s 512e SE 10TB 1EX2435

HDD SAS 12Gb/s 512e TCG 10TB 1EX2436

HDD SAS 12Gb/s 512e TCG-FIPS 10TB 1EX2437

HDD SAS 12Gb/s 4Kn TCG 10TB 1EX2433

HDD SAS 12Gb/s 4Kn TCG-FIPS 10TB 1EX2434

Encryption Volume Part Number

Table 27: Western Digital Ultrastar DC HC510

Drive Type Interface

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510 HDD SAS 12Gb/s 512e TCG 10TB 1EX0486

HDD SATA 6Gb/s 512e SE 10TB 1EX0499

HDD SATA 6Gb/s 512e ISE 10TB 1EX0497

HDD SATA 6Gb/s 512e SED 10TB 1EX0498

HDD SATA 6Gb/s 4Kn SE 10TB 1EX0496

HDD SATA 6Gb/s 4Kn ISE 10TB 1EX0494

HDD SATA 6Gb/s 4Kn SED 10TB 1EX0495

HDD SAS 12Gb/s 512e SE 10TB 1EX0487

HDD SAS 12Gb/s 512e ISE 10TB 1EX0485

Sector

Size

Encryption Volume Part Number

24

User Guide

1. Overview

1.18 List of Compatible Drives

Drive Type Interface

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

Ultrastar DC HC510

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 512e TCG-FIPS 10TB 1EX1341

HDD SAS 12Gb/s 4Kn SE 10TB 1EX0484

HDD SAS 12Gb/s 4Kn ISE 10TB 1EX0482

HDD SAS 12Gb/s 4Kn TCG 10TB 1EX0483

HDD SAS 12Gb/s 4Kn TCG-FIPS 10TB 1EX1340

Table 28: Western Digital Ultrastar DC HC520

Drive Type Interface

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 12TB 1EX1015

HDD SATA 6Gb/s 512e ISE 12TB 1EX1013

Sector

Size

Sector

Size

Encryption Volume Part Number

Encryption Volume Part Number

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

Ultrastar DC HC520

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SED 12TB 1EX1014

HDD SATA 6Gb/s 4Kn SE 12TB 1EX1012

HDD SATA 6Gb/s 4Kn ISE 12TB 1EX1010

HDD SATA 6Gb/s 4Kn SED 12TB 1EX1011

HDD SAS 12Gb/s 512e SE 12TB 1EX1009

HDD SAS 12Gb/s 512e ISE 12TB 1EX1007

HDD SAS 12Gb/s 512e TCG 12TB 1EX1008

HDD SAS 12Gb/s 512e TCG-FIPS 12TB 1EX1338

HDD SAS 12Gb/s 4Kn SE 12TB 1EX1006

HDD SAS 12Gb/s 4Kn ISE 12TB 1EX1004

Ultrastar DC HC520

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 4Kn TCG 12TB 1EX1005

25

User Guide

1. Overview

1.18 List of Compatible Drives

Drive Type Interface

Ultrastar DC HC520

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 4Kn TCG-FIPS 12TB 1EX1339

Table 29: Western Digital Ultrastar DC HC530

Drive Type Interface

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 14TB 1EX1793

HDD SATA 6Gb/s 512e SED 14TB 1EX1794

HDD SATA 6Gb/s 4Kn SE 14TB 1EX1790

HDD SAS 12Gb/s 512e SE 14TB 1EX1791

HDD SAS 12Gb/s 512e ISE 14TB 1EX1583

HDD SAS 12Gb/s 512e TCG 14TB 1EX1792

Sector

Size

Sector

Size

Encryption Volume Part Number

Encryption Volume Part Number

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

Ultrastar DC HC530

w/ 3.5 in. drive carrier

HDD SAS 12Gb/s 512e TCG-FIPS 14TB 1EX1855

HDD SAS 12Gb/s 4Kn SE 14TB 1EX1788

HDD SAS 12Gb/s 4Kn TCG 14TB 1EX1789

HDD SAS 12Gb/s 4Kn TCG-FIPS 14TB 1EX1854

Table 30: Western Digital Ultrastar DC HC550

Drive Type Interface

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SE 16TB 1EX2476

HDD SATA 6Gb/s 512e SED 16TB 1EX2477

HDD SAS 12Gb/s 512e SE 16TB 1EX2473

HDD SAS 12Gb/s 512e TCG 16TB 1EX2474

Sector

Size

Encryption Volume Part Number

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550 HDD SATA 6Gb/s 512e SE 18TB 1EX2481

HDD SAS 12Gb/s 512e TCG-FIPS 16TB 1EX2475

26

User Guide

1. Overview

1.18 List of Compatible Drives

Drive Type Interface

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

Ultrastar DC HC550

w/ 3.5 in. drive carrier

HDD SATA 6Gb/s 512e SED 18TB 1EX2482

HDD SAS 12Gb/s 512e SE 18TB 1EX2478

HDD SAS 12Gb/s 512e TCG 18TB 1EX2479

HDD SAS 12Gb/s 512e TCG-FIPS 18TB 1EX2480

SSD with 2.5-inch Drive Carrier

Table 31: Western Digital Ultrastar SS300

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 400GB

SSD SAS 12Gb/s RI-3DW/D ISE 400GB

Sector

Size

Encryption Volume Part Number

Part

Number

No longer

available

No longer

available

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D TCG 400GB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s ME-10DW/D SE 400GB

SSD SAS 12Gb/s ME-10DW/D ISE 400GB

SSD SAS 12Gb/s ME-10DW/D TCG 400GB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s RI-3DW/D SE 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 800GB

SSD SAS 12Gb/s RI-3DW/D TCG 800GB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 800GB

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D SE 800GB

No longer

available

27

User Guide

1. Overview

1.18 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

Ultrastar SS300

w/ 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D ISE 800GB

SSD SAS 12Gb/s ME-10DW/D TCG 800GB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 1.6TB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 1.6TB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 1.6TB

SSD with 3.5-inch to 2.5-inch Drive Carrier

Table 32: Western Digital Ultrastar SS200

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 400GB

Part

Number

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Part

Number

No longer

available

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D ISE 400GB

SSD SAS 12Gb/s RI-3DW/D TCG 400GB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s RI-1DW/D TCG 480GB

SSD SAS 12Gb/s RI-3DW/D SE 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 800GB

SSD SAS 12Gb/s RI-3DW/D TCG 800GB

SSD SAS 12Gb/s RI-1DW/D TCG 960GB

SSD SAS 12Gb/s RI-3DW/D SE 1.6TB

SSD SAS 12Gb/s RI-3DW/D ISE 1.6TB

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

28

User Guide

1. Overview

1.18 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS200

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D TCG 1.6TB

SSD SAS 12Gb/s RI-1DW/D TCG 1.92TB

SSD SAS 12Gb/s RI-3DW/D ISE 3.2TB

SSD SAS 12Gb/s RI-1DW/D ISE 3.84TB

SSD SAS 12Gb/s RI-1DW/D SE 7.68TB

Table 33: Western Digital Ultrastar SS300

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D SE 400GB

SSD SAS 12Gb/s RI-3DW/D ISE 400GB

Part

Number

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Part

Number

No longer

available

No longer

available

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s RI-3DW/D TCG 400GB

SSD SAS 12Gb/s ME-10DW/D SE 400GB

SSD SAS 12Gb/s ME-10DW/D ISE 400GB

SSD SAS 12Gb/s ME-10DW/D TCG 400GB

SSD SAS 12Gb/s ME-10DW/D TCG-FIPS 400GB

SSD SAS 12Gb/s RI-3DW/D SE 800GB

SSD SAS 12Gb/s RI-3DW/D ISE 800GB

SSD SAS 12Gb/s RI-3DW/D TCG 800GB

SSD SAS 12Gb/s RI-3DW/D TCG-FIPS 800GB

SSD SAS 12Gb/s ME-10DW/D SE 800GB

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

No longer

available

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

SSD SAS 12Gb/s ME-10DW/D ISE 800GB

No longer

available

29

User Guide

1. Overview

1.18 List of Compatible Drives

Drive Type Interface Drive Writes Encryption Volume

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

w/ 3.5 in. to 2.5 in. drive carrier

Ultrastar SS300

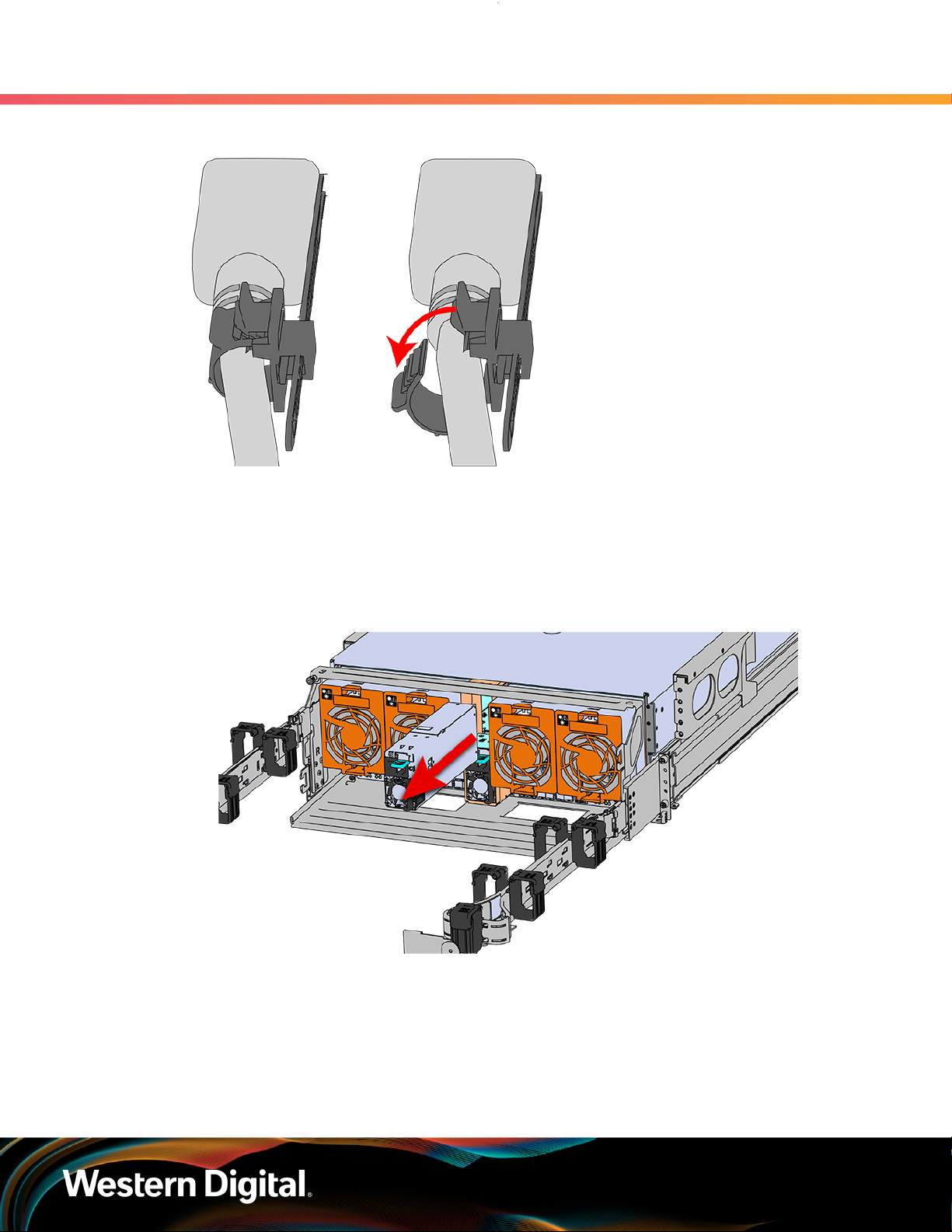

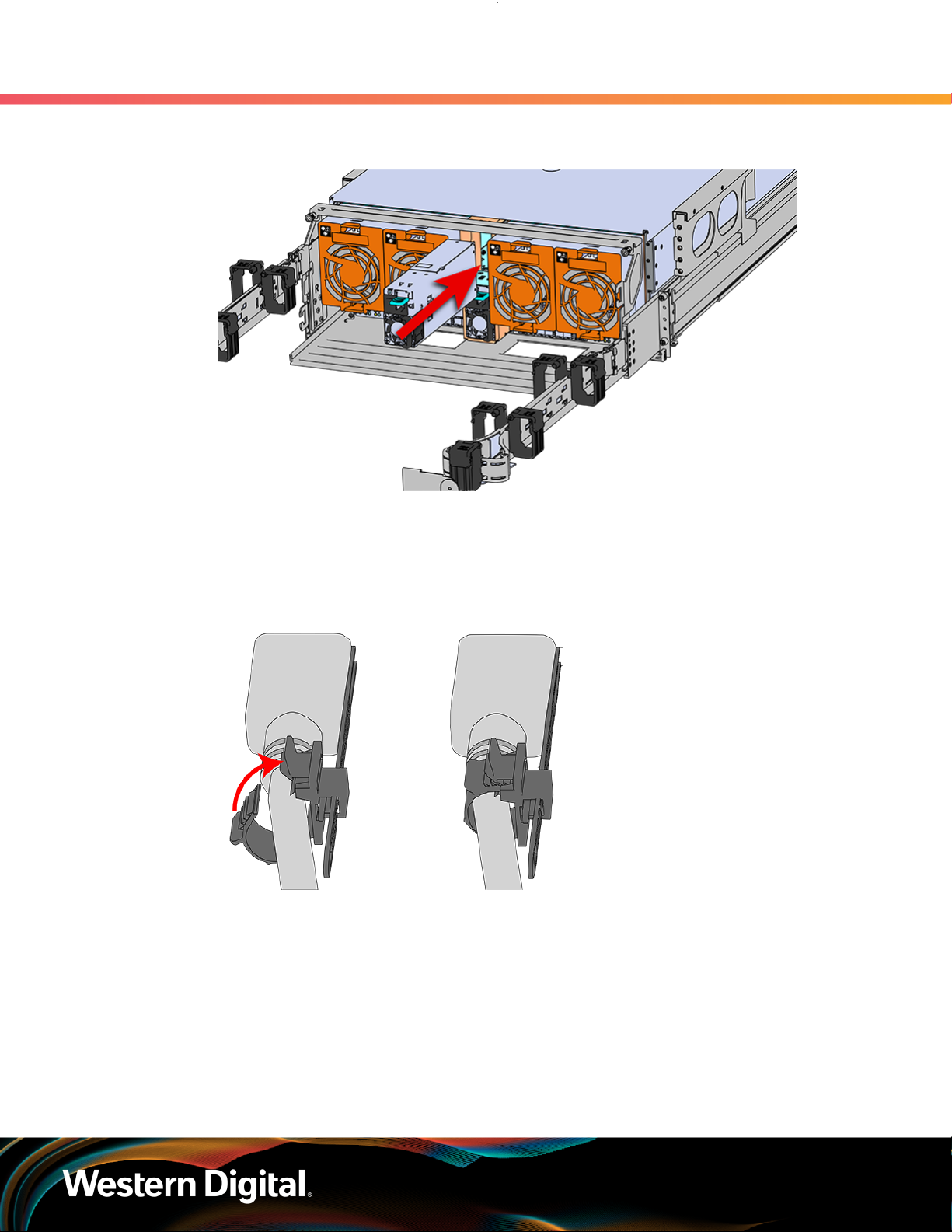

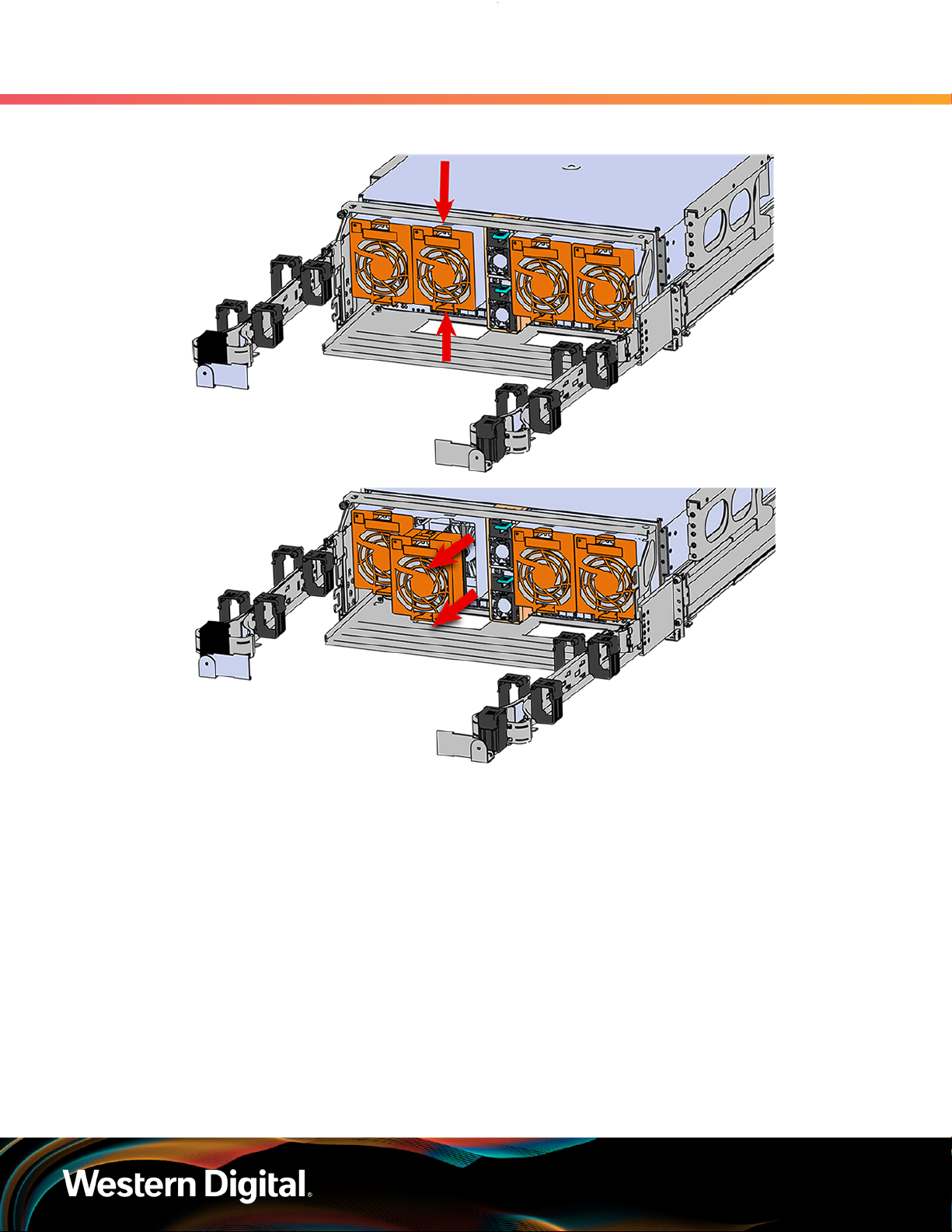

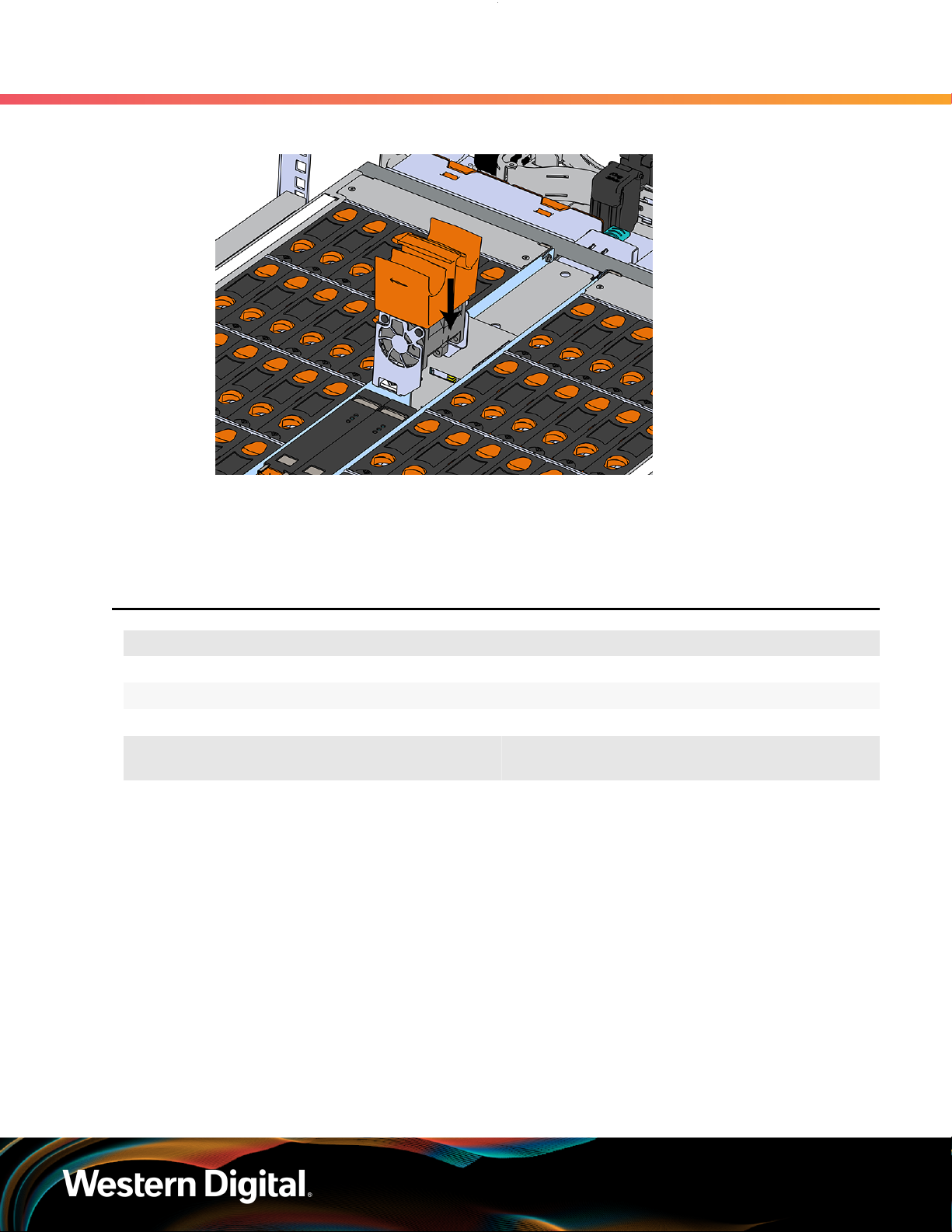

w/ 3.5 in. to 2.5 in. drive carrier