Page 1

WFE 20D

Betriebsanleitung - Mode d’emploi - Gebruiksaanwijzing - Istruzioni per l’uso - Operating

Instructions - Instruktionsbok - Manual de uso - Betjeningsvejledning - Manual do utilizador Käyttöohjeet - √‰ËÁ›Â˜ §ÂÈÙÔ˘ÚÁ›·˜ - Kullan∂m k∂lavuzu -

Návod k pouÏití - Instrukcja obs∏ugi Üzemeltetési utasítás - Návod na pouÏívanie - Navodila za uporabo - Kasutusjuhend Naudojimo instrukcija - Lieto‰anas instrukcija

Page 2

S

E

DK

GB

Table of contents Page

1. Caution! 14

2. Description 14

Technical data 14

3. Commissioning 14

4. Operating the unit 15

5. Breakdown assistance 16

6. Maintenance, working information 16

7. Replacement parts 16

8. Accessories 16

9. Shipment 16

10. Appendix 16

Innehållsförteckning Sidan

1. Observera! 17

2. Beskrivning 17

Tekniska data 17

3. Idrifttagande 17

4. Användning 18

5. Felsökning 18

6. Underhåll, arbetsbeskrivning 19

7. Reservdelar 19

8. Tillbehör 19

9. I leveransen ingår 19

10. Bilaga 19

Indice Página

1. Atención! 20

2. Descripción 20

Datos técnicos 20

3. Puesta en servicio 20

4. Manejo del aparato 21

5. Eliminación de fallos 22

6. Mantenimiento, indicación para eltrabajo 22

7. Repuestos 23

8. Accesorios 23

9. Volumen de suministro 23

10. Apéndice 23

Indholdsfortegnelse Side

1. Forsigtig! 24

2. Beskrivelse 24

Tekniske Data 24

3. Ibrugtagning 24

4. Betjening af apparatet 25

5. Fejlafhjælpning 25

6. Vedligehold, Arbejdsanvisning 26

7. Reservedele 26

8. Tilbehør 26

9. Leveringsomfang 26

10. Bilag 26

D

F

NL

I

Inhaltsverzeichnis Seite

1. Achtung! 1

2. Beschreibung 1

Technische Daten 1

3. Inbetriebnahme 1

4. Bedienungs des Gerätes 2

5. Problem und Lösung 3

6. Wartung, Arbeitshinweise 3

7. Ersatzteile 3

8. Zubehör 3

9. Lieferumfang 3

10. Anhang 3

Table des matières Page

1. Attention! 4

2. Description 4

Caractéristiques techniques 4

3. Mise en service 4

4. Commande de l’appareil 5

5. Remèdes aux dérangements 6

6. Entretien, consigne de travail 6

7. Pièces de rechange 7

8. Accessoires 7

9. Ensemble de la livraison 7

10. Annexe 7

Inhoud Pagina

1. Attentie! 8

2. Beschrijving 8

Technische gegevens 8

3. Ingebruikneming 8

4. Bediening van het toestel 9

5. Opheffing van storingen 10

6. Onderhoud, advies 10

7. Onderdelen 10

8. Toebehoren 10

9. Omvang van de levering 10

10. Aanhangsel 10

Indice Pagina

1. Attenzione! 11

2. Descrizione 11

Caratteristiche tecniche 11

3. Messa in funzione 11

4. Impiego dell’apparecchio 12

5. Eliminazione di guasti 13

6. Manutenzione, note sul lavoro 13

7. Parti di ricambio 13

8. Accessori 13

9. Volume di fornitura 13

10. Appendice 13

Page 3

WFE 20D

Page 4

DK

P

FIN

E

GB

I

S

NL

F

D

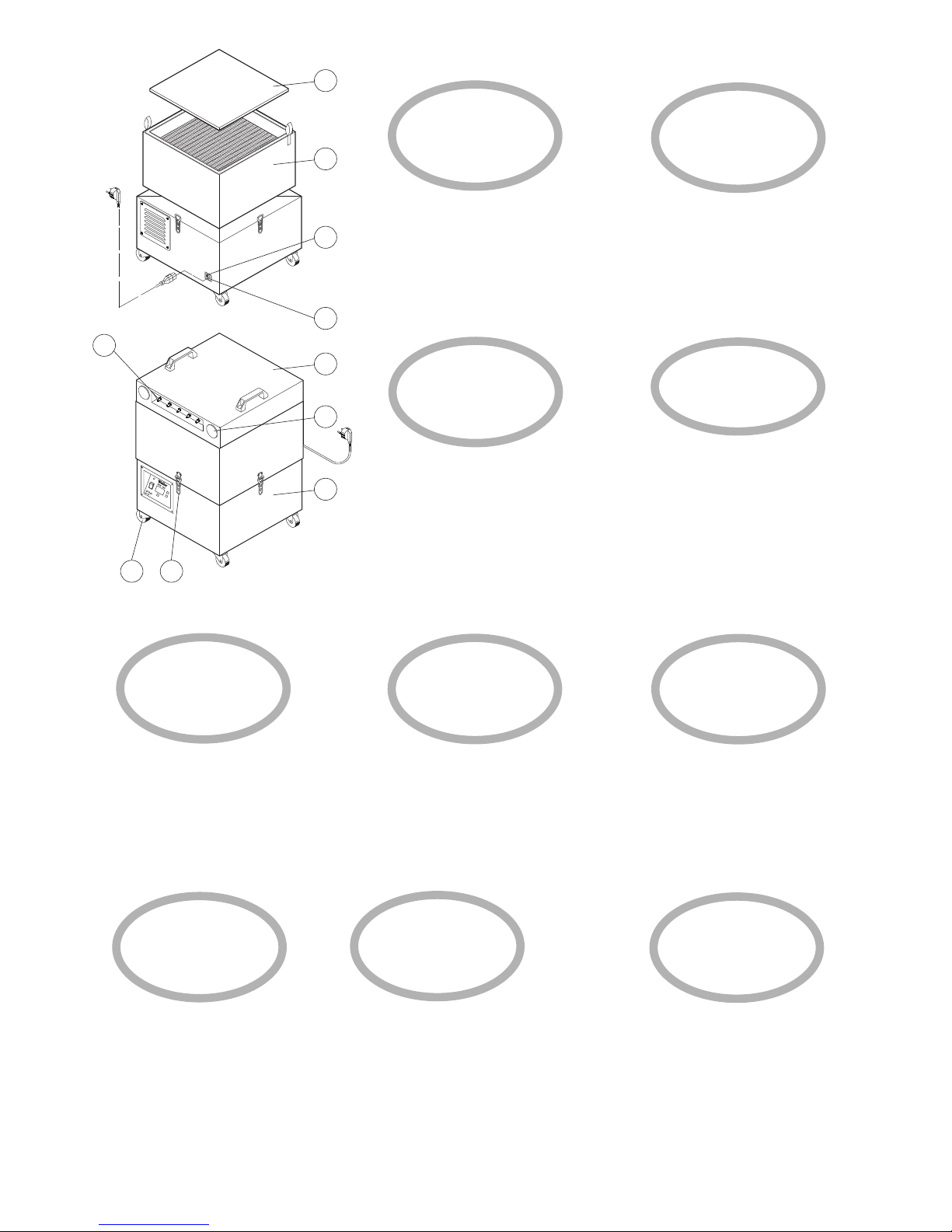

1

2

8

9

10

7

3D9R802

6 5

4

3

1. Aansluitkast vacuüm

2. Turbinekast

3. Vacuümaansluiting pijpsysteem DN40

4. Vacuümaansluiting steeknippel

5. Spanslot

6. Transportrollen

7. Compactfilter

8. Voorfilter

9. Netaansluiting

10.Zekering

1. Boîtier de raccordement au vide

2. Carter de la turbine

3. Raccordement au vide système

de tuyauterie DN40

4. Raccordement au vide nipple

enfichable

5. Tendeur d’assemblage

6. Roulettes de transport

7. Filtre compact

8. Premier filtre

9. Raccordement au secteur

10.Fusible

1. Anschlussgehäuse Vacuum

2. Turbinengehäuse

3. Vacuumanschluss Rohrsystem DN40

4. Vacuumanschluss Stecknippel

5. Spannschloss

6. Transportrollen

7. Kompaktfilter

8. Vorfilter

9. Netzanschluss

10.Sicherung

1. Vacuum connection housing

2. Turbine housing

3. Vacuum connection for DN40 hose

system

4. Nipple for push-on vacuum

connection

5. Locking clamp

6. Transport rollers

7. Compact filter

8. Pre-filter

9. Mains connection

10. Fuse

1. Carter di attacco per vuoto

2. Carter della turbina

3. Attacco per vuoto sistema a tubi

DN40

4. Attacco per vuoto nipplo spinato

5. Tenditore a vite

6. Rotelle di trasporto

7. Filtro compatto

8. Prefiltro

9. Attacco di alimentazione

10.Fusibile

1. Anslutningsdel vakuum

2. Turbinhus

3. Vakuumanslutning rörsystem DN40

4. Vakuumanslutning insticksnippel

5. Spännlås

6. Transporthjul

7. Kompaktfilter

8. Förfilter

9. Nätanslutning

10. Säkring

1. Liitäntäkotelo vakuumi

2. Turbiinikotelo

3. Vakuumiliitäntä putkijärjestelmä

DN40

4. Vakuumiliitäntä pistenippa

5. Kiristyslukko

6. Kuljetusrullat

7. Kompaktisuodatin

8. Esisuodatin

9. Verkkoliitäntä

10.Sulake

1. Caja de conexión para vacío

2. Caja de turbina

3. Toma de vacío sistema de tubos

DN40

4. Toma de vacío boquilla de

empalme

5. Cierre tensor

6. Ruedas de transporte

7. Filtro compacto

8. Filtro previo

9. Conexión a la red

10.Fusible

1. Forbindelseshus, vakuum

2. Turbinehus

3. Vakuumtilslutning rørsystem

DN40

4. Vakuumtilslutning stiknippel

5. Bardunstrammer

6. Transportruller

7. Kompaktfilter

8. Forfilter

9. Nettilslutning

10.Sikring

1. Carcaça de conexão do vácuo

2. Carcaça da turbina

3. Conexão de vácuo do sistema de

tubagem DN40

4. Conexão de vácuo do niple de encaixe

5. Fechadura tensão

6. Rolos de transporte

7. Filtro compacto

8. Filtro prévio

9. Conexão da rede

10. Fusível

Page 5

P

11. Interruptor de rede eléctrica

12. Interface RS232

13. Display

14. Tecla "UP"

15. Tecla "DOWN"

16. Tecla "TIMER"

17. Indicador nível do filtro

E

11. Interruptor de alimentación

12. Interfaz RS232

13. Display

14. Tecla "UP"

15. Tecla "DOWN"

16. Tecla "TIMER"

17. Indicador de estado del filtro

I

11. Interruttore di rete

12. Interfaccia RS232

13. Display

14. Tasto "UP"

15. Tasto "DOWN"

16. Tasto "TIMER"

17. Indicatore di livello del filtro

D

11. Netzschalter

12. RS232 Schnittstelle

13. Display

14. "UP" Taste

15. "DOWN" Taste

16. "TIMER" Taste

17. Filterzustandsanzeige

11

17

4D9R809

12 13

16

14

15

S

NL

DK

GB

F

11. Netafbryder

12. RS232 Grænseflade

13. Display

14. "UP" Knap

15. "DOWN" Knap

16. "TIMER" Knap

17. Filtertilstandsviser

11. Mains switch

12. RS232 Interface

13. Display

14. "UP" button

15. "DOWN" button

16. "TIMER" button

17. Filter status display

11. Interrupteur d’alimentation

12. Interface RS232

13. Display

14. Touche "UP"

15. Touche "DOWN"

16. Touche "TIMER"

17. Affichage de l’état du filtre

11. Nätströmbrytare

12. RS232 Gränssnitt

13. Display

14. "UP"-knapp

15. "DOWN"-knapp

16. "TIMER"-knapp

17. Filterindikator

11. Netschakelaar

12. RS232 interface

13. Display

14. "UP" toets

15. "DOWN" toets

16. "TIMER" toets

17. Filter toestandsindicator

Page 6

14

Thank you for placing your trust in our company by purchasing the WELLER WFE 20D soldering fumes extractor.

Production was based on stringent quality requirements

which guarantee the perfect operation of the device.

1. Caution!

Please read these Operating Instructions and the attached

safety information carefully prior to initial operation. Failure

to observe the safety regulations results in a risk to life and

limb.

The manufacturer shall not be liable for damage resulting

from misuse of the machine or unauthorised alterations.

The WELLER WFE 20D soldering fumes extractor corresponds to the EC Declaration of Conformity in accordance

with the basic safety requirements of Directives

2004/108/EC and 2006/95/EC + 2004/42/EC.

2. Description

The WELLER Soldering Fume Extraction Device WFE 20D has

a powerful maintenance-free turbine, making is perfectly

suited to continuous operation in industry. The unit was

designed for direct extraction at the soldering iron and is

suitable for surface extraction.

A digital electronics system allows simple and convenient

operation of the available functions. The vacuum created by

the turbine is controlled in standard mode (mode 0) electronically to the preset value of 8.000 Pa. This value can be

changed individually in mode 2.

If low extraction power is sufficient, the control setpoint can

be reduced in mode 2. If mode 2 has been set, the unit must

be switched over to the desired operating mode to prevent

an inadvertent change of the setpoint value. In addition, the

turbine speed can be changed manually in speed-controlled

mode 1 in the range 20% - 100%.

For connection to the pipe system DN40, a max. of 2 vacuum connections (3) are available. The pipe system can be

arranged individually by positioning the vacuum connections

(plug-in nipples) for the soldering irons (max. 20) as

required. Alternatively, 5 vacuum connections are provided

directly on the unit for soldering iron fume extraction.

The standard composition of the installed 3-stage filter (fine

dust filter, HEPA filter and wide-band gas filter) is specially

adapted to soldering fumes. With the use of the type-tested

HEPA filters in Class H13, the separation rate of the filter set

upon delivery is 99.95% as per EN 1822 with a particle size

of 0.12 m. These figures are only achieved with the use of

original parts. A required filter change is indicated by a display of a differential pressure measurement on the unit.

Using a standard RS232 interface, all of the unit's functions

can be operated and remotely controlled. An operating hours

code and operating hours specification widen the scope of

the unit's functions.

3. Commissioning

Direct interconnection of the FE soldering bits

The WELLER WFE 20D soldering fume extractor is fitted out

for the direct interconnection of a maximum of 5 WELLER FE

soldering bits. To connect up the vacuum hose, first remove

the sealing lid and then push the hose directly onto the pushon nipple (4). The FE soldering bit unit uses a vacuum hose

that is 2.5 m long. If the soldering stations are further away

(up to 5 m), a DN17 extension hose can be used (this can be

obtained as an accessory). Push-on nipples must be fitted to

the end of the DN17 hose and the unit.

Indirect interconnection via a DN40 hose system

(accessory)

The WELLER WFE 20D is interconnected to the vacuum hose

system via a flexible fume extraction hose NW44 for indirect

operation. In this case the 5 push-on nipples (4) remain

sealed and the sealing plug (3) for the hose system has to be

removed. In order to connect up the hose system for the FE

English

Technical data

Dimensions L X W X H: 450 mm X 450 mm X 695 mm

Weight: 45 kg

Voltage: 230 V/50 Hz

Electrical power rating: 630 VA

Vacuum (controlled): 8,000 Pa

Maximum quantity supplie: 100 m3/h

Noise emission level: 51 dB(A)

Filter: Stage 1 Pre-filter F5

Stage 2; 3 Class H13 high efficiency sub-micron particle air filter

(99.95% particles up to approx. 0.12 µm)

combined with a wide-band gas filter

(50% AKF, 50% Puratex)

Page 7

English

soldering bits, a Ø 7.0 mm hole must be tapped in the

required position, the push-on nipple must be screwed into it

and the vacuum hose from the FE soldering bits must then

be pushed onto the nipple.

Electrical connection

The nominal voltage must be checked against the details

given on the nameplate prior to commissioning. If the mains

voltage is correct, connect the WFE 20D to the mains supply

(9) and switch on the equipment using the mains switch (11).

A green LED (filter is OK) indicates that the unit is running.

The percentage details for the turbine rotational speed are

shown on the display (13).

4. Operating the unit

Operating mode

The unit is in mode 0 when it leaves the factory. Vacuum is

controlled to 8.000 Pa. This is the ideal setting for direct

extraction with WELLER FE soldering irons. Changes are not

possible in mode 0. However, if you require a different vacuum for control, this can be changed in setting mode 2 from

5.000 Pa to 8.000 Pa in steps of 100 Pa. (Display of 50 – 100)

Switching operating mode

Hold down the UP and DOWN (14/15) buttons simultaneously when switching on. The currently set operating mode is

shown in the display (ex works setting -0-). If the TIMER button (16) is additionally pressed, the unit can be switched to

mode 1 or mode 2. When the UP and DOWN button is

released, the unit starts in the set operating mode. In operating mode 1, the turbine is speed-controlled. The turbine

speed and thus the extraction power can be adjusted steplessly between 20% - 100% using the UP/DOWN button

(14/15). Setting mode 2 should only be used for modifying

the control setpoint. The unit should then be switched to

operating mode 0. Operating mode 0 now uses the modified

control setpoint.

Filter checks

The filter status display (17) indicates when (through filter

differential pressure measurement) the permitted degree of

contamination has been exceeded and when the filter insert

has to be changed. The red filter control LED will illuminate

and the unit will be switched off. The sub-micron particle filter and wide-band gas filter are fitted one on the other, so

that they can be changed together as a compact filter.

The fine dust filter (8) (filter mat), is the pre-filter level of the

compact filter (7) and therefore has to be changed more

often. The pre-filter mat change is satisfactory, if the red LED

(17) is no longer illuminated when the equipment is switched

back on.

Displaying the filter operating hours

Press the TIMER button (16) and the current filter operating

hours will be displayed (display X 10). Flashing display. The

operating hours display must be manually reset after a filter

change. Keep the TIMER button (16) pressed down until the

display is reset to 000.

Filter operating hours default setting

The filter operating hours can be entered as a default setting

for better handling of the filter change intervals. When the

default operating hours setting has expired, the unit will be

switched off and “filter change required” will be indicated by

a flashing display (13) and the illumination of the red LED

(17).

Press the TIMER button (16) to enter the default operating

hours setting. The current filter operating hours will now

flash on the display. Press the UP/DOWN buttons (14/15)

simultaneously whilst the display is flashing. Release

UP/DOWN buttons (14/15) and now use them to enter the

default operating hours.

RS232 Interface

It is possible to control the WFE 20D via a PC using the integrated standard RS232 interface (12). This enables the full

range of system functions to be used or remotely controlled.

Remote control

The remote control (which is available as an accessory) can

be operated via the RS232 interface (12). The unit’s main

functions can be transmitted using this remote control.

●

Switching the unit On/Off

●

Speed setting in mode - 1 -

●

Filter status display

Knowing that the WFE 20D can be operated via a remote

control is helpful when selecting the site for the unit.

Decommissioning

Attention!

A high concentration of pollutants will result in the

active carbon heating up. The equipment should be run

for several minutes in a pollutant free state before being

switched off in order to prevent unwanted heating up.

15

Page 8

16

7. Replacement parts

See Exploded Page 66 for replacement parts for standard

installations

Fine dust filter F7

Wide-band gas filter (50% AKF, 50% Puratex) without an H13

particulate air filter

8. Accessories

0058735909 Remote control

Pipe system DN40 (Page 67)

9. Shipment

1 WFE 20D including filter set

1 connecting cable

1 Operating manual

1 Safety information

10. Appendix

Accessories for DN40 pipe system

Subject to technical alterations and amendments!

See the updated operating instructions at

www.weller-tools.com.

English

6. Maintenance, working information

Various fluxes, flux components as well as different dust particles in the extracted air can significantly reduce the filter’s

working life.

The sub-micron particles in the air increase when soldering

or welding on varnished insulated wire. The standardised F5

filter mat should be exchanged for a class F7 fine dust filter

for these or similar applications.

A compact filter with a greater quantity of active carbon

(without particulate air filter stage) should be used when

extracting adhesive vapour.

Filter changes

The mains plug must always be pulled out of the mains

socket before any maintenance work is undertaken. To

change the filter you must first open the locking clamps (5)

between the turbine housing (2) and the filter housing (1)

and then lift off the filter housing. Pull the vacuum hose off

of the compact filter. The compact filter (7) and the fine dust

filter (8) can be removed using the carrying straps. The fine

dust filter is laid inside the compact filter (see exploded

drawing 66).

Attention!

The minimum pressure hose must be reconnect ed correctly and the holding latches must be turned

downwards when replacing the filter.

Dirty filter are classified as hazardous waste.

5. Breakdown assistance

Malfunction Cause Solution

Extraction power missing Pipe system leaking Reseal the pipe system

Filter is dirty Change the filter

Vacuum is too low Increase the extraction power

(mode 1 only)

WFE 20D is not running Thermally switched off Leave the WFE 20D to cool down

Switch on again after approx. 3 hours.

Filter display is red Filter is full Change the filter

Unit is not running Minimum pressure hose Reconnect the hose to the filter

was not replaced after

the filter change

Sub-micron particle Pre-filter has not been Use a pre-filter

becoming dirty to quickly used Fit an F7 filter

Use a preliminary separator if the

proportion of solid matter is high.

Page 9

66

Explo Drawing

Page 10

67

Pipe system DN 40

36

5 36 329 99

5 36 324 99

5 36 343 99

5 36 338 99

5 36 320 99

5 36 343 99

5 36 326 99

36 338 99

5 36 322 99

5 36 323 99

5 344 99

5 36 319 99

5 36 316 99

3D9R811

266

182

163

170

157

7

7

5

5 36 321 99

80 2000 180

57

118

266

Page 11

68

Circuit Diagram

4D3R812

1

EC - Hoch-

druckgebläse

M

~

2

5

6

ws

3

4

sw

br

rt

gn

ge

br

58735901

sw

ws

4D3R812

X1

C1

R4

R5

R6

R3

R1

R2

N1

D1D2

S2

S1

S3

T3 T2 T1

A3 A2 A1

D1

Netzanschluß

230V

Netz-

schalter

T3,15A

Page 12

www.weller-tools.com

Weller®is a registered Trademark and registered Design of Apex Tool Group, LLC.

© 2011, Apex Tool Group, LLC.

T005 57 147 04 / 07.2011

T005 57 147 03 / 06.2008

GERMANY

Weller Tools GmbH

Carl-Benz-Str. 2

74354 Besigheim

Phone: +49 (0) 7143 580-0

Fax: +49 (0) 7143) 580-108

FRANCE

Apex Tool Group S.A.S.

25 av. Maurice Chevalier BP 46

77832 Ozoir-la-Ferrière, Cedex

Phone:+33 (0) 1 60.18.55.40

Fax: +33 (0) 1 64.40.33.05

GREAT BRITAIN

Apex Tool UK Limited

4

th

Floor Pennine House

Washington, Tyne & Wear

NE37 1LY

Phone: +44 (0191) 419 7700

Fax: +44 (0191) 417 9421

ITALY

Apex Tool S.r.I.

Viale Europa 80

20090 Cusago (MI)

Phone: +39 (02) 9033101

Fax: +39 (02) 90394231

SWITZERLAND

Apex Tool Switzerland Sàrl

Rue de la Roselière 8

1400 Yverdon-les-Bains

Phone: +41 (024) 426 12 06

Fax: +41 (024) 425 09 77

AUSTRALIA

Apex Tools

P.O. Box 366

519 Nurigong Street

Albury, N. S. W. 2640

Phone: +61 (2) 6058-0300

CANADA

Apex Tools - Canada

164 Innnisfil street

Barrie Ontario

Canada L4N 3E7

Phone: +1 (905) 455 5200

USA

Apex Tool Group, LLC.

14600 York Rd. Suite A

Sparks, MD 21152

Phone: +1 (800) 688-8949

Fax.: +1 (800) 234-0472

CHINA

Apex Tools

18

th

Floor, Yu An Building

738 Dongfang Road

Pudong, Shanghai

200122 China

Phone: +57 (2) 691 0900

Loading...

Loading...