Page 1

VideoPath

®

VS-100

VideoSigmoidoscope

Operating

Manual

Endo Menu

Service Manual

Page 2

Thank you for your purchase of a Welch Allyn Flexible

VideoSigmoidoscope.The operating and maintenance instructions

found in this manual should be followed to ensure many years of

reliable service. Please read these instructions thoroughly before

attempting to use your new Flexible VideoSigmoidoscope.

WARNING: The user of this equipment should be thoroughly trained in

the medical procedures appropriate to the equipment. Furthermore, time

should be taken to read and understand these instructions before performing any procedures. Instructions for other equipment used in conjunction with any VideoEndoscope (e.g., suction machines) should also be

read and understood. Failure to do so may result in injury to the patient

and/or damage to the instrument.

While this manual describes the recommended protocol for inspecting

and operating the equipment, it does not outline procedural techniques.

Only physicians trained and versed in flexible endoscopy should use this

equipment.

CAUTION: Federal (USA) law restricts this device to sale by/to or on the

order of a physician or other appropriately licensed medical professional.

Infection Control Note

This manual includes a current list of disinfecting and sterilizing solutions

and processes. However, since infection control procedures involve

complex and controversial issues and are constantly changing, it is recommended that the users of this equipment keep informed of the latest

information and regulations pertaining to infection control.

Page 3

Table of Contents

Conventions .......................................................................................................2

Specifications.....................................................................................................2

Components.......................................................................................................3

Nomenclature and Function...........................................................................6

Flexible VideoSigmoidoscope............................................................................6

Light Source ......................................................................................................8

Water Bottle/Cleaning Bottle .............................................................................9

Preparation and Inspection for Use............................................................10

Prior to Initial Use ............................................................................................10

System Set-up .................................................................................................10

Physical System Inspection.............................................................................12

Operations ........................................................................................................15

Procedure.........................................................................................................15

Holding the Instrument....................................................................................16

Preparation Before Insertion of the VideoEndoscope......................................16

Insertion and Withdrawal.................................................................................17

Biopsy Passage................................................................................................18

Cleaning and Disinfection .............................................................................19

Endoscope Internal Schematic........................................................................20

Semi-Automated Cleaning Method...............................................................22

Cleaning at the Examination Room .............................................................22

Leakage T esting...........................................................................................24

Disinfection Procedure #1 (Using Tray)........................................................26

Disinfection Procedure #2 (Total Immersion) ..............................................27

Final Rinse...................................................................................................28

Manual Cleaning Method................................................................................28

Cleaning at the Examination Room .............................................................28

Leak T est Procedure....................................................................................30

Cleaning the Instrument..............................................................................32

Enzymatic Cleaning Solutions..........................................................................34

Cleaning of Accessories – Biopsy Forceps......................................................34

High-Level Disinfection....................................................................................35

Disinfecting Solutions..................................................................................35

Sterilization and Aeration.............................................................................36

Ethylene Oxide Gas Sterilization......................................................................36

Cold Sterilization..............................................................................................37

Other Sterilization Methods.............................................................................37

Accessory Sterilization.....................................................................................38

Accessory and Instrument Storage............................................................38

Servicing ...........................................................................................................39

Care and Maintenance Tips..........................................................................40

Troubleshooting...............................................................................................42

VS-100 Sigmoidoscope 1

Page 4

Conventions

WARNING alerts the user to possible serious injury, death or other

adverse reaction associated with the use or misuse of the device.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It also alerts against unsafe

practices.

NO

TE provides supplemental information to the text and indicates a

potentially hazardous situation, which, if not avoided, may result

in property damage. Additionally, it highlights important information on the use of this equipment.

Specifications

Parameter Sigmoidoscope (30500)

Angle of View 145°

Depth of View 3-100mm

Tip Deflection Up: 180°

Down: 180°

Right: 160°

Left: 160°

Distal Rigid Diameter 213.6mm

Insertion T ube Diameter 212.8mm

Diameter of Accessory 22.8mm

Suction Channel

Insertion T ube 70cm

Working Length

Total Length 103cm

2 VideoPath

Page 5

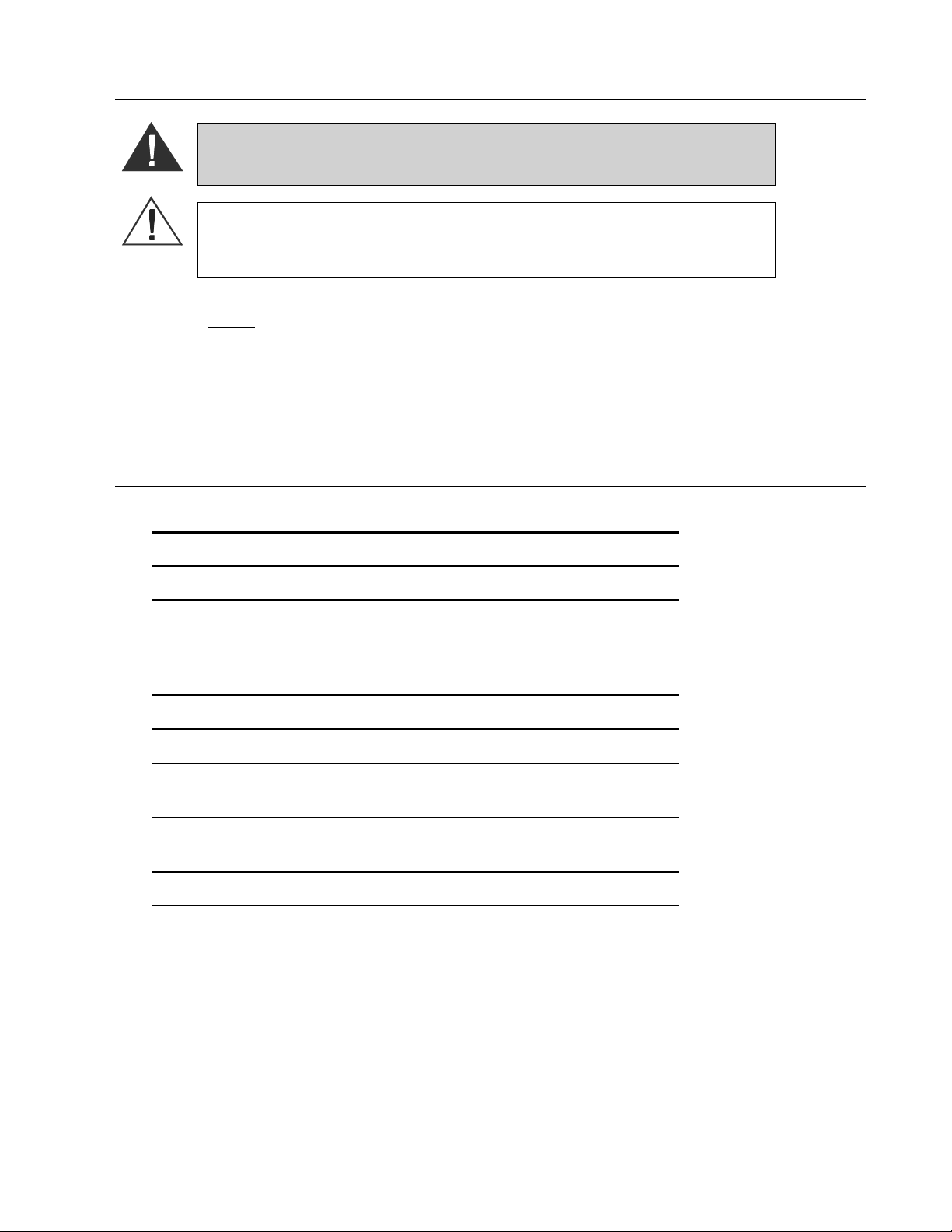

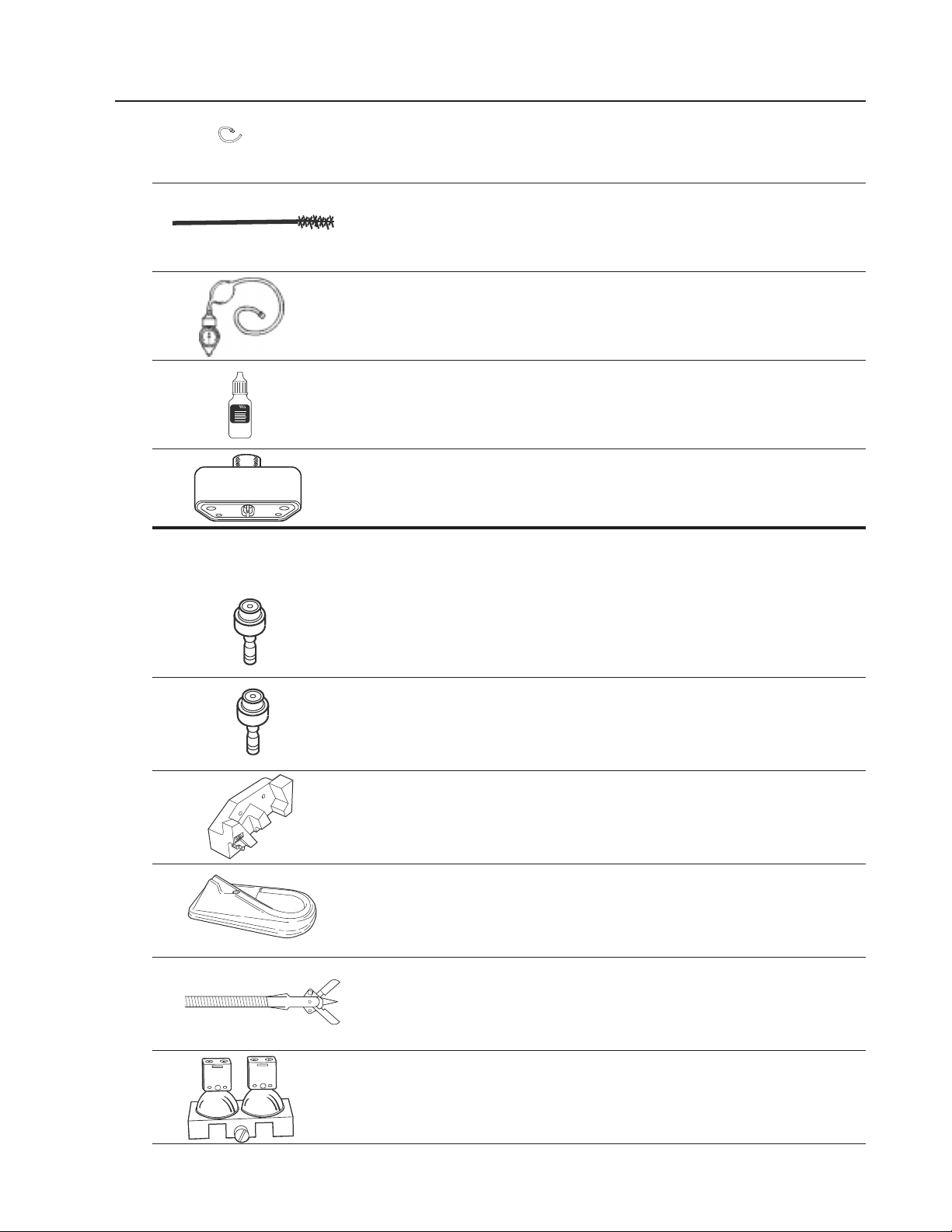

Components

Flexible VideoSigmoidoscope Set Includes:

30500 Flexible VideoSigmoidoscope

31020 Channel Cleaning Brush (2 each)

31021 Valve Reprocessing Caps

33930 Biopsy Seals (10 each)

31023 60cc Syringes (2 each)

33924 Air/Water Nozzle Cleaning Brush

31024 Air/Water Valve “O” Ring Kit

31025 Suction Valve “O” Ring Kit

31027 Air/Water Reprocessing Adapter

31029 Shipping/ET O Vent Cap

31030 Distal Reprocessing Cap (6 each)

VS-100 Sigmoidoscope 3

Page 6

Components (continued)

31038 Suction Reprocessing Adapter

31031 Valve Well Cleaning Brush

31037 Leakage T ester

33918 Valve Lubricant

31028 Soaking Cap

Optional Accessor ies (not included in set):

31032 Air/Water V alv e

31033 Suction Valv e

31035 Instrument Hanger

33902 Disinfection Tray

33950 Biopsy Forceps w/Window and Needle (Sigmoid)

04060 Lamp Replacement Assembly

4 VideoPath

Page 7

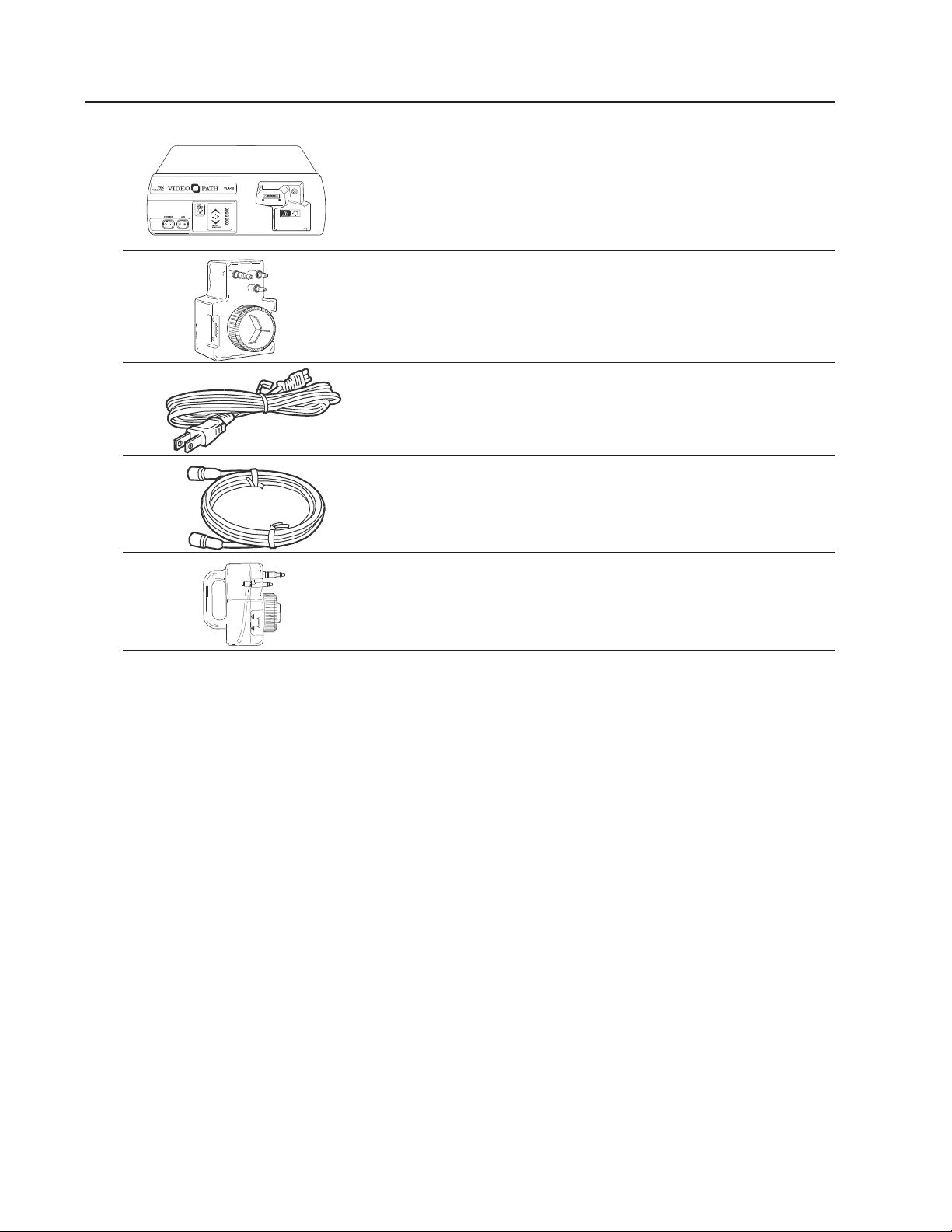

Components (continued)

VLX-10 Light Source Includes:

40500 Light Source

45510 Water Bottle

761076-0 Power Cord

45512 S-VHS Video Cable

45520 Cleaning Bottle

VS-100 Sigmoidoscope 5

Page 8

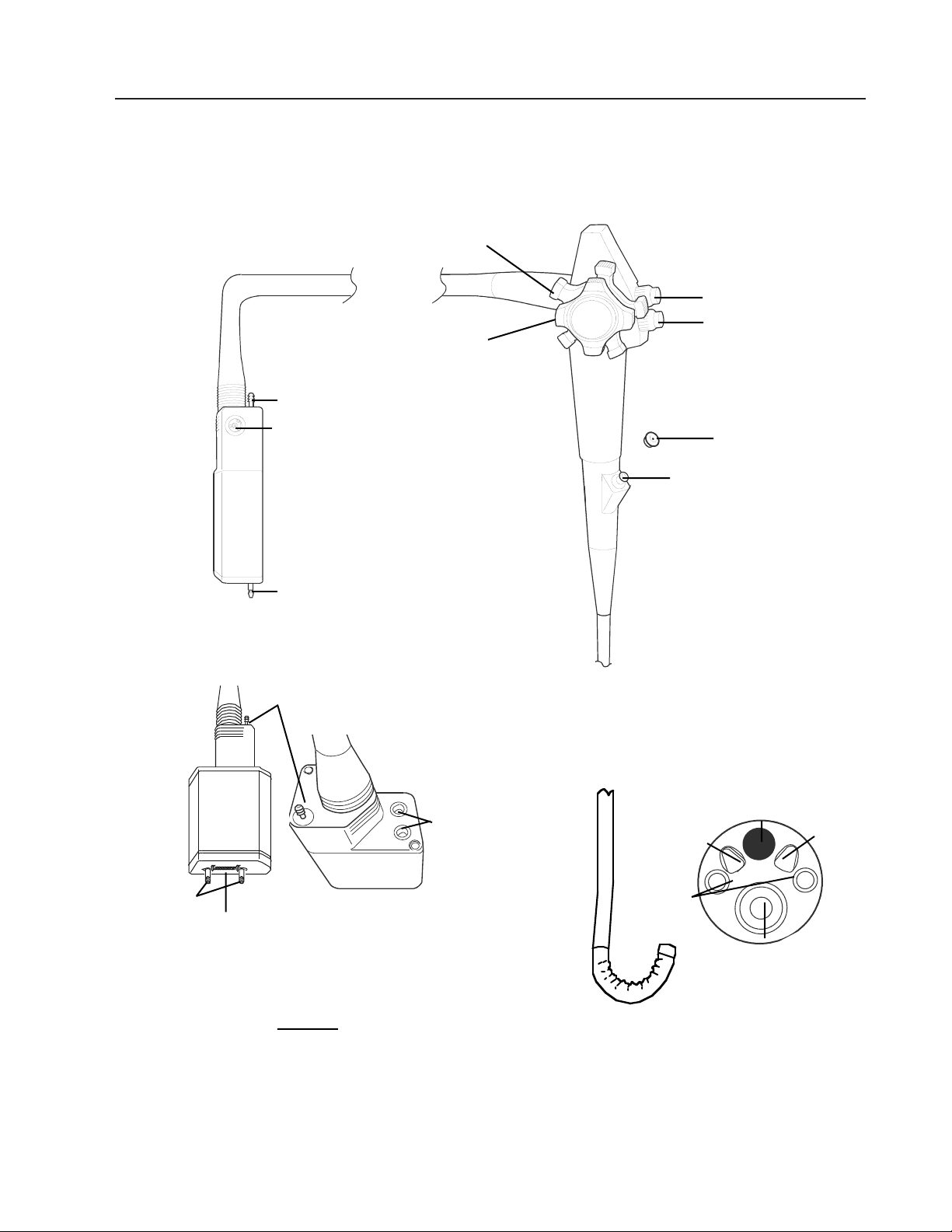

Nomenclature and Function

Flexible VideoSigmoidoscope

VideoSigmoidoscope

6 VideoPath

CONTROL BODY

INSERTION TUBE

BENDING SECTION

DIST AL TIP

ENDOSCOPE CONNECTOR

TERMINAL

Suction Valv e

Air/Water V alv e

Biopsy Seal

Biopsy Port

Up/Down Deflection

Control Knob

Air

Nozzle

Light

Guides

Biopsy/Suction

Channel

Objective Lens

Water

Nozzle

Suction Port

Side View

Rear/T op V iew

Front/Bot tom

View

Soaking Cap

ET O/Shipping Vent

Electrical Contacts

Air/Water

Input Ports

Suction Port

Right/Left

Deflection

Control Knob

Light Guide

Light

Guides

Page 9

Nomenclature and Function (continued)

Flexible VideoSigmoidoscope

CONTROL BODY

Suction V alve – Depress to aspirate fluids or air through the biopsy/suction channel.

Air/Wat er V alve – Covering the vent hole in the top of the valve delivers pressurized air

through the air nozzle in the distal tip. Covering the hole and fully depressing the valve

delivers pressurized water through the water nozzle in the distal tip.

Biopsy Seal – Allows passage of accessories while preventing escape of fluids and air.

Biopsy Port – For introduction of biopsy forceps and other accessories.

Up/Down Deflection Control Knob – Rotation of the knob toward the operator will

deflect the bending section up. Rotation away will deflect the bending section down.

Right/Left Deflection Control Knob – Rotation of the knob toward the operator will

deflect bending section left. Rotation away will deflect the bending section right.

INSERTION TUBE – Cont ains random light guides, biopsy/suction channel, air and water

lines, steering cables and wires from CCD (Charge Coupled Device).

BENDING SECTION – Contains articulating vertebra that allows deflection in two planes. DIST AL TIP

Air Nozzle – Directs pressurized air across objective lens to remove moisture and to

distend cavity being examined.

Light Guides – Provide illumination of examination area.

Biopsy/Suction Channel – Opening from which biopsy forceps and other accessories

exit and where fluid/debris is aspirated when the suction valve is depressed.

Objective Lens – Contains the lens system that provides depth of field and field of view.

Water Nozzle – Directs pressurized water, via the water nozzle, across objective lens to

remove debris.

ENDOSCOPE CONNECTOR TERMINAL

Air/Water Input Ports – Couples with the air/water bottle to allow the introduction of

pressurized air and water to the instrument.

Suction Port – Port where the auxiliary suction machine hose is attached to the

instrument.

Soaking Cap – Covers electrical contacts during immersion (cleaning/disinfection).

Electrical Contacts – Provides power to the endoscope and provides pathway for video signal input into the light source.

ETO/Shipping V ent – Vent where ETO/Shipping Vent Cap couples to equalize instrument’s

internal pressure with room pressure during shipping and ETO gas sterilization.

Light Guides – Couple to lamps in light source to provide illumination.

VS-100 Sigmoidoscope 7

Page 10

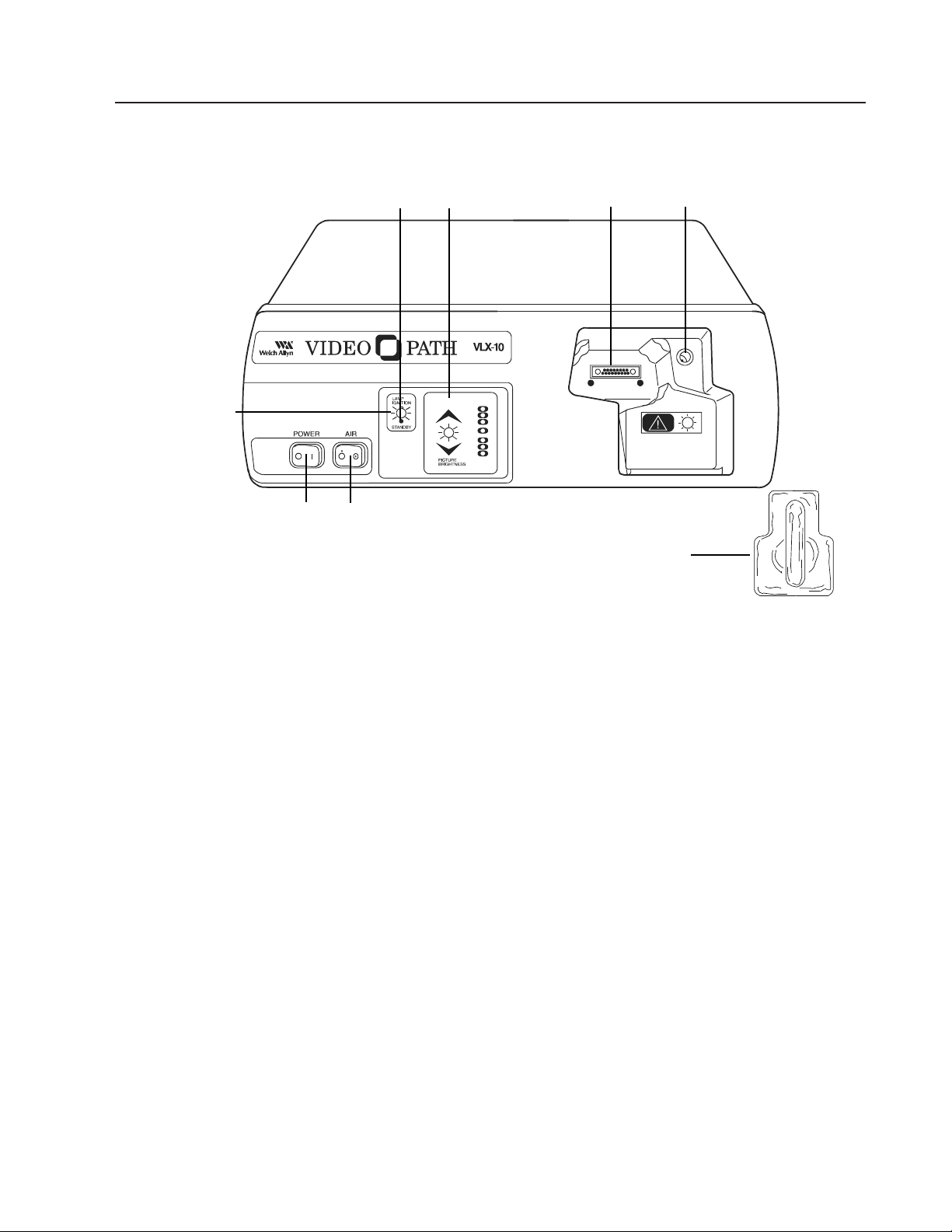

Nomenclature and Function (continued)

Light Source

Front Panel

Main Power Switch – Primary power control for the light source. If not activated, other

controls will not function.

Air Pump Switch – Activates flow of air at air output connector in light source’s endo-

scope connector port.

Lamp Ignition – Activates the lamps when switch is depressed and main power switch

is on.

Lamp Standby Indicator – When LED blinks, lamps cannot be ignited even if lamp igni-

tion switch is depressed.

Endoscope Connector Port – Accepts VideoEndoscope connector terminal to transmit

light, electrical signals, water, and air through the endoscope.

Water Bottle – Couples to endoscope connector terminal’s air and water input ports and

light source’s air output port.

Air Output Port – Couples to water bottle to provide air and water to the endoscope.

Picture Brightness Control – Pressing up or down arrows adjusts image on monitor to

desired average brightness level (level indicated by illuminated green LED).

8 VideoPath

Main

Power

Switch

Air

Pump

Switch

Lamp

Ignition

Lamp

Standby

Indicator

Endoscope

Connector

Port

Air Output

Port

Picture

Brightness

Control

Water

Bottle

Page 11

Composite

Nomenclature and Function (continued)

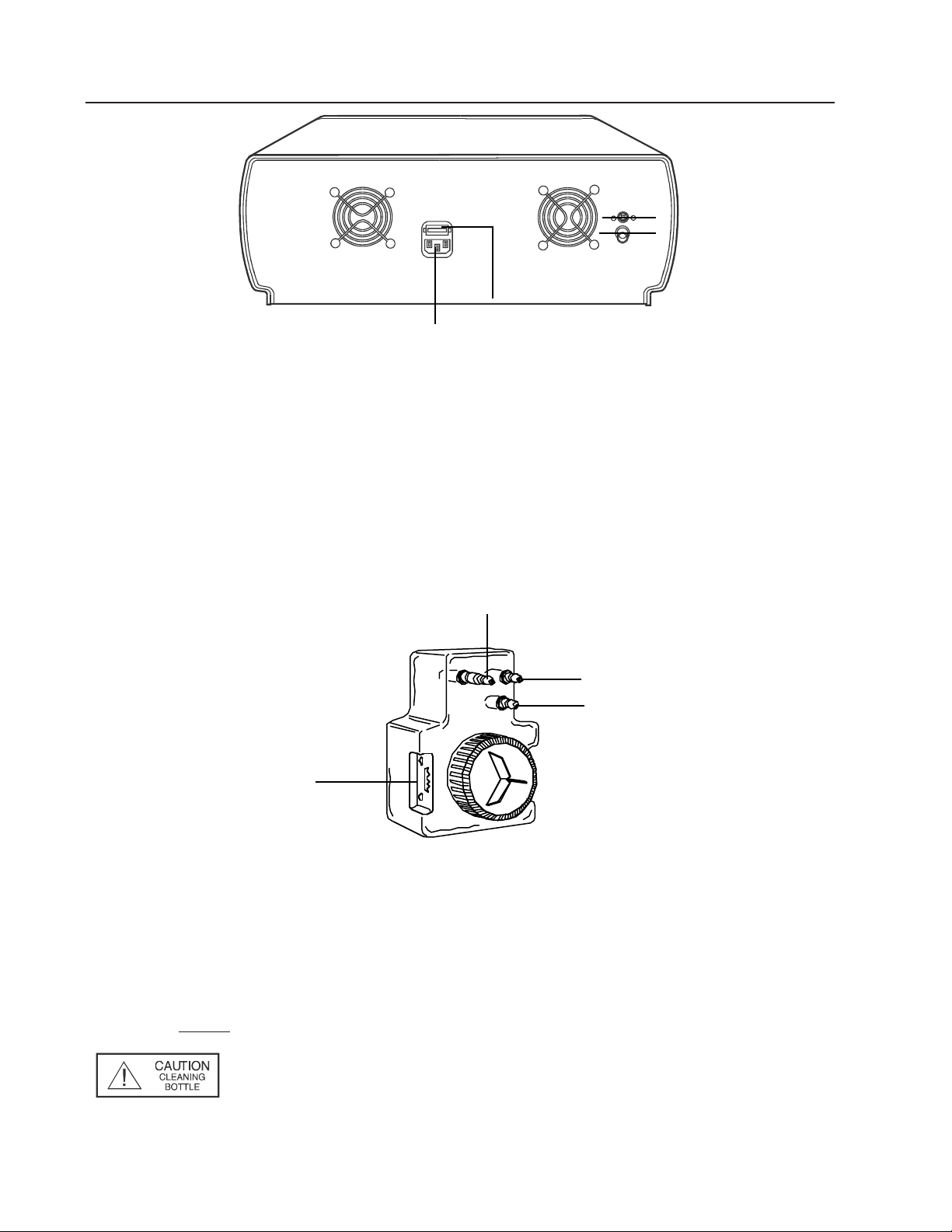

Back View

Power Supply Cord Receptacle – Couples with power cord which should be plugged into

an 115V hospital grade outlet.

S-Video – Outputs S-Video or Y/C, 4 pin DIN.

Composite – Outputs NTSC (composite video), BNC connector.

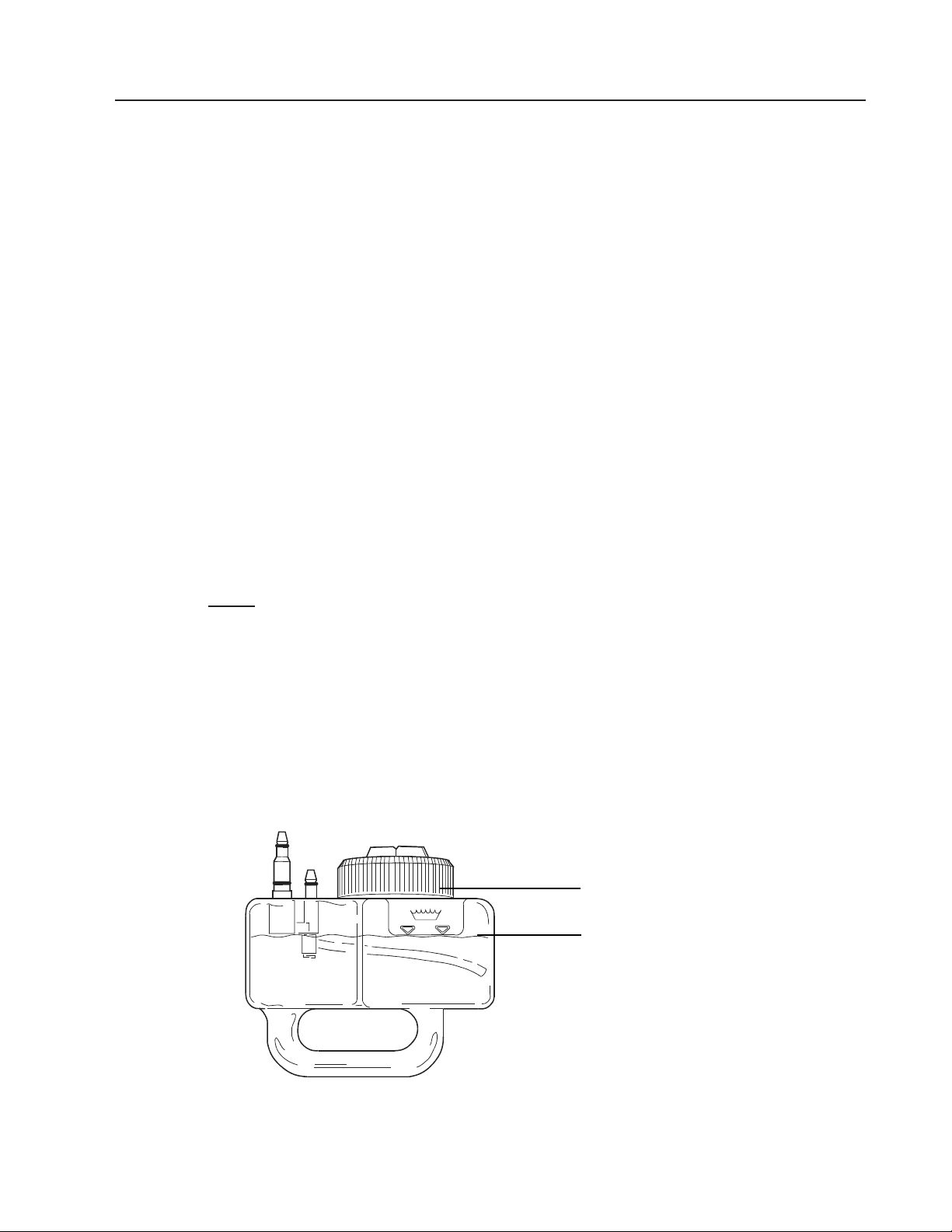

Water Bottle/Cleaning Bottle

Water Bottle

Air Input Terminal – Couples to light source air output port.

Air Output Terminal – Couples to VideoEndoscope air input port.

Water Output Terminal – Couples to VideoEndoscope water input port.

Fill Line – Indicates maximum water level bottle should be filled to.

NO

TE: The Cleaning Bottle is identical to water bottle with the exception

that it allows fluid to be introduced into the air input port of the

endoscope. The cleaning bottle can be easily identified via the

red caution label on the front of the bottle.

VS-100 Sigmoidoscope 9

Fill Line

Air Input

Terminal

Air Output Terminal

Water Output Terminal

S-Video

Power Supply

Cord Receptacle

Fuse Drawer

Page 12

Preparation and Inspection for Use

Prior to Initial Use

Before preparation or set up of the equipment, check all components received against

the list of components (see components section) to verify a complete set. If parts are

missing, please notify Welch Allyn. Review the nomenclature, set-up, operation, and

cleaning/disinfection sections to become familiar with the equipment.

Specifically, inspect:

Video Sigmoidoscope

Insertion T ube – for tears, cuts, dents, bubbles, bumps

Control Section – depress valves and test bending section deflection to assure smooth

rotation of controls.

Biopsy Port – pass cleaning brush through biopsy/suction channel to verify smooth passage

Leak T est – the watertight integrity of the instrument should be verified following the

procedures outlined on page 24.

Light Source

Cabinet – for any dents, scratches or other abnormalities

Water Bottle – for any cracks, leaks, etc.

System Set-up

NOTE: The instrument should be cleaned and disinfected prior to initial

use, following the steps starting on page 22 and 28.

1. Connect the power cord to the power cord receptacle on the back of the light source.

2. Plug the remaining end of the power cord into a properly grounded 110-120 volt AC

outlet.

3. Fill the water bottle to the fill line with clean, distilled water and replace the sealing cap.

10 VideoPath

Fill Line

Sealing Cap

Page 13

Preparation and Inspection f or Use (continued)

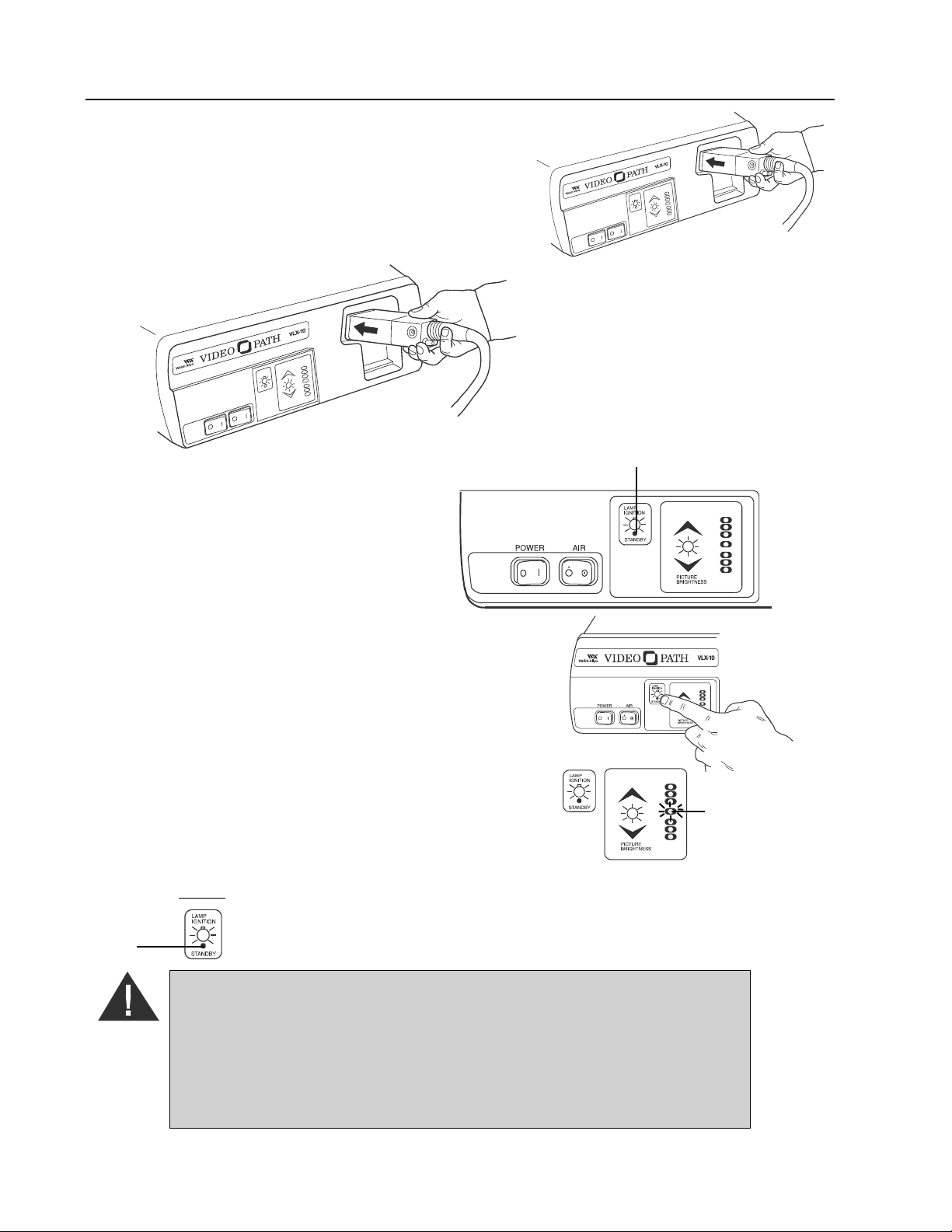

4. Plug the endoscope connector terminal into the

endoscope connector port of the light source.

The endoscope connector terminal should fully

engage and “click” into place.

5. Plug the water bottle into the

recessed area on the front panel

of the light source. This will couple

the water bottle to the light

source’s air output port and the

VideoSigmoidoscope’s connector

terminal’s air/water input ports.

6. Activate the Power switch on the

front panel. The green Lamp

Ignition/Stand-By light will blink for

approximately 11 seconds. Once the

LED stops blinking, the lamps are

ready to be ignited.

7. Once the green Lamp Ignition/Standby light remains

lit, press the Lamp Ignition Switch. The lamps will

ignite and the Lamp Ignition/Standby light will go

out. The lamps require 11 seconds to warm up. This

length of time will be indicated by the center LED of

the Picture Brightness Indicator, which blinks until

the lamps reach full intensity. Once the Picture

Brightness Indicator remains constant, the lamps are

fully warmed up, and the system is ready for use.

NO

TE: If the Light Source is powered up without having the Video-

Sigmoidoscope attached, the lamp ignition Standby LED will

remain blinking and lamp ignition cannot occur.

WARNING: Once lamps have been lit, do not remove the instrument

from the light source without turning the main power switch off or

putting the lamps on Stand-By by pressing the Lamp Ignition switch. If

the

VideoSigmoidoscope is removed from the light source, avoid looking

directly into the intense light provided by the light source to prevent

damage to your eyes.

VS-100 Sigmoidoscope 11

Standby LED Light

Standby

LED

Center

LED of the

Picture

Brightness

Indicator

Page 14

Preparation and Inspection f or Use (continued)

8. Activate the Air switch to verify functionality of the pump. Air should begin to flow immediately out of the top hole in the air/water valve on the control section of the instrument.

Physical System Inspection

Before inspecting the system, the VideoEndoscope should be tested to verify that it is watertight. Refer to the Leak Test procedures on page 24.

The following steps should be repeated prior to every procedure to verify that the system is

working properly. If any problem is encountered, immediately consult the troubleshooting

section of this manual or contact Welch Allyn Customer Service (1-800-535-6663) for assistance.

Insertion T ube, Umbilical T ube, and Bending Section

N

OTE: The insertion tube may have a slight curve when first removed

from the package due to product settling. This can be eliminated by

storing the instrument with the insertion tube in a straight position.

1. Inspect the insertion tube and bending section for tears, cuts, dents, bubbles, bumps or

other abnormalities on the surface.

2. Run your fingers carefully over the entire length of the insertion tube and bending section

to check for protruding braid.

3. Inspect the umbilical cord for outward indications of damage (e.g., dents, cuts).

CAUTION: To avoid harm to the patient and further damage to the equipment, Do Not use a VideoSigmoidoscope with outward signs of damage.

NO

TE: Make sure the distal end of the instrument is not damaged. The

distal end has an atraumatic non-removable tip. Do Not try to

remove the distal tip. Doing so will result in damage to the distal

portion of the instrument.

12 VideoPath

Page 15

Preparation and Inspection f or Use (continued)

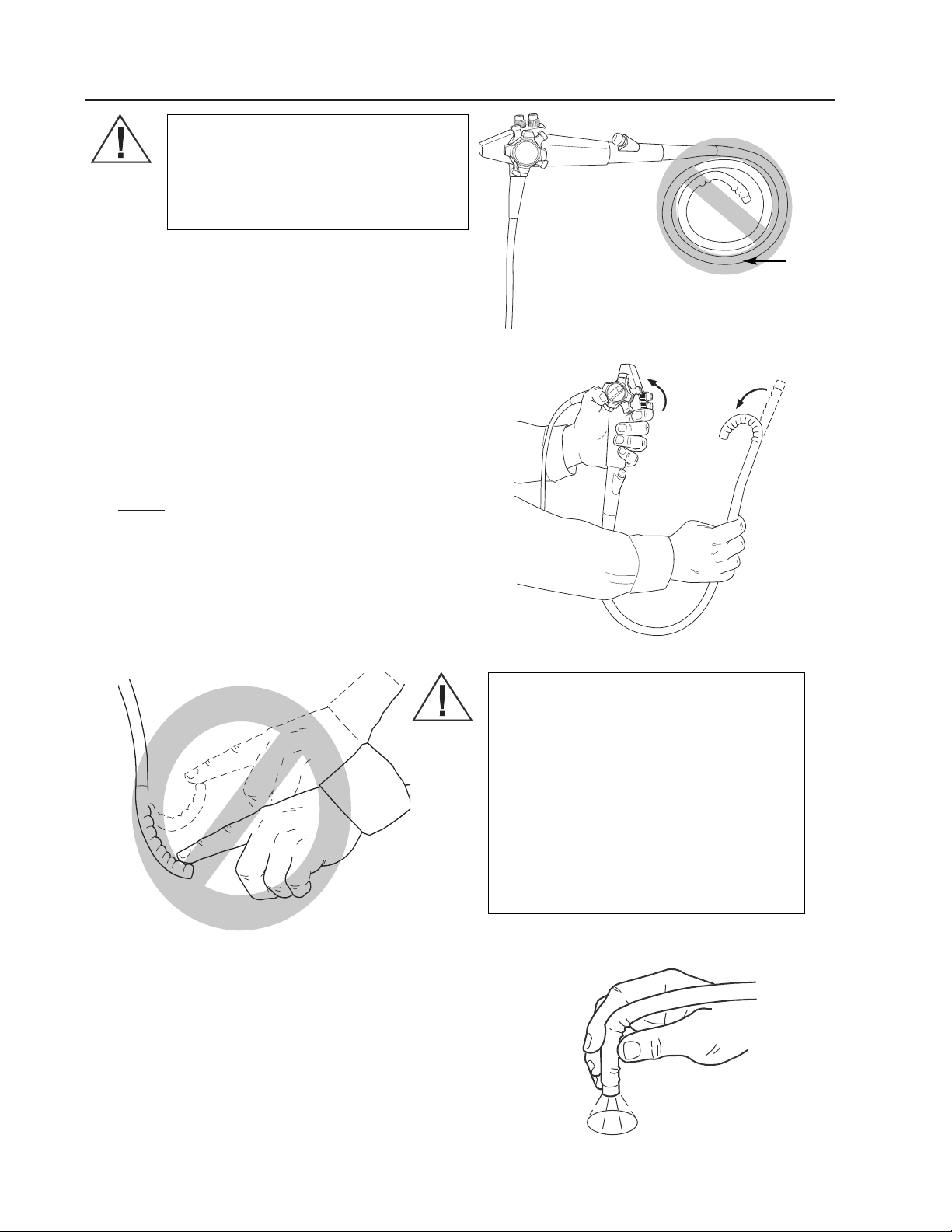

CAUTION: Do Not wind the insertion

tube into a tight radius. Serious

internal damage could result. Proper

storage procedures are outlined

on page 38.

Deflection Controls

1. Rotate the up/down and right/left deflection

control knobs to the limit in each direction.

The knobs should rotate without excess

friction or grinding.

NO

TE: Do Not attempt to rotate the deflection

knobs past their limits. This can result

in severe damage to the steering

mechanism.

CAUTION: Do Not deflect the bending

section of the VideoSigmoidoscope

by hand. This applies excess force

to the deflection mechanism and

may result in steering cable failure.

If the deflection controls do not

operate smoothly, there may be

internal damage. Do Not use the

VideoSigmoidoscope. Doing so will

result in injury to the patient or further

damage to the VideoSigmoidoscope.

Inspection of Light Guides and Optics

1. With the lamps on, hold the distal tip approximately

40mm from any surface.

2. Verify light is being emitted from both light guides.

VS-100 Sigmoidoscope 13

Do Not

Wind

Page 16

Preparation and Inspection f or Use (continued)

Inspection of Air Feed Valve

1. Place the tip of the bending section into a container of clear water. Cover the hole in

the top of the air/water feed valve (green ring). Do not depress the valve. Air should

flow freely from the air nozzle in the distal tip of the instrument and the water should

bubble vigorously.

2. Remove your finger from the valve – the bubbling should end immediately.

Inspection of Water Feed Valve

1. Depress the air/water valve completely to initiate the flow of water from the water nozzle

in the distal tip of the instrument. Water should flow in a constant stream over the objective lens and light guides. Upon initial set-up, depress and hold the valve for several

seconds for water to fill the entire line.

NO

TE: If air or water do not flow from the distal tip, refer to the

Troubleshooting section (page 42).

Inspection of Suction Mechanism

1. Connect the suction tubing from the suction machine to the Suction Port hose barb on

the endoscope connector terminal.

2. Immerse the distal tip of the bending section into clear water and completely depress

the suction valve (orange ring). Make sure biopsy seal is in place.

3. Verify aspiration by viewing water flow into suction receptacle. Releasing valve should

stop suction immediately.

14 VideoPath

Cover

Depress

Depress

Suction Port

Page 17

Preparation and Inspection f or Use (continued)

NOTE: It is import ant that the rubber biopsy seal on the biopsy port is in

good condition. Worn seals will result in poor suction and leakage

and should be replaced.

Inspection of Biopsy/Suction Channel

1. Check for kinks in the flexible shaft of the biopsy forceps.

2. Clean any debris from the biopsy forceps before using them.

3. Make sure the handle mechanism on the forceps works

freely and the jaws open and close freely.

4. Close and inspect the jaws of the forceps to make sure the

cups are in proper alignment. If there is a spike in the forceps, make sure the spike is completely straight and within

the cups.

WARNING: It is important that forceps or accessories not be used if they

show any sign of damage or if they do not operate correctly. If the forceps or an accessory does not work properly during a procedure, serious

injury to the patient could result. Use of damaged forceps or accessories

could also result in damage to the VideoEndoscope.

5. Straighten the VideoSigmoidoscope and insert the forceps through the biopsy port.

If resistance is encountered, contact Welch Allyn Technical Service. Do Not insert

the accessory further. Damage could occur to the instrument. Do Not use the

VideoSigmoidoscope.

Operations

Procedure

The methods and techniques of flexible sigmoidoscopy are well defined and documented.

Endoscopy training seminars and preceptorship programs are also in existence worldwide.

No attempt is made in this manual to outline the medical procedure or techniques of flexible

sigmoidoscopy. The physician should always take care to understand the clinical background

of each patient and the possible contraindications of the procedure.

Before beginning the procedure, make sure the patient is prepared for the examination using

the normal steps required for endoscopy.

WARNING: The light source and connected endoscope should not be

used with electrosurgical generators. The VS-100/VLX-10 Sigmoidoscope

system has not been designed for therapeutic procedures.

VS-100 Sigmoidoscope 15

Page 18

Operations (continued)

Holding the Instrument

The control section is designed for the left hand. The

“V” formed by the left thumb and index finger should

be positioned beneath the area where the umbilical

cord exits the control section. The suction and

air/water valves are controlled by the index finger and

middle finger respectively. The up/down deflection

control is operated by the thumb. The right hand is

used to advance and rotate (torque) the insertion

tube. In some instances, it may be necessary to have

an assistant hold the insertion tube while the right/left

deflection control is rotated by the right hand.

Preparation Before Insertion of the VideoEndoscope

WARNING: Make sure the VideoSigmoidoscope is properly disinfected or

sterilized prior to every use. Current infection control guidelines require

that VideoSigmoidoscopes and their patient contact accessories be subjected to high level disinfection or sterilization.

1. Use a clean gauze to gently wipe the insertion tube.

2. Moisten a cotton-tip swab with alcohol and gently

clean the objective lens on the distal tip. If a lens

cleaner (anti-fogging agent) is used, apply it first to

gauze or other applicator. Make sure to wipe off all

excess cleaner.

3. Apply a medical grade water soluble lubricant

(e.g., KY Jelly) to the bending section and

insertion tube. Do Not use petroleum based

lubricants. Do Not contaminate the lens with

lubricant.

16 VideoPath

Lens

Bending

Section

Page 19

Operations (continued)

Insertion and Withdrawal

1. Slowly insert the lubricated instrument.

2. Use the deflection controls to guide the instrument through the lumen. The deflection

of the tip should be done under direct vision in a gentle and deliberate manner.

WARNING: If resistance is encountered, Do Not force the deflection

controls. Doing so may result in serious injury to the patient and/or

damage the instrument.

Do Not advance the instrument if the lumen is not visible. Blind advancement could result in perforation of the patient’s colon.

If during the procedure, the deflection controls cease to function or the

image is lost due to a power shortage, lamp or processor failure, etc.,

terminate the examination. Return one (or both) of the deflection controls

to the neutral position. Slowly withdraw the VideoSigmoidoscope from

the patient. Do Not operate the controls during withdrawal.

3. A collapsed lumen can be opened by insufflation. Cover the hole on the top of

the air/water valve to inflate the colon. Adequate insufflation can be maintained by

insufflation and periodic aspiration of air. Use the suction control to decrease the

level of insufflation.

WARNING: It must be recognized that variations in air flow (pressure

and volume) for patient insufflation may exist from one manufacturer’s

equipment (light source and/or endoscope) to another. It is, therefore,

important to closely monitor the patient at all times and to aspirate

excessive air to prevent over insufflation and patient discomfort.

4. Fluid, secretions, and liquid stool can be aspirated by depressing the suction valve,

thus improving visualization. Do Not try to aspirate solid material since this will clog

the suction channel.

CAUTION: Care should be taken to avoid sucking mucosa into the suction channel. This phenomena can result in a “suction polyp” that can be

mistaken for a lesion.

5. Lubricant, mucous and fecal materials can cloud or fog the objective lens. Use the

air/water and suction control valves alternately to clean the objective lens.

NO

TE: Water drops retained on the lens can be removed by covering

the hole on top of the air/water valve, pushing air through the

scope and over the lens.

6. Before removing the VideoSigmoidoscope, aspirate any remaining air to reduce any

patient discomfort.

7. Before withdrawing the scope, return the bending section to the neutral position.

Always withdraw the VideoSigmoidoscope under direct visualization.

VS-100 Sigmoidoscope 17

Page 20

Operations (continued)

Biopsy Passage

1. Biopsy forceps and accessories should be inserted through

the biopsy seal and into the channel. Hold the forceps handle so that the jaws are fully closed during insertion.

NO

TE: Failure to insert the forceps in the fully closed

position may cause serious damage to the

biopsy/suction line.

Temporary resistance will be experienced when the cups

are first passed through the seal. Advance the forceps using

short strokes, started by grasping the forceps sheath tightly

at about 5cm from the cups.

WARNING: If resistance is encountered during the passage through the

bending section, relax the deflection angle until the passage is smooth

and easy. Wetting the forceps with water or a medical grade silicone

lubricant will promote easier passage. Never apply excessive pressure

when inserting any accessory into the biopsy channel, since the channel

may be damaged, resulting in malfunction of the VideoEndoscope and

costly repairs.

If the biopsy seal “Splits” or leaks while the VideoSigmoidoscope is in place, remove

the defective seal and replace it.

NO

TE: When replacing the biopsy seal, rotate the

seal one full turn clockwise after pushing on

the luer lock fitting to insure a proper seal.

NO

TE: Always flush the biopsy/suction channel

immediately after a procedure by aspirating

clear water through the channel (see the

Cleaning instructions). This flushing will

assist passage of instruments in

subsequent procedures.

2. Collect a tissue sample by opening the forceps and advancing the open cups up

against the mucosa. Carefully close the cups until resistance is felt, and then hold.

Gently pull back on the forceps until a small tissue sample is removed. Always keep

the accessory in view during advancement.

3. Withdraw the forceps with the cups closed. Opening the cups during withdrawal may

damage the biopsy channel.

18 VideoPath

Page 21

Operations (continued)

NOTE: If the forceps fail to close during a procedure,

close the cups by winding the proximal portion of the forceps cable around your index

finger. If the forceps still do not close, retract

the cups as close as possible to the distal tip

and slowly withdraw the instrument under

direct visualization.

Because of the effect that accessories

used in the biopsy/suction channel of the

VideoSigmoidoscope can have on the performance of the VideoSigmoidoscope itself, it is

strongly recommended that only Welch Allyn

accessories be used with Welch Allyn instruments. If a unique or highly specialized

accessory is available from another source,

please contact Welch Allyn to arrange for a

test of its compatibility before using it

through the W elc h Allyn VideoSigmoidoscope.

Cleaning and Disinfection

Endoscope Internal Schematics

These schematic illustrations are intended to provide the user with a better understanding of

how the Welch Allyn VideoSigmoidoscope works. All the internal channels are indicated to

better show their relationship to one another. This understanding should assist the user in

caring for and reprocessing the VideoSigmoidoscope.

The design of VideoSigmoidoscopes and its components allows for efficient and effective

cleaning and disinfecting by either manual methods or automated processes prior to

patient use.

Standard size luer lock and/or luer-slip fittings are used on the connectors on all cleaning/

disinfecting adapters and scope inlet ports. These locks and fittings easily accommodate

reprocessing devices or systems available from other manufacturers.

As illustrated in the schematics, the cleaning system promotes efficient unidirectional flow of

solution beginning from connections at the endoscope connector terminal, traveling up channels in the umbilical cord to the valve cylinders in the control section, passing through the

channels in the insertion tube and finally exiting nozzles or channel openings at the distal tip

of the scope.

The elimination of multiple branching channels, combined with a direct and straightforward

pathway for solutions to travel maximizes flow efficiency and ensures contact of disinfectant/sterilant with all internally exposed channel surfaces.

VS-100 Sigmoidoscope 19

Page 22

Cleaning and Disinfection (continued)

WARNING: It is imperative that flexible VideoEndoscopes and other

semi-critical devices be reprocessed such that high level disinfection is

achieved with an EPA registered sterilant/disinfectant. It should be noted

that any endoscope automated reprocessing device or system* must be

cleared for marketing by the FDA via the 510 (k) premarket notification or

PMA approval process.

Only reprocessing solutions/systems satisfying the above conditions and tested and found to

be compatible by Welch Allyn should be used with Welch Allyn products.

*Liquid chemical germicides (disinfectants/sterilants) to reprocess medical devices come under FDA regulation and new products must, therefore, undergo a 510 (k) premarket notification submission prior to introduction into interstate commerce.

Internal Schematic

NO

TE: Endoscopic instruments should be meticulously cleaned

immediately after each use prior to disinfection or sterilization.

Endoscopes are delicate and will degrade, if not cleaned properly,

due to the effects of digestive contents (e.g., blood, mucous).

The methods outlined on the following pages have been tested

and verified to have no damaging effects. Therefore, it is important to adhere to these procedures.

20 VideoPath

Valve Reprocessing Cap

Valve Reprocessing Cap

Biopsy Port

From Syringe (under vacuum)

Insertion T ube

Distal Head

Distal Reprocessing Cap

(fluid collects in cap from air and

water lines and is then pulled

through suction line)

Endoscope Connector

Terminal

Cleaning Fluid

Cleaning Bottle

To Suction Container

(suction pump pulls vacuum

on closed system)

Umbilical T ube

Suction Line

Water

Air

Page 23

Cleaning and Disinfection (continued)

Required Equipment (for cleaning and disinfection):

Basin of Clean Water

Basin of Enzymatic Solution

Gauze Pads

Disposable Gloves

31020 Channel Cleaning Brush

31021 Valve Reprocessing Caps

31023 60cc Syringes (2 each)

33924 Air/Water Nozzle Cleaning Brush

31027 Reprocessing Adapter

31030 Distal Reprocessing Cap

(semi-automated cleaning only)

31028 Soaking Cap

31037 Leak T ester

33918 Valve Lubricant

31038 Suction Reprocessing Adapter

31031 Valve Well Cleaning Brush

VS-100 Sigmoidoscope 21

Page 24

Cleaning and Disinfection (continued)

WARNING: The importance of meticulous mechanical cleaning of Video

Endoscopes cannot be overemphasized. Prior to disinfection or sterilization, all instruments must be scrupulously cleaned. Failure to do so could

result in incomplete or ineffective disinfection and/or sterilization.

The bending section of the instrument should be handled with care during the cleaning process. The most common failure that results in an

instrument being returned for repair is a leak in the bending section rubber due to a pin hole leak. Do Not strike the bending section against any

hard surface or use abrasive material to wipe clean.

Semi-Automated Cleaning Method

(Utilizing the #45520 Cleaning Bottle)

The following steps should be performed immediately after removal of the instrument from a

patient. For further clarification of the channels affected by this process, please refer to the

internal schematic on page 20.

NO

TE: Protective garments (i.e., gloves, gowns, face masks or shields)

should always be worn during the cleaning process to minimize

the risk of cross contamination.

Cleaning at the Examination Room

Power-off and Wipedown

Remove scope from patient. Turn off suction pump and light source. Leave the scope

plugged into light source and suction tubing attached.

Wipe off insertion tube with enzymatic cleaner and gauze to remove any debris.

Perform Semi-Automated Cleaning Process using enzymatic cleaner.

Note: If for some reason the Semi-Automated Cleaning Process cannot

be performed, refer to the Manual Cleaning Process outlined

later in this section.

Semi-Automated Cleaning Process

Enzymatic Cleaner

See list of approved enzymatic cleaners on page 34.

Remove Water Bottle (45510) from light source. Locate the

Cleaning Bottle (45520) and fill it to the line with enzymatic

cleaner. Dry excess fluid from the exterior of the bottle and

insert it into the light source.

Remove valve plungers and biopsy seal from the scope and

place them in a small container of enzymatic cleaner.

22 VideoPath

Page 25

Cleaning and Disinfection (continued)

Replace the plungers with the corresponding color-coded Valve Reprocessing Caps (31021).

Attach Distal Reprocessing Cap (31030).

Load a 60cc (31023) syringe with enzymatic cleaner.

Attach to the biopsy port.

Turn on suction

pump. Power up

the light source

and turn on the air

pump. Run until

no enzymatic

cleaner remains in

the cleaning bottle. Empty the suction pump collection bottle periodically throughout the procedure.

When completed, turn off the light source and then

the suction pump.

Disconnect the suction pump tubing from the suction port. Remove the syringe, valve

reprocessing caps and the distal reprocessing cap.

Mechanically Cleaning the Channels

The Channel Cleaning Brush (31020) can now be used to clean the various channels. Insert

the brush into the suction valve well, directing it towards the opening in the

side of the wall which is furthest away from the deflection knobs. Advance

the brush until it exits the suction port on the endoscope connection terminal. Clean away any debris with a soft, lint-free gauze pad moistened with

enzymatic cleaner and repeat until debris no longer

appears on the brush.

Next, insert the channel cleaning brush into the

open suction valve well and direct it towards the

bottom of the channel. Feed the brush through the

opening until resistance is felt (approx. 15 cm). Do

not use excessive force. Withdraw the brush and

clean away any debris using a gauze pad moistened with enzymatic

cleaner. Repeat the process until debris no longer appears on the

brush.

Insert the brush into the open biopsy port and advance

it until it exits from the distal tip of the instrument. Remove debris from the

brush with a gauze pad and withdraw it from the channel. Repeat until no

debris appears on the brush.

Insert the Suction Valve Well Cleaning Brush (31031)

into the suction valve well and clean the surface of the

well by rotating the brush while inserting and removing.

Using the Air/Water Nozzle Cleaning Brush (33924),

clean the nozzles at the distal tip of the instrument.

VS-100 Sigmoidoscope 23

Suction T ube

Distal

Reprocessing Cap

Distal

Reprocessing

Cap

Page 26

Cleaning and Disinfection (continued)

Leakage Testing

Stage 1

Remove the cleaning bottle and scope from the light source.

After making sure that the Leakage Tester (31037) and the ETO vent on the endoscope

connector terminal are dry, attach the leakage tester to the ETO vent. They should be

screwed together until snug to insure a watertight seal.

After making sure that the pressure release valve on the back of the gauge is closed,

(turn fully counter-clockwise) pressurize the inside of the instrument by pumping the

hand bulb until the indicator needle is within the TEST zone. Do not overpressurize

or the scope may be damaged.

Observe the gauge indicator needle. It should remain in the TEST zone for at least one

minute. If it does not remain in the TEST zone, the scope has a leak. Contact the Welch Allyn

Service Dept. immediately before any further processing so that proper steps can be taken

to prevent any damage to the endoscope.

Leakage Testing

Stage 2

If no leaks are determined during the Stage 1 test,

the instrument should now be tested for loss of

integrity in the watertight construction due to small

pinholes.

Attach the Soaking Cap (31028) to the endoscope

connector terminal to seal off the electrical contacts. Make sure the leakage tester is securely

attached to the ETO Vent port and that the gauge

indicator needle is still in the TEST zone.

24 VideoPath

Page 27

Cleaning and Disinfection (continued)

Immerse the entire instrument, with all

valves and biopsy seals removed, into enzymatic cleaner. Immerse only a small part of

the leakage tester tubing. Never immerse

the entire leakage tester.

Carefully observe the instrument for bubbles

while deflecting the distal tip in all 4 directions. Observe for at least one minute. A

few bubbles may initially rise from the biopsy channel or recessed areas of the scope.

This is normal. If bubbles continue to rise

from the same location, a leak is indicated.

Remove the scope immediately from the

basin and contact the Welch Allyn Service

Dept. before any further processing so that

proper steps can be taken to prevent any

damage to the endoscope.

Mechanically Cleaning the Exterior of the Instrument

If the scope has successfully passed the leakage test it should now be cleaned.

Make sure

that the leakage tester remains securely attached to the endoscope light source connector.

While still immersed in the enzymatic cleaner, gently but thoroughly wash the entire exterior

surface of the endoscope with a gauze pad moistened with enzymatic cleaner. In addition,

wash the valves plungers, biopsy seal and reprocessing cap with enzymatic solution.

Clean Wat er Rinse

Remove the endoscope and accessories from the enzymatic solution and immerse it in a

container of clean water. Rinse all components thoroughly.

After removing the instrument from the water,

open the pressure release valve on the leak-

age tester to release the air pressure. Remove the leakage tester

. Never connect or discon-

nect the leakage tester under water. The instrument will be severely damaged.

Remove the soaking cap from the light source connector.

Semi-Automated Cleaning Process

Clean Wat er

Refill the cleaning bottle and 60cc syringe with clean water and repeat the Semi-Automated

Cleaning Process as previously described to remove enzymatic cleaner from the channels.

Remove the syringe and the distal reprocessing cap. Leave the valve reprocessing caps in

place. Remove the cleaning bottle and the scope from the light source.

Now proceed with disinfection of the instrument by using

either

Disinfection Procedure #1

(Using Tray) or #2 (Tot al Immersion).

VS-100 Sigmoidoscope 25

Page 28

Cleaning and Disinfection (continued)

Disinfection Procedure #1 (Using Tray)

See the list of approved disinfectants on page 35.

Fill the tube of the Disinfection Tray (33902) to the black dot with an approved

glutaraldehyde-based disinfection solution. Solution should also be added to the basin

in the center of the tray.

Advance the endoscope insertion tube completely into the disinfection tray tube.

Place the air/water valves, suction valves and biopsy seal into the basin for soaking.

Attach the Suction Reprocessing Adapter (31038) to the

suction port on the endoscope light source connector.

Connect an empty 60cc syringe to the adapter.

Connect another empty 60cc syringe to the biopsy port

on the control section of the endoscope.

Attach the Air/Water Reprocessing Adapter (31027) to the

endoscope light source connector. Drawing from the

basin, fill another 60cc syringe with disinfectant and

connect it to the adapter.

Draw 30cc’s of fluid into the syringe connected to the suction reprocessing adapter. Leave

the syringe attached.

Draw 30cc’s of fluid into the syringe on the biopsy port. Leave the syringe attached.

Inject all fluid from the prefilled 60cc syringe until the syringe is empty. If necessary, let any

trapped air vent through the disinfection tray tube. Leave the syringe attached. All the

channels have now been filled with disinfectant.

Following the solution manufacturer’s recommendations for high level disinfection, allow the

instrument to soak for the proper time period.

Following the disinfection soak cycle ....

Disconnect the empty 60cc syringe from the air/water reprocessing adapter, fill it with air

and reattach it.

Draw an additional 30cc’s of fluid into the syringe connected to the biopsy port, then remove

it and purge the disinfectant into the soak basin. Fill the syringe with air and reattach it.

Disconnect the remaining syringe and purge the disinfectant into the soak basin. Fill it with

air and reattach it to the suction reprocessing adapter.

Slowly inject air into all channels. Allow air to purge through the soaking tube.

Remove all syringes and adapters.

Slowly withdraw the endoscope from the disinfection tray. Rinse the insertion tube with

clean water and wipe it with a gauze pad to remove any residual disinfectant. Remove all

accessories from the basin and rinse them thoroughly with clean water.

Proceed to Final Rinse.

26 VideoPath

Air/Water

Reprocessing

Adapter

Page 29

Cleaning and Disinfection (continued)

Disinfection Procedure #2 (Total Immersion)

See the list of approved disinfectants on page 35.

Fill a covered basin with activated disinfectant to a level that will allow the entire instrument

to be immersed in solution.

Connect the Air/Water Reprocessing Adapter (31027) to the air and water ports on the

endoscope connector.

Attach the color-coded valve reprocessing caps.

Attach the soaking cap to the endoscope connector terminal.

Place the entire endoscope into the basin making sure that all surfaces are immersed in

the disinfectant. Place the air/water and suction valves and the biopsy seal into the

solution as well.

Fill a 60cc syringe with disinfectant and attach it to the

air/water reprocessing

adapter. Fill another

60cc syringe and attach

it to the

biopsy port.

Depress the plungers

of both syringes to

fill all channels with

disinfectant.

Following the solution manufacturer’s recommendations, allow the instrument to soak for the

proper time period.

Following the disinfection soak cycle ....

Remove the endoscope connector terminal from the disinfectant and uncouple the syringe from

the adapter. Also remove the other syringe. Fill both syringes with air and reattach.

Inject air from both syringes to purge the lines of disinfectant. Repeat until bubbles appear indicating that all solution has been removed.

Remove the instrument from the solution and uncouple the syringes and the adapter.

Place the entire instrument into a basin or sink of clean water. Thoroughly wipe down the exteri-

or of the instrument to remove any residual solution. Remove all accessories from the basin and

rinse them thoroughly with clean water.

Proceed to Final Rinse.

VS-100 Sigmoidoscope 27

Air/Water

Reprocessing Adapter

Air/Water

Reprocessing Cap

Suction Reprocessing

Cap

Page 30

Cleaning and Disinfection (continued)

Final Rinse

Perform the

Semi-Automated Cleaning Process

, this time using

Clean Water

. Attach the light

guide connector to the light source and follow the steps in the Semi-Automated Cleaning

Process section above, this time using

Clean Water

instead of enzymatic solution.

The Semi-Automated Cleaning Process may be repeated with alcohol, if desired, to promote

drying. Use only 70% Isopropyl alcohol.

Apply a thin coating of Welch Allyn Valve Lubricant (33918) to the Air/Water Valve “O” Rings

(31024) and Suction Valve “O” Rings (31025). Remove air/water and suction caps and insert

the valves into the open valve wells. Reattach the Biopsy Seal (33930) to the biopsy port.

Disconnect the endoscope from the light source and hang it on the Instrument Hanger

(31035) to dry.

Manual Cleaning Method

(Alternative to the Semi-Automated Cleaning Process described above)

Cleaning at the Examination Room

The following steps should be performed immediately after

removal of the instrument from a patient.

NO

TE: Protective garments (i.e., gloves, gowns,

face masks or shields) should always be

worn during the cleaning process to minimize the risk of cross contamination.

Immediately after the instrument is removed from the

patient, put the lamps on stand-by by pressing the lamp

ignition switch. Next, wipe off all debris from the insertion tube with a soft, lint-free cloth

moistened with enzymatic cleaner. See page 34 for a list of compatible cleaners.

28 VideoPath

Page 31

Cleaning and Disinfection (continued)

With the instrument still coupled to the suction machine, insert the distal tip into

the enzymatic solution and depress the suction valve. Aspirate solution through the

biopsy/suction channel until the solution exiting from the suction port is clean and

free of debris. Alternate aspiration of solution and air for 5-10 seconds.

Keeping the distal tip in the container of solution (air switch is still “on”), depress the

air/water feed valve (green valve) for 5-10 seconds. Release the valve and cover the hole on

top for 5-10 seconds. This will expel any mucous, debris, etc. which may have entered the air

and water nozzles during the procedure.

Turn off the light source and then the suction pump, and remove the suction line from the

endoscope suction port.

Grasp the water bottle handle and pull back

gently to disconnect the bottle from the

light source.

Detach the endoscope connector terminal

from the light source by grasping the

umbilical cord strain relief and pulling

back gently. The instrument is now ready

to be transported to the cleaning room for

further processing.

Mechanically Cleaning the Channels

Remove the valve plungers and biopsy seal from the scope and place them in a small container of enzymatic cleaner. The Channel Cleaning Brush (31020) can now be used to clean

the various channels. Insert the brush into the suction valve well, directing it towards the

VS-100 Sigmoidoscope 29

Cover

Cover

Depress

Page 32

Cleaning and Disinfection (continued)

opening in the side of the wall which is furthest away from the deflection

knobs. Advance the brush until it exits the suction port on the endoscope

connection terminal. Clean away any debris with a soft, lint-free gauze pad

moistened with enzymatic cleaner and repeat until debris no longer appears

on the brush.

Next, insert the channel cleaning brush into the open suction valve well and

direct it towards the bottom of the channel.

Feed the brush through the opening until resistance is felt (approx. 15 cm). Do not use excessive force. Withdraw the brush and clean away

any debris using a gauze pad moistened with

enzymatic cleaner. Repeat the process until debris no longer

appears on the brush.

Insert the brush into the open biopsy port and advance it until it

exits from the distal tip of the instrument.

Remove debris from the brush with a gauze

pad and withdraw it from the channel. Repeat

until no debris appears on the brush.

Insert the Suction Valve Well Cleaning Brush

(31031) into the suction valve well and clean the

surface of the well by rotating the brush while

inserting and removing.

Using the Air/Water Nozzle Cleaning Brush

(33924), clean the nozzles at the distal tip of

the instrument.

Leakage Testing

Stage 1

Remove the cleaning bottle and scope from the light source.

After making sure that the Leakage Tester (31037) and the ETO vent on the endoscope

connector terminal are dry, attach the leakage tester to the ETO vent. They should be

screwed together until snug to insure a watertight seal.

After making sure that the pressure release valve on the back of the gauge is closed,

(turn fully counter-clockwise) pressurize the inside of the instrument by pumping the

hand bulb until the indicator needle is within the TEST zone. Do not overpressurize

or the scope may be damaged.

30 VideoPath

Page 33

Cleaning and Disinfection (continued)

Observe the gauge indicator needle. It should remain in the TEST zone for at least one

minute. If it does not remain in the TEST zone, the scope has a leak. Contact the Welch Allyn

Service Dept. immediately before any further processing so that proper steps can be taken

to prevent any damage to the endoscope.

Leakage Testing

Stage 2

If no leaks are determined during the

Stage 1 test, the instrument should

now be tested for loss of integrity in

the watertight construction due to

small pinholes.

Attach the Soaking Cap (31028) to

the endoscope connector terminal to

seal off the electrical contacts. Make

sure the leakage tester is securely

attached to the ETO Vent port and

that the gauge indicator needle is still

in the TEST zone.

Immerse the entire instrument, with

all valves and biopsy seals removed,

into enzymatic cleaner. Immerse

only a small part of the leakage tester

tubing. Never immerse the entire leakage tester.

VS-100 Sigmoidoscope 31

Page 34

Cleaning and Disinfection (continued)

Carefully observe the instrument for bubbles while

deflecting the distal tip in all 4 directions. Observe for

at least one minute. A few bubbles may initially rise

from the biopsy channel or recessed areas of the

scope. This is normal. If bubbles continue to rise from

the same location, a leak is indicated. Remove the

scope immediately from the basin and contact the

Welch Allyn Service Dept. before any further processing so that proper steps can be taken to prevent any

damage to the endoscope.

Mechanically Cleaning the Exterior of the Instrument

If the scope has successfully passed the leakage test it should now be cleaned.

Make sure

that the leakage tester remains securely attached to the endoscope light source connector.

While still immersed in the enzymatic cleaner, gently but thoroughly wash the entire exterior

surface of the endoscope with a gauze pad moistened with enzymatic cleaner. In addition,

wash the valves plungers, biopsy seal and reprocessing cap with enzymatic solution.

Enzyme Cleaning the Channels of the Instrument

Connect the Air/Water Reprocessing Adapter (31027) to the air and water ports on the

endoscope connector.

Attach the color-coded valve reprocessing caps.

Attach the soaking cap to the endoscope connector terminal.

Fill a 60cc syringe with enzymatic cleaner and attach it to the air/water reprocessing adapter.

Fill another 60cc syringe and attach it to the biopsy port.

Depress the plungers of both syringes to fill all channels.

Following the solution manufacturer’s recommendations, allow the instrument to soak for

the proper time period.

32 VideoPath

Air/Water

Reprocessing Adapter

Air/Water

Reprocessing Cap

Suction Reprocessing

Cap

Page 35

Cleaning and Disinfection (continued)

Following the soak cycle, remove the instrument from the solution and place into a sink or

basin filled with clean water, along with the air/water, suction valves and biopsy seal.

Rinse the exterior of the instrument (including valves and seal) thoroughly to remove any

residual solution.

Lift the endoscope connector terminal out of the basin and remove the syringe coupled to

the air/water reprocessing adapter. Refill the syringe with clean water and reattach. Inject

clean water into the air and water lines to rinse. Continue until the water exiting from the

air and water nozzles is clear.

Remove the syringe connected to the biopsy port and fill with clean water. Reconnect and

inject water until it sprays from the open biopsy/suction channel and the suction port.

Continue until the water exiting from channel and port is clear.

WARNING: Make sure that ALL internal channels (e.g., air, water,

suction), the outside of the instrument, and components are thoroughly

rinsed with clean water to remove any remaining enzymatic detergent

solution.

Uncouple both syringes. Fill with air, recouple and inject air through the lines to dry.

Repeat until water does not exit from the channels.

Lift the entire instrument out of the clean water and place on a clean, dry towel to dry

(valves and biopsy seal, as well).

Gently dry the outside surfaces of the instrument with a soft, clean, lint-free cloth. Dry the

objective lens with a cotton-tipped applicator. Open the pressure release valve on the

leakage tester to release the air pressure. Remove the leakage tester. Never connect or

disconnect the leakage tester under water. The instrument will be severely damaged.

NO

TE: 70% alcohol, followed by air may be introduced through the

channels to promote drying.

The instrument is now ready to be disinfected.

VS-100 Sigmoidoscope 33

Page 36

Cleaning and Disinfection (continued)

Enzymatic Cleaning Solutions

NOTE: Specific references to brand name is not an endorsement of

efficacy as a cleaning solution. Tests have shown these solutions

to be compatible with Welch Allyn endoscopes, providing the

manufacturer’s directions are followed.

The materials listed below are considered safe for use with the Welch Allyn

VideoSigmoidoscope if used according to the manufacturer’s instructions for cleaning

and in accordance with procedures detailed in the cleaning section of this manual.

Brand Name Source Usage

Endozime The Ruhof Corp.

Klenzyme Calgon Vestal Labs Follow

Enzy-Clean Burnishine Products Manufacturer’s

Metrizyme Metrex Research Corp. Instructions

Enzol J & J Medical

These solutions must be enzymatic detergents or other cleaning agents specially

formulated to clean endoscopes.

WARNING: Before disinfection or sterilization, be sure that any enzymatic

cleaning solution is thoroughly rinsed off all surfaces. Cleaning solutions

should not be combined with disinfecting or sterilizing solutions since

they can alter the germicidal effectiveness.

Cleaning of Accessories – Biopsy Forceps

1. Clean reusable forceps immediately after each use since dried blood, mucous, or other

debris may cause damage and make it impossible to use the forceps. If forceps are not

clean prior to sterilization, the user may not be able to reprocess them properly.

2. Place the forceps in a container of warm water and enzymatic detergent. Do Not tightly

coil or kink the flexible shaft.

3. Clean the handle and flexible shaft with a soft, clean cloth. Carefully and gently clean the

biopsy cups, pivot pin, and needle with a soft brush.

4. Rinse any remaining detergent from the forceps by rinsing the entire forceps with clean

water while manipulating the handle and biopsy cups mechanism.

34 VideoPath

Page 37

Cleaning and Disinfection (continued)

NOTE: Make certain all detergent is removed from the inner mecha-

nism of the forceps. Any remaining detergent after the water

evaporated causes increased friction that may cause the mechanism not to work. Any remaining detergent also may interfere in

the subsequent sterilization process.

5. After the forceps are cleaned and thoroughly rinsed, dry them gently with a soft, clean

lint free cloth. Do not tightly coil or kink or put tension on the flexible shaft of the forceps.

NO

TE: Clean all other reusable accessories (e.g., channel cleaning

accessories, cleaning brushes) and scope components (e.g.,

rubber biopsy seals, air/water and suction control valves) in the

same way as the forceps were cleaned.

High-Level Disinfection

The Welch Allyn VideoEndoscopes are manufactured from a variety of special materials

which optimize the instrument’s performance, but may not withstand some disinfection

solutions and methods.

Prior to disinfection, the instrument should be thoroughly cleaned and dried following the

methods previously discussed. Incomplete or improper cleaning will decrease the effectiveness of the disinfection process.

CAUTION: Before complete immersion in any disinfecting solution,

make sure the instrument has been leak tested. Refer to instructions

on page 24.

Disinfecting Solutions

NOTE: Specific references to brand name is not an endorsement of

efficacy as a disinfecting solution. Tests have shown these solutions to be compatible with Welch Allyn endoscopes, providing

the manufacturer’s directions are followed.

The materials listed below are considered safe for use with the Welch Allyn flexible Video

Endoscope if used according to the manufacturer’s instructions for cleaning and in accordance with procedures explained in the disinfecting section of this manual.

Solution Brand Name Source Usage

Cidex (14 day) (2.4%) J & J Medical

Follow

Glutaraldehyde Wavicide-01 (2.5%) Wave Energy System Inc.

Manufacturer’s

Metricide (14 day) (2.6%) Metrex Research Corp.

Instructions

VS-100 Sigmoidoscope 35

Page 38

Cleaning and Disinfection (continued)

NOTE: Do not use any other solutions until a sample has been sent to

Welch Allyn for compatibility testing.

Refer to the infection control note located on the inside cover of

the manual.

CAUTION: Before immersing the scope, remove the ETO/Shipping vent

and place the soaking cap on the electrical contacts located on the endoscope connector terminal.

For clarity the reader may wish to refer to the internal schematic on

page 20 showing the pathways involve d during the disinfection process.

Sterilization and Aeration

Before sterilizing the instrument make certain to thoroughly follow the cleaning instructions in

the cleaning section of this manual. It is up to the user to determine if the sterilization procedures described in this section meet the requirements of the facility.

CAUTION: NEVER put the instrument in a steam autoclave.

Ethylene Oxide Gas Sterilization

If Ethylene Oxide (ETO) Gas sterilization is performed on this instrument, make sure to follow

the steps below. This is an acceptable method of sterilization for this instrument, however

the steps are different from those used for other endoscopes.

1. Properly clean and dry the instrument according to the instructions presented previously

in this manual. Remove all component parts (e.g., air/water valve, suction valve, biopsy

seal, etc.).

36 VideoPath

Page 39

Cleaning and Disinfection (continued)

WARNING: If all surface areas are not completely dried, the ETO gas may

not make contact with the contaminated surfaces, causing incomplete or

ineffective sterilization.

Important: Before placing the instrument in a gas sterilizer or aeration chamber, be sure to:

• Couple the Shipping/ETO vent to the ETO vent on the endoscope connector terminal.

• The soaking cap (Part No. 31028) should not be attached and must be OFF of the electrical contacts.

WARNING: Failure to attach the Shipping/ETO Vent Cap will result in

severe damage to the instrument.

NO

TE: This is the opposite procedure from the immersion instructions.

• Make sure the temperature does not exceed 55°C (131°F).

• Make certain the pressure does not exceed 24 psi.

• Make sure the humidity does not exceed 50%.

• Make certain the sterilization procedure does not exceed

4 hours.

2. After ETO Gas sterilization, 72 hours of aeration at room temperature must follow. The

aeration time may be shortened to 12 hours if an aeration chamber is used. The temperature must not exceed 55°C (131°F).

Cold Sterilization

If Ethylene Oxide (ETO) Gas sterilization is not available, the Welch Allyn VideoSigmoidoscope

can withstand immersion in glutaraldehyde solution for a maximum of 12 hours to achieve

cold sterilization. Before fully immersing the instrument, perform the leakage test described

in the Leakage Testing section.

CAUTION: NEVER IMMERSE THE ENDOSCOPE FOR MORE THAN 12

HOURS. After the 12 hours, thoroughly rinse the instrument to remove all

of the glutaraldehyde solution.

After rinsing the instrument, attach the Shipping/ETO Vent to balance the internal and external

humidity.

Other Sterilization Methods

In addition to the ETO and Cold Sterilization methods, Welch Allyn VideoEndoscopes are also

compatible with the Steris Sterilization System/Process. Call Welch Allyn Customer Service at

1-800-535-6333 for additional information.

CAUTION: While there are other types of cleaning and/or sterilization systems or processes available, these types may have damaging effects on

the instrument because of the heat sensitive nature and/or the specific

biocompatible materials used in construction of the endoscopes.

VS-100 Sigmoidoscope 37

Page 40

Cleaning and Disinfection (continued)

To avoid damage to the instrument, check the compatibility of reprocessing systems/

processes other than described in this manual with your Welch Allyn representative.

Accessory Sterilization

WARNING: According to current infection control guidelines all acces-

sories that break the mucosal barrier (e.g., biopsy forceps), must be

sterilized.

Before sterilizing the accessories, make certain to thoroughly follow the cleaning instructions

in the Cleaning Section of this manual. It is up to the user to determine if the sterilization

procedures described in this section meet the requirements of the facility.

1. Once the accessories have been cleaned and thoroughly dried, Ethylene Oxide (ETO) Gas

sterilization can be performed.

2. Aeration is necessary after the accessories have been subjected to ETO sterilization.

Accessory and Instrument Storage

1. Make sure all water is removed from the instrument and accessories.

2. Store the instrument with the insertion tube and umbilical cable as straight as possible. If

coiling is necessary, the insertion tube and umbilical cable should not be wound in more

than one loop.

3. Do Not store the instrument in an area exposed to temperature extremes, high humidity, or

direct sunlight. The storage area should be dr y and clean.

4. Apply silicone oil to the cups of the biopsy forceps to prevent rust.

5. Couple the Shipping/ETO vent to the instrument to balance the internal and external

humidity. Before storing, remove all valves, biopsy seals, soaking caps, etc. to allow

thorough drying of internal parts.

WARNING: Prior to storage, it is important that no residual water be left

within any internal channels/lumens of the instrument or accessories.

Thoroughly dry all instrument surfaces to reduce the potential for bacteria

colonization during storage.

6. Use optional Welch Allyn wall hanger to store instrument securely (#31035).

38 VideoPath

Page 41

Servicing

Prior to returning any instrument for repair to Welch Allyn, the instrument should first undergo

appropriate reprocessing/decontamination procedures for the purpose of infection control.

1. All instruments requiring repair should be shipped in the original shipping package with

appropriate packing along with comments describing the instrument damage and complaint.

2. A repair/return authorization number, contact name and phone number of the individual

responsible for authorizing repairs, as well as shipping address should be included.

3. The ETO/Shipping vent should be attached to the instrument if it will be shipped by air

freight.

4. Any accessories potentially related to the scope damage or complaint also should be

included with the VideoSigmoidoscope.

5. Soaking caps (if applicable) also should be returned with the VideoEndoscope to

check/confirm the integrity of their watertight seal.

NO

TE: Instrument repairs should only be performed by an authorized

Welch Allyn service facility. Welch Allyn assumes no liability for

any patient/user injury, instrument damage or malfunction, or

reprocessing failure due to repairs made by unauthorized

personnel.

Customer Service Telephone Assistance: 1-800-535-6663

For repairs, ship to:

Welch Allyn Repair Department

4341 State Street Road

Skaneateles Falls, NY 13153

VS-100 Sigmoidoscope 39

Page 42

Care and Maintenance Tips

Flexible endoscopes have been an invaluable tool in the medical community’s armamentarium

to successfully diagnose and treat a wide variety of illnesses in patients for several decades.

Perhaps due to their longevity and progressive design changes over the years which have simplified their use, flexible endoscopes have been somewhat taken for granted and have erroneously not been considered highly technological medical devices.

In fact, current generation flexible endoscopes, although easier to clinically use, are more

sophisticated than ever. Special reprocessing instructions must be followed to make sure the

instruments are patient ready and patient safe. Special care and handling must be exercised

and practiced to prevent instrument malfunction and prolong the reliability of the endoscope.

The burden of responsibility to make sure of safe and reliably functioning instruments is left

in the hands of the healthcare professionals who actually care for and reprocess flexible

endoscopes.

Naturally, equipment manufacturers share this responsibility and tremendous efforts have been

spent in designing instruments which could be reprocessed and maintained as easily as possible. However, due to the nature of their use and application, flexible endoscopes must be subjected to special cleaning procedures, followed by a disinfection or sterilization process after

each and every patient use.

To highlight and simplify what may appear to some as being complicated maintenance

and reprocessing instructions, Welch Allyn strongly recommends that users review the

following suggestions and advice on the care and maintenance of your Welch Allyn flexible

VideoEndoscope.

These tips, particularly those involving scope reprocessing, should not be construed as “shortcuts” and are not intended as substitute directions for complete instructions found elsewhere

in the owner’s manual.

• Avoid soaking of the instrument with accessories (e.g., forceps, injection or aspiration needles) or any sharp-edged objects which could inadvertently scratch or cut the distal bending

section sheath. (Subsequent flexing back and forth of the rubber sheath could eventually

stretch the scratched rubber until a pinhole appears and leak develops.)

• Exposure to a compatible enzymatic detergent is essential to thorough cleaning of all surfaces of the instrument. Rinsing and drying after cleaning is imperative to prevent dilution of

the disinfectant/sterilant.

• Do not reuse disposable accessories intended for single patient or one-time use.

• Do not expose the instrument or accessories to harsh chemical solutions. Strictly adhere to

exposure times recommended by the manufacturers of compatible solutions.

• Avoid contact of any flexible portion of the instrument with any sharp objects (e.g., bed

frames, table top corners, sink drains, accessories hanging in storage cabinets) at any time

during the handling, reprocessing, or storage of the instrument.

• Avoid stretching of the bending section rubber sheath at the distal portion of the scope.

During mechanical cleaning of the instrument with a dampened gauze, do not use excessive force. A gentle back and forth wiping motion should be sufficient to remove gross

debris. Subsequent soaking in an enzymatic detergent will clean the remainder of the

debris.

• Disinfectants and sterilants are toxic substances by nature. All residual solution must be

thoroughly rinsed and dried prior to each patient use.

• The key to preventing clogged air or water channels/nozzles is to immediately flush the

channels upon removal from the patient. This should be followed by soaking with an enzymatic detergent.

40 VideoPath

Page 43

Care and Maintenance Tips (continued)

• Avoid attempting to remove or unscrew the instrument’s components which should not be

removed. Parts such as the distal portion on the end of the bending section and any rubber

strain reliefs on either the insertion tube or umbilical cord are essential to the watertight

integrity of the instrument. Removal or loosening of these components and subsequent

immersion could lead to fluid invasion into the instrument.

• Avoid excessive and/or tight bends in the insertion tube and umbilical cord. Tight curling of

these portions of the instrument can result in serious internal damage.

• Never articulate the bending section by applying force directly to the bending section. This

can cause serious damage to the internal steering cables.

• If resistance is felt during rotation of the deflection control knobs, do not apply excess

force.

• Check for any sharp edges on all surfaces of an automated cleaning/reprocessing unit

which may come in contact with an endoscope. Some units may have sharp edged wire

mesh filters and baskets or inlet/outlet ports which could damage the instrument.

• The air/water and suction control valves must be screwed down onto their respective

cylinders on the instrument’s control body to function properly. This is unlike other

manufacturer’s semi-disposable valves with a rubber base which do not have threads to

secure attachment.

• Do NOT overtighten the cap to the water bottle assembly. Overtightening could cause the

cap to crack.

• Do NOT introduce air bubbles into the instrument’s internal channels during flushing of

cleaning and/or disinfecting/sterilizing solutions since the bubbles could interfere in the

effectiveness of the disinfection/sterilization process.

• Do NOT store the instrument and accessories in the carrying case since this type of dark,

humid, and unventilated environment is conducive to bacteria colonization which increases

the risk of cross-contamination.

• Prior to each use, check the condition of all accessories.

Do NOT use any accessories with kinked or bent flexible shafts.

Do NOT use forceps with misaligned cups and/or bent needles/spikes.

Do NOT use aspiration or injection needles which are not retractable or whose sharp tips

cannot be protected.

DO NOT use cleaning brushes without smooth or rounded distal tips.