Page 1

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

13

II. 5. PERFORMANCE SPECIFICATIONS

The performance specifications of the Welch Allyn Vital Signs Monitor are as follows:

CUFF PRESSURE RANGE

0 mmHg - 300mmHg

INITIAL CUFF INFLATION

Default cuff inflation pressure is 160 mmHg. Operator may change this default in

configuration mode. Options are 120, 140, 160, 180, 200, 240 and 280 mmHg.

SYSTOLIC DETERMINATION

Maximum: 250 mmHg

Minimum: 60 mmHg

DIASTOLIC DETERMINATION

Maximum: 160 mmHg

Minimum: 30 mmHg

BLOOD PRESSURE ACCURACY

Blood pressure accuracy meets or exceeds SP10-1992 AAMI standards for non-invasive

blood pressure accuracy (AAMI standard: ± 5 mmHg mean error; 8 mmHg standard

deviation). Blood pressure accuracy is validated for pressure measurement using the

upper arm only, with the patient in a seated position. Blood pressure is validated against

manual auscultatory readings.

BLOOD PRESSURE DETERMINATION TIME

20 seconds to 45 seconds typical, 165 seconds maximum.

PULSE RATE DETERMINATION

Maximum: 200 bpm

Minimum: 40 bpm

PULSE RATE ACCURACY

SpO2Module Heart Rate (Nonin

®

) ±3.0%

SpO2Module Heart Rate (Nellcor Puritan Bennett

TM

) ±3 bpm

Blood Pressure Algorithm Heart Rate ±5.0%

OVERPRESSURE CUTOFF

295 mmHg to 330 mmHg

TEMPERATURE DETERMINATION

Normal and Monitor Modes: Maximum 108.0°F (42.2°C)

Minimum 84.0°F (28.9°C)

TEMPERATURE ACCURACY

Temperature accuracy meets ASTM E112-86: "Standard Specification for Electronic

Thermometer for Intermittent Determination of Patient Temperature."

Page 2

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

14

TEMPERATURE DETERMINATION TIME (ORAL)

Normal Mode: ORAL: 4 seconds typical, 15 seconds maximum

Monitor Mode: ORAL: 3 minutes

OXYGEN SATURATION RANGE (SpO2%)

40-99% oxygen saturation

SpO2ACCURACY

Nonin

®

Pulse Oximeter Module

Saturation (%SpO2± 1 Standard Deviation*)

70-99% ± 2 digits

< 70% unspecified

Nellcor Puritan Bennett

TM

Pulse Oximeter Module

Saturation (%SpO2± 1 Standard Deviation*)

70-99% ± 3 digits

< 70% unspecified

* Standard Deviation is a statistical measure: up to 32% of the readings may fall outside

these limits.

BATTERY CHARGING

To at least 90% capacity in 12 hours. Unit will operate and charge battery simultaneously

when connected to power source.

A fully charged battery will support 200 "typical" blood pressure determinations taken at 3

minute intervals. Battery is 90-100% charged after 12 hours of charging. The battery automatically charges when the monitor is powered through the AC power transformer. The

battery will charge faster when the instrument is not in operation.

II. 6. A. TECHNICAL SPECIFICATIONS:

MECHANICAL SPECIFICATIONS

DIMENSIONS

Height 6.5 inches (16.5cm)

Length 8.6 inches (21.8cm)

Depth 5.0 inches (12.7cm)

WEIGHT

Approximately 6 pounds (2.8Kg)

COLOR

Oral/Axillary Temperature Probe - Blue

Rectal Temperature Probe - Red

Page 3

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

15

MOUNTING

Self-Supporting on rubber feet

IV Pole Mountable

Custom Mobile Stand

Wall Mountable

Attaches to Bed Rail

PORTABILITY

- May be hand carried when held by the recessed handle.

- When attached to an IV pole, or mounted on its custom mobile stand, the

monitor and accessories can be wheeled from patient to patient.

- When attached to the bed rail may be transported with the patient within the

hospital environment.

OPERATOR INSTRUCTIONS/ALARM INTERPRETATION

Comprehensive Operator Manual available. Quick reference operator instruction card

available.

II. 6. B. ELECTRICAL SPECIFICATIONS

POWER REQUIREMENTS

Patient-Rated isolation transformer is connected to AC mains power source:

North American Version: 120VAC, 60 Hz., 0.20A Input Source; 8Vdc, 0.75A Output Source

International Versions: 230VAC or 240VAC, 50Hz., 0.20AInput Source; 8Vdc, 0.75AOutput Source

BATTERY

Lead acid, with external recharge capability.

II. 6. C. ENVIRONMENTAL SPECIFICATIONS

OPERATING TEMPERATURE

+10°C to +40°C

+50°F to +104°F

*Exception: Thermometry module will not maintain its performance

characteristics below 60°F (16°C).

OPERATING ALTITUDE

-170m to +4877m

-557ft. to +16,000ft.

II. 6. D. TRANSPORTATION/STORAGE CONDITIONS

STORAGE TEMPERATURE

-20°C to +50°C

-4°F to +122°F

RELATIVE HUMIDITY

15 to 90% (non-condensing)

Page 4

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

60

SECTION V

TROUBLESHOOTING/

MAINTENANCE/CALIBRATION

1. Troubleshooting: Error Indications and Interpretation

2. Troubleshooting: General Guide to Problems and Corrective Actions

3. Maintenance

a. Cleaning

b. Storage

c. Battery Removal and Replacement

4. Calibration

a. Blood Pressure Calibration Check

b. Temperature Calibration Check

c. SpO2Calibration Check

Page 5

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

61

V. 1. TROUBLESHOOTING:

ERROR INDICATIONS AND INTERPRETATION

The following table of alarm conditions and error codes is intended to provide the operator with a quick reference to the descriptions and probable causes of the error codes. For

service level troubleshooting, refer to the service manual.

When responding to a Monitor alarm, always CHECK THE PATIENT FIRST and then

proceed to check the Monitor.

Press CANCEL to reset patient alarm conditions.

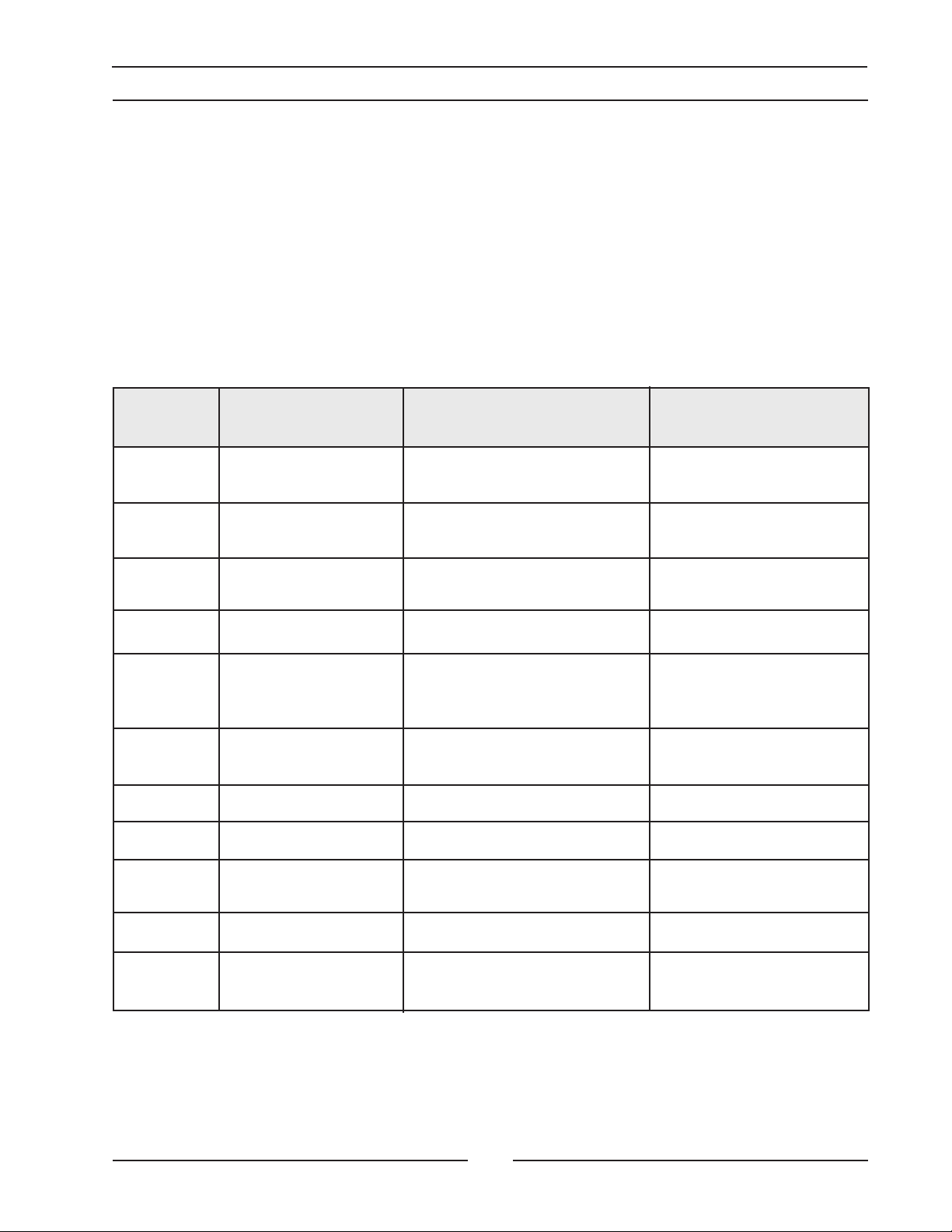

ERROR MEASUREMENT DESCRIPTION CORRECTIVE

CODE MODE ACTION

C01 Blood Pressure Measurement cycle was -------

cancelled by operator

C02 Blood Pressure Autozero Failure Check for air obstruction,

limit patient movement

C03 Blood Pressure Inflation too rapid Check for kinked hose or air

obstruction

C04 Blood Pressure Excessive inflation time Check for air leaks

C05 Blood Pressure Excessive noise Check patient condition, cuff

placement, limit patient

movement

C06 Blood Pressure Measurement was outside Check patient condition

of Monitor's measurement range

E10 Blood Pressure Cuff overpressure condition Check patient condition

C20 Temperature Broken/missing probe Replace probe

C21 Temperature Probe not ready Replace probe in holder,

wait 15 seconds, retry

E0.0 thru E9.9 Temperature Internal malfunction Contact customer service

"P" Temperature Loss of tissue contact Insure proper probe

positioning

Page 6

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

62

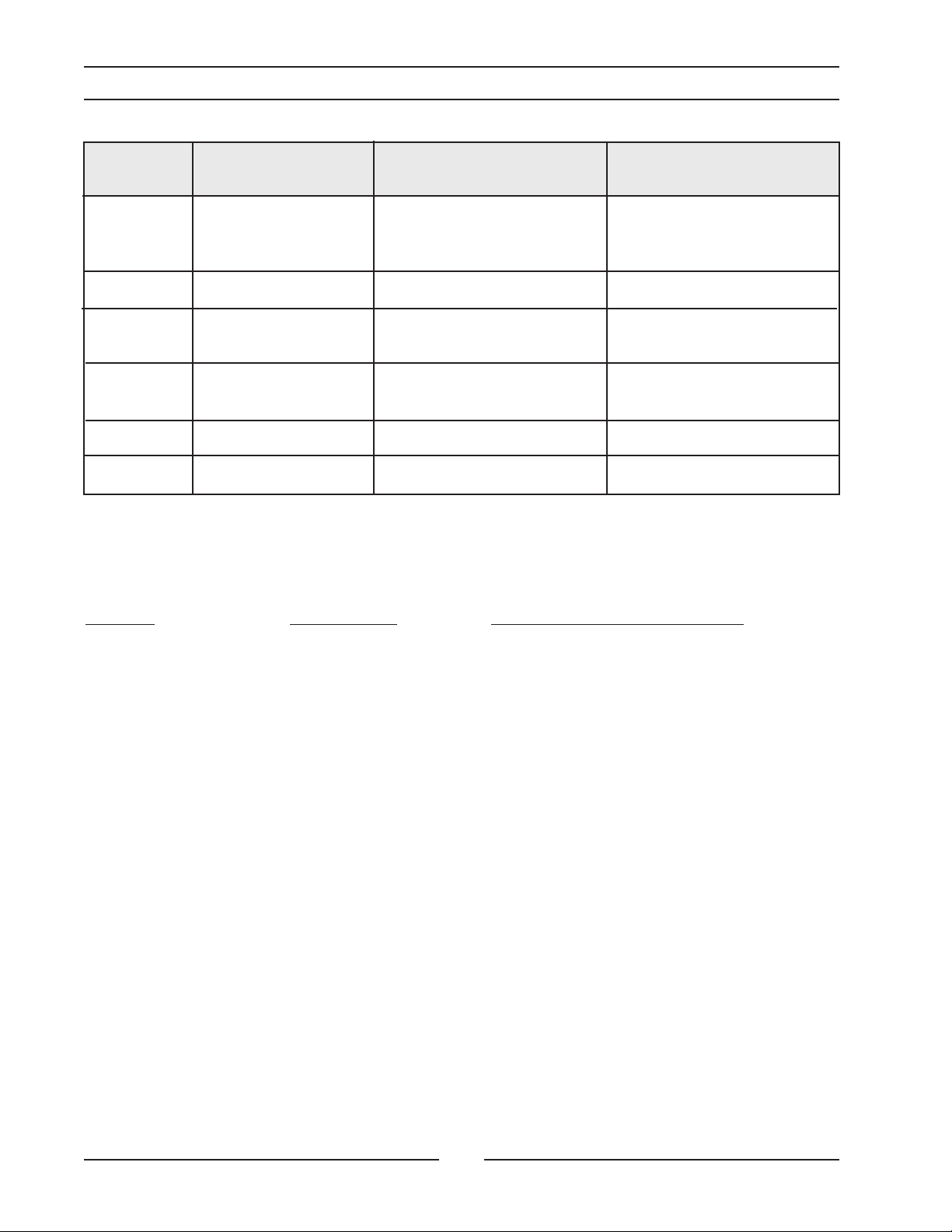

ERROR MEASUREMENT DESCRIPTION CORRECTIVE

CODE MODE ACTION

"--" SpO

2

Sensor Error Check patient condition,

sensor position and

connection

E7 SpO

2

Internal Malfunction Contact customer service.

E11 General Internal safety violation Check patient, contact

customer service

E12 General Ambient temperature out Adjust temperature or

of range monitor location

E13 General Battery failure Use wall transformer

E20 thru E50 General Internal malfunction Contact customer service

V.2. TROUBLESHOOTING: GENERAL GUIDE TO

PROBLEMS AND CORRECTIVE ACTIONS

Incorrect cuff size

Note: Use Welch Allyn approved cuffs

only.

Patient’s arm position

Arm movement during blood pressure

cycle

Blood pressure taken over clothing

Arrhythmia

Incorrect reference

Change in blood pressure from auscultatory reading to Welch Allyn Vital Signs

Monitor reading

Poor auscultatory sound recognition

by observer

Determine correct cuff size:

• Use reference markings on cuff

• Measure patient’s arm circumference midway between elbow and

shoulder (see page 42 of Operator’s Manual to select correct cuff

size).

Ensure patient’s arm is at heart level.

Keep arm still during blood pressure cycle:

• Movement may cause inaccuracies from artifact.

Blood pressure should be taken on a bare arm.

Check for regularity of heart rate:

(palpate pulse or check monitor)

• Moderate to severe heart rate irregularities may make blood

pressure difficult to measure.

Use the correct Korotkoff sound to determine diastolic blood

pressure.

• Many listeners incorrectly equate diastolic blood pressure with the

disappearance of sound only (phase 5). The Welch Allyn Vital Signs

Monitor was developed using the American Heart Association recommendations, which state that phase 5 be used unless sound continues

to 0 mmHg, in which case the change in the quality of sound (phase

4) is to be used.

Deflate cuff no faster than 3 mmHg per second:

• One of the major sources of error in auscultatory blood pressure

measurement is deflating the cuff too quickly. The American Heart

Association recommends deflation no faster than 3 mmHg per

second.

Only use a sphygmomanometer that is known to be in calibration:

• Blood pressure taken with an un-calibrated sphygmomanometer

may be very inaccurate.

Check blood pressure immediately prior to Welch Allyn Vital Signs

Monitor Reading.

Use higher quality stethoscope. Have a different observer check

patient’s blood pressure.

1 INACCURATE

BLOOD PRESSURE

READINGS

Please note:

Differences of up to 10mmHg should be

considered normal and will occur for a

number of reasons including intrapatient

BP variability, observer hearing differences,

and auscultatory deflation rate.

Symptom Possible Cause Explanations and Corrective Action

Page 7

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

63

Leak in pneumatic system

Arm movement during cycle

Tubing movement artifact

Ensure all cuff attachments are tight.

Carefully check for tubing leaks in blood pressure cuff and tubing

attachment to monitor.

Keep arm still during blood pressure cycle:

• movement may cause inaccuracies from artifact

Do not contact tubing during blood pressure cycle:

• movement may cause inaccuracies from artifact

2 CUFF INFLATION

& DEFLATION

WITH NO BLOOD

PRESSURE

READING

DISPLAYED

(or error code in display)

Connections from monitor to cuff

loose

Check all connections. (Do not over tighten).

3 NO CUFF

INFLATION

Broken probe

Improper probe placement

Probe not replaced

Replace probe.

Consult Technical Manual.

Notify Biomedical department or Welch Allyn Technical Support.

Wait for display window to read OrLbefore placing probe.

Place probe in most posterior sublingual pocket.

Notify Biomedical department or Welch Allyn Technical Support.

Replace probe in holder prior to taking another temperature.

4 TEMPERATURE

MALFUNCTION

Improperly attached sensor

Cable incorrectly plugged into

monitor

Sp02disabled

Incorrect Sensor

Insert the patient’s finger completely into sensor

Ensure sensor cable is correctly plugged into monitor

Ensure Sp02is enabled (check Configuration Mode)

Ensure that correct manufacturers sensor is in use

• Nonin®and Nellcor Puritan Bennett™ sensors are not

interchangeable

5 SpO

2

MALFUNCTION

• Sensor in Place but No Sp02on

Display

• Inaccurate Sp02Reading

Paper will not advance Consult Technical Manual

Notify Biomedical department or Welch Allyn Technical Support.

6 PRINTER

MALFUNCTION

Low battery

Monitor not powering up

Check connections between monitor and transformer, and transformer and wall receptacle.

Unplug unit from wall receptacle and check for breaks in cord. If

connections secure, check electrical outlet

• Charging light will be on if connections are OK and the monitor is

plugged into a working outlet

Notify Biomedical Department or Welch Allyn Technical Support.

7 MONITOR WILL

NOT TURN ON

Pressure Preset too high Check default Pressure Preset setting: (in Configuration Mode)

• Unless patient has underlying systolic hypertension, set pressure

preset at 160 mmHg. (If systolic blood pressure greater than

pressure preset, monitor will automatically increase an additional

40 mmHg)

8 CUFF TOO TIGHT

(Over inflation)

Inappropriate size cuff

Cuff applied inside out

Determine cuff size with the cuff markings or refer to chart in

Operator’s Manual for determining cuff size.

• If cuff continues to pop off, notify Biomedical Department or Welch

Allyn Technical Support.

Re- apply cuff:

• Make sure Welch Allyn label is facing away from arm.

9 CUFF POPPING

OFF

Symptom Possible Cause Explanations and Corrective Action

Page 8

WELCH ALLYN VITAL SIGNS MONITOR OPERATOR MANUAL

64

Normal operation

Pressure Preset too high

Patient movement

Small leak in pneumatic system

Typical time to take a reading is 20 to 45 seconds. 165 seconds

is the maximum.

Check default Pressure Preset setting. (in Configuration Mode)

Have patient sit still.

Do not have arm tight against chest wall as respirations may affect

speed and accuracy of blood pressure measurement.

Check cuff and tubing for leaks.

10 CUFF DEFLATING

TOO SLOWLY

QUICK GUIDE TO TAKING A MANUAL (AUSCULTATORY) BLOOD PRESSURE

1 Collect appropriate equipment.

Use a certified accurate sphygmomanometer and quality

stethoscope.

Select a blood pressure cuff of a suitable size. Use a blood

pressure cuff of the largest appropriate size for patient (see

markings on inside of cuff).

2. Have the patient assume a comfortable position with the

upper arm relaxed at heart level and the lower arm passively

supported.

3. Expose the area of the brachial artery by removing clothing,

or move a sleeve, if not too tight, above the area where the

cuff will be placed.

4. Center the cuff bladder so that the lower edge is at least 1

inch (2.5cm) above the bend of inner arm of the elbow.

5. Palpate the brachial or radial pulse.

6. Inflate the cuff until the pulsation disappears. Then continue

to inflate until the pressure reads 30 mmHg above the point

where the pulse disappeared.

7. Listen carefully with stethoscope over brachial artery while

controlling the release of air at a rate of 3 mmHg per second.

8. Systolic is determined by reading the manometer gauge

when the first faint but clear tapping sound is heard with

the stethoscope.

9. Diastole, in adults, is determined by reading the manometer

gauge to the closest even number when the last sound is

heard.

10. Release the air quickly after at least 10 to 20 mmHg of

silence.

Many sphygmomanometers are inaccurate. Low quality stethoscopes do not transmit sound well enough for blood pressure

sounds to be heard accurately. Acuff that is either too large or too

small will produce an inaccurate reading.

If the arm is not at the proper level, inaccurate readings will result.

Clothing over the artery hinders the ability to hear and may cause

inaccurate readings. Tight clothing may cause vessel congestion and

inaccurate readings.

This places the cuff in the best position for occluding the blood flow

through the brachial artery.

Determines the most accurate location for assessment and approximation of systolic pressure.

Facilitates identification of Phase One of Korotkoff sounds.

One of the major sources of error in auscultatory blood pressure

measurement is deflating the cuff too quickly. It is a normal operation of the Welch Allyn Vital Signs Monitor to deflate at the

American Heart Association recommended 3 mmHg per second.

Follows AHArecommended standards.

Follows AHArecommended standards.

Diastolic blood pressure in children is the point at which the sound

becomes muffled.

Action EXPLANATION

Symptom Possible Cause Explanations and Corrective Action

Page 9

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 2: Service Set Up

2.3 Replacement Parts – Welch Allyn

In addition to individual parts listed below, S

PARE PARTS KITS have been made up for

your convenience. This assures that you will have all the mounting materials and other

small items needed for a repair. The foam pads mounted on the battery are one such

example. Kits will not be broken down. FOR AUTHORIZED REPAIR SITES ONLY.

Welch Allyn Replacement Parts:

PART#: DESCRIPTION:

130S46-E English Front Housing Kit

130S46-S Spanish Front Housing Kit

130S46-F French Front Housing Kit

130S46-G German Front Housing Kit

130S46-I Italian Front Housing Kit

130S51 Front Housing Switch Array

130S45* Main PCB Assembly

Includes: hardware

130S4* Display PCB Assembly

Includes: hardware

130S5* Valve

130S6 Pneumatic Connector

Includes: connector, washer, nut, and grommet

130S39* Pump Assembly

Includes: pump, cable tie mount, 2 cable ties, foam pads, instructions, specifications

130S40E English Rear Housing Kit

130S40F French Rear Housing Kit

130S40G German Rear Housing Kit

130S40I Italian Rear Housing Kit

130S40S Spanish Rear Housing Kit

130S9 Power Jack

130S10 Back Panel

Includes: panel and hardware

130S41 Tubing Assembly

Includes: all tubing, “T” fitting, instructions

130S13 Bumpers (2 ea.)

130S14 Battery Access Plate

Includes: plate and hardware

130S47 Wire Harness

Includes: 14 pin MTA connector, 3 pin MTA connector, faston receptacles for the

power supply, power jack, battery, and valve lead wires all assembled

130S16 Temperature Plug

130S17 Printer Assembly

Includes: thermal printer, double faced adhesive foam all assembled

130S18* Printer Housing

Includes: housing, switch array, PCB, hardware, flex strip

130S48 RS232 Cable

Includes: DB9 connector, hardware, 4 pin MTA, lead wires all assembled

Includes: front housing with loose labels. Four different types of

labels for the four different configurations i.e.:

BP w/Printer Only,

BP w/Printer + Temp,

BP w/Printer + SpO2,

BP w/Printer + Temp +

SpO

2

7

Page 10

Section 2: Service Set Up

PART#: DESCRIPTION:

130S42* SpO2 PCB (Nonin)

Includes: PCB with cable attached, DB9 connector and cable (not attached),

and hardware with instructions

130S49 SpO2 Sensor Interconnect (Nonin)

Includes: lead wires and 4 pin MTA connector

130S52* Temperature PCB Assembly

Includes: PCB, hardware, lead wire and connectors

130S53 Temperature Connector

Includes: connector, lead wires and hardware

130S24 Temperature Probe Housing

Includes: housing and hardware

130S27 Printer Paper Cover

130S28 Cable, DB9 Female to DB9 Female 42" long

130S29E Software, Repair

130S43 Kit, Repair, Nellcor SpO2 PCB with connector

130S50 Kit, Repair, SpO2 Cable (Nellcor)

130S54 Kit, Repair, SpO2 Cable to Main (Nellcor)

130S37 Upgrade, Software, Version 3.11

41P100** Check Valve

117S144** DC to DC Converter

114S588** Pressure Sensor

66S530** “Printer, Flat Cable”

5200-01 Cuff Assy, Adult with 1 tube bag

5200-02 Cuff Assy, Lg Adult with 1 tube bag

5200-03 Cuff Assy, Child Print with 1 tube bag

5200-04 Bag, Adult with cut tube

5200-05 Bag, Lg Adult with cut tube

5200-06 Bag, Child with cut tube

5082-59 Cuff, Adult Black

5082-61 Cuff, Lg Adult Black

5082-63 Cuff, Child Print

5200-07 Pressure Hose with new Luer fitting

5200-08 Calibration T connector

5200-20 Probe, Oral 9 Ft, Diatek

5200-22 Probe, Rectal 9 Ft, Diatek

5200-40 Sensor, SSpO2 Finger Clip (3 meter cord) (Nonin)

5200-41 Sensor, SpO2 Ear Clip (Nonin)

5200-42 Sensor, SpO2 Flex (Nonin)

5200-44 Sensor, SSpO2 Reflectance (Nonin)

5200-45 Holder, SpO2 Reflectance Sensor (Nonin)

5200-46 Sensor, SpO2 Adult Finger Flexi-form (Nonin)

5200-47 Sensor, SpO2 Ped Finger Flexi-form (Nonin)

5200-50 Tape, SpO2 Sensor Attachment (Nonin)

5200-51 Tape Strips, Hydrogel for SpO2 (Nonin)

5200-52 Cable, SpO2 Extension 3 Ft (Nonin)

5200-53 Kit, SpO2 Finger Phantom Calibration (Nonin)

5200-54 Sensor, SpO2 Finger Clip (1 meter cord) (Nonin)

5200-12 Tubing, straight 8 ft. with fitting

5200-56 Pediatric Finger Clip Sensor (Nonin) 9 ft. cable

5200-55 Extension Cord 10 ft. for SpO2 sensor (Nonin)

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

8

Page 11

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

PART#: DESCRIPTION:

5200-60 Mobile Stand Kit

5200-61 Mobile Stand Kit, Modified

5200-62 Wall Mount Kit

5200-63 Wall Mount Kit, Modified

5200-64 IV Pole Kit

5200-65 IV Pole Kit, Modified

5200-66 Bed Rail Kit

5200-67 Bed Rail Kit, Modified

5200-68 Cuff Clip

5200-69 Accessory Pack

7052-25 Printer Paper (5 rolls)

5200-101 Transformer, USA 120V, 60 Hz

5200-102 Transformer, Europe 220V, 50 Hz

5200-103 Transformer, UK 230V, 50 Hz

5200-103 Transformer, Australia 230V, 50 Hz

5200-110 Power Cord, USA/Japan

5200-111 Power Cord, Europe

5200-112 Power Cord, UK

5200-113 Power Cord, Australia

5200-114 Power Cord, Switzerland

5200-115 Power Cord, South America

5200-84 Battery, 6 Volt Lead Acid

D-25 OXISENSOR II adult digit oxygen transducer (Nellcor)

D-25L OXISENSOR II adult digit oxygen transducer with long cable (Nellcor)

D-20 OXISENSOR II pediatric oxygen transducer (Nellcor)

R-15 OXISENSOR adult nasal oxygen transducer (Nellcor)

I-20 OXISENSOR II infant digit oxygen transducer (Nellcor)

EC-8 Extension Cable – 8 foot (Nellcor)

OXICLIQ-A Adult oxygen transducer for use only with OXICLIQ sensor cable OC-3 (Nellcor)

OXICLIQ-P Pediatric oxygen transducer for use only with OXICLIQ SENSOR CABLE MODEL OC-3 (Nellcor)

OXI-A/N OXIBAND adult/neonatal oxygen transducer (Nellcor)

OXI-P/I OXIBAND pediatric/infant oxygen transducer (Nellcor)

RS-10 Reflectance oxygen transducer (Nellcor)

D-YS DURA-Y oxygen transducer (Nellcor)

SRC-2 Portable oximetry tester (Nellcor)

DS100A DURASENSOR adult oxygen transducer (Nellcor)

OC-3 Cable, OXICLIQ Sensors (Nellcor)

D-YSE Ear Clip (use with DURA-Y sensor) (Nellcor)

D-YSPD Pedicheck Pediatric Spot-Check (use with DURA-Y Sensor) (Nellcor)

ASP-3 Sensor Assortment Pack (Nellcor)

05031-101 Diatek Probe Covers

5200-25 Temperature Cal. Key

01800-210 Model 9600 Temperature Cal. Kit 110V.

5200-85E Operations Manual

5200-145E Service Manual

Section 2: Service Set Up

* - Indicates that these parts can be traded in. If the part is under warranty, with a trade in you get full

credit. If the parts is out of warranty, you will get a 40% discount from the price.”

** - Only regional service centers may purchase these parts.

See section 1.1 for ordering parts.

9

Page 12

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 2: Service Set Up

2.4 Welch Allyn Vital Signs Monitor

Maintenance and Service Support

Owner Maintenance: Non-Technical customers can perform normal maintenance per the

instructions provided in the Operator Manual, Section V. End users will be able to perform basic

operations such as replacement of: hoses, cuffs, probes, printer paper and batteries. On this

level the unit will not be opened. However, opening of the WELCH ALLYN VITAL SIGNS MONITOR by untrained individuals may damage the unit and void the warranty.

Technical Service/Repair/Re-calibration: Properly trained and equipped bio-

medical departments and service centers will be able to utilize the content of this Service Manual.

Technical skills in electronics and PC skills are required. These departments and centers must

have service manual and re-calibration software, repair tools and test equipment as listed in this

manual. They must also have minimum recommended quantities of repair parts and sub-assemblies. See the listings of repair parts and kits in this manual.

11

Page 13

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

CLINICAL VITAL SIGNS MONITOR OPERATOR MANUAL

Section 3: Problem Diagnosis

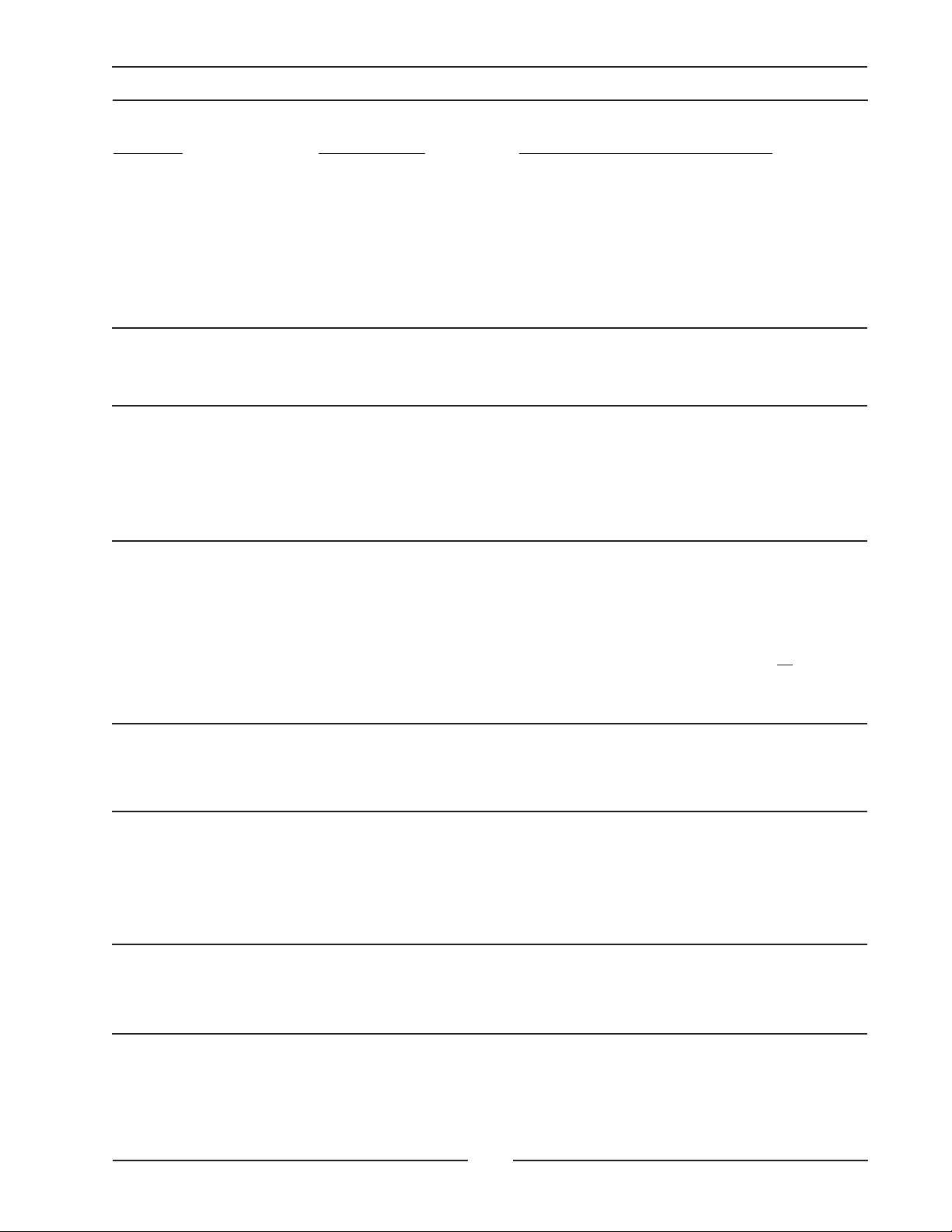

3.7 TROUBLE SHOOTING GUIDE

Symptom Possible Cause Explanations and

Corrective Action

1. Inaccurate

Blood Pressure

Readings

Please note: Differences

‘10mmhg should be considered

‘normal and will occur for a

number of reasons including

intrapatient BP variability,

observer hearing differences,

and auscultatory deflation rate.

Incorrect Cuff Size

Patient’s Arm Position

Arm Movement During

blood pressure cycle

Blood Pressure taken

over clothing

Arrhythmia

Incorrect Reference

Determine correct cuff size:

• use reference markings on cuff

• measure patient’s arm circumference

midway between elbow and shoulder

(see page 42 of Operator’s Manual to

select correct cuff size).

Ensure Patient’s arm is at heart level.

Keep arm still during blood

pressure cycle:

• movement may cause inaccuracies

from artifact

Blood Pressure should be taken on

a bare arm.

Check for regularity of heart rate:

(palpate pulse or check monitor)

• moderate to severe heart rate irregularities

may make blood pressure difficult to measure.

Use 4th Korotkoff sound to determine

diastolic blood pressure.

• Many listener’s incorrectly equate diastolic

blood pressure with the disappearance of

sound. The Vital Signs Monitor was developed

using the 4th sound, as recommended by

the American Heart Association.

Change in blood pressure

from auscultatory reading

to Vital Signs Monitor

reading

Poor auscultatory sound

recognition by observer

Deflate cuff no faster than 3mmhg per second:

• One of the major sources of error in ausculta-

tory blood pressure measurement is deflating

the cuff to quickly. The American Heart Association

recommends deflation no faster than 3mmhg

per second.

Only use a spygnomometer that is known

to be in calibration:

• Blood pressure taken with un-calibrated

sphygmomanometer may be very inaccurate.

Check blood pressure immediately prior to

Vital Signs Monitor Reading

Use higher quality stethoscope

Have a different observer check patient’s

blood pressure

19

Page 14

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 3: Problem Diagnosis

3.7 TROUBLE SHOOTING GUIDE

Symptom Possible Cause Explanations and

Corrective Action

2. Cuff Inflation &

Deflation With No Blood

Pressure Reading

Displayed. (or error code in

display)

3. No Cuff Inflation

4.

Temperature

Malfunction

• Error code displayed

Leak in pneumatic system

Arm Movement

During Cycle

Tubing Movement Artifact

Connections from

monitor to cuff loose

Broken Probe

Make sure all cuff attachments are tight.

Carefully check for tubing leaks on blood

pressure cuff and tubing attachment to

monitor.

Keep arm still during blood pressure cycle:

• movement may cause inaccuracies from

artifact.

Do not contact tubing during blood pressure cycle

• movement may cause inaccuracies from

artifact.

Check all connections. (Do not over tighten).

Replace Probe

Consult Technical Manual

Notify Biomedical department or Welch Allyn

Customer Service (800) 854-2904

Wait for display window to read ORL before

placing probe

• Low Temperature

Readings

• No Temperature Displayed

5.

SPO2 Malfunction

• Sensor in place but no

SPO2 on display

• Inaccurate SPO2 Reading

Improper Probe

Placement

Probe not Replaced

Improperly attached

sensor

Cable incorrectly

plugged into monitor

SPO2 disabled

Incorrect Sensor

Place probe in most posterior sublingual

pocket

Notify biomedical or Welch Allyn Customer

Service.

Replace probe in holder prior to taking

another temperature.

insert the patient’s finger completely into

sensor

Be sure sensor cable is correctly plugged

into monitor

Be sure SPO2 is enabled with Mode button -

(SPO2 light will be off when disabled)

Assure that correct manufacturers sensor is

in use - they are not interchangeable

21

Page 15

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 3: Problem Diagnosis

3.7 TROUBLE SHOOTING GUIDE

Symptom Possible Cause Explanations and

Corrective Action

6. Printer Malfunction

7. Monitor Will Not

Power Up

8. Cuff Too Tight

(over inflation)

Paper will not advance

Low Battery

Monitor not plugged in

Pressure Preset too high

Consult Technical Manual

Notify Biomedical or Welch Allyn Customer

Service.

Check connections between monitor and

transformer and wall receptacle.

Unplug unit from wall receptacle and check

for breaks in cord. If connections secure and

power supply is intact.

Notify Biomedical Department or Welch

Allyn Customer Service.

Check pressure preset setting:

• Unless patient has underlying systolic hyper-

tension, set pressure preset at 160mmhg.

(If Systolic blood pressure is greater than

‘pressure preset, monitor will automatically

‘increase an additional 40mmhg).

9. Cuff Popping Off

10. Cuff Deflating Too

Slowly

Inappropriate size cuff

Cuff applied inside out

Normal Operation

Pressure Preset too high

Determine cuff size with the cuff markings or

refer to chart in Operator’s Manual for

determining cuff size.

• If cuff continues to pop off, notify Biomedical

Department or Welch Allyn Customer Service.

Re apply cuff:

• make sure smooth surface of velcro is facing

patients arm

Deflate cuff no faster than 3mmhg per second:

• One of the major sources of error in ausculta-

tory blood pressure measurement is deflating

the cuff too quickly. The American Heart

Association recommends deflation no faster

than 3mmhg per second.

Check pressure preset setting

23

Page 16

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.1 Calibration T est

ABSTRACT: The following is the test procedures for the WELCH ALLYN VITAL SIGNS

MONITOR. We set this procedure up so that you can start at section 5.1 and go straight

through the procedure or you can skip around. However, you must do all of the test called

out in this section before a unit can be returned to field service.

NOTES:

A. The word “unit” in this text refers to the WELCH ALLYN VITAL SIGNS MONITOR.

B.

Menu|Choice

Exit command from the File menu.”

1. Connect the WELCH ALLYN VITAL SIGNS MONITOR unit to the manual test station

(see Section 2, Figure 2.2.1). Hook up the pressure lines to the coiled tubing of the

monitor and the RS 232/Service

port connector to the computer. Start the computer program by double clicking on

its program icon.

represents menu commands. Rather than use the phrase “choose the

2. Remove the battery and hook unit up to the power supply and the digital voltage

meter. Power supply should be set at 6.5Vdc.

3. Turn on the unit and in the program choose

information displayed on the screen matches that of the unit under test. Note : If the

software returns an ERROR message, check the communications link, and re-send

the command. If the communications return another error close the information dialog

box then select

selected. Place the unit into the “Detailed Test” mode by holding down the “start” and

“cancel” buttons as power is applied.

4. Observe the unit. Verify that the software versions displayed on the LED displays

meet the specifications called out in the Repair Test Specifications document.

5. Press the review button on the unit. The systolic window should read “CAL.”

6. Attach a pneumatic clamp to the 100cc and the 250cc volume, remove the clamp

from the 500cc volume.

7.

Choose Test|Calibration.

transducer manometer readings, unit battery reading, valve and pump status.

Tools|Options

The dialog box will display the units primary and safety

and check that the correct communications port is

Unit|Information.

Confirm that the

1

Page 17

Section 5: Test Procedures

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Note : Use Start button to close valve, and hand bulb to set the pressures.

8. Verify that the unit is within calibration specification at all the following target pressures: 0, 50, 150, and 250 mmHg. All target pressures have a tolerance of +/- 5

mmHg. Specification are found in the Repair Test Specifications document.

9. Press the “review” button until the systolic window reads “bat.”

10.Set the power supply to 5.7 +.05,-0 Vdc (5.7 to 6.0 Vdc). Verify that the voltage read-

ing of the unit meets specification called out in the Repair Test Specification document. Return the power supply to 6.0 ±0.25 Vdc upon completion of this test.

11 Press Close to exit from the “Test Calibration” dialog box.

2

Page 18

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.2 Current T ests

1. Connect the WELCH ALLYN VITAL SIGNS MONITOR unit to the manual test station.

Hook up the pressure lines to the coiled tubing of the monitor and the RS 232/Service

port connector to the computer. Start the computer program by double clicking on its

program icon.

2. Turn unit off unit then re-power unit allowing the unit to boot up into its normal mode.

3. Click on

a. Blank

b. Idle

c. Pump

d. SpO

e. Temperature

4. Verify these currents meet the specifications called out in the Repair Test Specification document.

5. Press Close button to exit dialog box.

Test|Current Levels.

2

Check the following current levels:

3

Page 19

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.3 Noise Levels

1. Connect the WELCH ALLYN VITAL SIGNS MONITOR unit to the manual test station.

Hook up the pressure lines to the coiled tubing of the monitor and the RS 232/Service

port connector to the computer. Start the computer program by double clicking on its

program icon.

2. Click on

3. Press Test button to retrieve the units internal pressure channel noise level. Verify

that the noise level meets the specification called out in the Repair Test Specification

document.

Test|Noise Levels.

5

Page 20

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.4 Button T est

1. Connect the WELCH ALLYN VITAL SIGNS MONITOR unit to the manual test station.

Hook up the pressure lines to the coiled tubing of the monitor and the RS 232/Service

port connector to the computer. Start the computer program by double clicking on its

program icon.

2. Choose

edges it, via the “Button Pressed” display. Each button should also cause the units

display to change to one of the settings noted below.

F,P - When printer option is installed

E - Usually multiple keys pressed.

Test|Button Test.

KEY RESPONSE

Power 0

Start 1

Cancel 2

Review 3

Auto 4

Silence 5

Down 6

Up 7

Select Alarm 8

Volume 9

Feed F

Print P

Invalid response E

Press each button and ensure that the computer acknowl-

3. Press Close button to exit from dialog box.

7

Page 21

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.5Print Quality

1. Connect the WELCH ALLYN VITAL SIGNS MONITOR unit to the manual test station.

Hook up the pressure lines to the coiled tubing of the monitor and the RS 232/Service

port connector to the computer. Start the computer program by double clicking on its

program icon.

2. Choose

of large and small ASCII characters. Verify the quality of the printer output. Once test

1 is complete, choose “test pattern 2.” The printer will print out a solid gray field. Verify

the quality of the printer output.

Note : This option will only work when the printer option is installed.

Test|Print Quality.

Choose “test pattern 1.” The printer will print out a pattern

9

Page 22

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.6 Pneumatics T ests

1. Connect the WELCH ALLYN VITAL SIGNS MONITOR unit to the manual test station.

Hook up the pressure lines to the coiled tubing of the monitor and the RS 232/Service

port connector to the computer. Start the computer program by double clicking on its

program icon.

2. Place unit into the “detailed test” mode. Do this by holding down the start and cancel

buttons as the unit is powered up. Clamp off the 500cc and 250cc volumes, leaving

the 100cc volume connected to the unit. Press the “review button” until “CAL” appears.

Press the Start button to close the units valve. Using the hand bulb inflate the unit to

the first test pressure, 250mmHg +/- 5mmHg (245 to 255 mmHg), and wait 15 seconds to stabilize.

3. Select

perform the first leak test. The test lasts 15 seconds. Once the test is complete the

pressure change is displayed in the “Pressure” box. Verify that the leak rate meets the

specification called out in the Repair Test Specification document.

Press the Cancel button to open the unit valve and release the pressure.

Note : The software will verify that the pressure is 250mmHg +/- 5mmHg, before it will

begin a leak test.

4. Open the valve on the bulb and release pressure to the second test pressure,

50mmHg +/- 5mmHg (45 to 55 mmHg), and wait 15 seconds to stabilize.

Press the Test button to perform the second leak test. The test lasts 15 seconds.

Once the test is complete the pressure change is displayed in the “Pressure” box.

Verify that the leak rate meets the specification called out in the Repair Test Specification document.

5. Press the Cancel button to open the unit valve and release the pressure.

Note : The software will verify that the pressure is 50mmHg +/- 5mmHg, before it will

begin a leak test.

Test|Pneumatic,

and then the “Leak Test” option. Press the Test button to

6. Power down the unit and power the unit back up allowing it to boot up into its normal

mode.

11

Page 23

Section 5: Test Procedures

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

7. Remove the clamp from the 250cc volume and place it on the 100cc volume. Select

the “Inflation Test” option, and press the Test button. The unit will perform an inflation

test. The inflation time is displayed in the “Timer” box. Verify that the inflation time

meets the specification called out in the Repair Test Specification document.

8. Remove the clamp from the 500cc volume and place it on the 250cc volume. Select

the “Dump Test” option, and press the Test button. The unit will perform a dump test.

The dump time is displayed in the “Timer” box. Verify that the dump time meets the

specification called out in the Repair Test Specification document.

9. Disconnect the test equipment pneumatic hose from the unit. Connect the large cuff

with coiled tubing to the unit’s manifold. Wrap the large cuff around the 500cc volume,

insuring that the white line, that runs along the end of the cuff, lines up with the “N” in

the word “RANGE.” Select the Deflation Test option, and press the “TEST” button. The

unit will do a normal blood pressure cycle and then display the step pressures in the

“Valve Step Array Data” box. Verify that the step array data meets the specifications

called out in the Repair Test Specification document.

Click on Close when all tests have been completed.

12

Page 24

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.7 Hardware Fail-safe

1. Connect the WELCH ALLYN MONITOR unit to the manual test station. Hook up the

pressure lines to the coiled tubing of the monitor and the RS 232/Service port connector to the computer. Start the computer program by double clicking on its program

icon.

2. Place the unit into the “Detailed Test” mode. Do this by holding the “start” and “cancel”

button as the unit is powered up. Press the review button until “CAL” appears in the

systolic window.

3. Select the

4. Select the “Over Pressure” test, remove the cuff from the unit and attach the test

station’s Pneumatic tubing to the unit. Press the Test button. Using the hand bulb,

slowly increase the pressure, while observing the external pressure meter. The unit

will return the hardware failsafe condition, E10. At this point, record the highest pressure observed on the external pressure meter. Verify that the over pressure value

meets the specification called out in the Repair Test Specification document.

5. Press the Review button until ‘LFE’ appears in the systolic window.

6. Press the ‘start’ button and allow the VSM unit to test the over 15mmHg fail safe (test

1) and the repeat cycle test (test 2).

7. If no errors appear in the systolic window during the duration of the tests, and the unit

goes into the “normal” life cycle tests, then the 15mmHg/repeat cycle tests are successful.

8. Press the cancel button to stop the ‘life test.’ Press review until the software version is

seen on the display. Turn unit ‘off’ then back ‘on’ into the normal mode.

Test|Hardware Fail-safe

menu item.

13

Page 25

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

5.8 SpO2 Tests

Section 5: Test Procedures

5.8.1 Nonin SpO

1. Connect the Nonin SpO2 simulator to the unit with the test cable. The reading of

the SpO2 should be within the specified range indicated on the simulator.

2. Reconnect the SpO2 sensor. Place the sensor onto your finger. The unit should

return a reading if the sensor is OK.

5.8.2 Nellcor SpO

1. Connect the Nellcor SpO2 simulator to the unit with the test cable. Make sure

that the following settings* of the simulator are selected:

Insure that the readings of the SpO2 are within the specifications indicated on

the simulator.

2

2

Rate: 112

Light: High 1

Modulation: High

RCAL Mode: RCAL63/Local

2. Reconnect the SpO2 sensor. Place sensor onto your finger. The unit should

return a reading if the sensor is OK.

*Note: On the Nellcor Simulator, if the settings are outside what is called out

above, the alarms will activate on the monitor.

15

Page 26

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.9 T emperature Tests

1. Disconnect the temperature probe from the unit leaving the probe itself in its housing.

Place the “CAL key” into the connector. Remove the probe from the housing. The

temperature should read the same as what is specified on the "cal" key. Remove the

“cal” key and reconnect the probe. Place probe back into the housing.

2. Make sure that the unit’s temperature option is in the “monitor mode”. Do this by

removing the probe from the housing and observing the temperature display. “Monitor

mode” should be seen in the lower right hand side of the display. If this is not seen,

wait approximately 60 seconds and the unit will change mode to the “monitor mode.”

3. Set up the Diatek 9600 calibrator. Set the calibrator to 96.4 F (35.8 C) or use a water

bath between 84 F (28.8 C) and 106 F (41.1 C). Allow the calibrator to stabilize for

three (3) minutes. Place the probe into the small hole in the calibrator. Observe the

temperature display, The reading should be within the specified range, within 30 - 45

seconds.

4. Place the probe back into the housing. Set the calibrator to 106 F (41.1 C). Allow the

calibrator to stabilize for three minutes. Remove the probe from the housing, the unit

must be in the monitor mode, if not wait until the unit is in that mode. Place probe into

the small hole at the top of the calibrator. The reading should be within the specified

range, within 60 seconds. If using a water bath skip this part of the test.

17

Page 27

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

Section 5: Test Procedures

5.10 Nurse Call Testing

1. Power the unit ‘on.’

2. Using a Ohm meter, place the probes onto pin 7 and pin 8 of the RS232 connector.

3. Ensure that the Ohm meter reads infinite resistance (open circuit).

4. Create an alarm condition E11 by pinching off the pneumatic tube approximately 1

inch from the pneumatic port and pressing the start button.

5. Observe the Ohm meter, the meter should read 0.0 Ohms (short circuit).

6. Press the cancel button to stop the alarm.

7. Observe the Ohm meter again. The meter should again read infinite resistance (open

circuit).

19

Page 28

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

VSM Failure Tracking Sheet

Section 5: Test Procedures

fm2004X.doc VSM Repair Form

Issue date: 5/18/99

21

Page 29

Section 5: Test Procedures

Welch Allyn Vital Signs Monitor Service Manual

Revision 1.0

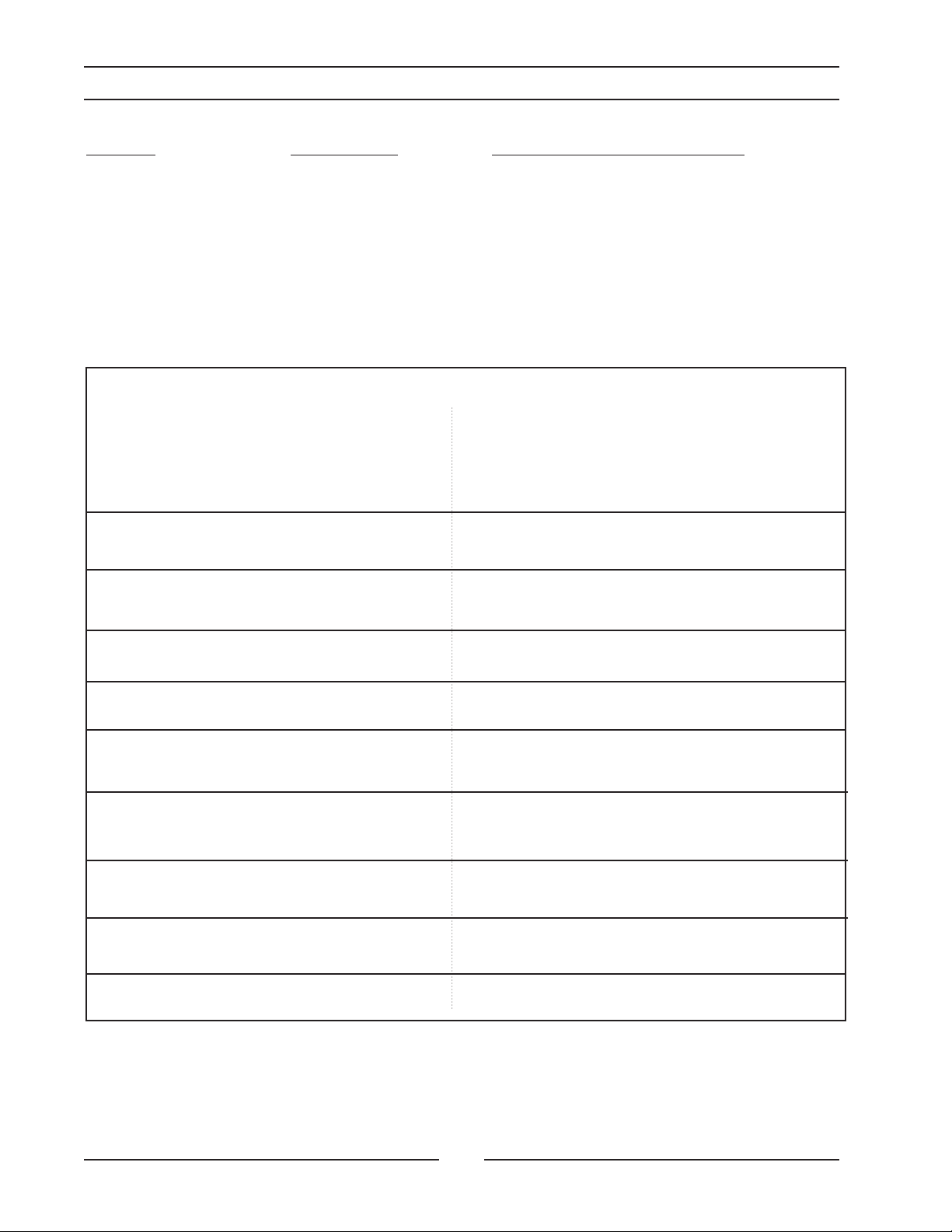

Test Information: Acceptable Ranges

Unit software version _____________________ (>5.0)

Temperature s/w ver. (If available) _____________________ (>21)

SpO2 software version (if available)

(Nonin:>7; Nellcor:>1.2.0.0)

Test pressure @ 0 mmHg _____________________ (-0.3 to 0.3mmHg)

Primary pressure @ 0 mmHg _____________________ (-0.75 to 0.75mmHg)

Safety pressure @ 0 mmHg _____________________ (±1mmHg)

Test pressure @ 50 mmHg _____________________ (45 to 55mmHg)

Primary pressure @ 50 mmHg _____________________ (±1.5mmHg)

Safety pressure @ 50 mmHg _____________________ (±1.5mmHg)

Test pressure @ 150 mmHg _____________________ (145 to 155mmHg)

Primary pressure @ 150 mmHg _____________________ (±1.5mmHg)

Safety pressure @ 150 mmHg _____________________ (±4.5mmHg)

Test pressure @ 250 mmHg _____________________ (245 to 255mmHg)

Primary pressure @ 250 mmHg _____________________ (±1.5mmHg)

Safety pressure @ 250 mmHg _____________________ (±7.5mmHg)

Testvoltage 5.5 Vdc _____________________ (5.5 to 6.0 Vdc)

Unit voltage 5.5 Vdc _____________________ (±0.05Vdc)

Blank mode current _____________________ (≤80mA)

Idle mode current _____________________ (≤800mA)

Pump current _____________________ (≤600mA)

SpO2 current (if available)

l Nonin

______

l Nellcor

______

(Nonin:≤80mA; Nellcor:≤120mA)

Temperature current (if available) _____________________ (≤15mA)

Noise level _____________________ (≤0.05mmHg)

Button test _____________________ (Pass/Fail)

Print quality (if available) _____________________ (Pass/Fail)

Unit leak @ 250 mmHg(245/255 mmHg)

Unit leak @ 50 mmHg (45/55 mmHg)

_____________________ (≤5mmHg)

_____________________ (≤5mmHg)

Inflation Time _____________________ (≤7 seconds)

Dump time _____________________ (≤10 seconds)

Deflation Test _____________________ (Pass/Fail)

Over pressure value _____________________ (296 to 329mmHg)

Over 15mm Hg _____________________ (Pass/Fail)

Under 15mm Hg _____________________ (Pass/Fail)

SpO2 sim. reading (if available)

(Nonin:98%,80BPM; Nellcor:81%,112BPM)

SpO2 sensor reading (if available) (Pass/Fail)

Temp. “Cal-key” read (if available) _____________________ (97.3±0.2˚F, 36.3±0.1˚C)

Temp. calibrator read (if available) _____________________

Temp. calibrator read (if available) _____________________

(96.1˚F to 96.7˚F) (35.6˚C to 36.0˚C)

(105.7˚F to 106.3˚F) (40.9˚C to 41.3˚C)

For test data specifications consult the Repair Test Specification Document.

22

Loading...

Loading...