Welch Allyn Vital Signs 52000 Service manual

Service Manual

This manual covers the Enhanced Vital Signs Monitor introduced

in June 1999. The Enchanced VSM is easily detected by a dark

blue "Silence" button on the front panel instead of a grey button.

Vital Signs Monitor

(52000 Series)

Protocol QuikSigns

(52000 Series)

95P445E Rev. C Copyright 1999

Welch Allyn, Inc.

4341 State Street Road

P.O. Box 220

Skaneateles Falls, NY 13153-0220

Revision Information

Revision History

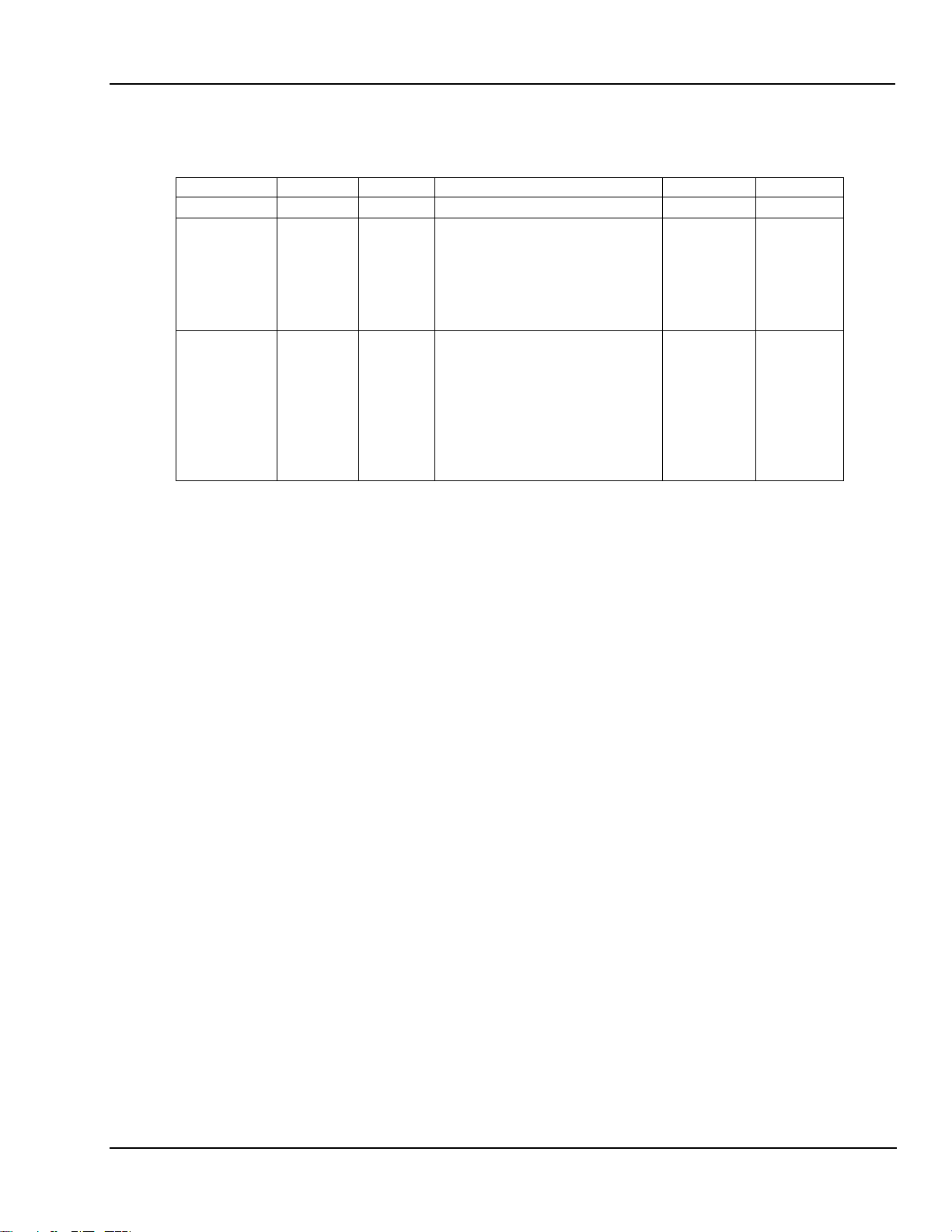

Date ECN# Revision Description Originator Approval

06/10/1999 A Introduction of Service Manual JDB JDB

10/06/03 5-46657 B Correction made to

temperature accuracy, part

numbers, error codes and

updates to the drawings.

Revised to meet Service

Manual Work Instructions.

12/12/03 5-46990 C Revised service and support

details in Section 1 and

Appendix E. Re-formatted

units of measurement to meet

NIST Standards. Corrected

grammar and punctuation.

Added page numbering to

blank pages.

JDB, DLK DLK

DLK RJS

Drawings and/or illustrations and/or part numbers in this document are for reference only. For the most current revision call the Welch Allyn Customer Service

phone number listed in Section 1.

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor i

ii Welch Allyn Vital Signs Monitor Service Manual 95P445E Rev. C

Table Of Contents

Section 1: General Information

To Service Personnel...................................................................................................... 1

Intent of Manual and Product Scope ............................................................................. 1

Limited Warranty.......................................................................................................... 2

Owner Maintenance...................................................................................................... 2

Warranty, Service, and Spare Parts................................................................................ 2

Periodic Calibration Requirements ................................................................................ 3

Incoming Inspection ...................................................................................................... 4

Introduction .................................................................................................................. 5

Basic System Operation ................................................................................................. 5

Specifications............................................................................................................... 10

Mechanical Specifications............................................................................................ 12

Electrical Specifications ............................................................................................... 13

Environmental Specifications....................................................................................... 13

Identification Label and Serial Numbering System Defined ......................................... 14

Firmware Identification ............................................................................................... 14

Section 2: Calibration/Service

Tools required for Service............................................................................................ 15

Test Equipment Bench Layout..................................................................................... 16

Voltage Calibration ..................................................................................................... 17

Pressure Calibration .................................................................................................... 17

Loading Unit Software................................................................................................. 18

Section 3: Troubleshooting

Diagnostic Procedure for Returned Units..................................................................... 19

Battery Voltage Check................................................................................................. 19

LED Functional Check ................................................................................................ 19

BP Functional Check ................................................................................................... 19

Printer Functional Check............................................................................................. 20

Functional Check ............................................................................................... 20

SpO

2

Temperature Functional Check.................................................................................... 20

Communication Functional Check .............................................................................. 20

Calibration Tests ......................................................................................................... 21

Current Tests............................................................................................................... 22

Noise Levels ................................................................................................................ 22

Button Test.................................................................................................................. 22

Print Quality............................................................................................................... 23

Pneumatic Tests........................................................................................................... 23

Fail Safe Testing .......................................................................................................... 24

SpO

Tests................................................................................................................... 25

2

Temperature Tests....................................................................................................... 26

Nurse Call Testing....................................................................................................... 26

Self Diagnostic Fault Codes ......................................................................................... 27

Main Board/Blood Pressure Error Codes ..................................................................... 27

Error Codes........................................................................................................ 27

SpO

2

Service Manual 95P 445E R ev. C Welch Allyn Vital Signs Monitor iii

Table Of Contents

Temperature Error Codes............................................................................................ 28

Temperature Error Code Correction............................................................................ 28

Complaint / Cause / Corrective Action ........................................................................ 29

Section 4 Disassembly/Assembly

Front Housing ............................................................................................................. 33

Main PCB.................................................................................................................... 34

DC to DC Converter (SpO2 Units Only)...................................................................... 36

Pressure Transducers on Main PCB ............................................................................. 38

Display PCB Removal.................................................................................................. 40

Key Pad (Switch Array) ............................................................................................... 42

Temperature PCB ........................................................................................................ 44

Specific Oxygen Board (Nonin SpO2 PCB).................................................................. 46

Specific Oxygen Board (Nellcor SpO2 PCB - MP205 or MP506)................................. 48

Pump/Motor Assembly................................................................................................ 50

Valve (Pneutronics)...................................................................................................... 52

Printer/Printer PCB/Keypad ......................................................................................... 54

Battery Placement........................................................................................................ 56

Appendix A: Repair Parts List

Repair Parts List........................................................................................................... 57

Appendix B: Product Structure/Accessories

Product Structure/Accessories ....................................................................................... 63

Appendix C: Assembly Drawings/Board layout

Assembly Drawings/Board Layout................................................................................ 69

Appendix D: Repair Test Specifications

Repair Tests Specifications ........................................................................................... 75

Unit Manometer Calibration ....................................................................................... 76

Manometer Accuracy Test........................................................................................... 76

Deflation Test.............................................................................................................. 77

Voltage Testing............................................................................................................ 77

Unit Current Tests....................................................................................................... 77

Noise Tes..................................................................................................................... 77

Hardware Fail-safe Tests ............................................................................................. 77

Tests................................................................................................................... 78

SpO

2

Temperature Option Testing ....................................................................................... 79

Printer Option Testing................................................................................................. 79

RS232 Testing ............................................................................................................. 79

RS423 Testing (Acuity Monitors)................................................................................ 79

Appendix E: Check List For Service Work

Check List for Service Work ......................................................................................... 83

iv Welch Allyn Vital Signs Monitor Service Manual 95P445E Rev. C

List of Tables and Figures

List Of Tables

Table 2-1. Tools required for calibration and repair of the Vital Signs Monitor. ......... 15

Table 3-1. Button press response table.......................................................................... 25

Table 3-2. Main board/blood pressure error code table............................................... 29

Table 3-3. SpO

Table 3-4. Temperature error code table. .................................................................... 28

Table 3-5. General Guide to Problems and Corrective Actions. ................................... 29

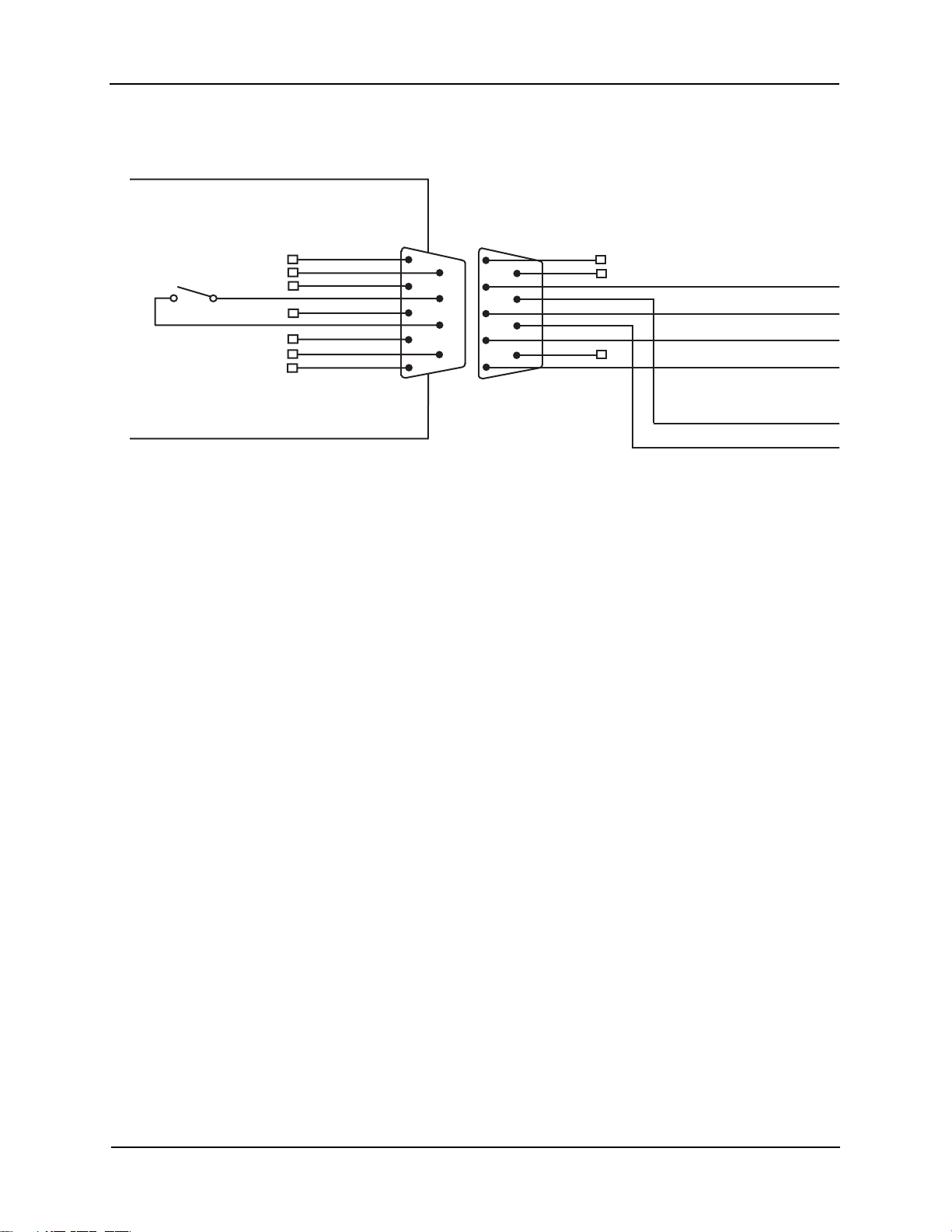

Figure 1-1. Nurse call interface diagram...................................................................... 10

Figure 1-2. Serial number label.................................................................................... 14

Figure 2-1. Bench layout for re-calibration and testing of the Vital Signs Monitor. ..... 16

Figure 4-1. DC to DC replacement. ............................................................................. 37

Figure 4-2. Pressure transducer replacement............................................................... . 39

Figure 4-3. RTV removal from NONIN SpO

Figure 4-4. SpO2 jack, wire side .................................................................................. 47

Figure 4-5. Bottom view of valve (Pneutronics). .......................................................... 53

error code table................................................................................. 27

2

List Of Figures

PCB..................................................... 47

2

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor v

vi Welch Allyn Vital Signs Monitor Service Manual 95P445E Rev. C

General Information Section 1

To Service Personnel

Read and understand the Vital Signs Monitor Operator's Manual and this service manual.

The information contained in these publications are subject to change without notice and

should not be construed as a commitment by Welch Allyn, Inc.

Welch Allyn assumes no responsibility for any errors that may appear in this manual. If the

product and/or its operation varies significantly from any description herein, please contact

the following:

Welch Allyn, Inc.

1-800-535-6663

315-685-4100

Fax (315)-685-3361

Welch Allyn, Inc.

4341 State Street Road

Skaneateles Falls, NY 13153

This product has been designed to provide a high degree of safety and reliability. However,

we can not guarantee against: deterioration of components due to aging, normal wear,

tampering, and abuse.

Only Authorized Welch Allyn personnel or agents must perform all service and repairs,

using approved Welch Allyn replacement parts and approved process materials. Failure to

follow these guidelines will invalidate the product warranty. Please refer to the product

warranty for specific coverage.

Intent of Manual and Product Scope

This manual provides technical service and re-calibration information to technicians

authorized to repair and re calibrate Welch Allyn, Inc. products. When used in conjunction

with the required test equipment and tools, technicians will be able to diagnose, repair, and

re-calibrate, and test the Vital Signs Monitor.

The manual includes: Re-calibration instructions, fault/cause analysis, step-by-step

disassembly and re-assembly procedures, repair, adjustment, and re-test procedures.

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 1

Section 1 General Information

Limited Warranty

Welch Allyn, Inc. warrants the Vital Signs Monitor, when new, to be free of defects in

material and workmanship and to perform in accordance with manufacturer's

specifications for a period of two years from the date of purchase from Welch Allyn, Inc.

or its authorized distributors or agents. Accessories (battery, cuff, tubing, temperature

probe, SpO2 sensor and transformer) carry a one-year warranty. Welch Allyn, Inc. will

either repair or replace any components found to be defective or at variance from

manufacturer's specifications within this time at no cost to the customer. It shall be the

purchaser's responsibility to return the instrument to Welch Allyn, Inc. or an authorized

distributor, agent or service representative. This warranty does not include breakage or

failure due to tampering, misuse, neglect, accidents, modification or shipping. This

warranty is also void if the instrument is not used in accordance with manufacturer's

recommendations or if repaired by other than Welch Allyn, Inc. or an authorized agent.

Purchase date determines warranty requirements. No other express warranty is given.

To receive service assistance or to ask questions regarding this warranty, please call your

nearest Welch Allyn Technical Support Center.

Owner Maintenance

Owner Maintenance: Non-Technical customers can perform normal maintenance per the

instructions provided in the Operator's Manual. End users will be able to perform basic

operations such as replacement of: hoses, cuffs, probes, and batteries. On this level the unit

will not be opened (except for the battery housing). Opening of the Vital Signs Monitor by

untrained individuals will damage the unit and void the warranty.

Warranty, Service, and Spare Parts

Warranty Service

All repairs on products under warranty must be performed or approved by Welch Allyn.

Unauthorized repairs will void the warranty. In addition, whether or not covered under

warranty, any product repair shall exclusively be performed by Welch Allyn trained and

certified service personnel.

Assistance and Parts

If the product fails to function properly or if assistance, service, or spare parts are required,

contact the nearest Welch Allyn Technical Support Center.

USA 1-800-535-6663 Latin America (+1) 305-669-9591

European Call Center (+353) 469-067-790 United Kingdom 0-207-365-6780

France (+33) 1-60-09-33-66 Germany (+49) 7477-927-173

Canada 1-800-561-8797 South Africa (+27) 11-777-7509

2 Welch Allyn Vital Signs Monitor Monitor Service Manual 95P445E Rev. C

General Information Section 1

Australia (+61) 2-9638-3000 Singapore (+65) 6291-0882

Japan (+81) 3-5212-7391 China (+86) 21-6327-9631

Before contacting Welch Allyn it is helpful to attempt to duplicate the problem and to

check all accessories to ensure that they are not the cause of the problem.

When calling, please be prepared to provide:

• The product name, model number and complete description of the problem

• The serial number of your product (if applicable)

• The complete name, address and phone number of your facility

• For out-of-warranty repairs or spare parts orders, a purchase order (or credit card)

number

• The required spare or replacement part number(s), for parts order

Repairs

If your product requires warranty, extended warranty, or non-warranty repair service,

please call first the nearest Welch Allyn Technical Support Center. A representative will

assist you in troubleshooting the problem and will make every effort to solve the problem

over the phone, avoiding potential unnecessary return.

In case the return cannot be avoided, the representative will record all necessary

information and will provide a Return Material Authorization (RMA) number, as well as

the appropriate return address.

A Return Material Authorization (RMA) number must be obtained prior to any return. Be

sure to note this number on the outside of your shipping box.

Packing Instructions

• If you have to return goods for service, follow these recommended packing instructions:

• Remove all hoses, cables, sensors, power cords, and ancillary products (as appropriate)

before packing, unless you suspect they are associated with the problem.

• Wherever possible use the original shipping carton and packing materials.

• Include a packing list and the Welch Allyn Return Material Authorization (RMA)

number.

• Be sure to note the (RMA) number on the outside of your shipping box.

It is recommended that all returned goods be insured. Claims for loss or damage to the

product must be initiated by the sender.

Periodic Calibration Requirements

Welch Allyn, Inc. recommends that the calibration of the Vital Signs Monitor be checked

on a yearly basis for BP, Temperature and SpO2 (if applicable).

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 3

Section 1 General Information

Incoming Inspection

NOTE: Use the following guidelines when unpacking the Vital Signs Monitor from its

shipping carton.

1. Before opening the Vital Signs Monitor shipping carton, check for damage.

2. If damage is apparent, stop unpacking the carton and contact the shipping company for

further instructions. If the carton is intact, unpack the Vital Signs Monitor.

3. With the Vital Signs Monitor out of its carton, check to see that all the items listed on

the packing slip are included.

4. If an item is missing, first check the carton, then check with your receiving department.

If necessary contact your nearest Welch Allyn representative.

5. Clean and disinfect by following the instructions printed in the Operator’s Manual.

Note: Perform all functional tests as listed in Section 3 before and after servicing. Operate

the Vital Signs Monitor to verify the customer complaint before making any changes to the

unit. Call the customer if the complaint is unclear.

If the unit has caused or is suspected of having caused an injury of any type: DO NOT

DISASSEMBLE OR REPAIR THE UNIT IN ANY WAY. Contact your nearest Welch

Allyn Customer Support Center immediately.

4 Welch Allyn Vital Signs Monitor Monitor Service Manual 95P445E Rev. C

General Information Section 1

Introduction

The Welch Allyn Vital Signs Monitor, also marketed as QuickSigns, is designed to noninvasively and automatically measure systolic and diastolic pressure, pulse rate,

temperature and oxygen saturation (SpO2) for adult and pediatric patients. THE WELCH

ALLYN VITAL SIGNS MONITOR IS NOT TO BE USED ON NEONATAL PATIENTS.

All blood pressure, pulse, temperature and SpO2 values can be viewed on a large, easy-to-

read display, and may be printed via the integrated printer as desired.

The rechargeable lead acid battery and variety of mounting accessories make the Welch

Allyn Vital Signs Monitor convenient for many locations. The operator may choose any

combination of simultaneous measurement modalities. This flexibility, combined with

features such as programmable alarms and automatic BP cycles, makes the Welch Allyn

Vital Signs Monitor ideal for a wide variety of patient monitoring needs.

Refer to the Welch Allyn Vital Signs Monitor Operator’s Manual for complete information

on Indications For Use, Special Features, Supplies and Accessories.

Basic System Operation

Blood Pressure Operating Modes

When a blood pressure measurement cycle is initiated, the cuff will automatically inflate to

the default pressure level.

The cuff will immediately begin to deflate in a stepped fashion and will determine systolic

pressure and diastolic pressure from the pulses sensed by the cuff at various pressure levels.

This is the oscillometric method of non-invasive blood pressure monitoring.

Blood pressure measurements may be initiated manually, or automatically at time intervals

determined by the user.

At the completion of a measurement cycle the systolic and diastolic pressures are displayed.

If the Monitor is in Automatic Mode, the measured values are kept on display until the

next BP measurement is initiated. When not in Automatic Mode, the measured values are

displayed for two minutes, after which time the display screen is blanked. The most recent

BP measurement may be recalled by pressing the REVIEW button.

When in Automatic Mode, if the unit is unable to determine the systolic or diastolic value,

the measurement will be automatically repeated once.

Blood Pressure Manual Mode

In the Manual Mode, a single blood pressure determination is made only when the START

button is pushed. The manual mode is the default mode of operation for blood pressure

determinations.

A measurement cycle may be cancelled at any time by pressing the CANCEL button. This

action immediately initiates a rapid cuff deflation.

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 5

Section 1 General Information

The blood pressure measurement data will appear on the display immediately following

the measurement. The display will blank after two minutes. If the display is blank, pressing

the REVIEW button on the front panel will recall the measurement. Up to 99 prior

measurements are available for review or printing.

In Blood Pressure Manual Mode, the following alarm limits may be activated; SYSTOLIC

HIGH LIMIT, SYSTOLIC LOW LIMIT, DIASTOLIC HIGH LIMIT, DIASTOLIC LOW

LIMIT, PULSE RATE HIGH LIMIT and PULSE RATE LOW LIMIT. Blood pressure

determinations, which activate alarms, are indicated by flashing displays and a repetitive

audible tone. If an alarm limit is violated, subsequent blood pressure determinations may

be made only after the alarm condition is reset by pressing any button on the Monitor's

display.

Blood Pressure Automatic Mode

The Automatic Blood Pressure Mode is entered by pressing the AUTO button. Pressing the

AUTO button displays a choice of 11 cycle interval times as follows: "St" (STAT mode), 1

minute, 3 minutes, 4 minutes, 5 minutes, 10 minutes, 15 minutes, 30 minutes, 45 minutes,

60 minutes and 90 minutes. These choices represent the time interval from the beginning of

one cycle to the beginning of the next automatic cycle. STAT mode allows the monitor to

take continuous blood pressure measurements for 15 minutes. In addition, the operator

may choose to disable the Auto Mode by choosing “--” (two dashes).

Note: In the 1-minute automatic cycle mode, the Welch Allyn Vital Signs Monitor will

automatically take blood pressure measurements in 1-minute intervals for up to 15

minutes.

A measurement cycle may be cancelled at any time by pressing the CANCEL button. This

action immediately initiates a rapid cuff deflation.

The blood pressure measurement data will appear on the display immediately following

the measurement and will remain displayed until the next measurement cycle is initiated.

In Blood Pressure Auto Mode, the following alarm limits may be activated; SYSTOLIC

HIGH LIMIT, SYSTOLIC LOW LIMIT, DIASTOLIC HIGH LIMIT, DIASTOLIC LOW

LIMIT, PULSE RATE HIGH LIMIT and PULSE RATE LOW LIMIT. Blood pressure

determinations, which activate alarms, are indicated by flashing displays and a repetitive

audible tone. Any alarm limit violation must be reset to continue automatically timed

blood pressure determinations. The alarm may be reset by pressing any button on the

Monitor's display.

Temperature Operating Modes

Thermometry measurements are made with the integrated Welch Allyn SureTempTM

thermometer. Oral and rectal probes utilize single-use disposable probe covers which limit

cross-contamination. Oral, axillary or rectal temperatures are taken using Normal or

Monitor operating modes. Axillary temperatures are taken using the oral probe.

6 Welch Allyn Vital Signs Monitor Monitor Service Manual 95P445E Rev. C

General Information Section 1

In Normal mode the thermometer's microprocessor "predicts" body temperature in about

4 seconds for oral temperatures, about 10 seconds for axillary temperatures and in about

15 seconds for rectal temperatures. The Monitor mode displays the patient's actual

temperature after 3 minutes for oral/rectal mode and 5 minutes for axillary mode, and will

continue to display an updated temperature as long as the probe remains in place.

Note: Normal mode axillary temperatures (10 seconds) are accurate only for children

under the age of four.

Note: The Welch Allyn Vital Signs Monitor is not intended to be used on Neonatal

patients.

Temperature readings may be displayed in Fahrenheit or Celsius scales.

Temperature Normal Mode

In Normal mode, the device will measure temperature at discrete intervals and then

calculate the rate of change according to a proven algorithm. This allows the thermometer

to predict the end point that the thermistor would reach if it were left in the mouth until it

reached mouth temperature. This predictive feature allows the thermometer to arrive at an

accurate oral temperature reading in approximately 4 seconds.

Normal mode is the default operating mode for temperature determinations.

Operator selectable patient alarm limits are not available in temperature Normal mode.

However, temperatures which are outside of the operating range of the device will be noted

on the temperature display.

Temperature Monitor Mode

Continuous Monitor mode operation is normally used for longer term monitoring and

when difficult situations prevent accurate temperatures from being taken in the Normal

mode. The probe must be in contact with tissue for at least three (3) minutes for accurate

oral/rectal temperature measurement and five (5) minutes for accurate axillary temperature

measurement. Monitor mode temperatures may not be identical to predicted 'Normal'

temperatures because of ambient temperature influence and other factors. The trend in

temperature is the important standard to be observed when in the Monitor mode.

Operator selectable patient alarm limits are not available in temperature Monitor mode.

However, temperatures which are outside of the normal operating range of the device will

be noted on the temperature display.

Operating Mode

SpO

2

The Welch Allyn Vital Signs Monitor incorporates the Nellcor Puritan BennettTM pulse

oximetry module which determines arterial oxyhemoglobin saturation (SpO

%) by

2

measuring the absorption of red and infrared light passed through the tissues. Changes in

absorption caused by pulsation of blood in the vascular bed are used to determine arterial

saturation and pulse rate.

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 7

Section 1 General Information

Oxygen saturation percent is calculated with each pulse detected, and thus the monitor

display is continually updated. The pulse signal bar graph is an indicator of the strength

and quality of the detected pulses.

When SpO2 is measured, the patient's pulse rate is also measured and displayed. A pulse

rate measurement from the SpO2 determination overrides a pulse rate measurement

derived from a blood pressure measurement.

When measuring SpO

the user may enable the SpO2 Pulse Tone feature. A short audible

2

tone is emitted with every patient heartbeat. The frequency of the tone is based on the

patient’s SpO2 level. The lower the frequency of the tone, the lower the patients SpO2 level.

In SpO

activated. A condition which violates the SpO

display and repetitive audible tone. Should a patient alarm condition for SpO

monitoring mode, operator selectable alarm limits for low SpO2% may be

2

low limit alarm is indicated by a flashing

2

or pulse rate

2

occur, the Monitor will indicate an alarm condition (flashing & beeping) while continuing

to monitor and display the patient's current SpO2%. The alarm will automatically reset

when the patient's condition returns to within the preset alarm parameters.

Should a patient alarm condition for SpO2 or pulse rate occur, the operator may invoke

"Silence Mode" by pressing the SILENCE button. This will silence the audible tone

(display will continue to flash), while the practitioner attends to the patient and the

monitor. Silence mode resets automatically after 30 seconds, or when the patient's

condition returns to within the preset alarm parameters.

Removal of the SpO2 sensor from the patient will initiate an alarm, unless the SpO2 and

pulse rate alarms are turned off. To reset the sensor alarm, press any button on the

Monitor's display.

is generally measured via pulses detected using a finger sensor. However, for certain

SpO

2

situations SpO2 may be measured at alternate sites including the earlobe, forehead and

toes. Special sensors must be employed in these situations.

SpO

Monitor Mode

2

The SpO

monitor performs most accurately with the fingerclip sensor, which may be used

2

on all fingers except the thumb. The finger clip sensor is recommended for spot checks or

short term continuous monitoring.

The device determines arterial oxyhemoglobin saturation (SpO2%) by measuring the

absorption of red and infrared light passed through the tissue. Oxygen saturation and

pulse rate are displayed on the LED digital display. On each detected pulse, the pulse signal

bar graph flashes. The intensity of this signal is a simple visual indicator of waveform

signal strength, and can identify situations where the pulsatile nature of the tissue may not

be adequate for an accurate SpO

correspond to the patient's pulse rate. This is an indication of the quality of the SpO

reading. The update interval of the bar graph should

2

2

signal.

8 Welch Allyn Vital Signs Monitor Monitor Service Manual 95P445E Rev. C

General Information Section 1

All Welch Allyn Vital Signs Monitors with pulse oximetry capability are equipped with a

pulse tone. This audible tone beeps in synchronization with each beat of the patient’s heart.

In addition, the frequency of the tone will vary based on the patient’s oxygen saturation

value. The higher the tone’s frequency, the higher the patient’s oxygen saturation value.

The user may change the pulse tone volume, or turn this feature off as necessary.

Pulse Rate Feature

The Welch Allyn Vital Signs Monitor is capable of determining pulse rate as an adjunct to

the blood pressure measurement and the SpO2 measurement.

The pulse rate, in beats per minute, will be determined primarily from the SpO2

measurement methodology. In the case where SpO

pulse rate display will be driven by data from the blood pressure measurement method.

There are two operator selectable alarm limits for the pulse rate. They are PULSE RATE

HIGH LIMIT and PULSE RATE LOW LIMIT. Pulse rates which activate alarm limits are

indicated by a flashing display and a repetitive audible tone.

is not available, or is disabled, the

2

Should a pulse rate alarm occur when the pulse rate measurement is derived from the

blood pressure measurement, no subsequent blood pressure or pulse rate measurements

may be made until the alarm is reset. The alarm may be reset by pressing any button on the

Monitor's display. Should a pulse rate alarm occur when the pulse rate measurement is

derived from the SpO

measurement, the monitor will indicate an alarm condition

2

(flashing & beeping) while continuing to monitor and display the patient's current SpO2%

and pulse rate. The alarm will automatically reset when the patient's condition returns to

within the preset alarm parameters.

Should a patient alarm condition for pulse rate occur during SpO2 monitoring, the

operator may invoke "Silence Mode" by pressing the SILENCE button. This will silence

the audible tone (display will continue to flash), while the practitioner attends to the

patient and Monitor. Silence mode resets automatically after 30 seconds, or when the

patient's condition returns to within the preset alarm parameters. If an alarm limit is

violated, subsequent determinations of any type may only be made after the alarm

condition is reset.

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 9

Section 1 General Information

NOTE: See Nurse Call Interface in the Operator’s Manual for complete information on

the Nurse Call interface.

Vital Signs Monitor

1

6

2

7

3

8

4

9

5

RS-232 DB-9

RS-232 Cable

1

6

2

7

3

8

4

9

5

Nurse Call Contacts:

30Vdc@1ampor

240Vac @ 1 amp

TX Data

RX Data

DTR

Ground

Nurse Call Common

Contact Wires Normally Open

Figure 1-1. Nurse call interface diagram.

The Welch Allyn Vital Signs Monitor provides a switch closure output between two pins of

the serial connector (pins 7 and 8). The output is universal in that it is compatible with a

wide variety of different systems with no polarity dependence. The Nurse Call output is

ohmically isolated from all circuitry.

The output is rated for 1 Amp at 240VAC or 30Vdc. During an alarm condition the output

is closed, otherwise the output is open. During a power off or power failure condition the

output is open.

Specifications

The performance specifications of the Vital Signs Monitor are as follows:

Patient Population

The Welch Allyn Vital Signs Monitor is designed for use with adult and pediatric patients.

Welch Allyn defines a pediatric patient as 29 days old and above. THE VITAL SIGNS

MONITOR IS NOT INTENDED FOR USE WITH NEONATES. Welch Allyn defines

neonates as children 28 days or less of age born at term (37 weeks gestation or more):

otherwise, up to 44 gestational weeks.

Cuff Pressure Range

0 mmHg - 300 mmHg

Initial Cuff Inflation

120, 140, 160, 180, 200, 240, 280 mmHg depending on pressure preset level. Pressure

preset default is 160 mmHg.

10 Welch Allyn Vital Signs Monitor Monitor Service Manual 95P445E Rev. C

General Information Section 1

Systolic Range

Maximum: 250 mmHg

Minimum: 60 mmHg

Diastolic Range

Maximum: 160 mmHg

Minimum: 30 mmHg

Blood Pressure Accuracy

Blood pressure accuracy meets or exceeds SP10-1992 AAMI standards for non-invasive

blood pressure accuracy (AAMI standard: ±5 mmHg mean error; 8 mmHg standard

deviation). Blood pressure accuracy is validated for pressure measurement using the upper

arm only, with the patient in a seated position. Blood pressure is validated against manual

auscultatory readings for adults and children above the age of 3. For children under age 3

blood pressures is validated against intraarterial readings. The monitor is not validated for

use with neonates.

Blood Pressure Determination Time

20 seconds to 45 seconds typical, 165 seconds maximum.

Pulse Rate Range (Using SpO2 determination)

Maximum: 200bpm

Minimum: 40bpm

Pulse Rate Accuracy

SpO2 Module Heart Rate (Nellcor Puritan Bennett)±3 bpm

Blood Pressure Algorithm Heart Rate ±5.0%

Overpressure Cutoff

295 mmHg to 330 mmHg

Temperature Ranges

Maximum – 108 °F (42.2 °C)

Minimum – 84.0 °F (28.9 °C)

Temperature Accuracy

Calibration Accuracy: ±0.2 °F (±0.1 °C)

Tempe rat ur e Dete rmination Time

(Oral) 4 seconds typical, 15 seconds maximum

(Axillary) 10 seconds typical

(Rectal) 15 seconds typical

Oxygen Saturation Range (SpO2%)

40-99% oxygen saturation

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 11

Section 1 General Information

SpO2 Accuracy

Nellcor MP205

±3% in the range of 70-100% oxygen saturation (1 Standard Deviation)

<70% unspecified by the OEM.

Nellcor MP506

Without Motion - Adults: 70 to 100% ± 2 digits*

With Motion - Adults: 70 to 100% ± 3 digits**

Low Perfusion: 70 to 100% ± 2 digits***

<70% unspecified by the OEM

Bio compatibility testing has been conducted on Nellcor sensors in compliance with

ISO10993-1, Biological Evaluation of Medical Devices, Part 1: Evaluation and Testing.

The sensors have passed the recommended bio compatibility testing and are therefore in

compliance with ISO 10993-1.

* Adult specifications are shown for OxiMax MAX-A sensors. Saturation accuracy will

vary by sensor type. Refer to the following Sensor Accuracy Grid.

**Applicability: OxiMax MAX-A, MAX-P, and MAX-I sensors.

*** Specification applies to monitor performance and was validated with Biotek and

Nellcor simulators.

Battery Charging (90%-100% capacity in 12 hours).

Unit will operate and charge battery simultaneously when connected to power source.

Mechanical Specifications

Dimensions

Height 6.5 inches (16.5 cm)

Length 8.6 inches (21.8 cm)

Depth 5.0 inches (12.7 cm)

Weight

Approximately 6 pounds (2.8 Kg)

Mounting

Self-supporting on rubber feet

Custom Mobile Stand

Custom Made Wall Mount

Custom IV pole mount

Attaches to bed rail

12 Welch Allyn Vital Signs Monitor Monitor Service Manual 95P445E Rev. C

General Information Section 1

Electrical Specifications

Power Requirements

Patient-Rated isolation transformer is connected to AC mains:

North American Version: 120 Vac, 60 Hz 0.20 A Input Source, 8 Vdc, 0.75 A Output

Source

International Version: 220-240 Vdc, 50-60 Hz 0.20A Input Source, 8 Vdc, 0.75 A Output

Source

Battery (Lead acid, with external charger)

A fully charged battery will support 200"typical" blood pressure determinations taken at 7

minute intervals. Battery is 90%-100% charged after 6-12 hours of charging. The battery

automatically charges when the Vital Signs monitor is powered through the AC power

transformer. The battery will charge faster when the instrument is not in operation.

Environmental Specifications

Operating Temperature

+10 °C to +40 °C (Except temperature 16 °C to 40 °C)

+50 °F to +104 °F

Storage Temperature

-20 °C to +50 °C

-4 °F to +122 °F

Relative Humidity

15% to 90% (non-condensing)

Operating Altitude

-170 m to +4877 m

-557 ft to +16,000 ft

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 13

Section 1 General Information

Identification Label and Serial Numbering System Defined

The identification label for the 52000 Series Vital Signs Monitor is shown below. It is

located on the bottom of the unit.

4341 State Street Road

Skaneateles Falls, NY 13153

Figure 1-2. Serial number label.

The serial number for the device would consist of nine (9) numbers and a bar code. These

would be located in the square below the words "52000 SERIES”. An example of the

number and the explanation is shown below:

200200001

The four digits on the left are the year of manufacture of the device.

The five digits on the right are the sequence of build starting with 00001 annually.

(The example number above would be the first unit built in 2002)

Firmware Identification

To confirm the software levels of the Vital Signs Monitor, place the unit into the

Configuration Test mode by holding down the “Start” button while the unit is being

powered up.

The main software versions will appear as follows:

• The main unit software will appear in the Systolic and Diastolic windows.

• The SpO2 option and temperature option (if installed) will appear in the SpO2 and Tem-

perature displays.

Note: Verify the firmware levels listed in Appendix D.

14 Welch Allyn Vital Signs Monitor Monitor Service Manual 95P445E Rev. C

Service Section 2

Tools required for Service

Table 2-1. Tools required for calibration and repair of the Vital Signs Monitor

DESCRIPTION TOOL # Manufacture

100 cc Test Volume T112819 Welch Allyn (6 week lead time)

250 cc Test Volume T112818 Welch Allyn (6 week lead time)

500 cc Test Volume T112854 Welch Allyn (6 week lead time)

Bulb and valve 5088-01 Welch Allyn

Pneumatic tubing (3 ea.) 5089-12 Welch Allyn

Test Cable (IR) 66P824 Welch Allyn

Test Cable (Service Cable Kit) 130S60 Welch Allyn

Repair software 130S57E Welch Allyn

Welch Allyn 9600 Calibrator 01800-210 Welch Allyn

Welch Allyn calibration key 06137-000 Welch Allyn

Spot Service Manual 4200-145E Welch Allyn

Pneumatic clamps (3) 21730-001 VWR Scientific 800-932-5000

Pliers Tool/Supply Store

Wire cutter Tool/Supply Store

Tweezers Tool/Supply Store

Torque bit (T8) Tool/Supply Store

Phillips screw driver Tool/Supply Store

T10 torx bit Tool/Supply Store

3/8 hex socket Tool/Supply Store

Cable tie tool Tool/Supply Store

Setra pressure meter (0-10 PSIG) 2270-01 Setra 800-257-3872

Netech pressure meter 200-2000IN Netech 800-547-6557

Nellcor patient simulator SRC-2 for MP205 Nellcor 800-635-5267

Nellcor patient simulator SRC-MAX for MP506 Nellcor

Nellcor test cable 8-Dec Nellcor

Digital timer 8456T12 McMaster Car 404-346-7000

"Y" fitting 9586TPK4 Festo 704-527-1427

"T" fitting (3) 9585TPK4 Festo

IBM compatible 486 133 MHz computer or better. The computer must have Windows 95

with a serial port. CPU must have 8 Megabytes of RAM.

2 Digital Multi-Meters. These meters must have 4 1/2 digit displays for accuracy.

Power Supply. 0-20 Vdc adjustable with 0-3A output.

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 15

Section 2 Service

Test Equipment Bench Layout

Figure 2-1 depicts recommended layout of test equipment and special tools required for

service and re-calibration of the Vital Signs Monitor.

500CC

Cylinder

3" tubing

DMM

Voltage

250 CC

Cylinder

Power

Supply

100CC

Cylinder

Digital Manometer

Setra Meter

or

Netech Meter

4"tubing

10" tubing to

the Vital

Signs Monitor

DMM

Current

2" tubing

15" tubing

3" tubing

to bulb and valve

-

Connect to - Power

of the Vital Signs Monitor

+++

--

-

+

Connect to + Power

of the Vital Signs Monitor

Vital Signs Monitor

Nelcor

Patient

Simulator

SRC-2 or

SRC-Max

Welch

Allyn

9600

Calibrator

PC, IBM

486

133 MHz.

Windows

95

Figure 2-1. Bench layout for re-calibration and testing of the Vital Signs Monitor.

16 Welch Allyn Vital Signs Monitor Service Manual 95P445E Rev. C

Service Section 2

Voltage Calibration

1. Connect the unit to the test station by hooking up the pneumatic tubing. Connect the

cable from the PC. Remove the battery and connect the power supply.

2. Place the unit into the "detailed test mode" by holding down the “Start” and “Cancel”

button while powering up the unit. Allow the software versions to be displayed then press

the review button until the unit displays "BAT" in the Systolic window.

3. Go to the repair software and select “Calibrate|Voltage”.

4. Adjust the power supply to 5.6 Vdc (+0.3 / -0.0 Vdc).

5. View the digital multi-meter (DMM) that is connected to the power supply. Read the

voltage. Move the cursor to the "Calibrated Voltage" box and type in the voltage that you

observe on the DMM. In the software, select "Update."

6. The software will then prompt you to enter a "Calibration Signature." Move the cursor

to the box and enter the three initials of your name or three letters of your facility. Select

"OK."

7. At this point, you should see the voltage on the display of the unit change to match that

of the DMM.

8. Re-adjust the power supply to 6.5 Vdc "0.25 Vdc.

Pressure Calibration

1. Connect the unit to the test station by hooking up the pneumatic tubing. Connect the

cable from the PC. Remove the battery and connect the power supply.

2. Place the unit into the "detailed test mode" by holding down the “Start” and “Cancel”

buttons while powering up the unit. After the software versions is displayed, press the

“Review” button until the unit displays "CAL" in the LCD window.

3. Go to the repair software and select “Calibrate|Manometer”.

4. Select the "calibrate" button to begin the calibration procedure.

5. The software will perform an auto-zero. If this is unsuccessful, the user will be prompted

to perform a zero potentiometer calibration. This is an automatic calibration. The user just

needs to answer YES or NO. A NO will cancel the calibration procedure.

6. Once the auto-zero is completed successfully, the "Gain Calibration @ 200 mmHg" box

is activated. This box consists of a slider control and a pressure display. To perform the

span calibration, inflate the unit, using the bulb and valve, to 200 mmHg " 5 mmHg. Wait

15 seconds to allow the pressure to stabilize. Adjust the slide control of the software until

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 17

Section 2 Service

the reading on the PC matches as close as possible to the reading of the pressure meter.

Once the difference has been minimized, select "record" and proceed following the

directions of the software.

7. Once the gain calibration is complete, the pressure calibration points can be calibrated.

There are three points that require calibration; 95, 195 and 285. First set the pressure to

the desired pressure value within " 5 mmHg. Wait 15 second for the pressure to stabilize.

Adjust the slide control of the software until the reading on the PC matches as close as

possible the reading of the pressure meter. Once the difference has been minimized, select

"record" after each setting. YOU MUST DO THIS FOR ALL THREE VALUES. Once

this is completed, select the "update" button.

8. The software will respond by asking, "Are you sure?" and then asking for a calibration

signature (your initials or three letters of your facility). Select "OK".

9. Select "close" to exit the calibration dialog box.

10. Cycle power to the unit for the changes in the calibration to take effect.

Loading Unit Software

WAR NI NG ! DO NOT REMOVE POWER OR TURN OFF THE UNIT DURING THE

SOFTWARE LOADING OPERATION! The unit will be in an unrecoverable state if this

happens!

NOTE: If the computer or the software malfunctions during the software loading

operation, re-boot the computer, re-start windows and start the Repair Software. The

Repair Software will start in the “Recovery Mode.” The software will prompt you to

continue/resume the software loading process.

1. Plug the wall transformer into the Vital Signs Monitor.

2. Connect the unit to the RS232 cable of the test station.

3. Start the Repair Software by clicking on its icon. Go into Unit/Update Software.

4. Select “Select File” button in the software.

5. Select the correct unit software (zenXXX.mot) file per instructions from the

manufacturer. (Where “XXX” is the number of the software version to be loaded)

6. Once the software file is selected, press the “OK” button. This will return you to the

Repair Software. The Repair Software will then ensure that the zenXXX.mot file you are

about to load into the unit is “Valid.” If so, press the “Load” button in the software.The

unit will take about 10 minutes to load the software. If the software file you have chosen is

“Not Valid,” repeat steps 4 and 5, select the correct version and then proceed. If problems

persist, please contact your nearest Welch Allyn Regional Service Center.

18 Welch Allyn Vital Signs Monitor Service Manual 95P445E Rev. C

Troubleshooting Section 3

Diagnostic Procedure for Returned Units

Notes:

A. The word "unit" in this text refers to the Vital Signs Monitor.

B. "Menu|Choice" represents menu commands. Rather than use the phrase "choose the exit

command from the File menu."

Battery Voltage Check

1. Remove the battery from the unit. With a digital multi-meter, check the voltage of the

battery. If the voltage of the battery is less than 6.0 Vdc, the battery needs to be charged.

Recharge the battery by placing the battery back into the unit and plug in the charger. Let the

battery charge for 8 hours. Allow the unit to set for 1 day and recheck the battery voltage. If

the voltage is below 6.0 Vdc, replace the battery.

2. Remove the battery from the unit. Connect the unit to the power supply. Set the power

supply to 6.5 Vdc " 0.25 Vdc. Power up the unit. If the unit does not power up:

A. Ensure that the power supply is connected to the unit and turned on.

B. Check that the fuse is not blown.

C. Change the main PCB.

D. Change the display PCB.

LED Functional Check

3.To check the display PCB, observe the unit during power up. All of the LED segments should

be lit for 1-2 seconds before the unit gets to its normal mode. If the unit has any LED segments

out, change the display PCB.

BP Functional Check

4. Run a couple of blood pressure cycles to ensure proper inflation/deflation and readings.

5. If the unit is not inflating/deflating properly:

A. Open up the unit by removing the 6 housing screws.

B. Check the unit for pinched tubing if the unit is deflating too slowly. With the

housing opened, re-run the blood pressure cycle to see if the deflating problem has been

fixed. Re-route tubing if pinch is found.

C. If there are no pinched tubes, change the valve.

D. If this still does not clear the problem of deflation too slow, check to ensure there

are no blockages of the tubing/port/valve in the unit.

E. Power down the unit. Place unit into configuration test mode by holding down

the "Start" and "Cancel" button as power is re-applied. Press the “Review” button

until "CALCAL" appears in the systolic window. Press the "Start" button to close

the valve. Inflate the unit, using the bulb and valve, to 250 mmHg. Confirm the unit meets

the specification for leaking called out in the Repair Test Specifications in Appendix D. If

the unit is leaking continue with step F.

Service Manual 95P445E Rev. C Welch Allyn Vital Signs Monitor 19

Section 3

F. Pinch off the tubing leading to the pump. If this stops the leak, change the pump.

G. Pinch off the tubing leading to the valve. If this stops the leak, change the valve.

H. Pinch off the tubing leading to the transducer. If this stops the leak, change the

Main PCB.

6. If the unit is inflating/deflating properly and if there is no reading given, change out the

main PCB.

Troubleshooting

Printer Functional Check

7. Load the printer with paper if there is no paper. Press the “form feed” button to see if

that will advance the paper. Next, press the “Print” button to see if the unit will print. If

these functions do not work, first change the printer PCB and re-test. If the problem is still

evident, change out the printer itself.

SpO2 Functional Check

8. Connect the correct patient simulator to the unit SpO2 connection by either the Nellcor

SpO2 test cable or the Nonin SpO2 test cable. Confirm readings meet the specifications

called out in the Repair Test Specifications in Appendix D. If there is no reading, change

out the SpO2 PCB.

Temperature Functional Check

9. Remove the temperature probe and view the temperature window on the display. Make

sure the temperature is in the "monitor mode." This will be displayed beside of the

temperature window. If the unit is not in monitor mode, wait approximately 40-60

seconds and the unit will automatically transfer into the monitor mode. Using the Welch

Allyn 9600 calibrator set at 96.4 °F/ 35.8 °C or using a water bath between 84 °F and 106

°F, place the probe into the small hole on top of the 9600 calibrator or into bath. If there is

no reading place the probe back into its housing, remove and retry. If there is still no

reading, change the probe and retry the test. If there is still no reading place the probe back

into the housing, unplug the probe and plug in the CAL-KEY (5200-25), remove the probe

and confirm reading meets specifications called out on the Repair Test Specifications in

Appendix D. If there is no reading at this point, change the temperature connector PCB

and Temperature PCB.

Communication Functional Check

10. Select Tools|Options to ensure that the communication port that the cable is connected

to is selected. Select "Test" and ensure that the Vital Signs Monitor responds accordingly.

If an error is present, ensure that the communication cable is connected to the Vital Signs

Monitor. Re-try the test. If the error is still present, first, change the communication cable.

If the error is still present, then change out the main PCB.

20 Welch Allyn Vital Signs Monitor Service Manual 95P445E Rev. C

Loading...

Loading...