Page 1

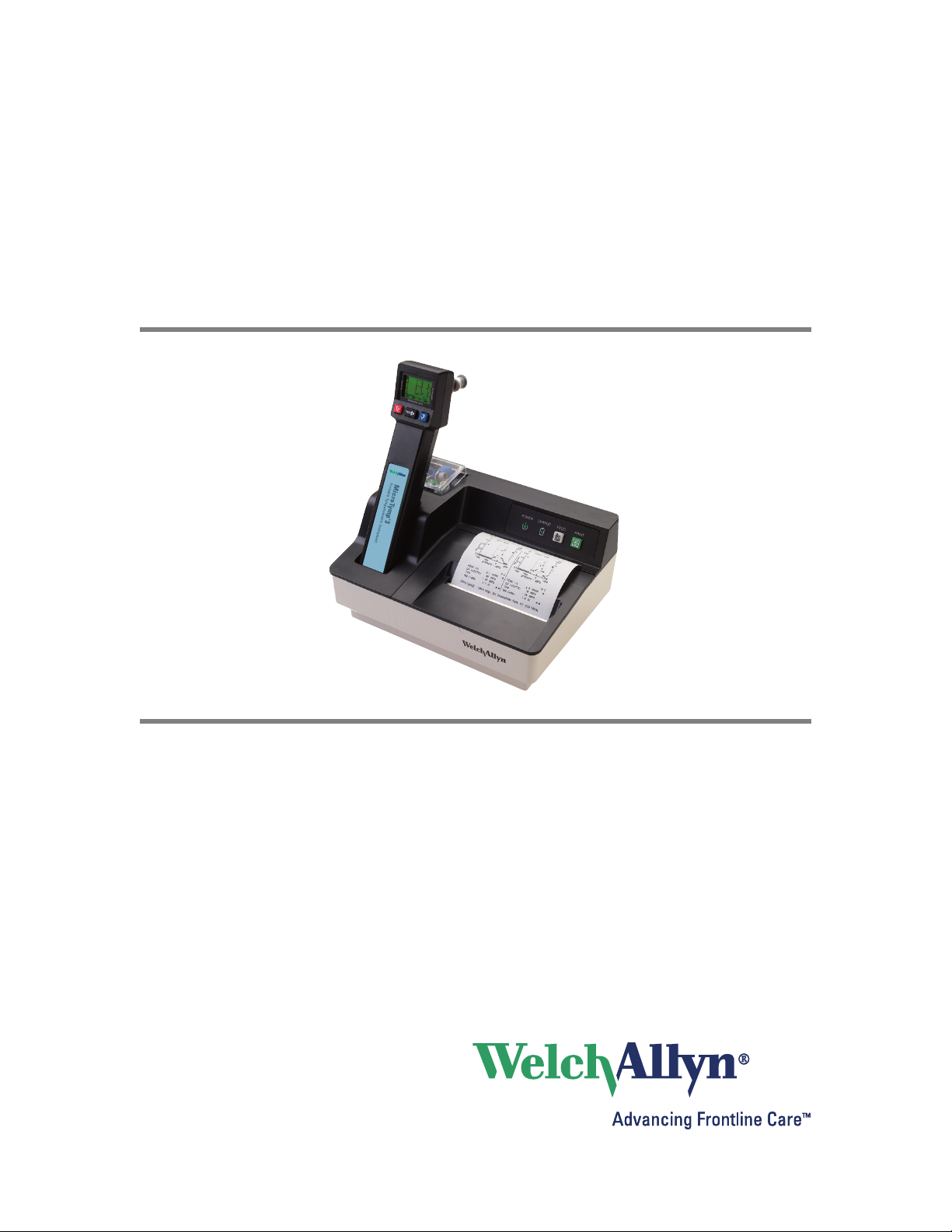

MicroTymp

MicroTymp

®

3 Handle and

®

Printer/Charger

Service manual

Page 2

Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

REF

© 2009 Welch Allyn. All rights are reserved. No one is permitted to reproduce or duplicate, in any form, this manual or any part

thereof without written permission from Welch Allyn.

Welch Allyn assumes no responsibility for any injury to anyone, or for any illegal or improper use of the product, that may result from

failure to use this product in accordance with the instructions, precautions, warnings, or statement of intended use published in this

manual.

Welch Allyn and MicroTymp are registered trademarks of Welch Allyn.

XP is trademark of Microsoft.

Software in this product is copyrighted by Welch Allyn or its vendors. All rights are reserved. The software is protected by United

States of America copyright laws and international treaty provisions applicable worldwide. Under such laws, the licensee is entitled

to use the copy of the software incorporated with this instrument as intended in the operation of the product in which it is

embedded. The software may not be copied, decompiled, reverse-engineered, disassembled or otherwise reduced to

human-perceivable form. This is not a sale of the software or any copy of the software; all right, title and ownership of the software

remain with Welch Allyn or its vendors.

For information about any Welch Allyn product, call the nearest Welch Allyn representative:

USA + 1 315 685 4560

Canada 800 561 8797 China + 86 216 327 9631

European Call Center + 35 3 46 906 7790 France + 33 1 60 09 33 66

Germany + 49 7477 92 71 86 Japan + 81 3 3219 0071

Latin America + 1 305 669 9003 Netherlands + 31 15 750 5000

Singapore + 65 6419 8100 South Africa + 27 11 777 7555

United Kingdom + 44 20 7365 6780 Sweden + 46 8 58 53 65 51

406695

Material No. 714876 Ver. A

Welch Allyn, Inc.

4341 State Street Road

Skaneateles Falls, NY 13153 -0220 USA

www.welchallyn.com

800 535 6663

Welch Allyn, Ltd.

Navan Business Park

Dublin Road, Navan

County Meath, Republic of Ireland

Australia + 61 2 9638 3000

Page 3

Contents

1 - Introduction and technical overview . . . . . . . . . . . . . . . . . . . . . . . . . 1

iii

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Supporting documents and definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Technical overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

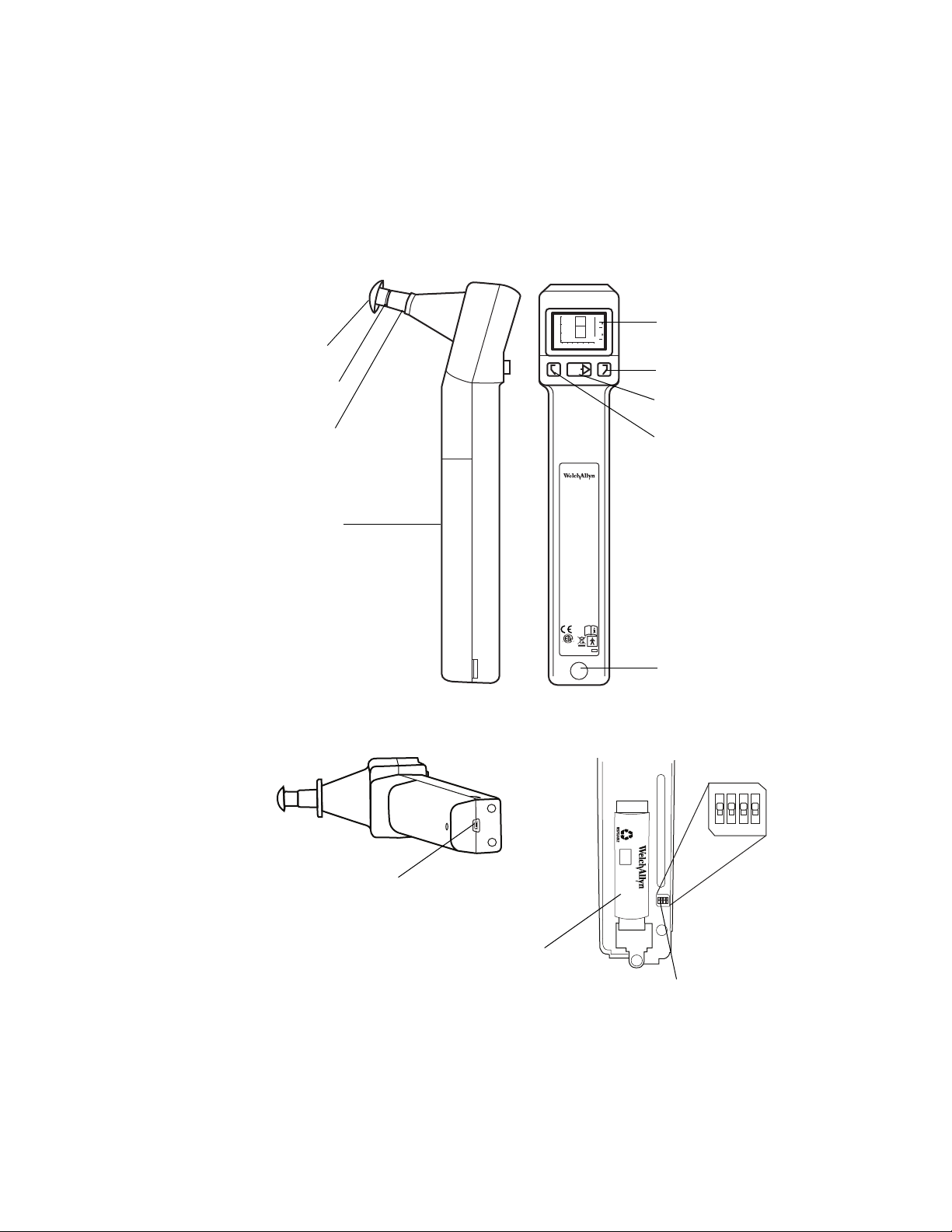

Controls, indicators, and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Handle components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Printer/Charger components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 - Testing and verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Bench test and calibration check - Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Purpose of test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preparation for test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Bench test procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Final Tester Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Testing Performed by the ATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bench test for the Printer/Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Proper powering up of unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Proper operation of print head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Agency tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dielectric strength test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Grounding continuity test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Leakage current test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3 - Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Printer/Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Noise troubleshooting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Leak troubleshooting procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Error and service code tables with troubleshooting procedure . . . . . . . . . . . . . 33

Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Retrieving and clearing error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Service codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4 - Disassembly and reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Handle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Page 4

iv Contents Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Removal/replacement of the LCD and keypad board assemblies . . . . . . . . 42

Removal/replacement of the power PCBA. . . . . . . . . . . . . . . . . . . . . . . . . . 43

Removal/replacement of the MCU PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacement of Lithium coin battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Proper placement of ESD shields in the back housing. . . . . . . . . . . . . . . . . 45

Printer/Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Removal/replacement of the top panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Removal/replacement of the main PC board and print head assemblies. . . 47

Removal/replacement of the contact housing and IR flex assemblies. . . . . 48

Removal/replacement of the printer keyboard/LEDs assembly . . . . . . . . . . 49

Removal/replacement of the RFI filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Removal/replacement of old main PC board and print head . . . . . . . . . . . . 50

A - Repair parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

B - Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Clean the handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Clean the printer/charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Clean the probe tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

C - Replacement parts and accessories . . . . . . . . . . . . . . . . . . . . . . . . 57

Page 5

1

Note

1

Introduction and technical overview

About this document

This document is written for technical professionals who are qualified to service medical

instruments. The intended technical environment is any location where service on such

devices is performed. This document describes how to test, calibrate, diagnose,

disassemble, and assemble the MicroTymp3 Handle and MicroTymp Printer/Charger.

Before attempting service on the tympanometer, you must read and understand this

document and all other information that accompanies the tympanometer and its

accessories.

Intended use

This device is an auditory impedance tester intended to detect possible otologic disorders

associated with the functioning of the middle ear.

About the device

Federal US law restricts sale of the device identified in this manual to, or on the order of, a

licensed physician.

Using this device’s 226-Hz and 1000-Hz tympanometry settings, you can quickly and

easily obtain objective results supporting diagnosis of otitis media with effusion and other

middle ear disorders. This information can result in more thorough diagnoses as well as

more effective monitoring, treatment, consultation, and referral.

The 226-Hz test data stored in the memory of the Handle may be printed using the

Printer/Charger. The Printer/Charger reads the information from the Handle and prints out

tympanograms and interpretation.

The Handle also provides the ability to test patients utilizing a 1000-Hz frequency

mode. This mode features a quick interpretation result that displays a Pass, Refer,

or Retest message on the LCD (see Chapter 4 of the DFU, part number 714694).

Results from the quick interpretation mode can be documented using the 1000Hz screening results card. Results from the 1000-Hz quick interpretation mode

will not print.

The switch to change the default frequency is located on the top of the power supply PC

board. The table on the next page gives the function choices of this switch pack.

Page 6

2 Introduction and technical overview Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Switch State Function

Switch 1 off 1000 Hz

Switch 1 on 226 Hz

Switch 2 off Platform communication

Switch 2 on Printer communication

Switches 3 and 4 Not used

The Printer/Charger also charges the rechargeable battery in the Handle.

For more detailed operating instructions, see the DFU for the MicroTymp3 Handle, part

number 714694.

Supporting documents and definitions

• Manufacturing Test Specifications for MicroTymp 2.5, DIR number 60029314

• DID for MicroTymp 2.5, DIR number 60029426

Definitions

• MicroTymp3 Directions for Use, DIR number 80015401

• MicroTymp Hardware Technical Specifications, DIR number 60030837

• How2 - MicroTymp 2.5 MPS, DIR number 70020334

ATE Automated Test Equipment

cc Cubic centimeter, a unit of volume

daPa Decapascal, the unit of air pressure used for tympanometric

measurements, 1 daPa = 1.04 mm H

EEPROM Electrically Erasable Programmable Read-Only Memory

LUT Look Up Table

mbar Unit of atmospheric air pressure measurement

mmho Acoustic millimho, the unit of acoustic admittance

MCU PCA Micro controller Unit Printed Circuit Board Assembly

PS PCA Power Supply Printed Circuit Board Assembly

USB Universal Serial Bus

0

2

UUT Unit Under Test

Vea Volume of ear canal

WACP Welch Allyn Communications Protocol

Page 7

Service manual Introduction and technical overview 3

Technical overview

The Handle hardware contains the necessary circuitry to perform, measure, and report

tympanograms. It is designed to be portable and rechargeable, and to interface with its

corresponding printer device.

In order to perform a tympanogram, the hardware must support a motor/pump assembly

that is capable of a positive and negative pressure in the ear canal. Simultaneously, a

speaker must drive a monotonic 226-Hz, 85 dB sound pressure into the ear. A

microphone amplifier and A/D converter are included to monitor this sound pressure. The

control of the system (tone and pressure), and display of the tympanogram are

implemented with two micro controllers. The hardware and software must provide a

closed-loop system that maintains the 85 dB sound pressure, regardless of the acoustical

admittance in the ear that changes with pressure.

In addition, the Handle shall be capable of performing fully the above function with a

1000-Hz, 83 dB tone.

In order to support the operator interface, the hardware supports an LCD and keypad with

three keys. In order to interface with the Printer/Charger, the Handle has an IR sensor

communication interface. The Handle is designed to start by the press of a button, or by

insertion into the printer/charger unit.

The Handle hardware system is broken down at the top level into three board-level

assemblies:

1) The MCU Board

2) The Power Supply Board

3) The LCD Board

There are other integral components such as the sensors, motor/pump assembly,

switches, USB port, and IR interface which play significant roles in the plotting of the

tympanogram, the powering up of the unit, and the communication of the unit with a

service computer, ATE testing station, or Printer/Charger.

The Power Supply Board can be broken down into these subsystems:

1. The keypad/power up logic is responsible to start the power supply and interrupt the

master MCU whenever a key is depressed. It also reports which key is depressed and

receives an input from the MCU to keep the system powered up.

2. The battery charger provides a constant current charge to the battery whenever the

Handle is in a printer base. When the battery voltage reaches 4.2 volts, the charger

shall cease charging the battery.

3. The battery detection reports a low battery warning to the micro controller.

4. The negative power supply is an inverting switched capacitor power supply used to

support the analog circuitry and the LCD display.

5. The pump motor control provides a selectable voltage to the motor in either forward

or reverse polarity.

6. The pump motor home detect determines whether the pump diaphragm is above or

below the home position.

7. The valve control provides a fixed voltage to the valve in either the open or closed

polarity.

Page 8

4 Introduction and technical overview Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

The MCU Board can be broken down into these subsystems:

1. The master micro controller is directly responsible for the sound pressure control

loop, operator interface, IR communication, USB communication, and power control.

2. The slave micro controller is directly responsible for the motor control, valve control,

and pressure amplifier.

3. The IR communication is a bidirectional link between the Handle and Printer/Charger

base.

4. The USB port is a bidirectional link between the Handle and either the ATE or the

service computer.

5. The speaker drive provides a 226-Hz sine wave to the speaker. The amplitude is

adjusted by the master MCU to control the sound compliance loop. Digital calibration

is also provided for speaker gain and system cavity size differences. These same

processes also apply to the 1000-Hz function of the Handle.

6. The microphone sends its signal to the A/D converter before filtering. This is true for

both the 226-Hz and 1000-Hz signals.

7. The ADC digitizes the output of the microphone amplifier to be used by the master

MCU in the compliance control loop. Digital calibration of the microphone gain is also

performed.

8. The pressure amplifier scales the signal from the pressure transducer and provides it

to the slave MCU. Digital calibration for transducer gain and offset are provided.

Page 9

Service manual Introduction and technical overview 5

TEST

-400 -200 0 200

2

0.5

0

1.0

1

GR

A

GR

C

PRESSURE - daPa

Ya - mmho

+200 Vea - cc

MicroTymp

®

3

Portable Tympanometric Instrument

0297

IEC TYPE 3

Skaneateles Falls, NY USA

US Pat #5,383,097

ANSI TYPE 4

Patent Pending

C

US

74227

23650

REF

ON CTS

ON

OFF

123

4

ON CTS

ON

OFF

123

4

72910

REF

+

-

Lithium

Ion

Liquid Crystal

Display (LCD)

Left memory button

Test button

Right memory button

Infrared data

transfer window

Tip

Probe

Tip

ejector

Battery

cover

Micro-USB port

NOTE: Reserved for future use

Lithium-ion

battery

Side view Front view

Bottom view

Interior view

Handle

switches

Controls, indicators, and connectors

Handle components

Page 10

6 Introduction and technical overview Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

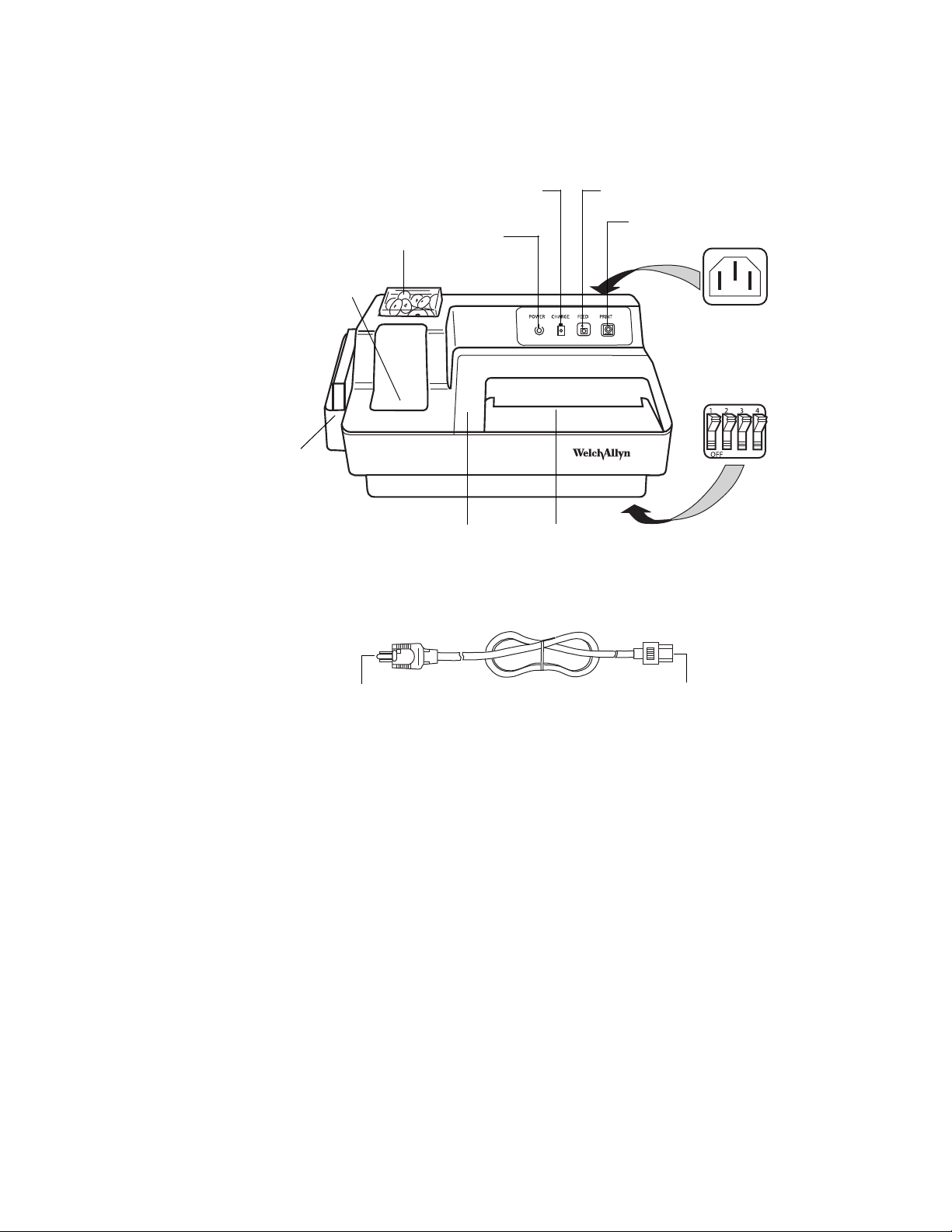

Power Cord

Tip box

POWER

indicator

CHARGE

indicator

FEED button

PRINT button

Paper

slot

Paper access

cover

Charging well for

MicroTymp 2 or 3

Card holder

with 1000-Hz

screening

results cards

IEC power cord

receptacle

Printer/Charger

switches

To IEC power

cord receptacle

To power

receptacle

Printer/Charger components

Page 11

Service manual Introduction and technical overview 7

TEST

GR

A

L

C

GR

-20ºC

+49ºC

95%95%

Symbols

Documentation symbols

Warning

(Warnings indicate conditions or practices

that could lead to illness, injury, or death.)

Consult instructions for use Hot surface

Operation symbols

POWER indicator FEED button

CHARGE indicator PRINT button

Caution

(Cautions indicate conditions or practices

that could damage the equipment or other

property)

TEST button RIGHT memory button

Gradient width adult LEFT memory button

Gradient width child Switch options ON/OFF symbol

Shipping, storing, and environment symbols

Temperature limits Relative humidity limit

This end up Recycle

Recycle the product separate from other

disposables. See www.welchallyn.com/

weee for collection point and additional

information.

R

Separate batteries from other disposables

for recycling.

Power and connectivity symbols

Lithium-ion

Page 12

8 Introduction and technical overview Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

0297

REF

SN

Certification symbols

Meets essential requirements of European

Medical Device Directive 93/42/EEC

74227

Class I equipment, Type BF

(Handle)

Class I equipment, Type B

(Printer/Charger)

Miscellaneous symbols

Reorder number Manufacturer

Complies with applicable U.S. and

Canadian medical safety standards

European regulatory manager

Serial number

Page 13

Service manual Introduction and technical overview 9

General warnings

WARNING Explosion risk. Do not use Handle or Printer/Charger near flammable

anesthetics.

WARNING Electric shock hazard. Do not attempt to disassemble the Printer/

Charger. Refer all servicing to Welch Allyn or a Welch Allyn authorized service

representative.

WARNING Electric shock hazard. Use the USB connector only to connect to

devices complying with IEC 60601-1 or other IEC standards as appropriate to the

device. The user is responsible for verifying that the system complies with the

requirements of the system standard IEC 60601-1-1 if additional devices are

connected to the Handle.

WARNING Improper handling or disposal of the battery can lead to heat

generation, smoke, bursting, or fire.

WARNING Do not disassemble, modify, or solder the battery.

WARNING

battery terminals.

WARNING To avoid short circuits, keep the battery terminals away from metal

objects.

WARNING Do not dispose of the battery in fire.

WARNING Do not expose the battery to temperatures above 80°C (176°F).

WARNING Use only the specified charger to charge the battery.

General cautions

Caution Charge only Handle #23640, Handle #23650, or AudioScope 3

(#23300) in the Printer/Charger.

Do not directly connect (short circuit) the positive (+) and negative (–)

Caution If the device has not been stored within the operating temperature

range, allow 24 hours minimum for it to return to operating temperature range

(15-35°C or 59-95°F) before using.

Page 14

10 Introduction and technical overview Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Caution Do not store either the Handle or Printer/Charger at temperatures

below -20°C (-4°F) or above +49°C (120°F). Continual exposure to extremely low

or high temperatures can permanently damage components.

Caution The battery must be removed if the Handle is to be stored or placed

anywhere other than in the powered Printer/Charger for more than one month.

Failure to do this can result in damage to the Handle.

Caution This instrument contains components which are static sensitive.

Before touching any internal Handle component, be sure that you have

discharged any static electricity by touching a grounded metal object.

Caution To prevent equipment damage, charge the Handle only with the

Printer/Charger (#7117x).

General notes

The Printer/Charger (#7117x) will charge and print data from the MicroTymp2 or

MicroTymp3 Handle. However, the original Printer/Charger (#7113x) will neither charge nor

print data from the MicroTymp3 Handle.

Please complete and return the warranty registration. It validates the warranty and allows

Welch Allyn to communicate calibration notices and software changes.

Page 15

11

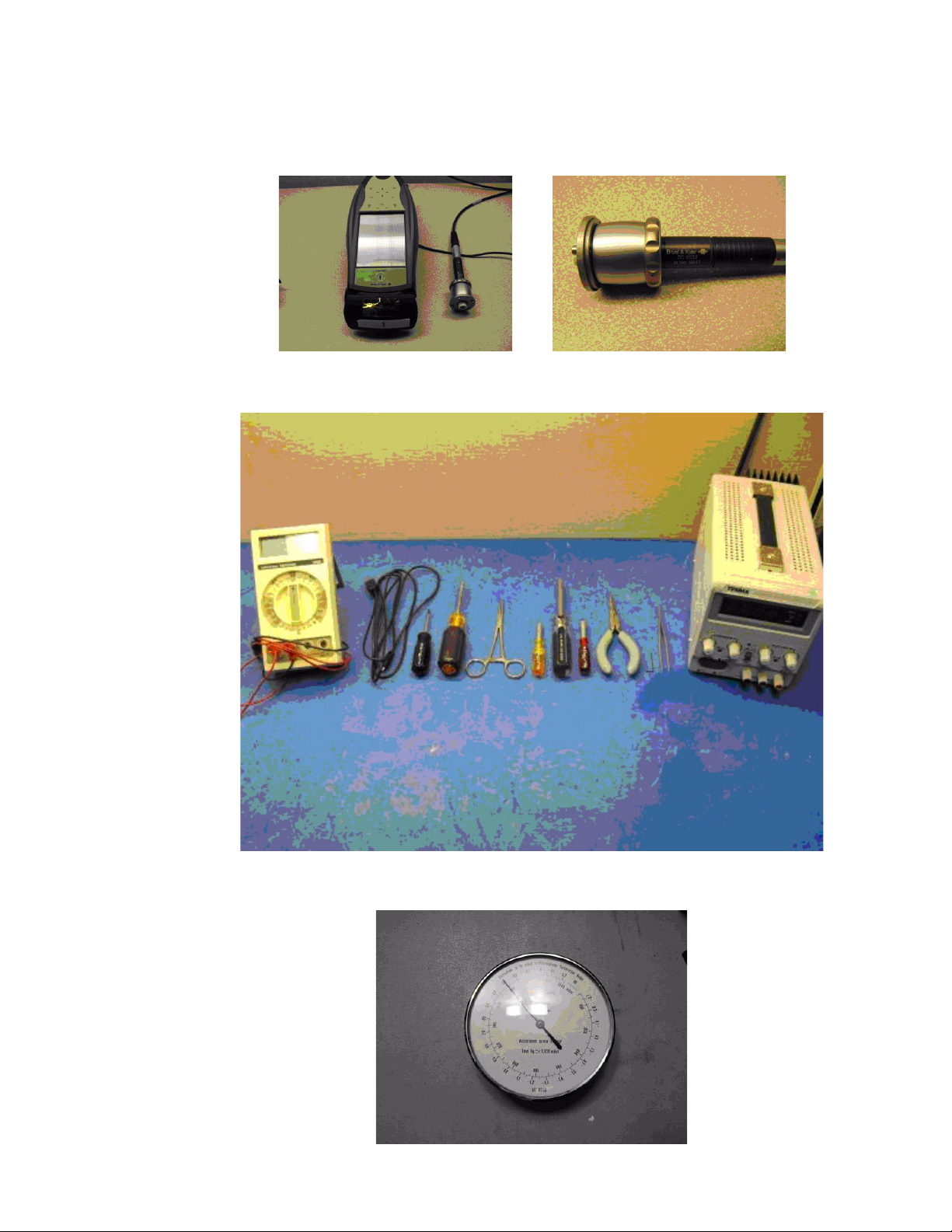

Pressure box (T-5657 or equivalent) Test cavity set (T20015974)

2

Too ls

Testing and verification

• Pressure applicator source with range of -400 to +300 daPa with 1 daPa

resolution

• Variable voltage (0-10 VDC) output power supply with at least 500 mA capacity

• Test cavity set, part number T20015974. See picture below for sizes.

• Handle

• Printer/Charger

• Digital voltmeter 3 ½ digit

• Hemostat or crimping needle nose pliers

• Set screw key, size 0.035

• Nut driver size 5/32 inch or 4 mm, thin wall preferred

• Other nut driver sizes needed: 3/16 inch and 1/4 inch

• Small and medium size Philips screwdrivers

• ROHS (lead free) soldering iron and lead free solder

•Tweezers

• Stop watch for leak test

• Service computer (Windows XP

25, 2009. This program will give control of the Handle during the bench test. For

Sample Client to work On-Host Version 1.0.0 or equivalent must be installed prior

to using the WACP Sample Application.

• USB cable (thin connector) for connection to service computer

• B&K sound level meter model 2250, with ½-inch microphone model 4192 and

2 cc coupler model 4946

• Barometric Pressure transducer, model 276 or equivalent (must measure

pressure in mmHg)

1

1

®

, or higher) with 'Sample Client,’ version June

1. These pieces are ATE. They are needed when the calibration is updated but not for the bench test.

Page 16

12 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

B&K sound level meter model 2250 1/2-inch microphone model 4192 and

2 cc coupler model 4946

Off-the-shelf tools

Barometer

Page 17

Service manual Testing and verification 13

Note

Note

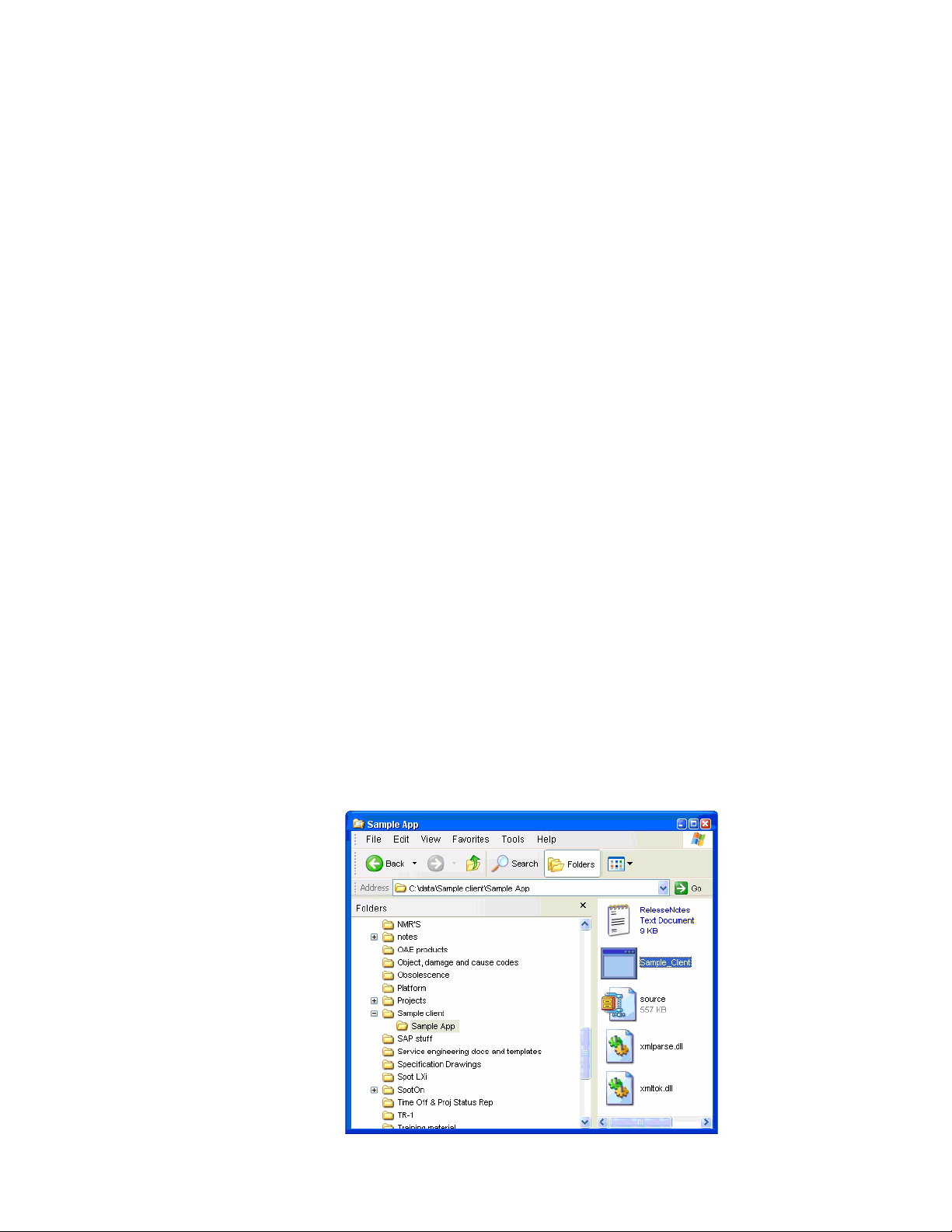

Sample client location

Bench test and calibration check - Handle

Purpose of test

To test for and detect problems in the following portions of the Handle:

1. Leak and vent rate

2. Noise (226 and 1000 Hz) and sweep rate test

3. Compliance check

For the purpose of detecting and repairing problems before the unit is run on the ATE.

This will alleviate failures on the final ATE test. Therefore, these tests should be

performed before final testing on the ATE.

Refer to the “Troubleshooting guide” starting on page 29 for solutions to the problems

encountered during the bench and ATE tests.

Preparation for test

Use only the functions of sample client as set forth is this manual.

1. Open the sample client program on the service computer by navigating to the

'Sample Client' folder. Open it and click on the 'Sample App' folder. Double click on

the 'Sample Client' file. Program will open. See opening screen picture.

2. Connect USB cable from Handle to service computer.

Any time a new battery is installed it is necessary to connect the MicroTymp

handle to the USB cable or insert it into the printer/charger for five seconds before

powering up the handle. (This enables the battery protection circuit).

Page 18

14 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Opening screen

Sample client menu

3. Select the choices as shown in the picture below: 1 for start, 1 for number of

connections, and 2 for USB.

4. An extensive menu should display on the service computer screen. Making sure that

the Handle is powered on, select the number of the 'Disable Power Timeout,'

selection number 20. This will enable the Handle to stay powered up throughout the

test.

Bench test procedures

Test 1 - Leak and vent tests

1. With the main menu still showing on the service computer screen, select number 12,

FmTYMP Test. The FmTYMP Test screen will show. Select number 3, Send

command. Select number 14, Set Valve. Select number 1 to close valve. An audible

click will be heard indicating the valve has been latched closed. Unit can now be

tested for leaks.

2. Connect pressure box to the probe tip of the Handle. Throw select switch on pressure

box to positive position and pressure/vent switch to pressure position.

Page 19

Service manual Testing and verification 15

Note

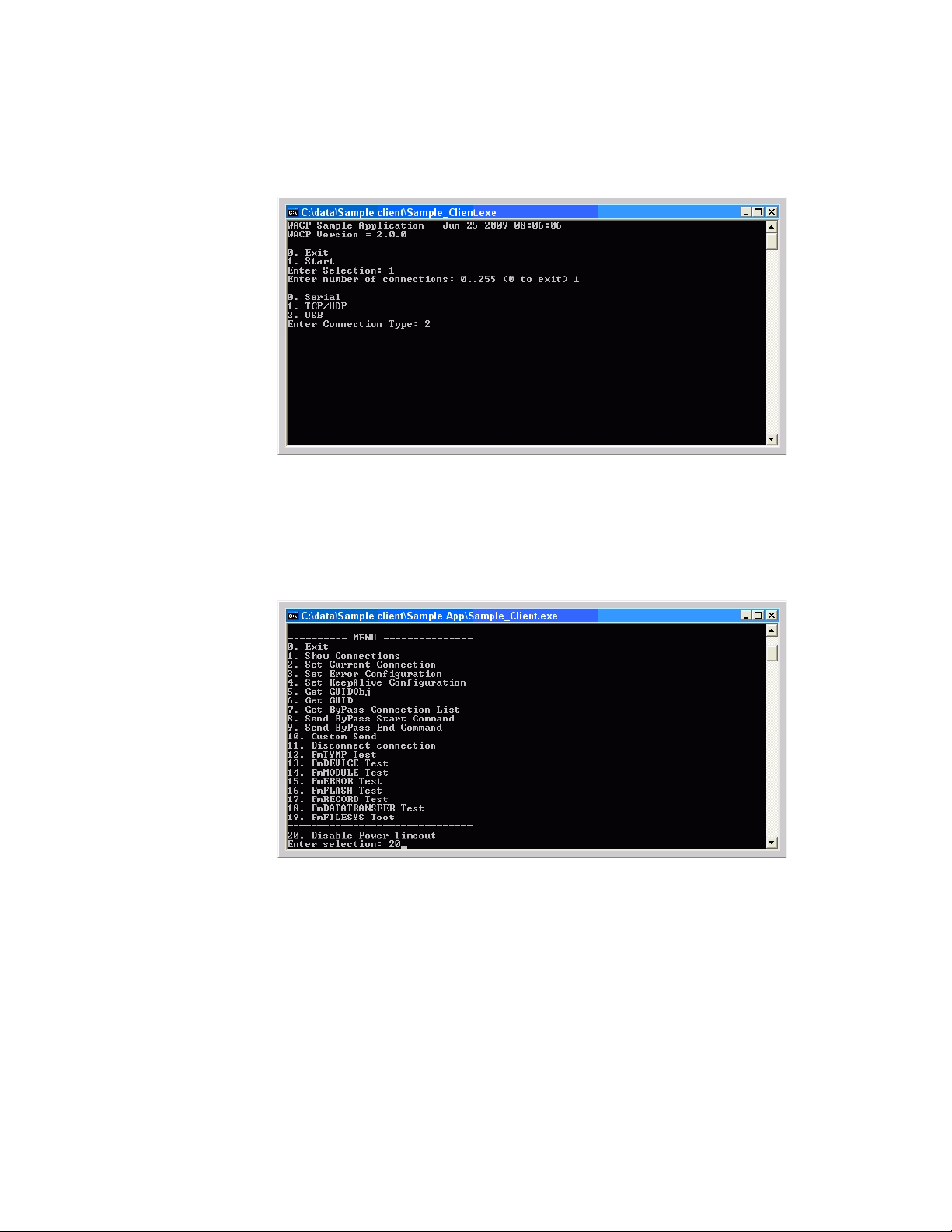

1000 Hz Typmanogram

Volume

of

tested

cavity

3. Adjust box to 300 daPa, let it sit for about ten seconds, and then observe the leak

rate. It must be less than 10 daPa in five seconds.

4. Vent the unit by throwing the pressure/vent switch on the box to vent position (V).

5. Put select switch in negative position and pressure/vent switch to pressure position.

6. Adjust pressure to -400 (meter will read +400), wait ten seconds, and then observe

leak rate. It must be less than 10 daPa in five seconds.

7. Readjust pressure to -400 daPa.

8. Open valve on Handle by selecting number 2, Open Valve, on the service computer.

Pressure should drop to zero in two seconds or less.

9. To re-enable the timeout circuit, simultaneously press/release all three buttons on

Handle. Unit will power down. Power up unit and confirm that unit powers down in

about fifteen seconds.

Test 2 - Noise and sweep rate tests

1. Set the unit to 226 Hz.

2. Put a 0.2 cc cavity on the probe tip. Hold unit upright and take a reading.

3. There should be a straight line across the bottom. Ideally, there should be no pixels

above the base line. If there are pixels one row above that is acceptable. Any pixels

two rows or more above the base line constitutes a failure. See pictures at the end of

this section.

4. Take four tympanograms and make sure all readings are a pass.

5. In addition, note the sweep across the bottom of the screen during a tympanogram. It

should move at an even speed. Make sure there is no notable slowdown or sudden

start/stops.

6. Repeat steps 2 through 5 for the 2.0 cc cavity.

7. Set the unit to 1000 Hz.

The cavity test for 1000 Hz will show the correct volume but not a straight line

across the bottom of the LCD. The line may be slightly elevated but no higher

than 0.4 mmho. It is important that the correct volume is displayed. A REFER

message will also appear on the LCD, and it does not indicate a problem.

8. Perform cavity tests for 1000 Hz with the 0.2 and 2.0 cc cavities.

Page 20

16 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Good tympanogram (226 Hz) Unacceptable tympanogram (226 Hz)

Note

Properly applied test cavity Printout of test tympanogram

No gap shown

Volume reading

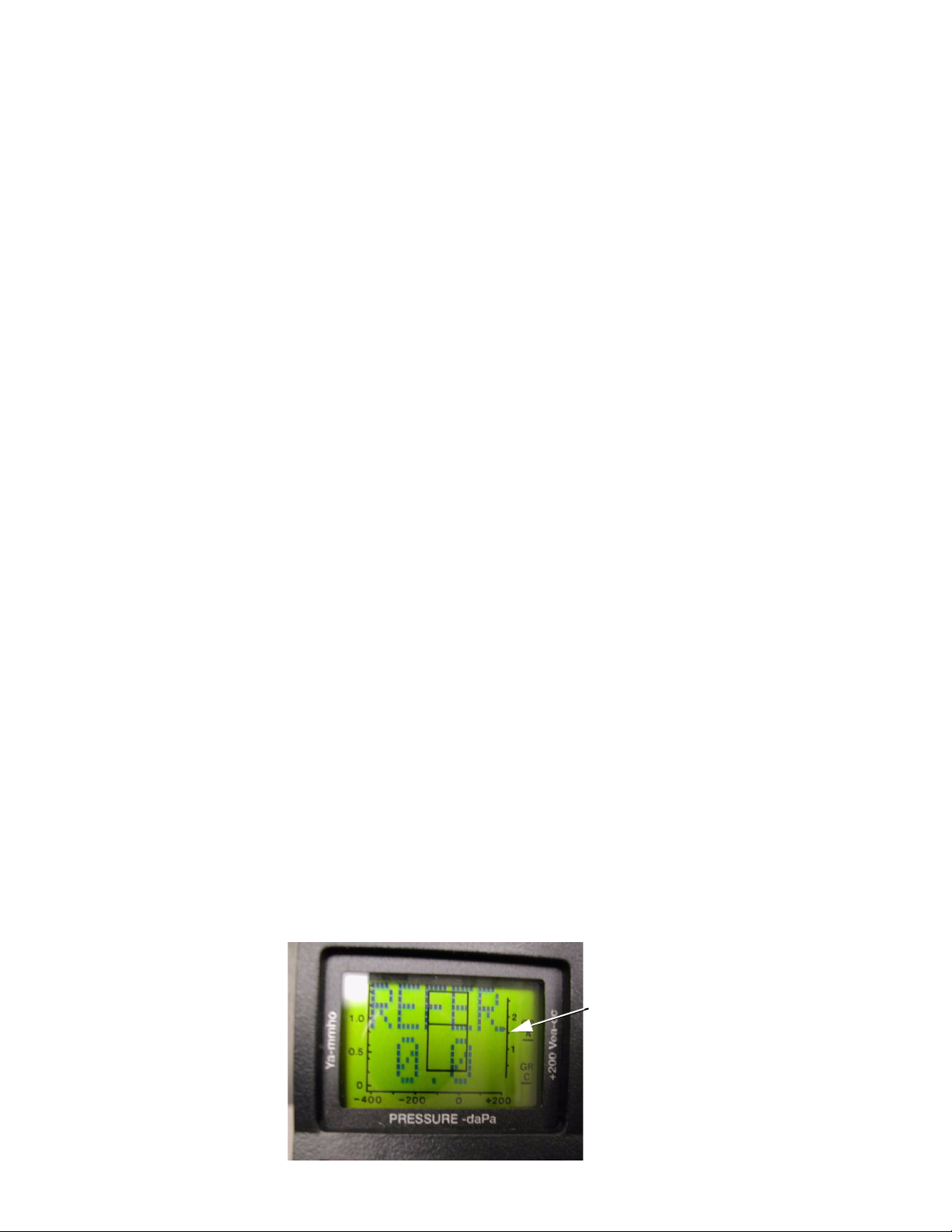

Test 3 - Compliance check for 226 Hz function only

1. Place a 0.5 cc cavity onto the probe tip. Make sure cavity fits properly. The rubber tip

from the cavity should not be pulling away from the white tip ejector. See picture

below.

2. Press the 'TEST' button on the Handle. The unit should take a reading as a flat line

across the bottom of the screen. Press the 'L' button to store the reading into the left

memory. Observe the 'LEFT STORE' message.

3. Insert Handle into Printer/Charger and print out results. The Vea reading should be

0.5 cc +/- 0.1 cc.

4. Repeat steps 1 through 3 with a 1.5 and a 2.4 cc cavity, but press the 'R' button to

store the readings into the right memory. The Vea reading should be the cavity size

+/- 0.1 cc.

Unit is now ready for final test on the ATE.

All units must be tested on the ATE before shipment to the customer.

Page 21

Service manual Testing and verification 17

Final Tester Setup

Before a unit can be tested on the final tester, the B&K meter must be calibrated at the

beginning of each shift. Please follow the instructions below to calibrate the tester.

1. Turn on the computer of the ATE tester.

2. Select the ATE Operator button at the Windows log-in screen.

3. Double-click the Shortcut to Platform icon.

4. After the MicroTymp 3 ATE test screen displays, select Setup.

5. Remove the 2cc coupler from the ATE Microphone. Rotate the lock ring on the 2cc

coupler counterclockwise to unlock the mechanism.

6. Place the ATE Microphone onto the calibration sound box.

Page 22

18 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Note

7. Press the On/Off button located on the side of the calibration sound box to turn

it on.

8. Select the Calibrate SLM button on the ATE Screen.

9. After the ATE screen displays "Calibration is Complete", rotate the lock ring on the 2cc

coupler counterclockwise to unlock the mechanism. Re-insert the B&K microphone

into the coupler and ensure that the microphone is fully seated before rotating the

lock ring clockwise to lock as shown below.

Check that the internal threads between the two coupler pieces are tight before

using the locking mechanism.

Page 23

Service manual Testing and verification 19

Lock

Ring on

2cc

coupler

Testing a Unit

Caution When removing the coupler (or any test cavities) from the Unit Under

Test (UUT), use the Tip Ejector to minimize the stress on the 2cc coupler and

tips.

Before testing each new unit, make sure the microphone is pushed all the way into

the 2 cc coupler and that the the coupler is locked.

Once the ATE instructs you to put on the 0.2 cc cavity, you must use the tip ejector on

the unit to disengage the microphone with the 2 cc coupler from the unit. DO NOT

pull the microphone off of the unit.

1. Prepare the unit for the ATE tester. Double click on test, then double click on test

again.

Page 24

20 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Note

2. Attach the unit to the battery simulator by the sliding battery simulator into the battery

holder on the unit’s power board. (The cover may be secured with a battery cover

screw.)

3. Attach USB cable to the bottom of the unit.

The USB symbol on the cable faces up toward the top (or label side) of the unit.

4. Place Unit Under Test (UUT) into the ATE Nest. Use the touch screen of the ATE (or

the mouse) to begin the test. Follow the ATE Tester direction on the screen.

Page 25

Service manual Testing and verification 21

QP6

FINAL TESTER

EquipmentMethod

Acceptance Criteria

Record

Include the IPA# if the unit fails any stage of the final test. Sign

and date the signature block for QP5 on the MT3 Handle DHR.

20015994 workstation

- Automated verification and calibration of units

- Unit passes all final tests

- Mark the appropriate PASS or FAIL checkbox for final test.

After the successful completion of the final test

1. Remove the unit from the printer/charger.

2. Remove the battery from the unit.

3. Set the unit aside.

4. Write the unit serial number, the date, and your initials on the printout.

5. Staple the printout to the DHR.

Page 26

22 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Testing Performed by the ATE

For reference only - actual numbers may change

Each Handle that is tested by the ATE receives the following tests:

1. Preliminary Current Check: 20 to 400 ma.

2. Test Initialization.

3. Firmware Check and Upgrade: new units only.

4. Low Battery Test: 2.9 volt DC threshold.

5. Electrical Current Test: 20 and 140 ma.

6. Configuration Switches Check.

7. EEPROM Read/Write: initialize new, read and save calibration (cal) record on existing

units.

8. Set Unit Information: name and model number, serial number, MCU and PS board

barcode information, device firmware version, date of first cal, date of last cal, ATE

software version for last cal and serial number of ATE used for last cal.

9. Real Time Clock Calendar Set and Test: write time and date and verify it can be set;

verify accuracy within ten seconds after being powered down for two minutes.

10. Button Test: check left, right, and test buttons.

11. LCD Test: all on, all off, checkerboard, inverse checkerboard.

12. Leak Rate Test: 10 daPa for five seconds at 200 and at -400 daPa.

13. Pressure Calibration: calibrate at 200, 0 and -400 daPa.

14. 226 Hz Sound Calibration and Verification: output set to 85.0 +/- 0.1 dB.

15. 226 Hz maximum Sound Pressure Level: max SPL less than 95 dB.

16. 226 Hz Microphone Calibration: microphone set to proper output with 85.0 dB output

from speaker.

17. 226 Hz Frequency Verification: frequency within +/- 4 Hz.

18. 226 Hz Total Harmonic Distortion (THD): THD needs to be less than 3% at 85.0 dB.

19. 1000 Hz Sound Calibration and Verification: output set to 83.0 +/- 0.1 dB.

20. 1000 Hz maximum Sound Pressure Level: maximum SPL less than 95 dB.

21. 1000 Hz Microphone Calibration: microphone set to proper output with 83.0 dB

output from speaker.

22. 1000 Hz Frequency Verification: frequency within +/- 20 Hz.

23. 1000 Hz Total Harmonic Distortion (THD): THD needs to be less than 3% at 83.0 dB.

24. Admittance LUT Generation and Verification: calibration test cavity admittance

adjusted for current barometric pressure to calibrate unit at sea level.

Page 27

Service manual Testing and verification 23

Note

Power switch

25. Admittance Accuracy: checked with 0.5, 1.5, and 2.4 cc cavities. Accuracy needs to be

within +/- 0.1 mmho for 226 Hz and +/- 0.4 mmho for 1000 Hz or +/- 5%, whichever is

greater.

26. Motor Speed Look up Table (LUT): created and checked with 0.2, 0.5, 1.0, 1.5, 2.0, and

2.5 cc cavities. Sweep time shall be 1500 +/- 25 ms.

27. EEPROM Verification: Checksum calculated by unit under test.

28. 226 Hz Admittance and Volume Accuracy Test (Noise): checked with 0.2, 1.0, 2.0, and

2.4 cc cavities, four times with each cavity. Vea accurate to +/- 0.1 cc. Maximum

allowable noise is 0.1 mmho on at least three of four times with each cavity.

29. 1000 Hz Admittance and Volume Accuracy Test (Noise): checked with 0.2, 1.0, 2.0,

and 2.4 cc cavities, four times with each cavity. Vea accurate to +/- 0.1 cc. Maximum

allowable noise is 0.4 mmho on at least three of four times with each cavity.

30. Printer/Charger Connectivity Test: connectivity shall be confirmed for charging the

battery and sending and printing data downloaded from the Handle to the printer.

31. All UUT result files shall be stored in the secure repository located on the ATE hard drive.

32. The ATE shall print all Test Results of the UUT.

33.

The ATE shall print the UUT Label Printout if there were no failed test results for the UUT

Failure of the Handle during any part of the ATE test necessitates running that

entire test upon repair of the problem.

Bench test for the Printer/Charger

Refer to the Troubleshooting guide in Chapter 3 for solutions to the problems

encountered during the bench test. The Printer/Charger requires no ATE final test.

Proper powering up of unit

1. Power printer up by plugging into suitable wall outlet. Make sure all switches on

bottom of unit are in the 'OFF' position.

.

2. Make sure there is data in both the left and right memory on the Handle.

3. With paper loaded into unit, the green power light should come on without blinking,

and there should be a single beep. The green charge light should not be lit.

4. Unplug unit and remove paper roll. Note paper roll installation.

Page 28

24 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Pull lever

Forward position

of lever

Pull lever

Backward position

of lever

5. Power up unit. Power light should blink in a pattern of one on, one off.

6. Install paper roll by feeding under gray rubber printer roll and pressing the feed button.

Push paper forward until it comes out at the top of the roller. Feed about three more

inches from this point.

7. Pull lever on right side of print head toward the front of printer. Power light should

blink twice in rapid succession.

8. Push lever all the way back. Power light should stop blinking and stay on. This is

normal operating mode for the Printer/Charger.

Proper operation of print head

1. Simultaneously depress/release the print and feed buttons to generate the following

printout:

Page 29

Service manual Testing and verification 25

Graph Tympanometric data Adult/child data

2. Make sure there are no gaps in the grid printout and that all lines of date are full with

no lines missing through the lettering.

3. Insert Handle into Printer/Charger well with the LCD screen facing forward. The

charge light should light.

4. Press the ‘PRINT’ button. Notice the printout. It should contain adult/child data,

tympanometric data, and the graph.

Page 30

26 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Printout with Switch 2 in ON position

Printout with Switch 3 in ON position

5. On the switch pack on under side of printer, put switch 2 to ON position. Press the

print button. Notice the printout. There is no adult/child data.

6. Put switch 3 to ON position. Press the ‘PRINT’ button. Notice the printout. There is

neither adult/child nor tympanometric data.

7. Put switches 2 and 3 back to OFF position and switch 1 to ON position. Remove

Handle from well for about three seconds, then re-insert. Handle will download data

then automatically print out a full set of data.

Agency tests

Dielectric strength test

Perform this test between primary wiring (both sides of supply terminals connected

together) and accessible dead metal parts (non-current carrying conductive parts) 1000

VAC (1200 VAC for one second).

Page 31

Service manual Testing and verification 27

Tes t p r obe

Unit under test

1 k resistor

15 uf capacitor 10.2 ohm resistor

Breakdown will normally be indicated by tripping of a suitable overload protector in the

test equipment, but an abrupt decrease or retarded advance of the voltmeter reading

could also be indicative of insulation failure. REF: UL544 par. 31.3.

A breakdown is also considered to have occurred if after the test the equipment does

not comply with risk current test even though there is no arcing, tracking, or other

evidence of a breakdown. REF: CSA 22.2 #125, 6.7.3 Note 5.

Grounding continuity test

This test checks the integrity of the earth ground by applying current through the earth

ground of the line cord and unit. The voltage is measured across the earth ground prong

of the outlet and any accessible metal part of the appliance, and this voltage shall not

exceed 2.0 volts. See calculation.

E = IR > E = 10 x 0.2 > E = 2 volts maximum

Statement from grounding continuity test standard: The resistance between the

grounding pin of the attachment plug and any accessible metal part of the appliance shall

not exceed 0.2 ohm. Test will be conducted using a 10 amp current source with a no-load

voltage not exceeding 6 volts DC for five seconds.

REF: UL544, PAR. 33.1A

IEC601-1, Clause 18 Par. F

Leakage current test

This test checks the current measured from any exposed metal parts to ground with an

input voltage of 120 volts AC at 60 Hz or 240 volts AC at 50 Hz and the ground wires

securely connected. The leakage current in these circumstances shall be less than 50

microamps. See circuit below. The voltage measured across the 1k resistor during this

test shall be 47.5 millivolts or less.

Page 32

28 Testing and verification Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Page 33

29

3

Handle

Troubleshooting guide

Problem Cause Corrective Action

No Tone Check solder connections on speaker/

microphone flex

Make sure speaker/microphone is

properly seated in boot and on SS tube

Check for a clogged SS tube in the

front housing

Defective speaker/microphone

Defective MCU PCB

Unit has tone but there is an open

message w/cavity on probe tip

Tympanogram fails noise test (second

pixel from right is high or missing)

LCD dim or not on Check VCC power; should be at least

Keypad button (s) not working Make sure flex is properly seated

Handle does not power up Low battery voltage

Handle does not download data to

Printer/Charger

Handle battery not charging Battery defective

Tympanogram not finishing, or

noticeably slowing down toward

-400 daPa

Shows leak message when attempting

tympanogram

Tympanogram noisy where the second

pixel is OK

Shows block message w/cavity on

probe tip

Shows block message at all times Debris in probe tip

Fails sound calibration Clogged probe tip tube (s)

Fails motor speed test on ATE Set screw too loose or too tight

Defective microphone

Clogged microphone tube

Defective MCU PCB

Microphone defective Replace microphone

4.8 volts

Defective LCD board

Keypad board defective

Flex cable loose

Defective PS board

Handle not powering up

Defective MCU PCB

Poor connection at charge contacts

PS board defective

Leak in unit

Pump pulley set screw too tight

Unit has a fast leak

Defective pump assembly

Defective or misaligned component Repair noise problem according to the

Unit out of calibration

Defective MCU PCB

Defective MCU PCB

Defective speaker

Defective MCU board

Defective drive belt

Leak in unit

Reflow solder connection

Reseat speaker/microphone as needed

Clean tube as necessary

Replace defective part

Replace MCU PCB

Replace microphone

Clean tube

Replace MCU PCB

Replace PS board

Replace LCD board

Reseat flex

Replace keypad board

Charge/replace battery

Reseat flex cable

Replace PS board

Solve power problem

Replace MCU PCB

Replace battery

Repair poor connection

Replace PS board

Repair leak according to the leak

repair procedure

Readjust set screw

Repair leak according to the leak

repair procedure

Replace pump assembly

noise repair procedure

Calibrate by running unit through ATE

test

Replace MCU PCB

Clean debris from probe tip

Replace MCU PCB

Clean probe tip tube(s)

Replace speaker

Replace MCU PCB

Readjust pulley set screw

Replace drive belt

Repair leak according to leak repair

procedure

Page 34

30 Troubleshooting guide Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Problem Cause Corrective Action

Unit fails current drain test on ATE Pump not finding home position

Defective PS or MCU board

LCD frozen, unresponsive Microcomputer MCU board has locked

up

MCU board has failed

Unit reads 'NEEDS SVC' Hard failure in unit Retrieve error code from sample client

Unit reads 'SYS CHK' Illegal condition in unit Power down by pressing/releasing all

Unit reads 'CAL DUE' One year has passed since last

calibration. Unit due for calibration.

Unit prints “No data. Reinsert Handle’ Switch 2 in wrong position on switch

pack in Handle

Replace pump

Replace appropriate PC board

Press/release all three buttons

simultaneously, then power on

Replace MCU board

program. See instructions in section 5.

Repair, perform bench test and run

through ATE.

three buttons simultaneously. Power

back up. If message goes away,

perform bench test and run through

ATE. If message persists see

instructions in section 5.

Perform bench test then calibrate unit.

Put Switch 2 in correct position

Printer/Charger

Problem Cause Corrective Action

Does not power up; fuse blown Defective print head

Defective main PCB

Does not power up; fuses OK Defective main PCB Replace main PCB

Does not feed paper Cable P302 not properly seated

Defective printout Paper defective

Does not receive data Cable P301 not properly seated

Power light does not light Cold solder joint at P302

Charge LED not lighting when Handle

is inserted into charging well

Charge LED on without Handle in well Defective main PCB Replace main PCB

Power LED blinking No paper in printer

Power LED blinking twice in rapid

succession

Unit fails Dielectric strength test Defective RFI filter

Unit fails ground continuity test Broken or frayed ground connection

Unit fails leakage current test Defective RFI filter

Print head lever out of position

Defective print head

Print head defective

Cold solder joint on contact housing

assembly or P301

Defective contact housing assembly

LED defective

Main PCB defective

Cold solder joint at P301, P302 or

contact housing assembly

LED defective

Defective print head

Print head lever in wrong position Put print head lever in correct position

Defective transformer on main PCB

Defective power cord

Short between circuitry on main PC

board and ground part(s)

Replace print head

Replace main PCB

Reseat cable P302

Put lever in correct position

Replace print head

Replace paper

Replace print head

Reseat cable P301

Reflow solder connection

Replace contact housing assembly

Reflow solder connection

Replace printer keyboard assembly,

p/n 711704-501

Replace main PCB

Reflow solder connection

Replace printer keyboard assembly,

p/n 711704-501

Install paper

Replace print head

Replace RFI filter

Replace main PCB

Repair broken connection

Replace power cord

Replace RFI filter

Remove short

Page 35

Service manual Troubleshooting guide 31

Noise troubleshooting procedure

The purpose to these instructions is to give a general procedure in fixing a noisy Handle

when the cause is not the microphone (second pixel on tympanogram is acceptable).

1. Verify the problem by testing the unit manually with 0.2 cc, 1.0 cc, 2.0 cc, and 2.4 cc

cavities.

2. If the unit is noisy when testing manually, proceed as follows:

a. Remove battery cover.

b. Examine all tubing for kinks, bends, or anything that might restrict air flow.

c. Make sure all tubing is connected to the right place and routed per the drawings.

d. Test whole system for leaks. Leaks will cause noise in the system. Refer to

“Test 1 - Leak and vent tests” on page 14.

3. Remove screws from front housing.

4. Break fiber strips from front housing.

5. Slowly remove the front housing from the back housing. While disassembling,

complete the following actions:

a. Check to see if the microphone, speaker, or pressure transducer parts are

touching each other or the front housing. If they are, this will cause noise in the

unit.

b. Check to see if the silicone tubing from the front housing to the ballast is pinched.

c. See if the bottom flex is routed per drawing around the LCD boss.

d. See if silicone tubing is routed correctly between the pump and frame.

6. Fully open and examine the front housing:

a. Inspect the arrangement of the microphone, speaker, and pressure transducer.

b. Check the positioning of the pump in the back housing.

c. Check to see if all padding is on the pump, top cap, and back housing, and that it

is positioned correctly.

7. Correct any problems identified and reassemble the Handle.

8. Check the Handle for noise. If the Handle is still noisy, disassemble the unit and

replace motor. Reassemble the unit and recalibrate. Perform a noise check.

9. If the unit is still noisy, replace the pump assembly and reassemble. Recalibrate the

unit and check for noise.

Page 36

32 Troubleshooting guide Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Pressure

transducer joint

Top c a p j oint

Ballast

connection

Valve

connection

'T' joint

Leak troubleshooting procedure

The purpose of this procedure is to isolate a leak in the pneumatic assembly of the Handle

so that an accurate diagnosis and repair can be performed.

For this procedure a Hemostat tool is required.

1. Hook up the pressure applicator source to the unit.

2. Using the sample client program, close the valve and apply about 200 daPa to the

unit.

3. Observe the leak rate. Apply the hemostat to the silicone hose between the pressure

transducer joint and the 'T' joint. See picture below.

4. Observe leak rate again. If leak rate remains constant or increases the leak is in the

pressure transducer area. Repair leak and retest. If leak rate stops, remove hemostat

and proceed to step 5.

5. Apply hemostat to hose between 'T' joint and top cap joint. If leak rate remains

constant or increases the leak is in the 'T' joint, ballast or valve areas. Proceed to step

6. If leak rate stops, leak is in the top cap joint or pump assembly. Repair leak and

retest.

6. Move hemostat to hose between valve and ballast. If leak rate remains constant or

increases the leak is either the 'T' joint or ballast area. Repair leak and retest.

7. If the leak rate stops, the leak is in the valve. Repair leak or replace power board and

retest.

Page 37

Service manual Troubleshooting guide 33

Error and service code tables with troubleshooting procedure

This procedure shows the error codes, their probable causes and solutions and the

method of logging of such codes.

Error codes

Code Description Probable cause

EF CHECKSUM_ERROR MCU problem

EE THREADX_ERROR MCU problem

ED AUDIO_ERROR MCU problem

EC SLAVE_COMM_ERROR MCU problem

EB HOME_PUMP_ERROR Pump or flex problem, PS problem

EA AUTO_ZERO_ERROR Pressure transducer or pump or sensor flex problem

E9 SLAVE_STATUS_REGISTER MCU problem

Error codes can be used to help determine the root cause of a problem condition. The

error log is listed in the following format “YYYY-MM-DD HH:MM:SS Category Code.” See

explanation of Category Code on page 34.

Retrieving and clearing error codes

To retrieve the errors from a unit, hook up the Handle to a service computer via USB

cable. Navigate to sample client program. Disable power timeout per “Preparation for

test” on page 13.

Type in the following sequence:

On main menu, enter 12, FmTYMP Test; enter 13, Data Transfer (LUTs, Logs,

EEPROM); enter 2, Logs; enter 1, Error. The following screen will appear.

Notice the second line from the bottom, MicroTympErrorLog.txt:Done 100%.

When this error log selection is executed the program will create a file called

‘MicroTympErrorLog’. This is in the ‘sample app’ folder. See screen shot on next page.

Page 38

34 Troubleshooting guide Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

If no errors are to be logged, the last two numbers on the error log in this file will be

00 00. This is called a ‘clean’ error log. See example below for explanation.

The date is retrieved from the real time clock on the Handle. The format of the date is

shown as: “2009-07-15 14:12:07”

Here is an example of a clean error log: "2009-01-01 00:02:07 00 00" where 00 indicates

no error category and 00 indicates no cause, or defective software function.

Below is an example of the error listings found in this file.

2009-09-04 17:08:37 EC CA See category code explanation below

2009-09-04 17:09:11 EC CA

2009-09-04 17:49:10 EC CA

2009-09-04 17:51:42 EC D1

2009-09-04 17:51:48 EC CA

2009-09-04 17:52:20 EC CA

2009-09-04 17:55:52 EC CA

2009-09-04 17:56:26 EC CA

2009-09-04 17:59:46 EC CA

2009-09-04 18:01:19 EC CA

2009-09-04 18:08:10 EC CA

Note that if data from another Handle is extracted, the program will overwrite the first file,

erasing that data from the first unit. To avoid this, rename or relocate the first file when

finished with the first unit.

To clear the error log, navigate to the main menu. Enter 12, FmTYMP tests; enter 3,

Send Command; enter 3, CLEAR_ERROR_LOG. Errors will be cleared.

Service codes

Service codes are those messages that display on the LCD of the Handle. They indicate

the condition of the unit. The available service codes are listed in the ‘Display’ column in

the table on the following page. With the exception of the codes ‘NEEDS SVC’ and

‘NEEDS CAL,’ all other codes can be reset by powering down, then powering up. There is

a table on the next page showing the service codes along with pertinent information that

the Handle will display.

1

1. Concerning the last two pieces of data, the first one listed is the error category code (EC) which is listed in step 1 on the previous page

and the particular data string (CA) which is causing the failure. Because these strings are usually software commands, they are not

listed in step 1. However, when an error log is displayed, this piece of data can be noted and if one data string stands out as occurring

most or all of the time a particular error occurs, the software code can be corrected to reduce or eliminate the string error, thus

reducing or eliminating the error itself.

Page 39

Service manual Troubleshooting guide 35

Note

Error condition Display Log Description Action by unit

Timer false

Calibration false

Calibration due

Processor exception

Stack overflow

Thread X Timeouts,

Thread X Queue Full

Queue Empty

I2S under/overruns

Checksum error (cal

data, device info)

Slave communication

errors

Home pump error SYS CHK Date, Service error

Auto zero error

CAL DUE Nothing The RTC clock is

CAL DUE Nothing Current calibration is

SYS CHK0 Nothing. Unit could

be in a state that

we could corrupt

the EEPROM

SYS CHK1 Nothing. Unit could

SYS CHK Date, Service error

SYS CHK Date, Service error

NEEDS SVC

(fatal)

NEEDS SVC

(fatal)

NEEDS SVC

(fatal)

be in a state that

we could corrupt

the EEPROM

code, eng error code

code, eng error code

Date, Service error

code, eng error code

Date, Service error

code, eng error code

code, eng error code

Date, Service error

code, eng error code

Displays CAL DUE for three

invalid (possible dead

RTC battery or bad

MCU board)

over one year old

Processor exception Can’t Log error. Displays SYS

Stack overflow Can’t Log error. Displays SYS

Thread X Timeouts,

Thread X Queue Full

Queue Empty

I2S under/overruns Logs error. Displays SYS CHK

The calibration data

is bad

Slave communication

errors

Home pump error Logs error. Retries until

Auto zero error Logs error. Displays SYS CHK

seconds then proceeds as

normal.

Displays CAL DUE for three

seconds then proceeds as

normal.

CHK0 and powers down after

three seconds.

CHK1 and powers down after

three seconds.

Logs error. Displays SYS CHK

and powers down after three

seconds.

and powers down after three

seconds.

Logs error. Displays NEEDS

SVC and powers down after

three seconds.

Logs error. Displays SYS CHK

and powers down after three

seconds. Displays NEEDS SVC

on next power up.

timeout. WA will be displayed

on the screen (power up splash

screen), but after 15 seconds,

display changes to SYS CHK.

and powers down after three

seconds. Displays NEEDS SVC

on next power up.

The error log can store up to 78 errors. Subsequent errors are overwritten on a

“first in, first out” basis.

Note that the NEEDS SVC message is fatal. When this occurs the unit must be serviced.

After servicing, run unit through complete ATE test.

All other service codes can be cleared by powering down/powering up. These are the

SYS CHK, the SYS CHK0, and the SYS CHK1. These codes indicate that an abnormal

condition has occurred in the unit. If powering down/powering up removes the code, the

unit is operable.

But if there is a hard failure in the unit, the code will return upon powering up. The service

person is free to power down/power up as many times as they see fit in an attempt to

remove the code. If the code continues to return, servicing will be necessary.

Page 40

36 Troubleshooting guide Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

There are two exceptions to this arrangement: the “slave communication” (EC) and

“autozero” (EA) error codes. When these codes occur, the unit will power down as it

would with any other code. Upon powering up again, the NEEDS SVC code will appear.

An example of the working of the SYS CHK code would be a home pump error failure

(EB). This is where the piston/diaphragm slips off of the top of the pump pulley. The unit

will attempt to drive the pump home by running the pump downward. If the pump pulley

fails to grab the piston/diaphragm in the time provided (about five seconds), the unit will

display SYS CHK. Powering down/up repeats the process. Often the pump pulley will grab

the piston/diaphragm and successfully drive the pump to ‘home’ position. When this

occurs the SYS CHK code does not return resulting in an operational unit. But if the

process is unsuccessful, the SYS CHK message will return. The service person can

repeat the process as many times as they will. If the pump pulley will not grab the piston/

diaphragm, the unit will need to be serviced.

Page 41

37

Note

4

Disassembly and reassembly

Handle

Caution ESD protection must be worn at all times while performing any

assembly or disassembly of either the Handle or Printer/Charger. Failure to

observe this can cause premature component failure in the field even though

such failure may not be evident at the time of the violation. Oftentimes

weakened components will operate, even as normal, for a period of time before

exhibiting failing characteristics. For this reason ESD protection is vital for long

term, proper operation of this equipment to occur.

It is also advisable to have a vice grip on hand in order to hold the subassemblies

stable while assembly and/or soldering is being performed on them.

Disassembly Procedures

Removal/replacement of front housing assembly

1. Remove battery cover by removing screw near bottom of handle. Lift off and remove

battery. To remove battery, push down and roll at positive end of battery. See positive

symbol on contact block.

Page 42

38 Disassembly and reassembly Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Side seal (also on other side) Pump pad

Transducer Speaker Microphone

2. Remove Welch Allyn logo on front housing and remove the two screws that hold the

front housing down. Gently rock housing side to side while lifting. Break glue bond

that exists between the side tabs and the housing. Slowly undo the seal that is on the

top of the pump and the two sides. When the front housing lifts up, turn it over and

away from you, taking care not to pull on the flex circuits.

3. Using a needle-nose pliers, remove the transducer by gripping part and pulling

straight out. Next, remove the speaker and microphone by reaching in and pulling

each component straight out, one at a time. Probe tip is now removed. Note that the

microphone has three contacts and the speaker has two contacts.

4. Assembly is the reverse of disassembly. When installing the speaker, microphone,

and pressure transducer onto the replacement probe tip, push straight onto

respective tubes. Do not force. See picture which follows this step for placement of

parts. Recommended torque specification is 2.0 in./lbs.

Caution The microphone must be put onto the correct tube as shown. The

speaker and microphone cannot be reversed because the tube for the

microphone is the raised center tube. Reversing these two components will alter

the sound output of the product, falsifying readings.

Caution When reassembling the front housing, make sure flex cable is clear of

the screws.

Page 43

Service manual Disassembly and reassembly 39

Speaker tube Microphone tube Transducer tube Microphone tube

Speaker Microphone Pin number one on flex cable

Main body of component Print on transducer

Removal/replacement of the front housing parts: speaker, microphone, and transducer

1. With the front housing removed, select the component that is to be replaced. If a

stable vice is unavailable, unsolder/solder the component while in the front housing

assembly for stability purposes.

2. Notice the flex cable and its orientation to the speaker and microphone. The flex cable

is laid over the main body of both components. The replacement must be installed

the same way. After the speaker/microphone is removed, pull component from the

boot. The boot is the silicone cover for each component. See picture below.

3. When replacing the pressure transducer, unsolder the four pins on the flex. Carefully

pull transducer through the flex, moving it side to side to break the remaining solder.

When installing the replacement part, make sure the printing on the one side of the

transducer is on the same side as the number one pin on the flex cable. Again,

carefully observe the orientation of the original part and install the replacement part

the same way.

Removal/replacement of the pump/motor assembly and associated parts

Pump/motor assembly

1. With front housing removed, remove pressure transducer and disconnect the long

silicone tube from the black connector in the transducer boot.

Page 44

40 Disassembly and reassembly Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Disconnect silicone tube Power board connector, below silicone tube

Pull silicone tube from this

location

Keypad board connector LCD connector

Motor wires O-ring drive belt

2. Remove flex cable from connector on LCD board. Remove flex cable from connectors

on the keypad and power boards. These are opposite ends of the same flex cable.

3. Gently pull long transducer silicone tube through the pump frame. Pull from the

ballast side of the pump.

4. Disconnect silicone tube from the black connector on the pump top cap. Pump/motor

assembly can now be removed from the Handle.

Once the pump motor assembly has been removed, another one can be installed or the

assembly can be further dismantled.

Motor/pulley assembly

To remove the motor, remove the two small straight edge screws on top of the split black

frame. Unsolder the black and red wires from the flex cable. Turn assembly over and

carefully remove the o-ring drive belt from motor pulley. Assembly is the reverse of

disassembly. Recommended torque specification is 8.0 in./oz.

Page 45

Service manual Disassembly and reassembly 41

Pulley retainer

Pump top cap

Piston/diaphragm assembly

O-ring drive belt

To replace the drive belt, remove pulley retainer. Remove belt from white pulley and

motor. Replace with new belt. To avoid getting skin oils on the belt, use tweezers.

Pump pulley

With pulley retainer removed, remove drive belt and unscrew pulley from pump. Install

new pulley the reverse of removal. See picture above. Recommended torque specification

is 1.5 in./lbs.

Piston/diaphragm assembly

Remove pulley retainer and top cap of pump assembly. Unscrew white pump pulley, and,

from the top of the pump assembly, remove the piston/diaphragm assembly by lifting

upward. Install new piston/diaphragm assembly in the reverse order of removal.

Recommended torque specification is 9.0 in./oz.

Page 46

42 Disassembly and reassembly Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Optical interrupter

LCD bezel fingers Retainer fingers Housing opening Shallow angle of retainer

Remove retainer

Install retainer

Optical interrupter

With the pump assembly in hand, unsolder the four flex cable connections from the

optical interrupter. Remove the two Philips head screws on side of pump opposite the

motor. Remove part and install the new part in reverse order. Recommended torque

specification is 9.0 in./oz.

Removal/replacement of the LCD and keypad board assemblies

1. With the front housing and pump/motor assemblies removed, remove the two

Philips head screws in the LCD module retainer, which is the black plastic frame

covering the keypad and LCD assemblies.

2. Lift and pull the retainer back to remove.

3. Replace desired part as it will lift freely out of the Handle housing.

4. Reassembly is reverse of disassembly. When reassembling, make sure LCD and

keypad assemblies are properly seated in the housing.

5. When installing retainer, put front through opening in housing first. The retainer must

be at a shallow angle or it will not insert into the opening in the housing.

6. Insert retainer through opening and slide finger of retainer over connector on LCD

board. Align retainer and screw into housing, making sure that the retainer fingers are

not on top of the LCD bezel fingers. Recommended torque specification is 2.75in./lbs.

Page 47

Service manual Disassembly and reassembly 43

Four pack switch

Lock washer

Flex cables out of path of board removal

Push shield back to clear USB port

Removal/replacement of the power PCBA

1. Remove pump/motor assembly by following steps 1 through 4 on page 39.

2. With a small size Philips screwdriver, remove the four screws located at each corner

of the power board. Note the different lengths of the screws between the two in the

rear and two in the front of the PC board. The screw closest to the four-pack switch

has a number six-lock washer underneath it.

3. Slide positive and negative charge contacts off the housing.

4. Hold the double flex cable to the side of the housing so it does not catch the power

board that is being removed.

5. Lift power board gently, starting from the front of board, closest to the pump/motor

assembly. The shield may have to be pushed toward the back of the Handle to allow

the USB connector to freely pass.

6. Replacement of new board is in reverse order of disassembly. Remember to keep the

flex cables clear of the board being installed. Recommended torque specification is

2.0 in./lbs.

Page 48

44 Disassembly and reassembly Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Removal/replacement of the MCU PCBA

1. With the power board removed, use a 4-mm or 5/32-inch driver to remove the four

standoffs that are holding the MCU board in the housing. Try to use a driver with thin

walls because of the proximity of the standoffs to the housing sides.

2. With all four standoffs removed, remove the two flex cables that are inserted in the

MCU board.

3. Gently lift MCU board, taking care to avoid catching the ESD shield.

4. Replacement is reverse of removal. When installing the new MCU board, make sure it

is properly laid over the pem studs.

5. Take care to start the standoffs in straight. If you start the standoff in crooked, you

might strip the threads of both the standoff and the pem stud. Recommended torque

specification is 2.0 in./lbs.

Page 49

Service manual Disassembly and reassembly 45

LCD shield ESD tape

Main ESD shield

Replacement of Lithium coin battery

1. Remove MCU board from housing.

2. Slide coin battery straight out.

3. Slide new coin battery straight in.

4. Push in until whole battery is inside edge of circuit board.

Proper placement of ESD shields in the back housing

See pictures below to observe correct placement of ESD shields in the Handle. This

would include the main body and the LCD shields.

Page 50

46 Disassembly and reassembly Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

Note

Keep ribbon cable clear of bottom of standoff

Black side of cable toward print head

Nylon bolt

Conductor side of cable away from print head

Philips screws

Printer/Charger

Caution

disassembly of either the Handle or Printer/Charger. Failure to observe this can cause

premature component failure in the field even though such failure may not be evident

at the time of the violation. Oftentimes weakened components will operate, even as

normal, for a period of time before exhibiting failing characteristics. For this reason

ESD protection is vital for long term, proper operation of this equipment to occur.

It is also advisable to have a vice grip on hand in order to hold the subassemblies

stable while assembly and/or soldering is being performed on them.

ESD protection must be worn at all times while performing any assembly or

Removal/replacement of the top panel

1. Turn Printer/Charger (referred to as printer) over and remove six Philips screws and

one nylon bolt. A medium-size Philips screwdriver and a 3/16-inch driver are needed.

2. Lift off top panel. Do not pull up too fast as the contact housing assembly and keypad

board cables are attached to the main PC board.

3. Carefully unplug cables from their respective connectors and remove top panel.

4. Replacement is the reverse of removal. Note orientation of cables when installing.

Recommended torque specification is 3.5 in./lbs. for screws and 7.0 in./oz. for the

nylon bolt.

Caution Never substitute a metal bolt for the nylon one. Doing so will cause the

fuse to blow on the main PC board upon power up.

Caution

panel. The screw will easily puncture the ribbon cable if it is pressed into the standoff.

Keep ribbon cable clear of bottom of standoff when re installing the top

Page 51

Service manual Disassembly and reassembly 47

Tight fit with 3/16-inch drive socket

¼-inch nuts

Four print head screws

Removal/replacement of the main PC board and print head assemblies

1. Remove top panel assembly.

2. Using a ¼-inch driver socket unscrew the two nuts holding the main PC board to the

bottom housing.

3. Lift the main PC board/print head assembly out of the bottom housing.

4. Remove the three AC power wires from the connector in the back of main board.

5. Using a thin-walled 3/16-inch driver, unscrew the four nuts off of the print head

assembly. Take precautions on the nut by the motor as the plastic housing encroaches

around the nut. It may be best to use a 3/16-inch open-end wrench on this nut.

6. Remove the print head, printer well, and printer mounting plate from the main board.

7.

Disconnect the three print head cables from connectors in the back of the main board.

8. If replacing the main PC board, obtain the new board and reassemble in the reverse

of disassembly. Start with the two screws with 1/4-inch nuts. Recommended torque

specification is 2.5 in./lbs. on the screws.

9. If replacing the print head assembly, obtain new print head and properly align it with

the mounting plate and printer well. Reassemble in the reverse order of disassembly.

Recommended torque specification is 2.75 in./lbs. for the nuts attaching the print

head.

Page 52

48 Disassembly and reassembly Welch Allyn MicroTymp3 Handle and MicroTymp Printer/Charger

IR flex assembly

Ferrite bead wrapped w/ mylar tape

Contact housing assembly

Tongue

Push tongue through opening

Removal/replacement of the contact housing and IR flex assemblies

1. Remove top panel.

2. With top panel in hand, grab the housing assembly on the IR PC board, push in, then

pull down. Assembly will come out of top panel assembly.

3. To remove the IR flex assembly, unsolder the four wires from the IR board. Observe

4. Remove the two screws. Discard defective IR flex assembly.

5. Obtain two of part number 761218. This is a half ferrite bead. Surround the flex of the

6. Screw assembly onto contact housing assembly. Re-solder the four wires onto the IR

7. To install the contact housing assembly align underneath the well opening of the top

color for each location.

new IR flex assembly and wrap about two revolutions tightly with mylar tape.

board. Recommended torque specification is 16.0 in./oz.

panel assembly. There is a little tongue on the contact housing assembly. Push it

through the small opening in the top panel assembly. Push forward and up. Contact

housing will snap into place.

Page 53