Page 1

Endo Menu

Service Manual

Proximal Camera Operating Instructions

Page 2

Fvi!!

Welch

Thank you for purchasing the Welch Allyn FX-100 Flexible Sigmoidoscope. The operating and maintenance instructions found in this

manual should be followed to ensure many years of accurate and

reliable service. Please read these instructions thoroughly before

attempting to use your new FX-100 Flexible Sigmoidoscope.

Allyn

Contents

Specifications

Components..

Nomenclature

Prior to Initial Use

System Setup

System Inspection

Operations........................................................................................

Electrosurgeryy

Cleaning and Disinfection

Cleaning..

Disinfection

Sterilization........................................................................................

Troubleshooting Chart

Maintenance and Storage

Service...............................................................................................

......................................................................................

......................................................................................

......................................................................................

...............................................................................

...................................................................................

............................................................................

...................................................................................

................................................................

.......................................................................................

....................................................................................

.....................................................................

................................................................

Page

No.

3

4

7

9

10

11

17

22

22

24

35

47

48

50

51

Page 3

Warning

The user of the FX-100 Flexible Sigmoidoscope should be thoroughly

trained in the medical procedures appropriate to the equipment.

Furthermore, time should be taken to read and understand these

instructions before performing any procedures. Instructions for

other equipment used in conjunction with the flexible sigmoidoscope

(e.g. electrosurgical generators, suction machines, snares, etc.)

should also be read and understood. Failure to do so may result in

injury to the patient and/or damage to the instrument.

While this manual describes the recommended protocol for inspecting

and operating the equipment, it does not outline procedure tech-

niques. Only physicians trained and versed in the procedure of flexible

sigmoidoscopy should use this equipment.

Specifications

Description

Working Length

Insertion Tube Diameter

Biopsy Channel Diameter

Bending Section

Deflection Range

Angle of View

Depth of Field

Inflation

Water Feed

Immersible

180

o

Up/Down

Specification

65 cm

13.6 mm

3.2 mm

160o Right/Left

o

100

3-100 mm

Automatic

Manual/Automatic

Yes

3

Page 4

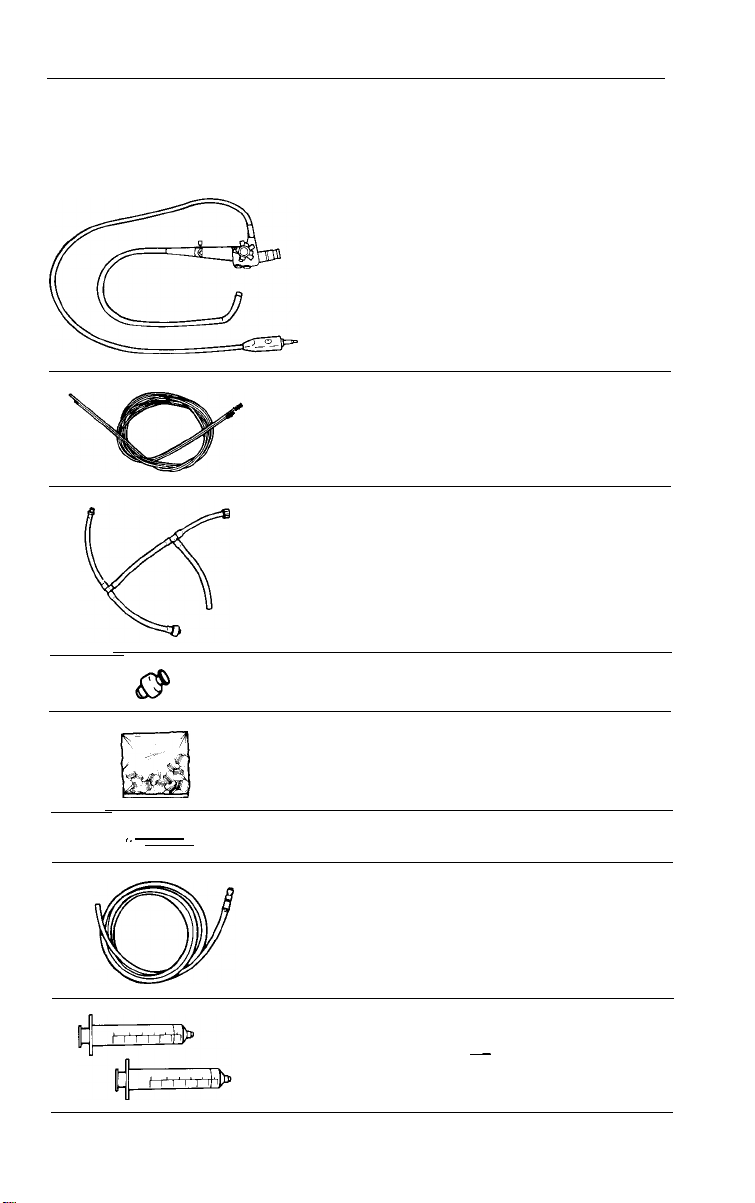

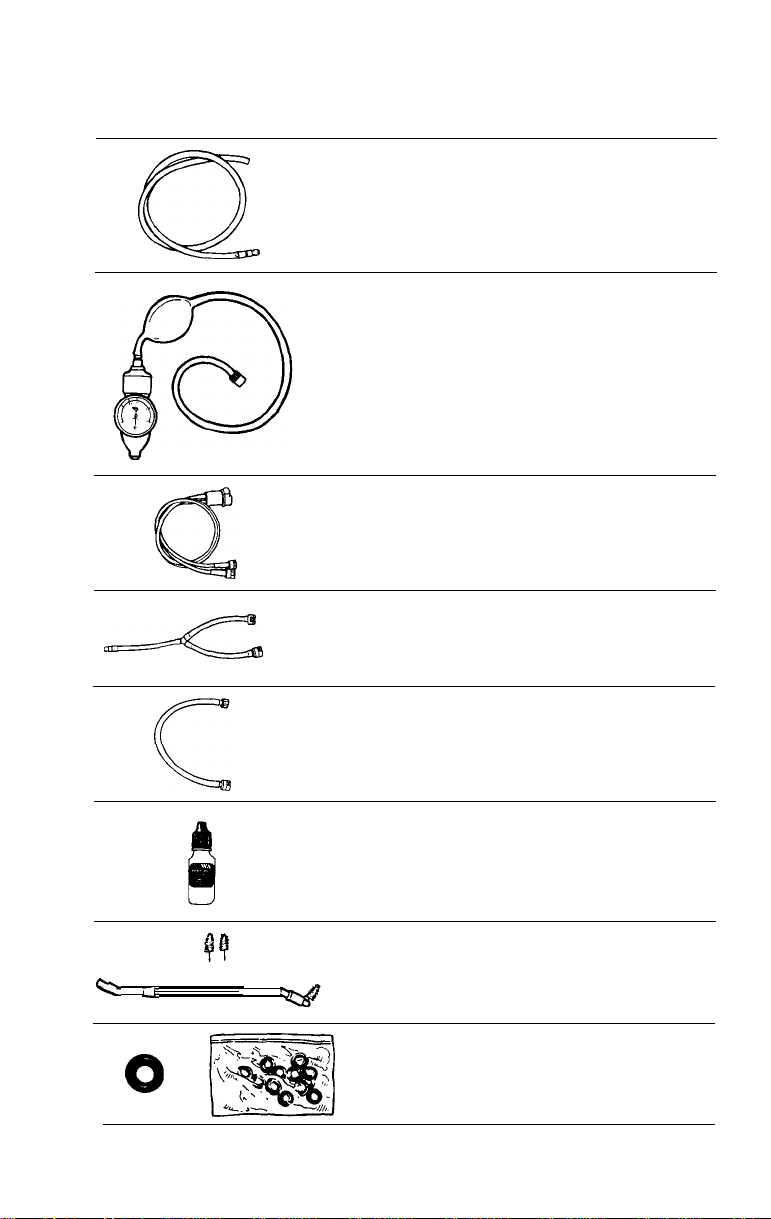

Components

FX-100 Flexible Sigmoidoscope

#33900 Fiber Optic Sigmoidoscope Includes:

FX-100 Fiber optic sigmoidoscope

#33910 Cleaning brushes (2 ea.)

#33911 All channel irrigator

#33919 Air/water disinfection cap

#33930

I.

#33907 Manual irrigation tubing

#33913 Suction tubing

#33908 2 Each

Biopsy seals (10 each)

-

30 cc syringe

4

Page 5

a

#33912 Biopsy cleanout adaptor

#33922 Leakage tester

#33906 Dual lumen air/water line

L

Q >_’

Q

(Actual Size)

c

ir4

#33916 Air/water disinfection line

#33914 Blowout adaptor

#33918

#33924 Air/Water nozzle

#33923

Valve lubricant

cleaning brush

Air/water & suction valve

"O"

rings (12 per bag)

5

Page 6

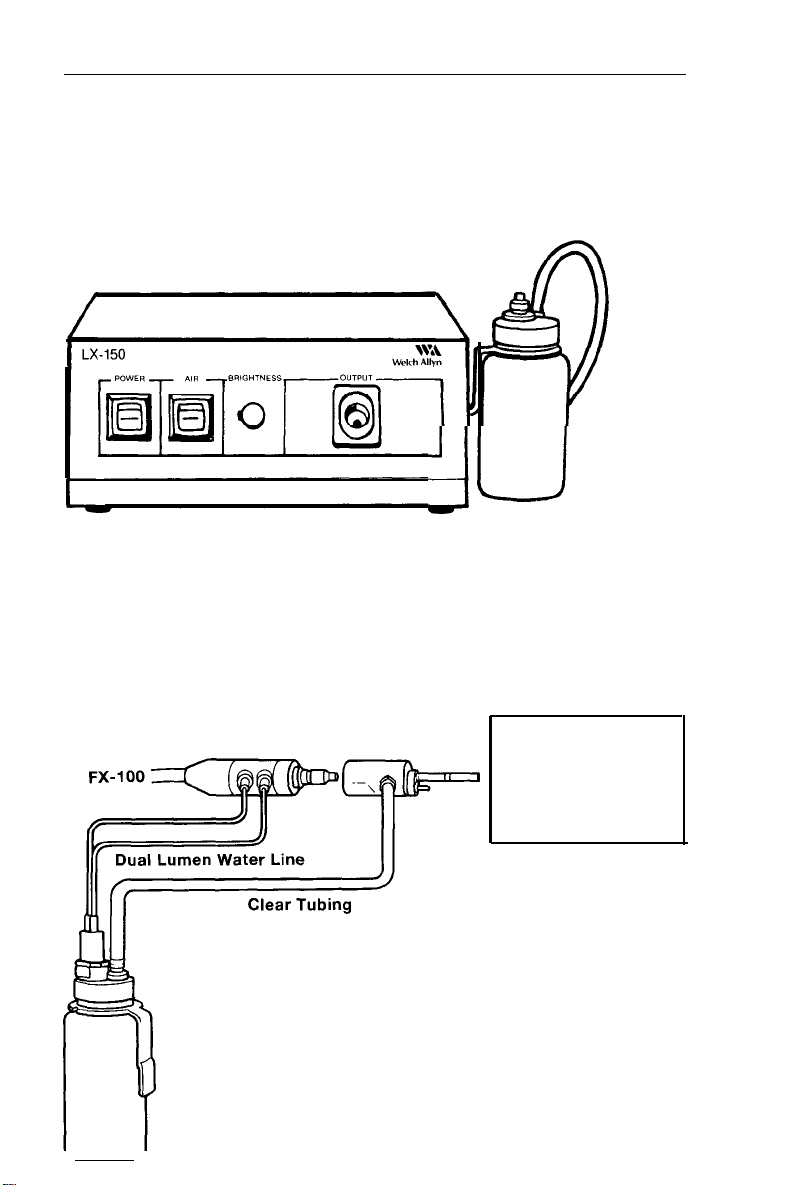

LX-150 Light Source

#45250

1.

2. Water bottle assembly - #33905

3. FX-100 Disinfection Video Tape

Light Source includes:

Light source - LX-150

Water

Bottle

Assembly

J_J

#33905

Adaptor

#45157 CLK-3 Adaptor (Olympus)

Allows the FX-100 to couple to an Olympus CLK-3 light source

CLK-3

AW

Adapter

Olympus CLK-3

Light Source

Allyn

Welch

Water Bottle

6

Page 7

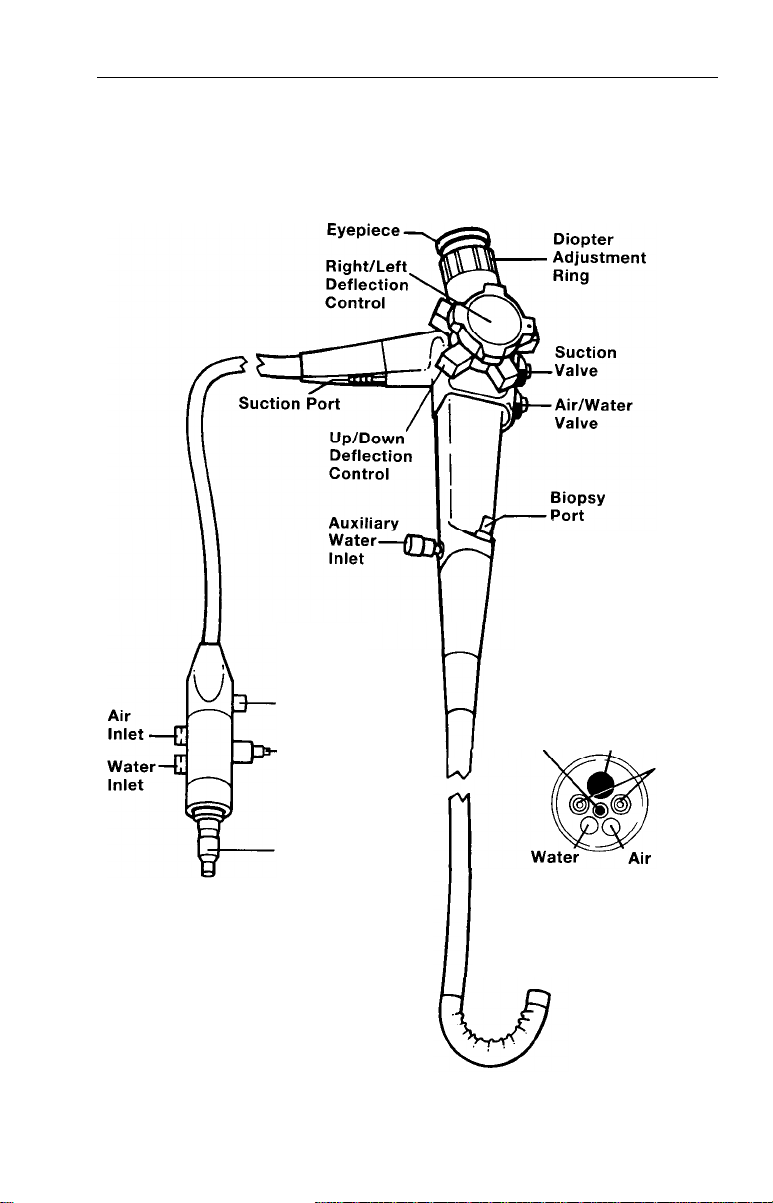

Nomenclature

Fiber Optic Sigmoidoscope

CONTROL

SECTION

ENDOSCOPE

CONNECTOR

TERMINAL

Ground

Cord

Connector

ETO

Vent

Connector

Light Guide

Terminal

Objective Biopsy/Suction

Lens

Nozzle

BENDING SECTION

7

Channel

Light

Guides

Nozzle

DISTAL

TIP

Page 8

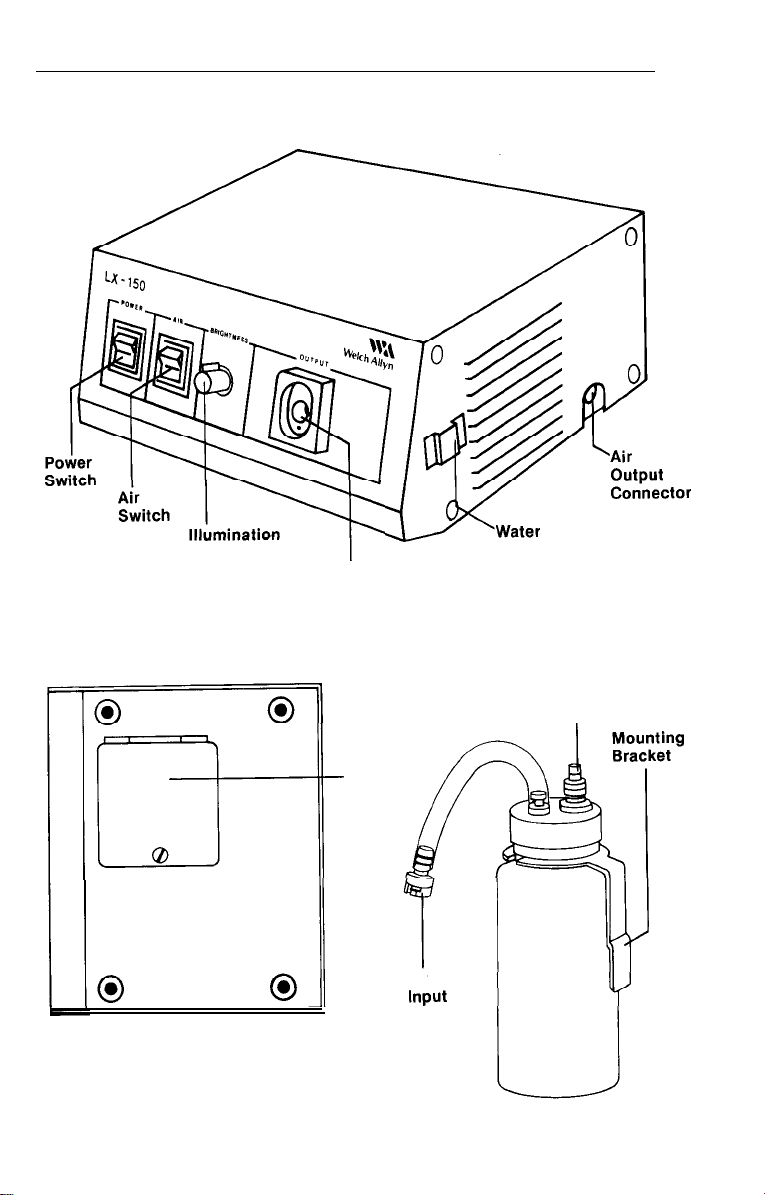

Light Source

Control

,

Mater

Endoscope

Connector Port

Bottle Connector

Bracket

Air/

Water

output

BOTTOM VIEW

Lamp

Access

Door

Air

Hose

WATER BOTTLE

8

Page 9

Prior to Initial Use

9

Before preparation or set up of the equipment, check all components

received against list of components (see components section) to

verify complete set. If parts are missing, please notify Welch

Allyn.

Review the nomenclature, setup, operation and cleaning/disinfection

sections to become familiar with the equipment.

Specifically, inspect:

Fiber Optic Sigmoidoscope

l Insertion tube

l Control section

to assure smooth rotation of controls

l Biopsy channel

channel to verify smooth passage

-

for tears, cuts, dents, bubbles, bumps

-

depress valves, test bending section deflection

-

pass cleaning brush through biopsy/suction

Light Source

l Cabinet

-

for any dents, scratches or other abnormalities

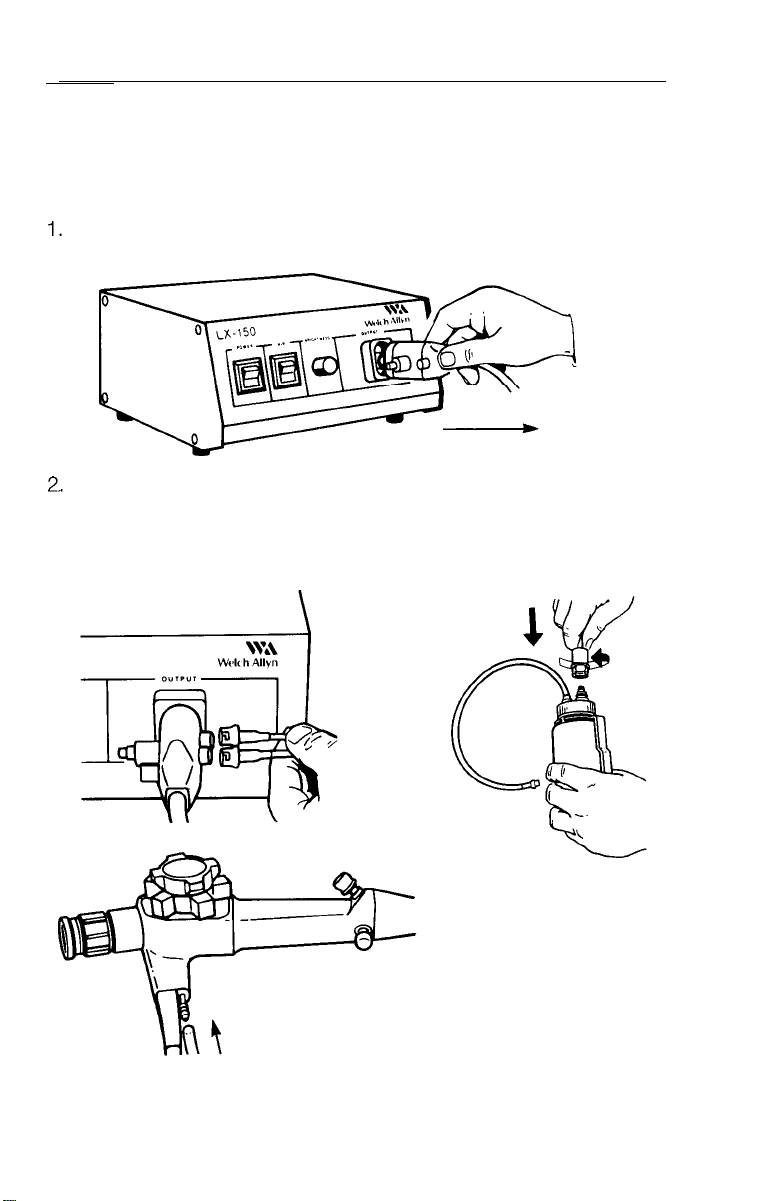

System Setup

Light Source

Plug the light source into a properly grounded 110-120 volt

AC outlet. Activate power and air switches to verify functionality

of illumination and pump.

Fill water bottle approximately 3/4 full of clean tap water. Replace

and tighten the cap and attach to water bottle bracket on the

right side of light source.

Connect air input hose on water bottle to air output connector on

right side of light source.

9

Page 10

System Setup

Fiber Optic Sigmoidoscope

NOTE:

use, following the steps starting on page 24 and 35, or in the FX-100

cleaning and disinfection video tape.

Endoscope should be cleaned and disinfected prior to initial

Plug endoscope connector terminal into endoscope connector port

of light source. Push gently until it “snaps” into place.

Connect ends of dual lumen air/water line to the color coded

air/water outputs on endoscope connector terminal (White =

Water, Green = Air). Attach remaining end to water bottle. Mount

3/4 filled water bottle on light source bracket and couple remaining

hose to air output connector.

Connect suction

3.

tube to suction port

on control section.

Attach remaining

end to suction

source receptacle.

4. Verify biopsy seal is seated in place over biopsy port opening.

10

Page 11

System Inspection

The following steps should be repeated prior to every procedure to

verify that the system is working. If any problem is encountered,

immediately consult the troubleshooting section of this manual or

contact your local Welch

assistance.

Physical Inspection:

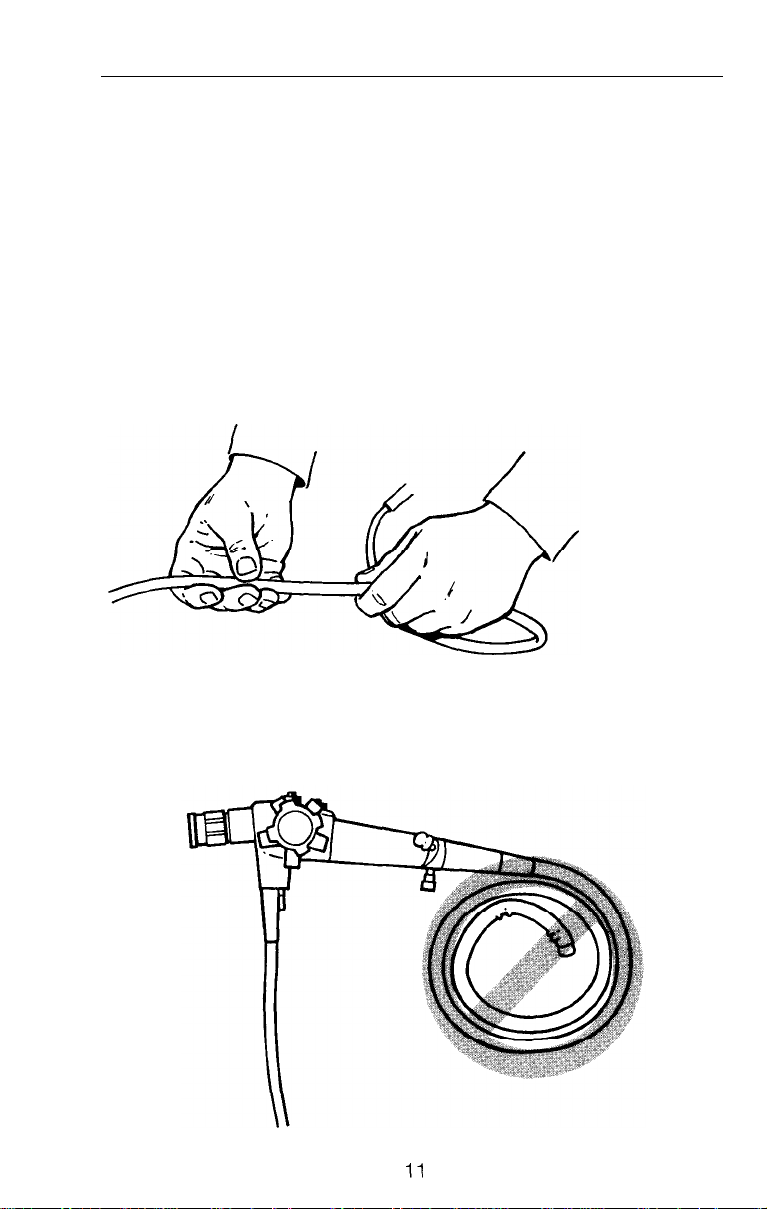

Insertion Tube and Bending Section

l Inspect the insertion tube for tears, cuts, dents, bubbles, bumps

or other abnormalities on the surface.

l

Run your fingers carefully over the entire length to check for

protruding braid, internal looseness or other abnormalities.

Allyn

distributor or representative for

CAUTION: Do not wind insertion tube into a tight radius. Serious

damage to internal fibers could result. Proper storage procedures

are outlined on page 50.

Page 12

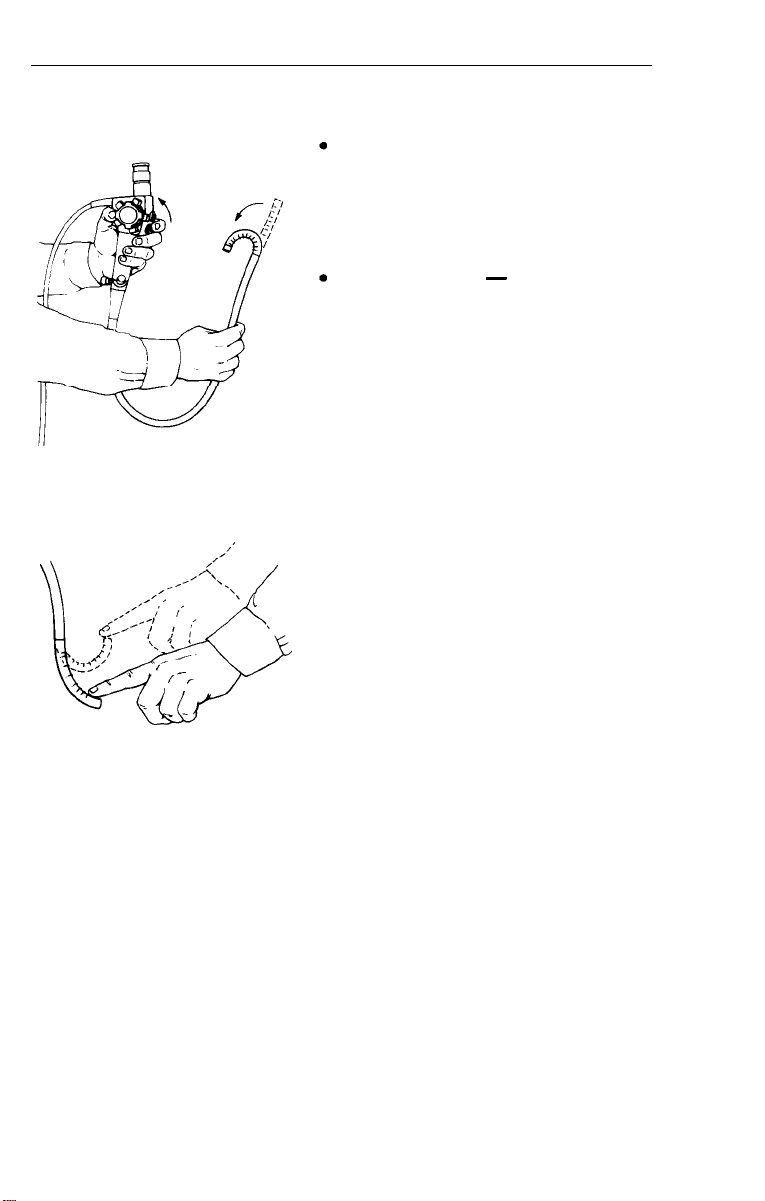

Deflection Controls

Operate deflection controls slowly

in all directions. Make sure that

deflection is smooth and that no

friction or grinding is present.

Up/down plane - rotate the up/

down deflection control knob to its

limit in each direction. It should

rotate without excess friction.

l Right/left plane

-

rotate the

right/left deflection control knob to

its limit in each direction. Unlike the

up/down control, a slight resistance

or “drag” should be apparent. This

is a design of the scope that allows

the bending section to remain in

position without holding the control

knob. The bending section should

not lock into position. To verify this,

deflect the control to maximum and

release. The bending section should

return to a straight or neutral posi-

tion by applying gentle pressure with

your index finger.

WARNING: If the resistance in the right/left deflection plane

is higher than normal, DO NOT USE the instrument. Contact

Welch Allyn Customer Service for assistance.

CAUTION: Do not deflect the bending section by hand. This

applies excess force to the deflection mechanism and may

result in failure.

12

Page 13

Light Source

1. Activate “power” switch. This will start the lamp and cooling fan.

CAUTION: Do not look directly into the endoscope connector

port when activating the light source.

2.

The output of the light source is then controlled by the illumination

intensity control. Clockwise rotation will increase illumination

output. Counter clockwise will decrease illumination.

3. Activate “air” switch. This will start the internal insufflation pump.

Inspection of Air Feed

1.

Place tip of bending section into clear water. Cover hole on top of

air/water valve with finger tip. Do not depress valve. Air should flow

freely through the instrument and water should bubble vigorously.

2. Remove finger - bubbling should end immediately.

13

Page 14

Inspection of Water Feed

1.

Depress air/water valve completely. Water should flow in a

constant stream over objective lens and light guides.

2.

Release valve - water flow should end immediately.

NOTE: Upon initial setup, depress and hold down valve for a few

seconds for water to completely fill line in instrument.

Inspection of Suction

1.

Verify that suction tubing is attached and suction machine is on.

Immerse tip of bending section into clear water and completely

2.

depress suction valve.

Verify aspiration by viewing water flow into suction receptacle.

3.

Releasing valve should stop suction immediately.

14

Page 15

Inspection of Manual

Water Feed

1.

Connect manual irrigation

tubing to auxiliary water

inlet on endoscope.

2. Fill syringe with clean tap

water and connect to

remaining end.

3. Feed water through inlet

and verify that it exits from

water nozzle over objective

lens and light guides.

NOTE: If leak occurs at inlet, tighten connector. If leak

continues, call Welch Allyn Customer Service.

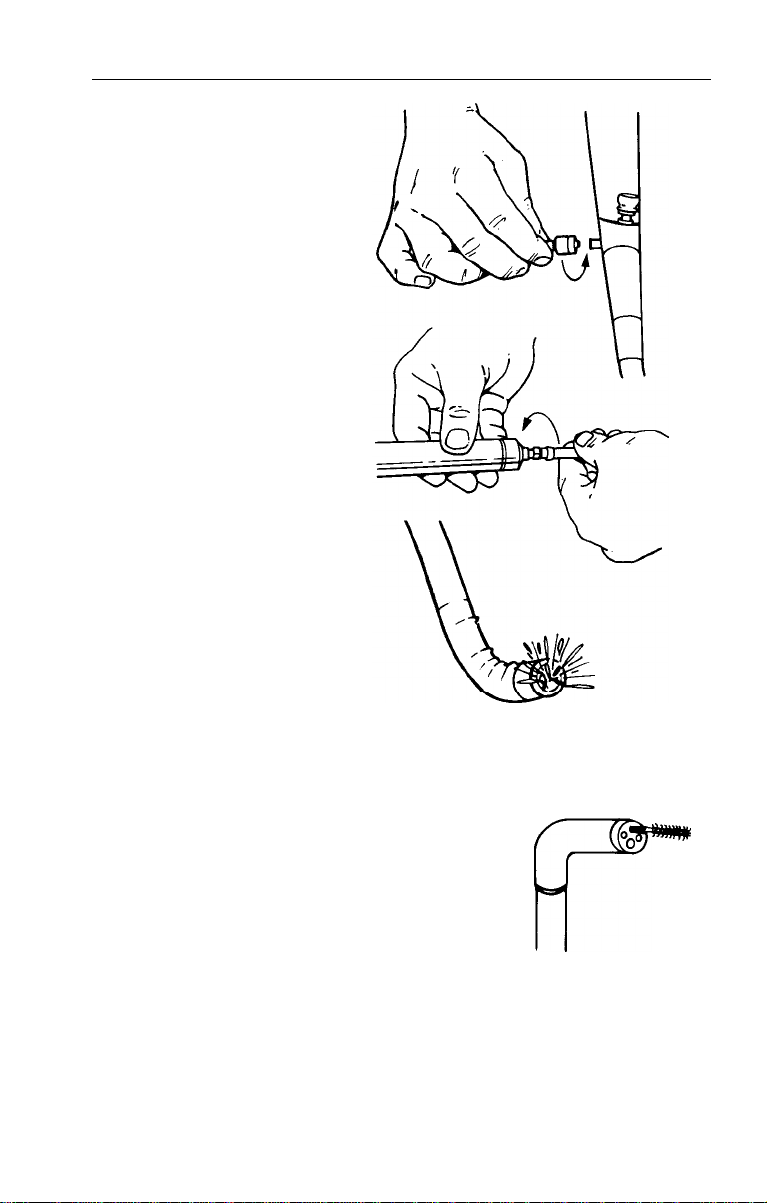

Inspection of Biopsy/Suction Channel

1.

Deflect bending section 90o in “up” direction.

2. Pass cleaning brush or forceps through the

biopsy channel to verify a clear pathway.

3. Repeat Steps "1 and 2” in three remaining

directions.

NOTE: If resistance is encountered, DO NOT force. Contact

Welch Allyn Customer Service.

15

I!=

“0 MB

Page 16

Inspection of Light

Guides and Optics

1.

With lamp on, hold distal tip

approximately 40 mm from

any printed surface.

2. Verify light is being emitted from light guides.

3.

Hold eyepiece to your eye and rotate diopter ring until print is in

focus. Verity focus from 10-40 mm from surface.

Inspection of Umbilical Cord

1.

Check the umbilical cord for cracks, dents, crushed and

twisted areas.

2.

Verify that the endoscope connector terminal’s light guide terminal

fitting is tight and does not move when moderate pressure is

applied.

NOTE:

prior to every use. (Follow steps starting on pages 22 and 47, or

demonstrated in the FX-100 cleaning and disinfection video tape).

Instrument should be cleaned, disinfected and sterilized

16

Page 17

Operations

Procedure

The methods and techniques of flexible sigmoidoscopy are well

defined and documented. Endoscopy training seminars and

preceptorship programs are also in existence worldwide.

No attempt is made in this manual to outline the medical procedure

or techniques of flexible sigmoidoscopy. The physician should always

take care to understand the clinical background of each patient and

the possible contraindications of the procedure.

Holding the Instrument

The control section is designed

for the left hand. The

formed by the left thumb and

index finger should be posi-

tioned beneath the area where

the umbilical cord exits the

control section. The suction

and air/water valves are con-

trolled by the index finger and

middle finger respectively. The

up/down deflection control is

operated by the thumb. The

right hand is used to advance

and rotate (torque) the insertion tube. In some instances,

it may be necessary to have

an assistant hold the insertion

tube while the right/left

deflection control is rotated

by the right hand.

"V"

17

Page 18

Insertion/Operation:

Objective Lens Focusing

l

Hold the distal tip

30-40

mm from a

flat, printed surface.

l

Rest eyepiece on cheek bone of

right eye.

l

Rotate the diopter ring until the

characters are sharp and in focus.

Insertion

l

Prior to insertion, the bending

section and distal portion of the

insertion tube should be lubricated

with a water soluble lubricant.

DO NOT cover the light guides or

objective lens.

l

DO NOT use lubricants that are petroleum based as these will

deteriorate the rubber covering the bending section.

NOTE:

Patient preparation should be adequate so that no fecal

material is present, If prep is poor, discontinue immediately.

NOTE:

If the image during insertion becomes red and out of focus

(a “red out”), this is a sign that the tip is in contact with the mucosal

wall. DO NOT ADVANCE FURTHER. Slowly withdraw the instrument

and gently inflate the colon until lumen is visible.

Light Intensity Adjustment

l

Once lumen is visible, adjust the

light intensity control to desired

setting.

NOTE:

The distal tip of the

sigmoidoscope may become warm,

if in continuous operation with

illumination set too high, and may

I

damage mucosa. Use the lowest

light setting possible.

18

Wkh.UW

U

\C\

U

Page 19

Tip Deflection

l

Slowly operate the deflection controls to guide the instrument

through the lumen

CAUTION: If resistance is encountered, DO NOT force deflec-

tion controls. Doing so may damage the instrument and/or

injure the patient.

CAUTION: DO NOT advance the instrument if lumen is not

visible. Blind advancement could result in perforation.

WARNING: If during the procedure the deflection controls

cease to function, terminate examination. Return both deflection

controls to the neutral position, by rotating the deflection

controls slowly until the “up” and “right” markings on the

control knobs are in line with the eyepiece. Slowly withdraw

the endoscope while viewing through the eyepiece. Do not

operate controls.

Flushing Objective Lens

l

Lubricant, mucous and fecal materials can cloud or fog the

objective lens. The lens can be cleared by depressing the

air/water valve.

l

If a more forceful wash is required, attach the manual irrigation

tubing to the auxiliary water inlet and flush with a syringe filled

with clean tap water.

l

Water drops retained on the lens can be removed by covering

the hole on top of the air/water valve.

Suction

l

Fluid, secretions, and liquid stool can be aspirated by depressing

the suction valve.

l

Aspiration will also remove excess air introduced during insufflation

CAUTION: Care should be taken to avoid sucking mucosa into

the channel. This phenomena can result in a “suction polyp”

that can be mistaken for a lesion.

19

Page 20

Insufflation

l

A collapsed lumen can be opened by insufflation. Cover air/water

valve to inflate colon. Adequate insufflation can be maintained by

insufflation and aspiration of air.

CAUTION: DO NOT overinflate the colon. This may cause

severe patient discomfort as well as inhibit insertion.

Biopsy Passage

l

Biopsy forceps and accessories should

be inserted through the biopsy seal and

into the channel.

l

The forcep should be advanced using

short strokes, started by grasping the

forcep sheath no more than 4 cm from

the channel opening.

WARNING: If resistance is encountered

during passage through the bending

section, relax deflection angle until

passage is smooth and easy. Wetting the forcep with water or a

medical grade silicon lubricant will promote easier passage.

l

If biopsy seal “spits” or leaks while instrument is in place, remove

defective seal and replace.

NOTE: When replacing biopsy seal,

rotate one full turn clockwise after

pushing on luer-loc fitting to insure

a proper seal.

NOTE: Always flush biopsy channel

immediately after a procedure by

aspirating clear water through the

channel (see cleaning). This will assist

passage of instruments in subsequent

procedures.

Obtaining a Biopsy

l

Collect tissue sample by opening forcep and advancing open cups

up against the mucosa. Close cups slowly until resistance is

and then hold. Gently pull back on forcep until small tissue sample

is removed.

WARNING: DO NOT open forcep until biopsy cups are out of

the biopsy channel and can be visualized. Doing so may damage

biopsy channel.

CAUTION: DO NOT exert excess force when closing forcep.

Such action may damage forcep.

20

felt,

Page 21

l

Always

withdraw

cups in a closed position.

NOTE: If forcep fails to close during

a procedure, close cups by winding

the proximal portion of the forcep

cable around your index finger. If

forcep still does not close, withdraw

cups as close as possible to the

distal tip and slowly withdraw the

instrument under direct visualization.

forcep

with the

Electrosurgery

Warning:

Before attempting endoscopic electrosurgery, the operator should

be thoroughly trained and versed in the technique and be knowledgeable of the risks associated with the procedure. There have been

reported cases of

ration. Therefore, any preparation that does not evacuate and clean

the bowel entirely, is a contraindication to this procedure. Medical

experts agree that this procedure is extremely hazardous if performed

with an enema prep only. However, if performing an electrosurgical

procedure through the flexible sigmoidoscope, the S-cord should be

attached to the sigmoidoscope and the remaining end to the chassis

of the electrosurgical generator.

colonic

explosion due to inadequate bowel prepa-

Electrosurgery Connections

Remove safety cap from ground

cord connector.

Connect the S-cord’s terminal nut to

the ground cord connector on the

endoscope connector terminal.

Secure the other end to the chassis

of the electrosurgical unit.

To reduce the risk of electric shock,

both physician and assistant

should wear rubber gloves.

DO NOT turn electrosurgical generator on until just prior to use.

I

21

Page 22

Cleaning and Disinfection

Endoscopic instruments should be cleaned immediately after each

use. Endoscopes are delicate and will degrade if not cleaned

promptly, due to the effects of digestive contents - blood, mucous,

etc. The methods outlined on the following pages have been tested

and verified to have no damaging effects. Therefore, these procedures

should be adhered to.

NOTE: Cleaning and Disinfection Program - The complete cleaning

and disinfection process has been videotape recorded to assist you

in learning the correct way to care for your instrument. The video tape

and accompanying laminated guide is included with the light source

in the top of the shipping box. If you did not purchase a light source

and would like Welch

Customer Service at l-800-535-6663.

Supplies Needed (for cleaning and disinfection)

Large basin of water

1.

Cleaning solution (soap solution)

2.

Gauze pads

3.

Disposable gloves

4.

Cleaning brush*

5.

Leakage tester*

6.

Biopsy

7.

2 Each - 30 cc syringe*

8.

Air/water nozzle cleaning brush*

9.

Blowout adaptor*

10.

cleanout

Allyn

to send you a video tape, please call

11. All channel irrigator*

12. Air/water disinfection line*

13. Air/water disinfection cap*

14.

Isopropyl alcohol

15.

Cotton Swabs

16.

Suction tubing*

17.

adaptor*

Suction machine

18.

Valve lubricant*

19. Soft bristle brush

22

Page 23

10

c

-55

11

U

17

*This component is included with the FX-100 Sigmoidoscope

12

15

1

18

16

19

@

13

23

Page 24

Cleaning

Immediately After Procedure...

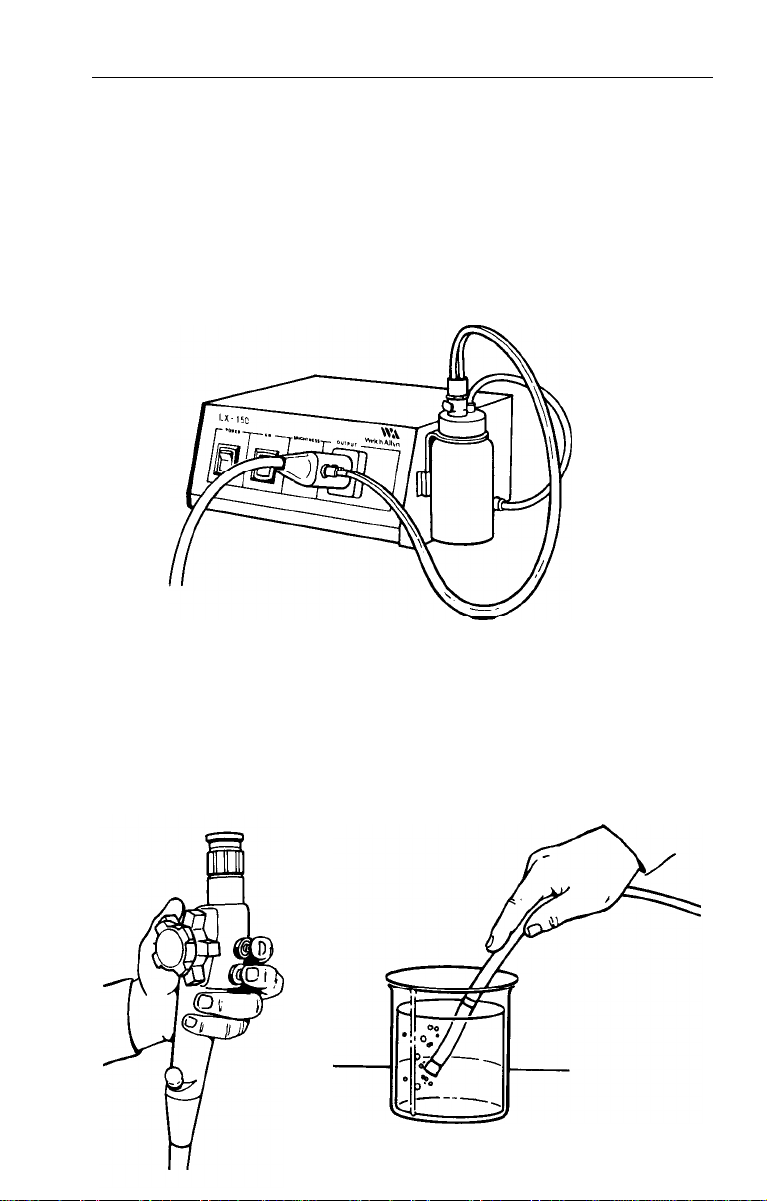

1.

With instrument still coupled to suction machine, insert distal tip into

clean water and depress suction valve.

Aspirate until water running through suction line is clear.

Turn off suction device and disconnect suction line.

2. Turn off “air” and “power” switches on light source. Disconnect dual

lumen air/water line from air and water inlets on endoscope connector terminal.

NOTE:

water bottle to drain any water in the line back into the bottle. If not

performed, the siphon created by the water system under pressure

will force the water through the open connectors. Tie the line in a loose

knot on too of the water bottle to avoid any dripping.

After disconnecting, elevate air/water line above the top of the

24

Page 25

3.

Remove the instrument from the light source by grasping the

endoscope connector and pulling back gently.

4.

Place the insertion tube into soap solution and scrub the insertion

tube lightly with a gauze pad dampened in soap solution.

5.

Remove the air/water valve (identified by two blue rings on the top

of the valve), grasp and pull up, place into soap solution. Replace

the valve with the air/water disinfection cap. Gently brush the air and

water nozzles in the distal tip with a soft brush to dislodge any debris.

Take care not to push any debri back into the air and water lines.

Disinfection Cap

25

Page 26

6. Locate the air/water disinfection line and

attach the side with two fittings to the air

Air/Water

Disinfection Line

and water inlets on the endoscope connector terminal. Fill a 30 cc syringe with

clean water and couple it to the remaining end. While holding down the air/water

disinfection cap with a finger, inject water

through the air/water lines until it sprays

from both nozzles in the distal tip.

n

Uncouple the syringe from the tubing.

7

The next step is to purge the water that was just introduced into

the air and water lines. This can be accomplished using one of the

following two methods:

Refill the 30 cc syringe with air. Re-couple to the air/water disin-

A)

fection line and inject air to purge the system. Repeat. Disconnect the syringe and air/water disinfection line.

OR

Couple the single end of the air/water disinfection line to the

B)

blowout adaptor. Re-seat the instrument’s connector terminal

into the connector port of the light box. Attach the free end of the

blowout adaptor to the air output connector on the side of the

light source. Activate light source “power” and “air” switches.

Hold down the air/water disinfection cap to blow both the air

and water lines dry. Continue for approximately 15 seconds.

Turn the switches on the light source to the “off” position and

disconnect all lines and the instrument from the light source.

Air/Water

Disinfection

Line

Steps A and B achieve the same results --- simply choose the step

that you can best incorporate into your routine for cleaning.

26

Page 27

8.

Perform Leak Test Procedure.

two stage test of the watertight integrity of the instrument. Air

pressure is introduced into the interior of the instrument by means

of a hand pump. The instrument is then checked for pressure decay

via a gauge and then visually.

The leakage test allows for a simple

Stage 1

BEFORE IMMERSION, the instrument should be tested for any

major loss of integrity in its watertight construction (example: major

tear in the bending section).

A. Secure the Leakage Tester to the

instrument’s endoscope connector terminal. The Leakage

Tester connector and the ETO vent connector MUST be dry

before securing. To properly connect, align air vent pin,

depress and rotate clockwise.

ETO

vent connector on the

27

Page 28

B. Pressurize the inside of the instrument by pumping the hand

bulb until the indicator needle on the gauge is within the

“TEST” zone. DO NOT pressurize into the “DANGER” zone;

doing so may result in serious damage to the instrument.

NOTE: Make sure that the pressure release valve on the back of the

gauge is closed.

Pressure

Release Valve

NOTE: The rubber covering the bending section will expand. This

indicates an increase in internal pressure and is normal.

C. Observe the gauge indicator needle to determine if the indicator

remains in the “TEST” zone. If the indicator drops out of the

“TEST” zone rapidly, a major leak in the instrument is indicated.

NOTE: Be certain that the pressure release valve has been

tightened.

DO NOT proceed to Stage II Test, if the indicator needle does

not remain in the “TEST” zone. Instead, contact Welch

Allyn

Customer Service.

28

Page 29

Stage

29

After determining the absence of any major leak in Stage I testing,

the instrument may be immersed in clean water to test for loss of

integrity in the watertight construction due to small pin hole leaks.

A. With the Leakage Tester securely attached to the instrument

and the gauge indicator needle in the “TEST” zone, the entire

instrument may be immersed in clean water.

II

NOTE:

its tubing should be immersed. NEVER immerse the entire Leakage

Tester.

B.

Only the Leakage Tester connector and a small portion of

Observe the instrument carefully. A few bubbles may initially

rise from recessed areas of the scope. This is normal. If a continuous stream of bubbles is observed from the same spot, a leak

is indicated. Immediately remove the scope from the water.

DO NOT attempt to use the instrument for a procedure. Clean

and disinfect the instrument to the best of your ability without

immersing it and call Welch

l-800-535-6663.

Allyn

Customer Service at

29

Page 30

9. After removing the instrument from water, release the air

pressure by opening the pressure release valve on the handle of

the Leakage Tester. After the gauge indicates “ZERO”, disconnect the Leakage Tester from the scope.

NOTE:

NEVER connect or disconnect the Leakage Tester under

water. This will cause leakage of water into the instrument and

Leakage Tester.

10.

Remove suction valve (identified by two red rings on the top of

the valve) and white biopsy seal by grasping and pulling upwards.

Place them in soap solution to soak.

Biopsy

Seal

30

Page 31

Biopsy

Port

Clean

out

Adaptor

w

12.

Place the distal end of the instrument and the other end of the

cleanout adaptor into the soap solution. Activate suction machine

and cover the open suction valve well with a finger to aspirate soap

solution through the biopsy/suction channel in all directions.

Continue for about 10 seconds. Turn off suction machine and

disconnect all tubing.

Page 32

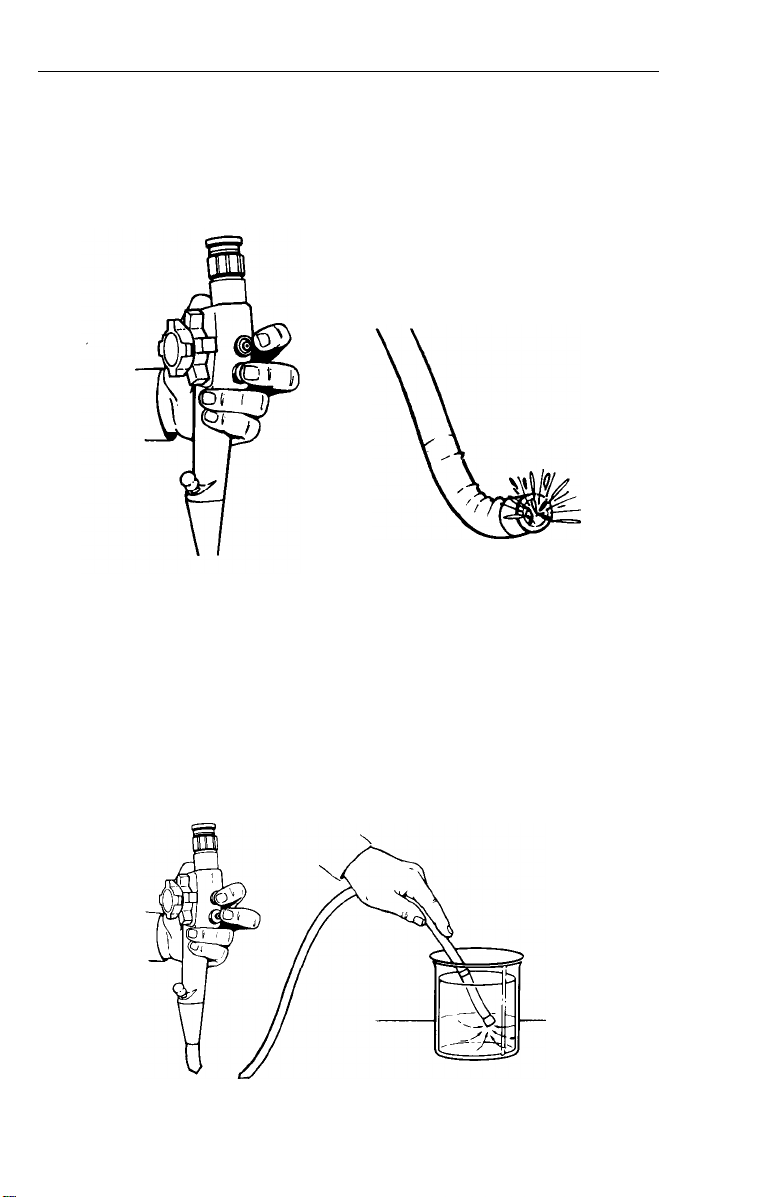

13. Insert a cleaning brush through biopsy/suction pathways in

three directions:

a. Insert cleaning brush into the suction valve well perpendicular

to the top of the control section. Advance the brush until it

emerges from the suction port. Remove any debris from the

brush with a gauze pad, and remove the brush by pulling

back through the instrument.

b. Insert the cleaning brush into the open biopsy port and

advance for about 6 to 10 inches. Remove the brush and

clean any solid debris off the tip using a gauze pad.

c. Insert brush back into suction valve well, angle it 45 degrees

toward the distal tip and advance until it exits the biopsy/

suction channel opening in the distal tip. Remove all debris

from the tip of the brush with a gauze pad soaked in soap

solution and pull back to remove.

A

NOTE: If brush will not pass-DO NOT force. Disinfect instrument to

the best of your ability and contact Welch

Allyn

Customer Service at

l-800-535-6663.

WARNING: Forcing brush through can damage the suction

channel.

32

Page 33

14. Place the entire instrument into soap solution and gently brush all

external surfaces with a soft bristled brush. Brush the air/water inlet

nozzles with the air/water nozzle brush across the nozzle openings,

take care not to push any debris back into the air and water line.

Gently scrub the valves and biopsy seal with a soft bristle brush.

r\/

15.

Remove instrument from soap solution and reattach suction

line. Place instrument, valves and biopsy seal into clean water.

Rinse thoroughly.

NOTE:

Rinse valves thoroughly as residue can cause valve to stick.

16.Turn on suction machine. With instrument immersed in clean water,

cover open suction valve well with finger to aspirate clean water

through the channel to rinse. Continue for approximately 15 seconds.

17. Lift entire instrument out of basin of water and, with the suction

valve well still covered, aspirate air through biopsy/suction line

for 60 seconds to dry channel.

33

Page 34

18. Disconnect suction line, dry exterior

of instrument thoroughly. Dry the valves

and biopsy seal and set aside.

19. Reattach the air/water disinfection line

to the air and water inlets on the in-

strument’s connector terminal.

Air/Water

Disinfection Line

20.The

next step is identical to step #7 and it’s purpose is to

thoroughly dry the lines. This can be accomplished using one of the

following two methods:

A) Refill the 30 cc syringe with air. Re-couple to the air/water disin-

fection line and inject air to purge the system. Repeat.

Disconnect

the syringe and air/water disinfection line.

OR

B) Couple the single end of the air/water disinfection line to

the blow-out adaptor. Re-seat the instrument’s connector

terminal into the connector port of the light box. Attach the free

end of the blowout adaptor to the air output connector on the

side of the light source. Activate light source “power” and “air”

switches. Hold down the air/water disinfection cap to blow both

the air and water lines dry. Continue for approximately 15 seconds.

Turn the switches on the light source to the “off” position and

disconnect all lines and the instrument from the light source.

-

Steps A and B achieve the same results

simply choose the step that

you can best incorporate into your routine for cleaning.

The instrument is ready for sterilization/disinfection.

Air/Water

Disinfection

Line

Page 35

Disinfection

The Welch Allyn flexible sigmoidoscope is manufactured from a variety

of special materials which optimize instrument performance, but may

not withstand some disinfection solutions and methods.

l

Prior to disinfection, flexible endoscopes should be thoroughly cleaned

and dried following the methods previously defined. Incomplete or

improper cleaning will decrease the effectiveness of solution exposure.

l

Welch Allyn cannot recommend a disinfection solution on the basis of

germicidal effectiveness.

WARNING: All instruments and accessories must be thoroughly

rinsed after exposure to disinfection solutions. This removes all

toxic residue and will prevent patient irritation and instrument

degradation.

Solution exposure times for disinfection should be verified with

solution manufacturer.

The materials listed below are considered safe for use with the

Welch Allyn flexible sigmoidoscope if used according to manufacturer’s instructions for disinfection and in accordance with the

following methodology.

These solutions are extremely aggressive, and failure to follow the

disinfection cycles precisely, including initial cleaning and final

rinsing, may result in shortening instrument life.

Recommended Cold Disinfecting Solutions

Glutaraldehyde (2.0% only)

Banicide Wavicide-01

Metricide Zorbicide

Cidex

WARNING: DO NOT use solutions that are oil based or contain

a surfactant (such as Cidex 7 or Cidex Plus). Additionally, bleach

solutions will permanently damage metal components of the

instrument.

NOTE:

To inquire about compatibility of the flexible sigmoidoscope with

disinfection solutions not listed, please call Welch Allyn customer service.

35

Page 36

Disinfection Tray

1.

Fill the disinfection tray’s clear tube with disinfectant to the black

indicator dot on the top of the tube.

2. Fill a small covered container with additional disinfection solution

and place the suction and air/water valves and biopsy seal into

the container to soak.

NOTE:

3. Connect the all channel irrigator.

Air/water disinfection cap is still attached to the instrument,

A) Seat the black rubber suction valve well adaptor into the open

suction valve well. Push down to snap the connector into place.

B) Connect the silver luer-lock to the open biopsy port.

C) Push free tubing onto the suction port.

D) Connect a 30 cc syringe to the luer-lock fitting on the all

channel irrigator.

36

Page 37

4.

Connect the air/water disinfection line to the inlets on the

endo-

scope connector terminal. Fill a 30 cc syringe with disinfectant from

the covered container and connect the syringe to the end of the

tubing.

Air/water

Disinfection Line

5.

Slide insertion tube into the tray’s tube filled with disinfection solution

and position the instrument’s control section securely in the space

provided on the tray.

37

Page 38

6.

Carefully wind the umbilical cord and place in the provided space on

the tray. The attached syringes and tubing can hang over the side.

Pull back on the plunger of the empty syringe (connected to the

all channel irrigator) to aspirate disinfectant into the instrument’s

biopsy/suction channel. Continue until the syringe is half full (15 cc).

Leave the syringe connected and partially filled for the duration of

the soak cycle (usually 15-20 minutes, refer to solution manufacturer’s recommended time).

Hold down on the air/water disinfection cap and depress plunger

of the syringe connected to the air/water disinfection line. Continue

until fluid exits from the nozzles in the distal tip (i.e., until bubbling

from tip stops, or the syringe is half full). Leave syringe connected

for duration of soak cycle (usually 15-20 minutes, refer to the manufacturer’s recommended time).

After soaking for the disinfectant solution manufacturer’s recom-

mended time, depress the plunger on the syringe connected to

the all channel irrigator to expel solution.

10. Remove the syringe coupled to the air/water disinfection line and

inject the remaining solution into the small covered container.

11. To purge all remaining solution, remove both syringes, fill them

with air, reconnect, and one at a time, inject air into the channels.

NOTE: Remember to hold down the air/water disinfection cap when

injecting with the syringe coupled to the air/water disinfection line.

12. Detach the all channel irrigator and remove the instrument from

the tray.

38

Page 39

13. Place the insertion tube into a basin of clear water. Attach suction

line to the suction port and the biopsy

cleanout

adaptor to the open

biopsy port.

Suction

Biopsy

Clean out

Adaptor

M

Port

14. Place the suction and air/water valves and biopsy seal into the

basin of clean water to rinse.

15.

With distal tip of the instrument and free end of the cleanout

adaptor under water, activate the suction machine and cover the

open suction valve well with your finger to aspirate water through

the entire biopsy/suction channel to rinse. Continue for approximately 10-15

Page 40

16. Disconnect syringe attached to the air/water disinfection line, fill with

clean water, reattach to tubing, and inject water to rinse the air and

water lines. Repeat this 2-3 times to thoroughly rinse the channels.

17.The

next step’s purpose is to thoroughly dry the lines. This can be

accomplished using one of the following two methods:

A) Refill the 30 cc syringe with air.

Re-couple to the air/water

dis-

infection line and inject air to

Air/Water

Disinfection Line

_

I

purge the system. Repeat.

Disconnect the syringe and

air/water disinfection line.

OR

B) Couple the single end of the air/water disinfection line to the

blowout adaptor. Reseat the instrument’s connector terminal

into the connector port of the light box. Attach the free end of the

blowout adaptor to the air output connector on the side of the

light source. Activate light source “power” and “air” switches.

Hold down the air/water disinfection cap to blow both the air and

water lines dry. Continue for approximately

15

seconds. Turn the

switches on the light source to the “off” position and disconnect

all lines and the instrument from the light source.

-

Steps A and B achieve the same results

simply choose the step that

you can best incorporate into your routine for cleaning.

Terminal Port

Air/hater

Disinfection

Line

40

Page 41

18. Disconnect the air/water disinfection line and biopsy

cleanout

adaptor

19. Wipe off the exterior of the instrument with a gauze pad moistened

in clean water.

20. Lift the insertion tube out the basin. Cover the open suction valve

well and aspirate air through the channel to dry.

21

.Turn

off the suction machine, disconnect the suction line and dry

the instrument’s exterior.

22. Remove the valves and biopsy seal from the water and dry.

23.Apply a thin coat of valve lubricant to the valve’s

"O"

rings and

reseat them in the open valve wells. Reseat the biopsy seal.

24. Wipe off exterior of instrument with a gauze pad moistened in

isopropyl alcohol. Clean distal lens with cotton swab dipped in

isopropyl alcohol.

//

25. Hang scope with insertion tube straight to air dry.

Page 42

Disinfection - Immersion

1.

Fill covered basin with disinfectant to a level that will allow the entire

instrument to be immersed in solution.

2.

Place the air/water and suction valves and biopsy seal into solution

to soak.

NOTE:

3. Connect the all channel irrigator.

Air/water disinfection cap is still seated in the air/water valve well.

A) Seat the black rubber suction valve well adaptor into the open

suction valve well.

B) Connect the silver luer-lock to the open biopsy port.

C) Push end of remaining free tubing onto the suction port,

D) Connect a 30 cc syringe to the luer-lock fitting in the all channel

irrigator

42

Page 43

4.5.Connect the air/water disinfection line to the air and water inlets on

the endoscope connector terminal. Fill a 30 cc syringe with disinfectant and connect to the remaining end of the line.

Air/Water

Disinfection Line

Place the insertion tube and distal tip into the disinfection solution

while holding down the air/water disinfection cap, and depress the

plunger of the syringe connected to the air/water disinfection line.

Continue until the bubbles emerging from the air and water nozzles

(distal tip) stop (usually 15 cc of solution).

43

Page 44

6.

Immerse the entire instrument in the disinfectant, with the exception

of the syringes coupled to the all channel irrigator and the air/water

disinfection line.

7.

Draw back on the plunger of the syringe connected to the all

channel irrigator until all lines of the irrigator are filled with solution

(usually until syringe is half full).

Allow the instrument to soak in the disinfection solution for the

8.

manufacturer’s recommended time (usually around 15-20 minutes).

After the soaking, depress the plungers of both syringes to purge

9.

remaining disinfectant. Remove both syringes and fill with air, reconnect. Depress the plungers, one at a time, to force air through the

channels to purge the disinfectant. Repeat until clear.

NOTE: Remember to hold down the air/water disinfection cap when

injecting with the syringe coupled to the air/water disinfection line.

1

0. Remove

the instrument from the disinfectant and detach the all

channel irrigator.

11. Attach suction line to suction port and place instrument into a basin

of clean water.

12.To

rinse the air and water lines, disconnect the syringe coupled to

the air/water disinfection line. Fill with water, reattach, and while

holding down the air/water disinfection cap, depress the plunger

to inject water into the lines. Repeat 2-3 times.

44

Page 45

13.Remove

the syringe and air/water disinfection line and place the

endoscope connector tubing into the basin to rinse.

14. Place air/water suction valves and biopsy seal into the water to

rinse.

15.

Activate suction machine (suction line attached to suction port) and

while the instrument is underwater, cover open suction valve well to

aspirate water through the line to rinse. Continue for around 15

seconds.

16. Wipe down exterior of instrument in clean water to rinse off any

residual solution.

17. Lift the entire instrument out of the water and cover the open valve

well with a finger to aspirate air through to dry the channel.

18.Turn

off suction machine, disconnect the suction line, and dry the

exterior of the instrument.

45

Page 46

19. Lift the air/water and suction valves and biopsy seal from the water

and dry.

20. Apply a thin coating of valve lubricant to the valve’s “0” rings and

reseat them in the open valve wells.

21.

Wipe off exterior of instrument with a gauze pad moistened in

isopropyl alcohol. Clean distal lens with cotton swab dipped in

isopropyl alcohol.

22. Hang instrument with the insertion tube straight to dry.

46

Page 47

Sterilization

Thorough mechanical cleaning and drying of the flexible sigmoidoscope are prerequisites to sterilization. If gas sterilization is required,

the instrument should be sterilized following the methodologies

outlined below:

NOTE:

result in severe damage.

DO NOT steam autoclave the instrument. Doing so will

Procedure

1. Remove suction, air/water valves, biopsy seal prior to exposure.

ETO

2. Attach the

3. DO NOT exceed 130°F or 10 psi.

4. Remove vent cap prior to next procedure.

NOTE:

temperature is 7 days.

Gas exposure not to exceed 4 hours. Aeration time at room

vent cap (accessory) to the instrument.

47

Page 48

Troubleshooting Chart

Symptom Possible Cause Solution

Image is

not clear.

Inadequate

suction.

Eyepiece not Turn focus adjusting ring

adjusted to user’s

eyesight. is in sharp focus.

Distal objective

obscured.

Lenses dirty.

Water damage

to lens.

Suction valve

blocked.

Biopsy seal is worn.

Suction channel

blocked.

Suction pump not

on or tubing

disconnected.

(diopter ring) until fiber pattern

Rinse lens by injecting water

through auxiliary water inlet.

Remove scope and clean distal

objective and eyepiece with

cotton swab and alcohol.

Return scope to Welch Allyn

Service for evaluation/repair.

Remove valve, clean valve and

housing with a cleaning brush.

Lubricate

lubricant and replace.

Replace biopsy seal.

Call Welch Allyn Service

Department for instructions.

Verify good connection

between suction pump and

scope. Turn pump on.

"O"

rings with valve

No

insufflation.

Air pump not

turned on.

Air tubing not connected or pinched.

Air nozzle blocked.

Turn air pump on. Test scope

for air flow.

Verify that the dual lumen air/

water lines are securely attached.

Verify that water bottle input

connector is coupled to light

source.

Soak tip of scope in warm soapy

water for 2-3 minutes. Gently

brush with air/water nozzle cleaning brush. Connect dual lumen

disinfection

warm water through air/water

lines while cycling air valve. If

nozzle remains blocked, contact

Welch Allyn Customer Service.

48

line.

Gently inject

Page 49

Symptom Possible Cause Solution

No

Insufflation.

Water bottle cap not Tighten cap.

secured tightly.

(cont’d.)

Cannot

Water bottle empty.

Fill water bottle.

irrigate.

Water bottle cap not

Tighten cap.

secured tightly.

Suction

valve

sticks.

Dirty valve stem. Remove valve; clean valve and

housing with cotton swab and

alcohol; lubricate "O"rings with

valve lubricant and replace.

Biopsy seal Biopsy seal is worn. Replace biopsy seal.

“spitting”

or leaking.

Insufficient

articulation

Loose articulation

knob.

Return scope to Welch Allyn

for adjustment.

of tip.

Return scope to Welch Allyn

for adjustment.

Turn illuminator on and adjust

Return scope to Welch Allyn

Inadequate

illumination.

Degree of articulation

is less than specified.

Illuminator not

turned on. light to appropriate intensity.

Damage to light

transmitting fibers. for evaluation/repair.

Illuminator Not plugged into

not working.

electrical outlet. grounded outlet.

Lamp is

burned out.

Fuse is blown.

49

Plug illuminator into 120 volt

Replace lamp according to

instructions.

Call Welch Allyn

Service Department.

Page 50

Maintenance and Storage

Maintenance:

Suction and Air/Water Valves

l

Both suction and air/water valves should be inspected weekly.

To remove, pull up on ring around valve stem to remove from

its well.

l

Clean each valve well with a succession of pipe cleaners until

last cleaner is clean and dry (DO NOT use cotton tipped applicators).

Air/Water and Suction Valves

1.

Inspect valve stem.

"O"

2. Look closely at

3. If cracked or worn, replace.

4. To remove

"O"

rings into place over base of valve stem.

"O"

rings.

rings, grasp with tweezer and remove. Roll new

NOTE: Remove top

valve stem.

5.

Lubricate valves by reapplying a light coat of silicone lubricant to

"O"

rings.

"O"

ring first before those at the base of the

Biopsy Seals

To Seat:

clockwise.

To Remove:

To Flush Channel:

luer-lock fitting.

Disinfection/Sterilization:

products and alcohol.

NOTE:

lubricant can be injected into the chamber directly behind top

opening. This will ease entry of instrument into and through

biopsy channel.

Push seal onto luer-lock fitting and rotate one full turn,

Pull seal while rotating counterclockwise.

Remove seal and connect syringe directly to

Seal is compatible with all glutaraldehyde

To ease insertion of instruments, silicon or a water soluble

50

Page 51

Lens Cleaning

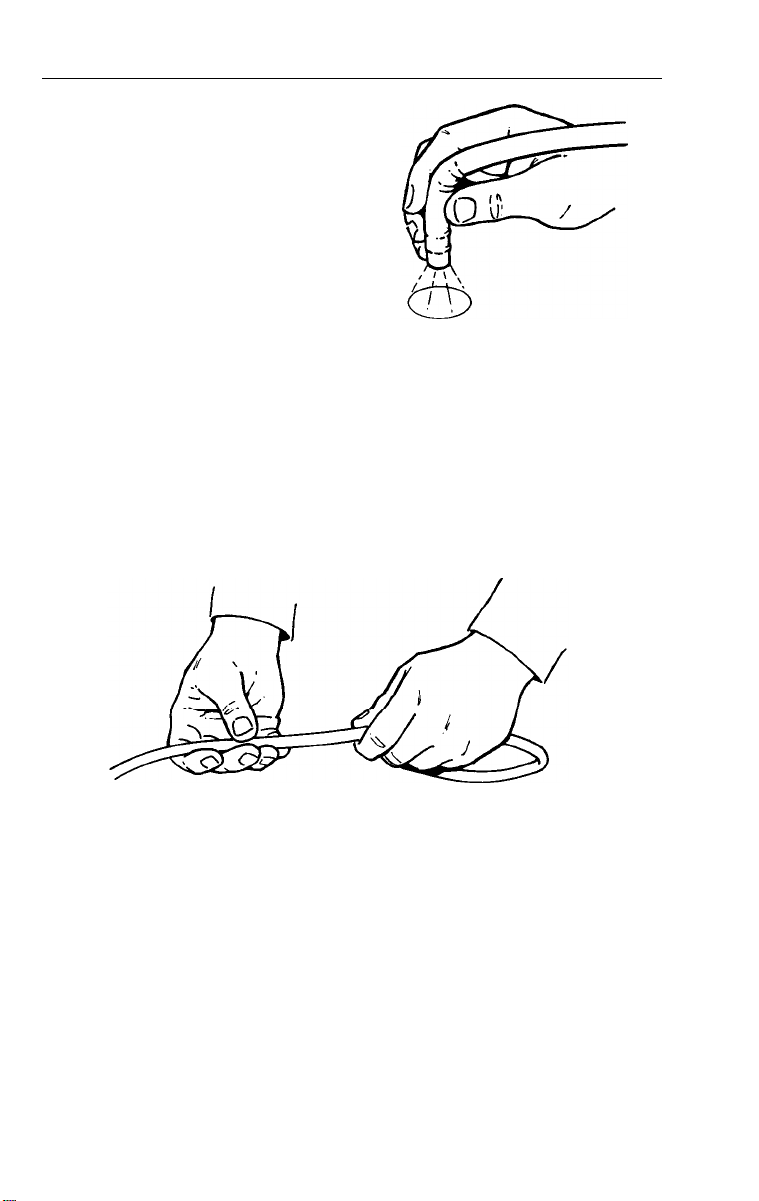

Moisten cotton-tipped applicator with 70% isopropyl alcohol.

Clean debris from objective lens and light guides.

NOTE: DO NOT use abrasive materials to clean lens. Doing so

could scratch and permanently damage optics system.

Storage

l Flexible sigmoidoscope should be stored with insertion tube and

umbilical cord as straight as possible. If coiling is necessary,

insertion tube and umbilical cord should not be wound in more

than one loop.

l Flexible sigmoidoscope should not be stored in areas exposed to

temperature extremes or high humidity. Storage area should be

dry and clean.

Other manufacturers’ accessories should be stored per their

recommendations.

Service

Customer Service

Telephone Assistance:

l-800-535-6663

For repairs on the FX-100, ship to:

Welch

Allyn

Repair Department

4341 State Street Road

Skaneateles Falls, NY 13153

51

Page 52

Loading...

Loading...