Page 1

Page 2

Thank you for purchasing the Welch Allyn FL-100 Intubating

Fiberscope and Light Source. The operating and maintenance

instructions found in this manual should be followed to ensure

many years of reliable service. Please read these instructions

thoroughly before attempting to use your new instrument.

Page 3

TABLE OF CONTENTS

Conventions ...................................................................................................................... 2

General Precautions........................................................................................................ 2

Symbols .............................................................................................................................. 2

Components ...................................................................................................................... 3

Nomenclature and Function ............................................................................................ 4

Fiberscope ...................................................................................................................... 4

Light Source .................................................................................................................... 5

Accessories........................................................................................................................ 6

Photographic Equipment .................................................................................................. 6

Preparation and Inspection for Use ................................................................................ 7

Inspection of Light Source .............................................................................................. 7

Inspection of Fiberscope.................................................................................................. 8

Preparation Prior to Insertion of Fiberscope.................................................................... 10

Operation ............................................................................................................................ 11

Pretreatment.................................................................................................................... 11

Insertion and Withdrawal ................................................................................................ 11

Care after Use .................................................................................................................... 12

Important Instructions...................................................................................................... 12

Care after Each Procedure................................................................................................ 12

Pre-cleaning at the Examination Room .......................................................................... 12

Cleaning at the Work Room ............................................................................................ 13

Enzymatic Cleaning Solution .......................................................................................... 15

Cleaning of Accessories .................................................................................................. 16

Schematics ........................................................................................................................ 17

Internal Schematics of a Welch Allyn Endoscope .......................................................... 17

Internal Schematic of the Welch Allyn FL-100 Intubating Fiberscope ............................ 18

Internal Schematic Showing Complete Cleaning/Disinfecting System............................ 18

Disinfection and Sterilization............................................................................................ 19

High-level Disinfection .................................................................................................... 19

Compatible Disinfecting Solutions .................................................................................. 21

Disinfection of Accessories.............................................................................................. 21

Sterilization and Aeration ................................................................................................ 22

Care During Storage.......................................................................................................... 24

Servicing ............................................................................................................................ 25

Care and Maintenance Tips .............................................................................................. 25

Leakage Tester Instructions.............................................................................................. 27

Dry Test, Stage I.............................................................................................................. 27

Wet Test, Stage II ............................................................................................................ 28

Specifications .................................................................................................................... 29

1

Page 4

CONVENTIONS

GENERAL PRECAUTIONS

The user of the FL-100 instrument should be thoroughly trained in the techniques of upper airway endoscopy.

This instrument is specifically designed to assist endotracheal intubation as well as diagnosis in the Upper

Airway. Do not use the FL-100 for any purpose other than that for which it is designed.

This manual describes the procedures for inspecting and preparing the instrument for use. It does not describe

the performance of an endoscopic procedure or any of the medical aspects of endotracheal intubation. This

instrument should only be used by physicians or practitioners trained in its use.

Failure to read and understand the material contained in this manual could result in patient injury. Also, failure

to follow the instructions provided herein could result in malfunction and/or damage to the instrument.

This manual contains instructions on the maintenance and reprocessing of the FL-100. Every effort has been

made to ensure that the listed disinfecting and sterilizing solutions and/or processes are compatible with this

instrument and are effective. Since infection control practices are constantly changing, Welch Allyn recommends

that the user remain aware of the latest practices and any federal, local, or hospital regulations pertaining to this

very important issue.

SYMBOLS

WARNING: Indicates a potentially hazardous situation which, it not avoided, could result in

death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury or property damage.

NOTE: Indicates a potentially hazardous situation which, if not avoided, may result in property damage. Also,

advises owner/operator about important information on the use of this equipment.

CAUTION: Federal Law (U.S.A.) restricts this device to sale by/to or on the order of a

physician or other appropriately licensed medical professional.

2

Page 5

COMPONENTS

Welch Allyn

RL-100

LENS CLEANER

Description Components/Qty. Accessories/Qty.

Fiberscope 65300 FL-100 Intubating

Fiberscope (1)

Light Adaptor 650031-3

Welch Allyn ACMI Adaptor (1)

65017 WAACMI

65004

Olympus CLK-3

65005

Olympus CLK-4

65010

Olympus ILK-3

65011 Machida

65014 Pentax

65016 Wolf

65018 Storz

Cap 650008 Eyepiece Cap (1)

Vent Cap 650028 ETO Vent Cap & Tag (1) 65012 each

Cleaner 650007 Lens Cleaner (1) 65304 each

Valve 653014 Rubber Suction Control 65304 each

Valves (3)

Seal 310183 Rubber Inlet Seals (10) 31039 (5)

Brushes 653012 Long 65302 Brush Set

653011 Short (Long, short and

653010 Suction Cylinder suction cylinder)

Cap 653013 Suction Cylinder 65303 each

Closure Cap (1)

49500 Welch Allyn

Light Source

65009 Leakage

Tester

3

Page 6

NOMENCLATURE AND FUNCTION

FIBERSCOPE

Diopter Adjustment Ring

Accommodates differences in eyesight

Immersible Mark

Green line indicates that

it is totally immersible

Diopter Position Marks (White)

Marks must align to ensure

proper focus for assistant’s

observerscope or camera

Deflection Control Lever

Deflects the distal end of

insertion tube 130° up or down

Suction Control Valve

Allows for aspiration through

the accessory/suction channel

Eyepiece

Ocular Lens

Anti-reflection multi-layer

coated optics for clean,

sharp image

Suction Nipple

Allows for attachment to external

suction device

Rubber Inlet Seal

Allows accessories to be passed

through, while preventing fluids and

air to escape

Accessory/Suction Channel Inlet

Allows biopsy forceps and other

accessories to be introduced

Umbilical Cable

Distal End

Accessory/

Suction Channel

Light Guides

Objective Lens

Bending Section

Insertion Tube

Diameter: 3.5 mm

Working length: 600 mm

ETO Vent Cap (Red)

Vents endoscope interior to equalize internal and

external pressure

Note: See sterilization section for use

Venting Connector

Seats ETO vent cap and leakage tester

Light Guide

The Welch Allyn sleeve part number 650031-3 is

standard and comes attached to instrument. Other

adaptor sleeves for other manufacturer’s light

sources are also available (see page 3).

4

Page 7

LIGHT SOURCE

FRONT

Power Switch

Light Control Knob

Fan Grill

Fuse Drawer

AC Power Input

Lamp Access

Knob

BACK

5

Page 8

ACCESSORIES

WELCH ALLYN LIGHT SOURCE (49500) CLEANING BRUSHES

White Bristle Flexible Shaft

CAUTION: It is strongly recommended that only Welch Allyn accessories be used with the

Welch Allyn FL-100 Intubating Fiberscope. Other accessories may adversely affect the performance of the fiberscope. If a unique or highly specialized accessory from another source

is required, please contact Welch Allyn to arrange a test of its compatibility before using it

with the Welch Allyn FL-100 Intubating Fiberscope.

Proximal End

Long (653012)

Short (653011)

Suction Cylinder

(653010)

PHOTOGRAPHIC EQUIPMENT

The Welch Allyn FL-100 Intubating Fiberscope is equipped with a universal eyepiece that will accommodate

most camera adaptors.

6

Page 9

PREPARATION AND INSPECTION FOR USE

Prior to use, the endoscope, Iight source and accessories must be carefully inspected for cleanliness and proper

function to determine that they are appropriate for patient use.

INSPECTION OF LIGHT SOURCE

Please refer to the operating manual of your Welch Allyn Light Source for complete instructions.

CAUTION: Verify that the supply voltage matches the voltage range indicated on the rear

of the Welch Allyn Light Source.

To prevent temporary blinding, turn power on only after the fiber optic bundle is plugged in

and the intensity control knob is set to the minimum position.

The fiber optic bundle port is hot when fiber optic bundle is removed.

1. With the power switch in OFF position, plug light source into a properly grounded hospital grade receptacle.

Welch Allyn light sources are equipped with a hospital grade plug and grounding conductor.

2. The standard Welch Allyn adaptor sleeve included on

FL-100 allows connection to and light transmission

from any Welch Allyn Iight source.

3. Depending upon the manufacturer, model and/or

type of light source to be used, an adaptor may be

needed to make a complete connection between the

source of illumination and the Welch Allyn FL-100

fiberscope. This depends on the manufacturer,

model and/or type of light source. For assistance,

please contact your local Welch Allyn distributor or

service facility.

4. Connect the endoscope light guide plug to the light

source.

5. Turn on the light source to check for proper functioning.

NOTE: Be sure that the correct adaptor is being used for light sources other than Welch Allyn.

WARNING: The risk of thermal injury exists whenever fiber optic instruments are used

with high intensity light sources.

The risk of injury is greatest:

• When a high intensity light source, such as the Welch Allyn HI•Lux lamp, is used.

• During close stationary observation and/or prolonged close contact with mucosa.

• When the fiberscope is advanced slowly through a narrow lumen.

Close stationary viewing should be avoided and the level of illumination should be limited

to the level necessary for adequate visualization.

7

Page 10

INSPECTION OF FIBERSCOPE

Before proceeding, the Welch Allyn FL-100 fiberscope

should be tested for water-tight integrity (example: tear

in the accessory/suction channel). To perform this test,

see the “Leakage Test Instructions” section (page 27).

1. INSPECTION OF THE INSERTION TUBE

a) Check the entire surface of the insertion

tube to assure that abnormal conditions such

as bite marks, wrinkles and dents are not

present. Any indentation in the flexible shaft

of the fiberscope can cause damage to the

fiber optics and internal mechanisms of the

fiberscope.

b) Check the umbilical cable for outward signs

of damage such as buckling, pinch marks, etc.

CAUTION: Do not use any fiberscope with outward signs of damage. An outwardly damaged

fiberscope may cause malfunction during a procedure and further damage the scope.

Leakage Tester

c) Be sure the entire fiberscope is clean and has been subjected to either a high-level disinfection or

sterilization process before each patient use.

NOTE: The distal end of the fiberscope must be protected against damage from impact. Never apply excess

force such as twisting or severe bending of the flexible portion of the fiberscope.

2. INSPECTION OF DEFLECTION CONTROL

To assure smooth articulation, slowly manipulate the deflection control lever. Be sure that a full and

appropriate range of deflection is possible.

CAUTION: If the deflection control lever is not operating smoothly, this may indicate

internal damage to the fiberscope. To avoid the possibility of further damage or malfunction during a procedure, never use the fiberscope if the deflection control lever is not

operating smoothly.

8

Page 11

3. SUCTION MECHANISM

a) Connect suction tubing from an external

suction source to the suction nipple located

on the control body. Place the distal tip of the

endoscope in a basin of water and depress

the suction control valve. Water should be

rapidly aspirated into the suction system

collection container.

b) Release the suction control valve to deter-

mine if the valve freely returns to its OFF

position and the aspiration of water ceases.

NOTE: A rubber inlet seal in good condition must be

on the accessory channel inlet to prevent the loss of

suction. Worn seals will result in leakage and should

be replaced.

Suction Nipple

Depress

Suction

Tube

To Suction Source

Rubber Inlet Seal

9

Page 12

PREPARATION PRIOR TO INSERTION OF FIBERSCOPE

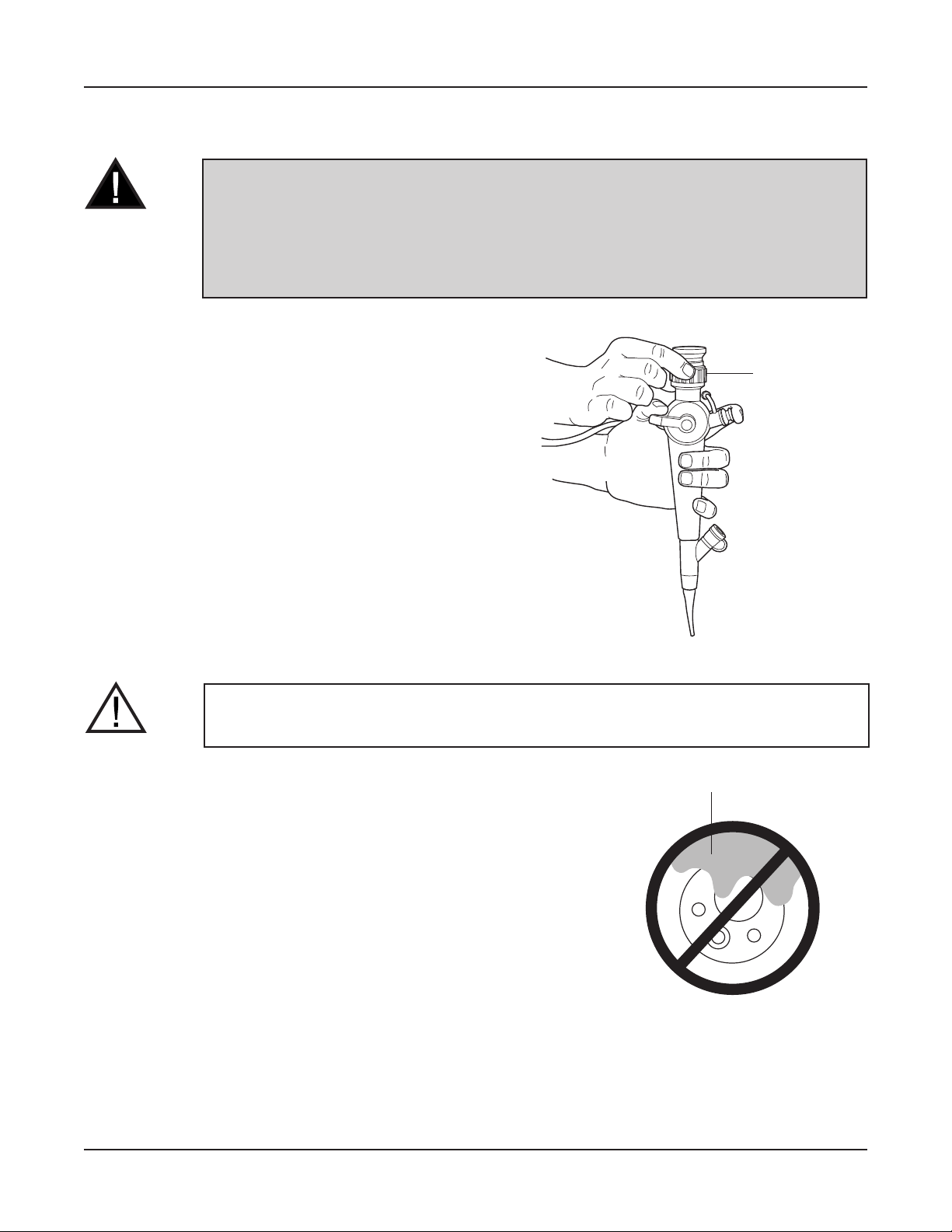

WARNING: Every fiberscope should be properly disinfected or sterilized before each use.

Current infection control guidelines require that endoscopes and their patient contact

accessories either be sterilized or at least be subjected to high-level disinfection. Only

the user can determine if an instrument has undergone appropriate infection control

procedures prior to each clinical use.

1. If needed, gently clean the objective lens with

a cotton-tip applicator moistened with alcohol.

A lens cleaner (anti-fogging agent) may also

be applied with gauze or appropriate applicator.

2. The user should adjust the diopter adjustment

ring to make sure that a clear view can be

obtained. (No further adjustment should be

necessary during a procedure.)

3. Use a bite block on the insertion tube to protect

the insertion tube after the scope is introduced.

4. Apply a medical grade water soluble lubricant to

the insertion tube. DO NOT use petroleum-based

lubricants.

Diopter

Adjustment Ring

10

CAUTION: Never allow excessive lubricant or lens cleaner on the object lens.

Lubricant

Page 13

OPERATION

WARNING: This instrument should only be used by qualified physicians who are

thoroughly familiar with all the characteristics of this instrument and who are well-versed

in the proper techniques of endoscopy.

PRETREATMENT

1. The patient should be prepared in the normal endoscopy regimen.

INSERTION AND WITHDRAWAL

1. Slowly insert the scope under direct vision. As the distal

end of the scope passes through the pharynx, the

patient should gently bite down on the bite block to

maintain the bite block’s position during the procedure.

2. Adjust the intensity of the light source to obtain a

brightness level suitable for observation.

3. The deflection control lever should be adjusted to

properly position the scope. The deflection of the tip

should be done under direct vision in a gentle and

in a deliberate manner.

4. If bronchial secretions or other debris are present in the

lungs making observation difficult, suctioning should be

performed.

5. Photography can be carried out as necessary.

6. Always withdraw the scope under direct

visualization.

WARNING: If for any reason the image is lost due to power shortage, lamp or light source

failure, etc., straighten the scope tip to its neutral position, and then carefully and slowly

withdraw the insertion tube from the patient.

11

Page 14

CARE AFTER USE

IMPORTANT INSTRUCTIONS

Cleaning-Disinfection-Sterilization: Welch Allyn Endoscopes

Endoscopic instruments should be properly cleaned immediately after each use, to maintain maximum performance and a long service life for the fiberscope. If the fiberscope is left uncleaned for some time after use, dried

blood, mucous or other debris may cause damage to the instrument and may interfere with the reprocessing

ability of the instrument.

WARNING: The importance of meticulous cleaning of the endoscope cannot be

over-emphasized.

Prior to disinfection or sterilization, all instruments must be scrupulously cleaned.

Failure to do so could result in incomplete or ineffective disinfection and sterilization.

CARE AFTER EACH PROCEDURE

PRE-CLEANING AT THE EXAMINATION ROOM

1. Immediately after removing the fiberscope from

the patient, gently wipe all debris from the insertion tube with a gauze moistened with an enzymatic cleaning solution. (See page 15 for a list of

compatible detergents.)

2. Place the distal end of the fiberscope into detergent solution and aspirate through the channel

for 5-10 seconds. Alternate aspiration of solution

and air several times to create agitation for better

pre-cleaning.

Aspirate

12

Page 15

CLEANING AT THE WORK ROOM

1. The fiberscope should be Leak Tested before

proceeding with any further cleaning steps.

NOTE: See section on Leakage Tester Instructions.

The hand-operated Welch Allyn Leakage Tester is

available as an optional accessory.

2. Prepare a basin with warm water and a mild

enzymatic detergent.

CAUTION: BEFORE IMMERSING: Take OFF the “Red” ETO gas sterilization venting cap.

The use of an enzymatic detergent immediately after each procedure to dissolve and

remove organic contaminants and proteinaceous debris is essential to the care and

maintenance of the endoscope from the standpoints of infection control and functionality.

3. Remove the rubber suction control valve and the

rubber inlet seal. Then thoroughly (but gently)

wash the entire surface of the endoscope and its

components. Allow all items to soak in an enzymatic solution for the time period recommended

by the manufacturer of the enzymatic detergent.

NOTE: Do not squeeze or severely bend the

insertion tube. Do not use any abrasive materials.

Be careful to avoid damage to the distal lenses.

Remove

Remove

Suction Control Valve

Remove

Rubber Inlet Seal

13

Page 16

4. Avariety of special brushes are provided to clean the

entire suction system. Brush clean the entire accessory/

suction channel:

a) Use the short cleaning brush and insert the

brush into the opening of the suction nipple.

Gently pass the brush until it appears in

the suction control valve receptacle. Repeat

several times (see Figure 1).

Suction Control

Valve Receptacle

(Cylinder)

Figure 1

Suction

Nipple

(a)

b) Next, insert the same short brush into the

opening at the bottom of the suction control

valve receptacle (cylinder) on the control head

(see Figure 2) and gently advance until resistance is felt (approximately 12 cm). DO NOT

USE EXCESS FORCE. Gently withdraw the

brush. Repeat several times.

NOTE: Be sure to inspect the bottom of the suction control

valve receptacle on the control head for any debris.

c) Insert the long brush into the accessory/suction

channel inlet port and gently advance the brush

until it exits the distal end of the scope. Clean

debris off the brush and then gently withdraw the

brush (see Figure 2).

Repeat several times ensuring that only a clean

brush is introduced into the channel each time.

d) Using the specially designed suction cylinder

cleaning brush, scrub clean the surfaces inside

the suction control valve receptacle on the control head (See Figure 3).

5. Install the suction cylinder closure cap as illustrated.

6. With the rubber inlet seal in place, a large luer slip

syringe can be attached to the end of the suction nipple

and used to flush enzymatic detergent solution into the

entire accessory/suction channel. Be sure the detergent

solution is allowed to remain in contact with the internal

channel surfaces for the recommended exposure time.

The enzymatic detergent should dissolve and/or dislodge

any debris that may be within these internal areas.

Suction Control Valve

Receptacle (Cylinder)

Accessory/Suction

Channel Inlet

(b)

(c)

Figure 2

Suction Cylinder

Figure 3

Suction Cylinder Closure Cap

7. After the scope has been exposed to the detergent

solution for an appropriate time, flush the accessory/

suction channel with air to purge remaining detergent.

WARNING: The enzymatic detergent solution should remain in contact with ALL

internal channels and external scope surfaces for the time period recommended by

the manufacturer of the detergent.

14

Figure 4

Page 17

8. Rinse the entire scope and all its components with clean water.

9. The entire accessory/suction channel should aIso be rinsed free of residual detergent using one of the

following methods:

a) With the suction cylinder closure cap still in place, fill a syringe with clean water and flush the

accessory/suction channel.

b) With the rubber inlet seal still in place, reinstall the rubber suction control valve and aspirate clean

water through the entire channel of the scope.

WARNING: It is important that ALL internal channels, external scope surfaces and

components be thoroughly rinsed with water to remove residuaI detergent solution.

Accessory Suction Channel

10. Purge water from the accessory/suction channel and scope components.

NOTE: 70% alcohol followed by compressed air, not greater than 24 PSI,

may be used to facilitate drying.

11. Gently dry all external surfaces of the fiberscope with a soft gauze.

Do not put tension on the insertion tube of the endoscope while drying, since the outer cover of the bending section may be excessively

Objective

Lens

stretched. Dry the objective lens with a cotton tip applicator.

Light Guides

Distal End

ENZYMATIC CLEANING SOLUTIONS*

Specific reference to brand names is not an endorsement of their efficacy as a cleaning solution. Tests

have shown these solutions to be compatible with Welch Allyn endoscopes, providing the manufacturer’s

directions are adhered to.

Brand Name Source Usage

Endozime The Ruhof Corp.

Klenzyme Calgon Vestal Labs

Enzy-Clean Burnishine Products

Metrizyme Metrex Research Corp.

Follow

Manufacturer’s

Instructions

Enzol Johnson & Johnson Medical

NOTE: Other solutions should not be used until a sample has been submitted to Welch Allyn for compatibility

testing.

*These solutions must be enzymatic detergents or other cleaning agents specially formulated to clean flexible endoscopes.

WARNING: Prior to disinfection or sterilization, it is imperative that the scope and its

components be thoroughly rinsed of any solutions previously used in the cleaning process.

The scope and its components should be thoroughly dried. Failure to do so could result

in ineffective or incomplete disinfection and sterilization.

15

Page 18

CLEANING OF ACCESSORIES

1. Accessories need to be cleaned immediately after each use, since dried blood, mucous or other debris may

cause damage to the instrument and interfere with the ability of the user to reprocess the device.

2. Place the accessories in a basin of warm water and a mild enzymatic detergent. Allow these to soak for the

time period recommended by manufacturer.

3. Clean by gently wiping with a soft gauze.

4. Rinse all residual detergent from the accessory by immersing it under clean water.

NOTE: All detergent must be removed from all the accessories. Any detergent that remains after the water

evaporates can interfere in the subsequent sterilization process.

CAUTION: DO NOT use ultrasonic cleaning methods on the fiberscope itself.

5. Ultrasonic cleaning of accessories is recommended, provided the manufacturer’s instructions and the

parameters below are followed:

Frequency Range 31-45 kHz

Optimum Frequency 10 kHz

Time 5-10 minutes

NOTE: DO NOT use caustic or abrasive solutions in the ultrasonic cleaner.

6. After cleaning and thoroughly rinsing, the accessories should be gently dried using a soft gauze.

NOTE: Other reusable accessories (channel cleaning adaptors, cleaning brushes, bite block, etc.) and scope

components (rubber inlet seals and rubber suction control valves, etc.) may be cleaned in a similar manner as

above. Ultrasonic cleaning methods are recommended for accessories and scope components whose entire

surfaces are not easily accessible by manual cleaning.

16

Page 19

SCHEMATICS

INTERNAL SCHEMA TICS OF A WELCH ALLYN ENDOSCOPE

The following internal schematics have been provided to assist users in better understanding the intricate

construction of Welch Allyn endoscopes. Knowledge of the various internal channels and tubes within an

instrument and their relationship to each other helps facilitate the reprocessing of the endoscope.

The FL-100 intubating fiberscope and its components have been specifically designed for efficient and effective

reprocessing before each use by either a manual or automated method.

Connectors on all Welch Allyn cleaning/disinfecting adaptors and scope inlet ports incorporate standard size

luer-lock and/or luer-slip fittings to easily accommodate reprocessing devices or systems available from other

manufacturers.

The internal schematics show that the Welch Allyn cleaning system promotes efficient unidirectional flow of solutions. Starting from the suction nipple at the control body, solutions travel up to the valve cylinder, pass through

the channel in the insertion tube and finally exit the channel opening at the distal tip of the scope. The elimination of multiple branching channels, combined with a direct pathway for solutions to travel, maximizes flow efficiency and ensures contact of disinfectant/sterilant with all internally exposed channel surfaces.

WARNING (USA): It is imperative that flexible endoscopes and other semi-critical devices

be reprocessed using at least high-level disinfection with an EPA registered sterilant/

disinfectant. It should be noted that any endoscope automated reprocessing device or

system* must be cleared for marketing by the FDA via the 510 (k) premarket notification

or PMA approval process. Only reprocessing solutions/systems satisfying the above

conditions and tested and found to be compatible by Welch Allyn should be used with

Welch Allyn products.

*Liquid chemical germicides (disinfectants/sterilants) to reprocess medical devices come under FDA

regulation and new products must, therefore, undergo a 510 (k) premarket notification submission

prior to introduction into interstate commerce.

17

Page 20

INTERNAL SCHEMATIC OF THE WELCH ALLYN FL-100 INTUBATING FIBERSCOPE

Accessory/Suction Channel

Accessory/Suction Channel Inlet

Suction Cylinder Control Valve

Suction Nipple

Umbilical Cord

To Suction Source

The illustration above shows the entire accessory/suction channel system in the Welch Allyn

FL-100 Intubating Fiberscope.

NOTE: All surface areas of the suction system must first be cleaned with an enzymatic detergent and

then exposed to a high-level disinfectant or sterilant.

INTERNAL SCHEMATIC SHOWING COMPLETE CLEANING/DISINFECTING SYSTEM

Accessory/Suction Channel

Accessory/Suction Channel Inlet

Suction Cylinder Closure Cap

Suction Nipple

Luer-Slip Syringe

with

Cleaning/Disinfecting

Solution

Umbilical Cord

To reprocess the Welch Allyn FL-100 Intubating Fiberscope, first an enzymatic detergent and then a high-level

disinfectant or sterilant must be used. All internal lumens and all external instrument surfaces and scope components (inlet seal, suction control valve, etc.) need to be exposed to detergent and disinfectant/sterilant. Exposure

times of detergent and disinfectant/sterilant must be strictly adhered to.

NOTE: All solution entrance ports and flow pathways are illustrated above.

18

Page 21

DISINFECTION AND STERILIZATION

HIGH-LEVEL DISINFECTION

Before disinfecting the endoscope, it must be completely

cleaned and dried (see “Care after Each Procedure” on

page 12). The user is responsible for determining if the

disinfecting techniques described here accomplish the

desired clinical effect. Before complete immersion in any

disinfecting solution, the endoscope needs to be “Leak

Tested” (see page 27).

CAUTION: BEFORE IMMERSING:

The “Red” ETO gas sterilization venting cap must be taken OFF.

1. Remove the rubber suction control valve.

2. Install the suction cylinder closure cap as illustrated.

3. a) The suction nipple, located on the control body, is designed with a standard luer slip fitting to accommodate

a syringe or other standard device. Fresh disinfecting solution should be drawn into (or flushed through)

the entire accessory/suction channel system. The rubber inlet seal should be in place during the flushing

process.

WARNING:Avoid introduction of air during this process and confirm that no air bubbles exit

the scope tip during flushing (or exit the suction nipple, if aspiration is used). The presence

of air bubbles could prevent contact of the disinfectant with channel surfaces.

b) While the entire scope is immersed and the suction system is filled with disinfectant, the suction

cylinder closure cap and the rubber inlet seal may be removed.

WARNING: It is imperative that ALL internal surfaces of the channels are in contact with the

disinfecting solution for the time period recommended by the manufacturer of the solution.

NOTE: Please refer to the internal schematics on page 18.

19

Page 22

4. While the entire instrument is immersed in disinfecting solution, the syringe used in previous

steps can be removed. The entire instrument,

however, should remain fully immersed in the

disinfecting solution.

5. The endoscope’s component parts should remain

in contact with the disinfecting solution for the

time period recommended by the manufacturer

of the solution. Make sure it is left in long enough

to accomplish the desired clinical effect.

6. After the endoscope and its component parts

have been in contact with the disinfecting solution for the appropriate time, flush the suction

system with air to purge remaining disinfectant.

Remove the scope and its components from the

solution. All residual disinfecting solution must

be thoroughly rinsed from the scope and its

components with clean water.

7. Remove the suction cylinder closure cap, reinstall the rubber suction control valve and the rubber inlet seal.

Thoroughly rinse all outer surfaces of the scope that contacted the disinfecting solution.

8. Attach the scope to an external suction source and aspirate clean water through the channel of the scope.

Then, aspirate air through the channel to remove the residual water.

NOTE: 70% alcohol should be flushed through all channels, followed by compressed air, not greater than

24 PSI, to facilitate drying.

NOTE: All final rinses should be made with sterile water.

9. Gently dry all external surfaces of the fiberscope with a soft gauze. Do not put tension on the insertion

tube while drying, since the outer cover of the bending section may be excessively stretched. Dry the ocular

lens of the eyepiece and the objective lens with a cotton-tip applicator.

20

Page 23

COMPATIBLE DISINFECTING SOLUTIONS

Specific reference to brand names is not an endorsement of their efficacy as a disinfecting solution. Tests have

shown these solutions to be compatible with Welch Allyn endoscopes, providing the manufacturer’s directions

are adhered to.

Solution Brand Name Source Usage

Glutaraldehyde Cidex (14 day) Johnson & Johnson Medical Inc.

Wavicide-01 Wave Energy System Inc.

Metricide (14 day) Metrex Research Corp.

Omnicide NS Omnitec Medical Corp.

Calgo-Cide 14 Calgon Vestal Labs

Sekusept Forte Henkel

Aldehyde Sporcid 10% Fresenius

Tegoment 2% TH. Goldschmidt

NOTE: Other solutions should not be used until a sample has been submitted to Welch Allyn for

compatibility testing.

NOTE: Please refer to the “General Precautions” on page 2 regarding infection control.

DISINFECTION OF ACCESSORIES

WARNING: Current infection control guidelines require accessories that break the

mucosal barrier to be sterilized.

Follow

Manufacturer’s

Instructions

Before disinfecting the accessories, such as bite block, suction control valve, brushes, etc., they must be

completely cleaned and dried (see “Care after Each Procedure”, page 12). The user is responsible for

determining if the disinfecting techniques described here accomplish the desired clinical effect.

1. The accessory should be entirely immersed in disinfecting solution.

2. All accessory surfaces should remain in contact with the disinfecting solution for the time period

recommended by the manufacturer of the solution and acceptable by the user as appropriate.

3. After it has been immersed in the disinfecting solution for the appropriate amount of time, remove it

from the solution.

4. Rinse all residual disinfecting solution from the accessory by totally immersing it in water.

5. After thoroughly rinsing, the accessories should be gently dried using a soft gauze. Compressed

air may also be used to facilitate drying.

NOTE: All final rinses should be made with sterile water.

21

Page 24

STERILIZATION AND AERATION

Before sterilizing the fiberscope, it must be completely cleaned and dried (see “Care after Each Procedure”,

page 12). The user is responsible for determining if the sterilizing techniques described here accomplish the

desired clinical effect.

CAUTION: NEVER place the fiberscope in a steam autoclave!!

NEVER subject the fiberscope to ultrasonic cleaning methods!!

A) ETHYLENE OXIDE GAS STERILIZATION

Ethylene Oxide (ETO) Gas Sterilization can be

performed on these endoscopes. The following

special instructions, which differ from other

endoscopes, must be followed to ensure the

proper performance of the instrument.

1. The endoscope must first have been properly

cleaned and thoroughly dried (see “Care after

Each Procedure”, page 12). Each of the component parts should be removed (suction control

valve, rubber inlet seals, etc.).

WARNING: Failure to thoroughly dry all surface areas could result in incomplete or

ineffective sterilization. Moisture could prevent contact of the ETO gas with the actual

contaminated surfaces.

22

Page 25

2. IMPORTANT: Prior to placing the FL-100 Intubating

Fiberscope in a gas sterilizer or aeration chamber:

a) The “Red” ETO Gas Sterilization Venting Cap

MUST be “ON” securely.

NOTE: This is opposite of the immersion instructions.

b) Temperature must not exceed 55°C (131°F).

c) Pressure must not exceed 24 PSI.

d) Humidity must not exceed 50%.

e) Sterilization procedure must not exceed

4 hours.

3. Following ETO Gas Sterilization, aeration time of 72 hours at room temperature is required.

4. Aeration Chamber: To shorten the aeration time to 12 hours, an aeration chamber may be used,

provided the temperature does not exceed 55°C (131°F).

CAUTION: Prior to placing these endoscopes in an aeration chamber, the “RED” ETO

Gas Sterilization Venting Cap MUST be “ON” securely.

ETO Gas Sterilization Cap

B) COLD STERILIZATION

For those situations where Ethylene Oxide (ETO) Gas Sterilization capability is not available, Welch Allyn endoscopes have been designed to withstand immersion in Glutaraldehyde solution for a maximum of 10 hours to

achieve “Cold Sterilization”. Never fully immerse a Welch Allyn endoscope without first conducting “Leakage

Testing” (see page 27).

CAUTION: NEVER EXCEED 10 HOUR MAXIMUM IMMERSION.

After immersion, the instrument must be thoroughly rinsed to remove all residual Glutaraldehyde solution.

After being thoroughly rinsed, Welch Allyn endoscopes must be allowed to “breathe”, balancing internal and

external humidity, by attaching the “RED” ETO Venting Cap.

23

Page 26

C) OTHER METHODS OF STERILIZATION

In addition to ETO and “Cold Sterilization” techniques, Welch Allyn endoscopes have been found to be

compatible** with the Steris Sterilization®System/Process.

**Based upon current data, repeated use of the Steris System could cause fading of the black anodized metallic components

of Welch Allyn endoscopes. This discoloration is cosmetic in nature only and continued use should not affect the functionality

or watertight integrity of the endoscope.

CAUTION: Other types of cleaning and/or sterilization systems/processes are available

for the reprocessing of medical devices. However, due to the heat sensitive nature and/

or the specific biocompatible materials used in the construction of flexible endoscopes,

some of these marketed systems/processes/solutions could have detrimental effects on

flexible endoscopes.

To avoid the potential for instrument damage, confirm the compatibility of such reprocessing

systems/solutions with Welch Allyn prior to use with any Welch Allyn products.

CARE DURING STORAGE

Thoroughly remove all water from the scope and

accessories. Be sure both are clean and dry.

1. Prior to storage, remove all valves, inlet seals, etc.

to allow thorough drying of internal areas.

2. During storage, the insertion tube of the scope,

the umbilical cable and the accessories should

be kept as straight as possible.

3. The storage area should be dry and airy. Avoid

high humidity, high temperature and areas exposed

to the direct rays of the sun.

4. The “RED” ETO Venting Cap should be placed on

the scope to allow the scope to “breathe”, balancing

internal and external humidity while it is storaged.

WARNING: Prior to storage, it is important that no residual water be left within any internal

channels/lumens of the endoscope or accessories. Thoroughly dry all instrument surfaces

to reduce the potential for bacteria colonization during storage.

NOTE: 70% Alcohol followed by compressed air, NOT greater than 24 PSI, should be used to facilitate drying of

the internal channels.

24

Page 27

SERVICING

Before returning any instrument for repair to Welch Allyn, the instrument should first undergo appropriate reprocessing/decontamination procedures for the purpose of infection control.

1. All instruments requiring repair should be shipped in the original carrying case with appropriate packing, along

with comments describing the instrument damage and complaint.

2. Arepair purchase order number, contact name and phone number of the individual responsible for authorizing repairs, as well as shipping address should be included.

3. The “Red” ETO Gas Sterilization Venting Cap needs to be attached to the instrument, when shipped by

air freight.

4. Any accessories potentially related to the scope damage or complaint should also be returned with the

endoscope.

5. Soaking caps (if applicable) should also be returned with the scope to check/confirm the integrity of their

watertight seal.

NOTE: Instrument repairs should only be performed by an authorized Welch Allyn service facility. Welch Allyn

assumes no liability for any patient/user injury, instrument damage or malfunction, or reprocessing failure due to

repairs made by unauthorized personnel.

CARE AND MAINTENANCE TIPS

Flexible endoscopes have been used to successfully diagnose and treat a wide variety of illnesses for several

decades. Progressive design improvements have made current generation flexible endoscopes, such as the

Welch Allyn FL-100 Intubating Fiberscope, easier to use, although they are more technologically sophisticated

than ever.

To ensure that the instruments are patient-ready and patient-safe, special reprocessing instructions must be followed. To prolong the reliability of the endoscope and prevent instrument malfunction, special care and handling

must be exercised. The health-care professionals who actually care for and reprocess flexible endoscopes are

ultimately responsible for ensuring safe and reliably functioning instruments.

Tremendous efforts have been made in designing instruments that can be reprocessed and maintained as easily

as possible. However, due to the nature of their use and application, flexible endoscopes must be subjected to

special cleaning procedures, followed by a disinfection or sterilization process after every patient use.

Welch Allyn strongly recommends that users review the following suggestions and advice on the care and maintenance of your Welch Allyn endoscopes. However, these tips, particularly those involving scope reprocessing,

should not be interpreted as “shortcuts” and are not intended to substitute directions for the complete instructions found elsewhere in the owner’s manual.

• Avoid soaking the endoscope with accessories (forceps, injection or aspiration needles, etc.) or any sharp-

edged object which could inadvertently scratch or cut the distal bending section sheath. (Subsequent flexing

back and forth of the rubber sheath could eventually stretch the scratched rubber until a pinhole and leak

develops.)

• Exposure to a compatible enzymatic detergent is essential for thorough cleaning of all surfaces of the endo-

scope. Rinsing and drying after cleaning is imperative to prevent dilution of the disinfectant/sterilant.

25

Page 28

• Do NOT reuse disposable accessories intended for single patient or one-time use.

• Do NOT expose the endoscope or accessories to harsh chemical solutions. Strictly adhere to exposure times

recommended by the manufacturers of compatible solutions.

• Avoid contact of any flexible portion of the endoscope with any sharp-edged objects (bed frames, table top cor-

ners, sink drains, accessories hanging in storage cabinets, etc.) at any time during the handling, reprocessing

or storage of the endoscope.

• Avoid stretching of the bending section rubber sheath at the distal portion of the scope. During mechanical

cleaning of the scope with a dampened gauze, do not use excessive force. Agentle back and forth wiping

motion should be sufficient to remove gross debris. Subsequent soaking in an enzymatic detergent will clean

the remainder of debris.

• Disinfectants and sterilants are toxic substances by nature. All residual solution must be thoroughly rinsed and

dried prior to each patient use.

• Avoid attempting to remove or unscrew scope components which should not be removed. Parts such as the

distal portion of the light guide plug and any rubber strain reliefs on either the insertion tube or umbilical cable

are essential to the watertight integrity of the instrument. Removal or loosening of these components and

subsequent immersion could lead to fluid invasion into the endoscope.

• Check for any sharp edges on all surfaces of an automated cleaning/reprocessing unit which may come in con-

tact with an endoscope. Some units may have sharp-edged wire mesh filters and baskets or inlet/outlet ports

which could damage your scope.

• Do NOT introduce air bubbles into the scope’s internal channels during flushing of cleaning and/or disinfect-

ing/sterilizing solutions as these bubbles could interfere in the effectiveness of the disinfection/sterilization

process.

• Do NOT store the endoscope and accessories in the carrying case. This type of dark, humid and unventilated

environment is conducive to bacteria colonization, which increases the risk of cross-contamination.

• Prior to each use, check the condition of all accessories.

Do NOT use any accessories with kinked or bent flexible shafts.

Do NOT use forceps with misaligned cups and/or bent needles/spikes.

Do NOT use aspiration or injection needles which are not retractable or whose sharp tips cannot be protected.

Do NOT use cleaning brushes without smooth or rounded distal tips.

Use of any of the above accessories could result in channel damage and costly repairs.

• Verification of the efficacy level of glutaraldehyde (via test strips or similar methods) is recommended to ensure

potency of glutaraldehyde to achieve high-level disinfection.

• Instrument repairs should only be performed by an authorized Welch Allyn service facility. Welch Allyn assumes

no liability for any patient/user injury, instrument damage or malfunctions, or reprocessing failure due to repairs

made by unauthorized personnel.

26

Page 29

LEAKAGE TESTER INSTRUCTIONS

The leakage test is a simple two (2) stage test of the watertight integrity of the instrument. Air pressure is introduced into the interior of the instrument via a hand pump. The FL-100 scope is then checked for pressure decay

by using a pressure gauge. Asecondary visual check is also performed.

Air Bladder

Scope Connector

Figure 1

DRY TEST, STAGE I

BEFORE IMMERSION, Welch Allyn endoscopes

should be tested for any loss of integrity in their

watertight construction (example: major tear in

accessory/suction channel).

1. Remove the Red ETO Vent Cap from the light

guide. The leakage tester connector and the air

vent on the light guide MUST be completely dry

before connecting the Leakage Tester.

2. Secure the Leakage Tester connector to the air

vent on the scope’s light guide (where the Red

ETO Vent Cap was removed).

Faceplate

Hand Bulb

Pressure Release Valve

3. Confirm that the pressure indicator is at “0”.

NOTE: Make sure the pressure release valve on the

back of the gauge is closed before squeezing the

gauge bulb.

4. Pressurize the scope by pumping the hand bulb

until the indicator on the gauge is in the GREEN

2

zone (0.16-0.20 kg/cm

).

NOTE: During the leak test procedure, the insertion

tube of the scope should be flexed in various positions and the distal bending section should be fully

angulated in all directions to confirm the absence of

a leak.

DO NOT pressurize into the RED Danger zone. Doing

so may cause serious damage to the scope (Figure #3).

5. Observe the gauge pressure to determine if the

indicator remains in the GREEN zone. If the indicator drops from the GREEN zone rapidly, a major

Ieak is indicated.

NOTE: NEVER IMMERSE the entire instrument if the

gauge indicator does not remain in the GREEN zone.

Instead, contact your Welch Allyn Service Center.

Figure 2

Scope Connector

Light Guide

Figure 3

Air Bladder

Vent

Figure 4

27

Page 30

WET TEST, STAGE II

After determining that there are no major leaks in Stage I testing, Welch Allyn endoscopes may be immersed in

clean water to test for loss of integrity in the watertight construction.

1. With the Leakage Tester securely attached to the scope and the scope pressurized with the gauge indicator in

the GREEN zone, the entire scope may be immersed in clean water (Figure #5).

NOTE: Only the Leakage Tester connector and a small portion of its tubing should be immersed. NEVER

immerse the entire Leakage Tester.

2. Observe the instrument carefully while deflecting the distal tip of the scope in all directions. Afew bubbles

may initially occur from recessed areas of the scope. This is normal. If a continuous stream of bubbles is

observed from the same location, a leak is indicated. DO NOT use the scope! Immediately remove it from

the water (Figure #6).

3. After removing the scope from water, release the air pressure within the scope by opening the pressure

release valve on the handle of the Leakage Tester. After the gauge indicates “zero”, disconnect the Leakage

Tester from the scope.

NOTE: NEVER connect or disconnect the Leakage Tester under water. This will cause leakage of water into the

scope and Leakage Tester. This can cause damage to both instruments.

4. If leakage was discovered, thoroughly dry the instrument and contact your Welch Allyn Service Center.

5. If no leakage was discovered, you may proceed with cleaning and disinfection of the scope as described in

the Owner’s Manual.

28

Figure 5 Figure 6

Page 31

SPECIFICATIONS

Accessory/Suction

Channel

Light Guide

Objective Lens

Angle of View 90°

Depth of Field 3-50 mm

Diopter +2 to -8 dptr.

Tip Deflection Up 130°, down 130°

Rigid Distal Diameter 3.4 mm

Insertion Tube Diameter 3.5 mm

Diameter of Accessory/Suction Channel 1.4 mm

Insertion Tube Working Length 600 mm

Total Length 800 mm

NOTE: Specifications are subject to change without notice.

DISTAL END

Up 130°

3.5 mm

0°

1.4 mm

Light Guide

DISTAL TIP BENDING SECTION

Down 130°

29

Page 32

Medical Division

4341 State Street Road

P.O. Box 220

Skaneateles Falls, NY 13153-0220

(800) 535-6663

FAX (315) 685-3361

Printed in U.S.A.

Part No. 653001 Rev. C

Loading...

Loading...