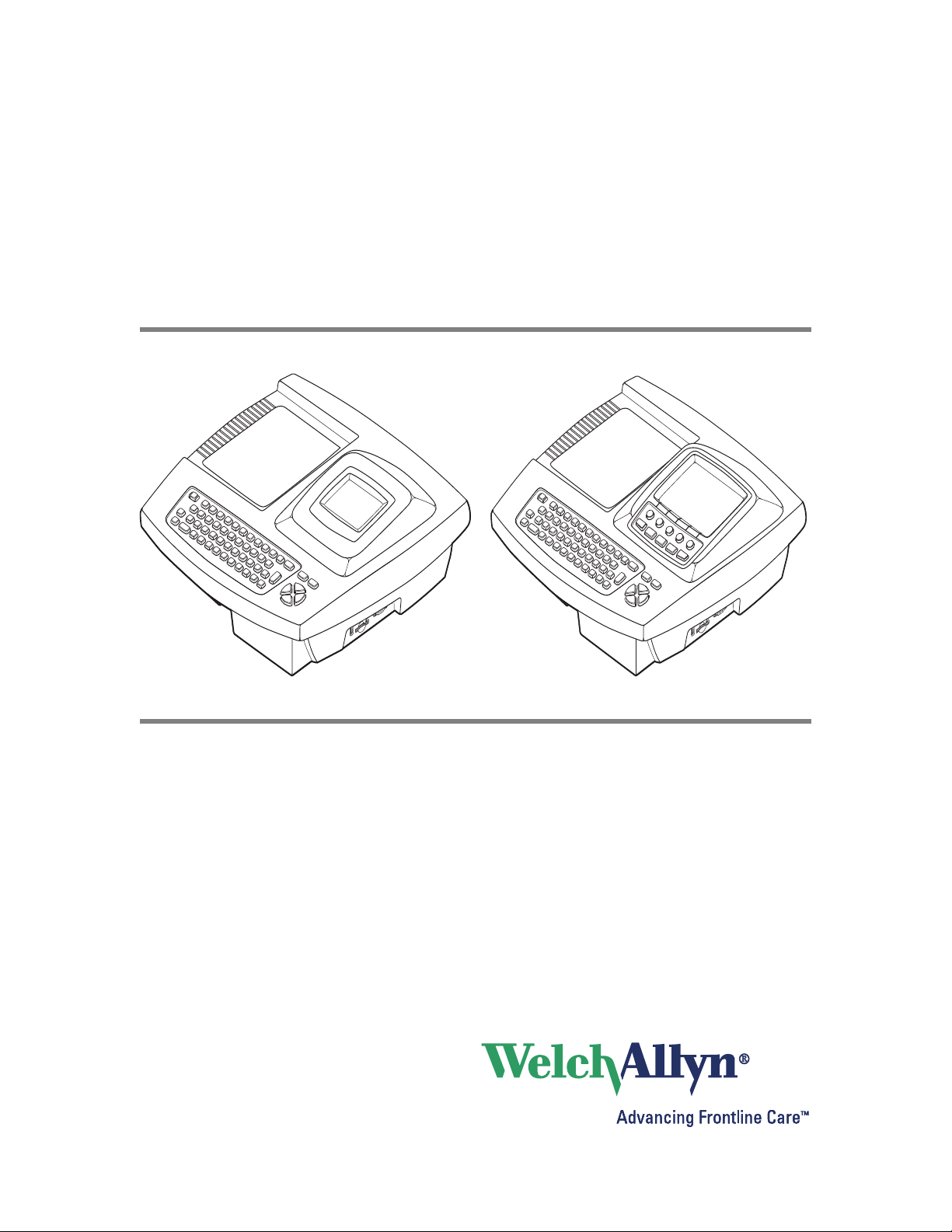

CP 100 and CP 200™ 12-Lead

Resting Electrocardiograph

TM

CP 100TM 12- Lead Resting Electrocardiograph

CP 200

12- Lead Resting Electrocardiograph

Service Manual

ii Welch Allyn CP 100 and CP 200 Electrocardiograph

Copyright 2005, Welch Allyn, Inc. All rights are reserved. No one is permitted to reproduce or duplicate, in

any form, this manual or any part thereof without permission from Welch Allyn.

Caution: Federal US law restricts sale of the device identified in this manual to, or on the order of, a

licensed physician.

Welch Allyn assumes no responsibility for any injury, or for any illegal or improper use of the product, that

may result from failure to use this product in accordance with the instructions, cautions, warnings, or

indications for use published in this manual.

Welch Allyn is a registered trademark of Welch Allyn, Inc., and CP 200, CP100, and CardioPerfect are

trademarks of Welch Allyn, Inc.

SD is a trademark of Toshiba.

Software in this product is Copyright 2005, Welch Allyn, Inc., or its vendors. All rights are reserved. The

software is protected by United States of America copyright laws and international treaty provisions

applicable worldwide. Under such laws, the licensee is entitled to use the copy of the software

incorporated within this instrument as intended in the operation of the product in which it is embedded.

The software may not be copied, decompiled, reverse-engineered, disassembled or otherwise reduced to

human-perceivable form. This is not a sale of the software or any copy of the software; all right, title and

ownership of the software remains with Welch Allyn or its vendors.

For information about any Welch Allyn product, please call Welch Allyn Technical Support:

USA 1 800 535 6663

+1 315 685 4560

Canada 1 800 561 8797 China +86 216 327 9631

European Call Center +353 46 906 7790 France +33 15 569 5849

Germany +49 747 792 7186 Japan +81 33 219 0071

Latin America +315 685 2644 Netherlands +31 15 750 5000

Singapore +65 6419 8100 South Africa +27 11 777 7555

United Kingdom +44 207 365 6780 Sweden +46 85 853 6551

Australia +61 29 638 3000

800 074 793

Part Number (manual only): 704340 Rev D

Welch Allyn

PO Box 220

Skaneateles Falls, NY 13153-0220

www.welchallyn.com

Printed in USA

0297

Contents

1 - Safety Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

iii

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Servicing the Electrocardiograph Safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrostatic Discharge (ESD). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Purpose and Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Non-Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Technical Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Returning Products. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommended Service Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls, Indicators, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

“System Settings” Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

About the Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Moving Through the Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reviewing the Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CP 100 and CP 200 Electrocardiograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Entering the Service Info Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Print Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Battery Life Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Printer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Export Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Import Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Delete Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Lead Off Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Service Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 - Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Functional Verification Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Full Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

iv Contents Welch Allyn CP 100 and CP 200 Electrocardiograph

Operating/Non-Printing Mode Current Test . . . . . . . . . . . . . . . . . . . . . . . . . 30

Battery Accuracy Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Sleep/Standby Mode Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Charger Detect Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LED Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

LCD Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Set Unit Initial Configuration/SD Slot Test . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ECG Communication Test (ECG Input test and lead off) . . . . . . . . . . . . . . . 33

Spirometer Communication Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

USB Communications Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Beeper Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Printer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Dielectric Strength Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hi-Pot Test Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chassis, Earth and Patient Leakage Current Tests. . . . . . . . . . . . . . . . . . . . 39

Checklist and Test Results Report Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Problem-Solving Suggestions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Service Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5 - Disassembly and Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . 47

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Torque Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Opening the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Replacing the Printer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replacing the Paper Tray Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Replacing the Platen Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Replacing the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Replacing the Stepper Motor and Gear Box. . . . . . . . . . . . . . . . . . . . . . . . . 57

Replacing the Battery or Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Replacing the Battery (DC) Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Replacing the Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Replacing the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Replacing the IEC (AC input) Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing the LCD Inverter and LCD Assembly (CP 200) . . . . . . . . . . . . . . 64

Replacing the Function Keypad Assembly (CP 200) . . . . . . . . . . . . . . . . . . . 65

Replacing the Keyboard Assembly (CP 200) . . . . . . . . . . . . . . . . . . . . . . . . 66

Replacing the LCD Assembly (CP 100) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing the Keyboard Assembly (CP 100). . . . . . . . . . . . . . . . . . . . . . . . . 68

6 - Field Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Field Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Service Manual CP 100 and CP 200 Electrocardiograph v

A - Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

B - EMC Guidance and Manufacturer’s Declarations . . . . . . . . . . . . . 79

C - Software Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

D - Interconnect Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

CP 200 Interconnect Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

CP 100 Interconnect Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

vi Contents Welch Allyn CP 100 and CP 200 Electrocardiograph

1

1

Safety Summary

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Servicing the Electrocardiograph Safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Safety Summary CP 100 and CP 200 Electrocardiograph

Introduction

The safety summary, and all additional specific warnings and cautions located throughout

the documentation, must be read and understood by all users of the CP 100 and CP 200

Electrocardiograph.

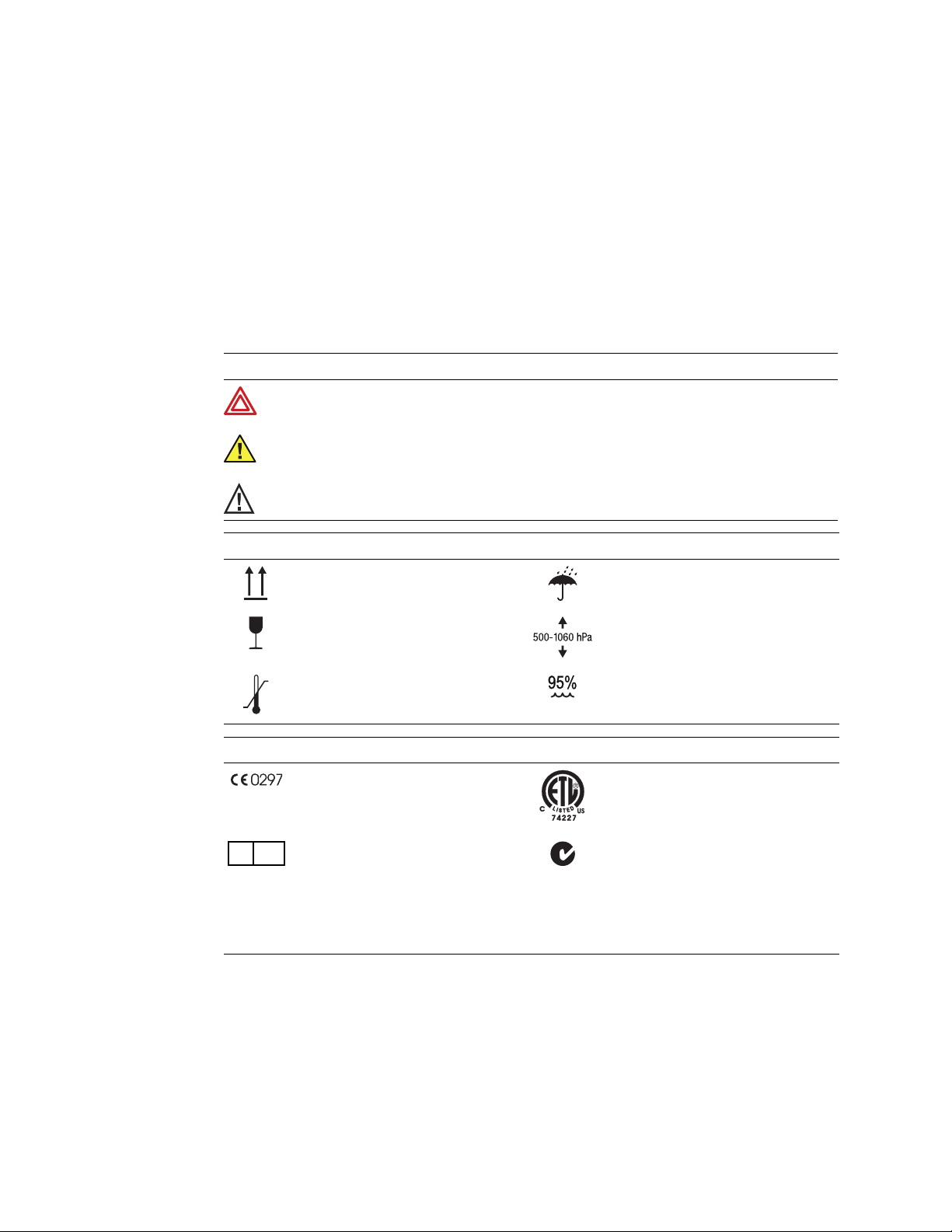

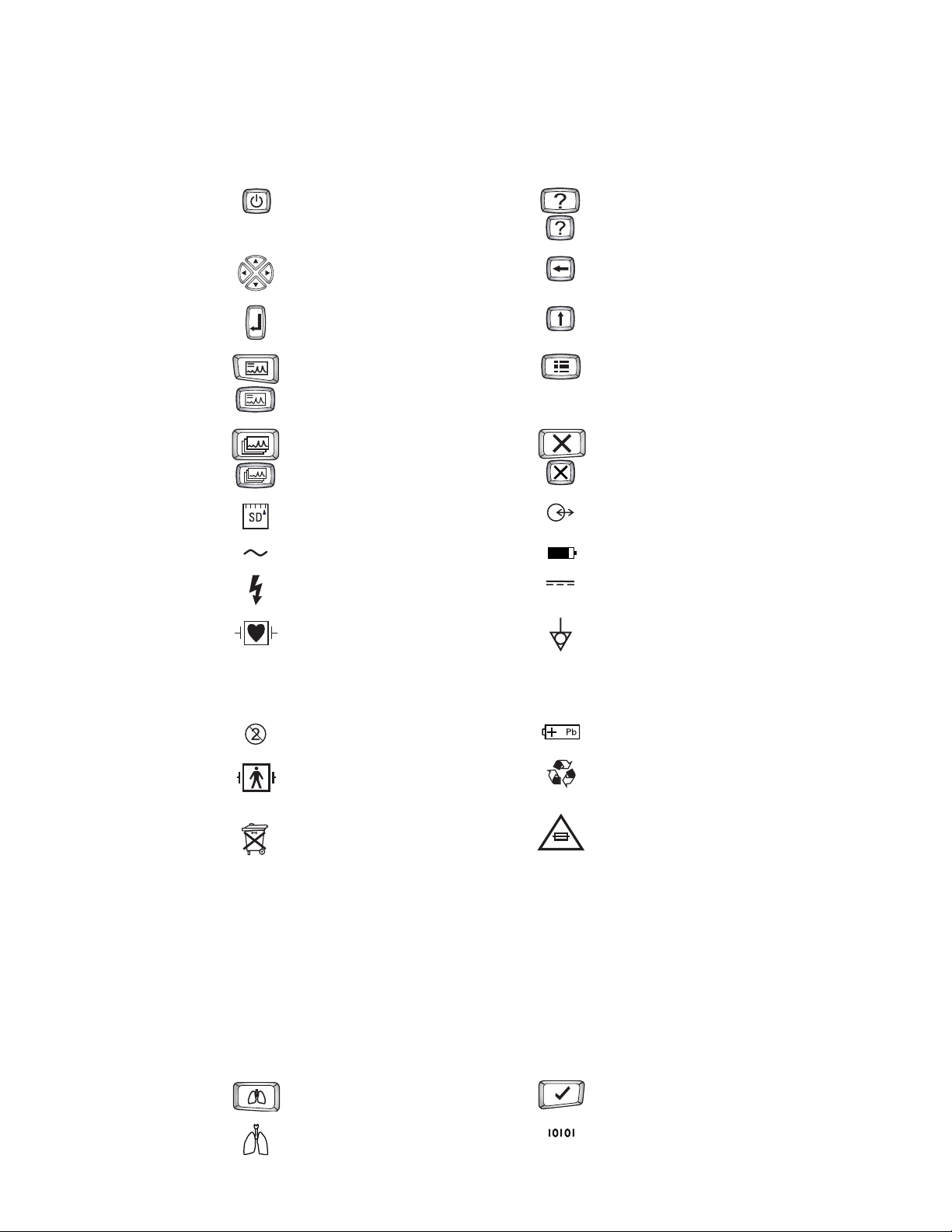

Symbols

The symbols illustrated on the following pages may appear on the electrocardiograph, the

packaging, the shipping container, or in this manual.

Documentation Symbols

WARNING Indicates conditions or practices that could lead to illness, injury, or

death.

Caution In the manual, indicates conditions or practices that could damage the

equipment or other property.

Caution On the product, means “Consult accompanying documentation.”

-20°C

EC REP

Shipping, Storing, and Environment Symbols

This end up Keep dry

Fragile Altitude limits

+49°C

Temperature limits Relative humidity limit

Certification Symbols

Meets essential requirements of European

Medical Device Directive 93/42/EEC

European Regulatory Manager

Welch Allyn LTD.

Navan Business Park

Dublin Road

Navan, County Meath, Republic of Ireland

Tel.: 353-46-90-67700

Fax: 353-46-90-67756

N344

Complies with applicable U.S. and Canadian

medical safety standards

Australian registered importer

Directions for Use Safety Summary 3

Operation Symbols

For details on the keys, see “Keyboard Functions” on page 14.

On/standby (off) Help

Navigation arrows Backspace

Enter Shift

Auto ECG Menu

Rhythm ECG Stop/Cancel

SD memory card slot Com port A

(for patient cable)

Alternating current Battery charge level

Dangerous voltage Direct current

Defibrulation-proof type CF applied parts

Ground equipotential

(while the electrocardiograph is safety-rated

“CF” for direct cardiac contact it is not

intended to be connected directly to the

patient’s heart; only surface contact with the

patient’s skin is intended).

Do not reuse. Sealed lead-acid battery

Type BF Defibrillator proof Recycle

Do not dispose of this product as unsorted

municipal waste. Prepare this product for

reuse or separate collection as specified by

T2.0A/250V

AC fuse replacement information

Directive 2002/96/EC of the European

Parliament and the Council of the European

Union on Waste Electronic and Electrical

Equipment (WEEE). If this product

is

contaminated, this directive does not apply.

For more specific disposal information, see

www.welchallyn.com/weee,

or contact Welch Allyn Customer Service at

+44 207 365 6780.

Additional Operation Symbols for CP 200

Spirometry Key OK

Spirometry port Com port B

(for USB cable)

4 Safety Summary CP 100 and CP 200 Electrocardiograph

Servicing the Electrocardiograph Safely

Before using or servicing the electrocardiograph, you must read and understand the

following safety-related information.

General Warnings

The following warning statements apply to electrocardiograph use in general. Warning

statements that apply specifically to particular procedures, such as connecting the patient

cable or performing an ECG test, appear in the corresponding sections of the manual.

Warning statements indicate conditions or practices that could lead to illness, injury, or

death.

Warnings Related to the Environment

WARNING To avoid a possible explosion, do not use the electrocardiograph in

the presence of flammable anesthetics.

WARNING When transporting the electrocardiograph on a cart, tuck the

patient cable away from the wheels so that it does not present a hazard.

WARNING Do not use the CP 100 and CP 200 Electrocardiograph in an MRI

suite or hyperbaric chamber.

WARNING Do not autoclave the CP 100 and CP 200 Electrocardiograph or

patient cable.

Warnings Related to Accessories and Other Equipment

WARNING For operator and patient safety, peripheral equipment and

accessories that can come in direct patient contact must be in compliance with

all appropriate safety, EMC, and regulatory requirements. See “EMC Guidance

and Manufacturer’s Declarations” on page 79

WARNING All signal input and output (I/O) connectors are intended for

connection of only devices complying with IEC 60601-1, or other IEC standards

(for example, IEC 60950), as appropriate to the device. Connecting additional

devices to the electrocardiograph may increase chassis or patient leakage

currents. To maintain operator and patient safety, consider the requirements of

IEC 60601-1-1. Measure the leakage currents to confirm that no electric shock

hazard exists.

WARNING The electrocardiograph has not been designed for use with highfrequency (HF) surgical equipment and does not protect against hazards to the

patient.

Directions for Use Safety Summary 5

Warnings Related to Using the Electrocardiograph

WARNING Avoid positioning any leads or cables so that they could easily trip

someone.

WARNING Satisfactory maintenance procedures must be implemented, or

equipment failure and health hazards may result.

Warnings Related to Repairing the Electrocardiograph

WARNING Only qualified service personnel should attempt to repair the

electrocardiograph. In case of a malfunction, call Technical Support and precisely

describe the problem. For phone numbers, see page ii.

WARNING While under warranty, the electrocardiograph must be serviced

only by a Welch Allyn service technician.

WARNING Electrostatic discharge (ESD) can damage or destroy electronic

components. Handle static-sensitive components only at static-safe

workstation.

WARNING Consider all electrical and electronic components of the monitor as

static-sensitive.

Electrostatic Discharge (ESD)

Electrostatic discharge is a sudden current flowing from a charged object to another

object or to ground. Electrostatic charges can accumulate on common items such as

foam drinking cups, cellophane tape, synthetic clothing, untreated foam packaging

material, and untreated plastic bags and work folders, to name only a few.

Electronic components and assemblies, if not properly protected against ESD, can be

permanently damaged or destroyed when near or in contact with electrostatically charged

objects. When you handle components or assemblies that are not in protective bags and

you are not sure whether they are static-sensitive, assume that they are static-sensitive

and handle them accordingly.

• Perform all service procedures in a static-protected environment. Always use

techniques and equipment designed to protect personnel and equipment from

electrostatic discharge.

• Remove static-sensitive components and assemblies from their static-shielding bags

only at static-safe workstations—a properly grounded table and grounded floor mat—

and only when you are wearing a grounded wrist strap (with a resistor of at least 1

megohm in series) or other grounding device.

6 Safety Summary CP 100 and CP 200 Electrocardiograph

• Use only grounded tools when inserting, adjusting, or removing static-sensitive

components and assemblies.

• Remove or insert static-sensitive components and assemblies only with monitor

power turned off.

• Insert and seal static-sensitive components and assemblies into their original staticshielding bags before removing them from static-protected areas.

Always test your ground strap, bench mat, conductive work surface, and ground cord

before removing components and assemblies from their protective bags and before

beginning any disassembly or assembly procedures.

General Cautions

The following caution statements apply to electrocardiograph use in general. Caution

statements that apply specifically to particular procedures, such as connecting the patient

cable or performing an ECG test, appear in the corresponding sections of the manual.

Caution statements indicate conditions or practices that could damage the equipment or

other property.

Caution When removing the electrocardiograph from storage, allow it to

thermally stabilize to surrounding environmental conditions before using it.

Caution To prevent possible damage to the keypad, do not use sharp or hard

objects to press keys. Only use fingertips.

Caution Do not expose the patient cable to strong ultra-violet radiation.

Caution Do not pull or stretch the patient cable. Doing so could result in

mechanical or electrical failures. Form the patient cable into a loose loop before

storing.

Caution Avoid positioning the patient cable where it might get pinched or

stepped on. If the cable’s impedance is altered, measurements might no longer

be accurate, and repair might be necessary.

Caution Using the equipotential terminal for anything but grounding purposes

may contribute to damage of the device.

Caution Use only parts and accessories supplied with the device and available

through Welch Allyn. The use of accessories other than those specified may

result in degraded performance of this device.

Caution Portable and mobile RF communications equipment can affect the

performance of the electrocardiograph.

Caution Other medical equipment—including but not limited to defibrillators,

ultrasound machines, pacemakers, and other stimulators—may be used

simultaneously with the electrocardiograph. However, such devices may disturb

the electrocardiograph signal.

7

2

Overview

Purpose and Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Service Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Product Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommended Service Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls, Indicators, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

“System Settings” Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

About the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Moving Through the Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reviewing the Device Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CP 100 and CP 200 Electrocardiograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

Purpose and Scope

The service manual is a reference for periodic preventive maintenance and corrective

service procedures for the Welch Allyn CP 100 and CP 200 Electrocardiograph.

Corrective service is supported to the level of field-replaceable units. This includes some

circuit-board assemblies and some subassemblies, case parts, and other parts. See “Field

Replaceable Parts” on page 69 for complete list of user-replaceable service parts.

Note

This guide provides troubleshooting information, assembly procedures, and instructions

for functional testing and performance verification. It is intended for use only by

technically qualified service personnel.

Repair and replacement of the main board is not supported. All service work on

the main board must be performed by certified and qualified service personnel at

an authorized Welch Allyn service center.

Caution No component-level repair of circuit boards and subassemblies is

supported. Use only the repair procedures described in this manual.

WARNING When performing a service procedure, follow the instructions

exactly as presented in this manual. Failure to do so could damage the monitor,

invalidate the product warranty, and lead to serious personal injury.

Service Options

Warranty Service

All repairs on products under warranty must be performed and/or approved by Welch

Allyn. Refer all warranty service to Welch Allyn Factory Service or another authorized

Welch Allyn Service Center. Obtain an RMA number for all returns to Welch Allyn Factory

Service – see Returning Products (page 9).

Caution Unauthorized repairs will void the product warranty.

Non-Warranty Service

Welch Allyn Factory Service and authorized Service Centers support non-warranty repairs.

Contact any Welch Allyn regional service center for pricing and service options.

Welch Allyn offers modular repair parts for sale to support non-warranty service. This

service must be performed only by qualified end-user biomedical/clinical engineers using

this service manual.

The Welch Allyn Electrocardiograph Service Information supports certain service

functions. For information about any Welch Allyn product, please call Welch Allyn

Technical Support: (page ii).

Service Manual CP 100 and CP 200 Electrocardiograph 9

Technical Support Services

Welch Allyn offers the following technical support services:

Telephone support

Loaner equipment

Service agreements

Replacement service parts

Factory Service

For information on any of these services, contact Welch Allyn at the numbers listed on

page ii

Returning Products

To return a product for service, contact Welch Allyn Technical Support and request a

Return Material Authorization (RMA) number.

Note

To ship the unit, please observe these packing guidelines:

Welch Allyn does not accept returned products without an RMA.

• When requesting an RMA, please have the following information available:

• Product name, model number, and serial number

• A complete return shipping address, including a contact name and phone

number; include any special shipping instructions

• A purchase-order number or credit-card number if the product is not covered by

warranty

• A full description of the problem or service request

• Remove from the package all hoses, connectors, cables, sensors, power cords,

and other ancillary products and equipment, except those items that might be

associated with the problem.

• Use the original shipping carton and packing materials, or as close an

approximation as possible.

• Include a packing list.

• Write the Welch Allyn RMA number with the Welch Allyn address on the outside

of the shipping carton.

United States federal regulations require that any unit received by Factory Service must

be free from blood-borne pathogens before processing. All incoming products are cleaned

as well as possible, but products that cannot be effectively cleaned cannot be accepted

for repair. Please thoroughly clean all organic residues from the product before shipment.

This will ensure safe receipt, processing and repair, and will help expedite the return of

your device.

10 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

Product Configurations

Model numbers for the configurations are as follows:

Model Number Description

CP 1 CP 100 Electrocardiograph

CP 1A CP 100 Electrocardiograph w/Interpretation

CP 2 CP 200 Electrocardiograph

CP 2A CP 200 Electrocardiograph w/Interpretation

CP 2S CP 200 Electrocardiograph w/Spirometry

CP 2AS CP 200 Electrocardiograph w/Interpretation & Spirometry

Recommended Service Intervals

Interval or Condition Action Recommended Procedure

Every 6 – 24 months (per

hospital protocols)

Battery does not hold a charge Check battery capacity

Unit has been dropped or

otherwise damaged

Unit malfunctioning Complete Functional test Functional Verification (page 29)

Unit does not pass Functional

Verification

Complete Functional test Functional Verification (page 29)

Battery Accuracy Test (page 31)

Replace battery

Complete Functional test Functional Verification (page 29)

Troubleshooting and repair followed by functional test

Return to authorized service center

Replacing the Battery or Fuse (page 58)

Troubleshooting (page 41)

Disassembly and Repair Procedures (page

47)

Functional Verification (page 29)

Returning Products (page 9)

Service Manual CP 100 and CP 200 Electrocardiograph 11

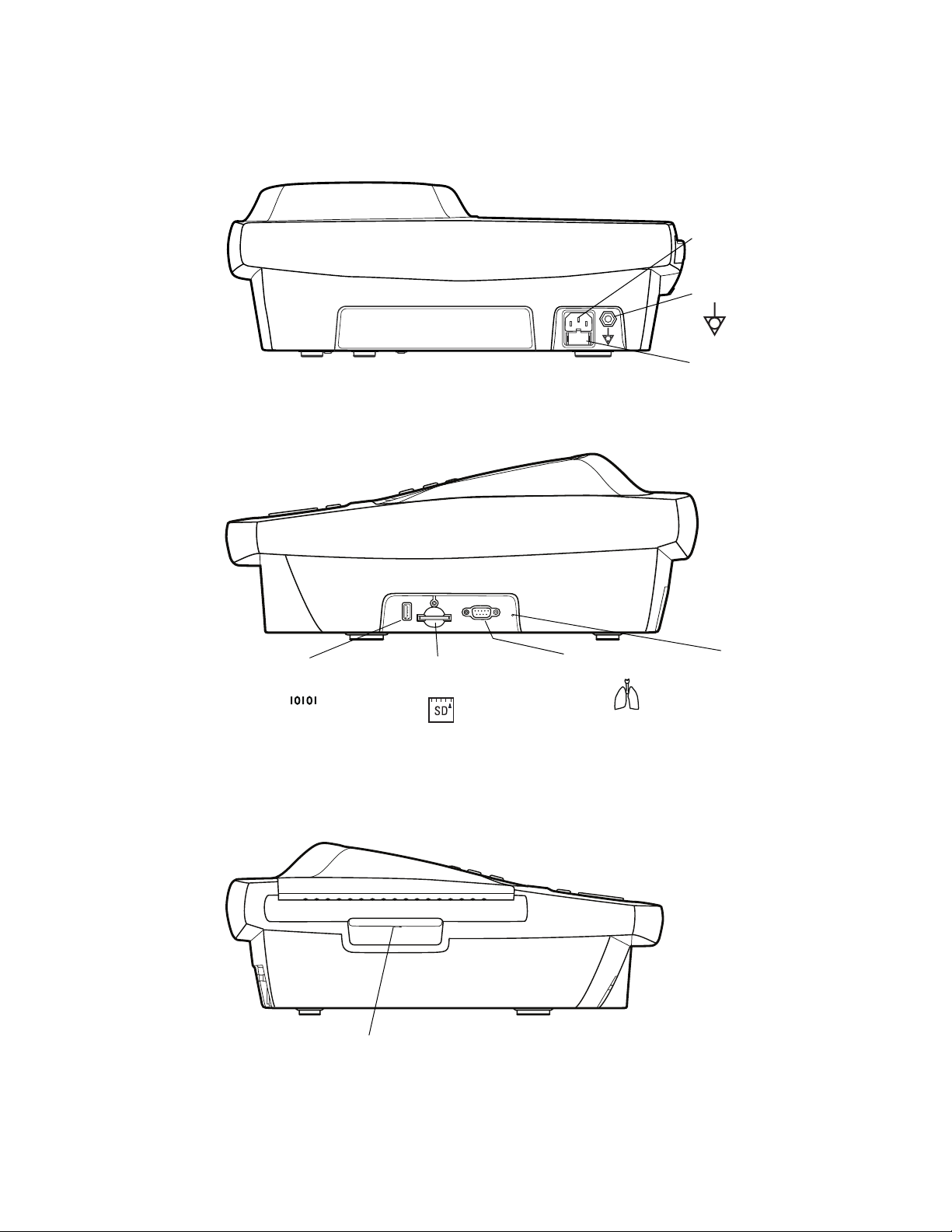

Controls, Indicators, and Connectors

This section describes the controls, indicators, and connectors that are part of the

electrocardiograph.

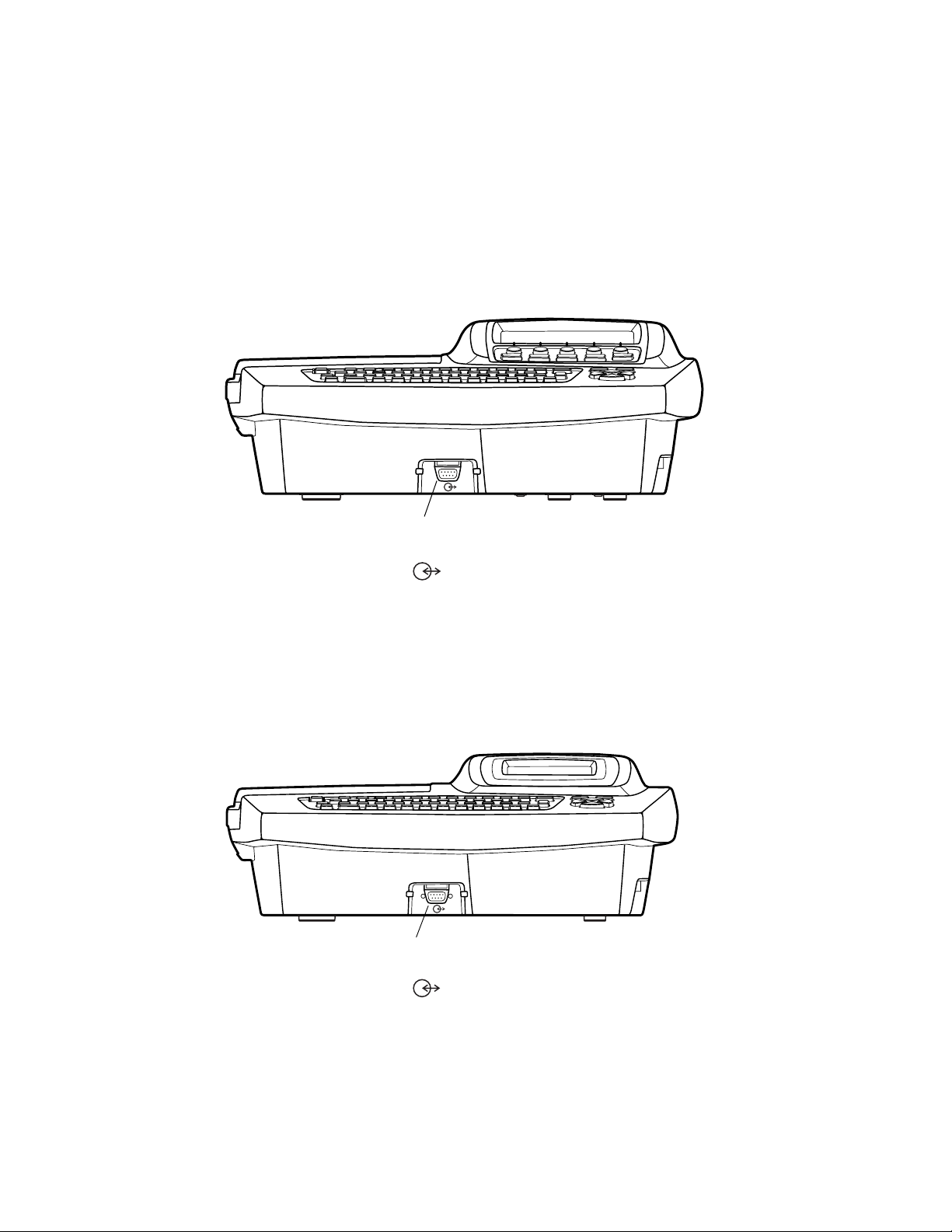

Figure 1. Top of CP 200 Electrocardiograph

Softkeys and functions keys

See Figure 10 on page 15.

Keyboard

See Figure 8 on page 14.

Figure 2. Top of CP 100 Electrocardiograph

Keyboard

See Figure 9 on page 14.

12 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

Figure 3. Back of Electrocardiograph

AC power inlet

Equipotential stud

AC fuses

Figure 4. Right Side of Electrocardiograph

Com port B

(for USB cable)

SD memory card

slot

(Not functional on CP 100)

Figure 5. Left Side of Electrocardiograph

Paper tray latch

Spirometry port

(Not functional on CP 100)

Reset

Button

Service Manual CP 100 and CP 200 Electrocardiograph 13

Figure 6. Front of CP 200 Electrocardiograph

Com port A

(for patient cable)

Figure 7. Front of CP 100 Electrocardiograph

Com port A

(for patient cable)

14 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

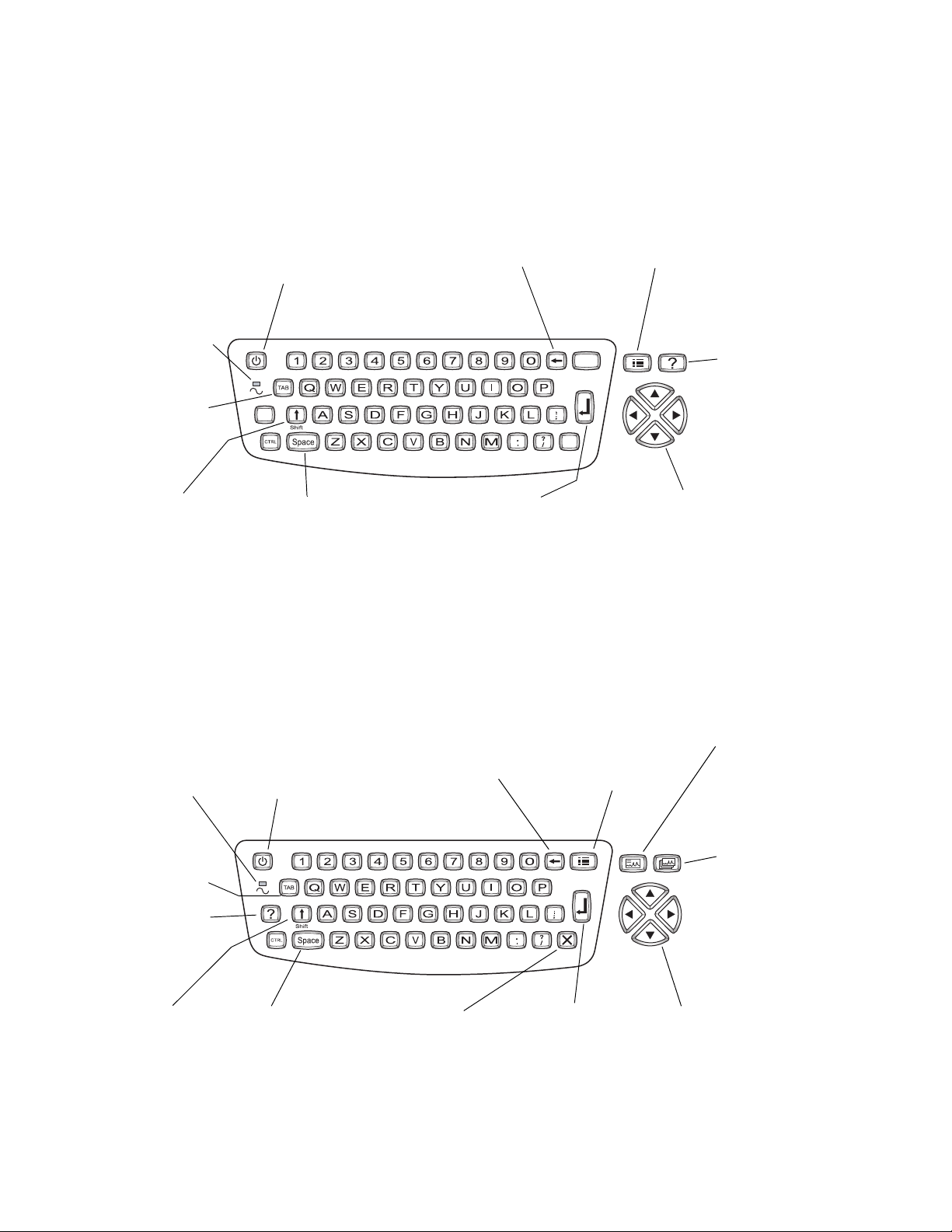

Keyboard Functions

Figure 8. Keyboard for CP 200 Electrocardiograph

On/Off

See “ Powering the

Electrocardiograph” in the

Directions of Use manual.

Green LED

Lights up when the

electrocardiograph is

connected to AC

power.

Ta b

Moves through the

data-entry fields.

Shift

Capitalizes letters.

Space

Enters a space.

Figure 9. Keyboard for CP 100 Electrocardiograph

Backspace

Deletes the character to the

left of the cursor.

Enter

See “Moving Through the Menus” on

page 18.

Menu

See “About the Main Menu”

on page 17.

Help

See the Directions For

Use manual.

Navigation arrows

See “Moving Through the

Menus” on page 18.

Green LED

Lights up when the

electrocardiograph is

connected to AC

power.

Ta b

Moves through the

data-entry fields.

Help

See the Directions

for Use manual.

Shift

Capitalizes letters.

On/Off

See “ Powering the

Electrocardiograph” in the

Directions of Use manual.

Space

Enters a space.

Stop/Cancel

Stops any current activity.

See “Moving Through the

Menus” on page 18.

Backspace

Deletes the character to the

left of the cursor.

Enter

See “Moving Through the

Menus” on page 18.

Menu

See “About the Main

Menu” on page 17.

Auto ECG

Begins Auto ECGs,

normal and stat.

Rhythm ECG

Begins a Rhythm ECG.

.

Navigation arrows

See “Moving Through the

Menus” on page 18.

Service Manual CP 100 and CP 200 Electrocardiograph 15

Figure 10. Softkeys and Function Keys for the CP 200 Electrocardiograph

Softkeys

These softkeys display text or images that

correspond to the unlabeled buttons below

them. The content changes from screen to

screen.

Softkey buttons

These buttons activate the functions displayed

above them. If a softkey is blank, pressing its

Auto ECG Spirometry Rhythm ECG Stop/Cancel OK

button has no effect.

Function Keys

Auto ECG

Begins Auto ECGs, normal and stat.

Spirometry

Begins spirometry tests.

See spirometry manual.

Rhythm ECG

Begins Rhythm ECGs.

Stop/Cancel

Stops any current activity.

See “Moving Through the Menus” on page 18.

OK

Accepts data that you have entered, or chooses a highlighted item.

See “Moving Through the Menus” on page 18.

16 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

“System Settings” Menu Tree

P 200 Menu Tree

System Settings

Device

Configuration

Set Date/Time

Language

Date Format

Time Format

Weight Unit

Height Unit

Power-Save

Device ID

Audio Beeper

Flow Unit

Pressure Unit

Temperature

Increase Display Contrast

Decrease Display Contrast

Contact Information

Previous Menu

* Applicable for spirometry only.

*

*

*

CP 100 Menu Tree

Device

Info

About

Print Settings

Enable Options

Upgrade Software

Service Info

Previous Menu

System Settings

Device

Administration

See “Managing Data” in the

Directions for Use manual.

Service Info

Print Log

Battery Life Test

Printer Test

Export Files

Import Files

Delete Files

Serial Number

Lead Off Thershold

Service Tests

LCD Test

Previous Menus

Device

Configuration

Set Date/Time

Language

Date Format

Time Format

Weight Unit

Height Unit

Power-Save

Device ID

Audio Beeper

Increase Contrast

Decrease Contrast

Contact Information

Previous Menu

Device

Info

About

Print Settings

Enable Options

Upgrade Software

Service Info

Previous Menu

Service Info

Print Log

Battery Life Test

Printer Test

Export Files

Import Files

Delete Files

Serial Number

Lead Off Thershold

Service Tests

Previous Menus

Service Manual CP 100 and CP 200 Electrocardiograph 17

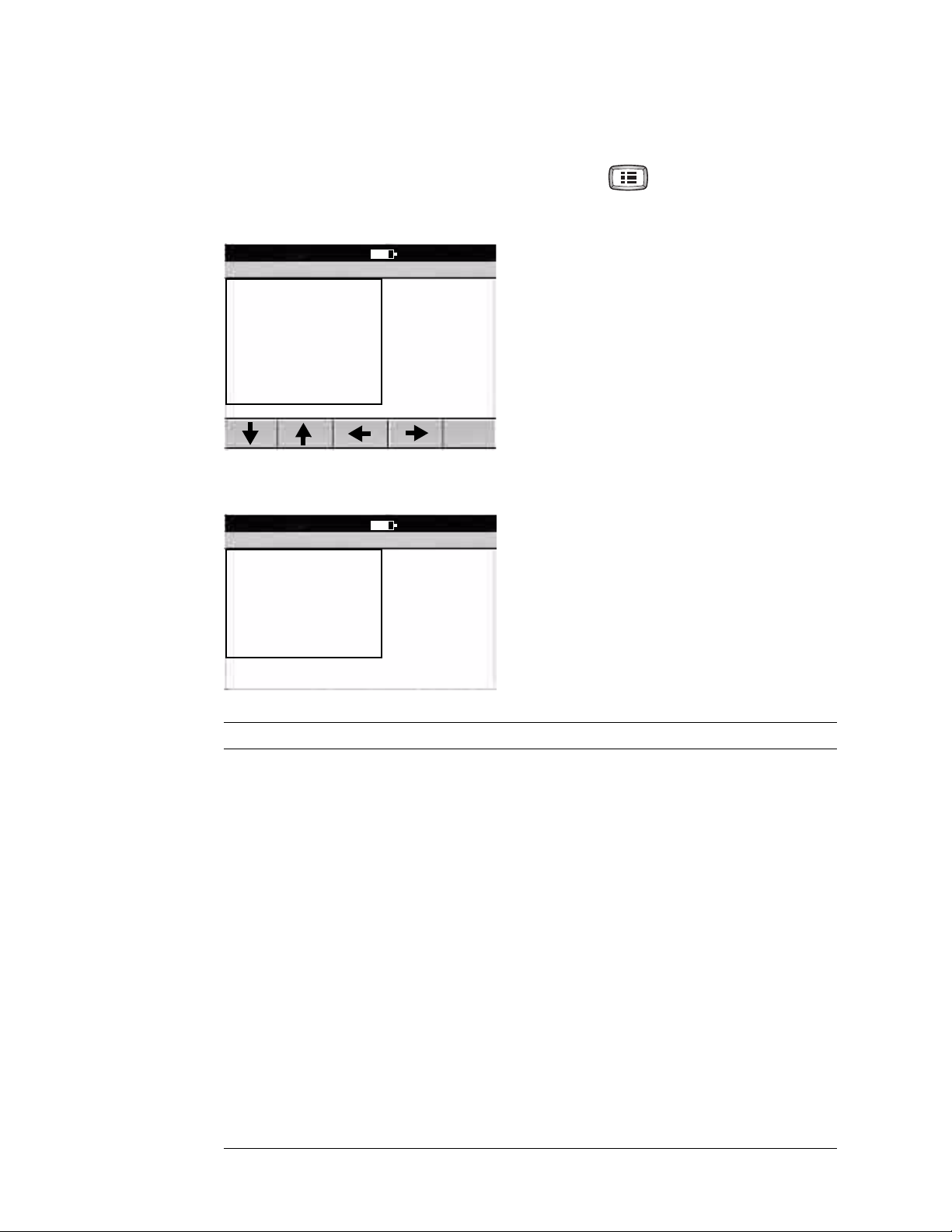

About the Main Menu

The main menu appears when you press the Menu key .

Figure 11. Main Menu CP 200

Main Menu

1 Test Directory

2 Scheduled Patients

3 ECG Settings

4 Spirometry Settings

5 System Settings

6 Edit Medication List

7 Edit History List

0 Exit

Figure 12. Main Menu CP 100

Main Menu

1 ECG Settings

2 System Settings

0 Exit

9:17AM Mar 16 05

9:17AM Mar 16 05

Submenu Purpose Procedure

Test Directory View, change, print, or send saved tests. (CP

200 Only)

Scheduled Patients View the scheduled patients list, add

patients to the list, or delete patients from

See the Directions for Use manual on your

specific model.

See the Directions for Use manual on your

specific model.

the list. (CP 200 Only

ECG Settings Review or change ECG settings: Auto

Report format, Rhythm Report format, and

See the Directions for Use manual on your

specific model.

so on.

Spirometry Settings Review or change spirometry settings:

display settings, print settings, and so on. (CP

See the Directions for Use manual on your

specific model.

200 Only

System Settings Review or change system settings: device

configuration, device info, user setup, and

See the Directions for Use manual on your

specific model.

so on.

Edit Medication List Edit the list of medication choices available

to choose during patient data entry. (CP 200

See the Directions for Use manual on your

specific model.

Only

Edit History List Edit the list of clinical conditions available to

choose during patient data entry. (CP 200

See CP 200 Electrocardiograph Directions for

Use manual.

Only

18 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

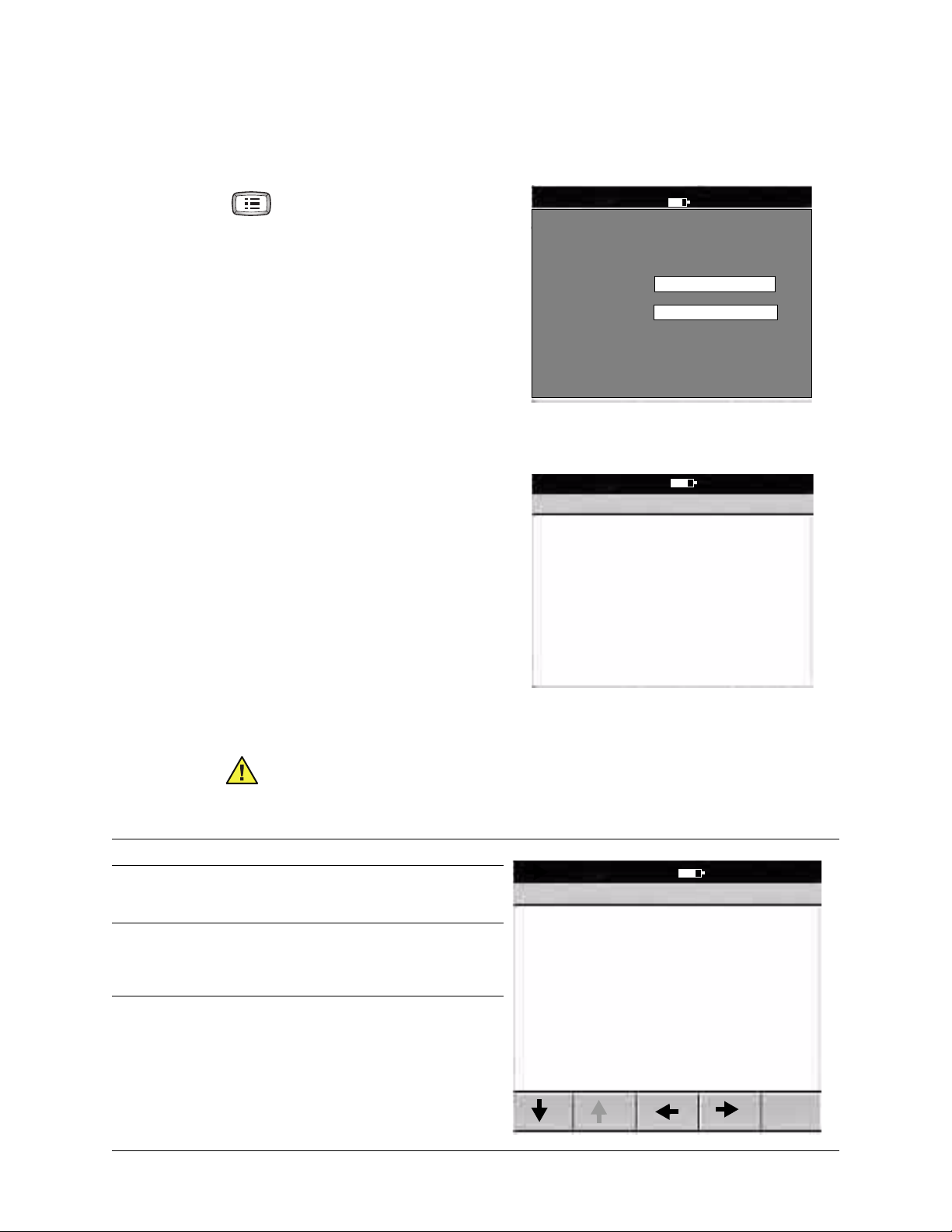

Moving Through the Menus

Figure 13. CP 200 Standard Menu Figure 15. CP 200 Parent Menu With Submenu

ECG Setup : Edit Auto Report 1

1 Format

2 Interp Settings

3 Patient Data

0 Previous Menu

9:17AM Mar 16 05

Figure 14. CP 100 Standard Menu

Edit Auto Report

1 Format

2 Interp Settings

3 Patient Data

0 Previous Menu

9:17AM Mar 16 05

Edit Auto Report 1 : Format

1 Lead Arrangement

2 Rhythm Lead 1

3 Rhythm Lead 2

4 Rhythm Lead 3

5 Extended Measurements

6 Average Cycles

0 Previous Menu

9:17AM Mar 16 05

3x4

3x4 +1R

3x4 +3R

6x2

12x1

6x2 50 mm/s

6x2 10 Ext.

No Print

Figure 16. CP 100 Parent Menu with Submenu

Format

1 Lead Arrangement

2 Rhythm Lead 1

3 Rhythm Lead 2

4 Rhythm Lead 3

5 Extended Measurements

6 Average Cycles

0 Previous Menu

9:17AM Mar 16 05

3x4 +1R

3x4 +3R

6x2

12x1

6x2 50 mm/s

6x2 10 Ext.

No Print

Desired Actions Keys to Press

To move up or down a list or (keyboard or softkey arrows)

To open a standard menu (Figure 13)

or or

or item’s number or letter

To move from parent menu to submenu on same

screen (Figure 15)

To perform an action

or

To accept data

To check or uncheck a checkbox

To return to parent menu from submenu on same

screen (Figure 15) or

(To select the highlighted submenu

item.)

or

(To make no change.)

To move back through the menus or zero key

To move through data-entry fields

To return to the “Main Screen” from a standard menu

(Figure 13)

Note

Keyboard and softkey arrows work the same way.

Service Manual CP 100 and CP 200 Electrocardiograph 19

Reviewing the Device Information

1. Press the Menu key .

2. Choose System Settings > Device Info.

The following screen appears.

Figure 17. “Device Info” CP 200 Screen

System Setup : Device Info

1 About

2 Print Settings

3 Enable Options

4 Upgrade Software

5 Service Info

0 Previous Menu

9:17AM Mar 16 05

Figure 18. “Device Info” CP 100 Screen

Device Info

1 About

2 Print Settings

3 Enable Options

4 Upgrade Software

5 Service Info

0 Previous Menu

9:17AM Mar 16 05

3. Select the desired item:

Item Description

About Displays the following information about the electrocardiograph:

• serial number

• modules configured

• version numbers

Print Settings CP 200 = Prints your ECG, spirometry, and system settings as well as medication &

history lists.

CP 100 = Prints your ECG and system settings.

Enable Options Contact Technical Support. For phone numbers, see page ii.

Upgrade Software Contact Technical Support. For phone numbers, see page ii.

Service Info Accessible to service support only. See Service Menus (page 20)

20 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

CP 100 and CP 200 Electrocardiograph

Service Menus

Entering the Service Info Screen

This menu is password protected and only Welch Allyn Authorized Technician can access

the Service Menus,)

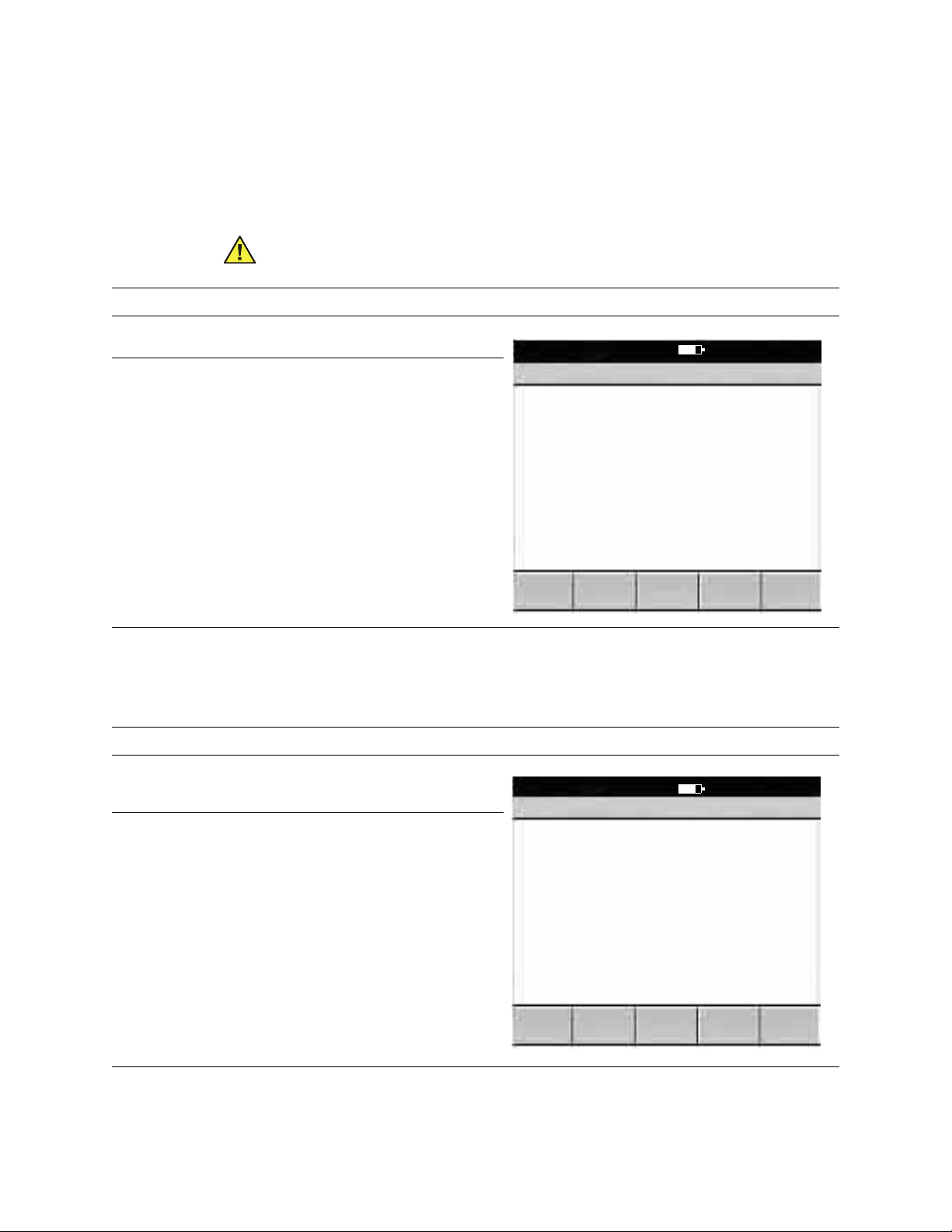

CP 200 Service Info Screen

Procedure Figure 19. CP 200 “User Login”

1. Power ON unit.

2. Press Menu key.

3. Choose System Setting> Device Info> Service Info

The “UserLogin” screen appears. See Figure 19.

UserLogin

9:17AM Mar 16 05

Use the “Tab” or “Arrow” keys to move the cursor from field to field.

Enter the following:

User ID: Service (case sensitive)

Password:normser (case sensitive)

4. Press “Done” using the softkey. Do not use the“Enter” key.

The “Service Info” screen appears see Figure 20

User ID

Password

Enter valid user ID and password

Change

Password

Cancel

Figure 20. CP 200 “Service Info” Screen

9:17AM Mar 16 05

Service Info

1.Print Log

2.Battery Life Test

3.Printer Test

4.Export Files

5.Import Files

6. Delete Files

7.Serial Number

8.Lead Off Thershold

9.Service Tests

A LCD Test

0.Previous Menus

Done

Service Manual CP 100 and CP 200 Electrocardiograph 21

CP 100 Service Info Screen

Procedure Figure 21. CP 100 “UserLogin” Screen

1. Power ON unit.

2. Press Menu key.

3. Choose System Setting > Device Info > Service Info

User Login

9:17AM Mar 16 05

The “UserLogin” screen appears. See Figure 21.

User ID

Use the “Arrow” keys to move the cursor from field to field.

Password

Enter the following:

User ID: Service (case sensitive)

Done

Password:normser (case sensitive)

4. Highlight “Done” using the down arrow key.

5. Press “Enter” key.

The “Service Info” screen appears. See Figure 22

Figure 22. CP 100 “Service Info” Screen

9:17AM Mar 16 05

Service Info

1. Print Log

2. Battery Life Test

3. Printer Test

4. Export Files

5. Import Files

6. Delete Files

7. Serial Number

7. Lead Off Thershold

8. Service Tests

0. Previous Menus

Print Log

Caution These printouts can be very long. Only use the printouts if necessary.

To stop the printouts press Stop/Cancel.

Function Description

Print Events: This prints all events stored in the unit in descending

order by date and time. Used for development of the

software. Has no Service value.

Print Errors: This prints any errors that occurred in the unit, in

descending order by date and time, during normal

operation. This can be valuable to use when the enduser says he/she has been having problems.

Print All: This prints the Print Events and Print Errors as

described above.

Figure 23. “Print Log” Screen

Print Log

1.Print Events

2.Print Errors

3.Print All

0.Previous Menus

9:17AM Mar 16 05

22 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

Battery Life Test

This displays the percentage of battery life remaining on the battery, based on the number

of charges it has incurred. This percentage approximates the life left in the battery based

on this information.

Caution Only reset when the battery has been replaced and charged for at

least 12hrs continuously.

Function Description

Reset Resets the battery life to 100%. This is used only

when the battery has been replaced

Reset Pages Resets page count for the number of prints made on

the printer. Should only be reset when print head has

been replaced.

Printer Test

Function Description

Figure 24. “Battery Life Test” Screen

9:17AM Mar 16 05

Battery Life Test

Battery Life Remaining: 99%

Reset

Reset

Pages

Figure 25. Printer Test” Screen

Exit

Test Page Prints a test page which repeats until the “Cancel”

button is pressed. Refer to Functional Verification test

for explanation. See Printer Test (page 35).

Ramp Test Prints a one page ramp test. Refer to Functional

Verification test for explanation. See Printer Test

(page 35).

Printer Test

Test Page

9:17AM Mar 16 05

Select a print test

Ramp

Page

Exit

Service Manual CP 100 and CP 200 Electrocardiograph 23

Export Files

Use the “Export Files” function when the Main PCB is replaced, to reinstall the

customer’s saved ECG information and spirometry (CP 200 Only) or the unit’s original

configuration after repair.

Caution The tests exported to the SD memory card contain patients’ medical

information and should be treated the same as any confidential medical

information.

Note

If you are performing all functions you only need one SD memory card. Use a

formatted blank SD memory card installed in the unit for each function.

Function Description

Export Log Files Exports the Event log to a SD memory card in a folder

called Log. Once complete, a message appears at

bottom of the screen stating if the export was

successful or not.

Export Audit Trail

(CP 200 ONLY)

Export Tests (CP 200

ONLY)

Export

Configuration Files:

Exports the audit information of the unit to a SD

memory card in a folder called Audit. Once complete

a message appears at bottom of screen stating if

export was successful or not.

Note: Audit information is available if Audit trail

is turned on in Device Administration. See the CP

200 Directions for Use manual

Exports all tests in the memory to a SD memory card

in a folder called Tests for importing after repair.

Exports the configuration of the unit (i.e. print

formats, patient data settings, logins, etc.) to a SD

memory card in a folder called Config for importing

after repair.

Figure 26. “Export Files” Screen

Export Files

1.Export Log Files

2.Export Audit Files

3.Export Tests

4.Export Configuration Files

0.Previous Menus

9:17AM Mar 16 05

24 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

Import Files

Function Description

Import Tests (CP 200

ONLY)*

Imports previously exported tests from the SD

memory card.

*Before importing tests, you must delete the previous

copies from the unit using the “Delete Files” menu.

Import

Configuration Files

Imports previously exported configuration files from

SD memory card.

After the import configurations files process is

complete, the screen displays a reset prompt. Press

any key to reset, and then follow the prompts to set

the date and time.

Delete Files

Figure 27. “Import Files” Screen

Import Files

1.Import Tests

2.Import Configuration Files

0.Previous Menus

Caution No warning is displayed when you delete files/tests.

9:17AM Mar 16 05

Function Description

Delete Log Files Deletes log files (event and error) from unit.

Delete Audit Files:

Deletes the Audit Log file from the unit.

(CP 200 ONLY)

Delete Tests: (CP

200 ONLY)*

Delete

Deletes ALL saved ECG and Spirometry tests in

memory.

Deletes the Configuration files from the unit.

Configuration Files:

Note

*Before importing the tests file, you must delete any previous tests from the unit using

the “Delete Files” menu.

You do not have to delete the Configuration files on the unit before importing a

Configuration files from SD memory card. All previous Configurations Files on the unit will

be overwritten during the importing process.

Figure 28. “Delete Files” Screen

Delete Files

1.Delete Log Files

2.Delete Audit Files

3.Delete Tests

4.Delete Configuration Files

0.Previous Menus

9:17AM Mar 16 05

Service Manual CP 100 and CP 200 Electrocardiograph 25

Serial Number

Used to enter the S/N of the unit after a Main Board has been replaced.

Note

For use by Welch Allyn Authorized Repair facilities.

Lead Off Threshold

The Lead Off Threshold setting provides a mechanism to increase/decrease the sensitivity

of the device to lead impedance. Lead impedance is the electrical resistance of a lead.

Lead impedance can rise if there is poor electrode/skin contact. As lead impedance rises,

the input signals become imbalanced, resulting in a poor quality signal.

If the lead impedance for any of the leads is above the threshold, the device replaces the

poor quality signal received from the patient cable with a square wave to indicate to the

user that the affected signals are not usable. The lead impedance of each of the leads is

independent, but there is a single threshold value. The threshold can be any of 15 values,

from 1 (lowest threshold) to 15 (highest threshold). The default threshold is 7. If the

threshold is changed to 1, it causes Lead Off all of the time, and setting it to 15 causes the

leads to never appear “Off”

Function Description

Lead Off Threshold The Lead Off Threshold setting is provided to diagnose problems with the front end. By increasing the Lead

Off Threshold setting, the device accepts higher impedance signals, instead of replacing them with square

waves. Although the device displays poorer quality signals, they may be unsuitable for diagnostic purposes,

because they could be significantly distorted.

The Default setting for the Lead Off Threshold to 7

To access and change the Lead Off Threshold

Select Main Menu > Service Info > Device Info > Lead Off Threshold

Service Tests

Only authorized Welch Allyn Authorized Technicians are to perform the service tests.

Note

Function Description

CPWSTEST.EXE Used to help troubleshoot USB issues.

MEANSMDWTESTER.EXE: Strictly used for development purposes.

To exit any of the applications press the “Enter” or”OK” key.

Enable USB: Turns USB port on to be recognized by computer.

Disable USB: Turns USB port off so it is not recognized by computer.

26 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

Function Description

MMCSDTEST.EXE: Used to test the SD memory card write/read function of the unit. Can also be used to test an SD memory card

for problems.

GO: Starts the SD memory card test by pressing “G”

STOP: Stops the SD memory card test by pressing “S”

ERASE ALL: Erases all files written by this tester by pressing “E”

Card Present: If checked the unit detects the SD memory card inserted.

Write Protect: If checked the unit detects the lock is enabled on the SD memory card.

Pulse: Flashes when test is active

Note: Once the test is started it runs continuously. Press the “S” key to stop the test.

NORMANDY.EXE: Used to return to the ECG program.

NORMTESTER.EXE Strictly used for development purposes.

PPPTEST.EXE Strictly used for development purposes.

PPPTEST2.EXE Used to see battery and charger status/state. There are a number of selections on this screen. Listed below

are the most commonly used functions. To activate a selection press the letter that coincides with the

selection.

Real-time: Activates a real-time monitoring of the readings from the battery circuit.

Battery Voltage: Unplugged from AC this reflects the Voltage of the battery in millivolts; plugged into

AC this reflects the charge voltage in millivolts.

Fast charge = 6800 – 7300

Trickle charge = 6300 – 6800

Battery Current: Indicates charge current in mA when charger is on.

Charger State: Indicates if charge circuit is on or off

Charge State: Indicates if the Fast Charge is on or off

Fast Charge On: Turns fast charge on. If battery is fully charged the sensing circuit can work against

you. It only changes the reading for a brief second before switching back.

Fast Charge Off: Turns fast charge off.

Charger On: Turns charger on when plugged into AC.

Charger Off: Turns charger off.

Service Manual CP 100 and CP 200 Electrocardiograph 27

Function Description

PPPTEST3.EXE Used to see printer assembly status/state. There are a number of selections on this screen. Listed below are

the most commonly used functions. To activate a selection press the letter that coincides with the selection.

Real-time: Activates a real-time monitoring of the readings from the printer assembly.

+24 V State: Status of voltage applied to printhead for printing. Only turns on when motor is on.

Step Motor State: Status of paper drive motor.

Paper Exhaust State: Status of paper in unit.

OK indicates paper is loaded.

Exhausted indicates out of paper.

Paper Status: 'JAM' indicates printer was unable to feed paper and detect a cue mark in the required

time. 'OK' indicates no jam.

Door State: This is equivalent to the Paper Exhaust State. There is no separate door sensor/switch.

Printhead Temperature State: State of printhead temperature. If temperature is too high, the printer

does not print.

Printhead Temperature (C): Indicates temperature of the printhead in Celsius.

Turn ON Motor: Turns stepper motor on to drive paper.

Turn OFF Motor: Turns stepper motor off.

PPPTEST4.EXE Used to see printer Assembly status/state. There are a number of selections on this screen. Listed below are

the most commonly used functions. To activate a selection press the letter that coincides with the selection.

Real-time: Activates a real-time monitoring of the readings from the printer assembly.

Feed to Next Page: Advances paper to next page.

Set Speed to 10 mm/s: Sets paper speed to 10mm/s.

Set Speed to 25 mm/s: Sets paper speed to 25mm/s.

Set Speed to 50 mm/s: Sets paper speed to 50mm/s.

Turn On Motor: Turns stepper motor on to drive paper.

Turn Off Motor: Turns stepper motor off.

Get Paper Registration State: Indicates if the sensor has identified the installed paper. Note: If you

open the door and close it, you must feed the paper to next page so unit can detect a cue mark. When the

unit detects a cue mark, the state changes to YES.

Get Cue Levels: Indicates sensing level for the cue sensor for different paper states.

< 10: Indicates paper door open or out of paper.

10 - 90: Indicates cue sensor over a paper cue mark.

> 190: Indicates cue sensor over white paper.

28 Overview Welch Allyn CP 100 and CP 200 Electrocardiograph

29

3

Functional Verification

Functional Verification Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Full Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Checklist and Test Results Report Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

30 Functional Verification Welch Allyn CP 100 and CP 200 Electrocardiograph

Functional Verification Overview

This section describes the procedure for a complete functional test to support

recommended preventive-maintenance schedules.

A checklist of the functional tests is provided on page 40. It is recommended that you

print a copy of the checklist each time you perform the functional verification procedure,

so you can record and save the test results. If the electrocardiograph ever requires

service, the records of test results often facilitate troubleshooting.

Functional verification does not require opening the device case.

Full Functional Check

WARNING Only qualified service personnel should perform a full functional

checkout procedure.

Whenever the electrocardiograph is serviced or problems are suspected, Welch Allyn

recommends a Functional Check.

Equipment Required

Commercially Available General-purpose/Medical Test Equipment

Item Manufacturer

Power Supply Variable, 0 – 8 VDC, 5.0A

AC withstand voltage (hi-pot) tester Associated Research 3605 or equivalent

Electrical Safety Analyzer w/ECG Fluke DNI 232D or equivalent

Computer PIII or better, CardioPerfect installed, available USB port

SD Memory Card 64Mb or Greater

USB Cable A – A type (WA P/N 401435)

Spirometry Dongle Serial Version (W/A P/N 703552)

Operating/Non-Printing Mode Current Test

When the unit is powered on, the AC is disconnected and the LCD on, the unit’s current

is:

CP 100 Current CP 200 Current

125 to 250 mA @ 6.4V DC ± .05 675 to 825 mA @ 6.4V DC ± .05

(minimum), with voltage and current indicators

1. Unplug unit from line power

2. Connect a DC power supply, adjusted for 6.4V DC ± .05, in place of the battery.

3. Verify the current draw is within limits as indicated for unit after powering the unit up.

Service Manual Functional Verification 31

Battery Accuracy Test

When a voltage of 6.2 ± 0.05 VDC is supplied to the unit battery terminals, and the AC is

disconnected from the unit, the unit reports a “Normal to High” voltage.

When a voltage of 5.45 ± 0.05VDC is supplied to the unit battery terminals, and the AC is

disconnected from the unit, the unit reports a “critically low” voltage.

Note

1. Unplug unit from line power.

2. Connect a DC power supply in place of the battery.

3. Adjust power supply to 6.2VDC.

4. Turn the unit on, and then verify the unit does not indicate a low or critically low

5. Adjust power supply to 5.45 VDC.

6. Verify the unit indicates a critically low power and will shut down.

The unit may have a 5 to 10 second delayed response.

battery.

Sleep/Standby Mode Current Test

When the unit is powered on and the AC is disconnected, and the unit is in low power

standby mode, the unit’s current is:

CP 100 Current CP 200 Current

< 5 mA < 5 mA

1. Unplug the unit from line power and adjust the power supply to 6.4V DC ± .05.

2. Connect the DVM in series with the positive battery connection from the power

supply.

3. Press the on/standby button.

4. Verify the LCD turns off and that the current draw is less than indicated for the unit.

5. Disconnect the power supply.

Note

There may be up to a 10 sec delay in the drop of current due to the progressive

hibernation mode.

Charger Detect Test

1. Connect a DVM to the battery harness while observing correct polarity.

2. Plug the unit into the AC power, and power ON.

3. Choose Main Menu > Systems Setting > Device info > Service Info > Service

Tests>PPPTEST2.EXE.See “Service Tests” on page 25.

32 Functional Verification Welch Allyn CP 100 and CP 200 Electrocardiograph

4. Turn fast charge ON. Check DVM for 6.8 to 7.3 VDC.

5. Turn fast charge off. Check DVM for 6.3 to 6.8 VDC.

6. Unplug the unit from the AC power.

7. Disconnect the DVM and install the battery.

LED Test

Verify the Power LED light is on when unit is plugged in, and verify the light is off when

unit is unplugged.

1. Plug the unit into AC power.

2. Verify the AC indicator LED under the On/Standby button is lit.

3. Unplug the AC power cord.

4. Verify the LED is off.

5. Plug the unit back into AC power.

LCD Test

CP 200

CP 100

Note

1. Choose Main Menu > Systems Setting > Device info > Service Info > LCD Test.

2. Verify the test pattern is visible without breaks and is consistent over the entire

3. Verify Contrast can be adjusted to adequately see the display.

1. Disconnect the patient cable.

2. Turn ON unit. The patient hook up screen appears.

3. Verify the display is visible without breaks.

Note

There may be a few seconds delay in the LED response to the line being removed

and added.

screen.

If contrast adjustment is needed refer to the Directions for Use manual for

CP 100.

Set Unit Initial Configuration/SD Slot Test

Initial Configuration of Unit

1. Verify the Serial Number on the unit is the same as displayed on the unit’s screen. If

incorrect, enter correct S/N. See ““System Settings” Menu Tree” on page 16, Service

Info.

Service Manual Functional Verification 33

Select Main Menu > System Settings > Device Info > Service Info > Serial

Number.

2. If the main board was replaced and a configuration files were exported, import the

configuration files, see “Import Files” on page 24.

3. Print the Configuration of the unit.

Select Main Menu > System Settings > Device Info > Print Settings

4. Verify the settings from the printout.

a. Check for software version installed.

b. S/N of the unit.

c. Interpretation (if applicable).

If imported, check any customized customer settings.

SD Slot Test

1. Insert a formatted SD memory card into the unit.

2. Choose Main Menu > System Settings > Device info > Service Info > Service

Tests>MMCSDTEST.EXE file.

3. Press G to start the test. After 30 seconds the MyFile.TXT increases one increment.

4. Press S to stop the test and confirm that no errors are reported.

ECG Communication Test (ECG Input test and lead off)

Test the patient cable and lead off indications connection.

1. Connect a known good Patient Cable w/leads

2. Connect to ECG simulator with V1/C1 lead disconnected.

3. Power ON unit.

4. Verify the lead placement screen shows V1/C1 lead flashing and all other leads

should appear not flashing.

5. Remove LL from the Simulator and verify LL flashes with all V/C leads grayed, RA,LA

& RL should not be flashing.

6. Connect all leads to the simulator.

7. Verify all leads stop flashing and the next screen appears in approximately three

seconds.

Spirometer Communication Test

CP 200 (Only)

Verify and test the connection of a Spirometer Dongle to the serial port.

1. Attach a known good spirometer dongle to the spirometer port on the side of the unit.

2. Power ON unit.

34 Functional Verification Welch Allyn CP 100 and CP 200 Electrocardiograph

3. Press the Spirometry button

4. Verify that the unit opens the Spirometry module without errors.

USB Communications Test

Verify the test connection between the unit and the CardioPerfect Workstation computer.

1. Connect the unit to the computer using a USB A-A Cable.

2. The computer should recognize the CP 200 connected and load the driver for

communication.

3. Transfer an ECG record to the CardioPerfect Workstation.

a. Press the Menu button.

b. Choose Test Directory.

c. Press the Search softkey.

d. Press the WorkStation softkey.

Beeper Test

4. Verify the record was transferred into the workstation.

Turn on and test the Audible beeper by using the keyboard keys.

1. P o w e r On unit.

2. Choose Main Menu > System Settings > Device Configuration >

Audio Beeper > set to ON.

3. Exit the Main Menu

4. Verify that an Audible beep is heard when invalid keys are pressed on the keyboard.

5. If the Audio Beeper was originally set to off, choose Main Menu >

System Settings > Device Configuration > Audio Beeper > set to OFF to return

the Audio Beeper to its original setting.

Service Manual Functional Verification 35

Keyboard Test

The unit detects all the keys pressed listed in Table 1, “Keyboard Keys”.

Table 1. Keyboard Keys

Key CP 100 CP 200

’5’ 5 5

‘R’ R R

‘D’ D D

‘X’ X X

Backspace Back a space Back a space

‘P’ P P

Down Down a field Down a field

Up Up a field Up a field

1. P o w e r On unit.

2. Press Auto ECG. See Figure 9 on page 14 for button location.

3. The patient information screen appears.

4. Press the Keys indicated in Table 1, “Keyboard Keys” and verify the corresponding

action.

Printer Test

5. Use the softkeys to verify the correct response for the keys (Only for the CP 200 unit).

See Figure 10 on page 15.

Note

1. Plug unit into AC power to perform the printer test.

2. Choose Main Menu > System Settings > Device Info > Service Info > Printer

3. Press the “Test Page” softkey. The test print starts after a few seconds.

4. Press the “Cancel” softkey when the second page has completed printing.

5. Use the second test print page to verify correct operation. See Table 2, “Print

Please note these measurements are dependent upon the tracking of the paper

being in the center. Please make sure there is no curling/crinkling of the paper at

the top or bottom when printing.

Test.

Verification Check List” and Figure 29 on page 36.

36 Functional Verification Welch Allyn CP 100 and CP 200 Electrocardiograph

Table 2. Print Verification Check List

Point Description

Point A Verify the distance of the arc on the circle from the top edge of the paper is 37mm +/-

Point B Verify the distance of the arc on the circle from the left edge of the paper is 45mm +/-

Point C Verify line is straight and without breaks from top to bottom

Point D Verify thick black line is Uniform in Blackness without breaks from top to bottom

Point E Verify line is straight and measures 200mm +/- 4mm

Point F Verify the print is readable

Point G Verify the lead in and output trail of the cue sensor are between 19 and 82mm down

Point H Verify the cue sense pattern is between 97 and 135mm down from the 200mm line

3mm

5mm

from the 200mm line measured in point E

measured in point E

Figure 29. Test Printout Example

Service Manual Functional Verification 37

Ramp Page Test Printout

1. Press the Ramp Page key.

2. Verify the top of the ramp cuts off between 250 and 550 on the gauge printed.

Figure 30. Ramp Printout Example

38 Functional Verification Welch Allyn CP 100 and CP 200 Electrocardiograph

Dielectric Strength Test

It is important to complete the dielectric strength test after any procedure in which the

monitor is opened to verify proper patient isolation.

WARNING Failure to run the dielectric test when indicated could cause serious

injury to patients, and could lead to damage to the monitor.

WARNING Always follow the tester manufacturer’s operation instructions

exactly. Failure to perform this test properly can result in serious injury or death.

WARNING This test must be performed by qualified service personnel only.

WARNING Run this test, only, on an insulated table top, and away from other

people and equipment.

WARNING Must avoid connector shell and pe ground because pe is only

resistant to 500 Vac.

WARNING The patient isolation test involves exposure to extremely high

voltages and is extremely hazardous.

The patient isolation test requires an AC Withstand Voltage (hi-pot) Tester, such as the AR

3605 or equivalent. If this equipment is not available, Welch Allyn can perform the patient

isolation test for you quickly, for a nominal fee

.

To create test cables for the patient isolation test. See “Hi-Pot Test Connections” on

page 39.

Set up the test parameters on the AC Withstand Voltage Tester as follows:

Note

Refer to the tester manufacturer’s operation manual for complete details on set

up and use.

Parameter Specification

Voltage 1500Vac

Maximum Limit 5.00mA

Minimum Limit 0.15 mA

Ramp Up 10 s

Dwell 1 min.

Delay 0.5 s

Ramp Down 0.0 s

Arc Sense 0

Frequency Local line (50 Hz or 60 Hz)

Continuity Off

Connect Off

To create test cables for this procedure. See “Hi-Pot Test Connections” on page 39.

1. Connect the modified power cord between the return jack on the tester and the AC

input of the unit.

2. Connect the high voltage cable between the equipotential stud and the high voltage

on the tester.

3. Press the test button to run the AC withstand voltage test.

Service Manual Functional Verification 39

4. Verify the electrocardiograph passed the test. (If the unit current never exceeds

5.00mA, the shielding is sufficient.)

Hi-Pot Test Connections

Cable Electrocardiograph Connection Hi-Pot Tester Connection

Connector/

Cable

Power Cord IEC Power cord AC Input

Connect to Wiring Connect to

Connector

Hot and neutral (black and white) wires connected together and

terminated appropriately for your hi-pot tester. Cut and terminate

the ground (green) wire to prevent possible injury.

Return

Chassis, Earth and Patient Leakage Current Tests

Verify continued electrical safety of the device, using IEC 60601-1 or ANSI/AAMI ES1

methods and limits. Test for the following:

• Earth leakage

• Chassis leakage

• Patient leakage

Note

Refer to the Electrical Safety Analyzer manual for complete details on set-up and

use for testing.

40 Functional Verification Welch Allyn CP 100 and CP 200 Electrocardiograph

Checklist and Test Results Report Form

Use a copy of the form to track your progress though the validation tests.

Electrocardiograph Serial #:

Tested by:

Test date:

Initial Test Result Pass

(or N/A)

Operating Non-Printing

Mode Current

Battery Accuracy Normal:

Sleep/Standby Current (mA)

Charger Detect Fast Charge: (VDC)

LED

LCD

Initial Configuration/

SD Card

ECG Communication

Spirometry

USB Communication

Beeper

Keyboard

CP 100: ______ (mA)

CP 200: ______ (mA)

Critical:

Trickle: (VDC)

Fail

Printer Test Page:

Ramp Page:

41

4

Troubleshooting

Problem-Solving Suggestions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Service Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

42 Troubleshooting Welch Allyn CP 100 and CP 200 Electrocardiograph

Problem-Solving Suggestions

Caution Replace parts, components, or accessories only with parts supplied or

approved by Welch Allyn. The use of any other parts can lead to inferior device

performance and will void the product warranty.

This section includes several tables:

• Lead quality problems (Ta ble 3)

• System failure problems (Tab le 4, on page 43)

• System messages (Tab le 5, on page 44)

If you try these suggestions and still have problems, contact Technical Support. For phone

numbers, see “For information about any Welch Allyn product, please call Welch Allyn

Technical Support:” on page ii

Table 3. Lead Quality Problems

Condition Causes Actions

A red dot is flashing on the Lead Off

screen. (CP 200)

A dot is flashing on the Lead Off screen.

(CP 100)

OR

• Electrode contact may be poor.

• A lead may be loose.

• Reattach the lead.

• Replace the electrode.

• Verify that the electrode area has been properly

prepared: shaved, cleaned with alcohol or

acetone, allowed to dry.

• Verify that electrodes have been properly stored

and handled.

Lead-off information is displayed on the

screen.

OR

One or more leads prints as a square

wave:

Wandering baseline (an upward and

downward fluctuation of the waveforms):

Muscle tremor interference (random,

irregular voltage superimposed on the

waveforms). May resemble or coincide

with AC interference:

• Electrodes that are dirty, corroded,

loose, or positioned on a bony area.

• Insufficient or dried electrode gel.

• Oily skin or body lotions.

• Rising and falling of chest during rapid

or apprehensive breathing.

• Patient is uncomfortable, tense,

nervous.

• Patient is cold and shivering.

• Exam bed is too narrow or short to

comfortably support arms and legs.

• Arm or leg electrode straps are too

tight.

• Clean skin with alcohol or acetone.

• Reposition or replace electrodes.

• Help patient relax.

• If wandering baseline persists, turn the baseline

filter on. See “Base Line Filter” in the CP 200

Directions for Use Manual.

See “Adjust Baseline Filter” in the CP 100

Directions for Use Manual.

• Help patient get comfortable.

• Check all electrode contacts.

• If interference persists, turn the muscle-tremor

filter on. See “Muscle Filter” in the CP 200

Directions for Use Manual.

See “Adjust Muscle Filter” in the CP 100

Directions for Use Manual.

• If interference still persists, the problem is

probably electrical in nature. See the following

suggestions for reducing AC interference.

Service Manual Troubleshooting 43

Table 3. Lead Quality Problems (continued)

Condition Causes Actions

AC interference (even-peaked, regular

voltage superimposed on the waveforms).

May resemble or coincide with muscletremor interference.

• Electrodes that are dirty, corroded,

loose, or positioned on a bony area.

• Insufficient or dried electrode gel.

• Patient or technician touching an

electrode during recording.

• Patient touching any metal parts of an

exam table or bed.

• Broken lead wire, patient cable, or

power cord.

• Electrical devices in the immediate

area, lighting, concealed wiring in

walls or floors.

• Improperly grounded electrical outlet.

• Incorrect AC filter frequency setting or

AC filter is turned off.

• Check all electrode contacts and lead wires.

• Verify that the patient is not touching any metal.

• Verify that the AC power cable is not touching

the patient lead cable.

• Verify that the proper AC filter is selected. See

“Mains Filter” in the Directions For Use manual.

• If interference persists, unplug the

electrocardiograph from AC power and run it on

the battery. If this solves the problem, you’ll

know that the noise was introduced through the

power line.

• If interference still persists, the noise may be

caused by other equipment in the room or by

poorly grounded power lines. Try moving to

another room.

Table 4. System Failure Problems

Condition Causes Actions

Won't turn on when plugged into AC

power.

Won't turn on when unplugged from AC

power.

Shuts down during printing Battery low or bad. • Recharge the battery. See “Recharging a Fully

Prints fewer than 10 reports on a full

battery charge.

• Faulty AC power connection.

• Blown AC fuses.

• No AC power.

• Battery disconnected or incorrectly

connected.

• Battery low, not charging, depleted, or

bad.

• Blown battery fuse.

Degraded battery. Replace battery. See“Replacing the Battery or Fuse”

• Check the AC power source.

• Check the AC fuses. See “Replacing the AC

Fuses” in the Directions for Use manual.

• Check battery connections. See“Replacing the

Battery or Fuse” on page 58.

• Recharge the battery. See “Recharging a Fully

Discharged Battery” in the Directions for Use

manual.

• Replace battery. See“Replacing the Battery or

Fuse” on page 58.

• Replace battery fuse. See “Replacing the Battery

(DC) Fuse” on page 60.

Discharged Battery” in the Directions for Use

manual.

• Replace battery. See“Replacing the Battery or

Fuse” on page 58.

on page 58.

44 Troubleshooting Welch Allyn CP 100 and CP 200 Electrocardiograph

Table 5. System Messages (alphabetical order)

System Message Problems Actions

“A test is being printed that has not been

saved and will be lost. Continue

shutdown?” (CP 200)

“Audit Trail is too large. Please print and

purge.” (CP 200)

“Battery extremely low. Please connect

AC power.”

“Insufficient space available” Not enough space on memory card. • Delete some tests from the card at a PC.

“Memory card error” Problem writing to memory card. • Verify that the write-protect tab is in the

“Out Of Paper” • Printer is out of paper.

was pressed while printing an

Auto ECG.

Audit information is approaching its

maximum allotted storage.