Page 1

Installation instructions for PU-Overvoltage in Mains Control.

This equipment may only be installed by fully qualified personnel. Please note:

the local installation regulations specific to the country of use must be observed.

1. Application

The PU-C overvoltage serves for the protection of low voltage consumer’s installations and electronic

devices against surges resulting from atmospheric discharges (lightning) or switching operations. The

PU-C meets the requirements of IEC 61643-1 01/02 Class II, VDE 0675, part 6, class C 11/89, draft and

DIN VDE 0675. Part 6, A2, 10/96 and ÖVE SN 60 part 4 and part 1 and the Ö Norm 8001. Highly

efficient metal-oxide varistors are used for voltage limiting components. For the PU 3+1C we use a spark

gap between L-PE or PE-N.

2. Notes on installation

2.1 Site of installation

The PU-C

The PU-C must be installed in the meter cubicle or distributing cabinet in such a way that the terminal

room is protected against unauthorised access. The overvoltage protection must be installed by trained

service personnel. The regulations covering the construction of a installation with overvoltage protective

equipment is described in VDE V 0100 part 534; 4/99: Selection and construction of operating

equipment. This norm (in preparation) is in conjunction with the following norms.

1 IEC 60364-4-43 “Protection from overvoltage resulting from atmospheric conditions and resulting

from switching activity.“

2 IEC 61024-1 “Protection of buildings against lightning strikes“.

3 IEC 61312-1 “Protection against electromagnetic lightning impulse“.

2.2 Electrical connection

The PU-C overvoltage protection must be connected with short lines between the (outer) supply

conductor (L1, L2, L3) and the neutral conductor (N) and the earth (PE) of the consumer’s installation.

The parallel routing of non-protected lines and protected lines must be avoided. For connection

examples, see figures 1 and 2.

2.2.1 Connection to (outer) supply conductor and neutral conductor.

As a rule, the same conductor cross-section is selected for the connecting lines to the PU arrester as for

the (outer) supply conductor (L1, L2, L3) and the neutral conductor (N). In the event of a reduction of the

cross-section, a protective device (e.g. service fuse) must be provided for short-circuit protection of the

connecting lines. The arrester terminals must not be used as tee-off terminals. The PU-C back-up fuse

can be selected up to a maximum of 125 A. Series connected residual-current devices (RCD) must be

surge proof.

Notes:

Use a 3-pole PU-C in a TN-C-S network, (see picture 1/ if the PEN line is used separately as PE and N,

then select a 4-pole PU 4 C or the PU 3+1 C).

According to DIN VDE 0100-534/A1 10/96, it is possible in a TT network to install a 4-pole PU-C

protector, together with an arrester disconnector. The module PU 3+1C (old name PU 4 C TT ) catalogue

number 841637, offers the best installation prerequisites if a potential transfer is to be avoided without

the use of an arrester disconnector.

The PU 3 C for 385 V is to be installed in IT networks with 230 V line-to-line voltage.

2.2.2 Connection to earth

The arrester’s earth conductor must be connected by the shortest possible route (≤ 0,5m) to the earth

terminal of the consumer’s installation. Longer connection lines reduce the efficiency of the overvoltage

protector. Parallel routing with other electrical lines must be avoided. The earthed equipotential bonding

strip is available for connection with the equipotential bonding of electrical consumer’s installations (see

figures 1 and 2).

° It must always be ensured that the arrester earth is connected with the consumers installation.

° For TN systems, the PEN conductor and the earth conductor of the arrester must be interconnected.

° The PEN conductor of the electricity supply company must not be used as an earth electrode.

° Where the PE rail or PEN rail of a distribution board is used as an earth terminal, these must be

connected via a separated earth conductor to the earth electrode of the consumer’s installation.

Page 2

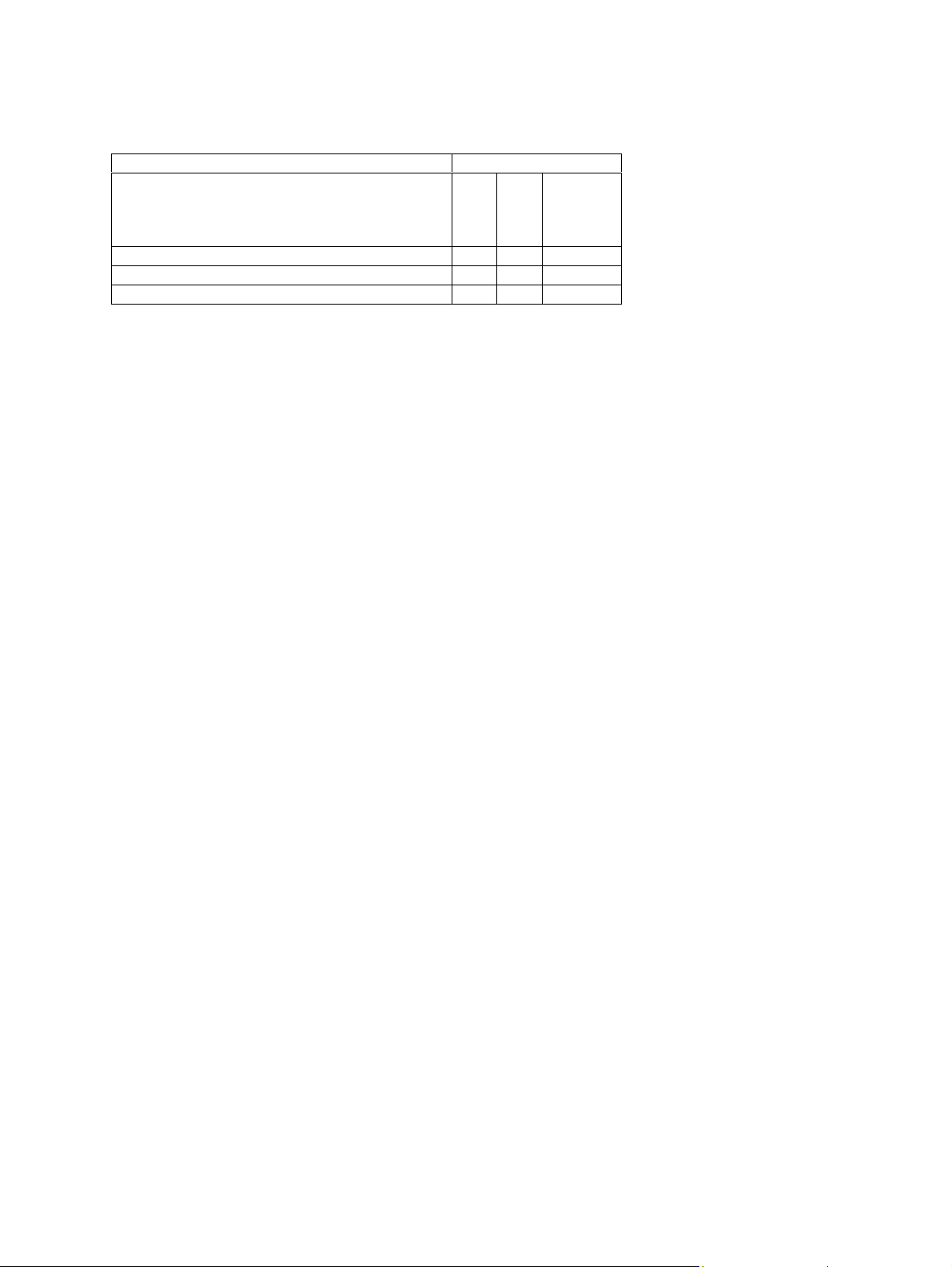

The cross-section of the arrester earth conductor is determined, as with the main equipotential bonding

conductors, according to table 1. The conductor must have 0,5 times the cross-section of the main

protective conductor, the upper limit is fixed at 25 mm2 Cu. A lower limit of 10 mm2 Cu is required.

Cross section mm

Main protective conductor

- from the power source or

≤ 16 25 ≤ 35

2

- house service box or main distribution board

outgoing protective conductor.

Supply conductor ≤ 35 50 ≥ 70

Earth conductor of arrester 10 16 25

Table 1

3. Functional check

PU overvoltage arresters must be subjected to a visual inspection, especially during thunderstorms. If

the colour of the inspection window turns red, the arrester must be replaced by trained service personal.

3.1 Maintenance

If the charge eliminator shows a red window as in 3., it must be replaced with a new one by trained

service personal. The individual charge eliminators are pluggable and encoded according to their

voltage. The varistor arrester must be removed when measuring the insulation resistance according to

DIN VDE 0100 part 610. To remove, pull on the upper parts of the varistor.

The charge eliminator compatible with the rated voltage of the plant must be re-installed.

Technical Data: PU xC PU xC PU xC PU xC PU xC PU 3+1 C PU 3+1 C

Max. Voltage V~ U

280 385 75 130 550 280 385

c

Rated diversion current i

20 kA 20 kA 15 kA 20 kA 20 kA 20 kA 20 kA

sn

of top part

Max. test current per Unit

1-way block i

2-way block i

3-way block i

4-way block i

Operating temperature range. - 40 °C to + 80

Conductor size 16- 25 mm

10 - 25 mm

40 kA 40 kA 15 kA 40 kA 40 kA 40 kA 40 kA

smax

70 kA 70 kA 40 kA 70 kA 70 kA

smax

100 kA 100 kA 100 kA 100 kA 100 kA

smax

100 kA 100 kA 100 kA 100 kA 100 kA 100 kA 100 kA

smax

°

C

2

(stranded wire) 6- 10 mm2 (solid wire)

2

(flexible )

Assembly Snap-on mounting on 35 mm top-hat rails

according to DIN 43 880 A1. draft 6.81

Colour. Light grey, RAL 7035 orange orange

Material. Polyamide 6.6

Protection IEC 529 : IP 20

Dimensions

1-way block complete width 18 mm

2-way block complete width 36 mm

3-way block complete width 54 mm

4-way block complete. width 72 mm

Depth. 55.0 mm

• For DC-Applications please contact the manufacturer.

4. Connection of remote signalling unit

Page 3

4.1 Remote signalling by means of monitoring modules

Type PU x CR

As the signalling contact in the PuxCR is a change-over contact, connections are made to terminals

11/14 (normally open contact) and/or to terminals 11/12 (normally closed contact).

The terminals 11/12 are closed during normal operations (window green). At the same time, the

terminals 11/14 are opened (window red). In the case of a malfunctioning (window red) the terminals

11/14 are closed and the terminals 11/12 are opened.

The connection is carried out with stranded conductors (e.g. NYM), whereby parallel conductor routing of

supply lines and the earth conductor must be avoided. Replacing a suppressor circuit with a surge

suppressor reduces interference in and around the analysing unit.

4.2 Remote signalling by means of light barrier Type PU-O/S-E

Every PU-C is automatically suitable for telemonitoring purposes and can be retrofitted at any given

time. Mount the transmitter on the left, and the receiver on the right next to the PU blocks on the

top-hat rail and connect both devices to 230 V. Subsequently connect the remote signalling unit to

terminals 11 and 14 and/or 11 and 12, described in item 4.1. The system an now be used to

simultaneously monitor up to 40 overvoltage arresters.

Technical Data : PU x-CR PU O/S -E

Monitoring module Receiver/transmitter

with relay output

Max. permissible 250 V~, 24 V- 250 V~ Un 230 V~

switching voltage

Max. permissible 1 A, 2 A 250 mA I

switching current

Signalling contact 1 Change-over contact

4.3 Overvoltage Protection with the 3+1 PU module

The PU3+1C 230/400V fulfils the requirements of the die VDE 0100, Part 531/A and the PU3+1C 385V

fulfils the requirement of the Ö-Norm 8001-§18.

Between the Phase L and the Neutral N are plugable Varistors and between the Neutral N and the Earth

PE is a plugable spark gap.

If the charge eliminator shows a red window as in 3., it must be replaced with a new one by trained

service personal.

4.4 Special Instruction for installation into metal Cabinets

To reach the clearance of the PU into metal cabinets these facts has to be done:

A plastic gap WTW part No 1058800000 or the WEW/2 part No. 106120 0000 has to be installed at the

side of the PU to the metal Cabinet.

If you use the PU x CR with the monitoring contact, you have to reduce the voltage of the monitoring

System to 48V.

Special for the PU with Uc: 550V, you have to put the plastic cover into the hole for the screwdriver after

installation. These plastic cover is packed in the box together with the PU for UC :550V

40 mA

N

4.3 Approvals

T2

PU x C for 230/400 V mains control according to ÖVE SN 60 part 4 and part 1.

All PU´s with Uc: 130V, 280V, 385V, 550V are approved by the IEC 61643-1 and marked with CE.

The PU´s with Uc : 130V, 280V, 550V are UL

approved.

Page 4

Protection according to IEC

Protection according to IEC

61024-1, IEC 61312-1

60364-4-443

Fig. 1 Overvoltage protective equipment in TN network

Fig. 2 Overvoltage protective equipment in TT Network with the 3+1 PU Module

1 Main supply system

2 Electrical circuit distributor

3 Branch circuit area

4 Main equipotential bonding strip

5 Overvoltage protection protective equipment Class I for lightning protection potential equalizer

5a 3+1 PU Unit with N-PE Lightning current arrestor

6 Main equipotential bonding conductor

7 Overvoltage protection-protective equipment Class II PU 3 C / PU 4 C

8 Overvoltage protection-protective equipment Class III PU D in the TN System

8a Overvoltage protection-protective equipment Class III PU D in the TT System

9 9a Overvoltage protection protective equipment Class II PU 3+1 C for TT System

10 RCD ( Residual-current device)

11 Arrester disconnector

HAK Service panel

R Earth

R

e

Wh Measuring device

F1 Input terminal fuse

F2 Fuse for PUxB necessary only by max. 160 A (depending on type of routing ), if F1> 160 A.

F3 Fuses for Electrical circuit distributor

F4 Fuse for PUxC necessary only by max. 125 A (depending on type of routing), if F1> 125 A.

F5 Circuit breaker 16 A

*1) Construction before taking measurements should be agreed with the local ESC.

*2) If a lightning protecting equipotential equalizer exists, then it must be connected to the earthable points

Equipment earth

of the overvoltage protective equipment.

Loading...

Loading...