Page 1

PRO-H SERIES INDUSTRIAL PO

WER SUPPLIES

INSTALLATION INSTRUCTIONS

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

1

Page 2

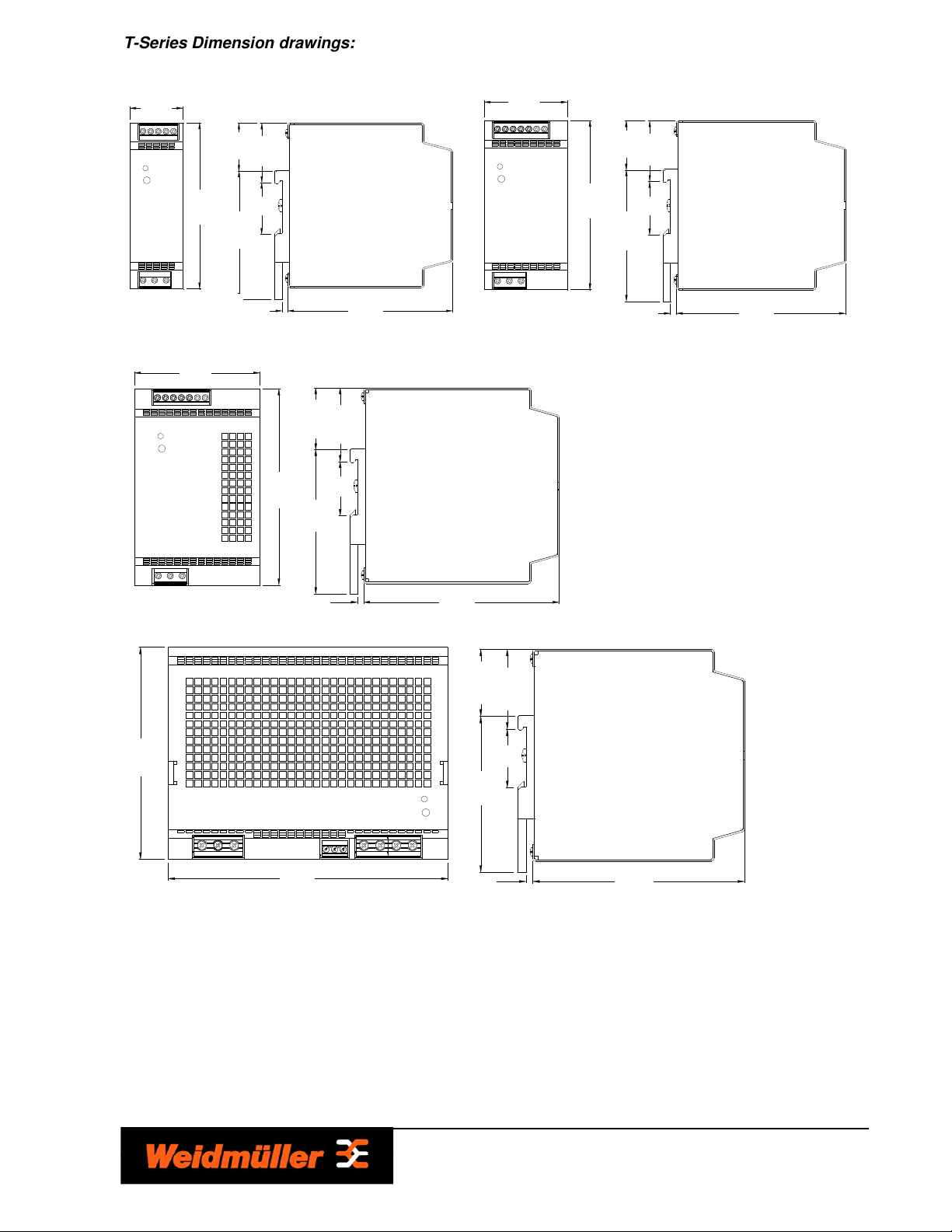

T-Series Dimension drawings:

PRO-H Series Dimension drawings

CP T SNT

CP T SNT 360W (24v 15A, 48V 7.5A)

CP T SNT 600W (24V 25A, 48V 12.5A)

70W 12V 6A, CP T SNT 90W 24V 3.8A CP T SNT 140W and CP T SNT 180W variants

(1.38)

35

)

)

.3

4

1

(

.5

1

3

(

3

9

3

)

3

3

.

4

(

0

1

1

Weight: 1.0lb

Gewicht:

80

0.5kg

(3.15)

)

6

.5

.3

4

1

3

(

)

7

.3

3

(

.5

5

8

(0.16)

4

)

6

.5

1

(

.5

9

3

)

2

.9

4

(

5

2

)

2

1

.6

3

(

2

9

(0.16)

(4.33)

110

)

5

.8

1

(

.1

7

4

)

6

.5

.3

4

1

3

(

4

125

(4.92)

(2.13)

54

Weight: 1.4lb

Gewicht:

0.7kg

)

6

)

5

.5

1

.8

(

1

(

39.5

47.1

)

.3

1

(

3

3

)

3

.3

4

(

0

1

1

.5

4

3

)

7

.3

3

(

.5

5

8

4

(0.16)

Weight: 2.4lb

Gewicht:

1.1kg

)

4

.5

1

(

9

3

)

6

.3

1

(

(4.33)

110

)

2

.9

4

(

125

)

6

.3

1

34.5

(

)

2

.6

3

(

92

Weight: 6.0lb

165

(6.5)

(0.16)

Gewicht:

4

125

(4.92)

2.8kg

Note

This i

nstruction cannot claim all details of possible equipment variations, nor in particular can they provide for every possible

example of installation, operation or maintenance. Further information is available from your local distributor office or from the

PRO-H Series data sheet. Subject to change without prior notice.

In order to guarantee safe operation of these power supplies and to be able to make use of all the functions, please

read these instructions thoroughly!

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

2

Page 3

Warning

The pow

er supplies are constructed in accordance with the safety requirements of IEC/EN/UL 60950-1, CSA-C22.2 No.

60950-1-03, UL508, CSA-C22.2 No. 14-95, EN60204, EN50178, EN61558-2-4, CSA C22.2 No. 213 (Class I and II, Division

2) and ANSI/ISA 12.12.01. They fulfil the requirements for CE-compatibility and carry the CE-mark and are UL & cUL

approved by CSA and UL.

The PRO-H Series built-in power supplies were designed especially for use in process automation and other industrial applications.

Components with dangerously high voltage and high stored energy are located in the device. However, these are

inaccessible. Failure to properly maintain the power supply can result in death, severe personal injury or substantial property

damage. The power supplies may only be installed and put into operation by qualified personnel. The

corresponding national regulations (e.g. UL, CSA, ANSI, VDE, DIN) must be observed. The successful and safe operation of

this power supply is dependent on proper storage, handling, installation and operation.

The potentiometer to adjust the output voltage is only allowed to be actuated using an insulated screwdriver, because

accidental contact may be made with parts inside the power supply carrying dangerous voltages.

Please observe following points before putting the device into operation:

• Read operating instructions thoroughly.

• That the mains connection has been carried out by a competent person and protection against electrical shock is

guaranteed!

• That the device can be disconnected outside the power supply in accordance with the regulations as in IEC/EN/UL/CSA

60950 or other national regulations.

• That the protective earth is connected.

• That the input wiring is sufficiently protected and dimensioned!

• That the output wiring is dimensioned according to the maximum output current or separately protected!

• Sufficient cooling is guaranteed!

• The temperature of the housing can become very high, depending on the ambient temperature and load.

Caution:

Risk of electrical shock and electrical discharge. The power supply must not be opened until at least 5 minutes after complete

disconnection of the mains.

Electrostatic sensitive device. Qualified and trained personnel only may open the power supply.

Attention: In case of non-observance or exceeding the mentioned limiting value of the data sheet, the function

and

electrical safety can be impaired and can destroy the power supply.

Before installation ensure that the main switch is switched off and prevented from being

switch

ed on again. In case of non-observance, touching of any live components or improper

dealing with this power supply can result in death or fatal injury.

Dang

er: Never work on power supplies if power is applied!

1. D

escription and construction

The PRO-H Series power supplies are built-in units. The mounting position has to fulfil the requirements for fireproof case according to UL60950,

EN 60950 or other appropriate national standard. The relevant UL regulations or equivalent national regulations must be observed during

IEC/

installation.

The PRO-H Series power supplies are designed for mounting on a DIN rail TS35 (DIN EN 50022-35x15/7.5) and for operation from 115 or

230VAC, 50/60Hz (Universal input voltage range for CP T SNT 70W 12V 6A, CP T SNT 90W 24V 3.8A and auto range for CP T SNT 140W

12V 12A, CP T SNT 180W 24V 7.5A, CP T SNT 180W 48V 4A, CP T SNT 360W 24V 15A, CP T SNT 360W 48V 7.5A, CP T SNT 600W 24V

25A and CP T SNT 600W 48V 12.5A single-phase systems.

The output voltage of the PRO-H Series power supplies is potential-free (floating), protected against short circuit and open circuit conditions (see

Fig 1.1, Fig 1.2 and Fig 1.3).

2. Installation

A sufficiently strong DIN-rail has to be provided. The correct mounting position for optimal cooling performance must be observed. Above and

below the power supply a minimum free space of 80mm [3.15in] is required and on each side of the power supply a minimum space of 50mm

[1.97in] is required which allows air convection. The air temperature measured 10mm [0.39in] below the power supply must not exceed the

specified values in the data sheet. Observe power derating above ambient temperatures of 40°C and at low line. (see Fig 4.1 and Fig 4.2)

2.1 Assembly

To fix unit on the DIN-rail, hook top part of clip on DIN-rail, push down- (see Fig 2.1) and inwards (see Fig 2.2) until you hear a clipping sound.

To remove the unit, pull the latch of the clip with the aid of an insulated flat head screwdriver (see Fig 2.3). When clip has cleared bottom DIN

rail remove the screwdriver from recess. Lift the unit off DIN-rail. See Fig 2.4.

Wall mounting or chassis mounting can be achieved by use of optional mounting brackets CP MB01 (1 bracket, see Fig. 6.1) for CP T SNT

(70W 12V 6A, 90W 24V 3.8A, 140W 12V 12A, and 180W xx) or CP MB02 (2 brackets, see Fig. 6.2 and Fig. 6.3) for CP T SNT (360W xx,

600W xx) . Remove the DIN-clips by removing the screw and place the mounting brackets in the same place as the DIN-clips.

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

3

Page 4

2.

12.0 AH/250V

2 Connecting cable

Only qualified personnel may carry out the installation. The devices are equipped with PCB plug connectors (CP T SNT 70W 12V

6A, CP T SNT 90W xx, CP T SNT 140W 12V 12A, CP T SNT 180W xx and CP T SNT 360W xx) or PCB terminals (CP T SNT 600W xx). This

reliable and easy-to-assemble connection method enables a fast connection of devices and a visible isolation of the electrical connection if

necessary.

2.2.1 Input (Fig. 5.1, Fig 5.2, Fig 5.3 and Fig. 5.4 Connector J1):

The 100-240VAC connection is made by using the L, N and

Suff

iciently dimensioned input wiring has to be ensured (see 2.2.1.1). A protective device (fuse, MCB, etc; see 2.2.1.2) and an easily

accessible isolating device for disconnecting the power supply from mains must be provided. The protective earth conductor has to be

connected.

If flexible wires are used the wires have to be terminated. (e.g. by using ferrules)

connections and has to be carried out in accordance with the local regulations.

Note: This unit contains an automatic input voltage selection switch. Do not change the input voltage from 110/115Vac to

230/240Vac without disconnecting the input supply line first.

2.

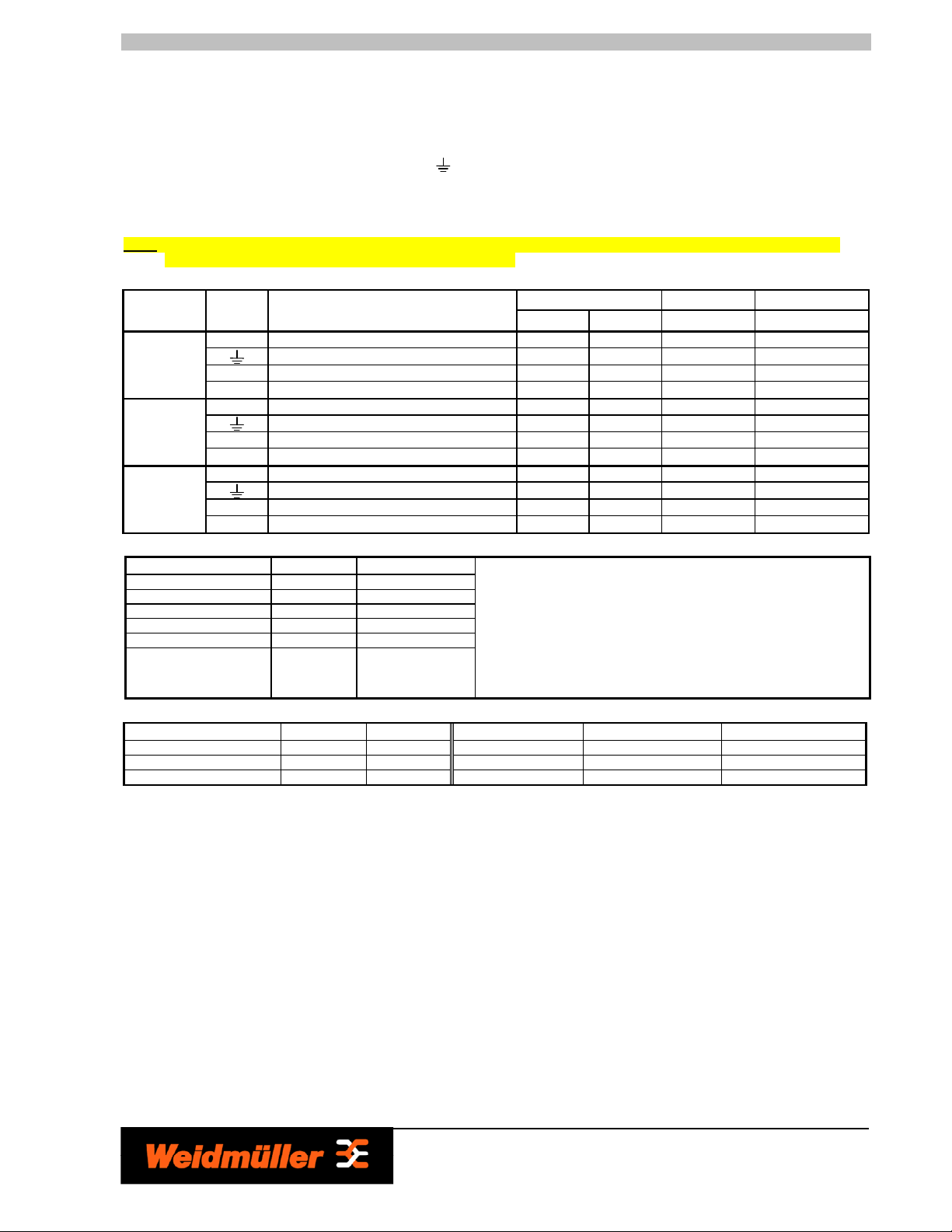

2.1.1 Connections and terminal assignment

Unit Terminals Function

CP T SNT (90W

24

V 3.8A, 180W

24V 7.5A,

180W 48V 4A)

CP T SNT (70W

12

V 6A, 140W

12V 12A, 360W

24V 15A, 360W

48V 7.5A)

CP T SNT

(6

00W 24V 25A,

600W 48V

12.5A)

L1 & N Input Voltage (85 – 264VAC or 115/240VAC) 0.5 … 2.5 24 … 12 0.5 – 0.6 7.0

+ & - Output Voltage (24VDC) 0.5

Signal DC-OK, active output and relay outputs 0.2 … 2.5 32 … 12 0.5 – 0.6 7.0

L1 & N Input Voltage (85 – 264VAC or 115/240VAC) 0.5 … 2.5 24 … 12 0.5 – 0.6 7.0

+ & - Output Voltage (12VDC and 24VDC) 1.0 … 2.5 18 … 12 0.5 – 0.6 7.0

Signal DC-OK, active output and relay outputs 0.2 … 2.5 32 … 12 0.5 – 0.6 7.0

L1 & N Input Voltage (115 / 230VAC) 1.0

+ & - Output Voltage (24VDC) 2.0

Signal DC-OK, active output and relay outputs 0.2 … 2.5 32 … 12 0.5 – 0.6 7.0

Pr

otective Earth Conductor 0.5 … 2.5 24 … 12 0.5 – 0.6 7.0

Pr

otective Earth Conductor 0.5 … 2.5 24 … 12 0.5 – 0.6 7.0

Pr

otective Earth Conductor 1.0 … 4.0 18 … 10 0.5 – 0.6 7.0

Solid or stranded wires Torque Stripping length

[m

m2] [AWG] [Nm] [mm]

… 2.5 24 … 12 0.5 – 0.6 7.0

… 4.0 18 … 10 0.5 – 0.6 7.0

… 4.0 12 … 10 0.5 – 0.6 8.0

2.2.1.2 Internal Fuse

Model Ratings Marking

CP T SNT 70W 12V 6A 4.0 AH/250V F1 4.

CP T SNT 90W 24V 3.8A 4.0 AH/250V F1 4.

CP T SNT 140W 12V 12A 4.0 AH/250V F1 4.

CP T SNT 180W xx 4.0 AH/250V F1 4.

CP T SNT 360W xx 6.3 AH/250V F1 6.

CP T SNT 600W xx 12.0 AH/250V F1

0 AH/250V

0 AH/250V

0 AH/250V

0 AH/250V

3 AH/250V

CAUTION: Fo

r continued protection against risk of fire

replace with same type and rating of fuse! This

fuse should be changed only by authorised and

trained personnel because it is soldered on the

board

If the internal fuse is triggered, there is most

probably an internal malfunction which must be

inspected in the factory. Due to that return this

device to your local distributor.

2.

2.1.3 Recommended external Fuses (MCB)

Model Ratings Characteristic

CP T SNT 70W 12V 6A 6 - 16A / 250V

CP T SNT 90W 24V 3.8A 6 - 16A / 250V

CP T SNT 140W 12V 12A 6 - 16A / 250V

2.2.2 Output (F

The 12VDC, 24VDC or 48VDC connection is made using the “+” and “-“ connections. All output terminals should be connected to the load.

Make sure that all output lines are dimensioned according to the maximum output current (see 2.2.1.1) or are separately protected! The wires

on the secondary side should have large cross sections in order to keep the voltage drops on these lines as low as possible.

To achieve a reliable and shockproof connection strip the connecting ends according 2.2.1.1. If flexible wires are used the wires have to be

terminated. (e.g. by using ferrules)

At the time of delivery, the output voltage is either 12VDC, 24VDC or 48VDC. The output voltage can be set (using an insulated screwdriver)

from 12 to 14VDC, 24 to 28VDC or 48 to 56VDC on the potentiometer (see Fig. 5.1, Fig. 5.2, Fig. 5.3 and Fig. 5.4).

The device is electronically protected against overload and short circuit. In the event of malfunction, the output voltage is limited to 20VDC for

12VDC units, 35VDC for 24VDC units or 60VDC for 48VDC units.

ig. 5.1, Fig 5.2, Fig 5.3 and Fig. 5.4 Connector J2):

B CP T SNT 180W xx 6 - 16A / 250V B

B CP T SNT 360W xx 10 - 16A / 250V B

B CP T SNT 600W xx 16 - 25A / 250V B

Model Rat

ings Characteristic

2.2.3 Signalling (Fig. 5.1, Fig 5.2, Fig 5.3 and Fig. 5.4 Connector J2):

The two DC-OK outputs are for enabling monitoring of the functions of the power supply. A floating signal contact (see Fig. 5.1, Fig 5.2, Fig 5.3

and Fig. 5.4 Connector J2, pin 6 & pin 7) and an active DC-OK signal (see Fig. 5.1, Fig 5.2, Fig 5.3 and Fig. 5.4 Connector J2, pin 5) are

available. The DC-OK LED also enables a visual evaluation of the function of the power supply directly on site.

2.2.3.1 Floating contacts (Fig. 5.1, Fig 5.2, Fig 5.3 and Fig. 5.4):

The floating signal contacts opens and signals a drop in the output voltage below: 12VDC units between 9 and 11VDC; 24VDC units

between 18 and 22VDC; 48VDC units between 36 and 44VDC. Relay contacts are available at CP T SNT 70W 12V 6A and CP T SNT 90W

24V 3.8A: Connector J2, pin 4 and pin 5 / CP T SNT 140W 12V 12A, CP T SNT 180W xx and CP T SNT 360W xx: Connector J2, pin 6 and pin

7 / CP T SNT 600W xx: Connector J5, pin 1 and pin 2). Signals and ohmic loads up to 30VDC and currents of up to 1A can be connected on

the 12VDC and 24 VDC units or 48VDC and current up to 0.5A for 48VDC units. For heavily inductive loads such as relay, a suitable protection

circuit (e.g. damping diode) is necessary.

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

4

Page 5

2.

2.3.2 Active signal output (Fig. 5.1, Fig 5.2, Fig 5.3 and Fig. 5.4):

11VDC ±1VDC (12VDC units), 22VDC ±2VDC (24VDC units) or 44VDC ±4VDC (48VDC units) is applied between the “DC-OK” (CP T SNT

70W 12V 6A and CP T SNT 90W 24V 3.8A: Connector J2, pin 3 / CP T SNT 140W 12V 12A, CP T SNT 180W xx and CP T SNT 360W xx:

Connector J2, pin 5 / CP T SNT 600W xx: Connector J5, pin 3) and “-“ (Connector J2, pin 1) and can carry up to 40mA max. (12VDC units) or

10mA max (CP T SNT 90W 24V 3.8A(N) or 20mA max. (other 24VDC units) or 15mA max (48VDC units). This signal output is referenced to –

Vout (GND) and signals when the output voltage drops below: 12VDC units between 9 and 11VDC; 24VDC units between 18 and

22VDC; 48VDC units between 36 and 44VDC by switching from high to low.

The DC-OK signal is decoupled from the power output. It is thus not possible for parallel-switched devices to provide external supply. The DCOK signal can be directly connected to a logic input for evaluation.

2.2.3.3 Signal loop:

The two above-mentioned signals can be easily combined.

Example: Monitoring of two devices.

Use the active signal output of device 1 and loop in the floating signal output of device 2. In the event of malfunctioning a common alarm is

available. Up to 5 units can be looped in. This signal combination saves wiring costs and logic inputs.

2.2.3.4 DC-OK LED:

The DC-OK LED is a two colour LED which indicates the status of the output and enables visual evaluation of the function locally in the control

cabinet. DC-OK LED green – normal operation. DC-OK LED red – output failure if input mains is still present.

3. Function

3.1 Output characteristic curve:

In the case that the ambient temperatures is not higher than +40°C, the device can continuousely supply Iout max (see datasheet). In the

event of a higher load, the operating point follows the U/I charateristic curve by use of overcurrent protection. The output current is limited at

Iout max. by use of a constant current characteristic with automatic restart if the short circuit or over load condition has been removed.

The U/I characteristic curve ensures that heavily capacitive loads can be fed without problems.

Current Limitation Curve of TSP Power Supplies

Current Limitation Curve

110.00

100.00

90.00

80.00

70.00

60.00

[%]

out

50.00

V

40.00

30.00

20.00

10.00

0.

00

0.00 10.00 20.00 30.00 40.00 50 .00 60.00 70.00 80.00 90.00 1 00.00 110.00 120.00 130.0 0

I

[%]

out

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

5

Page 6

3.2 Thermal behavior:

)

The dev

ice should not be operated at higher loads than indicated on the derating graphs Fig. 4.1 and Fig. 4.2). The device does switch off at

thermal overload. After sufficent cooling the device will switch on again.

3.3 Parallel operation:

Maximum 5 devices of the same type can be connected in parallel to enable increased output power. For n parallel connected devices the

output current can be increased to n x Imax. Parallel connection to increase efficiency is used for the expansion of existing systems. It is

advisable to use parallel connection if the power supply does not cover the current requirement of the most powerful consumer. Otherwise the

consumers should be spread among individual devices independent of one another.

To provide a proper and reliable start-up the jumper at connector J4 has to be set (see Fig. 5.1, Fig. 5.2, Fig. 5.3 & Fig. 5.4). If the jumper is set

between pin 1 and pin 2 of connector J4 the unit is in normal mode. If the jumper is set between pin 2 and pin 3 on connector J4 the unit can be

paralleled. At delivery this jumper is set for normal operation (between pin 1 and pin 2 of connector J4).

If the output voltage is adjusted, a uniform distribution of power is guaranteed by setting all parallel operated power supplies to exactly the

same output voltage. To ensure symmetrical distribution of power, we recommend designing all cable from the power supply as busbar of the

same length and with the same conductor cross section. The system makes it advisable to install a protective circuit at the output of each

device when more than two power supplies are connected in parallel (e.g. decoupling diode or DC fuse). This prevents high reverse feed

currents in the event of a secondary device fault.

3.3.1 Redundancy operation:

Possible by use of our redundancy module CP T RM 10 or CP T RM 20. With this module and two power supplies of the PRO-H Series (CP T SNT

70W 12V 6A, CP T SNT 90W 24V 3.8A, CP T SNT 140W 12V 12A, CP T SNT 180W 24V 7.5A and CP T SNT 360W 24V 15A in combination

with CP T RM 10 or CP T SNT 600W 24V 25A in combination with CP T RM 20) a highly reliable, true redundant power system can be

configured without any additional components. This module enforces the equivalent sharing of the output current by each power supply. The

system is fully redundant and provides the output power even if one power supply has completely failed e.g. by short circuit on the output. In

the event of either, one power supply failing or being disconnected, the second unit will automatically supply the full current to the load. The

redundancy of the system is monitored and if lost, indicated by an alarm output. The inputs are hot swappable and can be loaded up to 15A

each (CP T RM 10) or up to 25A each (CP T RM 20).

3.6 Remote ON/OFF:

The standard unit provides a remote on/off function by use of pin 2 at connector J3 (see Fig. 3.1, Fig. 5.1, Fig. 5.2, Fig. 5.3 & Fig. 5.4). To

switch off the power supply a connection between Connector J3 pin 2 (-S) and Connector J2, pin 1 (–Vout) by use of a 1kΩ resistor has to be

made. At open connection between J3 pin 2 and J2 pin 1 the device is providing the adjusted output voltage.

4. Additional information for the North American Market for UL508

The PRO-H series power supplies are built-in units and must be installed in a cabinet with minimum dimensions of:

400mm (Width) x 500mm (Height) x 200mm (Depth)

Operating Temperature Ranges and load derating:

4.1

Model Operating Temperature Range

CP T SNT 70W 12V 6A -25 – 40°C 100%

CP T SNT 90W 24V 3.8A -25 – 40°C 100%

CP T SNT 140W 12V 12A -25 – 40°C 100%

CP T SNT 180W xx -25 – 4

CP T SNT 360W xx -25 – 4

CP T SNT 600W xx -25 – 4

0°C 100% (40 – 60°C Load derating by 3.0W/°C)

0°C 100% (40 – 60°C Load derating by 6.0W/°C)

0°C 100% (40 – 60°C Load derating by 6.0W/°C)

(40 – 60°C Load derating by 0.5W/°C)

(40 – 60°C Load derating by 1.5W/°C)

(40 – 60°C Load derating by 3.0W/°C)

(60 – 70°C Load dera

(60 – 70°C Load dera

(60 – 70°C Load dera

(60 – 70°C Load dera

(60 – 70°C Load dera

(60 – 70°C Load dera

ting by 2.0W/°C)

ting by 2.0W/°C)

ting by 4.0W/°C)

ting by 4.0W/°C)

ting by 8.0W/°C)

ting by 16.0W/

°C

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

6

Page 7

6.

all Models; User selectable standard mode and

Technical Specifications

6.1 Input Specifications

Model range

CP T SNT 70W 12V

6A

& CP T SNT

90W 24V 3.8A

CP T SNT 140W

12

V 12A & CP T

SNT 180W 24V

7.5A, 48V 4A

CP T SNT 360W

(2

4V 15A, 48V 7.5A)

CP T SNT 600W

(2

4V 25A, 48V

12.5A)

* Input

voltage

100-240VAC

85-26

(47-63 Hz)

100-120VAC/

220-230VAC

85-132 VAC/

187-264 VAC

(47-63 Hz)

Auto range

power

4VAC

* Observe output current derating at operation below an input voltage of 110VAC (see Fig. 4.2).

**

Output voltage adjustable 12 - 14VDC, 24 - 28VDC and 48 - 56VDC

*** Maximum current at nominal output voltage (Vout nom) and operating temperature up to +40°C max.

max.

Output-

78 Watt

90 Watt

156 Watt

180 Watt

192 Watt

360 Watt

360 Watt

600 Watt

600 Watt

** Output

voltage

Factory Set ±1%

12 VDC

24 V

DC

12 VDC

24 V

DC

48 VDC

24 VDC

48 V

DC

24 VDC

48 V

DC

*** Output

current

I

115 VAC 230 VAC 115 VAC 230 VAC at 230VAC

ou

t max

6.5 A

3.75 A

13.0 A

7.5 A

4.0 A

15.0 A

7.5 A

25.0 A

12.5 A

Input current

at full load typ.

2.0 A

2.1 A

2.5 A

2.8 A

2.8 A

5.0 A

5.0 A

10.0 A

10.0 A

1.0 A

1.0 A 12.0 A 20.0 A

1.4 A

1.5 A

1.5 A

2.5 A

2.5 A

5.0 A

5.0 A

6.2 Output Specifications

Regulation

- Input Variation (Line Regulation)

- Load Variation (Load Regulation)

Output Voltage adjustable Range

wit

h Potentiometer

Ripple and Noise (20MHz Bandwidth)

Overload protection Th

Electronic Short Circuit Protection Continuous Con

Parallel Operation

Over Voltage Protection (OVP) Trigger point at 20V

Hold-up Time at

Reverse Voltage Protection

(Power

back immunity)

Status Indicator (two colours)

Power Good Signal Tr

Max. Capacitive Load Unlim

V

- V

in min

in max

10% - 100% of I

12 V Model

24 V Model

48 V Model

at V

in

nom

und I

out max

out max

0.5% max

0.5% max

2.0% in parallel operation

12 - 14 VDC

24 - 28 VDC

48 - 56VDC

200mV pk-pk max

ermal protection Automatic restart

stant current. Automatic restart

up

parallel mode by jumper on PCB

to 5 Power Supplies possible

(Jumper position see Fig. 5.1, 5.2, 5.3 & 5.4)

DC 12VDC units

35VDC 24VDC units

60VDC 48VDC units

full load and Vin = 115VAC

at full load and Vin = 230VAC

10ms min.

20ms min

16VDC

35VDC

63VDC

Green

LED

igger threshold 12VDC units

Red LED

24VDC units

48VDC units

Active output signals CP T SNT 70W 12V 6A

(referenced to –V

CP T SNT 90W 24V 3.8A

24V

) CP T SNT 140W 12V 12A

ou

t

DC units

48VDC units

Relay output DC-OK = Contact closed

Normal operation

Output failure – if AC input mains is present

9 – 11 VDC

18 – 22 VDC

36 - 44 VDC

11.0VDC ±1.0VDC / 20mA max.

11.0VDC ±1.0VDC / 40mA max.

22.0VDC ±2.0VDC / 10mA max.

22.0VDC ±2.0VDC / 20mA max.

44.0VDC ±4.0VDC / 15mA max.

30VDC / 1.0A max. for 12 / 24VDC models

48VDC / 0.5A max. for 48VDC models

ited

Inrush current

max. at +25°C (<2ms)

13.0 A 25.0 A

16.0 A 25.0 A

25.0 A 30.0 A

Efficiency

ty

82.0 %

85.0 %

85.0 %

88.0 %

90.0 %

87.0 %

89.0 %

89.0 %

91.0 %

p.

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

7

Page 8

6.

3 General Specifications

Operating Temperature Range See Fig. 4.1 and Fig. 4.2 -25°C … +70°C (above +40°C load derating)

Cooling Con

Storage Temperature Range -25°

Load Derating above +40°C (104°F) see

Humidity (non condensing) 95%

Pollution Degree 2

Temperature Coefficient 0.02%/

Reliability, calculated MTBF

in ac

cordance to IEC 61709

Switching Frequency depen

Remote ON/OFF see

Safety class in

Case protection in

Isolation See Saf

Safety and Hazardous Location

Approv

als

Electromagnetic compatibility

(EMC) Emissions

Electromagnetic compatibility

(EMC) Immunity

Immunity to conducted radio frequency disturbances [0.15-80MHz]

Environment Vib

Enclosure Material Alum

Mounting DI

Connection Pluggable screw terminals (plugs included)

-

in a

ccordance to the product family

standard Power Supply Industrial

Conducted EMI on terminals

in a

ccordance to the product family

standard Power Supply Industrial

Electrostatic discharge (ESD)

Elect

Radiated RF Fields [80 – 1000MHz]

Electrical fast transients / Bursts

Electrical fast transients / Bursts

Power frequency field immunity

CP T SNT 60W xx

CP T SNT 140W 12V 12A

CP T SNT 120W xx,

240W, xx 480W xx)

ding on Model 50 … 140kHz typ.

Fig. 5.1, 5.2, 5.3 & 5.4 2 pin connector (see Fig. 3.1)

accordance to IEC 536 Class 1

accordance to IEC 529 IP20

IEC SI-1729_B3

UL file E236157

UL file E255651

CSA file 246286

CSA file 246286

CSA file 246286

CSA file 246286

CE Mark

Rad

Input Current harmonics EN 61000-3-2 Class A

rostatic discharge (ESD)

Surge (Mains Supply)

Surge (Mains Supply)

Surge (Signal Supply)

Voltage sag immunity

N-Rail mounting

Wall mounting

iated EMI

Flicker EN 61000-3-3

Voltage Dips

Shock

Tel: (800) 849-9343

Fax: (804) 379-2593

-13°F … +158°F (above +104°F load derating)

vection cooling; no internal fan

C … +85°C

-13°F … +185°F

Fig. 4.1

rel H max.

K

>1.8 Mio. hours

>1.2 Mio. hours

>0.9 Mio. hours

connect –S via a 1kΩ to –Vout Device off

ety Standards

CB-Scheme as per IEC 60950-1

cULus Listed to UL508, CSA C22.2 No. 14

cRUus to ANSI/UL60950, CSA60950

CSA to C22.2 No. 107.1

cCSAus to CSA60950, ANSI/UL60950

cCSAus C1D2 to C22.2 No. 213, UL1604

cCSAus C1Z2 to CSA60079-15, UL60079-15 & ANSI/ISA 12.012.01

EN 60950-1, EN 50178, EN 61558-2-4

EN 61204-3

Area

EN 55022 Class B, EN 55011 Class B, FCC Part 15-B

EN 55022 Class B, EN 55011 Class B, FCC Part 15-B

CP

T SNT 70W 12V 6A and CP T SNT 90W 24V 3.8A up to full

output power

CP T SNT 140W 12V 12A and CP T SNT 180W 24V 7.5A up to 120

watt only

CP T SNT 360W 24V 15A up to 240 watt only

CP T SNT 600W 24V 25A up to 480 watt only

EN 61204-3

Area

Standard Level

IEC / EN 61000-4-2 ±4kV Contact discharge B

IEC / EN 61000-4-2 ±8kV Air discharge B

IEC / EN 61000-4-3 10V/m B

IEC / EN 61000-4-4 ±2kV Mains Supply B

IEC / EN 61000-4-4 ±1kV Signal Supply B

IEC / EN 61000-4-5 ±1kV between L & N B

IEC / EN 61000-4-5 ±2kV between L & PE and N & PE B

IEC / EN 61000-4-5 ±1kV between ax & PE B

IEC / EN 61000-4-6 10V B

IEC / EN 61000-4-8 30A/m B

IEC / EN 61000-4-11 70% UN / 40%/100% UN B / C

SEMI F47

ration

IEC 60068-2-6 3 axis, sine sweep, 10 … 55Hz, 1g, 1oct/min.

IEC 60068-2-27 3 axis, 15g, half sine, 11ms

For DIN-Rails as per EN 50022-35 x 15 / 7.5

(snap-on self-locking spring)

With wall mounting bracket

inium (Chassis) / Zinc plated Steel (Cover)

support@weidmuller.com

www.weidmuller.com

Description Perf. criteria

Date: 28 September

2009

Issue: 1.0

Page

8

Page 9

Bl

ock diagram CP T SNT 70W 12V 6A, CP T SNT 90W 24V 3.8A, CP T SNT 90W 24V 3.8AN &

Fig. 1.1

Block diagram CP T SNT 140W 12V 12A, CP T SNT 180W 24V 7.5A, CP T SNT 180W 48V 4A, CP T SNT 360W 24V 15A &

CP T SNT 360W 48V 7.5A

Fig. 1.2

Block diagram CP T SNT 600W 24V 25A & CP T SNT 600W 48V 12.5A

Fig. 1.3

To fix the power supply on DIN-rail

Re

mote ON/OFF function

J3

Fig. 2.1 Fig. 2.2

To remove the power supply from DIN-rail

Connect J3 pin 2 (S-) to output

GN

D (-) through 1K00 resistor

Fig. 3.1

Fig. 2.3 Fig. 2.4

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

9

Page 10

CP T SNT 600W xx

Lo

ad Derating at operating temperatures above 40°C

110

100

90

80

70

60

50

Output Power [%]

40

30

2

0

10

0

-25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

Fig.: 4.1

Load Derating at low input voltage

CP T SNT 180W 24V

3.

8A

CP T SNT 140W xx

CP T SNT 360W xx

CP T SNT 70W 12V 6A

CP T SNT 140W 12V 12A

Operating Temperature Range [°C]

Fig.: 4.2

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

10

Page 11

Connectors of CP T SNT 70W 12V 6A & CP T SNT 90W 24V 3.8A with output Voltage adjustment

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Co

nnectors of CP T SNT 140W 12V 12A, CP T SNT 180W 24V 7.5A & CP T SNT 180W 48V 4A with Output

Voltage adjustment

J2

J1

5

1 2

3 4

J

4

123

1

2

J3

Fig.: 5.1

1 2 3

J1

J2 J3 J4

Ea

rth GND (-) S+ Normal mode

Ne

utral Vout (+) S- Common

Li

ve DC-OK Signal - Parallel mode

-

-

DC-OK Relay contact 1

DC-OK Relay contact 2

1 2 3 456

7

- -

- -

J2

1

2

J4

1J3

2

3

Fig.: 5.2

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

J1

1 2 3

J1

J2 J3 J4

Ea

rth GND (-) S+ Normal mode

Ne

utral GND (-) S- Common

Li

ve Vout (+) - Parallel mode

- Vout (+) - -

- DC-OK Signal - -

- DC-OK Relay contact 1

- DC-OK Relay contact 2

- -

- -

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

11

Page 12

Co

nnectors of CP T SNT 360W 24V 15A & CP T SNT 360W 48V 7.5A with Output Voltage adjustment

1 2 3 4 5 6 7

J

2

J3

1

2

J

4

23 1

Fig.: 5.3

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

J1

1 2 3

J1 J2 J3 J4

Ea

rth GND (-) S+ Normal mode

Ne

utral GND (-) S- Common

Li

ve Vout (+) - Parallel mode

- V

-

-

-

DC-OK Relay contact 1

DC-OK Relay contact 2

out (+) - -

DC-OK Signal - -

- -

- -

Co

nnectors of CP T SNT 600W 24V 25A & CP T SNT 600W 48V 12.5A with Output Voltage adjustment

2 1

123

J4

J3

1 2 3 1 2

J1 J2J5

Fig.: 5.4

J1 J

1 2 3 1 2 31 2 3 4

2J5

Pin 1

Pin 2

Pin 3

Pin 4

J1 J2 J3 J4 J5

Earth GND (-) S+ Normal mode DC-OK Relay contact 1

Neutral GND (-) S- Common DC-OK Relay contact 2

Live Vout (+) - Parallel mode

DC-OK Signal

- Vout (+) - - -

31 2 3 4

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

12

Page 13

Wall mounting brackets (CP MB01) for CP T SNT 70W 12V 6A, CP T SNT 90W 24V 3.8A, CP T SNT 140W 12V

12

A and CP T SNT 180W xx

Fig.: 6.1

Wall mounting brackets (CP MB02) for CP T SNT 360W xx and CP T SNT 600W xx

Fig.: 6.2

Fig.: 6.3

Tel: (800) 849-9343

Fax: (804) 379-2593

support@weidmuller.com

www.weidmuller.com

Date: 28 September

2009

Issue: 1.0

Page

13

Loading...

Loading...