Weidmuller IE-SW-VL16T-14TX-2ST, IE-SW-VL16-16TX, IE-SW-VL16T-14TX-2SC, IE-SW-VL16-14TX-2ST, IE-SW-VL16T-16TX Hardware Installation Manual

...

Unmanaged Fast Ethernet Switch

ValueLine

IE-SW-VL16 Series

Hardware Installation Guide

8th Edition, March 2018

1243330000/07/04.18

Important note:

This document and additional product information can be

downloaded using following link:

http://www.weidmueller.com

► Select Product Catalogue

Select „Active Industrial Ethernet “

Select „ValueLine unmanaged Switches “

Select Product model

Click and expand section „Downloads “

Download needed software or documentation

Copyright Notice

Copyright 2018 Weidmüller Interface GmbH & Co. KG

All rights reserved.

Reproduction without permission is prohibited.

Overview

ATTENTION

subject to the following two conditions: (1) This device may not

The IE-SW-VL16 series of 16-port smart Ethernet switches provides an

economical solution for your Ethernet connections. As a bonus, the

built-in smart alarm function helps system maintainers monitor the health

of your Ethernet network.

IE-SW-VL16 series is available with an operating temperature range of 0

to 60°C or optional with extended operating temperature range from -40

to 75°C. The devices are designed to withstand a high degree of vibration

and shock. The rugged hardware design makes IE-SW-VL16 series

perfect for ensuring that your Ethernet equipment can withstand critical

industrial applications, such as in hazardous locations (Class 1 Division

2/ Zone 2), and complies with FCC, UL and CE Standards.

This device complies with part 15 of FCC Rules. Operation is

cause harmful interference, and (2) this device must accept

any interference received, including interference that may

cause undesired operation.

Package Checklist

Your Ethernet Switch is shipped with the following items. If any of these

items is missing or damaged, please contact your Weidmüller customer

service for assistance.

Ethernet Switch

Protective caps for unused ports

Hardware Installation Guide (printed)

Features

High Performance Network Switching Technology

10/100BaseT(X) (RJ45), 100BaseFX (SC/ST type, Multimode)

IEEE 802.3/802.3u/802.3x

Store and Forward switching process type, with 4K address entries

10/100M, Full/Half-Duplex, MDI/MDIX auto-sensing

Industrial Grade Reliablity

Power failure, port break alarm by relay output

Redundant dual DC power inputs

Broadcast storm protection to prevent network devices from crashing

Rugged Design

IP30, rugged high-strength case

DIN-Rail or panel mounting ability

- 2 -

Panel Layout

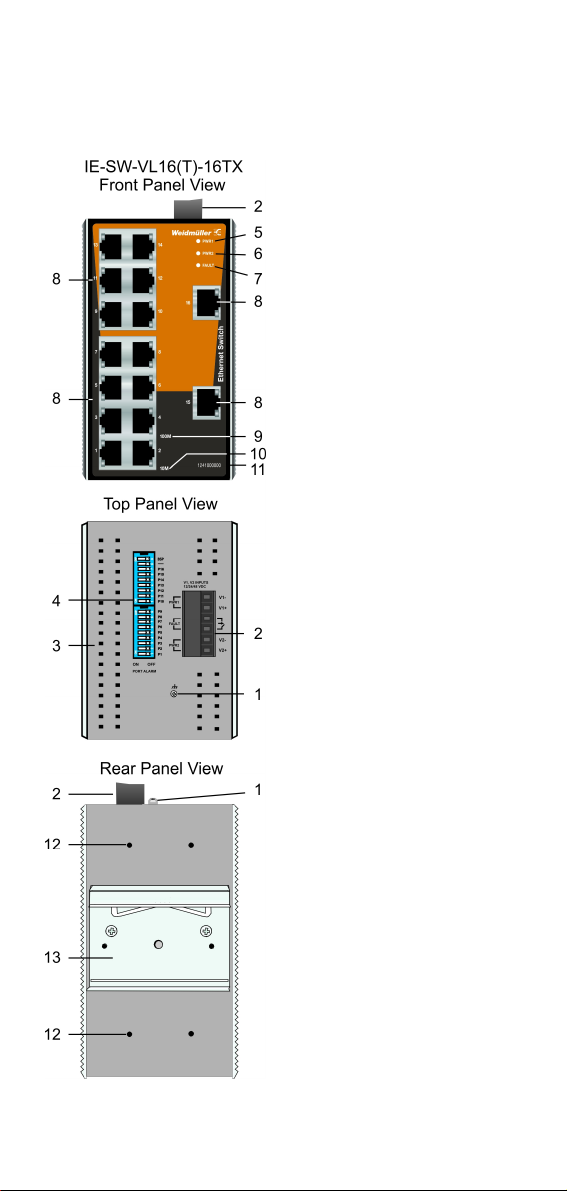

IE-SW-VL16(T)-16TX

1. Grounding screw

2. Terminal block for power input P1/P2

3. Heat dissipation orifices

4. DIP Switches

5. Power input PWR1 LED

6. Power input PWR2 LED

7. Fault LED

8. 10/100BaseT(X) Port

9. TP port’s 100 Mbps LED

10. TP port’s 10 Mbps LED

11. Article number

12. Screw hole for wall mounting kit

13. DIN-Rail Kit

- 3 -

Panel Layout

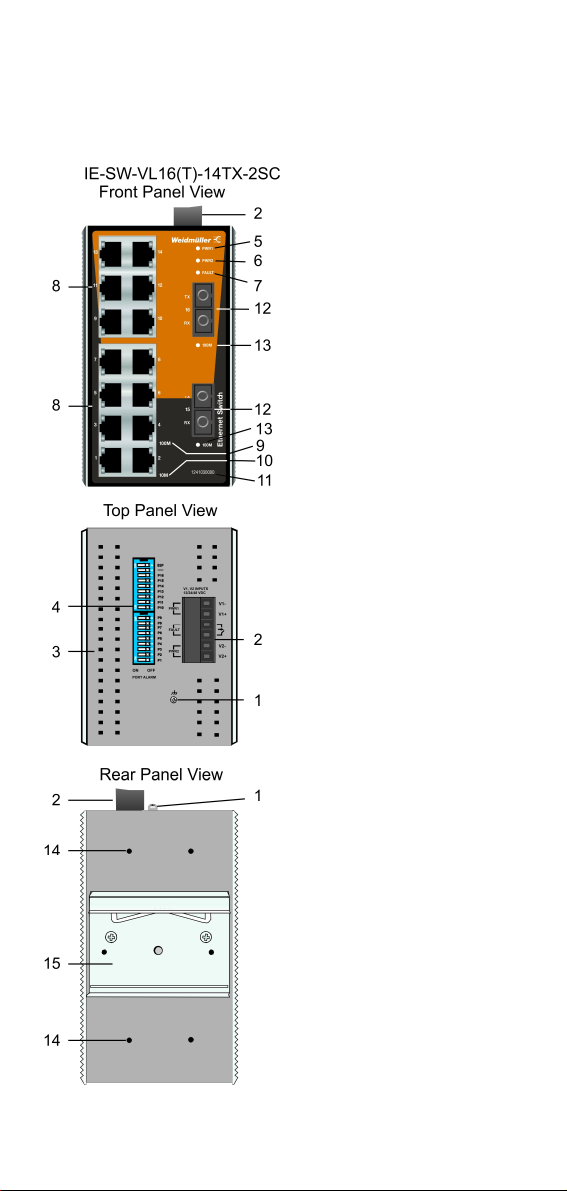

IE-SW-VL16(T)-14TX-2SC

1. Grounding screw

2. Terminal block for power input P1/P2

3. Heat dissipation orifices

4. DIP Switches

5. Power input PWR1 LED

6. Power input PWR2 LED

7. Fault LED

8. 10/100BaseT(X) Port

9. TP port’s 100 Mbps LED

10. TP port’s 10 Mbps LED

11. Article number

12. 100BaseFX Port

13. FX port’s 100 Mbps LED

14. Screw hole for wall mounting kit

15. DIN-Rail Kit

- 4 -

Panel Layout

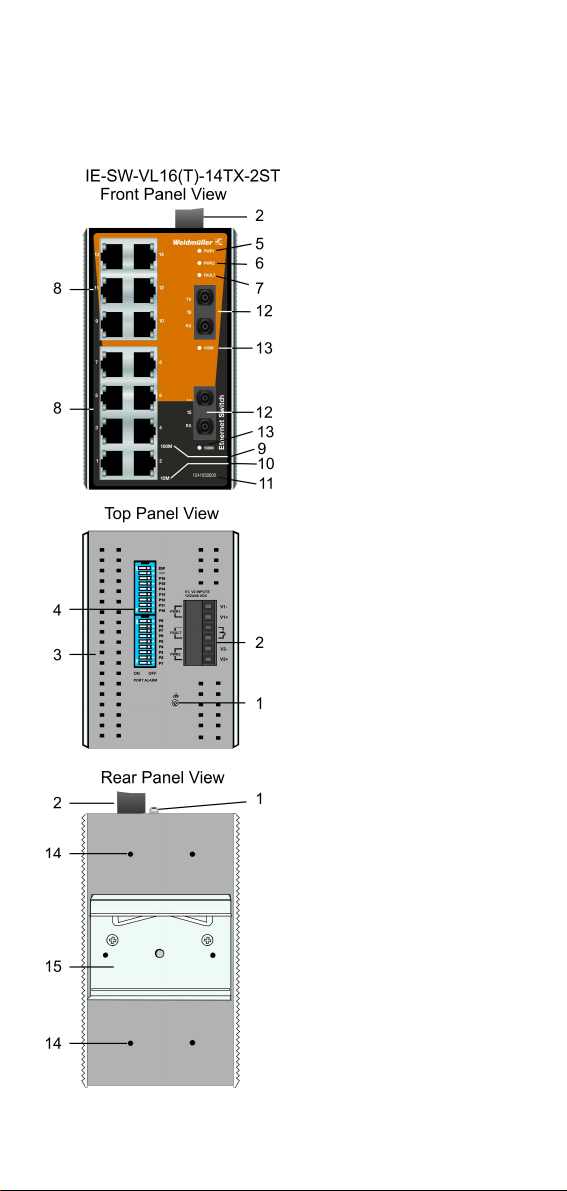

IE-SW-VL16(T)-14TX-2ST

1. Grounding screw

2. Terminal block for power input P1/P2

3. Heat dissipation orifices

4. DIP Switches

5. Power input PWR1 LED

6. Power input PWR2 LED

7. Fault LED

8. 10/100BaseT(X) Port

9. TP port’s 100 Mbps LED

10. TP port’s 10 Mbps LED

11. Article number

12. 100BaseFX Port

13. FX port’s 100 Mbps LED

14. Screw hole for wall mounting kit

15. DIN-Rail Kit

- 5 -

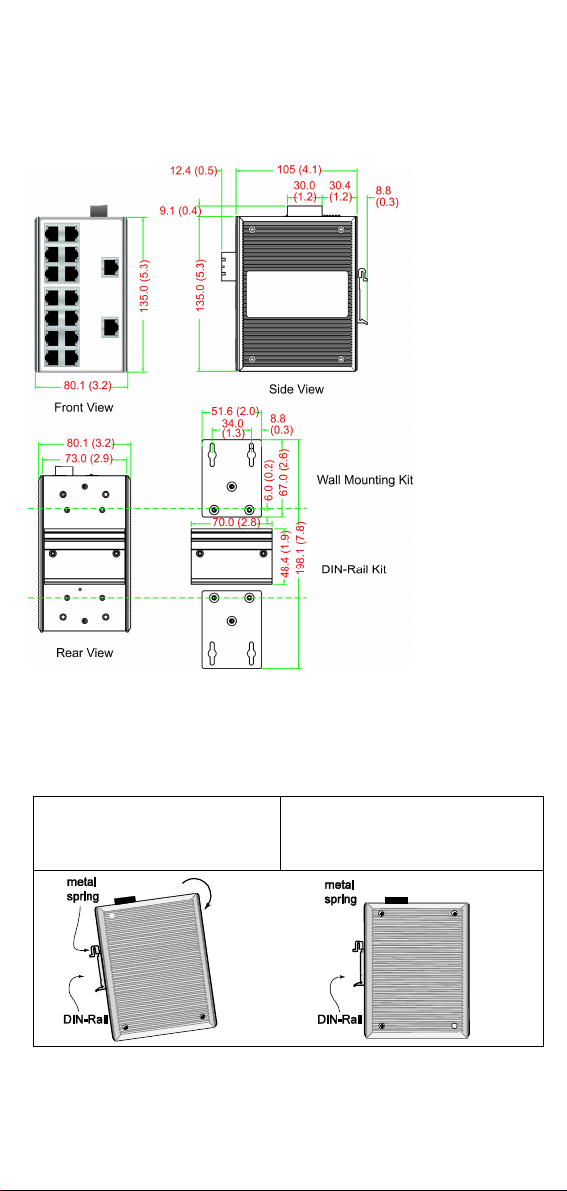

Mounting Dimensions

STEP 1

STEP 2

Units: mm (inch)

DIN-Rail Mounting

The aluminum DIN-rail attachment plate should already be fixed to the

back panel of the Ethernet Switch when you take it out of the box. If you

need to reattach the DIN-rail attachment plate, make sure the stiff metal

spring is situated towards the top, as shown in the figures below.

To remove the DIN-rail from the Ethernet Switch, simply reverse Steps 1

and 2.

:

Insert the top of the DIN-Rail into

the slot just below the stiff metal

spring.

:

The DIN-Rail attachment unit will

snap into place as shown below.

- 6 -

Loading...

Loading...