Page 1

CLS200 Series

User’s Guide

Watlow

1241 Bundy Boulevard

Winona, MN 55987

Customer Service:

Phone........1-800-414-4299

Fax.............1-800-445-8992

Technical Support:

Phone........+1 (507) 494-5656

Fax ............+1 (507) 452-4507

Email .........wintechsupport@watlow.com

Part No. 0600-3050-2000 Rev. A

November 2008

Page 2

Copyright © 1998-2003, Watlow Anafaze

Information in this manual is subject to change without notice. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form

without written permission from Watlow Anafaze.

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this Agreement will be free from defects in material and workmanship for a period of three years

from the date of shipment. The Customer shall provide notice of any defect to Watlow

Anafaze, Incorporated within one week after the Customer's discovery of such defect.

The sole obligation and liability of Watlow Anafaze, Incorporated under this warranty

shall be to repair or replace, at its option and without cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be

defective shall immediately be returned at the Customer's expense to Watlow Anafaze,

Incorporated. Replaced or repaired products or parts will be shipped to the Customer

at the expense of Watlow Anafaze, Incorporated.

There shall be no warranty or liability for any products or parts that have been subject to misuse, accident, negligence, failure of electric power or modification by the

Customer without the written approval of Watlow Anafaze, Incorporated. Final determination of warranty eligibility shall be made by Watlow Anafaze, Incorporated. If a

warranty claim is considered invalid for any reason, the Customer will be charged for

services performed and expenses incurred by Watlow Anafaze, Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original warranty

period, the warranty period for the replacement or repaired part shall terminate with

the termination of the warranty period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze, Incorporated

and the Customer's sole remedy with respect to the products. It is in lieu of all other

warranties, liabilities, and remedies. Except as thus provided, Watlow Anafaze, Inc.

disclaims all warranties, express or implied, including any warranty of merchantability or fitness for a particular purpose.

Please Note: External safety devices must be used with this equipment.

Page 3

Table of Contents

List of Figures xi

List of Tables xv

1 System Overview 1

Manual Contents 1

Getting Started 2

Safety Symbols 2

Initial Inspection 2

Product Features 3

CLS200 Parts List 5

Technical Description 7

CLS200 7

TB50 8

CLS200 Cabling 9

Safety 9

External Safety Devices 9

Power-Fail Protection 10

2 Installation 11

Typical Installation 12

Mounting Controller Components 12

Recommended Tools 13

Mounting the Controller 13

Mounting the TB50 16

Mounting the Power Supply 18

Mounting the Dual DAC or Serial DAC Module 19

System Wiring 21

Wiring Recommendations 21

Noise Suppression 22

Ground Loops 24

Power Connections 25

Wiring the Power Supply 25

Connecting TB50 to CLS200 27

Testing Your System 28

TB50 or TB18 Test 28

Digital Output Test 28

Digital Input Test 29

Doc.# 0600-3050-2000 Watlow Anafaze iii

Page 4

Table of Contents CLS200 Series User’s Guide

Sensor Wiring 29

Input Wiring Recommendations 30

Thermocouple Connections 31

RTD Input Connections 32

Reference Voltage Terminals 32

Voltage Input Connections 32

Current Input Connections 33

Pulse Input Connections 34

Wiring Control and Digital I/O 35

Output Wiring Recommendations 35

Cable Tie Wraps 35

Digital Outputs 35

Digital Inputs 38

TB18 Connections (CLS204 and CLS208 Only) 40

TB50 Connections 41

Analog Outputs 43

Wiring the Dual DAC 43

Wiring the Serial DAC 44

Serial Communications 45

EIA/TIA-232 Interface 45

EIA/TIA-485 Interface 47

EIA/TIA-485 Converters and Laptop Computers 49

3 Using the CLS200 51

Front Panel 52

Front Panel Keys 53

Displays 55

Bar Graph Display 55

Single Loop Display 57

Alarm Displays 58

System Alarms 60

Job Display 60

Changing the Setpoint 61

Selecting the Control Status 61

Manual and Automatic Control 61

Autotuning a Loop 62

Using Alarms 64

Alarm Delay 64

Failed Sensor Alarms 65

Process Alarms 66

Global Alarm 68

Ramp/Soak 69

4 Setup 71

How to Access the Setup Menus 71

How to Change a Parameter 72

Setup Global Parameters Menu

Load Setup From Job 75

Save Setup to Job 75

Job Select Digital Inputs 76

74

iv Watlow Anafaze Doc.# 0600-3050-2000

Page 5

CLS200 Series User’s Guide Table of Contents

Job Select Digital Inputs Active 77

Output Override Digital Input 77

Override Digital Input Active 77

Startup Alarm Delay 78

Keyboard Lock Status 78

Power Up Output Status 78

Process Power Digital Input 79

Controller Address 79

Communications Baud Rate 80

Communications Protocol 80

Communications Error Checking 80

AC Line Frequency 81

Digital Output Polarity on Alarm 81

EPROM Information 81

Setup Loop Input Menu 82

Input Type 83

Loop Name 84

Input Units 84

Input Reading Offset 84

Reversed T/C Detection 85

Input Pulse Sample Time 85

Linear Scaling Parameters 86

Input Filter 89

Setup Loop Control Parameters Menu 90

Heat or Cool Control PB 91

Heat or Cool Control TI 91

Heat or Cool Control TD 91

Heat or Cool Output Filter 91

Spread 92

Restore PID Digital Input 92

Setup Loop Outputs Menu 93

Enable or Disable Heat or Cool Outputs 94

Heat or Cool Output Type 94

Heat or Cool Cycle Time 95

SDAC Mode 95

SDAC Low Value 95

SDAC High Value 95

Heat or Cool Output Action 96

Heat or Cool Output Limit 96

Heat or Cool Output Limit Time 96

Sensor Fail Heat or Cool Output 97

Heat or Cool Thermocouple Break Output Average 97

Heat or Cool Linearity 98

Setup Loop Alarms Menu 99

High Process Alarm Setpoint 100

High Process Alarm Type 100

High Process Alarm Output Number 100

Deviation Alarm Value 100

High Deviation Alarm Type 101

High Deviation Alarm Output Number 101

Low Deviation Alarm Type 101

Low Deviation Alarm Output Number 101

Low Process Alarm Setpoint 102

Doc.# 0600-3050-2000 Watlow Anafaze v

Page 6

Table of Contents CLS200 Series User’s Guide

Low Process Alarm Type 102

Low Process Alarm Output Number 102

Alarm Deadband 102

Alarm Delay 103

Manual I/O Test 103

Digital Inputs 103

Test Digital Output 104

Digital Output Number 104

Keypad Test 105

Display Test 105

5 Extruder Control 107

Setup Loop Outputs Menu 107

Cool Output Nonlinear Output Curve 107

Defaults 108

Extruder Control Algorithm 110

6 Enhanced Features 111

Process Variable Retransmit 113

Setup Loop Process Variable Retransmit Menu 113

Process Variable Retransmit Example: Data Logging 115

Cascade Control 118

Setup Loop Cascade Menu 119

Cascade Control Example: Water Tank 121

Ratio Control 124

Setup Loop Ratio Control Menu 125

Ratio Control Example: Diluting KOH 126

Remote Analog Setpoint 129

Remote Analog Setpoint Example: Setting a Setpoint with a PLC 129

Differential Control 131

Differential Control Example: Thermoforming 131

7 Ramp/Soak 133

Features 134

Ramp/Soak Menus 136

Setup Global Parameters Menu 137

Ramp/Soak Time Base 137

Setup Ramp/Soak Profile Menu 137

Edit Ramp/Soak Profile 137

Copy Setup From Profile 138

Tolerance Alarm Time 138

Ready Segment Setpoint 138

Ready Segment Edit Events 139

External Reset Input Number 139

Edit Segment Number 140

Segment Time 140

Segment Setpoint 140

Edit Segment Events 141

Edit Segment Triggers 142

Segment Tolerance 143

vi Watlow Anafaze Doc.# 0600-3050-2000

Page 7

CLS200 Series User’s Guide Table of Contents

Last Segment 144

Repeat Cycles 144

Setpoints and Tolerances for Various Input Types 144

Using Ramp/Soak 145

Ramp/Soak Displays 146

Assigning a Profile to a Loop 148

Running a Profile 148

Holding a Profile or Continuing from Hold 150

Responding to a Tolerance Alarm 151

Resetting a Profile 151

In Case of a Power Failure 152

8 Tuning and Control 153

Control Algorithms 153

On/Off Control 154

Proportional Control 154

Proportional and Integral Control 155

Proportional, Integral and Derivative Control 155

Heat and Cool Outputs 156

Control Outputs 157

Output Control Signals 157

Output Filter 158

Reverse and Direct Action 159

Setting Up and Tuning PID Loops 159

Proportional Band (PB) Settings 159

Integral Settings 160

Derivative Settings 160

General PID Constants by Application 161

Proportional Band Only (P) 161

Proportional with Integral (PI) 161

PI with Derivative (PID) 161

9 Troubleshooting and Reconfiguring 163

When There is a Problem 163

Returning Your Unit 164

Troubleshooting Controllers 164

Process and Deviation Alarms 164

Failed Sensor Alarms 166

System Alarms 166

Other Behaviors 167

Corrective and Diagnostic Procedures 168

Low Power 168

Battery Dead 168

Ambient Warning 168

H/W Ambient Failure 169

H/W Gain or Offset Failure 170

Keys Do Not Respond 170

Checking Analog Inputs 171

Earth Grounding 172

Checking Control Outputs 172

Testing Control Output Devices 173

Doc.# 0600-3050-2000 Watlow Anafaze vii

Page 8

Table of Contents CLS200 Series User’s Guide

Testing the TB18 and TB50 173

Testing Control and Digital Outputs 173

Testing Digital Inputs 173

Additional Troubleshooting for Computer Supervised Systems 174

Computer Problems 174

Communications 175

Ground Loops 175

Software Problems 176

NO-Key Reset 176

Replacing the EPROM 176

Changing Communications 179

Installing Scaling Resistors 180

CLS204 and CLS208 Input Circuit 180

CLS204 and CLS208 Current Inputs 181

CLS204 and CLS208 Voltage Inputs 182

CLS204 and CLS208 RTDs and Thermistors 183

CLS216 Input Circuit 184

CLS216 Current Inputs 184

CLS216 Voltage Inputs 185

Scaling and Calibration 186

Configuring Dual DAC Outputs 186

Configuring Serial DAC Outputs 188

10 Linear Scaling Examples 189

Example 1: A 4-to-20 mA Sensor 189

Î

Example 2: A 0-to-5V

(dc) Sensor 191

Example 3: A Pulse Encoder 192

11 Specifications 193

CLS200 System Specifications 193

CLS200 Processor Physical Specifications 194

TB50 Physical Specifications 196

Inputs 200

Outputs 202

CLS200 Power Supply 205

Dual DAC Specifications 207

Dual DAC Inputs 208

Dual DAC Analog Outputs 208

Serial DAC Specifications 209

Serial DAC Inputs 210

Serial DAC Analog Outputs 211

Glossary 213

Index 221

Menu Structure 233

Declaration of Conformity 234

viii Watlow Anafaze Doc.# 0600-3050-2000

Page 9

1 System Overview

Figure 1.1—CLS200 Part Numbering 5

Figure 1.2—CLS200 Special Inputs Parts List 6

Figure 1.3—CLS200 Rear Views 7

Figure 1.4—CLS200 Front Panel 8

Figure 1.5—TB50 8

List of Figures

2 Installation

Figure 2.1—CLS200 System Components 12

Figure 2.2—Clearance with Straight SCSI Cable 14

Figure 2.3—Clearance with Right-Angle SCSI Cable 14

Figure 2.4—Wiring Clearances 15

Figure 2.5—Mounting Bracket 16

Figure 2.6—Mounting the TB50 16

Figure 2.7—TB50 Mounted on a DIN Rail (Front) 17

Figure 2.8—TB50 Mounted on DIN Rail (Side) 17

Figure 2.9—Mounting a TB50 with Standoffs 18

Figure 2.10—CLS200 Power Supply Mounting Bracket 19

Figure 2.11—Dual DAC and Serial DAC Dimensions 20

Figure 2.12—CLS200 Series Controller with TB18 25

Figure 2.13—CLS200 Series Controller with TB50 25

Figure 2.14—Power Connections with the CLS200 Power Supply 27

Figure 2.15—CLS200 Connector Locations 30

Figure 2.16—Thermocouple Connections 31

Figure 2.17—RTD Connections to CLS204 or CLS208 32

Figure 2.18—Linear Voltage Signal Connections 33

Figure 2.19—Linear Current Signal Connections 33

Figure 2.20—Encoder with 5V Î (dc) TTL Signal 34

Figure 2.21—Encoder Input with Voltage Divider 34

Figure 2.22—Digital Output Wiring 36

Figure 2.23—Sample Heat, Cool and Alarm Output Connections 37

Figure 2.24—Output Connections Using External Power Supply 38

Figure 2.25—TB50 Watchdog Timer Output 38

Figure 2.26—TB18 Watchdog Timer Output 38

Figure 2.27—Wiring Digital Inputs 39

Figure 2.28—Dual DAC with Current Output 43

Figure 2.29—Dual DAC with Voltage Output 44

Doc.# 0600-3050-2000 Watlow Anafaze ix

Page 10

List of Figures CLS200 Series User’s Guide

Figure 2.30—Single/Multiple Serial DACs 45

Figure 2.31—Connecting One CLS200 to a Computer Using EIA/TIA-232 46

Figure 2.32—EIA/TIA-485 Wiring 47

Figure 2.33—Recommended System Connections 48

3 Using the CLS200

Figure 3.1—Operator Displays 51

Figure 3.2—CLS200 Front Panel 52

Figure 3.3—Bar Graph Display 55

Figure 3.4—Single Loop Display 57

Figure 3.5—Single Loop Display, Heat and Cool Outputs Enabled 57

Figure 3.6—Single Loop Display with a Process Alarm 58

Figure 3.7—Failed Sensor Alarm in the Single Loop Display 58

Figure 3.8—Alarm Symbols in the Bar Graph Display 58

Figure 3.9—Activation and Deactivation of Process Alarms 68

4 Setup

Figure 4.1—CLS200 Menu Tree 73

Figure 4.2—Two Points Determine Process Variable Conversion 86

Figure 4.3—Process Variable Limited by Input Reading Range 87

Figure 4.4—Linear and Nonlinear Outputs 98

Figure 4.5—Digital Inputs Screen 104

5 Extruder Control

Figure 5.1—Cool Output Nonlinear Output Curve 108

6 Enhanced Features

Figure 6.1—Enhanced Features Option Menus 112

Figure 6.2—Linear Scaling of Process Variable for Retransmit 115

Figure 6.3—Application Using Process Variable Retransmit 116

Figure 6.4—Relationship Between the Primary Loop’s Output and the Secondary

Loop’s Setpoint 119

Figure 6.5—Application Using Cascade Control 121

Figure 6.6—Secondary Loop Setpoint Related to Primary Loop Output 123

Figure 6.7—Relationship Between the Master Loop’s Process Variable and the Ratio

Loop’s Setpoint 124

Figure 6.8—Application Using Ratio Control 127

7 Ramp/Soak

Figure 7.1—Sample Ramp/Soak Profile 133

Figure 7.2—Setup Ramp/Soak Profiles Menu 136

Figure 7.3—Positive and Negative Tolerances 143

Figure 7.4—Ramp/Soak Screens 145

x Watlow Anafaze Doc.# 0600-3050-2000

Page 11

CLS200 Series User’s Guide List of Figures

8 Tuning and Control

Figure 8.1—On/Off Control 154

Figure 8.2—Proportional Control 155

Figure 8.3—Proportional and Integral Control 155

Figure 8.4—Proportional, Integral and Derivative Control 156

Figure 8.5—Time Proportioning and Distributed Zero Crossing Waveforms 157

9 Troubleshooting and Reconfiguring

Figure 9.1—Removal of Electronics Assembly from Case 177

Figure 9.2—Screws Locations on PC Board 178

Figure 9.3—EPROM Location 178

Figure 9.4—Remove EPROM 178

Figure 9.5—Jumper Configurations 179

Figure 9.6—CLS204 and CLS208 Input Circuit 181

Figure 9.7—CLS216 Input Circuit 184

Figure 9.8—Dual DAC 187

Figure 9.9—Serial DAC Voltage/Current Jumper Positions 188

11 Specifications

Figure 11.1—CLS200 Processor Module Dimensions 194

Figure 11.2—CLS200 Clearances with Straight SCSI Cable 195

Figure 11.3—CLS200 Clearances with Right-Angle SCSI Cable 195

Figure 11.4—TB50 Dimensions 197

Figure 11.5—TB50 Dimensions with Straight SCSI Cable 198

Figure 11.6—TB50 Dimensions with Right-Angle SCSI Cable 199

Figure 11.7—Power Supply Dimensions (Bottom View) 206

Figure 11.8—Dual DAC Dimensions 207

Figure 11.9—Serial DAC Dimensions 209

Doc.# 0600-3050-2000 Watlow Anafaze xi

Page 12

List of Figures CLS200 Series User’s Guide

xii Watlow Anafaze Doc.# 0600-3050-2000

Page 13

2 Installation

Table 2.1—Cable Recommendations 22

Table 2.2—Power Connections 26

Table 2.3—Digital Output States and Values Stored in the Controller 36

Table 2.4—Digital Inputs States and Values Stored in the Controller 39

Table 2.5—TB18 Connections 40

Table 2.6—TB50 Connections for CLS204 and CLS208 41

Table 2.7—TB50 Connections for CLS216 42

Table 2.8—EIA/TIA-232 Connections 46

Table 2.9—RTS/CTS Pins in DB-9 and DB-25 Connectors 46

List of Tables

3 Using the CLS200

Table 3.1—Bar Graph Display Symbols 55

Table 3.2—Control Status Symbols on the Bar Graph and Single Loop Displays 56

Table 3.3—Alarm Type and Symbols 59

4 Setup

Table 4.1—Global Parameters 74

Table 4.2—Job Select Inputs 76

Table 4.3—Job Selected for Various Input States 76

Table 4.4—Firmware Option Codes 81

Table 4.5—Setup Loop Input 82

Table 4.6—CLS200 Input Types and Ranges 83

Table 4.7—Input Character Sets 84

Table 4.8—Input Reading Offset 85

Table 4.9—Display Formats 87

Table 4.10—Setup Loop Control Parameters 90

Table 4.11—Setup Loop Outputs 93

Table 4.12—Heat / Cool Output Types 94

Table 4.13—Setup Loop Alarms 99

Table 4.14—Manual I/O Test 103

5 Extruder Control

Table 5.1—Default Control Parameters for Fan Cool Output 109

Table 5.2—Default Control Parameters for Oil Cool Output 109

Table 5.3—Default Control Parameters for H2O Cool Output 109

Doc.# 0600-3050-2000 Watlow Anafaze xiii

Page 14

List of Tables CLS200 Series User’s Guide

6 Enhanced Features

Table 6.1—Application Example: Setting Up Process Variable Retransmit 117

Table 6.2—Application Example: Setting Up Cascade Control 122

Table 6.3—Application Example: Setting Up Ratio Control 128

Table 6.4—Application Example: Setting Up Remote Setpoint 130

Table 6.5—Application Example: Setting Up Differential Control 132

7 Ramp/Soak

Table 7.1—Ramp/Soak Specifications 135

Table 7.2—Trigger Latch Logic 143

Table 7.3—Display Formats 145

Table 7.4—Ramp/Soak Single Loop Display 146

Table 7.5—Ramp/Soak Control Status Symbols 147

Table 7.6—Ramp/Soak Profile Modes 150

8 Tuning and Control

Table 8.1—Proportional Band Settings 159

Table 8.2—Integral Term and Reset Settings 160

Table 8.3—Derivative Term Versus Rate 160

Table 8.4—General PID Constants 162

9 Troubleshooting and Reconfiguring

Table 9.1—Controller Alarm Codes for Process and Deviation Alarms 164

Table 9.2—Operator Response to Alarms 165

Table 9.3—Failed Sensor Alarm Codes 166

Table 9.4—Hardware Error Messages 166

Table 9.5—Other Symptoms 167

Table 9.6—Resistor Values for CLS204 and CLS208 Current Inputs 181

Table 9.7—Resistor Locations for CLS204 and CLS208 Current Inputs 181

Table 9.8—Resistor Values for CLS204 and CLS208 Voltage Inputs 182

Table 9.9—Resistor Locations for CLS204 and CLS208 Voltage Inputs 182

Table 9.10—Resistor Values for CLS204/208 RTD and Thermistor Inputs 183

Table 9.11—Resistor Locations for CLS204/208 RTD and Thermistor Inputs 183

Table 9.12—Resistor Values for CLS216 Current Inputs 184

Table 9.13—Resistor Locations for CLS216 Current Inputs 185

Table 9.14—Resistor Values for CLS216 Voltage Inputs 185

Table 9.15—Resistor Locations for CLS216 Voltage Inputs 186

Table 9.16—Dual DAC Jumper Settings 187

10 Linear Scaling Examples

Table 10.1—Input Readings 190

Table 10.2—Scaling Values 190

Table 10.3—Input Readings and Calculations 191

Table 10.4—Scaling Values 191

Table 10.5—Scaling Values 192

xiv Watlow Anafaze Doc.# 0600-3050-2000

Page 15

CLS200 Series User’s Guide List of Tables

11 Specifications

Table 11.1—Agency Approvals / Compliance 193

Table 11.2—Environmental Specifications 194

Table 11.3—Physical Dimensions 194

Table 11.4—Processor with Straight SCSI 195

Table 11.5—Processor with Right Angle SCSI 195

Table 11.6—Processor Connections 196

Table 11.7—TB50 Physical Dimensions 196

Table 11.8—TB50 Connections 197

Table 11.9—TB50 with Straight SCSI 198

Table 11.10—TB50 with Right Angle SCSI 199

Table 11.11—Analog Inputs 200

Table 11.12—Pulse Inputs 201

Table 11.13—Thermocouple Range and Resolution 201

Table 11.14—RTD Range and Resolution 201

Table 11.15—Input Resistance for Voltage Inputs 202

Table 11.16—Digital Inputs 202

Table 11.17—Digital Outputs Control / Alarm 203

Table 11.18—CPU Watchdog Output 203

Table 11.19—5V Î (dc) Output (Power to Operate Solid-State Relays) 204

Table 11.20—Reference Voltage Output (Power to Operate Bridge Circuit

Sensors) 204

Table 11.21—Processor Serial Interface 204

Table 11.22—Processor Power Requirements 204

Table 11.23—Power Supply Environmental Specifications 205

Table 11.24—Power Supply Agency Approvals / Compliance 205

Table 11.25—Power Supply Physical Specifications 205

Table 11.26—Power Supply with Mounting Bracket 205

Table 11.27—Power Supply Inputs 206

Table 11.28—Power Supply Outputs 206

Table 11.29—Dual DAC Environmental Specifications 207

Table 11.30—Dual DAC Physical Specifications 207

Table 11.31—Dual DAC Power Requirements 208

Table 11.32—Dual DAC Specifications by Output Range 208

Table 11.33—Serial DAC Environmental Specifications 209

Table 11.34—Serial DAC Physical Specifications 209

Table 11.35—Serial DAC Agency Approvals / Compliance 210

Table 11.36—Serial DAC Inputs 210

Table 11.37—Serial DAC Power Requirements 210

Table 11.38—Serial DAC Analog Output Specifications 211

Doc.# 0600-3050-2000 Watlow Anafaze xv

Page 16

List of Tables CLS200 Series User’s Guide

xvi Watlow Anafaze Doc.# 0600-3050-2000

Page 17

1

System Overview

Manual Contents

This manual describes how to install, set up, and operate a

CLS204, CLS208 or CLS216 controller. Each chapter covers a different aspect of your control system and may apply

to different users:

• Chapter 1: System Overview provides a component

list and summary of features for the CLS200 series

controllers.

• Chapter 2: Installation provides detailed instructions on installing the CLS200 series controller and its

peripherals.

• Chapter 3: Using the CLS200 provides an overview

of operator displays used for system monitoring and

job selection.

• Chapter 4: Setup provides detailed descriptions of

all menus and parameters for controller setup.

• Chapter 5: Extruder Control explains the additional features of a CLS200 controller equipped with Extruder Control Firmware.

• Chapter 6: Enhanced Features describes process

variable retransmit, ratio, differential and cascade

control features available with the enhanced features

option.

• Chapter 7: Ramp/Soak explains how to set up and

use the features of the ramp/soak option.

• Chapter 8: Tuning and Control describes available

control algorithms and provides suggestions for applications.

• Chapter 9: Troubleshooting and Reconfiguring

includes troubleshooting, upgrading and reconfiguring procedures for technical personnel.

Doc.# 0600-3050-2000 Watlow Anafaze 1

Page 18

Chapter 1: System Overview CLS200 Series User’s Guide

Chapter 10: Linear Scaling Examples provides an

example configuring a pressure sensor, a flow sensor,

and an encoder using linear scaling.

• Chapter 11: Specifications

tions of the controller and optional components.

lists detailed specifica-

Getting Started

The following sections provide information regarding product features, technical descriptions, safety requirements,

and preparation for operation.

Safety Symbols

These symbols are used throughout this manual:

•

Initial Inspection

WARNING!

CAUTION!

NOTE!

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate injury or property damage.

Indicates pertinent information or an item

that may be useful to document or label for

later reference.

Accessories may or may not be shipped in the same container as the CLS200, depending upon their size. Check the

shipping invoice carefully against the contents received in

all boxes.

2 Watlow Anafaze Doc.# 0600-3050-2000

Page 19

CLS200 Series User’s Guide Chapter 1: System Overview

Product Features

The CLS200 series controllers provide 4, 8 or 16 fully independent control loops. When used as a stand-alone controller, you may operate the CLS200 via the two-line 16character display and touch keypad. You can also use it as

the key element in a computer-supervised data acquisition

and control system; the CLS200 can be locally or remotely

controlled via an EIA/TIA-232 or EIA/TIA-485 serial communications interface.

The CLS200 features include:

•

Direct Connection of Mixed Thermocouple Sensors:

Connect most thermocouples to the controller

with no hardware modifications. Thermocouple inputs

feature reference junction compensation, linearization, process variable offset calibration to correct for

sensor inaccuracies, detection of broken, shorted or reversed thermocouples, and a choice of Fahrenheit or

Celsius display.

•

Accepts Resistive Temperature Detectors

(RTDs):

sensors with two choices for range and precision of

measurements. (To use this input, order a CLS204 or

CLS208 controller with scaling resistors.)

•

Automatic Scaling for Linear Analog Inputs:

CLS200 series automatically scales linear inputs used

with industrial process sensors. Enter two points, and

all input values are automatically scaled in your units.

Scaling resistors must be installed.

•

Dual Outputs:

and cool control outputs for each loop. Independent

control parameters are provided for each output.

•

Independently Selectable Control and Output

Modes:

proportioning, Serial DAC (digital-to-analog converter), or distributed zero crossing mode. Set up to two

outputs per loop for on/off, P, PI or PID control with reverse or direct action.

•

Control Outputs:

low process limits to operate digital outputs as on/off

control functions or alarms.

• Flexible Alarm Outputs: Independently set high/

low process alarms and a high/low deviation band

alarm for each loop. Alarms can activate a digital output by themselves, or they can be grouped with other

alarms to activate an output.

• Global Alarm Output: When any alarm is triggered,

the global alarm output is also triggered, and it stays

on until you acknowledge it.

Use 3-wire, 100 Ω, platinum, 0.00385-curve

The

The CLS200 series includes both heat

You can set each control output to on/off, time

Set high/low deviation and high/

Doc.# 0600-3050-2000 Watlow Anafaze 3

Page 20

Chapter 1: System Overview CLS200 Series User’s Guide

• CPU Watchdog: The CLS200 series CPU watchdog

timer output notifies you of system failure. Use it to

hold a relay closed while the controller is running, so

you are notified if the microprocessor shuts down.

• Front Panel or Computer Operation: Set up and

run the controller from the front panel or from a local

or remote computer. Watlow Anafaze offers WatView,

a Windows® compatible Human Machine Interface

(HMI) software package that includes data logging

and graphing features in addition to process monitoring and parameter setup screens.

• Modbus RTU Protocol, EIA/TIA-232 and 485

Communications: Connect to PLCs, operator interface terminals and third-party software packages using the widely supported Modbus RTU protocol.

• Multiple Job Storage: Store up to eight jobs in memory, and access them locally by entering a single job

number or remotely via digital inputs. Each job is a set

of operating conditions, including setpoints and

alarms.

• Nonlinear Output Curves: Select either of two nonlinear output curves for each control output.

• Autotuning: Use the autotune feature to set up your

system quickly and easily. The CLS200 internal expert system table finds the correct PID parameters for

your process.

• Pulse Counter Input: Use the pulse counter input

for precise control of motor or belt speed.

• Low Power Shutdown: The controller shuts down

and turns off all outputs when it detects the input voltage drop below the minimum safe operating level.

4 Watlow Anafaze Doc.# 0600-3050-2000

Page 21

CLS200 Series User’s Guide Chapter 1: System Overview

CLS200 Parts List

You may have received one or more of the following components. See Figure 2.1 on page 12 for CLS200 configuration

information.

• CLS200 series controller

• Controller mounting kit

• TB50 with 50-pin SCSI cable

• EIA/TIA-232 or EIA/TIA-485 communications cable

• Power supply with mounting bracket and screws

• Serial DAC (digital-to-analog converter)

• Special input resistors (installed in CLS200)

• User’s guide

2_ _–_ _ _ _ _ _

Number of Loops

04 = 4 loops

08 = 8 loops

16 = 16 loops

Controller Type

1 = Standard EPROM

2 = Extruder applications

3 = Ramp/soak option

4 = Enhanced features option (includes cascade, PV retransmit, ratio, remote setpoint)

Terminal Board

0 = No terminal board accessory

1 = 18-terminal block mounted on unit, no SCSI cable required

2 = 50-pin terminal board, includes 3 ft. SCSI cable

Power Supply

0 = No power supply

2 = 120/240V

(5V

SCSI Cables (for use with 50-pin terminal board)

0 = No special SCSI cable (3 ft. cable is included with 50-pin terminal board)

1 = 6 ft. SCSI cable

2 = 3 ft. right angle SCSI cable

3 = 6 ft. right angle SCSI cable )

Communications Cables (For EIA/TIA-232 communications with computer)

0 = No communications cable

1 = 10 ft. (3.0 m) communications cable, DB-9 female/bare wire

2 = 25 ft. (7.6 m) communications cable, DB-9 female/bare wire

3 = 50 ft. (15.2 m) communications cable, DB-9 female/bare wire

Serial Communications Jumper Settings

0 = EIA/TIA-232

1 = EIA/TIA-485

2 = EIA/TIA-485 terminated

Special Inputs (one or two digits)

(Standard unit is conf gured for thermocouples and -10 to 60mV linear inputs.

For other sensors, special inputs are required.

00 = Thermocouples and -10 to 60mV inputs only

XX = Number of current and voltage inputs. RTDs are not available on the CLS216. Include

leading zero as needed.

Å (ac), 50/60Hz panel mount power supply adapter

Î [dc] @ 4A, 15VÎ [dc] @ 1.2A) CE approved

___

Figure 1.1 CLS200 Part Numbering

Doc.# 0600-3050-2000 Watlow Anafaze 5

Page 22

Chapter 1: System Overview CLS200 Series User’s Guide

CLSSI _ _–_ _–_ _

If special inputs are ordered in the

controller part number, the following

is specified in the pa t description.

Special Input Type

20 = RTD1: 0.1°, -100.0 to 275.0° C (-148.0 to 572.0° F) (Not available on CLS216)

21 = RTD2: 1°, -120.0 to 840.0° C (-184.0 to 1544.0° F) (Not available on CLS216)

43 = 0 to 10 mA

44 = 0 to 20mA

50 = 0 to 100mV

52 = 0 to 500mV

53 = 0 to 1V

55 = 0 to 5V

56 = 0 to 10V

57 = 0 to 12V

Start Channel

XX = Channel number XX

End Channel

XX = Channel number XX

Note:

Make sure the number of special inputs specif ed is equal to

the number of special inputs in the controller part number.

Uninstalled kits are available.

Î (dc)

Î (dc)

Î (dc)

Î (dc)

(Not required for thermocouple sensor inputs)

Î (dc)

Î (dc)/4 to 20mAÎ (dc)

Î (dc)

Î (dc)

Figure 1.2 CLS200 Special Inputs Parts List

6 Watlow Anafaze Doc.# 0600-3050-2000

Page 23

CLS200 Series User’s Guide Chapter 1: System Overview

Technical Description

This section contains a technical description of each component of your CLS200 series controller.

CLS200

The CLS200 is housed in an 1/8-DIN panel mount package.

It contains the CPU, RAM with a built-in battery, EPROM,

serial communications, digital I/O, analog inputs, the

screen and touch keypad.

CLS200 Series

with SCSI Connector

CLS204 or CLS208

with TB18 Connector

Figure 1.3 CLS200 Rear Views

The CLS200 has the following features:

• Keypad and 2-line 16-character display.

• Screw terminals for the power and analog inputs and

communications.

• Input power is 12 to 24V

• A 50-pin SCSI cable connects the digital inputs and

outputs to the 50-terminal block (TB50). The CLS204

and CLS208 are available with an 18-terminal block

(TB18) in place of the SCSI connector, as shown in Fig-

ure 1.3.

The firmware resides in an EPROM. See Replacing the

EPROM on page 176 for information on removing and replacing the EPROM.

The operating parameters are stored in battery-backed

RAM. If there is a power loss the operating parameters are

unchanged. The battery has a ten-year shelf life, and it is

not used when the unit is on.

The microprocessor performs all calculations for input signal linearization, PID control, alarms and communications.

Î (dc) at 1 Amp.

Doc.# 0600-3050-2000 Watlow Anafaze 7

Page 24

Chapter 1: System Overview CLS200 Series User’s Guide

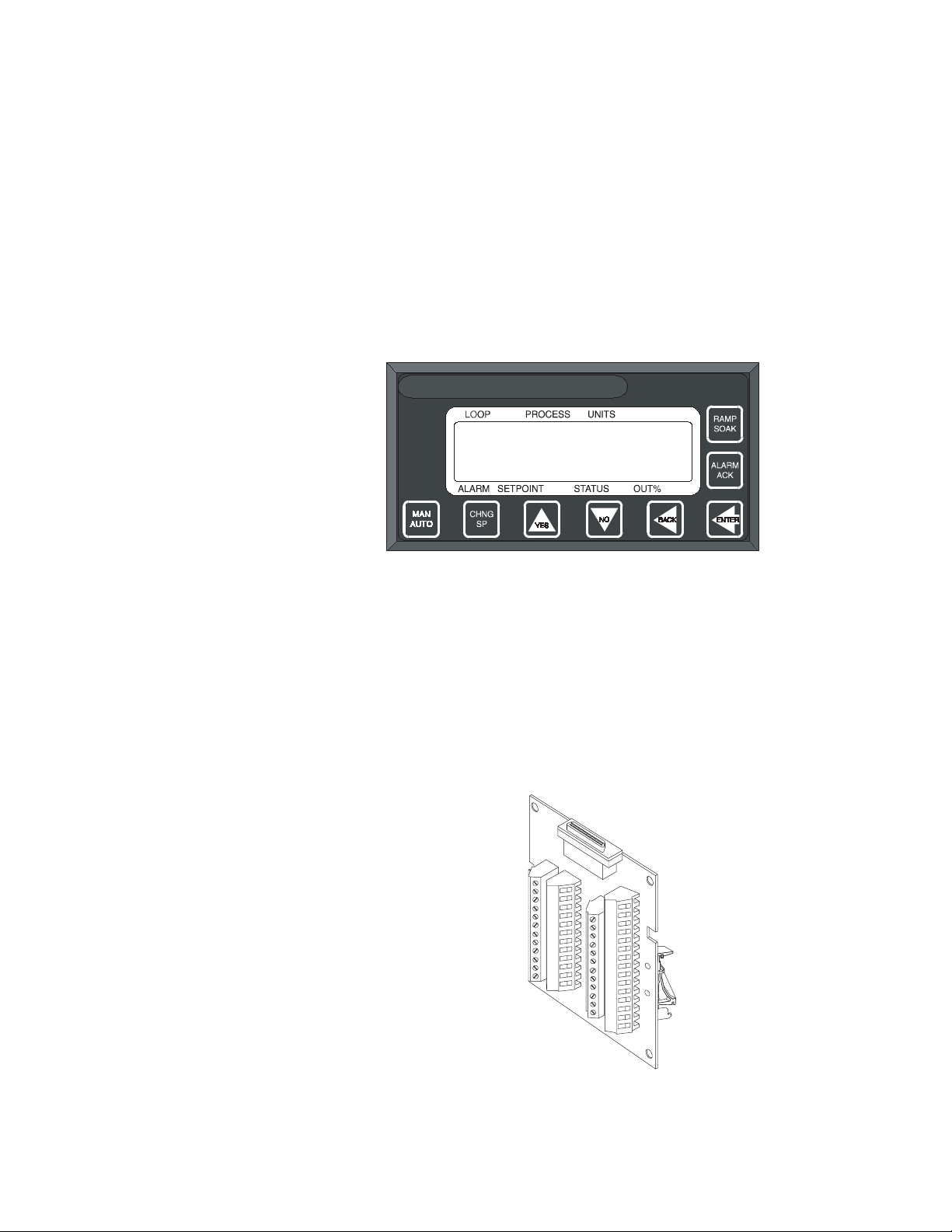

Front Panel Description

The display and touch keypad provide an intelligent way to

operate the controller. The display has 16 alphanumeric or

graphic characters per line. The 8-key keypad allows you to

change the operating parameters, controller functions, and

displays.

The information-packed displays show process variables,

setpoints, and output levels for each loop. A bar graph display, single loop display, scanning display and an alarm

display offer a real-time view of process conditions. Two access levels allow operator changes and supervisor changes.

WATLOW ANAFAZE CLS200

TB50

Figure 1.4 CLS200 Front Panel

The TB50 is a screw-terminal interface for control wiring

which allows you to connect relays, encoders and discrete I/

O devices to the CLS200. The screw terminal blocks accept

2

wires as large as 18 AWG (0.75 mm

connects the TB50 to the CLS200.

). A 50-pin SCSI cable

Figure 1.5 TB50

8 Watlow Anafaze Doc.# 0600-3050-2000

Page 25

CLS200 Series User’s Guide Chapter 1: System Overview

CLS200 Cabling

Watlow Anafaze provides cables required to install your

CLS200. A 50-pin SCSI cable connects the TB50 to the

CLS200.

The optional cable used to connect the CLS200 to a computer using EIA/TIA-232 communications has a DB9 or DB25

connector for the computer and bare wires for connecting to

the CLS200.

Safety

Watlow Anafaze has made every effort to ensure the reliability and safety of this product. In addition, we have provided recommendations that will allow you to safely install

and maintain this controller.

External Safety Devices

The CLS200 controller may fail full-on (100% output power) or full-off (0% output power), or may remain full-on if an

undetected sensor failure occurs. For more information

about failed sensor alarms, see Failed Sensor Alarms on

page 65.

Design your system to be safe even if the controller sends a

0% or 100% output power signal at any time. Install independent, external safety devices that will shut down the

system if a failure occurs.

Typically, a shutdown device consists of an FM-approved

high/low process limit controller that operates a shutdown

device such as an mechanical contactor. The limit controller monitors for a hazardous condition such as an undertemperature or over-temperature fault. If a hazardous condition is detected, the limit controller sends a signal to open

the contactor.

The safety shutdown device (limit controller and contactor)

must be independent from the process control equipment.

WARNING!

The controller may fail in a 0% or 100% power

output state. To prevent death, personal injury, equipment damage or property damage,

install external safety shutdown devices. If

must

death or injury may occur, you

install

FM-approved safety shutdown devices that

operate independently from the process control equipment.

With proper approval and installation, thermal fuses may

be used in some processes.

Doc.# 0600-3050-2000 Watlow Anafaze 9

Page 26

Chapter 1: System Overview CLS200 Series User’s Guide

Power-Fail Protection

In the occurrence of a sudden loss of power, this controller

can be programmed to reset the control outputs to off (this

is the default). Typically, when power is re-started, the controller restarts to data stored in memory. If you have programmed the controller to restart with control outputs on,

the memory-based restart might create an unsafe process

condition for some installations. Therefore, you should only

set the restart with outputs on if you are certain your system will safely restart. (See the Process Power Digital In-

put on page 79).

When using a computer or host device, you can program the

software to automatically reload desired operating constants or process values on power-up. Keep in mind that

these convenience features do not eliminate the need for independent safety devices.

Contact Watlow Anafaze immediately if you have any questions about system safety or system operation.

10 Watlow Anafaze Doc.# 0600-3050-2000

Page 27

2

Installation

This chapter describes how to install the CLS200 series

controller and its peripherals. Installation of the controller

involves the following procedures:

• Determining the best location for the controller

• Mounting the controller and TB50

• Power connection

• Input wiring

• Communications wiring (EIA/TIA-232 or EIA/TIA-

485)

• Output wiring

WARNING!

WARNING!

Doc.# 0600-3050-2000 Watlow Anafaze 11

Risk of electric shock. Shut off power to your

entire process before you begin installation

of the controller.

The controller may fail in a 0% or 100% power

output state. To prevent death, personal injury, equipment damage or property damage,

install external safety shutdown devices. If

failure may cause death or injury, you must

install FM-approved safety shutdown devices that operate independently from the process control equipment.

Page 28

Chapter 2: Installation CLS200 Series User’s Guide

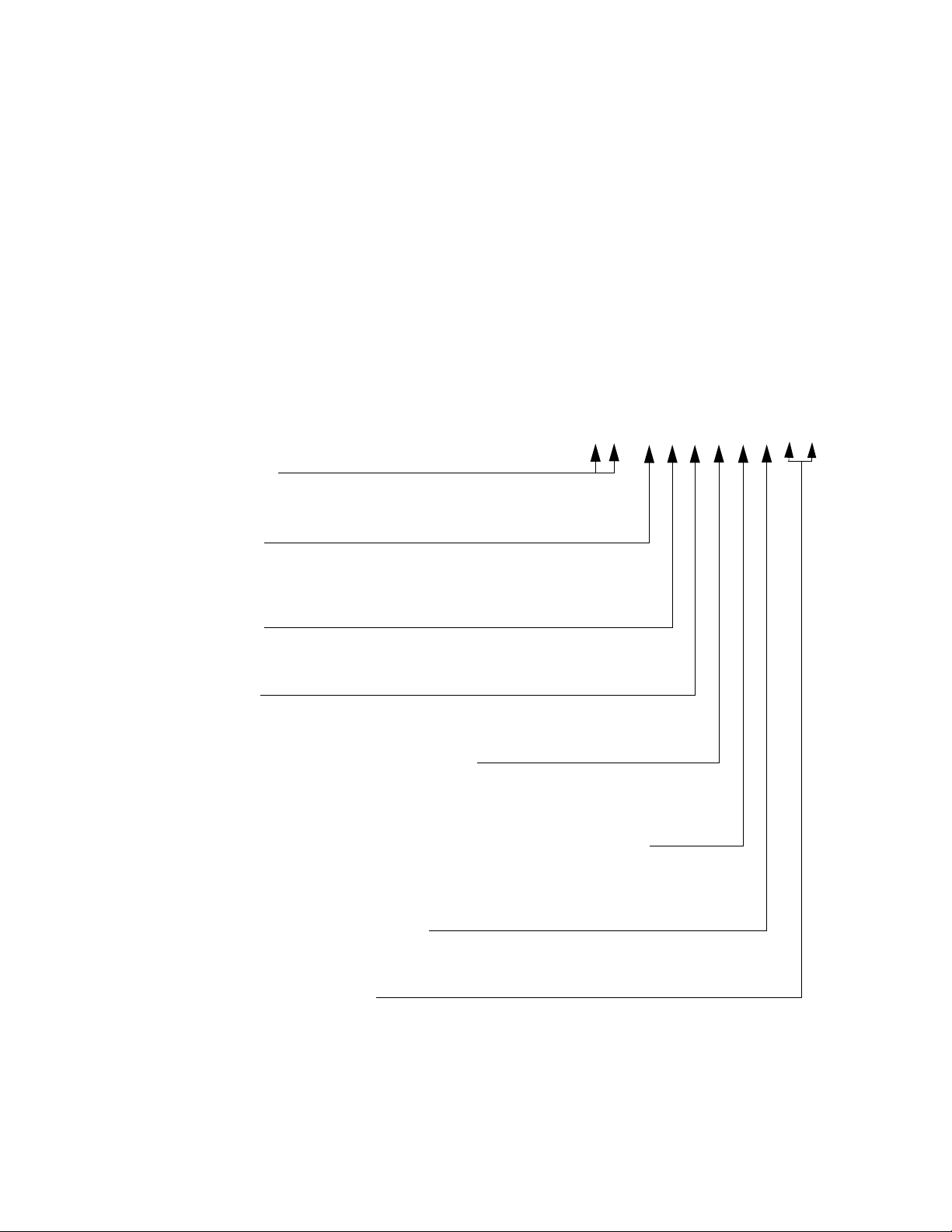

Typical Installation

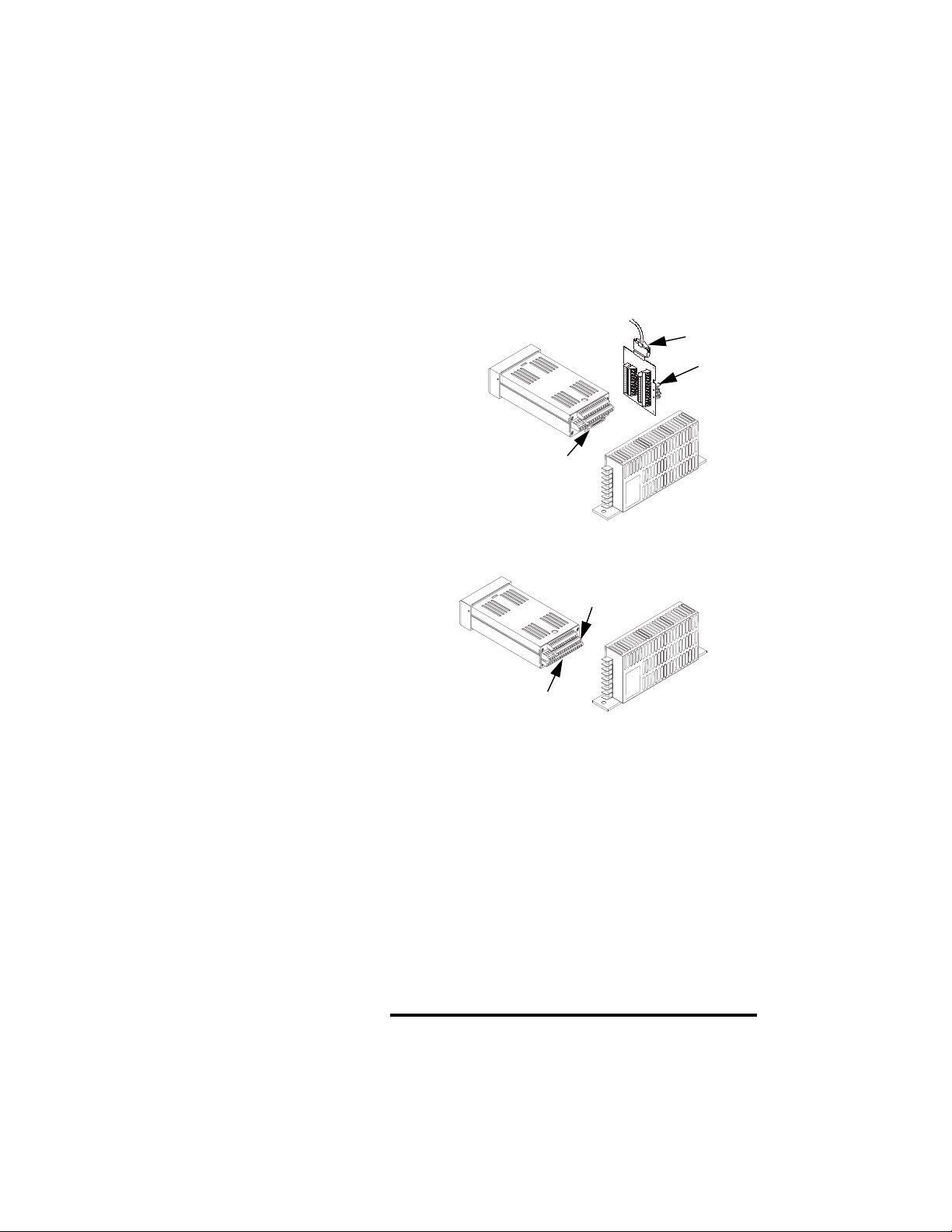

Figure 2.1 shows typical installations of the controller with

the TB50 and the TB18 terminal blocks. The type of terminal block you use greatly impacts the layout and wiring of

your installation site.

We recommend that you read this entire chapter first before beginning the installation procedure. This will help

you to carefully plan and assess the installation.

(See Figures 2.2 to 2.11.)

CLS200 with TB50

Signal Inputs

CLS200 with TB18

Signal Inputs

11 Digital Outputs (Control/Alarm)

2 Digital Inputs, 1 Digital/Pulse Input

SCSI Cable

CLS200

Power supply

CLS200

Power supply

Figure 2.1 CLS200 System Components

8 Digital Inputs,

35 Digital Outputs

(Control/Alarm)

Pulse Input

Mounting Controller Components

Install the controller in a location free from excessive heat

(more than 50º C [122° F]), dust, and unauthorized handling. Electromagnetic and radio frequency interference

can induce noise on sensor wiring. Select locations for the

CLS200 and TB50 such that wiring can be routed clear of

sources of interference such as high voltage wires, power

switching devices and motors.

NOTE!

12 Watlow Anafaze Doc.# 0600-3050-2000

For indoor use only.

Page 29

CLS200 Series User’s Guide Chapter 2: Installation

WARNING!

Recommended Tools

Mounting the Controller

To reduce the risk of fire or electric shock, install the CLS200 in a controlled environment,

relatively free of contaminants.

Use any of the following tools to cut a hole of the appropriate size in the panel.

• Jigsaw and metal file, for stainless steel and heavy-

weight panel doors.

• Greenlee 1/8-DIN rectangular punch (Greenlee part

number 600-68), for most panel materials and thicknesses.

• Nibbler and metal file, for aluminum and lightweight

panel doors.

You will also need these tools:

• Phillips head screwdriver

• 1/8 in. (3 mm) flathead screwdriver for wiring

• Multimeter

Mount the controller before you mount the terminal block

or do any wiring. The controller’s placement affects placement and wiring considerations for the other components

of your system.

Ensure there is enough clearance for mounting brackets,

terminal blocks, and cable and wire connections; the controller extends up to 7.0 inches (178 mm) behind the panel

face and the screw brackets extend 0.5 inch (13 mm) above

and below it. If using a straight SCSI cable, allow for an additional 1.6 inches (41 mm) beyond the terminal block. If

using a right-angle SCSI cable, allow an additional 0.6 inch

(15 mm). (See Figure 2.2 and Figure 2.3.)

Doc.# 0600-3050-2000 Watlow Anafaze 13

Page 30

Chapter 2: Installation CLS200 Series User’s Guide

1.0 inch 7.0 inches 1.6 inch

(25 mm) (178 mm) (41 mm)

Figure 2.2 Clearance with Straight SCSI Cable

1.0 inch 7.0 inches 0.6 inch

(25 mm) (178 mm) (41 mm)

Figure 2.3 Clearance with Right-Angle SCSI

Cable

14 Watlow Anafaze Doc.# 0600-3050-2000

Page 31

CLS200 Series User’s Guide Chapter 2: Installation

Maximum Panel Thickness

0.2 inch (5 mm)

1.80 ± 0.020 inch

(45.7 ± 0.5 mm)

3.63 ± 0.020 inches

(92.2 ± 0.5 mm)

Figure 2.4 Wiring Clearances

We recommend you mount the controller in a panel not

more than 0.2 in. (5 mm) thick.

1. Choose a panel location free from excessive heat (more

than 50° C [122° F]), dust, and unauthorized handling.

(Make sure there is adequate clearance for the mounting hardware, terminal blocks, and cables. The controller extends 7.40 in. (178 mm) behind the panel.

Allow for an additional 0.60 to 1.60 in. (15 to 41 mm)

beyond the connectors.)

2. Temporarily cover any slots in the metal housing so

that dirt, metal filings, and pieces of wire do not enter

the housing and lodge in the electronics.

3. Cut a hole in the panel 1.80 in. (46 mm) by 3.63 in. (92

mm) as shown below. (This picture is NOT a template;

it is for illustration only.) Use caution; the dimensions

given here have 0.02 in. (1 mm) tolerances.

4. Remove the brackets and collar from the processor

module, if they are already in place.

5. Slide the processor module into the panel cutout.

6. Slide the mounting collar over the back of the proces-

sor module, making sure the mounting screw indentations face toward the back of the processor module.

Doc.# 0600-3050-2000 Watlow Anafaze 15

Page 32

Chapter 2: Installation CLS200 Series User’s Guide

Bracket (top and bottom)

25

23

21

19

17

15

13

11

9

7

5

3

1

+

26

24

22

20

18

16

14

12

10

8

6

4

2

Bezel

Panel

Mounting Collar

Figure 2.5 Mounting Bracket

7. Loosen the mounting bracket screws enough to allow

for the mounting collar and panel thickness. Place

each mounting bracket into the mounting slots (head

of the screw facing the back of the processor module).

Push each bracket backward then to the side to secure

it to the processor module case.

8. Make sure the case is seated properly. Tighten the installation screws firmly against the mounting collar to

secure the unit. Ensure that the end of the mounting

screws fit into the indentations on the mounting collar.

Mounting the TB50

There are two ways you can mount the TB50: Use the preinstalled DIN rail mounting brackets or use the plastic

standoffs. Follow the corresponding procedures to mount

the board.

TB50

Mounted

with Standoffs

TB50

Mounted to

DIN Rail

Figure 2.6 Mounting the TB50

16 Watlow Anafaze Doc.# 0600-3050-2000

Page 33

CLS200 Series User’s Guide Chapter 2: Installation

DIN Rail Mounting

Snap the TB50 on to the DIN rail by placing the hook side

on the rail first, then pushing the snap latch side in place.

(See Figure 2.7.)

Figure 2.7 TB50 Mounted on a DIN Rail (Front)

To remove the TB50 from the rail, use a flathead screwdriver to unsnap the bracket from the rail. (See Figure 2.8.)

Removal

catch for

screwdriver

DIN Rail

snap latch

Hook side

Figure 2.8 TB50 Mounted on DIN Rail (Side)

Doc.# 0600-3050-2000 Watlow Anafaze 17

Page 34

Chapter 2: Installation CLS200 Series User’s Guide

Mounting with Standoffs

1. Remove the DIN rail mounting brackets from the

TB50.

2. Select a location with enough clearance to remove the

TB50, its SCSI cable and the controller itself.

3. Mark the four mounting holes.

4. Drill and tap four mounting holes for #6 (3.5 mm)

screws or bolts.

5. Mount the TB50 with four screws.

There are four smaller holes on the terminal board. Use

these holes to secure wiring to the terminal block with tie

wraps.

0.7 in

0.2 in

(5 mm)

2.6 in

(66 mm)

(18 mm)

Figure 2.9 Mounting a TB50 with Standoffs

Mounting the Power Supply

If you use your own power supply for the CLS200, refer to

the power supply manufacturer’s instructions for mounting

information. Choose a Class 2 power supply that supplies

an isolated regulated 12 to 24V

3.4 in

(86 mm)

0.2 in

(5 mm)

4 holes for

#6 (3.5 mm)

screws or bolts

SCSI Connector

0.2 in

(5 mm)

3.6 in

(91 mm)

Î (dc) at 1 A.

18 Watlow Anafaze Doc.# 0600-3050-2000

Page 35

CLS200 Series User’s Guide Chapter 2: Installation

Mounting Environment

Leave enough clearance around the power supply so that it

can be removed.

Two holes for #10 (5.0 mm) screws or bolts

1.4 inch

(36 mm)

Mounting Steps

7.5 inches

(191 mm)

CAUTION!

0.3 inch

(8 mm)

0.7 inch

8.1 inches

(206 mm)

(18 mm)

Figure 2.10 CLS200 Power Supply Mounting

Bracket

Use 6-32, 1/4-inch screws only. Longer

screws may extend too far into the power

supply and short to components, damaging

the power supply.

1. Attach the bracket to the power supply using the

bracket’s two center holes.

2. Select a location with enough clearance to remove the

power supply and bracket. (See Figure 2.10.)

3. When a location has been determined for the power

supply, mark the bracket’s two outer holes for mounting.

4. Drill and tap the two mounting holes. (The bracket

holes accept up to #10 [5.0 mm] screws.)

5. Mount the power supply on the panel.

6. Tighten the screws.

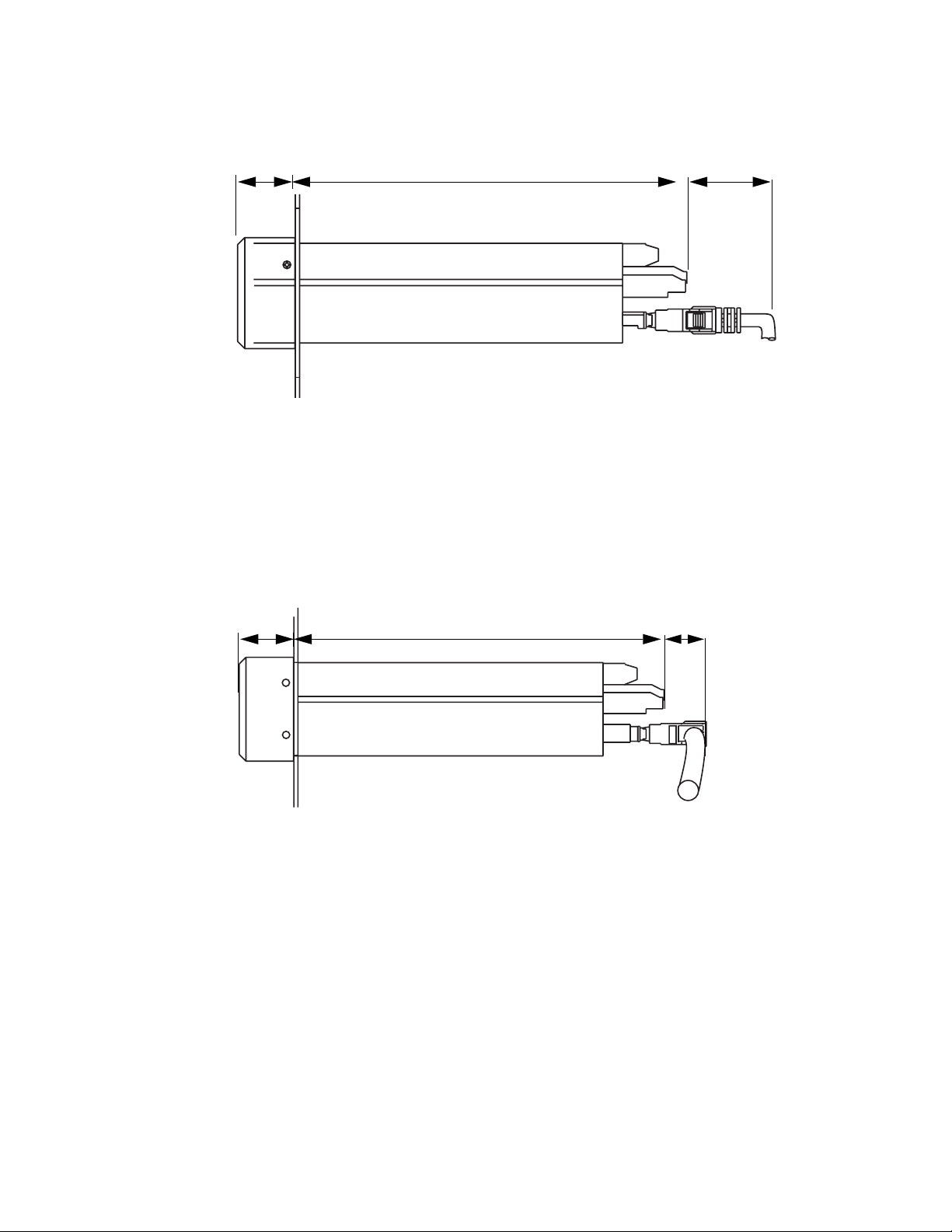

Mounting the Dual DAC or Serial DAC Module

This section describes how to install the optional Dual DAC

and Serial DAC digital-to-analog converters.

Doc.# 0600-3050-2000 Watlow Anafaze 19

Page 36

Chapter 2: Installation CLS200 Series User’s Guide

Installation

Installation of the Dual DAC and Serial DAC is essentially

the same. The main differences are in the dimensions and

the wiring. Follow this procedure to correctly install these

devices.

Jumpers

The output signal range of the Dual DAC and Serial DAC

modules is configured with jumpers. See

Configuring Dual

DAC Outputs on page 186 and Configuring Serial DAC

Outputs on page 188 for information on setting these jump-

ers.

Mounting

1. Select a location. The unit is designed for wall mounting. Install it as close to the controller as possible.

2. Mark and drill four holes for screw mounting. Holes

accommodate #8 (4.0 mm) size screws. See Figure 2.11

for screw locations. Install the unit with the four

screws.

3.62 in

(91 mm)

Electrical

connections

Dual DAC

4 holes for #8 (4.0 mm)

screws or bolts

Electrical

connections

3.7 in

(94 mm)

4.40 in

(112 mm)

0.3 in

(8 mm)

3.00 in

(76 mm)

(17 mm)

1.75 in

(44 mm)

0.37 in

(9 mm)

0.65 in

3.62 in

(91 mm)

Electrical

connections

Serial DAC

4 holes for #8 (4.0 mm)

screws or bolts

Electrical

connections

4.7 in

(119 mm)

5.40 in

(137 mm)

0.3 in

(8 mm)

3.00 in

(76 mm)

0.37 in

(9 mm)

0.65 in

(17 mm)

1.75 in

(44 mm)

Figure 2.11 Dual DAC and Serial DAC

Dimensions

20 Watlow Anafaze Doc.# 0600-3050-2000

Page 37

CLS200 Series User’s Guide Chapter 2: Installation

System Wiring

Successful installation and operation of the control system

can depend on placement of the components and on selection of the proper cables, sensors, and peripheral components.

Routing and shielding of sensor wires and proper grounding of components can insure a robust control system. This

section includes wiring recommendations, instructions for

proper grounding and noise suppression, and considerations for avoiding ground loops.

WARNING!

CAUTION!

Wiring Recommendations

To reduce the risk of electrical shock, fire,

and equipment damage, follow all local and

national electrical codes. Correct wire sizes,

fuses and thermal breakers are essential for

safe operation of this equipment.

Do not wire bundles of low-voltage signal

and control circuits next to bundles of highvoltage ac wiring. High voltage may be inductively coupled onto the low-voltage circuits,

which may damage the controller or induce

noise and cause poor control.

Physically separate high-voltage circuits

from low-voltage circuits and from CLS200

hardware. If possible, install high-voltage ac

power circuits in a separate panel.

Follow these guidelines for selecting wires and cables:

• Use stranded wire. (Solid wire can be used for fixed

service; it makes intermittent connections when you

move it for maintenance.)

• Use 20 AWG (0.5 mm2) thermocouple extension wire.

Larger or smaller sizes may be difficult to install, may

break easily, or may cause intermittent connections.

• Use shielded wire. The electrical shield protects the

signals and the CLS200 from electrical noise. Connect

one end of the input and output wiring shield to earth

ground.

• Use copper wire for all connections other than thermocouple sensor inputs.

Doc.# 0600-3050-2000 Watlow Anafaze 21

Page 38

Chapter 2: Installation CLS200 Series User’s Guide

Table 2.1 Cable Recommendations

Function Mfr. P/N

Analog Inputs

RTD Inputs

Thermocouple Inputs T/C Ext. Wire 2 20 0.5

Control Outputs and

Digital I/O

Analog Outputs

Computer Communication: EIA/TIA-232, 422

or 485, or 20 mA

Belden 9154

Belden 8451

Belden 8772

Belden 9770

Belden 9539

Belden 9542

Ribbon Cable

Belden 9154

Belden 8451

Belden 9729

Belden 9730

Belden 9842

Belden 9843

Belden 9184

No. of

Wires

2

2

3

3

9

20

50

2

2

4

6

4

6

4

AWG

20

22

20

22

24

24

22 to 14

20

22

24

24

24

24

22

mm

0.5

0.5

0.5

0.5

0.2

0.2

0.5 to 2.5

0.5

0.5

0.2

0.2

0.2

0.2

0.5

2

4,000 ft. (1,219 m)

4,000 ft. (1,219 m)

6,000 ft. (1,829 m)

Maximum

Length

Noise Suppression

Symptoms of RFI/EMI

The CLS200’s outputs are typically used to drive solid state

relays. These relays may in turn operate more inductive

types of loads such as electromechanical relays, alarm

horns and motor starters. Such devices may generate electromagnetic interference (EMI or noise). If the controller is

placed close to sources of EMI, it may not function correctly. Below are some tips on how to recognize and avoid problems with EMI.

For earth ground wire, use a large gauge and keep the

length as short as possible. Additional shielding may be

achieved by connecting a chassis ground strap from the

panel to CLS200 case.

If your controller displays the following symptoms, suspect

EMI:

• The controller’s display blanks out and then reenergizes as if power had been turned off for a moment.

• The process variable does not display correctly.

EMI may also damage the digital output circuit—so digital

outputs will not turn on. If the digital output circuit is damaged, return the controller to Watlow Anafaze for repair.

22 Watlow Anafaze Doc.# 0600-3050-2000

Page 39

CLS200 Series User’s Guide Chapter 2: Installation

Avoiding RFI/EMI

• To avoid or eliminate most RFI/EMI noise problems:

• Connect the CLS200 case to earth ground. The

CLS200 system includes noise suppression circuitry.

This circuitry requires proper grounding.

• Separate the 120 or 240V

low-level input and output leads connected to the

CLS200 series controller. Do not run the digital I/O or

control output leads in bundles with ac wires.

• Where possible, use solid-state relays (SSRs) instead

of electromechanical relays. If you must use electromechanical relays, try to avoid mounting them in the

same panel as the CLS200 series equipment.

• If you must use electromechanical relays and you

must place them in a panel with CLS200 series equipment, use a 0.01 microfarad capacitor rated at

1000VÅ (ac) (or higher) in series with a 47 Ω, 0.5 watt

resistor across the N.O. contacts of the relay load. This

is known as a snubber network and can reduce the

amount of electrical noise.

• You can use other voltage suppression devices, but

they are not usually required. For instance, you can

place a metal oxide varistor (MOV) rated at 130VÅ for

120VÅ (ac) control circuits across the load, which limits the peak ac voltage to about 180VÅ (ac) (Watlow

Anafaze part number 26-130210-00). You can also

place a transorb (back-to-back zener diodes) across the

digital output, which limits the digital output voltage.

Å (ac) power leads from the

Additional Recommendations for a Noise Immune System

It is strongly recommended that you:

• Isolate outputs through solid-state relays, where possible.

• Isolate RTDs or “bridge” type inputs from ground.

• Isolate digital inputs from ground through solid state

relays. If this is not possible, then make sure the digital input is the only connection to earth ground other

than the chassis ground.

• If you are using EIA/TIA-232 from a non-isolated host,

either (1) do not connect any other power common

point to earth ground, or (2) use an optical isolator in

the communications line.

Doc.# 0600-3050-2000 Watlow Anafaze 23

Page 40

Chapter 2: Installation CLS200 Series User’s Guide

Ground Loops

Ground loops occur when current passes from the process

through the controller to ground. This can cause instrument errors or malfunctions.

A ground loop may follow one of these paths, among others:

• From one sensor to another.

• From a sensor to the communications port.

• From a sensor to the dc power supply.

The best way to avoid ground loops is to minimize unneces-

sary connections to ground. Do not connect any of the following terminals to each other or to earth ground:

• Power supply dc common

• TB1, terminals 5, 6, 11, 12 (analog common)

• TB1, terminal 17 (reference voltage common)

• TB1, terminals 23, 24 (communications common)

• TB2, terminal 2 (dc power common)

Special Precautions for the CLS216

The CLS216 has single-ended inputs. All the negative sensor leads are tied to the analog common. That means there

is no sensor-to-sensor isolation. Proper grounding is critical

for this unit. Take these additional precautions with a

CLS216:

• Use all ungrounded or all well-grounded thermocouples, not a mix.

• If using a mixture of thermocouples or low-voltage inputs (<500 mV) and current inputs, connect the negative leads of the current transmitters to terminal 17

(Ref Com) on TB1.

• If using voltage transmitters, use only sourcing models or configuration. Sinking configurations will not

work.

• Isolate the controller’s communication port (if used) by

using an optically isolated 232-to-485 converter.

Personal Computers and Ground Loops

Many PC communications ports connect the communications common to chassis ground. When such a PC is connected to the controller, this can provide a path to ground

for current from the process that can enter the controller

through a sensor (such as a thermocouple). This creates a

ground loop that can affect communications and other controller functions. To eliminate a ground loop, either use an

optically isolated communications adapter or take measures to ensure that sensors and all other connections to

the controller are isolated and not conducting current into

the unit.

24 Watlow Anafaze Doc.# 0600-3050-2000

Page 41

CLS200 Series User’s Guide Chapter 2: Installation

Power Connections

This section covers making the power connections to the

CLS200 and connecting the TB50.

TB1

(to signal

TB2

(to power

supply)

Figure 2.12 CLS200 Series Controller with

TB18

inputs

TB18

(to digital

outputs)

TB2

(to power

supply)

Wiring the Power Supply

WARNING!

TB1

(to signal

inputs

SCSI-2

(to TB50)

Figure 2.13 CLS200 Series Controller with

TB50

Use a power supply with a Class 2 rating

only. UL approval requires a Class 2 power

supply.

Connect power to the controller before any other connections, This allows you to ensure that the controller is working before any time is taken installing inputs and outputs.

Doc.# 0600-3050-2000 Watlow Anafaze 25

Page 42

Chapter 2: Installation CLS200 Series User’s Guide

Table 2.2 Power Connections

Function Power Supply CLS200 TB2

NOTE!

DC Power

(Controller)

DC Common

Earth Ground Ground

1. Connect the dc common terminal on the power supply

to the dc common (-) terminal on CLS200 TB2.

2. Connect the positive terminal on the power supply to

the dc positive (+) terminal on CLS200 TB2.

3. If using an isolated dc output or another power supply

to power the loads, connect the dc common of the supply powering the loads to the dc common of the supply

powering the controller.

4. Use the ground connector on TB2 for chassis ground.

This terminal is connected to the CLS200 chassis and

must be connected to earth ground.

5. Connect 120/240V

+12 to 24V

12 to 24VÎ (dc)

Å (ac) power to the power supply.

Î (dc)

Common

+

-

Connect the dc common of the power supply

used for loads to the dc common of the supply powering the controller. If the supplies

are not referenced to one another, the controller’s outputs will not be able to switch the

loads.

NOTE!

When making screw terminal connections,

tighten to 4.5 to 5.4 inch-pound (0.5 to 0.6

Nm).

CAUTION!

Without proper grounding, the CLS200 may

not operate properly or may be damaged.

26 Watlow Anafaze Doc.# 0600-3050-2000

Page 43

CLS200 Series User’s Guide Chapter 2: Installation

CAUTION!

NOTE!

To prevent damage from incorrect connections, do not turn on the ac power before testing the connections as explained in Testing

Your System on page 28.

Do not connect the controller’s dc common

(COM) to earth ground . Doing so will de-

feat the noise protection circuitry, making

measurements less stable.

Power Supply

+V1 (5V)

0 (5V COM)

+V2 (+15V)

COM (15V COM)

-V2 (-15V)

Add jumper *

SSR

SSR

G

C

N

OMV

D

+

CLS200

**

SSR

SSR

ACN (AC Neutral)

120/240

Vı (ac)

Supply

* If using 5VÎ (dc) for outputs, jumper 5V common to 15V common.

** Connect terminals to ac panel ground.

Connecting TB50 to CLS200

(Ground)

ACL (AC Line)

white

N

black

H

green

G

**

1 2 3 4

+

5

Serial DAC

C

O

M

Figure 2.14 Power Connections with the

CLS200 Power Supply

1. Connect the SCSI cable to the controller.

2. Connect the SCSI cable to the TB50.

Doc.# 0600-3050-2000 Watlow Anafaze 27

Page 44

Chapter 2: Installation CLS200 Series User’s Guide

Testing Your System

This section explains how to test the controller after installation and prior to making field wiring connections.

TB50 or TB18 Test

Use this procedure to verify that the TB50 or TB18 is properly connected and supplied with power:

1. Turn on power to the CLS200. The display should read

CALCULATING CHECKSUM then show the bar graph

display. (See Figure 3.3.) If you do not see these dis-

plays, disconnect power and check wiring and power

supply output.

Digital Output Test

2. Measure the +5V

a) Connect the voltmeter’s common lead to TB50 or

TB18 terminal 3 or TB18 terminal 2.

b) Connect the voltmeter’s positive lead to TB50 or

TB18 screw terminal 1. The voltage should be

+4.75 to +5.25VÎ (dc).

Use this procedure to test the controller’s outputs before

loads are connected. If using it at another time for troubleshooting, disconnect loads from outputs before testing.

1. Connect a 500 Ω to 100 kΩ resistor between TB50 or

TB18 screw terminal 1 and a digital output terminal.

(See Table 2.5, TB18 Connections on page 40; Table

2.6, TB50 Connections for CLS204 and CLS208 on

page 41; or Table 2.7, TB50 Connections for CLS216 on

page 42.)

2. Connect the voltmeter’s positive lead to screw terminal 1.

3. Connect the common lead to the digital output terminal.

4. Use the digital output test in the MANUAL I/O TEST

menu to turn the digital output on and off.

Digital Output on page 104 and Digital Output Number on page 104.) When the output is ON, the output

voltage should be less than 1V. When the output is

OFF, the output voltage should be between 4.75 and

5.25V.

Î (dc) supply at the TB50 or TB18:

(See Test

NOTE!

By default, heat outputs are enabled. Only

disabled outputs may be turned on using the

manual I/O test. To test heat outputs, set the

corresponding loop to manual mode 100%

output. See Selecting the Control Status on

page 61.

28 Watlow Anafaze Doc.# 0600-3050-2000

Page 45

CLS200 Series User’s Guide Chapter 2: Installation

Digital Input Test

Use the following procedure to test digital inputs before

connecting to field devices:

1. Disconnect any system wiring from the input to be

tested.

2. Go to the DIGITAL INPUTS test in the MANUAL I/O

TEST menu. (See Digital Inputs on page 103.) This test

shows whether the digital inputs are H (high, or open)

or L (low, or closed).

3. Attach a wire to the terminal of the digital input you

want to test. See tables 2.5 to 2.7 on pages 40 to 42 for

connections.

a) When the wire is connected only to the digital in-

put terminal, the digital input test should show

that the input is H (high, or open).

b) When you connect the other end of the wire to the

controller common (TB50 terminal 3 or TB18 terminal 2), the digital input test should show that

the input is L (low, or closed).

Sensor Wiring

CAUTION!

This section describes how to properly connect thermocouples, RTDs, current and voltage inputs to your controller.

The controller can accept any mix of available input types.

Some input types require that special scaling resistors be

installed (generally done by Watlow Anafaze before the

controller is delivered).

All inputs are installed at the CH input connectors (TB1) at

the back of the controller. The illustrations below show the

connector locations for all the CLS200 series controllers.

Never run input leads in bundles with high

power wires or near other sources of EMI.

This could inductively couple voltage onto

the input leads and damage the controller, or

could induce noise and cause poor measurement and control.

Doc.# 0600-3050-2000 Watlow Anafaze 29

Page 46

Chapter 2: Installation CLS200 Series User’s Guide

Figure 2.15 CLS200 Connector Locations

Input Wiring Recommendations

Use multicolored stranded shielded cable for analog inputs.

Watlow Anafaze recommends that you use 20 AWG wire

(0.5 mm

also use 24 or 22 AWG wiring (0.2 mm

shielded twisted pair; some require a 3-wire input.

Follow the instructions pertaining to the type(s) of input(s)

you are installing.

The controller accepts the following inputs without any

special scaling resistors:

• J, K, T, S, R, B and E thermocouples.

• Linear inputs with ranges between -10 and 60 mV.

Any unused inputs should be set to SKIP or jumpered to

avoid thermocouple break alarms.

2

). If the sensor manufacturer requires it, you can

2

). Most inputs use a

30 Watlow Anafaze Doc.# 0600-3050-2000

Page 47

CLS200 Series User’s Guide Chapter 2: Installation

Thermocouple Connections

Connect the positive lead of any of the supported thermocouple types to the IN+ terminal for one of the loops and the

negative lead to the corresponding IN- terminal.

2

Use 18 or 20 AWG (0.5 or 0.75 mm

ple inputs. Most thermocouple wire is solid, unshielded

wire. When using shielded wire, ground one end only.

) for all the thermocou-

NOTE!

CH IN+

*CH IN-

*For CLS216 use Com

White

Red

Shield (if present)

Earth Ground

at Process End

Type J

thermocouple

Figure 2.16 Thermocouple Connections

When mixing current inputs with low-voltage

inputs (thermocouples or voltage inputs <1V)

to a CLS216, connect the current signal to the

IN+ and Ref Com terminals. If no low-voltage

sensors are used, connect current inputs to

the IN+ and Com terminals on TB1. For all inputs to a CLS204 or CLS208, connect the

sensors to the IN+ and Com terminals.

CAUTION!

Ground loops and common mode noise can

damage the controller or disrupt measurements. To minimize ground loops and common mode noise:

• With a CLS216, use only ungrounded ther-

mocouples with each thermocouple sheath

electrically connected to earth ground. The

negative sensor terminals on the CLS216 are

tied to analog common.

• With a CLS204 or CLS208, do not mix

grounded and ungrounded thermocouples. If

any thermocouple connected to the controller is of grounded construction, all thermocouples should be of grounded construction

Doc.# 0600-3050-2000 Watlow Anafaze 31

Page 48

Chapter 2: Installation CLS200 Series User’s Guide

and each should be connected to ground at

the process end.

• Connect the earth ground terminal on TB2

to a good earth ground, but do not connect

the analog common to earth ground. The

CLS200 uses a floating analog common for

sensor measurements. The noise protection

circuits on the sensor inputs function correctly only when the controller is correctly installed. See Ground Loops on page 24.

RTD Input Connections

This input type requires scaling resistors. Watlow Anafaze

recommends that you use a 100 Ω, 3-wire platinum RTD to

prevent reading errors due to cable resistance. If you use a

2-wire RTD, jumper the negative input to common. If you

must use a 4-wire RTD, leave the fourth wire unconnected.

Figure 2.17 RTD Connections to CLS204 or

Reference Voltage Terminals

The +5V Ref and Ref Com terminals are provided in order

to power external bridge circuits for special sensors. Do not

connect any other types of devices to these terminals.

Voltage Input Connections

This input type requires scaling resistors. Special input resistors installed at Watlow Anafaze divide analog input

voltages such that the controller sees a -10 to 60 mV signal

on the loop.

CH

CH

IN +

100 Ω RTD

IN -

Com

CLS208

32 Watlow Anafaze Doc.# 0600-3050-2000

Page 49

CLS200 Series User’s Guide Chapter 2: Installation

CLS204 and CLS208

Current Input Connections

CH IN+

CH IN-

CLS216

CH IN+

Com

Device with

Voltage

Output

Device with

Voltage

Output

Figure 2.18 Linear Voltage Signal Connections

This input type requires scaling resistors. Special input resistors installed at Watlow Anafaze for analog current signals are such that the controller sees a -10 to 60 mV signal

across its inputs for the loop.

CLS204 and CLS208

CH IN+

CH IN-

Device with

Current

Output

CLS216

CH IN+

Com/Ref Com

Device with

Current

Output

Figure 2.19 Linear Current Signal Connections

NOTE!

Doc.# 0600-3050-2000 Watlow Anafaze 33

When mixing current inputs with low-voltage

inputs (thermocouples or voltage inputs <1V)

to a CLS216, connect the current signal to the

IN+ and Ref Com terminals. When no lowvoltage sensors are used, connect current inputs to the IN+ and Com terminals on TB1.

For all inputs to a CLS204 or CLS208, connect the sensors to the IN+ and Com terminals.

Page 50

Chapter 2: Installation CLS200 Series User’s Guide

Pulse Input Connections

The CLS200 can accept a pulse input of up to 2000 Hz from

a device such as an encoder. The frequency of this input is

scaled with user-set parameters. See Setup Loop Input

Menu on page 82 and Chapter 9, Linear Scaling Examples.

This scaled value is the process variable for loop 5 on a

CLS204, loop 9 on a CLS208, or loop 17 on a CLS216.

The CLS200 can accommodate encoder signals up to 24V

(dc) using a voltage divider or can power encoders with the

5VÎ (dc) from the TB50 or TB18. The following figures illustrate connecting encoders. A pull-up resistor in the

CLS200 allows open collector inputs to be used.

Î

NOTE!

If the signal on the pulse input exceeds

10kHz the controller’s operation may be disrupted. Do not connect the pulse input to a

signal source that may exceed 10kHz.

CLS200 and TB50 or TB18

+5VÎ (dc)

10 kΩ

Figure 2.20 Encoder with 5V

CLS200 and TB50 or TB18

+5VÎ (dc)

10 kΩ

Pulse Input

Com

Pulse Input

Com

R2

Encoder

ÎÎ

ÎÎ

(dc) TTL Signal

R1

Encoder

Figure 2.21 Encoder Input with Voltage Divider

For encoders with signals greater than 5VÎ (dc), use a voltage divider to drop the voltage to 5 volts at the input. Use

appropriate values for R

excitation voltage. Be sure not to exceed the specific current load on the encoder.

34 Watlow Anafaze Doc.# 0600-3050-2000

and R2 depending on the encoder

1

Page 51

CLS200 Series User’s Guide Chapter 2: Installation

Wiring Control and Digital I/O

This section describes how to wire and configure the control

outputs for the CLS200 series controller.

NOTE!

Control outputs are connected to the

CLS200’s common when the control output

is on (low). Be careful when you connect external devices that may have a low side at a

voltage other than controller ground, since

you may create ground loops.

If you expect grounding problems, use isolated solid state relays and isolate the control

device inputs.

The CLS200 provides dual PID control outputs for each

loop. These outputs can be enabled or disabled, and are

connected via TB50 or TB18.

Output Wiring Recommendations

When wiring output devices, use multicolored, stranded,

shielded cable for analog outputs and digital outputs connected to panel-mounted solid state relays.

• Analog outputs usually use a twisted pair.

• Digital outputs usually have 9 to 20 conductors, depending on wiring technique.

Cable Tie Wraps

Once you have wired outputs to the TB50, install the cable

tie wraps to reduce strain on the connectors.

Each row of terminals has a cable tie wrap hole at one end.

Thread the cable tie wrap through the cable tie wrap hole.

Then wrap the cable tie wrap around the wires attached to

that terminal block.

Digital Outputs

The CLS200 series provides dual control outputs for up to

16 loops. The controller’s default configuration has all heat

outputs enabled and all cool outputs disabled. Disabling a

heat output makes that output available to be used as a

control or an alarm output. See Enable or Disable Heat or

Cool Outputs on page 94. The CPU watchdog timer output

can be used to monitor the state of the controller with an

external circuit or device. See CPU Watchdog Timer on

page 38.

Doc.# 0600-3050-2000 Watlow Anafaze 35

Page 52

Chapter 2: Installation CLS200 Series User’s Guide

Table 2.3 Digital Output States and Values

Stored in the Controller

State Value Description

Off High Open circuit