Watlow CLS200 User Manual

CLS200 Series

User’s Guide

Watlow

1241 Bundy Boulevard

Winona, MN 55987

Customer Service:

Phone........ |

1-800-414-4299 |

Fax............. |

1-800-445-8992 |

Technical Support: |

|

Phone........ |

+1 (507) 494-5656 |

Fax ............ |

+1 (507) 452-4507 |

Email ......... |

wintechsupport@watlow.com |

Part No. 0600-3050-2000 Rev. A

November 2008

Copyright © 1998-2003, Watlow Anafaze

Information in this manual is subject to change without notice. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form without written permission from Watlow Anafaze.

Warranty

Watlow Anafaze, Incorporated warrants that the products furnished under this Agreement will be free from defects in material and workmanship for a period of three years from the date of shipment. The Customer shall provide notice of any defect to Watlow Anafaze, Incorporated within one week after the Customer's discovery of such defect. The sole obligation and liability of Watlow Anafaze, Incorporated under this warranty shall be to repair or replace, at its option and without cost to the Customer, the defective product or part.

Upon request by Watlow Anafaze, Incorporated, the product or part claimed to be defective shall immediately be returned at the Customer's expense to Watlow Anafaze, Incorporated. Replaced or repaired products or parts will be shipped to the Customer at the expense of Watlow Anafaze, Incorporated.

There shall be no warranty or liability for any products or parts that have been subject to misuse, accident, negligence, failure of electric power or modification by the Customer without the written approval of Watlow Anafaze, Incorporated. Final determination of warranty eligibility shall be made by Watlow Anafaze, Incorporated. If a warranty claim is considered invalid for any reason, the Customer will be charged for services performed and expenses incurred by Watlow Anafaze, Incorporated in handling and shipping the returned unit.

If replacement parts are supplied or repairs made during the original warranty period, the warranty period for the replacement or repaired part shall terminate with the termination of the warranty period of the original product or part.

The foregoing warranty constitutes the sole liability of Watlow Anafaze, Incorporated and the Customer's sole remedy with respect to the products. It is in lieu of all other warranties, liabilities, and remedies. Except as thus provided, Watlow Anafaze, Inc. disclaims all warranties, express or implied, including any warranty of merchantability or fitness for a particular purpose.

Please Note: External safety devices must be used with this equipment.

Table of Contents

List of Figures xi

List of Tables xv

1 System Overview 1

Manual Contents 1

Getting Started 2

Safety Symbols 2

Initial Inspection 2

Product Features 3

CLS200 Parts List 5

Technical Description 7

CLS200 7

TB50 8

CLS200 Cabling 9

Safety 9

External Safety Devices 9

Power-Fail Protection 10

2 Installation 11

Typical Installation 12

Mounting Controller Components 12

Recommended Tools 13

Mounting the Controller 13 Mounting the TB50 16 Mounting the Power Supply 18

Mounting the Dual DAC or Serial DAC Module 19

System Wiring 21

Wiring Recommendations 21 Noise Suppression 22

Ground Loops 24

Power Connections 25

Wiring the Power Supply 25

Connecting TB50 to CLS200 27

Testing Your System 28

TB50 or TB18 Test 28 Digital Output Test 28 Digital Input Test 29

Doc.# 0600-3050-2000 |

Watlow Anafaze |

iii |

Table of Contents |

CLS200 Series User’s Guide |

Sensor Wiring 29

Input Wiring Recommendations 30

Thermocouple Connections 31

RTD Input Connections 32

Reference Voltage Terminals 32

Voltage Input Connections 32

Current Input Connections 33

Pulse Input Connections 34

Wiring Control and Digital I/O 35

Output Wiring Recommendations 35

Cable Tie Wraps 35

Digital Outputs 35

Digital Inputs 38

TB18 Connections (CLS204 and CLS208 Only) 40

TB50 Connections 41

Analog Outputs 43

Wiring the Dual DAC 43

Wiring the Serial DAC 44

Serial Communications 45

EIA/TIA-232 Interface 45

EIA/TIA-485 Interface 47

EIA/TIA-485 Converters and Laptop Computers 49

3 Using the CLS200 51

Front Panel 52

Front Panel Keys 53

Displays 55

Bar Graph Display 55

Single Loop Display 57

Alarm Displays 58

System Alarms 60

Job Display 60

Changing the Setpoint 61

Selecting the Control Status 61

Manual and Automatic Control 61

Autotuning a Loop 62

Using Alarms 64

Alarm Delay 64

Failed Sensor Alarms 65

Process Alarms 66

Global Alarm 68

Ramp/Soak 69

4 Setup 71

How to Access the Setup Menus 71

How to Change a Parameter 72

Setup Global Parameters Menu 74

Load Setup From Job 75 Save Setup to Job 75

Job Select Digital Inputs 76

iv |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

Table of Contents |

Job Select Digital Inputs Active 77

Output Override Digital Input 77

Override Digital Input Active 77 Startup Alarm Delay 78 Keyboard Lock Status 78 Power Up Output Status 78 Process Power Digital Input 79 Controller Address 79 Communications Baud Rate 80 Communications Protocol 80

Communications Error Checking 80 AC Line Frequency 81

Digital Output Polarity on Alarm 81

EPROM Information 81

Setup Loop Input Menu 82

Input Type 83

Loop Name 84

Input Units 84

Input Reading Offset 84 Reversed T/C Detection 85 Input Pulse Sample Time 85 Linear Scaling Parameters 86

Input Filter 89

Setup Loop Control Parameters Menu 90

Heat or Cool Control PB 91 Heat or Cool Control TI 91 Heat or Cool Control TD 91 Heat or Cool Output Filter 91 Spread 92

Restore PID Digital Input 92

Setup Loop Outputs Menu 93

Enable or Disable Heat or Cool Outputs 94 Heat or Cool Output Type 94

Heat or Cool Cycle Time 95 SDAC Mode 95

SDAC Low Value 95

SDAC High Value 95

Heat or Cool Output Action 96 Heat or Cool Output Limit 96 Heat or Cool Output Limit Time 96

Sensor Fail Heat or Cool Output 97

Heat or Cool Thermocouple Break Output Average 97

Heat or Cool Linearity 98

Setup Loop Alarms Menu 99

High Process Alarm Setpoint 100 High Process Alarm Type 100

High Process Alarm Output Number 100 Deviation Alarm Value 100

High Deviation Alarm Type 101

High Deviation Alarm Output Number 101 Low Deviation Alarm Type 101

Low Deviation Alarm Output Number 101 Low Process Alarm Setpoint 102

Doc.# 0600-3050-2000 |

Watlow Anafaze |

v |

Table of Contents |

CLS200 Series User’s Guide |

Low Process Alarm Type 102

Low Process Alarm Output Number 102

Alarm Deadband 102

Alarm Delay 103

Manual I/O Test 103

Digital Inputs 103

Test Digital Output 104

Digital Output Number 104

Keypad Test 105

Display Test 105

5 Extruder Control 107

Setup Loop Outputs Menu 107

Cool Output Nonlinear Output Curve 107

Defaults 108

Extruder Control Algorithm 110

6 Enhanced Features 111

Process Variable Retransmit 113

Setup Loop Process Variable Retransmit Menu 113

Process Variable Retransmit Example: Data Logging 115

Cascade Control 118

Setup Loop Cascade Menu 119

Cascade Control Example: Water Tank 121

Ratio Control 124

Setup Loop Ratio Control Menu 125

Ratio Control Example: Diluting KOH 126

Remote Analog Setpoint 129

Remote Analog Setpoint Example: Setting a Setpoint with a PLC 129

Differential Control 131

Differential Control Example: Thermoforming 131

7 Ramp/Soak 133

Features 134

Ramp/Soak Menus 136

Setup Global Parameters Menu 137

Ramp/Soak Time Base 137

Setup Ramp/Soak Profile Menu 137

Edit Ramp/Soak Profile 137

Copy Setup From Profile 138

Tolerance Alarm Time 138

Ready Segment Setpoint 138

Ready Segment Edit Events 139

External Reset Input Number 139

Edit Segment Number 140

Segment Time 140

Segment Setpoint 140

Edit Segment Events 141

Edit Segment Triggers 142

Segment Tolerance 143

vi |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

Table of Contents |

Last Segment 144

Repeat Cycles 144

Setpoints and Tolerances for Various Input Types 144

Using Ramp/Soak 145

Ramp/Soak Displays 146

Assigning a Profile to a Loop 148

Running a Profile 148

Holding a Profile or Continuing from Hold 150

Responding to a Tolerance Alarm 151

Resetting a Profile 151

In Case of a Power Failure 152

8 Tuning and Control 153

Control Algorithms 153

On/Off Control 154 Proportional Control 154

Proportional and Integral Control 155 Proportional, Integral and Derivative Control 155

Heat and Cool Outputs 156

Control Outputs 157

Output Control Signals 157 Output Filter 158

Reverse and Direct Action 159

Setting Up and Tuning PID Loops 159

Proportional Band (PB) Settings 159 Integral Settings 160

Derivative Settings 160

General PID Constants by Application 161

Proportional Band Only (P) 161 Proportional with Integral (PI) 161 PI with Derivative (PID) 161

9 Troubleshooting and Reconfiguring 163

When There is a Problem 163

Returning Your Unit 164

Troubleshooting Controllers 164

Process and Deviation Alarms 164 Failed Sensor Alarms 166 System Alarms 166

Other Behaviors 167

Corrective and Diagnostic Procedures 168

Low Power 168

Battery Dead 168 Ambient Warning 168 H/W Ambient Failure 169

H/W Gain or Offset Failure 170 Keys Do Not Respond 170 Checking Analog Inputs 171 Earth Grounding 172 Checking Control Outputs 172

Testing Control Output Devices 173

Doc.# 0600-3050-2000 |

Watlow Anafaze |

vii |

Table of Contents |

CLS200 Series User’s Guide |

Testing the TB18 and TB50 173 Testing Control and Digital Outputs 173

Testing Digital Inputs 173

Additional Troubleshooting for Computer Supervised Systems 174

Computer Problems 174 Communications 175 Ground Loops 175

Software Problems 176

NO-Key Reset 176 Replacing the EPROM 176

Changing Communications 179

Installing Scaling Resistors 180

CLS204 and CLS208 Input Circuit 180

CLS204 and CLS208 Current Inputs 181

CLS204 and CLS208 Voltage Inputs 182 CLS204 and CLS208 RTDs and Thermistors 183 CLS216 Input Circuit 184

CLS216 Current Inputs 184

CLS216 Voltage Inputs 185

Scaling and Calibration 186

Configuring Dual DAC Outputs 186

Configuring Serial DAC Outputs 188

10 Linear Scaling Examples 189

Example 1: A 4-to-20 mA Sensor 189

Example 2: A 0-to-5VÎ (dc) Sensor 191

Example 3: A Pulse Encoder 192

11 Specifications 193

CLS200 System Specifications 193

CLS200 Processor Physical Specifications 194

TB50 Physical Specifications 196

Inputs 200

Outputs 202

CLS200 Power Supply 205

Dual DAC Specifications 207

Dual DAC Inputs 208

Dual DAC Analog Outputs 208

Serial DAC Specifications 209

Serial DAC Inputs 210

Serial DAC Analog Outputs 211

Glossary 213

Index 221

Menu Structure 233

Declaration of Conformity 234

viii |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

List of Figures

1 System Overview

Figure 1.1—CLS200 |

Part Numbering 5 |

Figure 1.2—CLS200 |

Special Inputs Parts List 6 |

Figure 1.3—CLS200 Rear Views |

7 |

Figure 1.4—CLS200 Front Panel |

8 |

Figure 1.5—TB50 8 |

|

2 Installation

Figure 2.1—CLS200 System Components |

12 |

|

|

|

||

Figure 2.2—Clearance with Straight SCSI Cable |

14 |

|

|

|||

Figure 2.3—Clearance with Right-Angle SCSI Cable |

14 |

|

||||

Figure 2.4—Wiring Clearances |

15 |

|

|

|

|

|

Figure 2.5—Mounting Bracket |

16 |

|

|

|

|

|

Figure 2.6—Mounting the TB50 |

16 |

|

|

|

|

|

Figure 2.7—TB50 Mounted on a DIN Rail (Front) |

17 |

|

|

|||

Figure 2.8—TB50 Mounted on DIN Rail (Side) 17 |

|

|

||||

Figure 2.9—Mounting a TB50 with Standoffs |

18 |

|

|

|

||

Figure 2.10—CLS200 Power Supply Mounting Bracket |

19 |

|

||||

Figure 2.11—Dual DAC and Serial DAC Dimensions |

20 |

|

||||

Figure 2.12—CLS200 Series Controller with TB18 |

25 |

|

||||

Figure 2.13—CLS200 Series Controller with TB50 |

25 |

|

||||

Figure 2.14—Power Connections with the CLS200 Power Supply |

27 |

|||||

Figure 2.15—CLS200 Connector Locations |

30 |

|

|

|

||

Figure 2.16—Thermocouple Connections 31 |

|

|

|

|||

Figure 2.17—RTD Connections to CLS204 or CLS208 |

32 |

|

||||

Figure 2.18—Linear Voltage Signal Connections |

33 |

|

|

|||

Figure 2.19—Linear Current Signal Connections |

33 |

|

|

|||

Figure 2.20—Encoder with 5VÎ (dc) TTL Signal |

34 |

|

|

|||

Figure 2.21—Encoder Input with Voltage Divider |

34 |

|

|

|||

Figure 2.22—Digital Output Wiring |

36 |

|

|

|

|

|

Figure 2.23—Sample Heat, Cool and Alarm Output Connections |

37 |

|||||

Figure 2.24—Output Connections Using External Power Supply |

38 |

|||||

Figure 2.25—TB50 Watchdog Timer Output |

38 |

|

|

|

||

Figure 2.26—TB18 Watchdog Timer Output |

38 |

|

|

|

||

Figure 2.27—Wiring Digital Inputs |

39 |

|

|

|

|

|

Figure 2.28—Dual DAC with Current Output |

43 |

|

|

|

||

Figure 2.29—Dual DAC with Voltage Output |

44 |

|

|

|

||

Doc.# 0600-3050-2000 |

Watlow Anafaze |

ix |

List of Figures |

|

|

|

|

CLS200 Series User’s Guide |

||

Figure 2.30—Single/Multiple Serial DACs |

45 |

|

|

|

|

|

|

Figure 2.31—Connecting One CLS200 to a Computer Using EIA/TIA-232 46 |

|||||||

Figure 2.32—EIA/TIA-485 Wiring |

47 |

|

|

|

|

|

|

Figure 2.33—Recommended System Connections 48 |

|

|

|

|

|||

3 Using the CLS200 |

|

|

|

|

|

|

|

Figure 3.1—Operator Displays |

51 |

|

|

|

|

|

|

Figure 3.2—CLS200 Front Panel |

52 |

|

|

|

|

|

|

Figure 3.3—Bar Graph Display |

55 |

|

|

|

|

|

|

Figure 3.4—Single Loop Display |

57 |

|

|

|

|

|

|

Figure 3.5—Single Loop Display, Heat and Cool Outputs Enabled |

57 |

||||||

Figure 3.6—Single Loop Display with a Process Alarm |

58 |

|

|

|

|||

Figure 3.7—Failed Sensor Alarm in the Single Loop Display |

58 |

|

|||||

Figure 3.8—Alarm Symbols in the Bar Graph Display |

58 |

|

|

|

|||

Figure 3.9—Activation and Deactivation of Process Alarms |

68 |

|

|

||||

4 Setup |

|

|

|

|

|

|

|

Figure 4.1—CLS200 Menu Tree |

73 |

|

|

|

|

|

|

Figure 4.2—Two Points Determine Process Variable Conversion |

86 |

||||||

Figure 4.3—Process Variable Limited by Input Reading Range |

87 |

||||||

Figure 4.4—Linear and Nonlinear Outputs |

98 |

|

|

|

|

|

|

Figure 4.5—Digital Inputs Screen 104 |

|

|

|

|

|

|

|

5 Extruder Control |

|

|

|

|

|

|

|

Figure 5.1—Cool Output Nonlinear Output Curve |

108 |

|

|

|

|

||

6 Enhanced Features |

|

|

|

|

|

|

|

Figure 6.1—Enhanced Features Option Menus |

112 |

|

|

|

|

||

Figure 6.2—Linear Scaling of Process Variable for Retransmit |

115 |

||||||

Figure 6.3—Application Using Process Variable Retransmit |

116 |

|

|||||

Figure 6.4—Relationship Between the Primary Loop’s Output and the Secondary |

|||||||

Loop’s Setpoint 119 |

|

|

|

|

|

|

|

Figure 6.5—Application Using Cascade Control |

121 |

|

|

|

|

||

Figure 6.6—Secondary Loop Setpoint Related to Primary Loop Output 123

Figure 6.7—Relationship Between the Master Loop’s Process Variable and the Ratio Loop’s Setpoint 124

Figure 6.8—Application Using Ratio Control 127

7 Ramp/Soak

Figure 7.1—Sample Ramp/Soak Profile 133 |

|

Figure 7.2—Setup Ramp/Soak Profiles Menu |

136 |

Figure 7.3—Positive and Negative Tolerances |

143 |

Figure 7.4—Ramp/Soak Screens 145 |

|

x |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide List of Figures

8 Tuning and Control

Figure 8.1—On/Off Control 154 Figure 8.2—Proportional Control 155

Figure 8.3—Proportional and Integral Control 155

Figure 8.4—Proportional, Integral and Derivative Control 156

Figure 8.5—Time Proportioning and Distributed Zero Crossing Waveforms 157

9 Troubleshooting and Reconfiguring

Figure 9.1—Removal of Electronics Assembly from Case |

177 |

||

Figure 9.2—Screws Locations on PC Board 178 |

|

||

Figure 9.3—EPROM Location |

178 |

|

|

Figure 9.4—Remove EPROM |

178 |

|

|

Figure 9.5—Jumper Configurations |

179 |

|

|

Figure 9.6—CLS204 and CLS208 Input Circuit 181 |

|

||

Figure 9.7—CLS216 Input Circuit |

184 |

|

|

Figure 9.8—Dual DAC 187 |

|

|

|

Figure 9.9—Serial DAC Voltage/Current Jumper Positions |

188 |

||

11 Specifications

Figure 11.1—CLS200 Processor Module Dimensions |

194 |

|

|

|

Figure 11.2—CLS200 Clearances with Straight SCSI Cable |

195 |

|||

Figure 11.3—CLS200 Clearances with Right-Angle SCSI Cable |

195 |

|||

Figure 11.4—TB50 Dimensions 197 |

|

|

|

|

Figure 11.5—TB50 Dimensions with Straight SCSI Cable |

198 |

|

||

Figure 11.6—TB50 Dimensions with Right-Angle SCSI Cable |

199 |

|||

Figure 11.7—Power Supply Dimensions (Bottom View) |

206 |

|

||

Figure 11.8—Dual DAC Dimensions |

207 |

|

|

|

Figure 11.9—Serial DAC Dimensions |

209 |

|

|

|

Doc.# 0600-3050-2000 |

Watlow Anafaze |

xi |

List of Figures |

CLS200 Series User’s Guide |

xii |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

List of Tables

2 Installation

Table 2.1—Cable Recommendations |

22 |

|

|

Table 2.2—Power Connections |

26 |

|

|

Table 2.3—Digital Output States and Values Stored in the Controller |

36 |

||

Table 2.4—Digital Inputs States and Values Stored in the Controller |

39 |

||

Table 2.5—TB18 Connections |

40 |

|

|

Table 2.6—TB50 Connections for CLS204 and CLS208 41 |

|

||

Table 2.7—TB50 Connections for CLS216 42 |

|

||

Table 2.8—EIA/TIA-232 Connections |

46 |

|

|

Table 2.9—RTS/CTS Pins in DB-9 and DB-25 Connectors 46 |

|

||

3 Using the CLS200

Table 3.1—Bar Graph Display Symbols |

55 |

Table 3.2—Control Status Symbols on the Bar Graph and Single Loop Displays 56 |

|

Table 3.3—Alarm Type and Symbols |

59 |

4 Setup

Table 4.1—Global Parameters |

|

74 |

|

Table 4.2—Job Select Inputs |

76 |

|

|

Table 4.3—Job Selected for Various Input States 76 |

|||

Table 4.4—Firmware Option Codes 81 |

|

||

Table 4.5—Setup Loop Input |

82 |

|

|

Table 4.6—CLS200 Input Types and Ranges |

83 |

||

Table 4.7—Input Character Sets |

84 |

|

|

Table 4.8—Input Reading Offset |

85 |

|

|

Table 4.9—Display Formats |

87 |

|

|

Table 4.10—Setup Loop Control Parameters |

90 |

||

Table 4.11—Setup Loop Outputs |

93 |

|

|

Table 4.12—Heat / Cool Output Types 94 |

|

||

Table 4.13—Setup Loop Alarms |

99 |

|

|

Table 4.14—Manual I/O Test |

103 |

|

|

5 Extruder Control

Table 5.1—Default Control Parameters for Fan Cool Output |

109 |

Table 5.2—Default Control Parameters for Oil Cool Output |

109 |

Table 5.3—Default Control Parameters for H2O Cool Output |

109 |

Doc.# 0600-3050-2000 |

Watlow Anafaze |

xiii |

List of Tables CLS200 Series User’s Guide

6 Enhanced Features

Table 6.1—Application Example: Setting Up Process Variable Retransmit 117

Table 6.2—Application Example: Setting Up Cascade Control |

122 |

Table 6.3—Application Example: Setting Up Ratio Control 128 |

|

Table 6.4—Application Example: Setting Up Remote Setpoint |

130 |

Table 6.5—Application Example: Setting Up Differential Control |

132 |

7 Ramp/Soak

Table 7.1—Ramp/Soak Specifications |

135 |

Table 7.2—Trigger Latch Logic 143 |

|

Table 7.3—Display Formats 145 |

|

Table 7.4—Ramp/Soak Single Loop Display 146 |

|

Table 7.5—Ramp/Soak Control Status Symbols 147 |

|

Table 7.6—Ramp/Soak Profile Modes |

150 |

8 Tuning and Control

Table 8.1—Proportional Band Settings 159 Table 8.2—Integral Term and Reset Settings 160 Table 8.3—Derivative Term Versus Rate 160 Table 8.4—General PID Constants 162

9 Troubleshooting and Reconfiguring

Table 9.1—Controller Alarm Codes for Process and Deviation Alarms |

|

164 |

|

Table 9.2—Operator Response to Alarms 165 |

|

|

|

Table 9.3—Failed Sensor Alarm Codes |

166 |

|

|

Table 9.4—Hardware Error Messages |

166 |

|

|

Table 9.5—Other Symptoms 167 |

|

|

|

Table 9.6—Resistor Values for CLS204 and CLS208 Current Inputs |

181 |

||

Table 9.7—Resistor Locations for CLS204 and CLS208 Current Inputs |

181 |

||

Table 9.8—Resistor Values for CLS204 and CLS208 Voltage Inputs |

182 |

||

Table 9.9—Resistor Locations for CLS204 and CLS208 Voltage Inputs |

182 |

||

Table 9.10—Resistor |

Values for CLS204/208 RTD and Thermistor Inputs 183 |

Table 9.11—Resistor |

Locations for CLS204/208 RTD and Thermistor Inputs 183 |

Table 9.12—Resistor Values for CLS216 Current Inputs |

184 |

|

Table 9.13—Resistor Locations for CLS216 Current Inputs |

185 |

|

Table 9.14—Resistor Values for CLS216 Voltage Inputs |

185 |

|

Table 9.15—Resistor Locations for CLS216 Voltage Inputs |

186 |

|

Table 9.16—Dual DAC Jumper Settings 187 |

|

|

10 Linear Scaling Examples

Table 10.1—Input Readings |

190 |

Table 10.2—Scaling Values |

190 |

Table 10.3—Input Readings and Calculations 191

Table 10.4—Scaling Values |

191 |

Table 10.5—Scaling Values |

192 |

xiv |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

List of Tables |

11 Specifications

Table 11.1—Agency Approvals / Compliance |

193 |

|

||||

Table 11.2—Environmental Specifications |

194 |

|

||||

Table 11.3—Physical Dimensions |

194 |

|

|

|

||

Table 11.4—Processor with Straight SCSI |

195 |

|

||||

Table 11.5—Processor with Right Angle SCSI |

195 |

|||||

Table 11.6—Processor Connections |

196 |

|

|

|

||

Table 11.7—TB50 Physical Dimensions 196 |

|

|

||||

Table 11.8—TB50 Connections |

197 |

|

|

|

|

|

Table 11.9—TB50 with Straight SCSI |

198 |

|

|

|

||

Table 11.10—TB50 with Right Angle SCSI |

199 |

|

||||

Table 11.11—Analog Inputs |

200 |

|

|

|

|

|

Table 11.12—Pulse Inputs |

201 |

|

|

|

|

|

Table 11.13—Thermocouple Range and Resolution |

201 |

|||||

Table 11.14—RTD Range and Resolution |

201 |

|

||||

Table 11.15—Input Resistance for Voltage Inputs |

202 |

|||||

Table 11.16—Digital Inputs |

202 |

|

|

|

|

|

Table 11.17—Digital Outputs Control / Alarm |

203 |

|

||||

Table 11.18—CPU Watchdog Output |

203 |

|

|

|

||

Table 11.19—5VÎ (dc) Output (Power to Operate Solid-State Relays) 204 Table 11.20—Reference Voltage Output (Power to Operate Bridge Circuit

Sensors) 204

Table 11.21—Processor Serial Interface 204 Table 11.22—Processor Power Requirements 204

Table 11.23—Power Supply Environmental Specifications 205 Table 11.24—Power Supply Agency Approvals / Compliance 205

Table 11.25—Power Supply Physical Specifications |

205 |

|||

Table 11.26—Power Supply with Mounting Bracket 205 |

|

|||

Table 11.27—Power Supply Inputs |

206 |

|

|

|

Table 11.28—Power Supply Outputs |

206 |

|

|

|

Table 11.29—Dual DAC Environmental Specifications |

207 |

|||

Table 11.30—Dual DAC Physical Specifications |

207 |

|

|

|

Table 11.31—Dual DAC Power Requirements 208 |

|

|

||

Table 11.32—Dual DAC Specifications by Output Range |

208 |

|||

Table 11.33—Serial DAC Environmental Specifications |

209 |

|||

Table 11.34—Serial DAC Physical Specifications |

209 |

|

||

Table 11.35—Serial DAC Agency Approvals / Compliance 210 Table 11.36—Serial DAC Inputs 210

Table 11.37—Serial DAC Power Requirements 210

Table 11.38—Serial DAC Analog Output Specifications 211

Doc.# 0600-3050-2000 |

Watlow Anafaze |

xv |

List of Tables |

CLS200 Series User’s Guide |

xvi |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

1

System Overview

Manual Contents

This manual describes how to install, set up, and operate a CLS204, CLS208 or CLS216 controller. Each chapter covers a different aspect of your control system and may apply to different users:

•Chapter 1: System Overview provides a component list and summary of features for the CLS200 series controllers.

•Chapter 2: Installation provides detailed instructions on installing the CLS200 series controller and its peripherals.

•Chapter 3: Using the CLS200 provides an overview of operator displays used for system monitoring and job selection.

•Chapter 4: Setup provides detailed descriptions of all menus and parameters for controller setup.

•Chapter 5: Extruder Control explains the additional features of a CLS200 controller equipped with Extruder Control Firmware.

•Chapter 6: Enhanced Features describes process variable retransmit, ratio, differential and cascade control features available with the enhanced features option.

•Chapter 7: Ramp/Soak explains how to set up and use the features of the ramp/soak option.

•Chapter 8: Tuning and Control describes available control algorithms and provides suggestions for applications.

•Chapter 9: Troubleshooting and Reconfiguring includes troubleshooting, upgrading and reconfiguring procedures for technical personnel.

Doc.# 0600-3050-2000 |

Watlow Anafaze |

1 |

Chapter 1: System Overview |

CLS200 Series User’s Guide |

•Chapter 10: Linear Scaling Examples provides an example configuring a pressure sensor, a flow sensor, and an encoder using linear scaling.

•Chapter 11: Specifications lists detailed specifications of the controller and optional components.

Getting Started

The following sections provide information regarding product features, technical descriptions, safety requirements, and preparation for operation.

Safety Symbols

These symbols are used throughout this manual:

WARNING! Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION! Indicates a potentially hazardous situation which, if not avoided, could result in minor or moderate injury or property damage.

NOTE! Indicates pertinent information or an item that may be useful to document or label for later reference.

Initial Inspection

Accessories may or may not be shipped in the same container as the CLS200, depending upon their size. Check the shipping invoice carefully against the contents received in all boxes.

2 |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

Chapter 1: System Overview |

Product Features

The CLS200 series controllers provide 4, 8 or 16 fully independent control loops. When used as a stand-alone controller, you may operate the CLS200 via the two-line 16character display and touch keypad. You can also use it as the key element in a computer-supervised data acquisition and control system; the CLS200 can be locally or remotely controlled via an EIA/TIA-232 or EIA/TIA-485 serial communications interface.

The CLS200 features include:

•Direct Connection of Mixed Thermocouple Sensors: Connect most thermocouples to the controller with no hardware modifications. Thermocouple inputs feature reference junction compensation, linearization, process variable offset calibration to correct for sensor inaccuracies, detection of broken, shorted or reversed thermocouples, and a choice of Fahrenheit or Celsius display.

•Accepts Resistive Temperature Detectors (RTDs): Use 3-wire, 100 Ω, platinum, 0.00385-curve sensors with two choices for range and precision of measurements. (To use this input, order a CLS204 or CLS208 controller with scaling resistors.)

•Automatic Scaling for Linear Analog Inputs: The CLS200 series automatically scales linear inputs used with industrial process sensors. Enter two points, and all input values are automatically scaled in your units. Scaling resistors must be installed.

•Dual Outputs: The CLS200 series includes both heat and cool control outputs for each loop. Independent control parameters are provided for each output.

•Independently Selectable Control and Output Modes: You can set each control output to on/off, time proportioning, Serial DAC (digital-to-analog converter), or distributed zero crossing mode. Set up to two outputs per loop for on/off, P, PI or PID control with reverse or direct action.

•Control Outputs: Set high/low deviation and high/ low process limits to operate digital outputs as on/off control functions or alarms.

•Flexible Alarm Outputs: Independently set high/ low process alarms and a high/low deviation band alarm for each loop. Alarms can activate a digital output by themselves, or they can be grouped with other alarms to activate an output.

•Global Alarm Output: When any alarm is triggered, the global alarm output is also triggered, and it stays on until you acknowledge it.

Doc.# 0600-3050-2000 |

Watlow Anafaze |

3 |

Chapter 1: System Overview |

CLS200 Series User’s Guide |

•CPU Watchdog: The CLS200 series CPU watchdog timer output notifies you of system failure. Use it to hold a relay closed while the controller is running, so you are notified if the microprocessor shuts down.

•Front Panel or Computer Operation: Set up and run the controller from the front panel or from a local or remote computer. Watlow Anafaze offers WatView, a Windows® compatible Human Machine Interface (HMI) software package that includes data logging and graphing features in addition to process monitoring and parameter setup screens.

•Modbus RTU Protocol, EIA/TIA-232 and 485 Communications: Connect to PLCs, operator interface terminals and third-party software packages using the widely supported Modbus RTU protocol.

•Multiple Job Storage: Store up to eight jobs in memory, and access them locally by entering a single job number or remotely via digital inputs. Each job is a set of operating conditions, including setpoints and alarms.

•Nonlinear Output Curves: Select either of two nonlinear output curves for each control output.

•Autotuning: Use the autotune feature to set up your system quickly and easily. The CLS200 internal expert system table finds the correct PID parameters for your process.

•Pulse Counter Input: Use the pulse counter input for precise control of motor or belt speed.

•Low Power Shutdown: The controller shuts down and turns off all outputs when it detects the input voltage drop below the minimum safe operating level.

4 |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

Chapter 1: System Overview |

CLS200 Parts List

You may have received one or more of the following components. See Figure 2.1 on page 12 for CLS200 configuration information.

•CLS200 series controller

•Controller mounting kit

•TB50 with 50-pin SCSI cable

•EIA/TIA-232 or EIA/TIA-485 communications cable

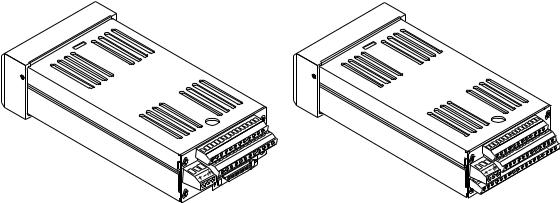

•Power supply with mounting bracket and screws

•Serial DAC (digital-to-analog converter)

•Special input resistors (installed in CLS200)

•User’s guide

2_ _–_ _ _ _ _ _ ___

Number of Loops

04 = 4 loops

08 = 8 loops

16 = 16 loops

Controller Type

1 = Standard EPROM

2 = Extruder applications

3 = Ramp/soak option

4 = Enhanced features option (includes cascade, PV retransmit, ratio, remote setpoint)

Terminal Board

0 = No terminal board accessory

1 = 18-terminal block mounted on unit, no SCSI cable required 2 = 50-pin terminal board, includes 3 ft. SCSI cable

Power Supply

0 = No power supply

2 = 120/240VÅ (ac), 50/60Hz panel mount power supply adapter (5VÎ [dc] @ 4A, 15VÎ [dc] @ 1.2A) CE approved

SCSI Cables (for use with 50-pin terminal board)

0 = No special SCSI cable (3 ft. cable is included with 50-pin terminal board) 1 = 6 ft. SCSI cable

2 = 3 ft. right angle SCSI cable

3 = 6 ft. right angle SCSI cable )

Communications Cables (For EIA/TIA-232 communications with computer)

0 = No communications cable

1 = 10 ft. (3.0 m) communications cable, DB-9 female/bare wire 2 = 25 ft. (7.6 m) communications cable, DB-9 female/bare wire 3 = 50 ft. (15.2 m) communications cable, DB-9 female/bare wire

Serial Communications Jumper Settings

0 = EIA/TIA-232

1 = EIA/TIA-485

2 = EIA/TIA-485 terminated

Special Inputs (one or two digits)

(Standard unit is conf gured for thermocouples and -10 to 60mV linear inputs. For other sensors, special inputs are required.

00 = Thermocouples and -10 to 60mV inputs only

XX= Number of current and voltage inputs. RTDs are not available on the CLS216. Include leading zero as needed.

Figure 1.1 CLS200 Part Numbering

Doc.# 0600-3050-2000 |

Watlow Anafaze |

5 |

Chapter 1: System Overview |

CLS200 Series User’s Guide |

CLSSI _ _–_ _–_ _

If special inputs are ordered in the controller part number, the following is specified in the pa t description.

Special Input Type (Not required for thermocouple sensor inputs)

20 = RTD1: 0.1°, -100.0 to 275.0° C (-148.0 to 572.0° F) (Not available on CLS216) 21 = RTD2: 1°, -120.0 to 840.0° C (-184.0 to 1544.0° F) (Not available on CLS216) 43 = 0 to 10 mAÎ (dc)

44 = 0 to 20mAÎ (dc)/4 to 20mAÎ (dc) 50 = 0 to 100mVÎ (dc)

52 = 0 to 500mVÎ (dc)

53 = 0 to 1VÎ (dc)

55 = 0 to 5VÎ (dc)

56 = 0 to 10VÎ (dc)

57 = 0 to 12VÎ (dc)

Start Channel

XX = Channel number XX

End Channel

XX = Channel number XX

Note:

Make sure the number of special inputs specif ed is equal to the number of special inputs in the controller part number.

Uninstalled kits are available.

Figure 1.2 CLS200 Special Inputs Parts List

6 |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

Chapter 1: System Overview |

Technical Description

This section contains a technical description of each component of your CLS200 series controller.

CLS200

The CLS200 is housed in an 1/8-DIN panel mount package. It contains the CPU, RAM with a built-in battery, EPROM, serial communications, digital I/O, analog inputs, the screen and touch keypad.

CLS200 Series |

CLS204 or CLS208 |

with SCSI Connector |

with TB18 Connector |

|

Figure 1.3 CLS200 Rear Views |

The CLS200 has the following features:

•Keypad and 2-line 16-character display.

•Screw terminals for the power and analog inputs and communications.

•Input power is 12 to 24VÎ (dc) at 1 Amp.

•A 50-pin SCSI cable connects the digital inputs and outputs to the 50-terminal block (TB50). The CLS204 and CLS208 are available with an 18-terminal block (TB18) in place of the SCSI connector, as shown in Figure 1.3.

The firmware resides in an EPROM. See Replacing the EPROM on page 176 for information on removing and replacing the EPROM.

The operating parameters are stored in battery-backed RAM. If there is a power loss the operating parameters are unchanged. The battery has a ten-year shelf life, and it is not used when the unit is on.

The microprocessor performs all calculations for input signal linearization, PID control, alarms and communications.

Doc.# 0600-3050-2000 |

Watlow Anafaze |

7 |

Chapter 1: System Overview |

CLS200 Series User’s Guide |

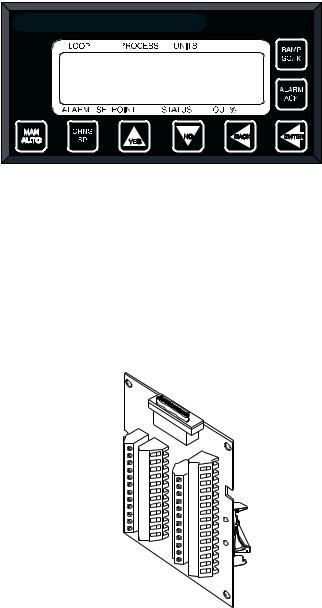

Front Panel Description

The display and touch keypad provide an intelligent way to operate the controller. The display has 16 alphanumeric or graphic characters per line. The 8-key keypad allows you to change the operating parameters, controller functions, and displays.

The information-packed displays show process variables, setpoints, and output levels for each loop. A bar graph display, single loop display, scanning display and an alarm display offer a real-time view of process conditions. Two access levels allow operator changes and supervisor changes.

WATLOW ANAFAZE CLS200

Figure 1.4 CLS200 Front Panel

TB50

The TB50 is a screw-terminal interface for control wiring which allows you to connect relays, encoders and discrete I/ O devices to the CLS200. The screw terminal blocks accept

wires as large as 18 AWG (0.75 mm2). A 50-pin SCSI cable connects the TB50 to the CLS200.

Figure 1.5 TB50

8 |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

Chapter 1: System Overview |

CLS200 Cabling

Watlow Anafaze provides cables required to install your

CLS200. A 50-pin SCSI cable connects the TB50 to the

CLS200.

The optional cable used to connect the CLS200 to a computer using EIA/TIA-232 communications has a DB9 or DB25 connector for the computer and bare wires for connecting to the CLS200.

Safety

Watlow Anafaze has made every effort to ensure the reliability and safety of this product. In addition, we have provided recommendations that will allow you to safely install and maintain this controller.

External Safety Devices

The CLS200 controller may fail full-on (100% output power) or full-off (0% output power), or may remain full-on if an undetected sensor failure occurs. For more information about failed sensor alarms, see Failed Sensor Alarms on page 65.

Design your system to be safe even if the controller sends a 0% or 100% output power signal at any time. Install independent, external safety devices that will shut down the system if a failure occurs.

Typically, a shutdown device consists of an FM-approved high/low process limit controller that operates a shutdown device such as an mechanical contactor. The limit controller monitors for a hazardous condition such as an undertemperature or over-temperature fault. If a hazardous condition is detected, the limit controller sends a signal to open the contactor.

The safety shutdown device (limit controller and contactor) must be independent from the process control equipment.

WARNING! The controller may fail in a 0% or 100% power output state. To prevent death, personal injury, equipment damage or property damage, install external safety shutdown devices. If death or injury may occur, you must install FM-approved safety shutdown devices that operate independently from the process control equipment.

With proper approval and installation, thermal fuses may be used in some processes.

Doc.# 0600-3050-2000 |

Watlow Anafaze |

9 |

Chapter 1: System Overview |

CLS200 Series User’s Guide |

Power-Fail Protection

In the occurrence of a sudden loss of power, this controller can be programmed to reset the control outputs to off (this is the default). Typically, when power is re-started, the controller restarts to data stored in memory. If you have programmed the controller to restart with control outputs on, the memory-based restart might create an unsafe process condition for some installations. Therefore, you should only set the restart with outputs on if you are certain your system will safely restart. (See the Process Power Digital Input on page 79).

When using a computer or host device, you can program the software to automatically reload desired operating constants or process values on power-up. Keep in mind that these convenience features do not eliminate the need for independent safety devices.

Contact Watlow Anafaze immediately if you have any questions about system safety or system operation.

10 |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

2

Installation

This chapter describes how to install the CLS200 series controller and its peripherals. Installation of the controller involves the following procedures:

•Determining the best location for the controller

•Mounting the controller and TB50

•Power connection

•Input wiring

•Communications wiring (EIA/TIA-232 or EIA/TIA485)

•Output wiring

WARNING! Risk of electric shock. Shut off power to your entire process before you begin installation of the controller.

WARNING! The controller may fail in a 0% or 100% power output state. To prevent death, personal injury, equipment damage or property damage, install external safety shutdown devices. If failure may cause death or injury, you must install FM-approved safety shutdown devices that operate independently from the process control equipment.

Doc.# 0600-3050-2000 |

Watlow Anafaze |

11 |

Chapter 2: Installation |

CLS200 Series User’s Guide |

Typical Installation

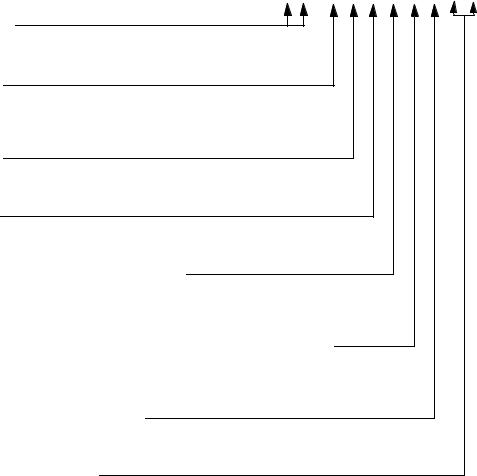

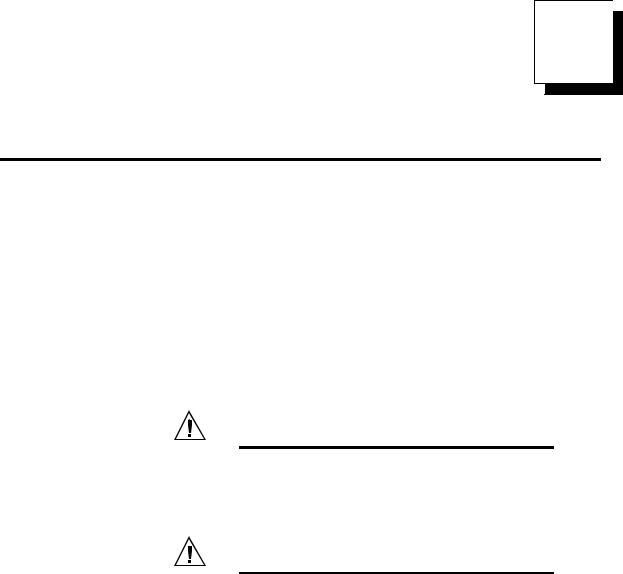

Figure 2.1 shows typical installations of the controller with the TB50 and the TB18 terminal blocks. The type of terminal block you use greatly impacts the layout and wiring of your installation site. (See Figures 2.2 to 2.11.)

We recommend that you read this entire chapter first before beginning the installation procedure. This will help you to carefully plan and assess the installation.

CLS200 with TB50 |

SCSI Cable |

8 Digital Inputs,

35 Digital Outputs

35 Digital Outputs

(Control/Alarm)

Pulse Input

Signal Inputs

CLS200

Power supply

CLS200 with TB18

Signal Inputs

11 Digital Outputs (Control/Alarm) |

CLS200 |

2 Digital Inputs, 1 Digital/Pulse Input |

Power supply |

Figure 2.1 CLS200 System Components

Mounting Controller Components

Install the controller in a location free from excessive heat (more than 50º C [122° F]), dust, and unauthorized handling. Electromagnetic and radio frequency interference can induce noise on sensor wiring. Select locations for the CLS200 and TB50 such that wiring can be routed clear of sources of interference such as high voltage wires, power switching devices and motors.

NOTE! For indoor use only.

12 |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

CLS200 Series User’s Guide |

Chapter 2: Installation |

WARNING! To reduce the risk of fire or electric shock, install the CLS200 in a controlled environment, relatively free of contaminants.

Recommended Tools

Use any of the following tools to cut a hole of the appropriate size in the panel.

•Jigsaw and metal file, for stainless steel and heavyweight panel doors.

•Greenlee 1/8-DIN rectangular punch (Greenlee part number 600-68), for most panel materials and thicknesses.

•Nibbler and metal file, for aluminum and lightweight panel doors.

You will also need these tools:

•Phillips head screwdriver

•1/8 in. (3 mm) flathead screwdriver for wiring

•Multimeter

Mounting the Controller

Mount the controller before you mount the terminal block or do any wiring. The controller’s placement affects placement and wiring considerations for the other components of your system.

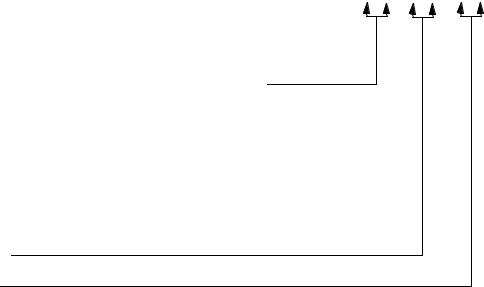

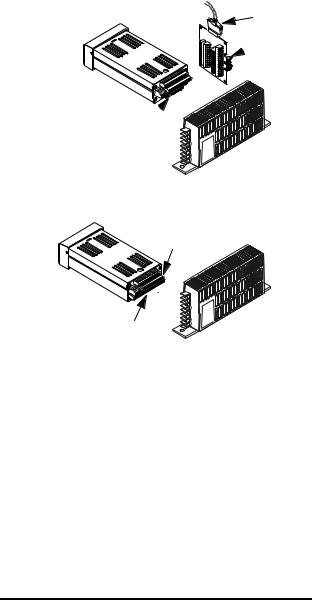

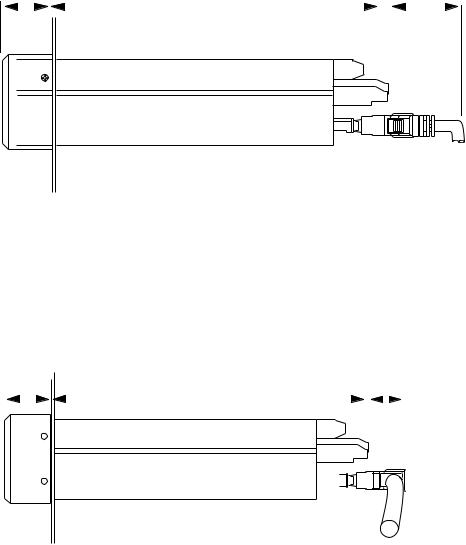

Ensure there is enough clearance for mounting brackets, terminal blocks, and cable and wire connections; the controller extends up to 7.0 inches (178 mm) behind the panel face and the screw brackets extend 0.5 inch (13 mm) above and below it. If using a straight SCSI cable, allow for an additional 1.6 inches (41 mm) beyond the terminal block. If using a right-angle SCSI cable, allow an additional 0.6 inch (15 mm). (See Figure 2.2 and Figure 2.3.)

Doc.# 0600-3050-2000 |

Watlow Anafaze |

13 |

Chapter 2: Installation |

CLS200 Series User’s Guide |

1.0 inch |

|

7.0 inches |

1.6 inch |

|||||

(25 mm) |

|

(178 mm) |

(41 mm) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 2.2 Clearance with Straight SCSI Cable

1.0 inch |

|

7.0 inches |

|

|

0.6 inch |

|||||||

(25 mm) |

|

(178 mm) |

|

|

(41 mm) |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 2.3 Clearance with Right-Angle SCSI

Cable

14 |

Watlow Anafaze |

Doc.# 0600-3050-2000 |

Loading...

Loading...