Page 1

Electrically Release Brakes

ERD Size 005 to 035 & ERD Size 060 to 300

Service Manual

P-2060-WE

SM321Agb - rev 11/04

SM321gb - rev 11/04

Page 2

Page 3

P-2060-WE

SM321Agb - rev 11/04

Electrically Release Brakes

ERD Size 005 to 035

Service Manual

Page 4

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the brakes are made in our factory from St Barthélemy d’Anjou,

and hereafter designated : ERD

are exclusively designed for incorporation into a machine and to be assembled with other equipment with a view to constituting a machine to

which direction 98/37/EC and Electromagnetic Compatibility directive 89/336 as amended apply.

The basic requirements of Low Voltage directive 73/23 (modified) are compiled with through full conformity with the following standards:

NFC 79300 and VDE 05808/8.65

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1 Technical specifications 2

2 Precautions and restrictions on use 2

2.1 Restrictions on use 2

2.2 Precautions 2

and safety measures

3 Installation 3

3.1 Transport - storage 3

3.2 Handling 3

3.3 Installing 3

4 Maintenance 3

4.1 Adjusting the airgap 3

4.2 Maintenance 3

1 Technical specifications (VAR00 and VAR02)

ERD Size 005 010 020 035

Nominal torque (standard version) Nm

Nominal airgap +0,1/-0,05 mm

Max. airgap mm

Maximum speed min

-1

Tightening torque of screws Nm

5

0,2

0,5

3600

2,4

Table 1

4.3 Spare parts 3

5 Electrical connection 4

5.1 Important recommendations 4

5.2 Power supply 4

6 Options 4

6.1 Torque adjustment 4

6.2 Detection kit 4

6.3 Hand release kit 5

6.4 Accessories 6

7 Appendices 6

7. 1 ERD VAR00 and VAR02 6

7.2 Options 6

10

0,2

0,65

3600

4,4

20

0,2

0,55

3600

7,8

35

0,3

0,8

3600

7,8

2 Precautions and restrictions on use

Symbol designating

an action that might

damage the brake

2.1 Restrictions on use

This equipment is designed for dry running.

Any oily material alters performance.

Exceeding the maximum rotation speeds

stated in the catalogue invalidates the warranty.

The equipment can be fitted either horizontally

or vertically.

This equipment is designed for an ambient

tem perature of 40°C maximum (155°C

insulation class).

Symbol designating an

action that might be

dan gerous to human safety

2.2 Precautions and safety measures

During maintenance, ensure that the

mechanism to be braked by the equipment is at

rest and that there is no risk of accidental startup. All intervention have to be made by qualified

personnel, owning this manual

Any modification made to the brake without

the express authorization of a representative of

Warner Electric, in the same way than any use

out of the contrac tual specifications accepted by

“Warner Electric”, will result in the warranty being

invalidated and Warner Electric will no longer be

liable in any way with regard to conformity.

Symbol designating an

elec trical action that might be

dangerous to human safety

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13

Page 5

3 Installation

3.1 Transport / storage

These units are delivered in packaging that

guarantees a 6 months storage period whether

transported by land, by air, or by sea to any

destination excepting tropical countries.

3.2 Handling

Avoid any impacts on the equipment so as not

to alter their performance.

Never carry the equipment by the electrical

supply cable.

3.2 Installing

NB : ERD Size 005 to 035 brakes are supplied

in kit form. The pre-assembled inductor is

supplied with airgap adjusted, see chapter 7

(appendix).

Customer shall maintain:

1. Squareness of flange mounting face

with shaft within 0,15 mm T.I.R. measured at

mounting shaft.

2. Concentricity of flange mounting with

mounting shaft within 0,15 mm T.I.R.

3. The mounting surface should be made of

steel or cast iron, square to the shaft with a

surface finish of 5 to 8 µm or a fine turned finish

over the contact area

If a friction flange (340) or (341) is supplied, fix it

first.

Switch the equipment on and confirm that the

friction disc rotates freely.

Cycle the brake a number of times and re-check

the value of the airgap. If the airgap is incorrect,

refer to chapter 4 (maintenance).

4 Maintenance

4.1 Adjusting the airgap

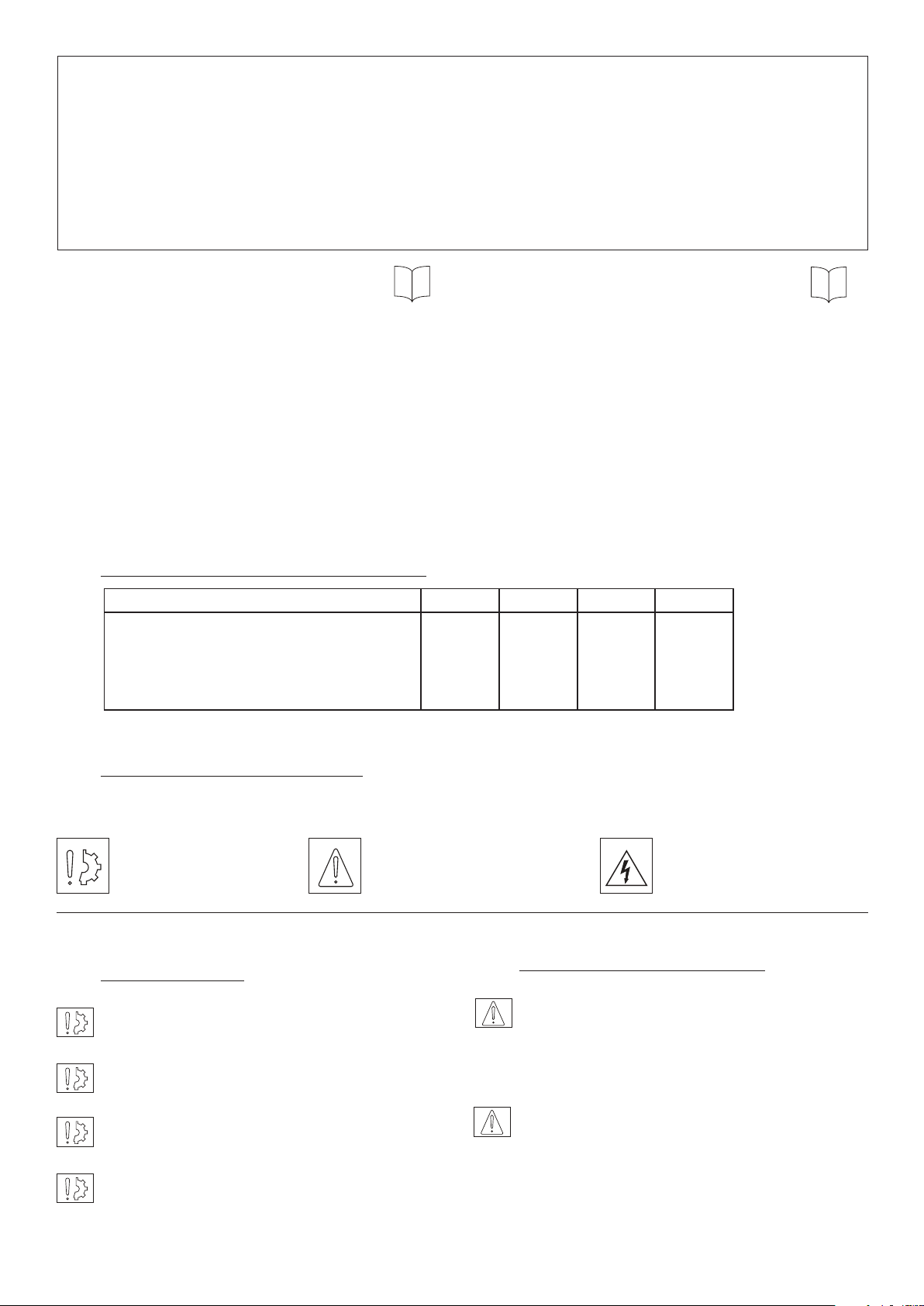

To reset the airgap (figure 1), undo the adjustment

bolts and adjust to obtain the necessary gap

size, (see table 1). Measure the airgap at several

points. Cycle the brake a num ber of times then

re-check.

Airgap

Adjusting screw

Fig. 1

4.2 Maintenance

Wear in the friction material causes an increase

in the air gap. Before reaching the maximum

airgap, see table 1, it is necessary adjust it, see

Fig. 1.

4.3 Spare parts

After several adjustments, variable according

to size and use, it is necessary to replace the

friction disc, see Fig. 2 and table 2.

Put the key into the shaft then slide the hub

(515) onto the shaft and secure it axially by

suitable means.

To replace the friction disc (312) or (315), undo the

fixing bolts (913) or (914) then take off the pre-

assembled induc tor (108) and then the friction

disc. Put the new friction disc into position then

Slide the friction disc (312) or (315) onto the

hub.

If a hand release kit is supplied, it is advisable to

refit the pre-assembled inductor and re adjust the

airgap, see paragraph 4.1.

E

mount it onto the pre-assembled inductor before

the inductor is fitted, see chapter 6.

Fit the pre-assembled inductor (108), remove

the transport shims (551) and fix using the fixing

bolts (913) or (914). Noting carefully the tightening

torque, see table 1.

Secure the bolts using a LOCTITE 270 type

Fig. 2

thermoplas tic liquid. If a dust cover (555) is

supplied, carefully slide it onto the equipment

before fitting.

ERD size 005 010 020 035

E min (mm) w/o hand

release

5,5 5,2 7,8 8,5

Table 2

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13 3

Page 6

5 Electrical connection

6 Options

ERD brakes have to be supplied with direct

current and are factory fitted with 400 mm long

wires. The polarity does not affect operation.

5.1 Important recommendations

All works on the electrical connections have to

be made with power off.

Ensure compliance with the nominal supply

voltage (inade quate supply causes a reduction

in the starting distance).

The connecting wires should be of sufficient

diameter to prevent voltage drops between the

source and equipment supplied.

I (A) / L (m) 0 to 10 m from 10 to 20 m

0 to 3 (A) 1,5 mm2 1,5 mm

3 to 6 (A) 1,5 mm2 2,5 mm

2

2

Tolerance for the supply voltage to the brake

terminals +5% / -10% (NF C 79-300).

6.1 Torque adjustment

Torque adjustment is only possible on

VAR02 (~ 50% of nominal torque).

Brakes are supplied adjusted to nominal torque.

Principle of torque reduction:

On VAR 02 (table 3), undo the adjustment ring

located at the rear of the inductor (see chapter 7).

Standard version

ERD Size 005 010 020 035

Nominal torque (Nm) 5 10 20 35

Max. number of turns

(adjustment ring)

4 4 4 4

Theoretical reduction in

torque for 1 turn of the

0,5 1,3 1,25 2,4

nut (Nm)

Table 3 (VAR 02)

6.2 Detection kit

5.2 Power supply

We advise the use of Warner Electric CBC 140-

1, CBC 140-2 or CBC 140-5 supply units (with

overexcitation and holding voltage)

The supply and switching method has a great

influence on the response time. Response times

shown in our cat alogues are for a supply at

nominal voltage with DC side switching.

In the event of AC switching, the braking

response time may be multiplied by 6.

To get very short brake release and braking

times, we advise the CBC 140-5 (please ask):

• With overexcitation on brake release, the start

time can be divided by 3 (according to the

supply voltage)

• Adjusting the hold voltage to 50% of

the nominal voltage reduces the brake

engagement time and its temperature rise

Fitting (Fig. 4)

Check that the brake is correctly set to the

nominal airgap. Tighten the M6 bolts in the

moving armature then fit the nut (see Fig. 4), then

fix the sensor using the M3 bolts and washers.

Magnet

Screw

washer M3

Moving

Armature

Nut

Switch

X

M5 screw

Fig. 4

Adjustment

Insert a shim 0,15 mm thick near to the bolt

between the face of the inductor and moving

armature. Switch the device on, tighten the bolt

to contact with the sensor until the switch point is

obtained then lock the bolt using the nut.

Warner Electric supply units provide protection

for coils and circuits. Where a brake is used

without our supply units, with switching on the

Check correct operation by making several

successive starts and releases.

DC, it is essential for the coil to be protected

against surges by a varistor fitted in parallel.

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13

Page 7

Switch Characteristics

Protection IP 40

Temperature: -40°C / +85°C

Switching power 5A - 250 VAC

Switch connection

Control position

Red

6.4 Accessories

Dust Cover – (555)

If you are using the brake in a clean environment

or it the surrounding atmosphere is loaded with

dust or humidity we recommend the use of a

dust cover.

Friction Disc Carrier – (312 or 315)

Black

Blue

2 positions

6.3 Hand release kit

Only for use with VAR02

Fitting (Fig. 5 and 6)

Check that the brake is correctly set to the

nominal airgap.

Washerscrew

Hand release

Axle

Spring

X

Fig. 5

Fit the bolts into the lever and through the inductor,

posi tion the springs in the moving armature, then

tighten nut as shown in Fig. 5, respecting dimension

X, see table 5.

Sizes 005 and 010 as standard are supplied with

a syn thetic version. On request, metallic version

for sizes 005 and 010 are also available.

Thick Friction Flange – (341)

If the mounting surface does not meet the

following specifications:

• cast iron or steel surface

• hardness 150 HB

• roughness 3,2 Ra (125 microinches)

• flatness 0,05 mm

then a thin or thick friction flange has to

be used.

Thin Friction Flange – (340)

This flange offers mounting at the inner diameter.

With the thin friction flange the mounting screws

are located at the outside.

Mounting Screw Kit – (913 or 914)

The short mounting screw kit supplied with

the thick flange is for mounting on the external

diameter threaded holes.

The long mounting screw kit supplied with the

thin flange is for mounting through the thin flange

on external diame ter or if ordered separately for

direct mounting without flange.

ERD Size 005 010 020 035

Dim. X (+0,2/0 mm) 111 1,5

Table 5

Removable

Handle

Fig. 6

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13 5

Page 8

7 Appendices

VAR00

7.1 ERD VAR00, VAR02

ERD VAR00

NO. Description

108 Mounted «DC» Magnet

312 Friction disc

315 Friction disc High Torque

515 Hub

551 Wedge

ERD VAR02

Airgap

551

312

315

515

108

VAR02

Airgap

551

NO. Description

108 Mounted «DC» Magnet

312 Friction disc

315 Friction disc High Torque

515 Hub

551 Wedge

7.2 Options

Options

NO. Description

340 Thin friction ange

341 Thick friction ange

418 Hand release kit

555 Dust cover

613 Detection kit

617 Connector kit

913 Set of short xing bolts

914 Set of long xing bolts

418

312

315

515

555

108

914

341

913

340

617

6 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13

613

Page 9

Electrically Release Brakes

ERD Sizes 060 to 300 & ERDD Sizes 120 to 600

Service Manual

P-2058-WE

SM321gb - rev 11/04

Page 10

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the combined clutches and brakes are made in our factory from St Barthélemy d’Anjou,

and hereafter designated : EM and EMER

are exclusively designed for incorporation into a machine and to be assembled with other equipments to create a machine. The operation of

the product is submitted to the conformity of the complete equipment, following the provisions of the machinery directive 89/392/EEC and if

electric to the EMC directive 89/336 /EEC.

The conformity of the electric units to the Low Voltage directive 72/23 is supported by the full respect of the following standards : NFC 79300

and VDE 05808/8.65.

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1 Technical specifications 2

2 Precautions and restrictions on use 2

2.1 Restrictions on use 2

2.2 Precautions and safety measures 2-3

3 Installation 3

3.1 Transport - storage 3

3.2 Handling 3

3.3 Installing 3

4 Maintenance 3

4.1 Adjusting the airgap 3

4.2 Maintenance 3

1 Technical specifications VAR00, VAR02

ERD Size 60 100 170 300

Nominal torque (STANDARD version) Nm

Nominal airgap +0,1/-0,05 mm

Pull-in airgap max. mm

Nominal torque (HIGH TORQUE version) Nm

Tightening torque of screws Nm

ERDD HT Size 120 200 340 600

Nominal torque (HIGH TORQUE version) Nm

Nominal airgap +0,1/-0,05 mm

Pull-in airgap max. mm

Tightening torque of screws Nm

4.3 Spare parts 4

5 Electrical connection 4

5.1 Important recommendations 4

5.2 Power supply 4

6 Options 4

6.1 Torque adjustment 4

6.2 Detection kit 5

6.3 Hand release kit 5

7 Appendices 6

7. 1 ERD VAR00 and VAR02 7

7.2 Options 7

60

0,3

0,8

80

24

160

0,3

0,8

24

100

0,3

0,9

130

24

260

0,4

0,9

24

170

0,3

0,9

220

24

440

0,4

0,9

24

300

0,3

1

400

48

800

0,4

1

48

Table 1

2 Precautions and restrictions on use

2.1 Restrictions on use

2.2 Precautions and safety measures

The equipment is designed for dry

running.

During maintenance, ensure that the Mechanism

to be braked by the equipment is at rest and

that there is no risk of accidental start-up.

Exceeding the maximum rotation speeds stated

in the catalogue invalidates the warranty.

The equipment can be fitted either horizontally or

vertically. The ERDD and HT version can only be

fitted horizontally.

All intervention have to be made by qualified

personnel, owning this manual.

Any modification made to the brake without

the express authorisation of a representative of

Warner Electric, in the same way than any use

out of the contrac tual specifications accepted by

This equipment is designed for an ambient

temperature of 40° maximum (155°C cladding

class).

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13

“Warner Electric”, will result in the warranty being

invalidated and Warner Electric will no longer be

liable in any way with regard to conformity.

Page 11

Symbol designating

an action that might

damage the brake

Symbol designating an

action that might be

dan gerous to human safety

Symbol designating an

elec trical action that might be

dangerous to human safety

3 Installation

3.1 Transport / storage

These units are delivered in packaging that

guarantees a 6 months storage period whether

transported by land, by air, or by sea to any

destination excepting tropical countries. (For

tropical destinations please consult Warner

Electric technical services).

3.2 Handling

Avoid any impacts on the equipment so as not

to alter their performance.

Never carry the equipment by the electrical

supply cable.

3.3 Installing

NB : ERD SZ060 to 300 brakes are supplied in

kit form. The Mounted inductor is supplied

airgap adjusted.

The ERDD HT brakes are delivered completely

mounted, the airgap is adjusted in our

workshop. See chapter 7 (appendix)

Do not grease the guiding splines (friction

disc / hub). It will change the brake’s

performances.

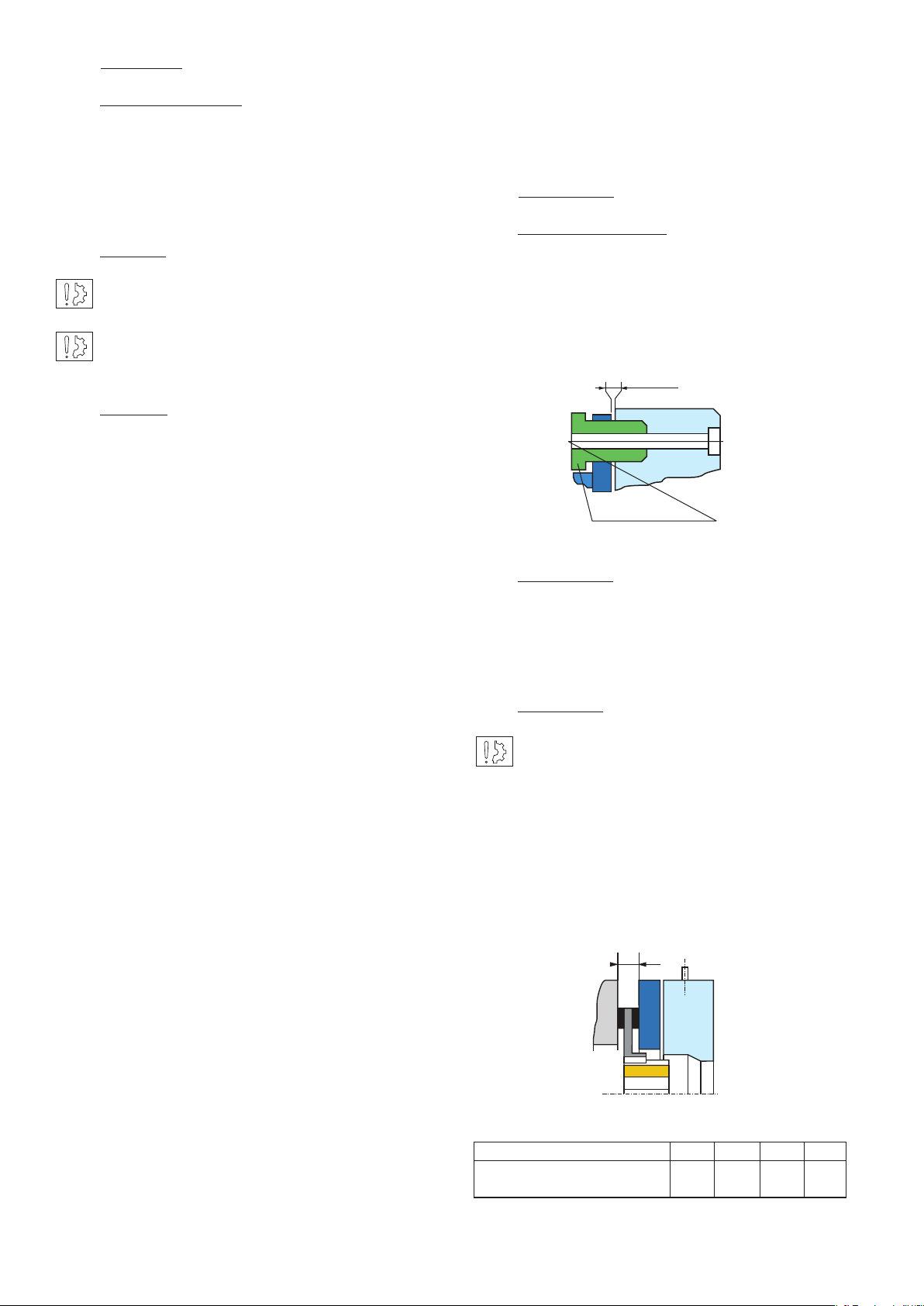

WATCH OUT ! Respect obligatory the direction

of the hub when mounting (see fig. 1 below)

ERD ERDD HT

Fig. 1

4 Maintenance

4.1 Adjusting the airgap

To adjust the airgap (Fig. 2), undo the adjustment

bolts in order to get the necessary value (see table

1). Check the value of the airgap at several points.

Make several motor manoeuvres stationary, then

again check the value of the airgap.

If a friction flange (341) is supplied, fix it first.

Put the key into the shaft then slide the hub

(515) onto the shaft and stop it axially by

suitable means.

Slide the friction disc (312) or (315) onto the

hub.

Fit the mounted inductor (107) or (108), remove

the wedge pieces (551) and fix it using the

fixing bolts (913) or (914).These screws have

to be tightened (see torque table 1). Secure the

bolts using a LOCTITE 270 type thermoplastic

liquid.

If a hand locking kit is supplied, it is preferable

to adapt it on the mounted inductor before the

inductor is fitted. (See chapter 6)

If a dust cover (555) is supplied, carefully slide it

onto the equipment before fitting it.

Switch the equipment on and confirm that the

friction disc rotates freely.

Make several motor manoeuvres stationary and

check the value of the airgap.

If the airgap is insufficient, refer to chapter 4

(maintenance)

Airgap

Adjusting screw

Fig. 2

ERD Size 060 100 170 300

E min (mm) 6 6 7,7 8

ERDD HT Size 120 200 340 600

E min (mm) 11,2 10 12,7 12,3

Table 2

4.2 Maintenance

Wear in the friction material causes an increase

in the air gap. Before reaching the maximum

airgap (see table 1), it is necessary adjust it (see

above).

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13 3

Page 12

4.3 Spare parts

After several adjustments, variable according

to size and use, it is necessary to replace the

friction disc (see Fig. 3 and table 2)

E

Fig. 3

To replace the friction disc(s) (312) or (315), undo

the fix ing bolts (913) or (914) then take off the

mounted induc tor (107) or (108) and then the

friction disc(s). Put the new friction disc(s) into

position then refit the mounted inductor and

adjust the airgap (see paragraph 4.1).

5 Electrical connection

ERD and ERDD HT brakes have to be supplied

with direct current and are factory fitted with

400 mm long wires. The polarity does not affect

operation.

5.1 Important recommendations

In the event of AC switching, the braking response

time may be multiplied by 6.

To get very short brake release and braking

times, we advise the CBC 140-5 (please ask):

• With overexcitation on brake release, the start

time can be divided by 3 (according to the

supply voltage)

• Adjusting the hold voltage to 50% of

the nominal voltage reduces the brake

engagement time and its temperature rise

Warner Electric supply units provide protection for

coils and circuits. Where a brake is used without

our supply units, with switching on the DC, it is

essential for the coil to be pro tected against

surges by a varistor fitted in parallel.

6 Options

6.1 Torque adjustment

Torque adjustment is only possible on VAR02 ( ~

50% of nominal torque).

Brakes are supplied adjusted to nominal torque.

Principle of torque reduction:

On VAR 02 (table 3), undo the adjustment ring

located at the rear of the inductor (see chapter

7).

All works on the electrical connections have to

be made with power off.

Ensure compliance with the nominal supply vol-

tage (inadequate supply causes a reduction in

the starting distance).

The connecting wires should be of sufficient

diameter to prevent voltage drops between the

source and equipment supplied.

I (A) / L (m) 0 to 10 m from 10 to 20 m

0 to 3 (A) 1,5 mm2 1,5 mm

3 to 6 (A) 1,5 mm2 2,5 mm

2

2

Tolerance for the supply voltage to the brake

terminals +5% / -10% (NF C 79-300).

5.2 Power supply

We advise the use of Warner Electric CBC 140

1, CBC 140-2 or CBC 140-5 supply units (with

overexcitation and holding voltage)

The supply and switching method has a great

influence on the response time. Response times

shown in our cat- alogues are for a supply at

nominal voltage with DC side switching.

STANDARD version

ERD Size 060 100 170 300

Nominal torque (Nm) 60 100 170 300

Max. number of turns

(adjustment ring)

Theoretical reduction in

torque for 1 turn of the

nut (Nm)

HIGH TORQUE version

ERD Size 060 100 170 300

ERDD Size 120 200 340 600

Nominal torque (Nm)

Max. number of turns

(adjustment ring)

Theoretical reduction in

torque for 1 turn of the

nut (Nm)

Table 3 (VAR02)

3 3 4,5 5,5

11 16 25 34

80 130 220 400

160 260 440 800

3 3 4,5 5,5

15 21 32 45

30 42 64 90

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13

Page 13

6.2 Detection kit

Fitting

6.3 Hand release kit

Only for use with VAR02

Magnet

Screw

washer M3

Moving

Armature

Nut

Switch

X

M5 screw

Fig. 4

Check that the brake is correctly set to the

nominal airgap. Tighten the M5 bolts in the moving

armature then fit the nut (see figure 4), then fix the

sensor using the M5 bolts and washers.

NB : The M3 fixing bolts are self tapping.

Adjustment

Insert a shim 0,15 mm thick near to the bolt

between the face of the inductor and moving

armature. Switch the device on, tighten the bolt

to contact with the sensor until the switch point

is obtained then lock the bolt using the nut.

Fitting: (Fig 5 and 6)

Check that the brake is correctly set to the

nominal airgap.

Washerscrew

Hand release

Axle

Spring

X

Fig. 5

Removable

Handle

Check correct operation by making several

successive starts and releases.

Switch characteristics

Protection IP 65

Temperature -40°C / +120°C

Cable 3 x 0,75 mm

Switching power: 8A-250VAC / 6A - 380 VAC

Switch connection

Control position

Red

Black

Blue

2 positions

Fig. 6

Fit the spindles in the lever, the springs in the

moving arma ture, then the bolts and washers as

shown in figure 5, res pecting dimension X (See

table 4)

ERD size 060 100 170 300

ERDD HT size 120 200 340 600

Dim. X (+0,2/0 mm) 111 1,5

Table 4

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13 5

Page 14

7 Appendices

7.1 ERD VAR00, VAR02

ERD VAR00

NO. Description

107 Mounted «AC» Magnet

108 Mounted «DC» Magnet

312 Friction disc

315 Friction disc High Torque

515 Hub

551 Wedge

Airgap

551

312

315

515

107

108

VAR00

ERD VAR02

NO. Description

107 Mounted «AC» Magnet

108 Mounted «DC» Magnet

312 Friction disc

315 Friction disc High Torque

515 Hub

551 Wedge

Airgap

551

312

315

515

107

108

VAR02

6 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13

Page 15

7.2 ERDD HT and options

ERDD HT

NO. Description

108 Mounted «DC» Magnet

312 Friction disc

315 Friction disc High Torque

320 Intermediate Disc

341 Thick Friction Flange

515 Hub

551 Wedge

914 Set of long Fixing Bolts

341 320

551

914

108

515

312

315

Options

NO. Description

339 Friction flange FERMG

341 Thick friction flange

418 Hand release kit

555 Dust Cover

613 Detection Kit

617 Connector Kit

913 Set of short xing bolts

914 Set of long xing bolts

555

617

339

418

341

914

913

613

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2060-WE • 2/13 7

Page 16

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and

sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original

purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s

prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to

the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer

Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-

3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found

defective under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for

transportation costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or

replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and

in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by

reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU

OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric Europe

7 rue Champfleur, B.P. 20095, St Barthelemy d’Anjou - France

+33 (0)2 41 21 24 24 • Fax: +33 (0)2 41 21 24 70

www.warnerelectric.com

Printed in USAP-2060-WE • 2/13

Loading...

Loading...