Page 1

Washdown Electro-Packs EP-250-W, EP-400-W

Foot Mounted Clutch/Brakes

P-1510

819-0475

Installation Instructions

Page 2

Contents

Product Description

Product Description . . . . . . . . . . . . . . . . . . . . . 2

Installation Instructions . . . . . . . . . . . . . . . . . . . 3

Electrical Connections. . . . . . . . . . . . . . . . . . . . 3

Burnishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Servicing Worn Components . . . . . . . . . . . . . . 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 4

Clutch/Brake Selection Information

Horsepower vs. Shaft Speed . . . . . . . . . . . . 5

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . 5

Mechanical Specifications . . . . . . . . . . . . . . 5

Electrical Coil Data . . . . . . . . . . . . . . . . . . . . 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty . . . . . . . . . . . . . . . . . . . . . . Back Page

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

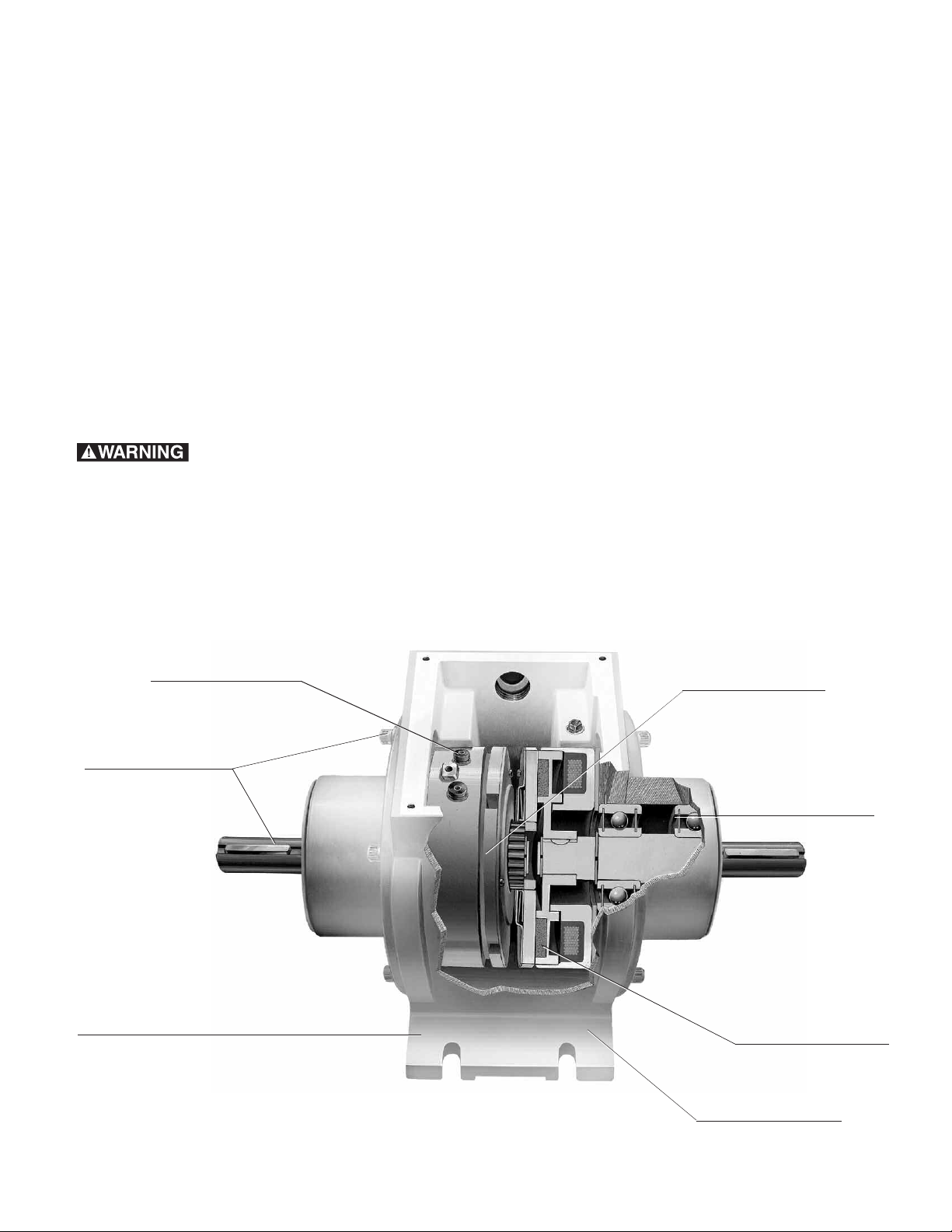

Base Mounted Clutch/Brake Combinations

in a Rugged Washdown Housing

Meets electrical codes

UL Listed or CSA Certified.

The Washdown Electro-Pack (EP-W) is a

pre-assembled foot mounted clutch/brake

package complete with input and output shafts.

EP-Ws are specifically designed for applications

that require washing with high-pressure spray

systems. Their smooth exterior reduces the

accumulation of food particles or other

contaminants, which can cause bacteria growth.

They are coated with a USDA approved nontoxic

white paint that is extremely resistant to chipping

and corrosion. All fasteners, shafts, and keys are

made from stainless steel to prevent corrosion,

and the bearings are sealed and shielded to

prevent contamination during washdown.

EP-Ws are ready to be installed in all standard

power transmission systems using V-belts and

pulleys, chains and sprockets, in-line couplings,

timing belt drives, or gear trains.

Pre-packaged

Over 20 major

components

have been pre-engi-

neered and pre-

assembled in a typical

Electro Pack. Ready-

to-go, straight from

the box.

Corrosion Resistant

Stainless steel shafts,

keys and fasteners.

Foot mounted

Bolt-it-down and wire-it-up. Allows for

quick replacement/reduced downtime.

Smooth exterior with USDA

Warner Electric • 800-825-9050 P-1510 • 819-0475

2

Heavy duty bearings

Sealed and shielded to

resist contamination.

Properly aligned for

maximum performance.

Maintenance free

Never needs lubrication.

Self-adjusting for wear of

clutch-brake friction faces.

Consistent performance.

BISSC Certified

approved white coating.

Page 3

Installation Instructions

C

C

B

B

Clutch/Brake

Control

DC

Vol t age

Clutch

Brake

AC

Vol t age

Input

Output

1. Review the selection procedure on page 5 to

determine if the selected Washdown

Electro-Pack (EP-W) is the appropriate size

and voltage for the intended application.

2. Identify the input end of the EP-W by locating

the word "INPUT" cast into the side of the

housing.

3. Mount the EP-W to a rigid surface that is flat

within the following tolerances. Position the

input end toward the intended drive system

input.

Electro-Pack Mounting Surface

Size Flatness

250 .004"

400 .004"

1. Remove the four screws and cover from the

top of the EP-W to gain access to the

electrical terminals on the clutch field and

brake magnet. (Figure 1)

2. Feed lead wires through one of the two 1/2"

conduit holes in the side of the EP-W housing.

3. Using the provided wire terminals, make the

proper electrical connections between the EPW and a suitable DC power supply. Refer to

Figure 2 for typical EP-W connections. Polarity

is not important when wiring Electro-Pack

units.

Warner Electric offers a full line of AC input, DC

output controls to meet the needs of most

clutch/brake applications. The service and

installation instructions included with each control

show the proper connections.

4. Attach the drive system hardware to the input

and output shafts of the EP-W. Be sure to

connect the power input to the input shaft of

the unit. Serious system damage may occur if

the power input is connected to the EP-W

output shaft. See page 5 for shaft

dimensions.

Electrical Connection

All electrical current must be

off when making electrical connections to

prevent injury or death which can result from

contact with live wires.

Figure 1

Warner Electric • 800-825-9050 P-1510 • 819-0475

Figure 2

4. Replace the cover and four screws.

Burnishing

To obtain optimum Electro-Pack performance, a

wear-in process called burnishing is required

between the clutch and brake friction faces within

the unit. Warner Electric Electro-Packs are

burnished at the factory, eliminating the need to

burnish the unit upon installation.

Maintenance

Properly applied and installed Electro-Packs do

not require service, lubrication, or maintenance.

The Washdown EP is designed to withstand

limited exposure to high ambient temperatures

and high-pressure wash systems, however

optimum appearance and wear life will be

obtained if this type of exposure is minimized.

3

Page 4

Servicing Worn Components

The normal wearing components of an ElectroPack are the brake magnet/armature, and the

clutch rotor/armature. Since special tools are

required to service these components, Warner

Electric does not recommend user service of the

Troubleshooting

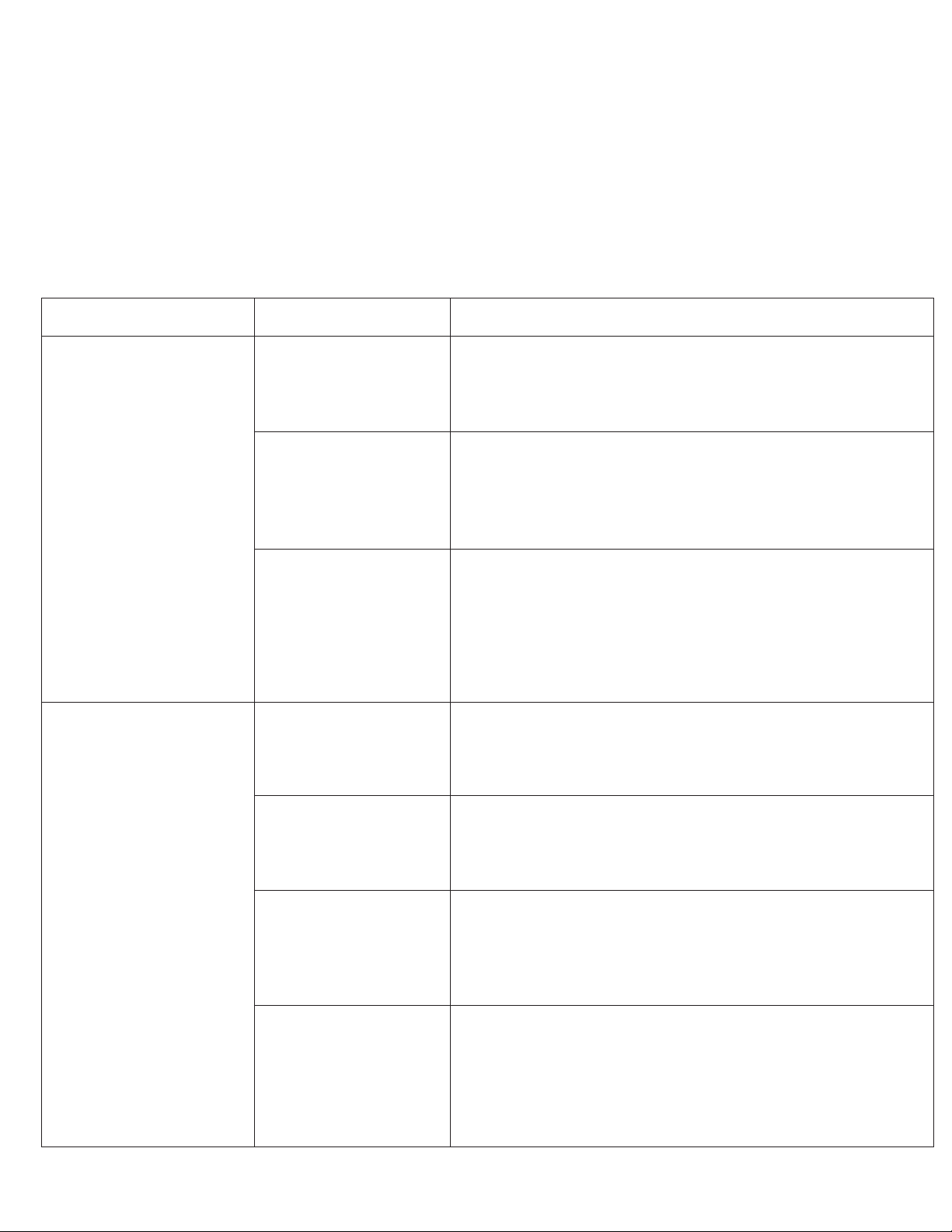

Problem Possible Cause Correction

No or insufficient DC power

supplied to clutch or brake

coils.

Incorrect coil resistance.

Clutch or brake fails to engage.

Clutch or brake air gap out of

adjustment.

units. For more information contact your Warner

Electric distributor, or call Warner Electric at

1-800-234-3369.

Remove the EP-W cover, turn on the electrical power to the terminals, and

check the voltage across each pair of terminals. The voltage at the terminals

should be within 5% of the units rated voltage. If not, adjust or change the

power supply to obtain the rated voltage.

Remove the EP-W cover, disconnect the lead wires from the terminals on the

clutch and brake coils, and measure the resistance of each coil with an

appropriate ohmmeter. Both resistance measurements should be within 10%

of the values listed in the Electrical Specifications of this instruction sheet. If

not, replace the EP-W with a new unit.

Remove the EP-W cover, and inspect the gaps between the clutch rotor and

armature, and the brake magnet and armature. The gaps should be no larger

than .023" for EP-W-250's, and .037" for EP-W-400's. Adjust the gaps by

axially moving the appropriate armature until the gap is correct. Once set,

turn the clutch and brake power on and off to confirm that they engage, and

rotate the input and output shafts to confirm that the friction surfaces do not

drag when disengaged. Readjust if necessary.

Clutch or brake slips.

EP-W not properly sized for

intended application

Insufficient DC power supplied to clutch or brake coils.

Incorrect coil resistance.

Clutch or brake friction faces

contaminated.

Review the Selection Information page of this instruction sheet to determine

if the EP-W is properly sized for the application. For additional assistance,

contact your Warner Electric distributor or Warner Electric Technical Support

at 1-800-825-9050.

Remove the EP-W cover, turn on the electrical power to the terminals, and

check the voltage across each pair of terminals. The voltage at the terminals

should be within 5% of the units rated voltage. If not, adjust or change the

power supply to obtain the rated voltage.

Remove the EP-W cover, disconnect the lead wires from the terminals on the

clutch and brake coils, and measure the resistance of each coil with an

appropriate ohmmeter. Both resistance measurements should be within 10%

of the values listed in the Electrical Specifications of this instruction sheet. If

not, replace the EP-W with a new unit.

Remove the EP-W cover and inspect the clutch and brake friction faces for

contaminants. The friction surfaces should have a dry, polished appearance

with some dust present. If they are wet or oily they can be carefully cleaned

with a solvent, but optimum performance may never be achieved once the

faces are contaminated. If slipping persists after cleaning, replace the EP-W

with a new unit.

Warner Electric • 800-825-9050 P-1510 • 819-0475

4

Page 5

1/50

1/20

1/12

1/8

1/6

1/4

1/3

1/2

3/4

1

1-1/2

2

3

p p

HP

100

1000

200 300 400 500 600

700

800 900

110 0 12 00 15 00 18 00 2 000 24 00 3 000 36 00 40 00 45 00 5 000

SHAFT SPEED AT CLUTCH (IN RPM)

EP-250

EP-400

Clutch/Brake Selection Information

Output

A

B

C

D

H

E

G

F

E

D

C

B

Input

Brake

Clutch

O

M

N

L

K

J

I

Horsepower vs. Shaft Speed

Mechanical Specifications

Model Size DC 1800 RPM lb. in. Output Input RPM lbs.

EP-250 24

EP-400 24

Electrical Coil Data

Voltage – DC 24 90 24 90

Resistance @ 20˚ C – Ohms 76.4 1079 73 1087

Current – Amperes .314 .084 .332 .083

Watts 7.5 7.51 8.04 7.45

Coil Build up – milliseconds 48 44 154 154

Coil Decay – milliseconds 15 13 60 55

Build-up time equals current to approximately 90% of steady state value and flux to 90%. Decay time equals current to approximately 10% of

steady state value and flux to 10%. Values are approximate because current changes lead or lag flux changes by a small amount.

Selection Procedure

Determine the shaft speed at the Electro

Pack location. The number listed at the

intersection of horsepower and speed is

the size Electro Pack you require.

Part Numbers

Model Voltage

No. DC Part No.

EP-250 24 5130-273-060

90 5130-273-061

EP-400 24 5131-273-030

90 5131-273-031

Voltage Horsepower @ Static Torque Inertia–WR2(lb-in2) Max. Weight

90

90

1/2 70 .331 .293 7,500 7.1

1 270 2.566 2.222 4,500 19.7

EP-250-W EP-400-W

Clutch/Brake Clutch/Brake

Dimensions All dimensions are nominal, unless otherwise noted.

Size ABC Min. DEFG Max. HIJKLMNO

250-W 1/8 x .4995 1.250 2.468 3.312 2.250 8.968 .312 Wide 5.281 2.318 .375 1.625 3.250 4.250 1/2 - 14 NPT

1/8 x .4985 (4 slots) 2.308 conduit x 2

7/8 Dia.

400-W 3/16 x .7495 1.875 3.515 4.593 2.500 11.781 .312 Wide 6.937 3.474 .500 2.578 5.156 6.000 1/2 - 14 NPT

3/16 x .7485 (4 slots) 3.464 conduit x 2

1-3/8 Dia.

Warner Electric • 800-825-9050 P-1510 • 819-0475

5

Page 6

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may

be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner

Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you will be

notified and, with your consent, the item will be repaired or replaced and returned to you at your

expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may

not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other

warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE

PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE,

INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished without

charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road

815-389-3771

www.warnerelectric.com

An Altra Industrial Motion Company

P-1510 819-0475 06/11 Printed in USA

• Fax: 815-389-2582

• New Hartford, CT 06057

Loading...

Loading...