Page 1

Electrically Released Motor Brake

Module for EM-MBFB and EUM-MBFB

P-1337

819-0314

Installation Instructions

Page 2

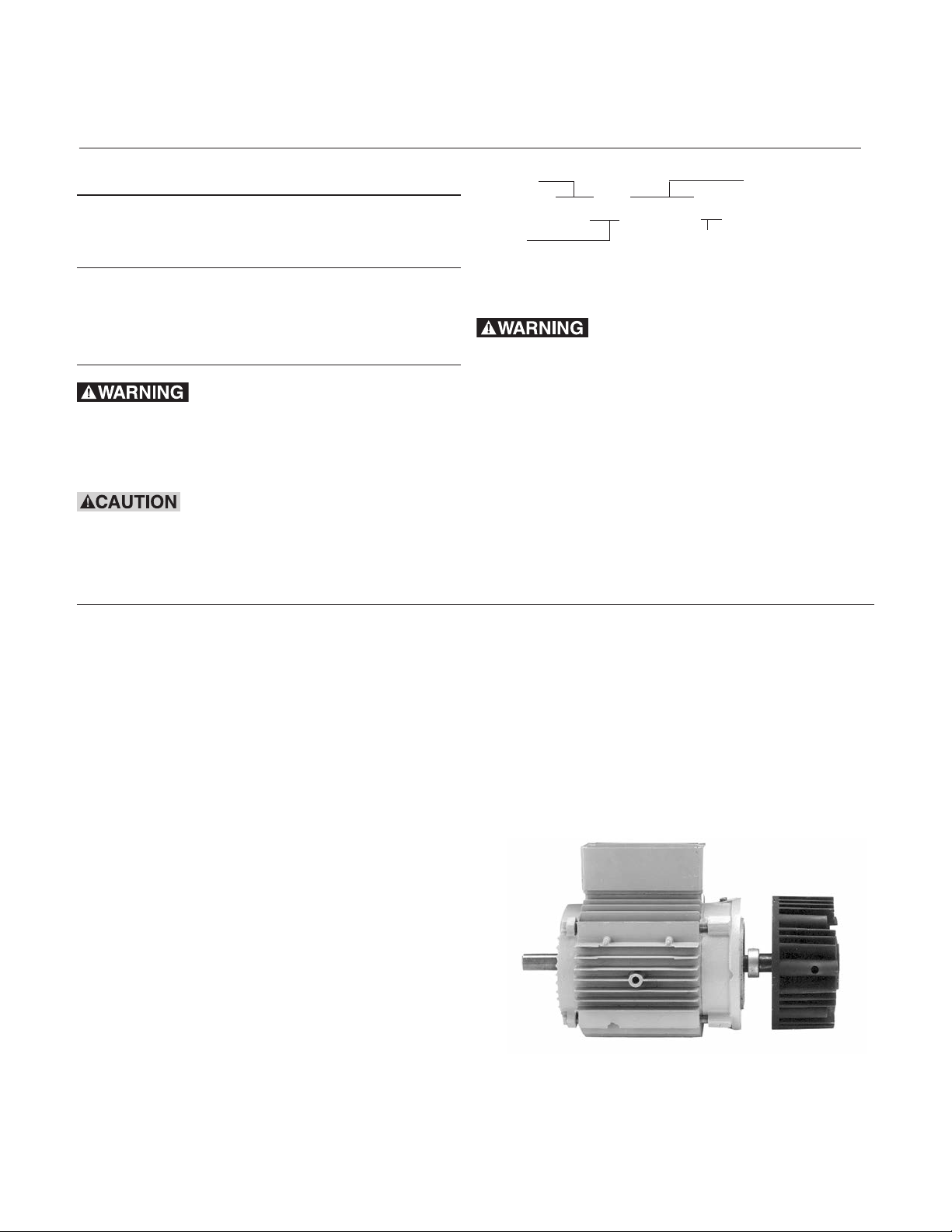

Warner Electric’s MBFB series of Electrically Released Brake Modules are designed for brake

only applications when mounted to the back of a NEMA C-face double shaft motor.

The fail safe brake engages when power goes off.

Model Part No.

EM 210-20MBFB-56 5371-169-030

EM 210-20MBFB-56, 24V 5371-169-033

EM 210-7/8-20MBFB-56 5371-169-072

EUM 210 7/8-20MBFB-32 5371-169-064

EUM 210 7/8-20MBFB-56 5371-169-068

EUM 210-20MBFB-32 5371-169-056

EUM 210-20MBFB-56 5371-169-060

Failure to follow these instructions may result

in product damage, equipment damage, and

serious or fatal injury of personnel.

If brake is to be applied with the

brake output shaft in a vertical condition

Warner Electric's application engineering

should evaluate application.

Model Configuration

EUM 210-20MBFB-32

Size Static Torque lb. ft.

The term “fail safe” describes a brake that

engages automatically when its full power is

shut off for whatever reason. The term, as

applied to brakes, designates a mode of

operation, not a guarantee of safety for the

equipment on which the brake is mounted

and for personnel who are near it.

Mounting Instructions

Step 1: Mounting the Brake to a Motor

The brake module (20) can be mounted

directly to the motor as follows:

A. Insert a key in the motor shaft keyway. Prick

punch the end of the motor shaft keyway to

prevent the key from sliding out.

B. A set collar is provided in the EM-210

mounting accessory to prevent the key from

sliding out. Slide the set collar against the

motor bearing and tighten the set screw

securely. (See Figure 1)

C. Align the motor shaft and key with the mating

shaft hole and key slot in the brake module.

D. Slide the module onto the motor shaft so the

module surface is snug against the motor face.

NOTE: Brake Module should slide freely

onto shaft and fit flush with motor c-face.

E. Secure the brake module in the motor C-face

with the four (4) long hex head capscrews.

Suggested torque for capscrews is 30-35 lb.ft.

(Figure 1)

Warner Electric • 800-825-9050 P-1337 • 819-0314

2

Page 3

Step 2: Electrical Connections

24 Volt Brake recommended controls are:

The conduit hole in the motor brake is threaded

for standard pipe conduit connectors. The wiring

diagram included with each Warner Electric control

shows the proper electrical connections to be made.

Note: Controls used must have adjustable

output voltage.

Connect the red wire from the unit to the “+”

terminal of the DC supply and the black wire from

the unit to the “-” terminal of the DC supply.

Note: Refer to the brake release adjustment

process on page 4.

Control Requirements

All Permanent Magnet Type Electrically Released

Brake Modules are polarity sensitive. Therefore, the

(+) red wire must be connected to the (+) terminal

and the (-) black wire to the (-) terminal.

Potentiometer control will then provide adjustment

for the proper brake release point as described in

the “brake release” procedure.

CBC-500-24, 24-30 VAC input

part no. 6024-448-002

CBC-550-24, 120/220/240/380/480 VAC input

part no. 6024-448-005

All Permanent Magnet type

Electrically Released Brake Modules are

polarity sensitive. See the service installation

sheet included with the control for connection

information.

Burnishing and Maintenance

No burnishing required, units are pre-burnished at

factory.

As with any friction-type device, some initial

concern should be given to wear rate.

Improper voltage setting can reduce the braking

life. Once the best release voltage has been

established, precautions should be taken to

prevent machine operators, or other personnel not

familiar with wear characteristics, from changing

the potentiometer setting arbitrarily.

See the service installation instruction provided with

controls for connection information.

To reach the normal wearing components, reverse

the installation procedure for the module assembly.

Wear Pattern

90 Volt Brake recommended controls are:

Wear grooves appear on the friction surfaces. This

*CBC-160-1 120 VAC input

part no. 6013-448-001

*CBC-160-2 220-240 VAC input

part no. 6013-448-002

CBC-200 120 VAC input

part no. 6011-448-001

CBC-300 120 VAC input

part no. 6021-448-001

CBC-500-90 120 VAC input

part no. 6024-448-003

CBC-550-90 120/220/240/380/480 VAC input

part no. 6024-448-006

*These controls are for use with conduit box kit

part no. 5370-101-042. All others require other

enclosures or alternate mounting.

Warner Electric • 800-825-9050 P-1337 • 819-0314

is a normal wear condition, and does not impair

functioning of the unit. Never machine the friction

surfaces to remove grooves or score marks

resulting from normal wear.

Heat

Excessive heat and high operating temperatures

are causes of rapid wear. Units, therefore, should

be ventilated as efficiently as possible, especially if

the application requires fast, repetitive cycle

operation.

3

Page 4

Foreign Materials

If units are used on machinery where fine,

abrasive dust, chips or grit are dispelled into the

atmosphere, a screen over the ventilation holes

may be necessary.

Where units are used near gearboxes or

transmissions requiring frequent lubrication, means

should be provided to protect the friction surfaces

from oil and grease to prevent serious loss of

torque.

Oil and grease accidentally reaching the friction

surfaces may be removed by wiping with a rag

dampened with a suitable cleaner, which leaves no

residue. In performing this operation, do not

drench the friction material. If the friction materials

have been saturated with oil or grease, no amount

of cleaning will be completely effective. Once such

a unit has been placed back in service, heat will

cause the oil to boil to the surface, resulting in

continued torque loss.

Brake Release Adjustment

Instructions for setting the

optimum release voltage of permanent magnet

applied/electrically released brakes.

The following procedure will result in the brake

releasing and allowing the load to be free to

move. Be sure the load is in a safe condition

before proceeding with this process.

In a permanent magnet applied/electrically

released brake, the attractive force between the

brake surfaces is created by permanent magnets.

The brake is electrically released by applying DC

power to the electro-magnetic coil in the brake

that opposes the permanent magnets. Electrically

released brakes are polarity sensitive: the positive

lead of the power supply must be connected to

the positive (red) lead of the brake, and the

negative lead of the power supply must be

connected to the negative (black) lead of the

brake. The power supply applied to the brake

must also be adjustable so that the optimum

release voltage for each individual brake can be

determined and set.

The following procedure describes

how to set the adjustable power supply to the

optimum release point of the brake. A volt-meter

is required to perform the procedure.

No power is applied to motor during this

procedure. Power normally supplied by motor

to brake control should be supplied by

alternate method.

After control is adjusted per steps below,

brake control may need to be fine tuned

(adjusted) with motor running to compensate

for any changes in supply voltage used.

1. With power off, connect the positive lead of

the power supply to the positive (red) lead of

the brake and the negative lead of the power

supply to the negative (black) lead of the

brake.

2. Connect a volt-meter to measure the voltage

applied across the brake.

3. Adjust the power supply to its lowest

possible output, then energize the power

supply only, to apply power to the brake.

4. Starting from the low point, slowly increase

the applied voltage until the brake armature

disengages from the magnet. Note and

record the applied voltage at this point.

5. Continue to slowly increase the applied

voltage until the armature re-engages the

magnet. If the maximum voltage available

from the supply does not cause the armature

to re-engage, the armature should be

manually assisted into engagement.

Note: If armature needs to be manually

assisted, armature should be pressed on

back side to make contact with friction

face of magnet.

Warner Electric • 800-825-9050 P-1337 • 819-0314

4

Page 5

6. With the armature re-engaged, slowly

reduce the applied voltage until the armature

disengages from the magnet. Note and record

the applied voltage at this point.

7. The optimum release point for the brake is

half-way between the two recorded voltage

readings. Adjust the supply to this optimum

release voltage.

Note: The above procedure should be done by

visually watching the armature move and may

be repeated if necessary from Step 1 through

Step 7.

If any problems should occur during adjustments or

application questions arise, please contact Technical

Support at 1-800-825-9050 Monday through Friday

7:30 a.m. - 4:30 p.m. central time.

Notes: Visit Warner Electric’s website at

www.warnerelectric.com for dimensional

drawings, weights, inertias and a complete

offering of our products including clutches, brakes,

and clutch or brake controls and service parts.

In addition, Warner Electric module products,

controls and service parts information can be found

in our catalog P-1234-WE. Call 815-389-3771 to

request any of our catalogs.

Warner Electric • 800-825-9050 P-1337 • 819-0314

5

Page 6

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within

a period of one (1) year from the date of original purchase for consumer, commercial or industrial

use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you will

be notified and, with your consent, the item will be repaired or replaced and returned to you at your

expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give any

other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1337 • 819-0314 8/11 Printed in USA

Loading...

Loading...