Page 1

Electro-Magnetic Single Disc

Clutch and Brake Combination EM and EMER

Service Manual

P-2055-WE

SM305gb - rev 11/04

Page 2

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the combined clutches and brakes are made in our factory from St Barthélemy d’Anjou,

and hereafter designated : EM and EMER

are exclusively designed for incorporation into a machine and to be assembled with other equipments to create a machine. The operation of

the product is submitted to the conformity of the complete equipment, following the provisions of the machinery directive 89/392/EEC and if

electric to the EMC directive 89/336 /EEC.

The conformity of the electric units to the Low Voltage directive 72/23 is supported by the full respect of the following standards : NFC 79300

and VDE 05808/8.65.

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1 Technical specifications 2

1.1 Description 2

1.2 Operation and principle 2

1.3 Basic data 2

2 Precautions and restrictions on use 3

2.1 Restrictions on use 3

2.2 Precautions 3

and safety measures

3 Installation 3

3.1 Transport - storage 3

1 Technical specifications

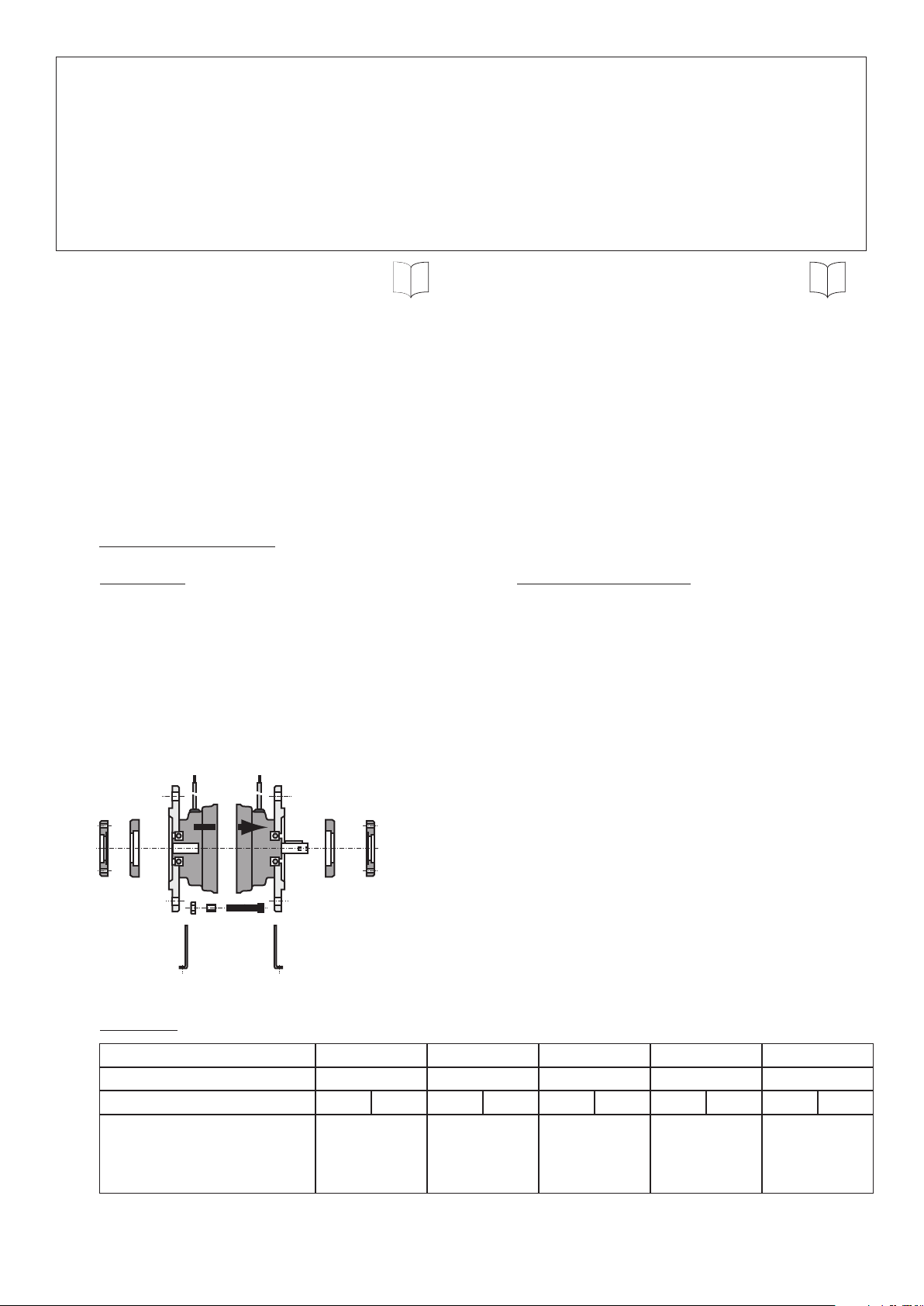

1.1 Description

Pre-assembled, combined assembly consisting

of a clutch and an electromagnetic brake in a

closed casing with mod ulable interfaces. An

arrow on the casing shows the movement

transmission direction. The start of the arrow

shows the input which is on the clutch side. The

end of the arrow shows the output which is on

the brake side of the unit.

Cover

INPUT

Cover

OUTPUT

3.2 Handling 3

3.3 Installing 3

3.3.1 Installing interfaces 3

3.3.2 Examples of typical assemblies 4

4 Electrical connection 4

4.1 Important recommendations 4

4.2 Power supply 4

5 Appendixes 5

5.1 EM and EMER general configuration 5

1.2 Operation and principle

EM and EMER clutches-brakes are mono

friction disk and operate dry, they are activated

or inactivated electro magnetically. The clutch

and brake, in the EM type version, are

engaged alternately whereas in the EMER

type version, the clutch and brake are

engaged simultaneously.

The EMER type describes the clutch-brake

where the brake is electrically retained. When

the EMER’s clutch and brake are no longer

powered, the permanent magnet brake

immobilizes movement and acts as a parking

brake.

Flange

Feet

Flange

1.3 Basic data

EM ER EM ER EM ER EM ER EM ER

Size 2 3 4 5 6

Transmissible Torque 7,5 4,5 15 9 25 14 50 28 130 76

Max. Speed min

Weight kg

Outer ø mm

Height of shaft on foot mm

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2055-WE • 2/13

Nm

-1

3600

2,9

112

63

3600

4

142

71

3600

7

180

90

3600

11

200

100

3600

23

240

132

Page 3

Symbol designating

an action that might

damage the brake

Symbol designating an

action that might be

dan gerous to human safety

Symbol designating an

elec trical action that might be

dangerous to human safety

2 Precautions and restrictions on use

2.1 Restrictions on use

This equipment is designed for dry running in an

IP 64 envelope. Any link to a casing with oil bath

must have non standard, reinforced strength

seals.

Exceeding the maximum rotation speed stated in

the basic data invalidates the warranty.

Clutch-brakes are normally fitted horizontally.

Clutch-brakes are supplied not burnished, they

only transmit about 50% of nominal torque

when new. The higher the speed and torque, the

shorter the bur nish in time. For critical applications

(fast cycles, accurate stop-start), a phase must

be provided to bed in the equip ment and in

this case a supply with overexcitation is par

ticularly recommended.

The equipment is designed for an ambient

temperature of 40° max. and has a 155°C

insulation class.

2.2 Precautions in use and safety measures

This equipment is maintenance-free because an

automatic wear compensator(autogap) is fitted.

If it has to be opened, ensure that it is completely

discon nected electrically and that there is no risk

of accidental start up. All intervention have to

be made by qualified person nel, owning this

manual.

Any modification made to the brake without

the express authorization of a representative of

Warner Electric, in the same way than any use

out of the contrac tual specifications accepted by

“Warner Electric”, will result in the warranty being

invalidated and Warner Electric will no longer be

liable in any way with regard to conformity.

3 Installation

3.1 Transport / storage

Our pre-assembled equipment is supplied in

individual packaging with a label stating the

order configuration.

Our clutches are supplied in packaging

guaranteeing a preservation period of 6 months

with land or air transport, or after transport by

ship to neighbouring continents (with out crossing

the tropics).

3.2 Handling

Never carry the equipment by its electricity

supply cables or connectors.

3.3 Installing

3.3.1 Installing interfaces

The interfaces for our equipment are in compliance

with European standards for motor clamps, shaft

ends and keying. After identifying the input and

output, the clutch-brake can be assembled with

the corresponding interfaces. There is no work or

adjustment to be performed on assembly with

our automatic wear compensation system.

There must be no impacts along the shafts that

could be sufficiently excessive to affect the

adjustment position of armatures fitted to the

autogap system.

If one of the armatures is unable to come into

contact with its friction lining because it is too

distant or blocked, it is however possible to

apply to the terminals of the corresponding

coil, an excess voltage from 20 to 50% of the

nominal value for a few seconds so as to put it

back in the right place.

The link clamp flanges and closure cover are

modulable interfaces. The clutch module or that

for the brake with a male shaft, VAR 01/02/04,

can only be associated with a cover or flange

of M1 male centering type. The clutch module

or that for the brake with a hollow shaft VAR

02/03/04 can only be associated with M2 or

M3 female centering type flanges. The M2 type

flange adapts with the B5 and B35 motor clamp

and the M3 type flange with the B14 and B34

motor clamp.

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2055-WE • 2/13 3

Page 4

3.3.2 Examples of typical assemblies

4.1 Important recommendations

SHAFT - INPUT

Sprocket

FOOT

SHAFT - INPUT

V-belt

sheave

Shaft

HOLLOW SHAFT FLANGE- INPUT

Flange motor

Hollow shaft

FLANGE - SHAFT

- OUTPUT

Gear

FLANGE - SHAFT

- OUTPUT

Gear

reducer

FLANGE - HOLLOW SHAFT

- OUTPUT

Worm gear

4 Electrical connection

EM and EMER should be supplied with direct

current and are fitted clutch side and brake side

with a 900 mm long cable or a connector to

supply them independently.

The polarity has no major effect on the operation

of the EM version, as opposed to the EMER

version for which the polarity marked must be

scrupulously complied with on the EMER brake.

Also, when fast, accurate cycling is required,

one seeks to avoid any residual torque being

generated by residual magnetic currents from the

clutch and brake that influence the armature’s

separation time.

For this, the coils must be correctly polarised and

we recommend that the clutch’s brown or red wire

and the brake’s blue or black wire are connected

to the electric potential.

All works on the electrical connections have to

be made with power off.

Be sure to comply with the nominal supply

voltage. Low supply level results in a reduction of

start distance and transmissible torque.

The connecting wires should be of sufficient cross

section to avoid drops in the voltage between the

supply and the equipment being supplied.

I (A) / L (m) 0 to 10 m from 10 to 20 m

0 to 3 (A) 1,5 mm2 1,5 mm

3 to 6 (A) 1,5 mm2 2,5 mm

2

2

Tolerance for supply voltage to the clutch and

brake terminals + 5% - 10% (NF C 79-300).

4.2 Supply, cabling

To control our clutch-brakes, Warner Electric

advises that you use one of its control units.

Different models, suited to each application, are

available:

• CBC 400/450 is the most basic, enabling the

clutch and brake to be engaged alternatively

or simulta neously, but without adjustment of

the voltage being possible.

• CBC 500/550 enables the clutch-brake to

be engaged alternatively or simultaneously

and the voltage is adjustable. It is especially

suited to EMERs where voltage adjustment is

necessary on the electro-retained brake.

• CBC 700 is a control unit with overexcitation

which enables a very fast rise in torque,

it is especially suited to fast cycles and very

accurate stops.

• CBC 750 is a control unit with very high

overexcitation. It is exclusively for similar

but more severe applications than CBC 700.

Warner Electric control units provide

protection for coils and circuits, as well as

anti-overlapping. In the event of our clutch-

brakes being used without one of our control

units, with DC circuit switching, it is essential

that the coil is protected against excessive

voltage by a varistor fitted in parallel.

For equipment with a terminal block, tab 1

is connected to the brown wire and tab 2 is

connected to the blue wire.

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2055-WE • 2/13

Page 5

5 Appendixes

5.1 EM and EMER general configuration

•Voltage: 24/90 VDC (EMER at 24 VDC only)

• With feet / without foot

• Male / hollow input shaft

• Male / hollow output shaft

• Supply by cables / connectors

• Male shaft on input or output with M1 cover / flange

• Hollow shaft on input or output with M2 flange / M1 flange

Size Shaft Flange M1 Flange M2 Flange M3

2 11 / 14 F115 / F130 F115 / F130 F75 / F85

3 14 / 19 F115 / F130 / F165 F115 / F130 / F165 F75 / F85 / F100

4 19 / 24 F130 / F165 F130 / F165 F100 / F115 / F130

5 24 / 28 F130 / F165 / F215 F165 / F215 F115 / F130

6 28 / 38 F215 / F265 F215 / F265 F165 / F215

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2055-WE • 2/13 5

Page 6

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and

sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original

purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s

prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to

the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer

Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-

3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found

defective under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for

transportation costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or

replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and

in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by

reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU

OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric Europe

7 rue Champfleur, B.P. 20095, St Barthelemy d’Anjou - France

+33 (0)2 41 21 24 24 • Fax: +33 (0)2 41 21 24 70

www.warnerelectric.com

Printed in USAP-2055-WE • 2/13

Loading...

Loading...