Page 1

P-213

819-0303

Electro-Module EM-50,

EM-100, EM-180, EM-210, EM-215

Service & Installation Instructions

An Altra Industrial Motion Company

Page 2

Contents

Pre-Installation Instructions

Pre-Installation Instructions . . . . . . . . . . . . . . . .2

Installation Instructions . . . . . . . . . . . . . . . . . . .4

Setting Airgap . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Coil Data . . . . . . . . . . . . . . . . . . . . . .8

Burnishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . .9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Overhung Load Data . . . . . . . . . . . . . . . . . . . .11

Dimensions and Specifications

EM-50-10 . . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-100-10 . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-180-10 . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-210-10 . . . . . . . . . . . . . . . . . . . . . . . . .12

EM-50-20 . . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-100-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-180-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-210-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-215-20 . . . . . . . . . . . . . . . . . . . . . . . . .13

EM-50-30 . . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-100-30 . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-180-30 . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-210-30 . . . . . . . . . . . . . . . . . . . . . . . . .14

EM-50-40 . . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-100-40 . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-180-40 . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-210-40 . . . . . . . . . . . . . . . . . . . . . . . . .15

EM-10-20 . . . . . . . . . . . . . . . . . . . . . . . . . .16

EM-10-40 . . . . . . . . . . . . . . . . . . . . . . . . . .17

EM-20-30 . . . . . . . . . . . . . . . . . . . . . . . . . .18

EM-30-40 . . . . . . . . . . . . . . . . . . . . . . . . .19

NEMA Frame Standards . . . . . . . . . . . . . .20

Warranty . . . . . . . . . . . . . . . . . . . .Back Page

A. Before installing the Electro-Module to a

motor or reducer, make certain that the EM

size and NEMA frame dimensions match

according to Table 1.

Corresponding

EM NEMA Shaft C-Face

Size Frame Sizes Dia. Pilot Dia.

50 48Y/56C 5/8 4-1/2

100 48Y/56C 5/8 4-1/2

180 143TC/145TC 7/8 4-1/2

210 182TC/213TC 1-1/8 8-1/2

215 213TC/215TC 1-3/8 8 1/2

Table 1

B. Check the motor for shaft endplay. If the

shaft can be moved axially .030” or more, the

module should not be installed since excessive thrust may occur between the rotor and

field. The motor should not be used unless

the endplay can be reduced.

C. Install your specific modular combination

according to the installation steps specified

in Table 2. Use only those steps indicated for

each combination.

Failure to follow these instructions may result in product damage, equipment

damage, serious or fatal injury to personnel.

Warner Electric • 800-825-9050 P-213 • 819-0303

2

Page 3

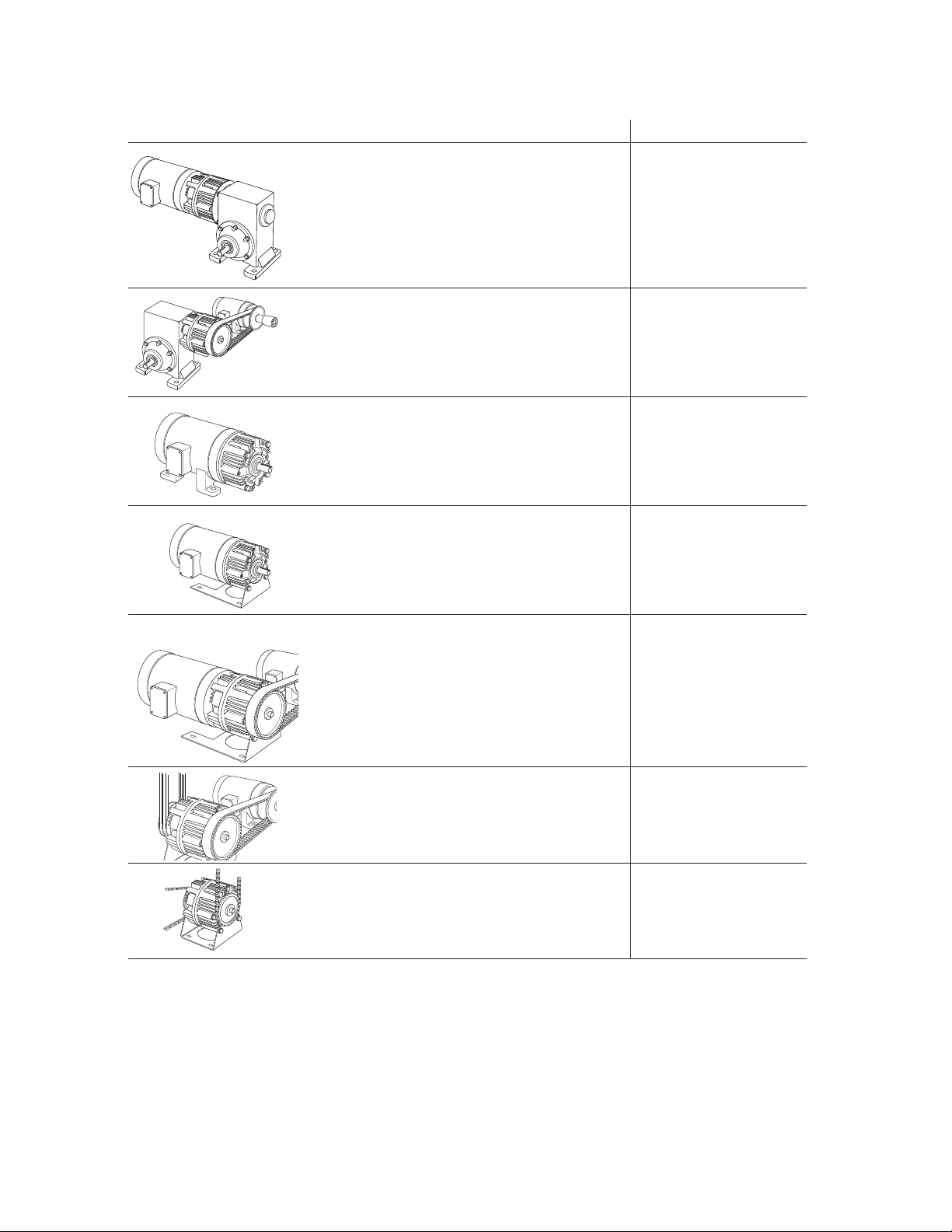

For these EM combinations: Use sections:

Electro Module Clutch-Brake Between A, B, C, G, H, I

C-Face Motor and Reducer – 10-20

Electro Module Clutch Between A, B, C, G, H, I

Motor and Reducer – 10-40

Electro Module Clutch Brake – 20-30 B, C, G, H, I

Electro Module Clutch – 30-40 B, C, G, H, I

Electro Module Brake D, C, G, H, I

on C-Face Motor – 20

Motor Mount Electro Module C, E, H, I

Clutch-Brake on C-Face Motor – 20-M

Motor Mount Electro Module ClutchBrake on C-Face Motor – 10-20-M A, B, C, E, H, I

Motor Mount Electro Module Clutch A, B, C, E, H, I

on C-Face Motor – 10-40-M

Base-Mounted B, C, F, H, I

Electro Module Clutch-Brake – 20-30-B

Base-Mounted B, C, F, H, I

Electro Module Clutch – 30-40-B

Table 2

Warner Electric • 800-825-9050 P-213 • 819-0303

3

Page 4

Installation Instructions

Section A: Mounting the Motor Clutch Module

(10 Module)

1. Examine the clutch adapter. Note that there

are gaps between the housing fins on roughly

half of the circumference of the unit. Mount

the clutch adapter with the open gaps down.

This will keep contaminants from falling into

the unit. There are four screws and washers.

These will be bolted through the adapter onto

the four holes in the face of the motor (See

Figure 1).

3. Slide the rotor onto the motor shaft. (See

Figure 3) Make sure the rotor hub slides

easily onto the shaft. If the fit is too tight,

polish the shaft with emery paper so the hub

will slide on easily. Do not use a hammer or

force the rotor hub onto the shaft. Slide the

rotor back off the shaft.

Figure 1

2. Look at the back side of the rotor and note

there are cardboard spacer buttons as

depicted in figure 2.

Figure 2

Figure 3

4. Insert key onto the shaft. Prick punch the

motor shaft keyway at the end of the key to

prevent the key from sliding out. Slide the

rotor onto the motor shaft until it bottoms

against the field.

5. Using an Allen Wrench securely tighten the

two setscrews in the rotor hub. (See Figure 4)

When the motor is turned on, the spacer buttons will quickly wear away and provide the

proper gap between the field and rotor. The

setscrews are accessible from the front of the

rotor on sizes 100, 180, 210, and from behind

the rotor on size 50 units.

Figure 4

Warner Electric • 800-825-9050 P-213 • 819-0303

4

Page 5

Section B: Bolting Two Modules Together

The brake module (20) and/or output clutch

module (40) may be assembled to the mounted

motor clutch module (10) or the input clutch (30).

1. Position the modules so that, in the usual

horizontal position, the ventilation holes are

down to prevent foreign matter from falling

into the units.

2. Bolt the modules together with the long hex

head bolts that are provided, see figure 5.

Mating pilot diameters assure proper alignment between module assemblies.

3. Proceed to Section C

Figure 6

Figure 5

Section C: Adjusting Airgap

For new installations it is necessary to adjust the

airgap between the friction faces of the clutch

and/or brake.

To set the airgap for an Electro-Module (EM) you

will need to access the armatures. On an EM

there are gaps between the fins on the housing

on 1/2 of the unit circumference. When looking

through this gap, you will see the fan on the

clutch rotor. In that fan there is a 1/2 x 1 inch

window. It is possible to look inside the unit and

see the armatures by looking through this window. When looking through this window you will

be looking between the two armatures of a

clutch/brake unit as shown in figures 6 and 7.

Figure 7

If the armature for either the clutch or the brake

is too far away from its mating friction surface, it

is possible to move this back into adjustment

using a flat blade screwdriver between the two

armatures. See figure 8.

Figure 8

Warner Electric • 800-825-9050 P-213 • 819-0303

5

Page 6

This is a three step process.

C-face mounting

If this boss extends

beyond the C-face

surface use the

spacer.

Do not use spacer

if boss is below the

C-face surface.

1. Simply slide the screwdriver through the

window and press the armature toward its mating friction surface.

2. Rotate the output of the unit. The rotor and the

window should stay in place when you do this.

Only the armatures will move. Rotating the

rotor will move the window.

3. Repeat steps 1 & 2 to ensure that the airgap

between armature and its mating friction surface is about 1/32” and that the armature is

kept square. (If the armature is cocked, it may

engage on one rim, giving the appearance of

engagement but failing to provide full torque.)

3. When using the EM-180-20 a possible interference may exist between the splined armature hub and some motors. (See Figure 10) A

spacer ring is provided with the EM-180

mounting accessory to provide the necessary

running clearance.

Section D: Mounting the Brake to a Motor

The brake module (20) can be mounted directly

to a motor.

1. Insert a key in the motor shaft keyway. Prick

punch the end of the (EM-50 and EM-100)

motor shaft keyway to prevent the key from

sliding out.

2. A set collar is provided in the EM-180 and

EM-210 mounting accessory to prevent the

key from sliding out. Slide the set collar up

against the motor bearing and tighten the

setscrew securely. (Figure 9)

Figure 10

Place the spacer ring between the brake

module housing and the C-face of the motor

when bolting the two units together.

4. Align the motor shaft and key with the mating

shaft hole and key slot in the brake module.

5. Secure brake module to the motor C-face with

the four (4) long 3/8-inch hex head capscrews.

Section E: Installing the Motor Mount (M)

A Motor Mount (M) can be installed to the brake

or output clutch module to provide a foot mounting for the complete assembly of module and

motor.

1. Remove the two (2) long hex head bolts from

the side of the module toward the ventilation

holes.

Warner Electric • 800-825-9050 P-213 • 819-0303

6

2. Mount the module on the Motor Mount so that

the base of the Motor Mount is underneath

the modules and motor. (See Figure 11) A pilot

diameter on the module mates with a pilot

diameter on the Motor Mount.

Figure 9

Page 7

Figure 11

3. Secure the Motor Mount in place with two (2)

longer mounting bolts and the two shorter

bolts all provided in the kit.

Section F: Installing the Base Mount

Section G: Mounting to a Reducer

The output side of a brake (20) or output clutch

(40) module may be mounted directly to a reducer.

1. Align the output shaft and key of the modules

with the corresponding shaft hole and keyway

of the reducer. Slide the assembly together,

matching the pilot diameter on the module with

a pilot diameter on the reducer. (Figure 13)

Modules 20-30 and 30-40 can be base-mounted.

1. Mount the modules so that the base is located

below the ventilation holes. A pilot diameter

on the end of each module mates with pilot

diameters on the base.

2. Secure the base to the modules with the four

(4) bolts provided. (Figure 12)

Figure 12

Figure 13

2. Bolt the module to the reducer flange. The

four (4) bolts required (3/8 - 16 UNC-2A) are

normally furnished with the reducer.

Section H: Electrical Connections

The conduit connection hole in the motor clutch

module (10), brake (20), and input clutch (30) are

threaded for standard conduit connectors. The

wiring diagram, included with each Warner Electric

control shows the proper electrical connections

that must be made. (Control Service Manual P-239

includes complete information on all standard

control power supplies.)

For clutch/brake combinations, connect the red

wire from one module and the black wire from the

other module to the same terminal of the DC supply. With most basic Warner Electric controls, one

terminal is normally used for two connections –

one from the brake and one from the clutch.

For wiring of clutches, brakes, and clutch/brake

combinations consult manual P-239 for the wiring

diagram of the control being used. These

clutch/brakes are not polarity sensitive.

Warner Electric • 800-825-9050 P-213 • 819-0303

7

Page 8

Electrical Coil Data

EM - 50 - 100 - 180 - 210 - 215

Voltage – D.C. 90 6 24

Clutch Brake Clutch Brake Clutch Brake

Resistance EM-50 452 452 1.86 1.86 31.8 31.8

@ 20˚ C - 0hms EM-100 392 392 1.8 1.8 26.7 26.7

EM-180 392 392 1.8 1.8 26.7 26.7

EM-210 248 248 1.22 1.22 17.9 17.9

EM-215 248

Amperes EM-50 .199 .199 3.23 3.23 .755 .755

EM-100 .23 .23 3.31 3.31 .896 .896

EM-180 .23 .23 3.31 3.31 .896 .896

EM-210 .363 .363 4.9 4.9 1.34 1.34

EM-215 .363

Watts EM-50 18 18 19 19 18 18

EM-100 21 21 20 20 21.5 21.5

EM-180 21 21 20 20 21.5 21.5

EM-210 33 33 30 30 32 32

EM-215 33

Build-up – milliseconds EM-50 52 53 52 53 52 53

EM-100 72 75 72 70 72 75

EM-180 72 75 72 70 72 75

EM-210 120 100 110 100 120 100

EM-215 100

Decay – milliseconds EM-50 6.2 5.0 6.5 5.0 6.2 5.0

EM-100 12 10 12 10 12 10

EM-180 12 10 12 10 12 10

EM-210 20 10 20 10 20 10

EM-215 10

Warner Electric • 800-825-9050 P-213 • 819-0303

8

Page 9

Section I: Burnishing

Intimate metal to metal contact is essential

between the armature and the metal rings (poles)

of the magnet or rotor. Warner Electric clutches

and brakes leave the factory with the friction

material slightly undercut to assure good initial

contact.

Normally, the desired wearing-in process occurs

naturally as the surfaces slip upon engagement.

The time for wear-in, which is necessary to

obtain the ultimate torque of the unit, will vary

depending on speed, load, and duty cycle.

If maximum torque is required immediately after

installation, the unit should be burnished by slipping the friction surfaces together at reduced

voltage. It is recommended that the burnishing

be done right on the application, if at all possible.

Burnishing at high speed will result in a smoother

wear-in pattern and reduce the time for burnishing. The voltage should be set at approximately

30% or 40% of the rated value.

The unit should be cycled on and off to allow

sufficient time between slip cycles to prevent

overheating.

When a Warner Electric brake or clutch is

properly assembled and installed, no further

servicing, lubrication, or maintenance should

be required throughout the life of the unit.

Troubleshooting

If an Electro-Module fails to engage, there are

several possible causes. These can be broken

down into two sub-headings: Electrical and

Mechanical.

A. Visually inspect to ensure that the lead wires

are not split or cut.

B. Using a voltmeter confirms that DC voltage is

reaching the lead wires when it should be

and that the coil resistance is correct.

Mechanical - A likely mechanical cause for a

clutch or brake not engaging when DC power is

applied is that the airgap between the friction

faces is too large. When power is applied to an

Electro-magnetic clutch/brake, the unit magnetically clamps the friction faces together. An airgap that is too large can keep the unit from

clamping together. If the airgap is too small the

faces will rub all of the time.

To adjust the airgap, see Section C on page 5.

Maintenance

As with any friction-type device, some initial

concern should be given to wear rate, as minor

adjustments in actuation time can sometimes

extend the life of the unit.

For clutch modules, the control potentiometer

should be set high to reduce the actuation time.

For brakes, the setting can be reduced to

extend the braking time and thereby extend the

life. Once the best actuation time has been

established, precautions should be taken to prevent machine operators, or other personnel not

familiar with wear characteristics, from changing

the potentiometer setting arbitrarily for affecting

minor operating changes.

Electrical - If a clutch or brake or clutch/brake

will not engage, review the wiring, switching and

connections.

Warner Electric • 800-825-9050 P-213 • 819-0303

9

Page 10

Wear Pattern

Torque Loss

Wear grooves appear on the friction surfaces.

This is a normal wear condition, and does not

impair functioning of the unit. Never machine

the friction surfaces to remove grooves or score

marks resulting from normal wear.

Heat

Excessive heat and high operating temperatures

are causes of rapid wear. Units, therefore,

should be ventilated as efficiently as possible,

especially if the application requires fast,

repetitive cycle operation.

Foreign Materials

If units are used on machinery where fine,

abrasive dust, chips or grit are dispelled into

the atmosphere, a screen over the ventilation

holes may be necessary.

Where units are used near gear boxes or

transmissions requiring frequent lubrication,

means should be provided to protect the

friction surfaces from oil and grease to prevent

serious loss of torque.

Oil and grease accidentally reaching the friction

surfaces may be removed by wiping with a rag

dampened with a suitable cleaner, which leaves

no residue. In performing this operation, do

not drench the friction material. If the friction

materials have been saturated with oil or grease,

no amount of cleaning will be completely effective. Once such a unit has been placed back in

service, heat will cause the oil to boil to the

surface, resulting in further torque loss.

If a brake or clutch module slips or loses torque

completely, the initial check should be the input

voltage to the magnet or field as follows:

90-Volt Series: Connect a DC voltmeter with a

range of 0-100 or more directly across the magnet or field terminals. With the power on and the

potentiometer turned up, a normal reading is 90

volts, although 85 to 95 is satisfactory. The

reading should drop as the potentiometer control is adjusted counter-clockwise.

24 Volt Series: Use a DC voltmeter of approximately 0-40 volt range. A normal reading is from

23 to 25 volts.

6-Volt Series: Use a DC voltmeter of approximately 0-15 volt range. A normal reading is from

5.5 to 6.5 volts depending on the power supply.

The above checks normally are sufficient.

Further checks may be made as follows: a low

range ammeter, when connected in series with

one magnet lead, will indicate amperes as

shown in chart on page 8. These readings are

with the power on and the potentiometer control

in the maximum position.

Ohmmeter checks should be made with the

power off and the circuit open (to be certain,

disconnect one lead to the magnet). A very high

or infinite resistance reading would indicate an

open coil.

If the above checks indicate that the proper

voltage and current is being supplied to the coil

mechanical parts should be checked to assure

that they are in good operating condition and

properly installed.

Warner Electric • 800-825-9050 P-213 • 819-0303

10

Page 11

Overhung Load Data (Shaft Side Load)

A

R

Overhung load data is provided in this

manual for the design engineer concerned

with a specific problem in this area. The

maximum allowable overhung load which

can be applied to the shaft of an ElectroModule may be determined by the use of

the accompanying chart.

Electro- Distance Load Applied Maximum

Module from Housing Face Load Rating

“A” Inches “R” Lbs.

EM-50 1" - Center of Shaft 177

2" - End of Shaft 123

3" 95

EM-100 1" - Center of Shaft 192

2" - End of Shaft 134

3" 104

EM-180 1" - Center of Shaft 192

2" - End of Shaft 134

3" 104

EM-210 1-3/8" - Center of Shaft 386

2-3/4" - End of Shaft 271

4-1/8" 208

EM-215 1-3/8" - Center of Shaft 386

2-3/4" - End of Shaft 271

4-1/8" 208

Based on B10 Life at 3600 RPM

The minimum pitch diameter pulley or sprocket

that can be used, for satisfactory bearing life, is

determined from the formula:

Min. P. D. = ––––––

2 T K

R

T - Torque, (lbs. in.). This is the torque actually

being transmitted, not necessarily the maximum

torque capacity of the Electro-Module.

Torque = –––––––––––

63025 x HP

RPM

K - the safety factor for the tension in the type

of drive.

Use: 1 for chain and sprocket

1 for timing belt

2 for V-belt

3 for flat belt

R - Radial load allowable (values at various distances from the housing face are given in the

chart).

Example: What is the minimum V-belt pulley

that can be applied to the center of the shaft

of an EM-50 module?

The torque requirement is 112 in. lbs.

Min. P. D. = –––––––––– = 2" minimum P. D.

pulley

2 x 112 x 2

224

Warner Electric • 800-825-9050 P-213 • 819-0303

11

Page 12

FE

A

B

C

Electrical

Connection

D

1/2" NPT

Typical End View

AA

BB

CC

DD

1/2" NPT

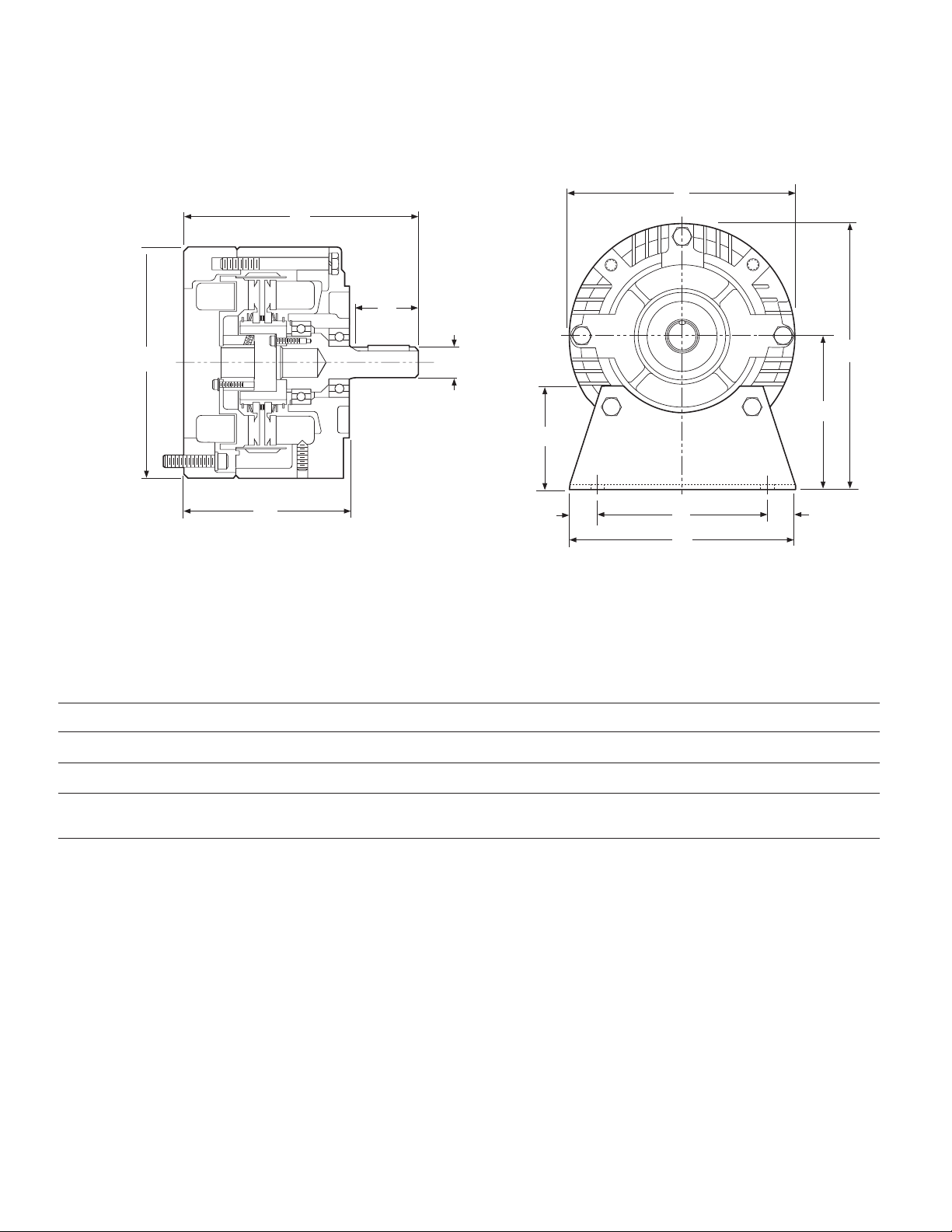

10 Motor Clutch Module

50-10

100-10

180-10

210-10

All dimensions are nominal, unless otherwise noted.

Size A Pilot Dia. B Dia. C D Dia. E Max. F Max. AA BB Min. CC DD Key

50 4.500 .625 .813 6.750 .599 1.563 30° 36 45° 3/16 x 3/16

100 4.500 .625 .813 6.750 .599 1.563 30° 36 45° 3/16 x 3/16

180 4.500 .875 .813 6.750 .599 1.563 30° 36 45° 3/16 x 3/16

210 8.500 1.125 .703 9.250 .625 1.313 25° 36 45° 1/4 x 1/4

Specifications

Model Size Voltage DC Static Torque (lb. ft.) Max. RPM Inertia–WR2(lb.ft.2) Weight (lbs) NEMA Frame Size

50 6, 24, 90 16 3600 .020 3.4 56C/48Y*

100 6, 24, 90 30 3600 .046 5.1 56C/48Y**

180 6, 24, 90 30 3600 .046 5.1 182C/143TC

210 6, 24, 90 95 3600 .188 9.1 213C/182TC

* For 56C/48Y Frame motors 3/4 HP and smaller the EM-100 size

may be used where extended life is desirable.

** EM-100 size is recommended for motors 1 HP and larger.

For NEMA Standard frame sizes, see page 20.

184C/145TC

215C/184TC

12

Warner Electric • 800-825-9050 P-213 • 819-0303

Page 13

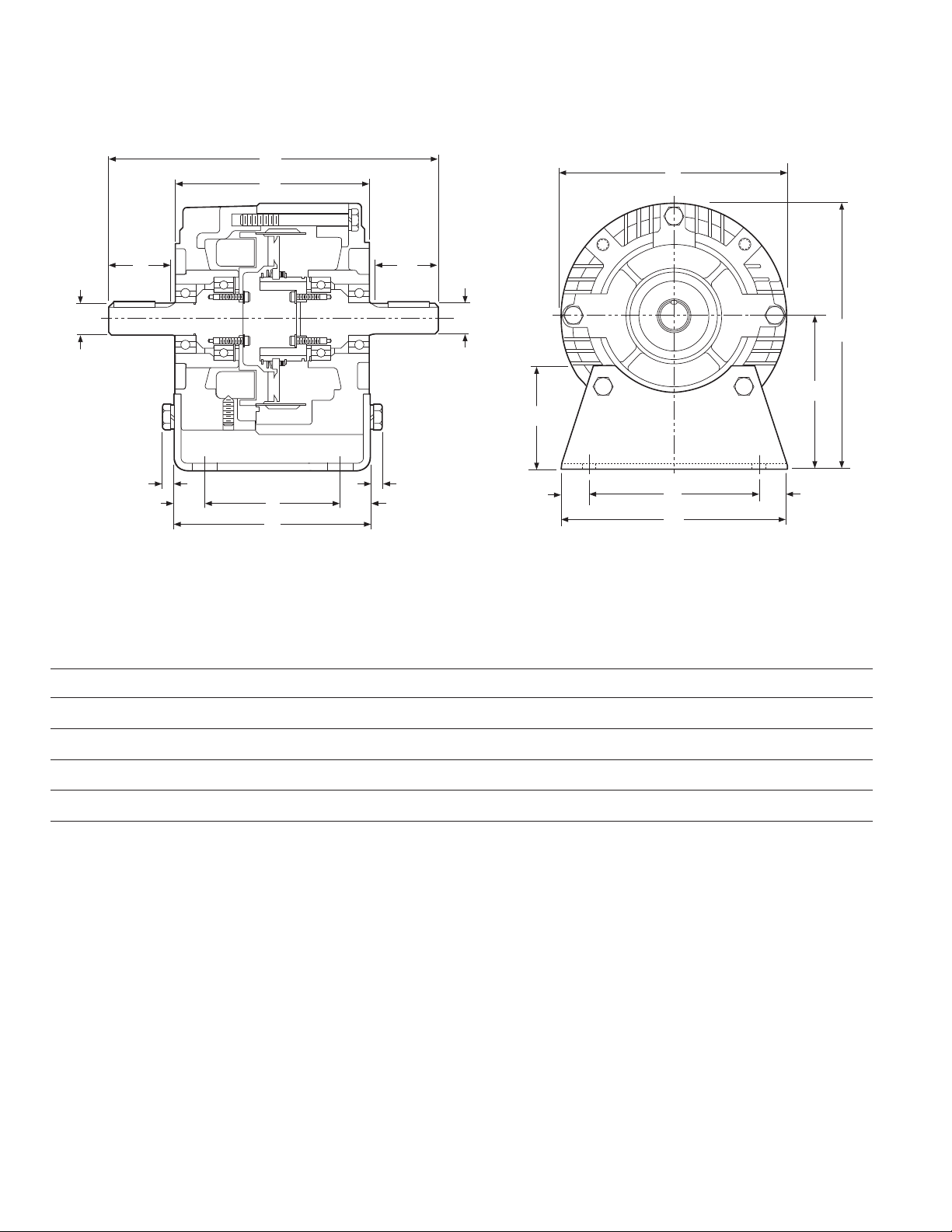

20 Brake Module

Typical End View

AA

BB

CC

DD

1/2" NPT

See

Note B

Electrical

Connection

See Note A

H

G

F

CDE

B

A

J

L

K

Notes:

A. Same overall dimensions apply

to Motor Brakes. 20MB Module

does not have an output shaft.

B. Clutch armature only applies

to EM-20.

I

50-20

100-20

180-20

210-20

215-20

All dimensions are nominal, unless otherwise noted.

Size ABCDE F G HIJ KL BB DD

Max. Max. Max. Dia. Dia. Keyway Min. Pilot Dia. Dia. AA Min. CC Key

50 5.188 3.125 .500 1.000 .156 3/8-16 UNC-2A 6.688 .625 3/16 X 1.813 4.500 .625 30° 36 45° 3/16 x 3/16

100 5.188 3.125 .500 1.000 .156 3/8-16 UNC-2A 6.688 .625 3/16 X 1.813 4.500 .625 30° 36 45° 3/16 x 3/16

180 5.266 3.125 .500 1.000 .156 3/8-16 UNC-2A 6.688 .875 3/16 X 1.891 4.500 .875 30° 36 45° 3/16 x 3/16

210 7.578 4.609 .594 1.500 .313 1/2-16 UNC-2A 9.344 1.125 1/4 X 2.500 8.500 1.125 25° 36 45° 1/4 x 1/4

215 8.078 4.609 .594 1.500 .313 1/2-16 UNC-2A 9.344 1.375 1/4 X 3.000 8.500 1.375 25° 36 45° 5/16 x 5/16

Specifications

Model Size Voltage DC Static Torque (lb. ft.) Max. RPM Armatures Arm. Hub Shaft Weight (lbs) NEMA Frame Size

50 6, 24, 90 16 3600 .014 .002 .001 6.6 56C/48Y*

100 6, 24, 90 30 3600 .036 .003 .002 8.1 56C/48Y**

180 6, 24, 90 30 3600 .036 .003 .002 8.1 182C/143TC

210 6, 24, 90 95 3600 .162 .021 .017 21.5 213C/182TC

215 90 95 3600 .162 .021 .019 22 213TC/215TC***

* For 56C/48Y Frame motors 3/4 HP and smaller the EM-100 size

may be used where extended life is desirable.

** EM-100 size is recommended for motors 1 HP and larger.

*** For 7-1/2 HP max.

Warner Electric • 800-825-9050 P-213 • 819-0303

Equally Spaced 3/16 x

(4) on 5.875 D. 1-3/8

Equally Spaced 3/16 x

(4) on 5.875 D. 1-3/8

Equally Spaced 3/16 x

(4) on 5.875 D. 1-3/8

Equally Spaced 1/4 x

(4) on 7.250 D. 2

Equally Spaced 1/4 x

(4) on 7.250 D. 2

Inertia–WR2(lb.ft.2)

For NEMA standard frame sizes, see page 20.

184C/145TC

215C/184TC

13

Page 14

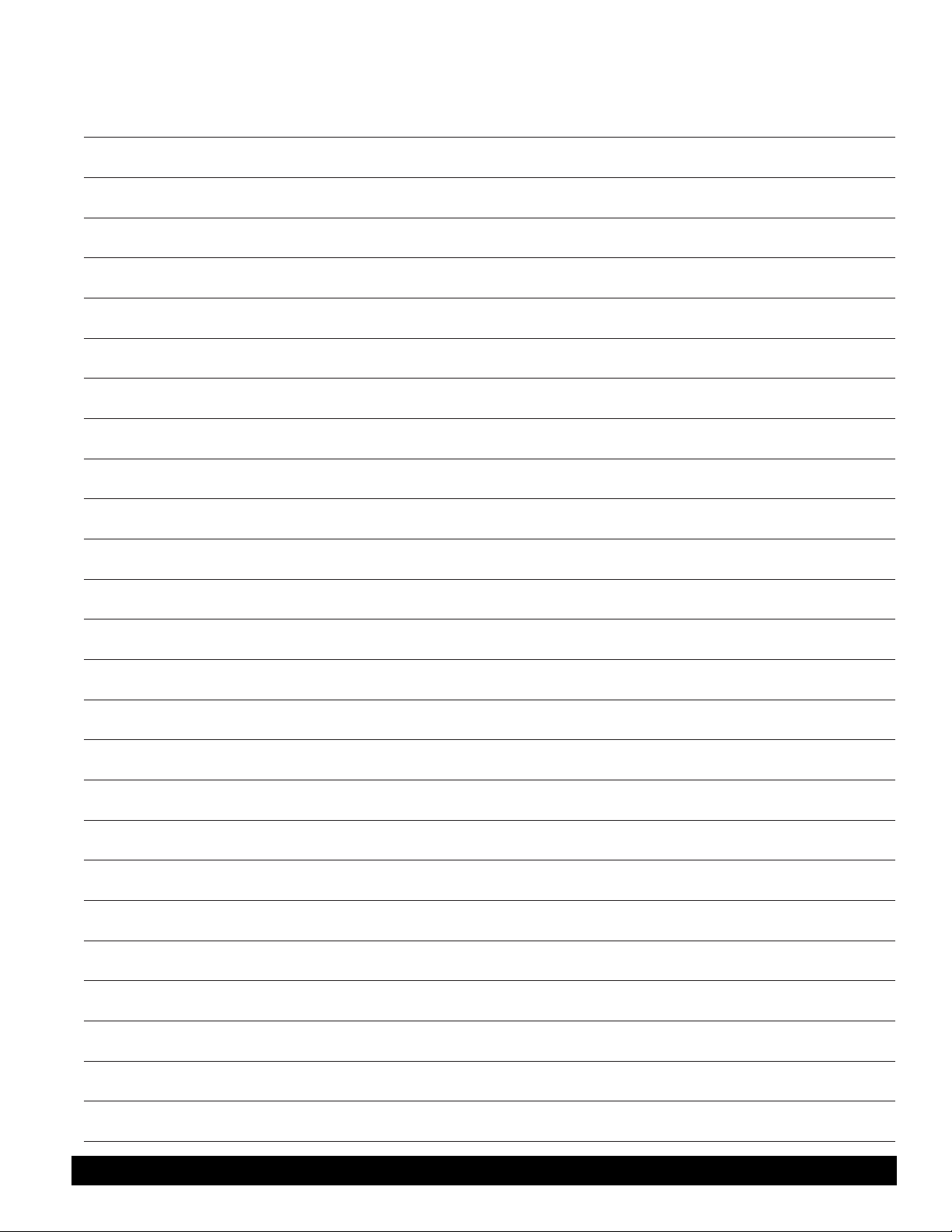

30 Input Clutch Module

Typical End View

AA

BB

CC

DD

1/2" NPT

G

AB

H

D

E

F

C

Electrical Connection

I

50-30

100-30

180-30

210-30

All dimensions are nominal, unless otherwise noted.

Size AB C D E F G I AA BB CC DD`

50 1.000 1.56 3/16 x 1.813 4.500 .625 4.328 2.266 6.688 30° 36 45° 3/16 x 3/16

100 1.000 1.56 3/16 x 1.813 4.500 .625 4.328 2.266 6.688 30° 36 45° 3/16 x 3/16

180 1.000 1.56 3/16 x 1.891 4.500 .875 4.391 2.266 6.688 30° 36 45° 3/16 x 3/16

210 1.500 .312 1/4 x 1/4 2.500 8.500 1.125 5.391 2.438 9.219 25° 36 45° 1/4 x 1/4

Specifications

Model Size Voltage DC Static Torque (lb. ft.) Max. RPM Rotor Shaft Weight (lbs) NEMA Frame Size

50 6, 24, 90 16 3600 .020 .001 6.4 56C/48Y*

100 6, 24, 90 30 3600 .046 .002 8.4 56C/48Y**

180 6, 24, 90 30 3600 .046 .002 8.4 182C/143TC

210 6, 24, 90 95 3600 .188 .017 19.8 213C/182TC

* For 56C/48Y Frame motors 3/4 HP and smaller the EM-100 size

may be used where extended life is desirable.

** EM-100 size is recommended for motors 1 HP and larger.

Max. Min. Pilot Dia. Dia. Max. H Dia. Min. Key

3/16 x 1-3/8

3/16 x 1-3/8

3/16 x 1-3/8

Inertia–WR2(lb. ft.)

For NEMA standard frame sizes, see page 20.

184C/145TC

215C/184TC

Warner Electric • 800-825-9050 P-213 • 819-0303

14

Page 15

40 Output Clutch Module

Typical End View

AA

BB

CC

DD

1/2" NPT

D

C

B

A

F

H

G

E

50-40

100-40

180-40

210-40

All dimensions are nominal, unless otherwise noted.

Size A B C D E F GHAA BB CC DD

Max. Max. Dia. Min. Pilot Dia. Dia. Min. Key

50 5.188 3.125 .156 6.687 3/16 x 1.813 4.500 .625 30° 36 45° 3/16 x 3/16

100 5.188 3.125 .156 6.687 3/16 x 1.813 4.500 .625 30° 36 45° 3/16 x 3/16

180 5.266 3.125 .313 6.687 3/16 x 1.891 4.500 .875 30° 36 45° 3/16 x 3/16

210 7.578 4.609 .313 9.344 1/4 x 2.500 8.500 1.125 25° 36 45° 1/4 x 1/4

Specifications

Model Size Voltage DC Static Torque lb. ft. Max. RPM Armatures Arm. Hub Shaft Weight (lbs) NEMA Frame Size

50 6, 24, 90 16 3600 .007 .002 .001 4.9 56C/48Y*

100 6, 24, 90 30 3600 .018 .003 .002 5.2 56C/48Y**

180 6, 24, 90 30 3600 .018 .003 .002 5.2 182C/143TC

210 6, 24, 90 95 3600 .181 .021 .017 15.2 213C/182TC

* For 56C/48Y Frame motors 3/4 HP and smaller the EM-100 size

may be used where extended life is desirable.

** EM-100 size is recommended for motors 1 HP and larger.

3/16 x 1-3/8

3/16 x 1-3/8

3/16 x 1-3/8

1/4 x 2

Inertia–WR2(lb. ft.)

184C/145TC

215C/184TC

For NEMA standard frame sizes, see page 20.

Warner Electric • 800-825-9050 P-213 • 819-0303

15

Page 16

EM-10/20 Clutch/Brake Combination

A

D

B

C

E

E

10

Motor Clutch

Module

20

Brake

Module

M

ONN

J

K

L

I

Note: Mounting base is optional and is ordered separately.

Motor Clutch (10) and Output Clutch (20) are ordered separately.

All dimensions are nominal, unless otherwise noted.

Size ABC DEIJKLMNONEMA Frame Size

50 6.750 4.844 1.813 6.750 .625 6.688 3.500 6.844 2.000 6.000 .500 5.000 56C/48Y*

100 6.750 4.844 1.813 6.750 .625 6.688 3.500 6.844 2.000 6.000 .500 5.000 56C/48Y**

180 6.828 4.844 1.891 6.750 .875 6.688 4.500 7.844 3.000 6.625 .813 5.000 182C/143TC

210 8.891 5.922 2.500 9.250 1.125 9.688 5.250 9.906 3.375 9.000 .625 7.750 213C/182TC

* For 56C/48Y Frame motors 3/4 HP and smaller the EM-100 size

may be used where extended life is desirable.

** EM-100 size is recommended for motors 1 HP and larger.

For NEMA standard frame sizes, see page 20.

184C/145TC

215C/184TC

Warner Electric • 800-825-9050 P-213 • 819-0303

16

Page 17

EM-10/40 Motor Clutch/Output Clutch Combination

A

D

B

10

Motor Clutch

Module

40

Output Clutch

Module

C

E

M

ONN

J

K

L

I

Note: Mounting base is optional and is ordered separately.

Motor Clutch (10) and Output Clutch (40) are ordered

separately.

All dimensions are nominal, unless otherwise noted.

Size ABC DEIJKLMNONEMA Frame Size

50 6.750 4.844 1.813 6.750 .625 6.688 3.500 6.844 2.000 6.000 .500 5.000 56C/48Y*

100 6.750 4.844 1.813 6.750 .625 6.688 3.500 6.844 2.000 6.000 .500 5.000 56C/48Y**

180 6.828 4.844 1.891 6.750 .875 6.688 4.500 7.844 3.000 6.625 .813 5.000 182C/143TC

210 8.891 5.922 2.500 9.250 1.125 9.688 5.250 9.906 3.375 9.000 .625 7.750 213C/182TC

* For 56C/48Y Frame motors 3/4 HP and smaller the EM-100 size

may be used where extended life is desirable.

** EM-100 size is recommended for motors 1 HP and larger.

For NEMA standard frame sizes, see page 20.

184C/145TC

215C/184TC

Warner Electric • 800-825-9050 P-213 • 819-0303

17

Page 18

EM-20/30 Brake/Input Clutch Combination

D

C

H

FGEF

H

D

C

A

B

M

ONN

J

K

L

I

30

Input Clutch

Module

20

Brake

Module

EM-20/30-B Brake/Input Clutch Combination – Base Mounted

Note: Mounting base is optional and is ordered separately.

Input Clutch (30) module and Brake Module (20) are

ordered separately.

All dimensions are nominal, unless otherwise noted.

Size ABC Min. D E FGH I J KLMNO

50 5.719 9.516 1.813 .625 5.672 .844 4.000 .344 6.688 3.500 6.844 2.000 6.000 .500 5.000

100 5.719 9.516 1.813 .625 5.672 .844 4.000 .344 6.688 3.500 6.844 2.000 6.000 .500 5.000

180 5.719 9.656 1.891 .875 5.672 .844 4.000 .344 6.688 4.500 7.844 3.000 6.625 .813 5.000

210 7.719 12.969 2.500 1.125 8.203 1.094 6.000 .438 9.688 5.250 9.906 3.375 9.000 .625 7.750

18

Warner Electric • 800-825-9050 P-213 • 819-0303

Page 19

EM-30/40 Input Clutch/Output Clutch Combination

B

A

D

C

FG

E

HH

F

C

D

30

Input Clutch

Module

40

Output

Clutch

M

ONN

J

K

L

I

EM-30/40 Input Clutch/Output Clutch Combination – Base Mounted

Note: Mounting base is optional and is ordered separately.

Input Clutch (30) module and Output Clutch (40) are

ordered separately.

All dimensions are nominal, unless otherwise noted.

Size ABC Min. D E FGH I J KLMNO

50 5.719 9.516 1.813 .625 5.672 .844 4.000 .344 6.688 3.500 6.844 2.000 6.000 .500 5.000

100 5.719 9.516 1.813 .625 5.672 .844 4.000 .344 6.688 3.500 6.844 2.000 6.000 .500 5.000

180 5.719 9.656 1.891 .875 5.672 .844 4.000 .344 6.688 4.500 7.844 3.000 6.625 .813 5.000

210 7.719 12.969 2.500 1.125 8.203 1.094 6.000 .438 9.688 5.250 9.906 3.375 9.000 .625 7.750

Electro-Modules are individual clutch or brake

units which are assembled together to comprise

a clutch, a brake or a clutch/brake combination.

Electro-Modules are designed for use with Cface motors and reducers. Some versions can

be base mounted as well.

The 10 Motor Clutch Module is designed to

mount on the face of the NEMA C-Face motor.

The rotor assembly has a hollow bore and is

mounted onto the shaft of the motor. The 10

Module cannot be used alone, it must be used

with either the 40 Module to create a clutch

combination or a 20 Module to create a

Prior to assembly ensure that the components

you have will create the unit you need.

clutch/brake combination.

Warner Electric • 800-825-9050 P-213 • 819-0303

19

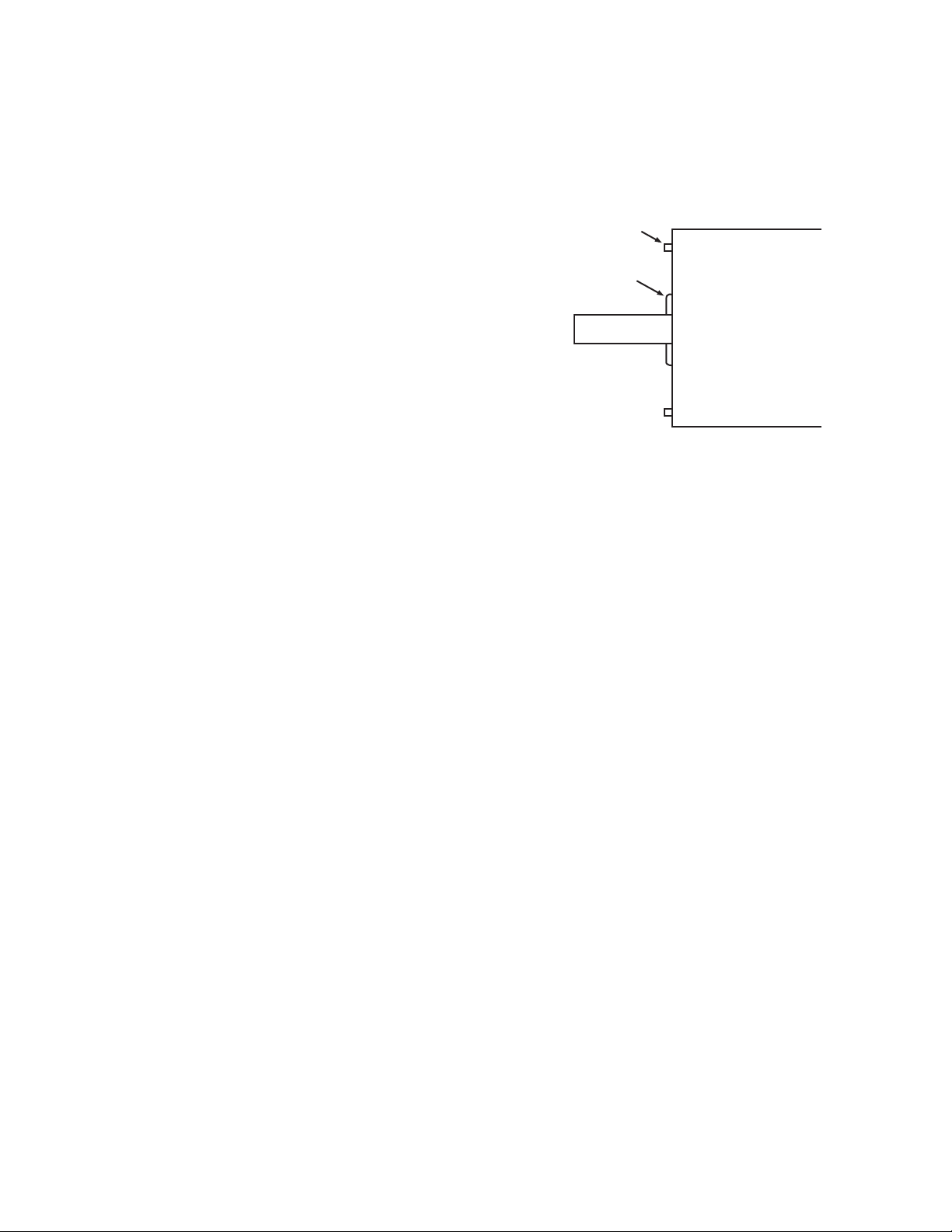

Page 20

S

R

AH

ES

AJ

AK

BF

BB

U

T

BF

The 20 Brake Module is designed to mount on

the face of the NEMA C-face motor or in

combination with other modules. The 20 can be

used alone when mounted on the output of a

motor. In this mode it is a brake only. When

combined with the 10 Module, it becomes a

clutch/brake for mounting on a motor shaft.

When combined with a 30 Module it becomes a

clutch/brake for base mounting.

The 30 Input Clutch Module is designed for

applications where the unit is coupled to the

motor or where sprocket or pulley is mounted

on the input shaft of the 30 Clutch module. The

30 Module cannot be used alone. It can be used

NEMA Frame Standards

with the 40 Module to create a clutch

combination or it can be used with a 20 Brake

Module to create a clutch/brake combination.

An optional base is commonly used with these

combinations to provide a foot mounting capa-

bility.

The 40 Output Module is used with either the 10

or the 30 Modules. It cannot be used alone.

When combined with a 10 Module or the 30

Module it completes a clutch combination.

Note: This manual addresses only Electro-

Modules with power engaged components.

Specifications

AH AJ AK BB BF ES RSTU

Module Size Length Center Dia. Pilot Dia. Depth Size, Qty. Length Keyway Width Ref. Dia.

50 2.06 5.875 4.500 5/32 3/8-16 UNC 1-1/4 .517 3/16 45° .625

100 2.06 5.875 4.500 5/32 3/8-16 UNC 1-1/4 .517 3/16 45° .625

180 2.04 5.875 4.500 5/32 3/8-16 UNC 1-1/4 .771 3/16 45° .875

210 2.56 7.250 8.500 5/16 1/2-13 UNC 2 .986 1/4 45° 1.125

215 3.12 7.250 8.500 5/16 1/2-13 UNC 2 1.201 5/16 45° 1.375

Note: Warner Modules are designed to comply with the NEMA frame standards of mounting. Reference for each particular frame size

is given at individual selection tables for each type Warner module.

Warner Electric • 800-825-9050 P-213 • 819-0303

20

Shaft Mtg. Bolt Mtg. Flange Pilot Mtg. Bolt Keyway Depth Over Keyway Mtg. Bolt Shaft

4 @ 90°

4 @ 90°

4 @ 90°

4 @ 90°

4 @ 90°

Page 21

NOTES

Warner Electric • 800-825-9050 P-213 • 819-0303 3

P-213 • 819-0303 21

Page 22

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product

manufactured and sold by it which proves to be defective in material or workmanship within a period of one (1)

year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric

LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges

prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by

writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois

61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If

found defective under the terms of this warranty, repair or replacement will be made, without charge, together

with a refund for transportation costs. If found not to be defective, you will be notified and, with your consent, the

item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident,

neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply

to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective

product and in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of

any kind incurred by reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither

assumes nor authorizes any other person to give any other warranty or to assume any other obligation or liability

on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT,

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other rights which vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice.

Weights do not include weight of boxing for shipment. Certified prints will be furnished without charge on request

to Warner Electric.

www.warnerelectric.com

31 Industrial Park Road

New Hartford, CT 06057

800-389-3771

Fax: 815-389-2582

P-213 819-0303 2/14 Printed in USA

An Altra Industrial Motion Company

www.altramotion.com

Loading...

Loading...