Page 1

12-1/4" x 3-1/2" Electric Wheel Brake

A-216

819-0244

Installation Instructions

Page 2

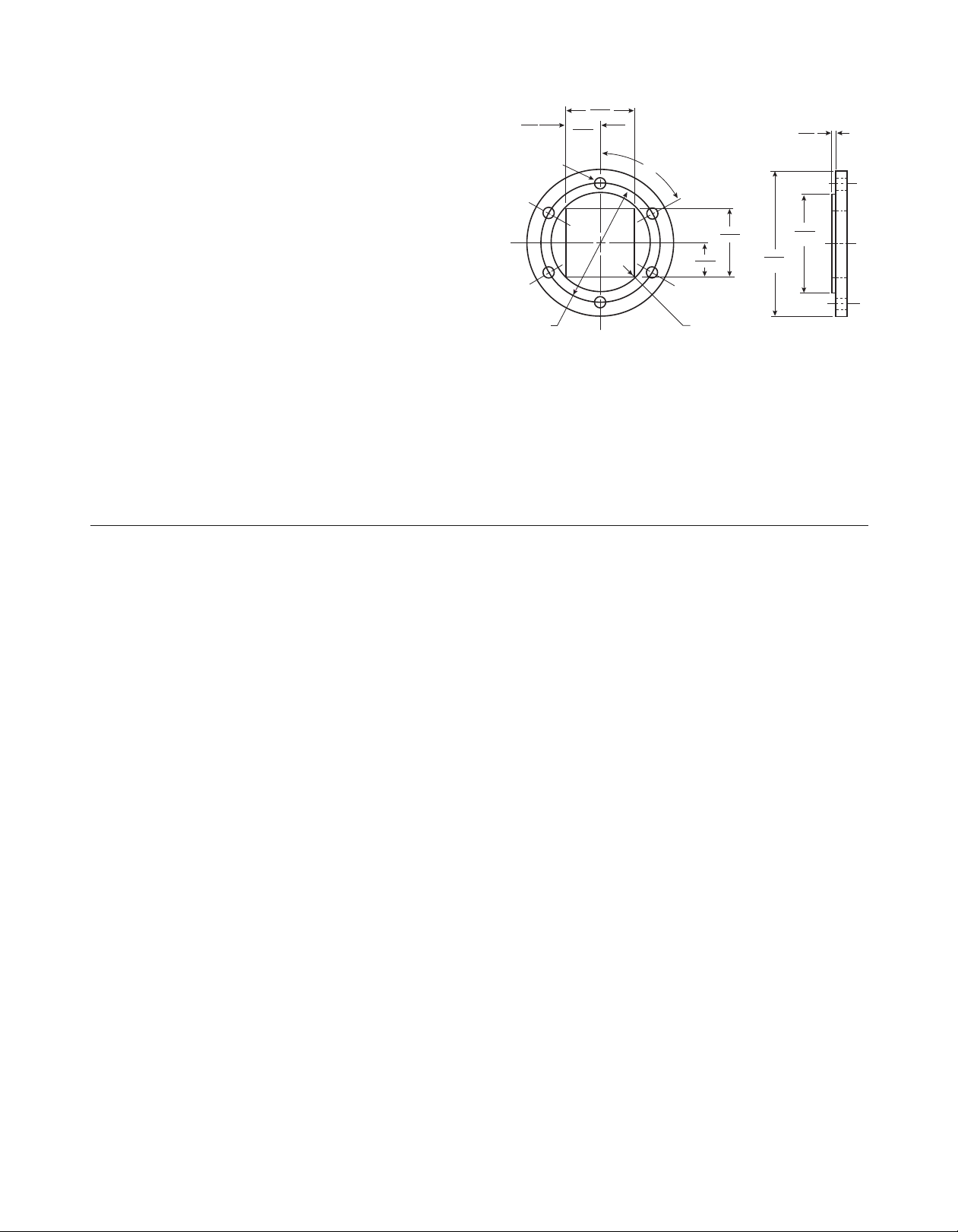

A

A

˚

14 1/8 dia.

12.260

12.250

finished

drum dia.

4.510

4.503

pilot dia.

4.515

4.490

dia.

11.750

11.715

dia.

.290/.265 Dia. (6) holes equally spaced on

11.000 dia. within .007 R. of true position

(C'sunk for 1/4 dia. 80∞ flat head machine

screws with nuts and lockwashers, or 80∞ flat head rivets)

.170 min.

1/2–20 UNF-2A, (6) req'd.

Equally spaced on 5.500 dia. within

.005 R. of true position to

4.510/4.503 pilot diameter

.540

dia. min.

2.125

max.

Torque to

71-79 ft. lb.

4

3

1

2

1.100 min.

.125 ref.

.224

.205

3.881 min.

4.068 max.

4.381 min.

4.752 max.

3.567

3.507

12.225

12.195

factory adjustment diameter over brake linings

Face View of Brake Assembly

(Drum and armature removed)

(2) 1/4 dia. terminal studs

Section A–A

The magnet arm will

clear a maximum axle

of 3 1/2" diameter

or a 3" square

positioned as shown

Contents

Failure to follow these

instructions may result in product

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Technical Specifications . . . . . . . . . . . . . . . . . .3

Installation Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Preparing the Brake Mounting Surface . . . . .3

Installing on Axle Flanges . . . . . . . . . . . . . . .3

Installing the Brake . . . . . . . . . . . . . . . . . . . .4

Preparing the Brake Drum . . . . . . . . . . . . . .4

Adjusting the Brake . . . . . . . . . . . . . . . . . . . .5

Installing the Trailer Brake Wiring . . . . . . . . .5

Replacement Parts . . . . . . . . . . . . . . . . . . . . . .6

Towing Products Required with your

12-1/4" x 3-1/2" Brakes

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Load Control . . . . . . . . . . . . . . . . . . . . . . . . .8

Front Axle Resistor . . . . . . . . . . . . . . . . . . . .8

Warranty . . . . . . . . . . . . . . . . . . . . . . .Back Page

Dimensions when used with .224/.205 Armature, Warner Electric Part No. 110-0124

damage, equipment damage, and

serious or fatal injury to personnel.

Right hand brake shown

Left hand brake opposite

Drawing No. I-26117

Warner Electric • 800-825-9050 A-216 • 819-0244

2

Page 3

Technical Specifications

5.5 00

DIA . B.C.

.14 0 R. M ax.

60∞

.53 5

.52 5

DIA . (6) HOLES

EQU ALLY SPACE D.

LOC AT ED WIT HIN

.00 5 R. O F

TRU E POSI TION.

3.0 60

3.0 30

1.5 30

1.5 15

1.5 30

1.5 15

3.0 60

3.0 30

.14 0

.12 0

6.6 25

6.5 95

DIA

.

4.5 00

4.4 98

DIA .

Brake Rating – 7,500 lbs. to 10,000 lbs. axle

rated per pair. Based on an average retarding

torque which will produce a minimum of 43.5%

2

retardation, or 14 ft./sec.

mph initial velocity with 13.3 in. to 17.2 in. rolling

radius tires, with 10.8 volts at the magnets.

Mounting – 6 holes on 5.5" B.C.

Electrical – 12 Volt D.C. system only

Lining Area – 90 sq. in.

deceleration from 20

Drum Swept Area – 135 sq. in.

Lining Thickness – 5/16" nominal

Assembly Weight – 25 lbs. per brake

7 lbs. per armature

Note: Use with armature type drum only.

12-1/4" x 3-1/2" Utility Brake

Installation Instructions

The performance of your Warner Electric 12-1/4"

x 3-1/2" brake depends greatly on accurate

installation. Since proper installation helps to

assure long life and dependable performance,

please follow these installation instructions

carefully. Pay particular attention to drawing

I-26117 on page 2 of the manual.

General Instructions

The Warner Electric 12-1/4" x 3-1/2" utility

brake is designed for use with one-piece steel

armature number 110-0124, mounted inside

the brake drums.

For other possible combinations, please consult

your Warner Electric sales representative or

Warner Electric at 815-389-3771.

Warner Electric • 800-825-9050 A-216 • 819-0244

Axle Flange

Flanges available from a factory source.

A. Preparing the Brake Mounting Surface

Before installing the brake, check the

concentricity and squareness of the brake

drum to the hub and spindle. To do this,

mount the drum on the spindle according

to the manufacturer’s specifications.

The following tolerances must be held:

Drum friction surface concentric to spindle

centerline within .015-inch T.I.R. (Total Indicator

Reading).

Armature surface square to spindle within

.020-inch T.I.R.

B. Installing on Axle Flanges

1. The axle flange on which the brake mounts

must have a 4.500/4.498-inch pilot diameter.

2. This axle flange must be welded concentric

to the spindle within .015-inch T.I.R.

(measured at the pilot diameter). The axle

must be square to the spindle within

.010-inch T.I.R. (measured at the brake

mounting surface). Refer to drawing I-26117.

3

Page 4

C. Installing the Brake

Note: Brakes are designed as either right hand

or left hand assemblies by the RH or LH

marked on the outside of each backing plate.

(See Figure 1). The arrow on Figure 1 indicates

the direction of forward travel.

Figure 1 - Brake Designation

3. Tighten each of the six nuts with

lockwashers to 71-79 ft.-lbs. torque. Tighten

them alternately and evenly before applying

full torque (see Figure 3). Note that the pivot

pin also serves as a mounting stud.

Retorque the nuts after 50 miles of driving

and periodically thereafter.

4. After the brake has been mounted to the

flange, operate the lever arm to assure that it

moves freely.

1. Mount the brake to the axle flange with the

anchor pin at the top, the magnet at the

bottom, and the curve of the actuating lever

pointing toward the front of the trailer (see

Figure 2).

Front

of Trailer

Figure 2 - Mounting Position

2. Check to be sure that the brake backing

plate mates properly to the axle flange pilot.

The brake must be square with the spindle

when bolted into place.

Figure 3 - Tightening Nuts

D. Preparing the Brake Drum

Armature mounting holes are drilled in the brake

drum as indicated on the dimensional drawing

I-26117, page 2.

Warner Electric Armature P/N 110-0124

(.224/.205 thick)

a. Fasten this one-piece steel armature

inside the drum with (6) 1/4-inch

diameter flat head machine screws

with nuts and lockwashers (Step b)

or (6) 80° flat head rivets (Step c).

b. Fasten each machine screw with two

nuts tightened against one another to

prevent loosening. Peening the ends of

the screws is recommended as an

additional safeguard against loosening.

Warner Electric • 800-825-9050 A-216 • 819-0244

4

Page 5

c. Install the rivets according to the drum

manufacturer’s recommendations.

d. Install the brake drum according to the

manufacturer’s recommendations.

E. Adjusting the Brake

1. New brakes come pre-adjusted from the

factory and normally should not require

additional adjustment when mated with

new drums. The drum should, however,

be checked for freedom of rotation after

mounting. If dragging occurs, the brake

must be readjusted.

2. Brakes should always be readjusted when

they are installed with remachined drums.

Note: Brakes should never be installed in

used drums without remachining the drum

braking surface.

3. Follow these instructions to adjust the brake:

c. Back off the adjuster (downward motion

of the adjusting tool) until the wheel turns

freely, usually 4 to 5 notches on the

adjusting nut.

d. Replace the plug to keep out dirt and

moisture.

e. Brake readjustment is recommended after

the first 500 miles of operation (when

shoes and drums have been seated).

F. Installing the Trailer Brake Wiring

1. Wire the brakes in parallel according to the

wiring diagram (Figure 5).

2. Use good quality, insulated, crimp-type

connectors that fit 1/4-inch diameter

terminals to attach the wires to the brake.

3. Remove the top nut, and check that the

bottom nut remains tight.

a. Remove the adjuster plug located at

the bottom of the brake and insert an

adjusting tool (see Figure 4).

Figure 4 - Brake Adjustment

b. With the wheel off the ground, expand

the shoes until the brake drags

significantly. The shoes are expanded

by the upward motion of the adjusting

tool which turns the adjusting nut.

4. Install one connector over each 1/4-inch

stud terminal with a star washer under the

connector. Lock into place with the top nut.

Warner Electric • 800-825-9050 A-216 • 819-0244

5

Page 6

Figure 5 - Brake Wiring

BATT E RY

1110-41

FRONT AXLE

RESISTOR

TRAILER

FRONT REAR

GROUND WIRE

BRAKE

TRAILER PLUG

BREAKAWAY

SWITCH

NEGATIVE TERMINAL

Replacement Parts

All wearable parts are replaceable with factory

original components packed in convenient kits

complete with instruction sheets. These kits are

available through Warner Electric’s Distributor

Network.

Shoes & Linings/Shoe Hold Down Spring Kit

Kit No. 1301-100-005

Warner Electric • 800-825-9050 A-216 • 819-0244

6

Magnet Kit

Kit No. 1301-100-014

Shoe Return Spring Kit

Kit No. 1301-100-008

Page 7

Armature Kit

Kit No. 1301-100-013

Lever Arm Kit, L.H. Lever Arm Kit, R.H.

Kit No. 1301-100-016 Kit No. 1301-100-015

Terminal Accessory Kit

Kit No. 1301-100-011

Adjuster/Adjuster Spring Kit

Kit No. 1301-100-006

Mounting Accessory Kit

Kit No. 1301-100-003

Warner Electric • 800-825-9050 A-216 • 819-0244

7

Page 8

Towing Products Required with Your

12-1/4" x 3-1/2" Brakes

The following section, “Towing Products

Required with Your 12-1/4" x 3-1/2" Brakes,”

describes associated controls and components

necessary to complete your brake system

installation. Please read it carefully.

Controller

Warner Electric has one controller available

specifically for use with the 12-1/4" x 3-1/2"

brake. The Utility Controller, Warner Electric part

number 1300-76, is rated at 30 amps and 4, 6 or

8 brakes. This controller is designed to properly

synchronize the towing vehicle and trailer

brakes. Using other controllers may result in

excessive trailer brake torque causing jerky

braking and poor towing vehicle-to-vehicle

braking synchronization.

Load Control

The installation of 12-1/4" x 3-1/2" brakes on

any trailer which will operate with loads less than

rated capacity or with varying loads requires a

load control, Warner Electric part number

1300-78, to be installed in the towing vehicle.

The Warner Electric Load Control compensates

for trailer load variations by limiting the

maximum torque output of the brakes by adding

dropping resistance in the electrical control line.

When towing a trailer loaded to brake rated

capacity, the Load Control must be set at

maximum braking. When pulling an empty or

partially loaded trailer, the Load Control must be

set between maximum and minimum braking at

a position just before the point at which trailer

tire skidding occurs when actuating the hand

control fully on. Failure to install and use the

Warner Electric Load Control will result in

excessive brake torque when stopping a trailer

loaded to less than brake capacity.

Warner Electric’s Utility Controller has an

adjustment knob to control trailer brake torque.

Labeled “More” (braking power) and “Less”

(braking power), this adjustment does not affect

maximum braking capacity of the trailer brakes.

Because of the wide variety of towing vehicles

encountered, balancing towing vehicle brakes

and trailer brakes is necessary for smooth,

synchronized stops. To achieve this, the

controller adjustment should be set to provide

a slight lead in trailer braking over towing vehicle

braking. Turning the adjustment knob in the

“More” direction will increase the trailer brake

rate of application, while turning in the “Less”

direction will decrease the trailer brake rate of

application. When proper adjustment has been

achieved, there should be no sensation of the

trailer pushing or pulling the towing vehicle

during a stop. When this setting has been

reached, no further adjustment should be

required. For operating with varying load

weights, read the following section on “Load

Control.”

Front Axle Resistor

The Warner Electric Front Axle Resistor, part

number 1100-41, is designed to balance braking

forces between front and rear axle on two-axle

trailers. Utility trailers with tandem axle rocker

arm suspension present a typical application.

This suspension tends to transfer weight from

the front axle to the rear axle during braking,

allowing the front wheels to prematurely lock

and skid. By automatically reducing the current

flow, the Warner Electric Front Axle Resistor

reduces front axle braking forces to improve

brake balance, reduce tire wear, and minimize

the wheel lock-up.

Warner Electric • 800-825-9050 A-216 • 819-0244

8

Page 9

Warner Electric • 800-825-9050 A-216 • 819-0244

9

Page 10

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner

Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges

prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be obtained

by writing the Customer Satisfaction Department, Warner Electric LLC, 802 East Short Street, Columbia

City, Indiana 46725, or by calling 260-244-6183.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made, without

charge, together with a refund for transportation costs. If found not to be defective, you will be notified and,

with your consent, the item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not

apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other warranty

or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice.

Weights do not include weight of boxing for shipment. Certified prints will be furnished without charge on

request to Warner Electric.

Warner Electric

802 East Short Street • Columbia City, IN 46725

260-244-6183 • Fax: 260-244-3928

www.warnerelectric.com

A-216 • 819-0244 8/11 Printed in USA

An Altra Industrial Motion Company

Loading...

Loading...