Page 1

P-2035-WE

SM309-gb-11/04

Electromagnetic

Toothed Clutch E320

Service Manual

Page 2

We: WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex declare

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the clutches made in our factories from St Barthélemy d’Anjou,

and hereafter designated: E320

are exclusively designed for incorporation into a machine and to be assembled with other equipments to create a machine. The operation of the

product is submitted to the conformity of the complete equipment, following the provisions of the machinery directive 98/37/EC and if electric to

the EMC directive 89/336 /EEC.

The conformity of the electric units to the Low Voltage directive 72/23 (mofified) is supported by the full respect of the following standards :

NFC 79300 and VDE 05808/8.65.

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1Technical specifications 2

2 Precautions and restrictions on use 2

2.1 Restrictions on use 2

2.2 Precautions in use 3

and safety measures

3Installation 3

3.1 Transport - storage 3

3.2 Handling 3

3.3 Installing 3

3.3.1 Installing VAR00/04/10/14 3

3.3.2 Installing VAR504 3

3.3.3 Installing VAR05 4

4Maintenance 4

5Electrical connection 4

5.1 Important recommendations 4

5.2 Power supply 4

6 Appendix 5

6.1 Drawings / Part numbers 6

that the clutches made in our factories from St Barthélemy d’Anjou, and hereafter designated : E320

are exclusively designed for incorporation into a machine and to be assembled with other equipments to create a machine. The operation of the

product is submitted to the conformity of the complete equipment, following the provisions of the machinery directive 98/37/EC and if electric to the

EMC directive 89/336 /EEC.

The conformity of the electric units to the Low Voltage directive 72/23 (modified) is supported by the full respect of the following standards : NFC

79300 and VDE 05808/8.65.

Drawn up in St Barthélemy d’Anjou, july 2002 E.

PRAT, General Managing Director

CONTENTS

1 Technical specifications 2

2 Precautions and restrictions on use 2

2.1 Restrictions on use 2

2.2 Precautions in use 3

and safety measures

3 Installation 3

3.1 Transport - storage 3

3.2 Handling 3

3.3 Installing 3

1Technical specifications

Size 20 50 100 200 400 800 1600

N max. VAR00 min

N max. VAR04/05 min

Dimension J

Weight VAR04/10/14 kg 1 1.2 2 3 4 7 14

±0.1

-1

5000 5000 4300 3600 3300 2700 2100

-1

- 3900350028002600 2100 1500

mm 0.3 0.4 0.5 0.5 0.5 0.6 0.7

3.3.1 Installing VAR00/04/10/14 3

3.3.2 Installing VAR504 3

3.3.3 Installing VAR05 4

4 Maintenance 4

5 Electrical connection 4

5.1 Important recommendations 4

5.2 Power supply 4

6 Appendix 5

6.1 Drawings / Part numbers 5-6

Coupling - - 28/38 38 42 48 55 75

Dimension E VAR05 mm - 20

+1.5/0

24

+1.8/0

26

+2/0

28

+2.1/0

30

+2.2/0

Weight VAR05 kg - 2,5 4.5 6.8 8.3 15.5 31

Size 3200 6400 12800 25600

N max. VAR00 min

N max. VAR04/05 min

Dimension J

±0.1

Weight VAR04/10/14 kg 29.5 82 145 254

Coupling - 90 125 - Dimension E VAR05 mm 45

Weight VAR05 kg 61 161 - -

NB: Data for catalogue equipment.

-1

1800 1500 1500 1200

-1

1400 1000 - -

mm 0.8 1 1 1

+3.4/0

+4.6/0

60

--

Table 1

40

+3/0

2 Precautions and restrictions on use

Symbol designating

an action that might

damage the brake

Symbol designating an action

that might be dan gerous to

human safety

Symbol designating an

elec trical action that might be

dangerous to human safety

Exceeding the maximum rotation speed listed

2.1 Restrictions on use

VAR00/10 units are designed for operation in

oil (not sealed bearings).

VAR04/14 and VAR05 are designed for dry

operation (sealed bearings).

in the catalogue will invalidate the guarantee.

The suitable ambient temperature for these

units is max. 40°C (Insulation class of 155°C).

E320 clutches are designed for horizontal

mounting. Consult our technical services if other

mounting positions are required.

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2035-WE • 2/13

Page 3

2.2 Precautions in use and safety measures

During maintenance, ensure that the machine’s

moving parts are stationary and that there is no

risk of accidental start-up. All intervention have to be

made by qualified personnel, owning this manual.

0,25 0,25

1

Any modification made to the brake without

the express authorisation of a representative

of Warner Electric, in the same way than any use out

of the contrac tual specifications accepted by “Warner

Electric”, will result in the warranty being invalidated

and Warner Electric will no longer be liable in any way

with regard to conformity.

3 Installation

3.1 Transport / storage

Our clutches and brakes are supplied in packaging

guar anteeing a preservation period of 6 months with

land or air transport, or after transport by ship to

neighbouring conti nents (without crossing the tropics).

3.2 Handling

Avoid any impacts on the equipment so as not

to alter their performance.

Never carry the equipment by the electrical

supply cable.

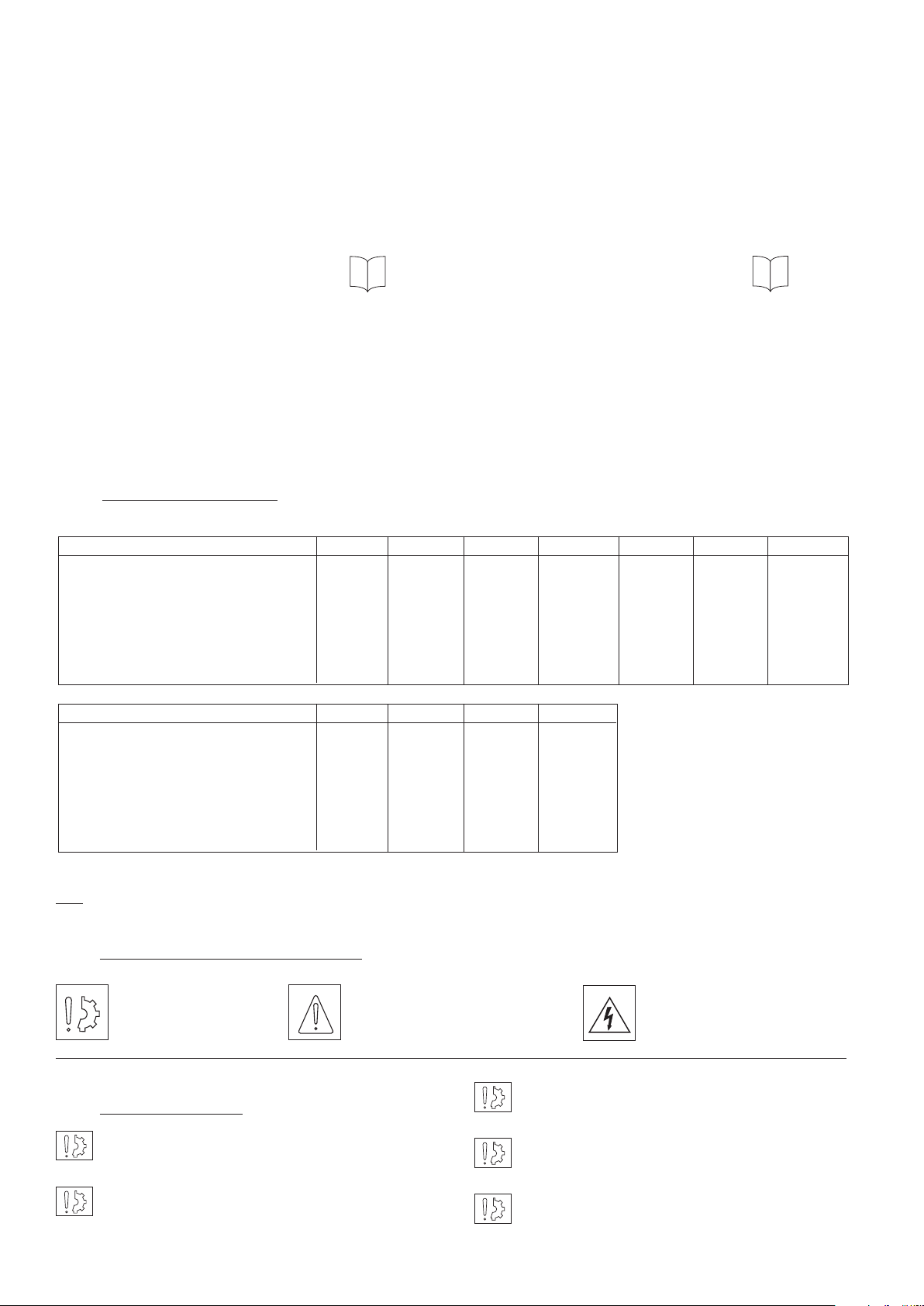

Fig. 1

3.3.1 Installing VAR00/VAR04/VAR10/VAR14

• Center the mobile toothed ring assembly (352) or the

mobile plate (353) on the driven part, then fix it

with screws and lock them

• After adjusting the driving key, mount inductor on

the shaft and fix it axially onto the shaft

It is important to tighten the locking screws from

mobile toothed assembly to the specified torque

(see table 2) or to the mobile plate (353) and secure

them with loctite 243 or an equivalent product.

While assembling the driving and driven parts,

it is essential to note the value J (which is the

distance between tooth heads), see Table 1.

3.3.2 VAR504

3.3 Installing

E320 are delivered with bore / tolerance H7 and keyway/

tolerance P9 according to NFE22175 / DIN6885 /

ISO R773 / BS 4235. The mobile plate assembly (353)

is delivered with bore / tolerance H7. We recommand to

use tolerance h6 for shaft and g6 for the mobile toothed

ring assembly (352).

Important: It is important to prevent inductor

(101) from rotating. It is the customers

responsibility to supply means to prevent inductor

rotating. i.e. retention pin in slot.Check gaps between

the inductor and the retention pin (see Figure 1) :

minimum 0,5 mm gap -1 mm gap at the slot bottom.

The pin should not generate any stress on the bearings.

In case of vibrations, it is strongly recommended to

insert a damping elastic slot between the anti-rotation

device and the anti-rotation slot and to fix the coil’s

cable the nearest of it to avoid whipping.

In the case where two co-axial shafts are

fitted, the recommended setover is 0,05 mm

maximum.

The angular misalignment should not be greater than

0,1 mm over a length of 100 mm. If this is the case,

use a VAR05 (flexible coupling).

Detection discs (aluminium or steel) compatible with

induc tive proximity sensor are provided with unit.

The position of the sensor should not obstruct the

travel of the toothed flange (352) (353).

We suggest to use the inductive sensor (615) provided

by our company, (see technical form).

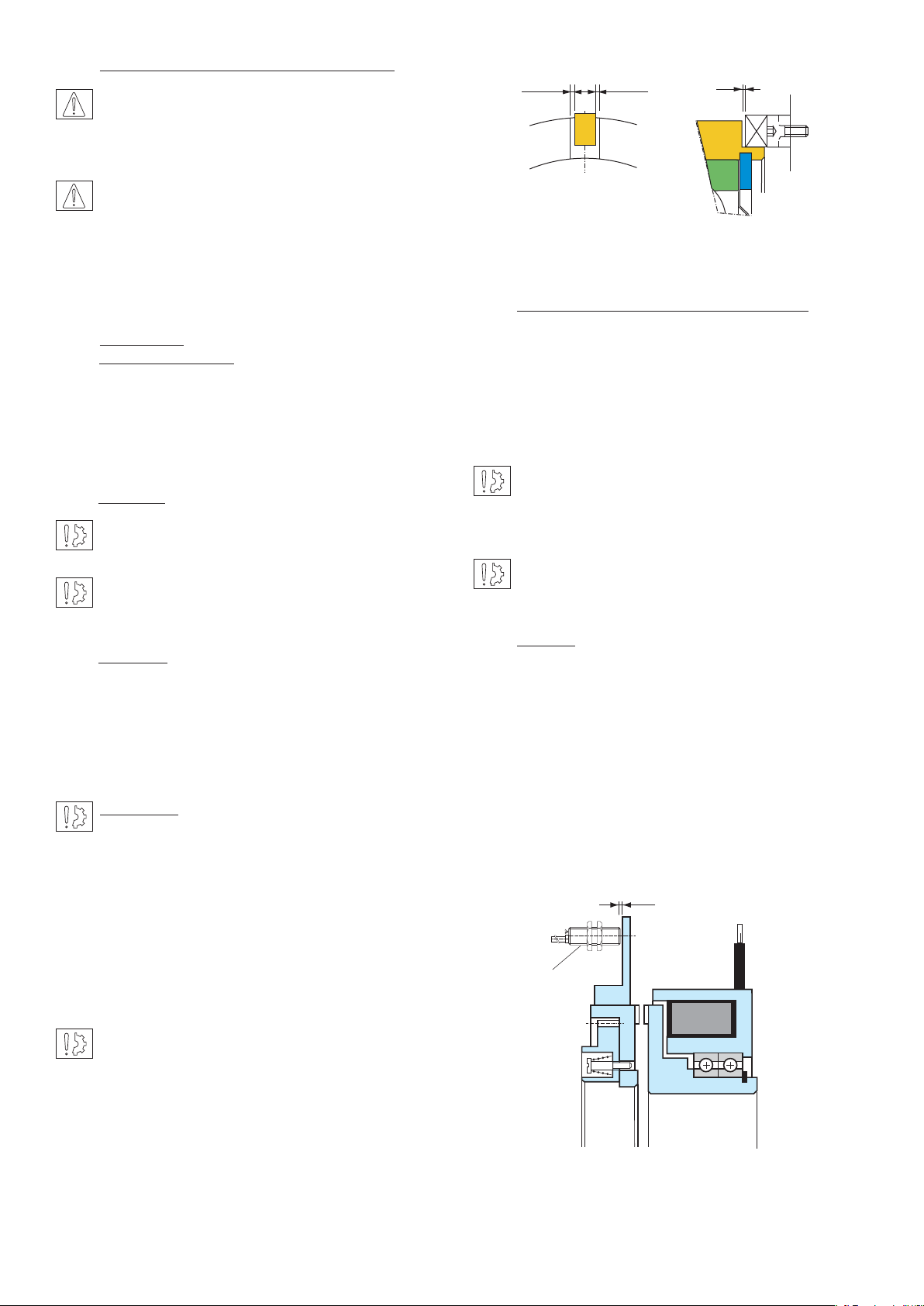

MOUNTING EXAMPLE

Airgap

Sensor

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2035-WE • 2/13 3

Page 4

3.3.3 Installing VAR05

5 Electrical connection

• After adjusting the driving key, mount the inductor

onto the shaft, then fit the adjusting spacer (526) and

the bearing assembly and finally lock the whole axially

on the shaft.

Sizes 3200 and 6400 : the coupling flange (528) is not

mounted in our workshops. After mounting the u to

thshaft, fit the flange with the screws provided to the

spe cified torque (see Table 2) and secure them with

Loctite 243 or equivalent.

Size 3200 6400

Screws M12 M16

Tightening torque 76 ± 8 Nm 189 ± 18 Nm

Table 2

NB.: VAR05 is delivered with a pre-adjusted airgap.

However check the value J between tooth heads after

mounting. (see Table 1).

E320 units must be supplied with direct current (D.C)

and are equipped with a 500 mm length wire. Polarity

does not affect the functioning.

5.1 Important recommendations

All works on the electrical connections have to

be made with power off.

Ensure compliance with the nominal supply voltage

(inade quate supply causes a reduction in the starting

distance and transmissible torque).

The connecting wires should be of sufficient diameter

to prevent voltage drops between the source and

equipment supplied.

I (A) / L (m) 0 to 10 m from 10 to 20 m

0 to 3 (A) 1,5 mm2 1,5 mm

3 to 6 (A) 1,5 mm2 2,5 mm

2

2

Tolerance in the supply voltage to the clutch terminals

+5% / -10% (NF C 79-300).

• Mount the coupling hub (507) onto the second

shaft and lock it axially

• Put the spider (730) inside the coupling flange (528)

• Assemble the driving part with the driven part and

insert the coupling hub with the spider (730)

While mounting the unit, it is essential that you

note value E (elastic coupling mounting),

see Table 1.

4 Maintenance

After continued operation it may become necessary to

change bearings. The inductor bearings are mounted

in a special way, and we recommend returning the unit

back to the factory for replacement.

5.2 Supply

For controlling these clutches, we advise the use of

Warner Electric supply units

Sizes 20 to 3200:

CBC 400-24, CBC450-24

CBC 140-5

Sizes 6400 to 12800:

CBC 140-5

Warner Electric supply units provide protection for coils

and circuits. Where a clutch is used without our supply

units, with switching on the DC, it is essential for the

coil to be protected against surges by a varistor fitted

in parallel.

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2035-WE • 2/13

Page 5

6 Appendix

6.1 Drawings / Part numbers

210

352

VAR00 / 04 / 10 / 14

Sizes 20 to 3200

617

J

101

803

949

210

353

VAR00 / 04 / 10 / 14

Sizes 6400 to 25600

351

350

617

101

803

949

Nr Description

101 Magnet

210 Driving hub

350 Bronze toothed rim

351 Steel toothed rim

352 Mobile toothed ring assembly

353 Mobile plate assembly

507 Coupling hub

526 Spacer adjustment

528 Coupling flange

730 Spider

801 Ball bearings

803 Centering ball bearing

949 Outside retainer

615 Inductive proximity sensor

617 Connector kit

526

210

803

949

617

352

101

E320 VAR04

VAR05

E

730528801

507

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2035-WE • 2/13 5

Page 6

6.1 Drawings VAR504

L (Disengaged)

E

L (Disengaged)

E

Size

20-3200

A

B

INDUCTIVE PROXIMITY SENSOR

615

M12 x 1

17 on flat

35

A

LED

Brown

Load

Black

Blue

Size

6400-25600

+

–

Sizes 50 100 200 400 800 1600 3200 6400 12800 25600

A 135 152 168 178 205 250 288 400 465 540

B 88 104 120 132 158 205 235 ––-

E 3333333555

L 12 14 15,5 16 20,5 28 40 37,5 42 59,5

CHARACTERISTICS

Rate operating distance (steel target) 2 mm

Monting shilded

Switching element function Normally open

Cable NPN, 3 x 0,34 mm2, 2 m

Usable supply voltage 18 V... 30 VDC

Ripple voltage ≤ 10 %

No load supply voltage ≤ 10 mA

Rated operational current 120 mA

Voltage drop ≤ 1,5 V

Off-state current ≤ 10 µA

Short circuit protection yes

Overload protection yes

6 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2035-WE • 2/13

Reverse battery protection yes

Wire break resistance yes

EMC Group A

Operating frequency 2000 Hz

Hysteresis≤ 15 %

Temperature drift≤ 10 %

Repeat accuracy≤ 10 %

Housing Nickel-plated brass

Front cap PBTP

Degree of protection (EN 60529) IP 67

Ambiant air temperature –25°C... +70°C

Page 7

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and

sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original

purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s

prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to

the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer

Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-

3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found

defective under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for

transportation costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or

replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and

in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by

reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU

OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric Europe

7 rue Champfleur, B.P. 20095, St Barthelemy d’Anjou - France

+33 (0)2 41 21 24 24 • Fax: +33 (0)2 41 21 24 70

www.warnerelectric.com

P-2035-WE • 2/13

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2035-WE • 2/13 7

Printed in USA

Loading...

Loading...