Page 1

P-2021

Dairy Cap Chuck

Service & Installation Instructions

An Altra Industrial Motion Company

Page 2

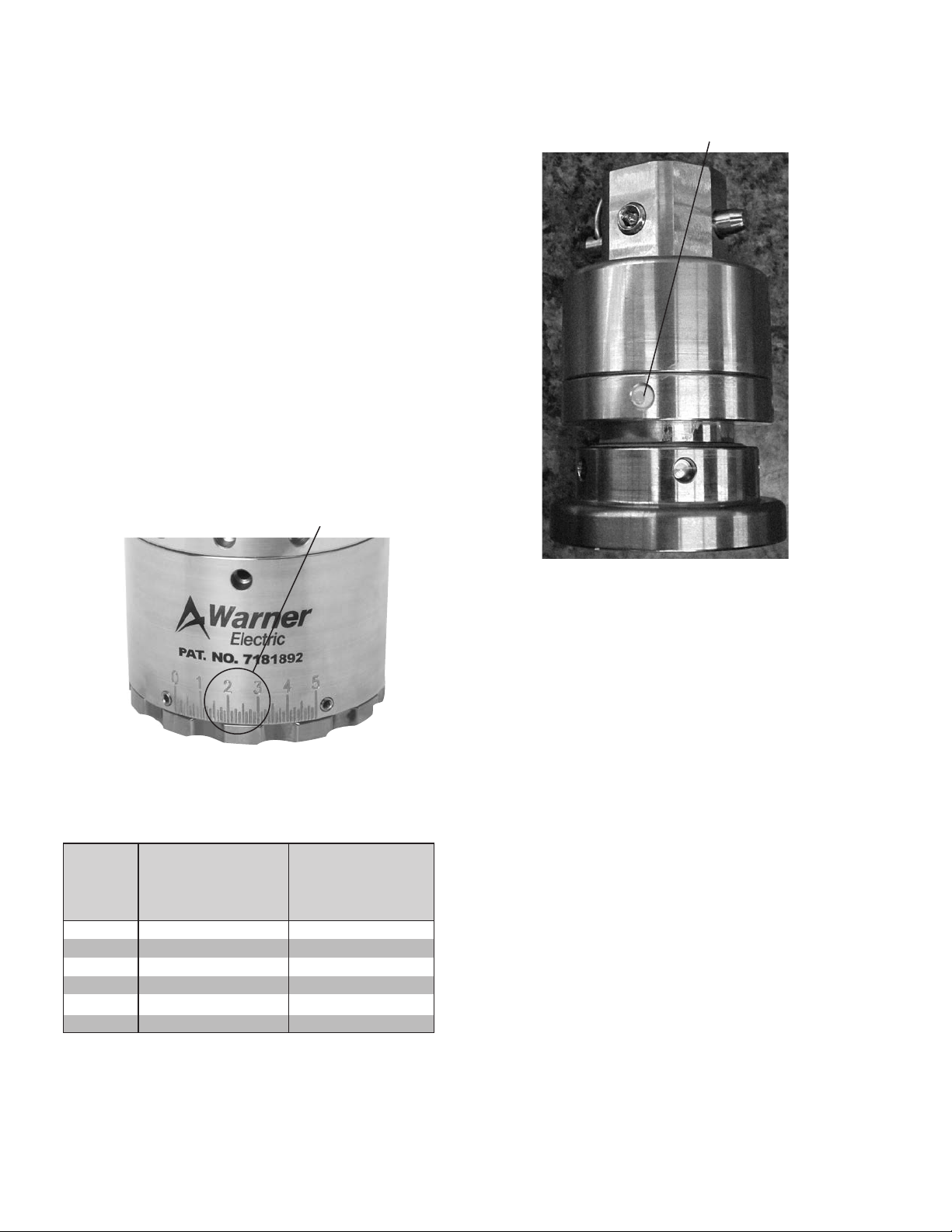

Setting Application Torque

1. Determine initial clutch setting from torque chart

below.

2. Loosen the torque adjustment screws. Rotate the

adjustment ring using the face spanner wrench to

the desired setting and then retighten the torque

adjustment screws. Do not use the set screw in

the slot on the backside of the housing for torque

adjustment. Tighten set screws to 8-10 lb-in.

Over tightening is not necessary and will strip the

screws or possibly damage the housing body.

3. For optimum results, check setting with a torque

wrench and FIX-0115* or FIX-0138.

*For use with DBJ closure

Application

Torque Setting

Recommended Maintenance

For CHF38-035 Chuck

Grease Port

Figure 1

Application Torque Setting Charts

Clutch

Setting

0.00 3.00 11.00

1.00 4.00 12.00

2.00 8.00 17.00

3.00 13.00 22.00

4.00 16.00 26.00

5.00 18.00 28.00

Application Torque

Standard Torque

Units (lb-in)

Application Torque

High Torque Units

(lb-in)

Figure 2

Disassemble, clean, and replace all wearing

parts in the headset every 7000 hours of

machine run time.

- See rebuild instructions for detailed information on

disassembly and assembly of Warner headsets.

- Dependent upon machine speed and washdown

procedure, some environments may require more

frequent rebuilds.

- CHF38-035 chucks cannot be submerged in

water. Proper cleaning procedures for the chucks

include wipe down operations or foaming. If

necessary chucks can be taken apart, cleaned

and rebuilt.

- Chucks can be greased if needed using lubrication

hole in chuck and needle fitting on grease gun.

Do not over grease as this will cause the chucks to

stick.

Note: CHF38-037 and later model chucks may be

submerged in water or COP/CIP cleaners. No

re-greasing is required.

2 Warner Electric • 800-825-9050 P-2021

Page 3

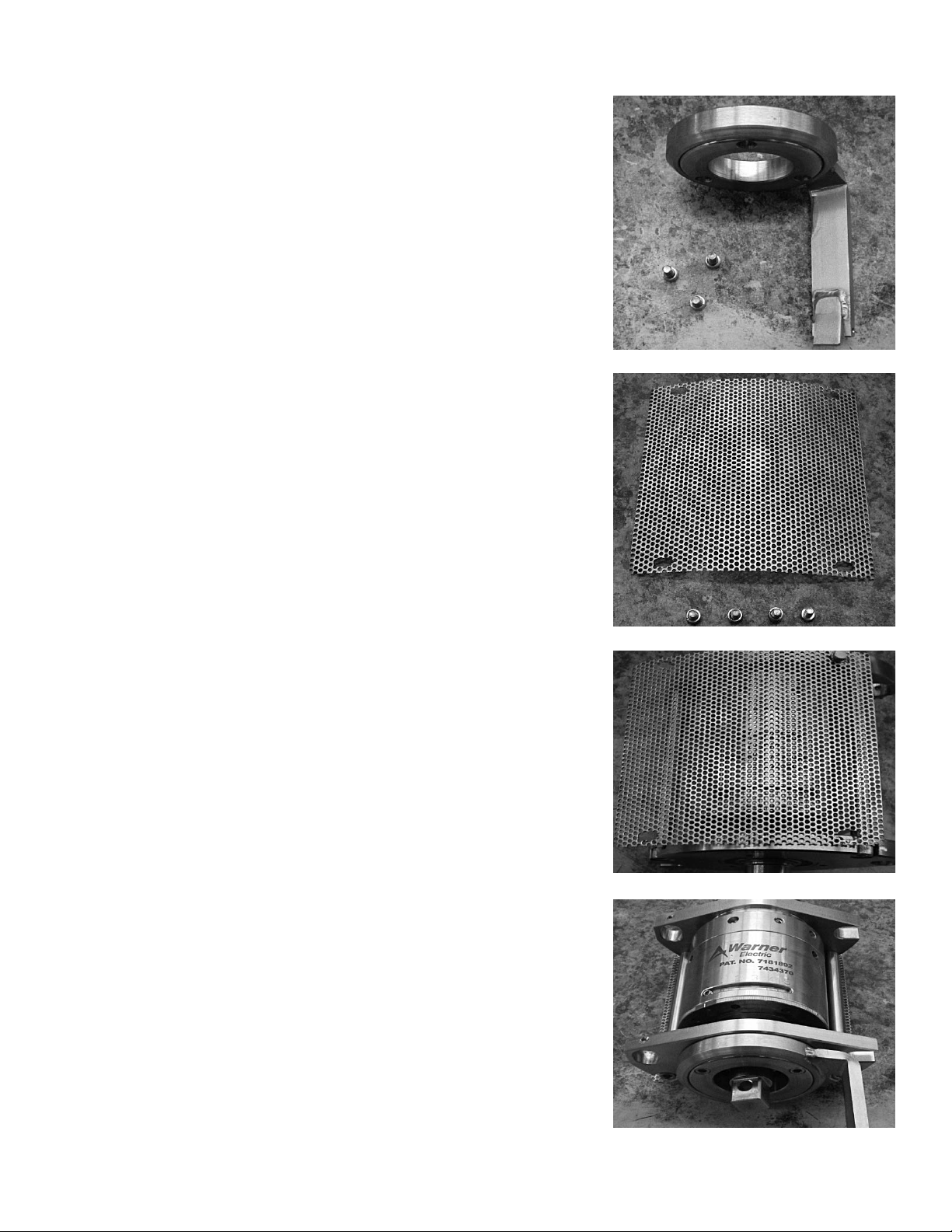

Installing Clutch

Remove handle. Set aside finger, three socket

head cap screws and lock washers. See figure 3.

Remove screen. Set aside screen, 4 screws, and

4 lock washers. See figure 4.

Figure 3

Install screen, 4 lock washers, and 4 screws onto

new unit. It may be necessary to widen original

holes on screen. See figure 5.

Install finger onto new unit. See figure 6.

*Depending on previous equipment a longer

nger may be necessary.

Figure 4

Figure 5

Figure 6

Warner Electric • 800-825-9050 P-2021 3

Page 4

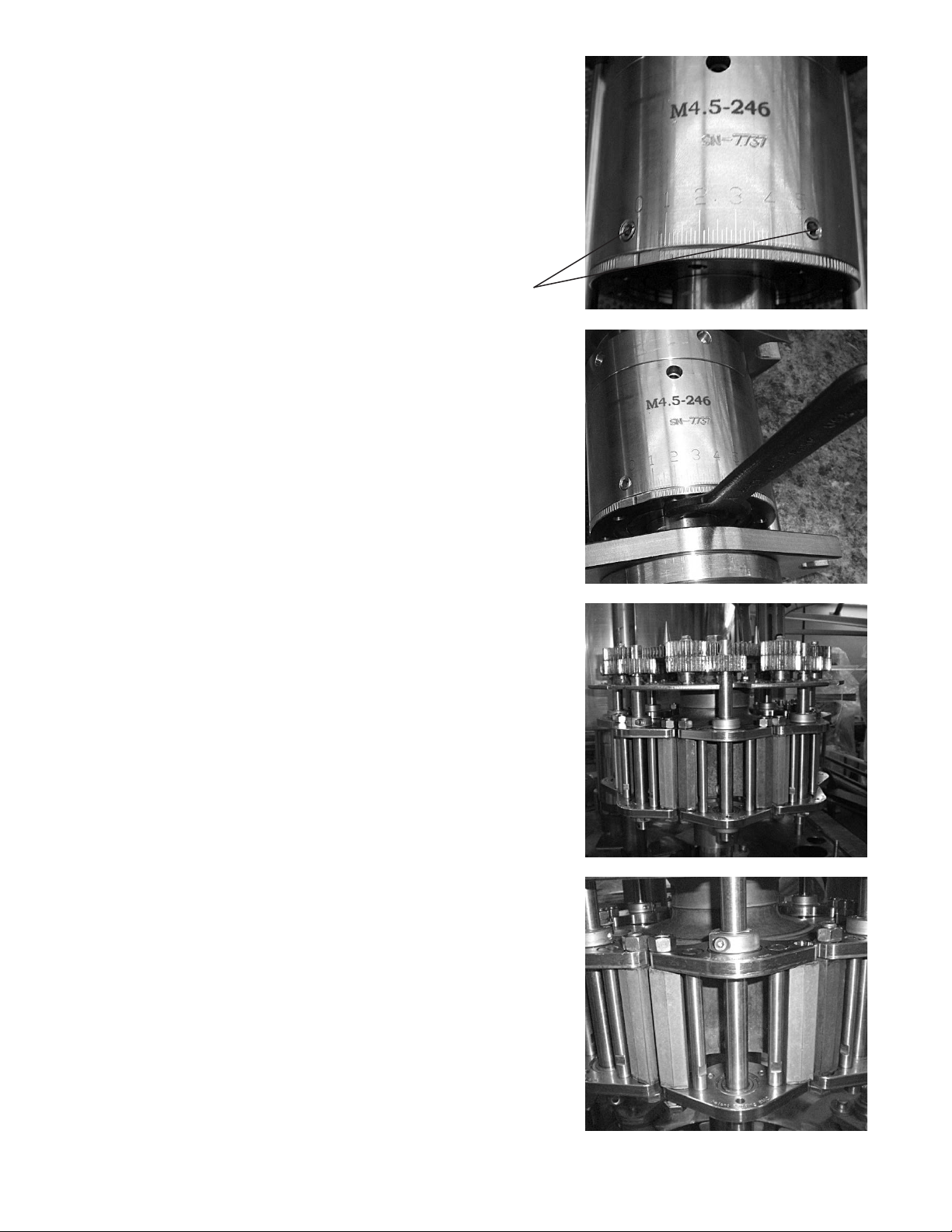

To set torque loosen the two set screws using

3mm Hex wench. Tighten set screws to 8-10 lbin. Over tightening is not necessary and will strip

the screws or possibly damage the housing body.

See figure 7.

Align visual marking with desired setting. Using a

face spanner wrench (YTL2-0002). Then tighten

down set screws. See figure 8.

Set Screws

Figure 7

Figure 8

Remove turret cover from top of machine.

See figure 9.

Figure 9

Remove the two bolts that hold the unit to the

machine. Set the bolts aside for later use. See

figure 10.

Figure 10

4 Warner Electric • 800-825-9050 P-2021

Page 5

Remove old unit from the machine. See figure 11.

Install new unit onto the machine. Use original two

bolts to secure unit from Figure 15. See figure 12.

Figure 11

Adjust gear position where necessary using 3mm

Hex wrench. Apply proper food grade lubricant to

gears. See figure 13.

Clutch installation is now complete. Install

remainder of clutches in the same manner. Adjust

clutch torque and machine turret height as needed.

See figure 14.

Figure 12

Figure 13

Figure 14

Warner Electric • 800-825-9050 P-2021 5

Page 6

Outer Bearing Rebuild

Remove snap ring from bottom plate. See figure 15.

Remove screws from bottom plate using 3/16” (3mm)

hex wrench. Remove bottom plate from unit. See

figure 16.

Figure 15

Remove set screw on the backside of housing using

3mm hex wrench. See figure 17.

Using spanner wrenches (YTL3-0008) and rubber

mallet separate clutch from top adapter. See figure 18.

Figure 16

Figure 17

Figure 18

6 Warner Electric • 800-825-9050 P-2021

Page 7

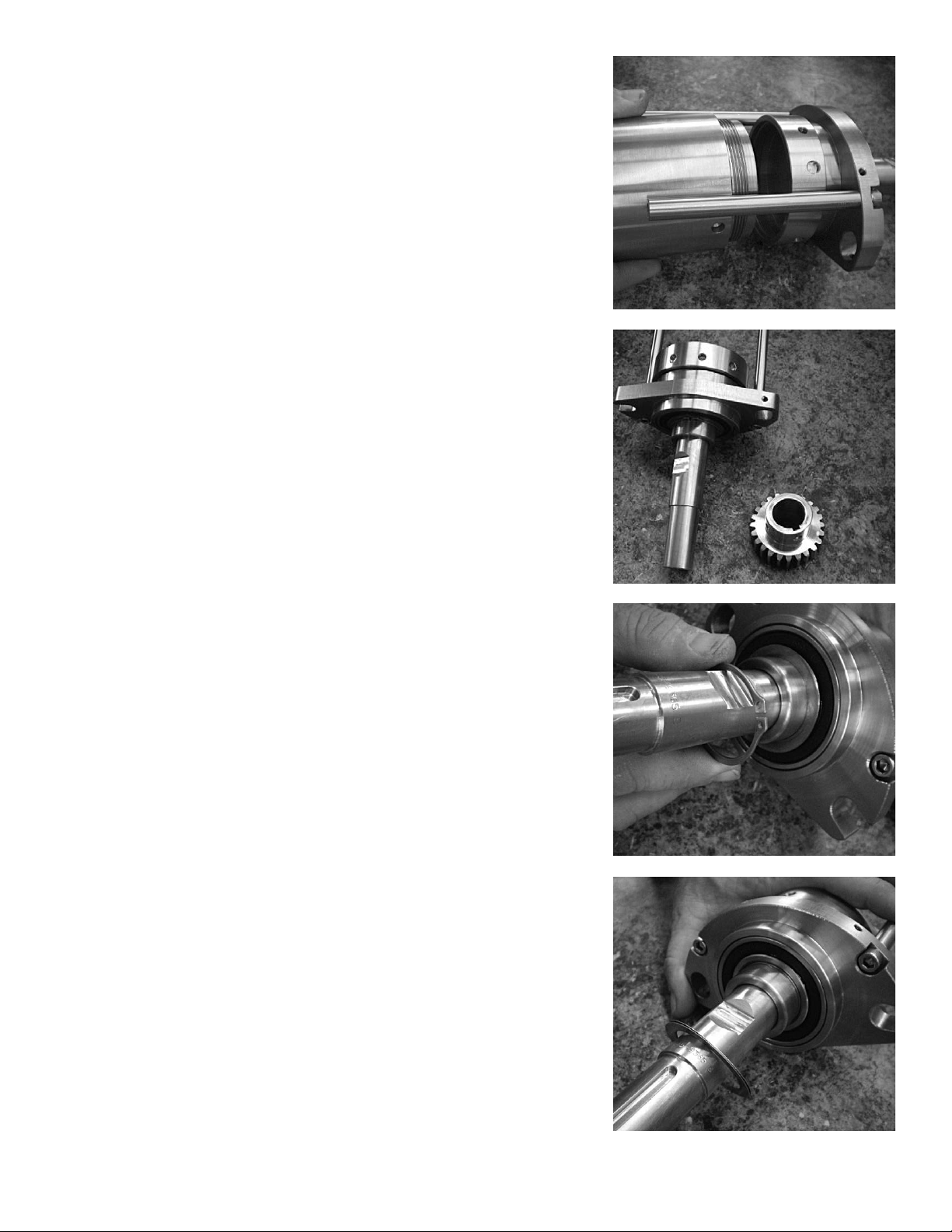

Remove clutch from top adapter. See figure 19.

Remove gear from shaft using 3mm Hex wrench.

See figure 20.

Figure 19

Remove retaining ring from shaft. See figure 21.

Remove shims from shaft. See figure 22.

Figure 20

Figure 21

Figure 22

Warner Electric • 800-825-9050 P-2021 7

Page 8

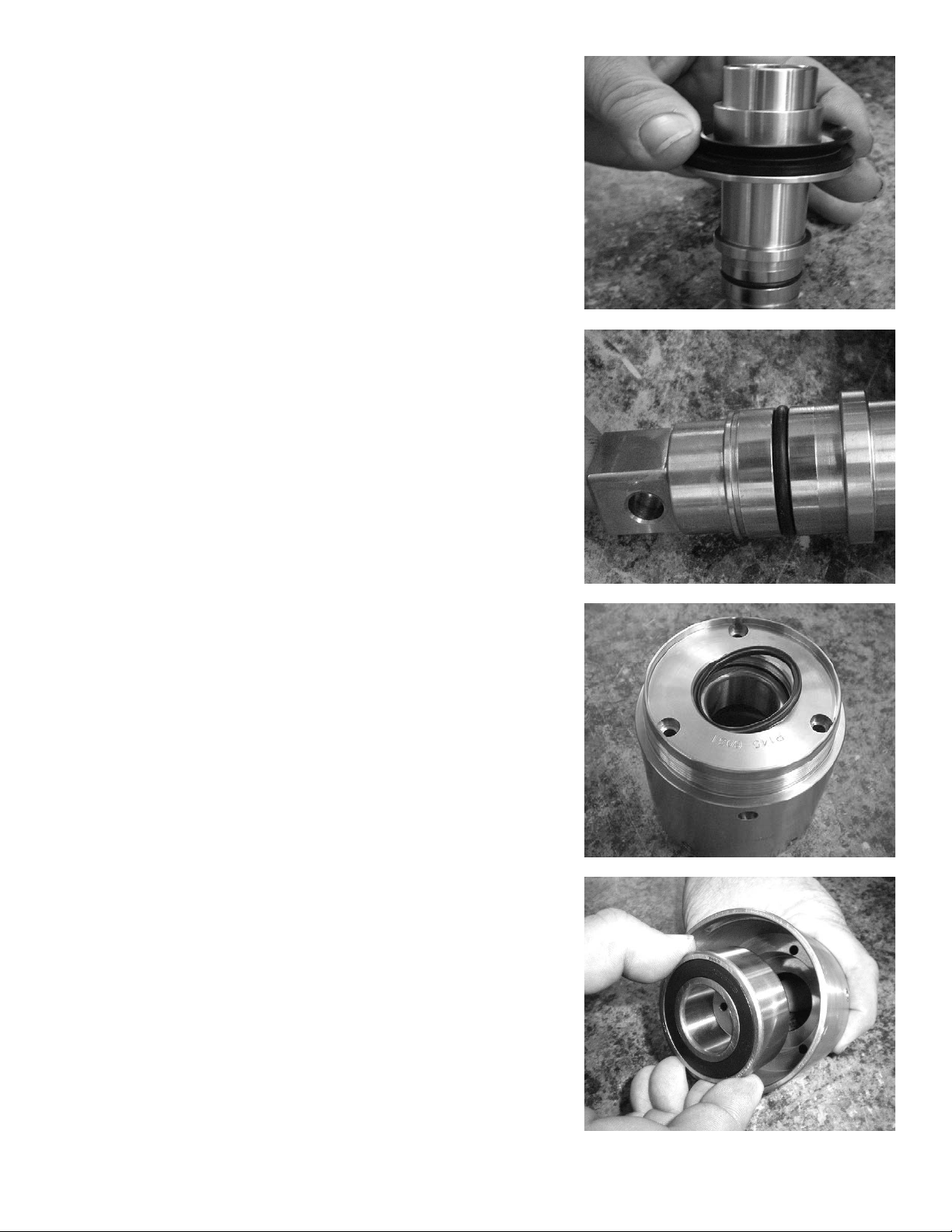

Remove shaft from top plate. See figure 23.

Replace the two bearings in the top plate.

Replace bearing in bottom plate. See figure 24.

Figure 23

Install shaft with adapter onto top plate. See figure

25.

Install shims onto shaft. See figure 26.

Figure 24

Figure 25

Figure 26

8 Warner Electric • 800-825-9050 P-2021

Page 9

Install retaining ring onto shaft. See figure 27.

Install gear onto top of shaft using 3mm Hex

wrench. See figure 28.

Figure 27

Install clutch onto adapter. See figure 29.

Using spanner wrenches (YTL3-0008) and rubber

mallet tighten down clutch onto adapter. See figure

30.

Figure 28

Figure 29

Figure 30

Warner Electric • 800-825-9050 P-2021 9

Page 10

Install set screw on back side of housing using

3mm hex wrench. Tighten set screws to 8-10 lbin. Over tightening is not necessary and will strip

the screws or possibly damage the housing body.

See figure 31.

Install bottom plate over shaft of clutch. Install

screws using 3/16” hex wrench onto bolts to hold

plate in place. See figure 32.

Figure 31

Install snap ring over shaft of clutch. See figure 33.

Figure 32

Figure 33

10 Warner Electric • 800-825-9050 P-2021

Page 11

Clutch Rebuild Procedure

Place unit into vice. Using FIX-0019 and 1 1/8”

or 28mm” socket wrench remove nut from top of

housing. See figure 34.

Remove the two set screws from housing of unit

using a 3mm hex wrench. See figure 35.

Figure 34

Move adjustable end plate until spring and pin are

visible. Remove pin and spring from housing. See

figure 36.

Pull magnet stack away from housing. Set magnet

stack aside. See figure 37.

Figure 35

Figure 36

Figure 37

Warner Electric • 800-825-9050 P-2021 11

Page 12

Remove three cap screws from top of housing

using 3mm hex wrench. Remove black driver

magnet from housing. See figure 38.

Remove spacer from magnet stack. See figure 39.

Figure 38

Figure 39

Remove hysteresis magnet from magnet stack.

See figure 40.

Remove adjustable end plate with black driver

magnet from shaft. See figure 41.

Figure 40

Figure 41

12 Warner Electric • 800-825-9050 P-2021

Page 13

Remove spacer and grease seal. See figure 42.

Remove O-ring from shaft. See figure 43.

Figure 42

Figure 43

Remove seal from top of housing. See figure 44.

Using an arbor press remove bearing from inside of

housing. See figure 45.

Figure 44

Figure 45

Warner Electric • 800-825-9050 P-2021 13

Page 14

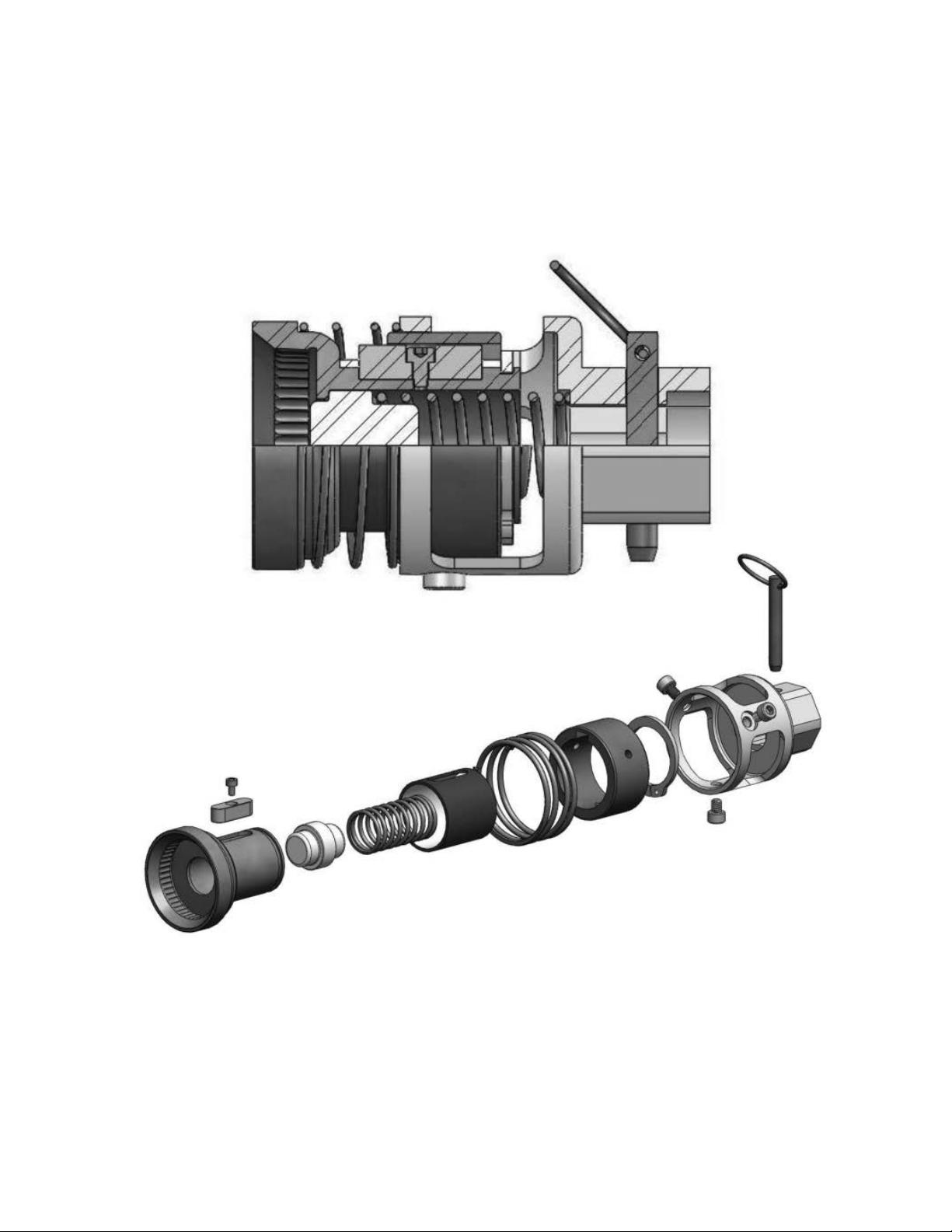

You will now have all of the pieces shown in the

picture to the right. Clean all pieces and replace

parts as needed. Use an alcohol based cleaning

solvent to clean the black driver magnets. Do

not use anything abrasive when wiping the black

driver magnets. Use a Scotch Brite deburr wheel

to polish the hysteresis magnet. See figure 46.

Turn housing over. Press new bearing in housing

using FIX-0002 and an arbor press. See figure 47.

Figure 46

Put in new seal. See figure 48.

Install end cap with black driver magnet into

housing. Be sure to line up holes for set screws.

See figure 49.

Figure 47

Figure 48

Figure 49

14 Warner Electric • 800-825-9050 P-2021

Page 15

Reinstall three cap screws on top of housing using

3mm hex wrench. See figure 50.

Place grease seal over spacer. See figure 51.

Figure 50

Figure 51

Install o-ring into grove of shaft. See figure 52.

Slide spacer with grease seal onto shaft. See figure

53.

Figure 52

Figure 53

Warner Electric • 800-825-9050 P-2021 15

Page 16

Once the spacer is placed on the shaft. Apply

thin layer of grease to the seal. See figure 54.

Apply thin layer of grease to black driver magnet

that is attached to the adjustable end plate. See

figure 55.

Figure 54

Slide adjustable end plate and magnet onto shaft.

See figure 56.

Slide hysteresis magnet onto shaft so that it rests

on the black driver magnet. See figure 57.

Figure 55

Figure 56

Figure 57

16 Warner Electric • 800-825-9050 P-2021

Page 17

Install spacer onto shaft. See figure 58.

Apply thin layer of grease to black driver magnet

inside housing. See figure 59.

Figure 58

Place magnet stack inside of housing. Line up the

hole on the adjustable end plate with one of the

set screw holes on the housing. Be careful as the

magnets will attract together and snap into place.

See figure 60.

Place small spring inside of the aligned holes. Then

place pin, flat side up, into the hole. See figure 61.

Figure 59

Figure 60

Figure 61

Warner Electric • 800-825-9050 P-2021 17

Page 18

Press down on pin with allen wrench and place

spanner wrench (YTL2-0002) onto adjustable

end plate. Turn the allen wrench and the spanner

wrench at the same time to lock pin into place.

See figure 62.

Turn adjustable end plate until witness mark falls

between the O and 5 torque markings. See figure

63.

Figure 62

Install the two set screws onto front of housing

using 3mm hex wrench. Do not tighten down yet.

See figure 64.

Place unit back into the vice. Apply Blue loctite to

the thread of the nut. Using FIX-0019 and 1 1/8”

or 28mm socket wrench reinstall the nut. Torque

nut down to 45 ft. lb. See figure 65.

Figure 63

Figure 64

Figure 65

18 Warner Electric • 800-825-9050 P-2021

Page 19

Using spanner wrench (YTL2-0002) adjust to

desired torque setting. See figure 66.

Tighten down set screws using 3mm hex wrench.

Tighten set screws to 8-10 lb-in. Over tightening is

not necessary and will strip the screws or possibly

damage the housing body. Reinstall unit. See figure

67.

Figure 66

Figure 67

Warner Electric • 800-825-9050 P-2021 19

Page 20

CHF38-035

Exploded View for Chuck Rebuild

Use Loctite on this

Connection

Grease Here

(4 Hole Locations)

20 Warner Electric • 800-825-9050 P-2021

Page 21

CHF38-037 & Later Models

Exploded View for Chuck Rebuild

(non-grease chuck)

Warner Electric • 800-825-9050 P-2021 21

Page 22

On-site Service Support

Warner Electric Capping Headsets

On-site service support is available for installation of new Warner headsets, rebuild support of existing Warner

headsets, training, etc. Our factory-trained and certified service department with over 50 years combined

experience can help prevent costly delays and down time of your capping operation.

Precision Tork is the ONLY Service Group that is factory

authorized to work on the Warner Electric headsets.

Services Provided:

• Installation of new equipment

• Machine audits and troubleshooting

• Service and repair of filling and capping equipment

• Consulting: New Installations-existing issues for filling and capping

• Develop new design for efficient production

• Assist with planning of preventative maintenance programs

• Operator and mechanical training

• Highly qualified trained field engineers ready to work on the following bottling equipment:

• Alcoa • Zalkin • Fowler • AROL

Precision Tork Service Benets:

• We manufacture the headsets!

• Most up-to-date designs available only through Precision Tork.

• Our service technicians are trained to rebuild your headsets to their existing revision level

OR upgrade them to the latest technology.

• Component parts and rebuild kits on hand so you do not incur downtime.

• Coming soon…secure website for headset information and parts ordering with a credit card.

To schedule a certied Warner Service Technician

contact Melissa Bottke at 1-888-350-1891

22 Warner Electric • 800-825-9050 P-2021

Page 23

Trouble Shooting

• Proper Operation: Before cap comes out of chuck the chuck should reach a stall point. At that point cap

will be completely tightened on bottle. It is important to have proper turret height and clutch torque

adjustment for this to occur.

• Loose Caps

• Torque setting on clutch to low; increase torque setting on clutch

• Turret position set to high while cap is being screwed onto bottle

• Cap will be pulled from chuck before properly tightened. To correct, lower turret of machine.

• Bottle Damage

• Can result if turret is set to low.

• Chuck will cause cap to be crushed onto bottle.

• To correct raise turret of machine.

• Sticky Chuck Float

• For proper operation, chuck must float up and down approximately 0.2 inches.

• If grease is washed out of chuck and chuck becomes dry, re-greasing chuck will become necessary.

• Chuck should move easily in and out without hang ups.

Information for Ordering Spare Parts

It is important to stock spare parts on hand to avoid unnecessary downtime. Warner recommends that you

stock at least two spare headsets per machine and a few bearing and magnet rebuild kits so that you have

the necessary parts on hand if you need them.

How to order spare parts – required information:

1. Purchase Order Number.

2. Warner headset model number/part number OR serial number

(only on models manufactured July 2007 and later).

3. Warner Component or Kit Part Number.

4. Preferred distributor to order from.

All orders will be routed through local distribution. Pricing and lead-time can be quoted by calling the

Manufacturing Facility at (888) 350-1891.

Warner Electric • 800-825-9050 P-2021 23

Page 24

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product

manufactured and sold by it which proves to be defective in material or workmanship within a period of one (1)

year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric

LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges

prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by

writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois

61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If

found defective under the terms of this warranty, repair or replacement will be made, without charge, together

with a refund for transportation costs. If found not to be defective, you will be notified and, with your consent, the

item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident,

neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply

to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective

product and in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of

any kind incurred by reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither

assumes nor authorizes any other person to give any other warranty or to assume any other obligation or liability

on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT,

THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER

EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also have

other rights which vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice.

Weights do not include weight of boxing for shipment. Certified prints will be furnished without charge on request

to Warner Electric.

www.warnerelectric.com

31 Industrial Park Road

New Hartford, CT 06057

800-389-3771

Fax: 815-389-2582

P-2021-WE 3/14 Printed in USA

An Altra Industrial Motion Company

www.altramotion.com

Loading...

Loading...