Page 1

Compressor Clutch

Replacement Procedure

P-1401

819-0316

Installation Instructions

Page 2

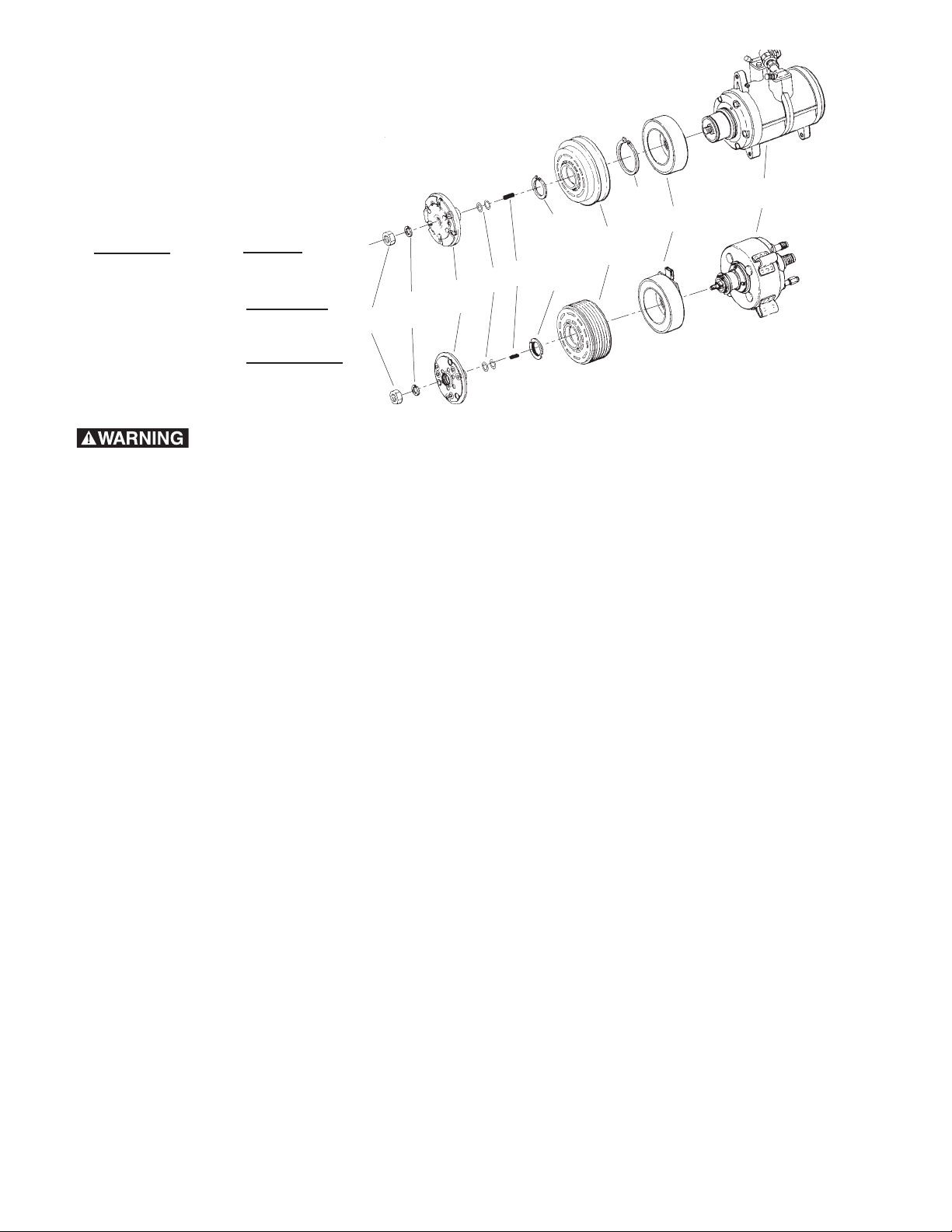

Warner Replacement Clutches

11

Shaft Nut

10

Lock

Washer

8

Shims

7

Key

6

Rotor/Pulley

Retainer nut

4

Rotor/Pulley

Assembly

2

Field Coil

1

Compressor

9

Hub/Armature

Assembly

5

Rotor/Pulley

Snap Ring

3

Field Coil

Snap Ring

HR980

FS6, C171, A590,

6E171, 10P15,

6P148, 6717

for the following compressors:

Denso

6E171

10P15

6P148

6C17

Ford

FS-6

Chrysler

C-171

Tecumseh

HR980

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Note: During compressor clutch removal DO

NOT pound on the clutch or compressor as

damage will result.

Step 1: Diagnose Clutch Failure

Most compressor clutch failures are a direct

result of an A/C system problem or failure.

Before installing a new clutch, determine what

caused the old clutch to fail and fix the system

problem. By simply replacing the clutch without

fixing the cause of the clutch failure, the new

clutch may fail in the same manner as the old

clutch. Please refer to the Warner Electric "Air

Conditioning Clutch Trouble Shooting Guide"

and the appropriate manufacturer's A/C

Service Manuals.

Warner Electric • 800-825-9050 P-1401 • 819-0316

2

Step 2: Removal of Hub/Armature Assembly

(9)

Special tools must be used to avoid damaging

the compressor.

A. Remove shaft nut (11) with a 13mm socket

wrench and spanner wrench.

B. Remove lock washer (10).

C. Remove hub/armature (9) with a hub/armature

removal tool (reference Chrysler Tool # C-4561

or equivalent).

D. Remove shims (8) from the hub/armature and

shaft.

Step 3A: Removal of Rotor/Pulley Assembly

(4) (All compressors except HR980)

A. Remove rotor/pulley snap ring (5).

B. Slide rotor/pulley assembly (4) off the

compressor (1) nose. If rotor/pulley assembly

is hot and will not slide, DO NOT FORCE! Allow

the clutch to cool and then proceed.

C. Proceed to Step 4.

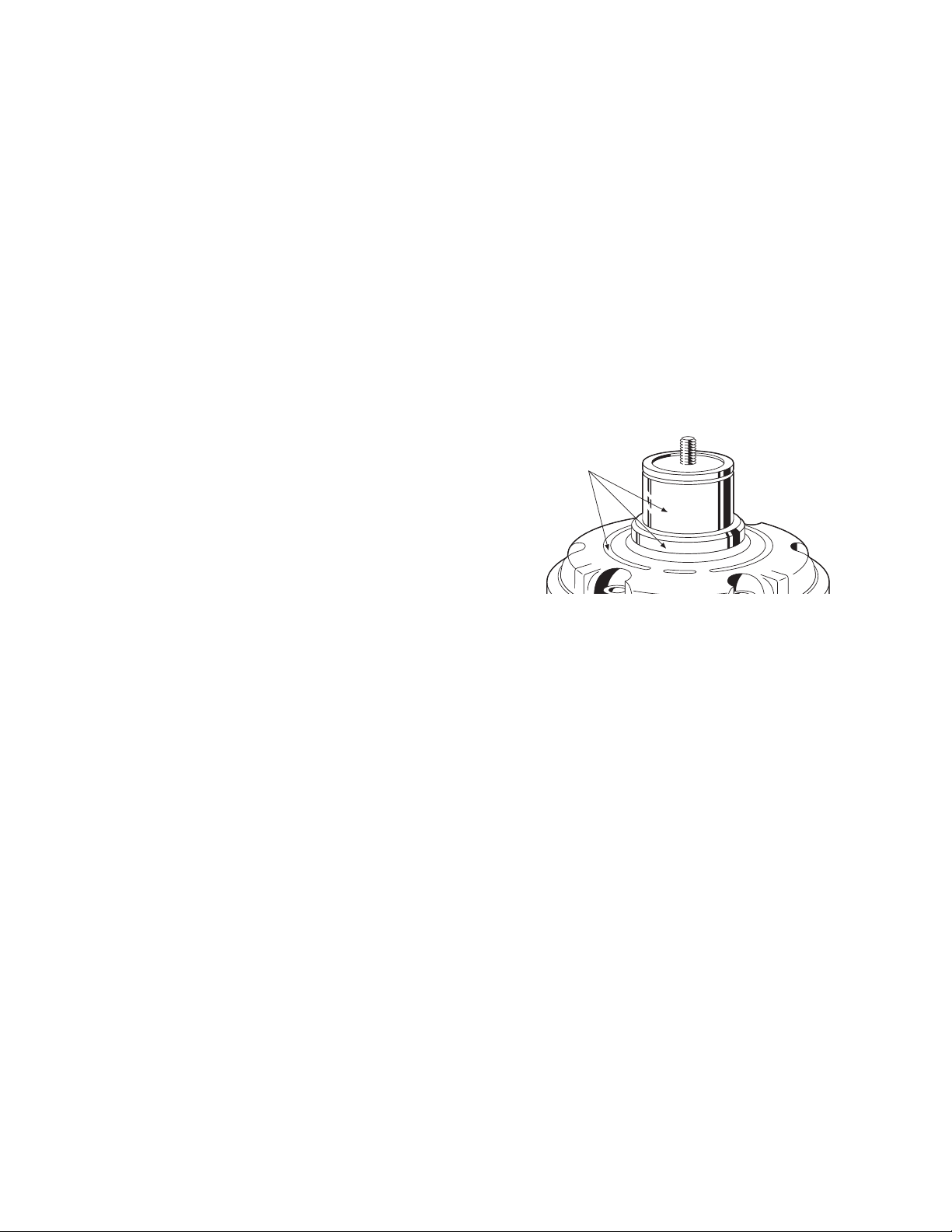

Page 3

Step 3B: Removal of Rotor/Pulley

Mounting

Surfaces

Assembly (4) and Field Coil Assembly (2)

(HR980 Compressor only)

A. Disconnect the electrical connection on the

field coil (2).

B. Unscrew the rotor/pulley retainer nut (6) with a

spanner wrench.

C. Slide the rotor/pulley assembly (4) off the

compressor (1) nose. If rotor/pulley assembly

is hot and will not slide, DO NOT FORCE!

Allow the clutch to cool and then proceed.

D. Remove field coil assembly (2).

Step 4: Removal of Field Coil Assembly (2)

(All compressors except HR980)

A. Separate electrical connection and, if

applicable, remove clutch wire retaining clip

from the compressor.

Installing Clutch on Compressor

Replace the complete clutch to ensure required

performance is achieved and warranty

requirements are met.

Step 1: Preparation of Compressor

A. Clean compressor nose of all dirt, grease

or debris. Check for evidence of oil leakage

from the front seal and through bolts of the

compressor. Repair or replace compressor

as appropriate.

B. Check mounting surfaces for nicks, burrs and

scratches (See Figure 1). Smooth with a file

or emery cloth, if necessary.

B. Remove field coil snap ring (3) retaining the

field coil.

C. Remove the ground screw on the compressor,

if used.

D. Slide the field coil (2) off the compressor

housing.

Figure 1

C. Make an electrical system check with all

electrical accessories turned on to ensure

that the voltage available to the clutch is

10.8 volts minimum.

Warner Electric • 800-825-9050 P-1401 • 819-0316

3

Page 4

Step 2A: Installing the Field Coil (2)

Rotor/Pulley

Assembly

Hub/Armature

Assembly

Field Coil

Assembly

Field Coil Assembly

Snap Ring

Compressor

Rotor/Pulley Assembly

Snap Ring

Fully seated

snap ring

Bevel

Compressor

Install with beveled face away from compressor

Snap Rings

Compressor

Correct

Incorrect

Clutch

Field

Coil

Assembly

Compressor

Rotate

Remove

Slack

Taut

Wire

PRE-1981

0.058 to 0.065

Inches Thick

POST-1981

0.075 to 0.081

Inches Thick

Thickness

Measurement

(All Compressors except HR980)

Note: Failure to install snap rings per these

instructions can be verified and will void the

compressor clutch warranty.

A. Align the hole in the back plate of the field

coil (2) with the anti-rotation pin in the

compressor end housing. Place the field

coil into position. Make sure that the lead

wires are routed directly to the retaining

clip on top of the compressor.

B. Install field coil snap ring (3).

Figure 2

Use the Correct Retaining Ring (3)

During the 1981 model year, the retaining

ring used to hold the Chrysler C171 field coil

assembly (2) in place was made thicker. Check

the thickness of the old ring which was removed

and verify that the new ring is the same

thickness (*except 6C17 Compressor). The field

coil assembly must be tight on the compressor.

*For a 6C17 Compressor, Install the field coil

assembly (2) with the retaining ring (3) provided

with the new Warner clutch. Discard the old

retaining ring.

Location of Clutch Snap Rings

Figure 3

Snap Ring

Correct and Incorrect Installation

Bevel

Note: When attaching the clutch ground wire to

the compressor, rotate the ring terminal

COUNTERCLOCKWISE to remove slack in

the wire. Failing to remove slack may result

in the pulley rubbing on the ground wire on

some models.

Figure 4

With a snap ring pliers, spread the field coil

snap ring (3) and insert it into the groove on the

compressor nose. (See Figure 2) To assure

assembly retention, ring bevel must face away

from the compressor. (See Figures 3 and 4)

Verify that the snap ring is fully seated in the

groove around its circumference to assure

assembly retention. (See Figure 4)

Attach the ground lead, if used, to the

compressor housing and tighten the screw

to 17 lb.in. torque. (See Figure 5)

Warner Electric • 800-825-9050 P-1401 • 819-0316

4

Right Wrong

Figure 5

Page 5

Rotor/Pulley

Retaining Nut

Hub/Armature

Assembly

Rotor/Pulley

Assembly

Field Coil

Assembly

Compressor

HR980

Step 2B: Installing the Field Coil (2)

and Rotor/Pulley Assembly (4) (HR980

Compressor only)

Step 3: Installing the Rotor/Pulley

Assembly (4) (All Compressors except

HR980)

A. Align square holes in the back plate of the

coil assembly (2) with lugs on the compressor

(1) housing.

B. With the field coil (2) in position, slide the

rotor/pulley (4) onto the compressor until it

butts against the field coil (2). (See Figure 6)

If the the rotor/pulley does not slide on easily,

check the mounting surface on the

compressor nose for nicks or burrs and

remove them. If the rotor/pulley still does not

slide on easily, rock the rotor/pulley back and

forth by hand until it slides completely onto

the compressor.

C. Install the rotor/pulley retainer nut (6) with

flange notches facing AWAY from the

rotor/pulley assembly. Tighten the retainer nut

to 65 to 75 lb.ft. torque.

D. Make electrical connection.

E. Proceed to Step 4.

Do not mar the rotor/pulley

and hub/armature friction surfaces.

Prevent any oil or grease from

contaminating the friction surfaces.

A. Install the rotor/pulley assembly (4) onto the

compressor (1). If the rotor/pulley does not

slide on easily check the compressor nose for

nicks or burrs and remove. If the rotor/pulley

still does not slide on easily, rock the

rotor/pulley back and forth by hand until it

slides completely onto the compressor (1).

B. Make sure there is no interference between

the field coil (2) or lead wires and the rotating

rotor/pulley (4).

C. Install the rotor/pulley snap ring (5). With a

snap ring pliers, spread the snap ring and

insert it into the groove on the compressor

nose. (See Figure 2) To assure assembly

retention, the snap ring bevel must face away

from the compressor. (See Figures 3 and 4)

Figure 6

The snap ring pliers must not

contact the bearing seal or a seal failure may

result.

D. Verify that the snap ring (5) is fully seated

in the groove around its circumference to

assure assembly retention. (See Figure 4)

Warner Electric • 800-825-9050 P-1401 • 819-0316

5

Page 6

0.020

(0.51)

0.040

(1.02)

Rotor/Pulley to

Hub/Armature Airgap

(Measured 3 places

120° apart)

to

Step 4: Installing the Hub/Armature

Assembly (9)

A. Align the hub keyway with shaft key (7) and

slide the hub/armature (9) onto the compressor

shaft.

B. Set the rotor/pulley to hub/armature air gap at

0.020 to 0.040 inches by adding or removing

shims (8). Measure using a feeler gauge at 3

locations 120° apart. (See Figure 7)

C. Install the lockwasher (10) and shaft nut (11).

Torque to 155 lb.in. using a torque wrench and

spanner wrench.

Use a hub/armature removal

tool (reference Chrysler tool C-4561 or

equivalent) to install and remove the

hub/armature (9).

Do not use screwdrivers

between the hub/armature and rotor/pulley

to remove hub/armature as clutch will be

damaged.

Step 5: Clutch Assembly Check

A. Rotate the clutch and check for rubbing or

interference.

B. Reinstall belts per manufacturer's service

manual. Do not over tighten.

C. Recheck the airgap at 3 or 4 points and

check for clutch rubbing.

D. Important: Burnish as follows. Run the

clutch at 2500 to 3000 RPM. Cycle the clutch

ON and OFF at a rate of 10 to 15 times per

minute maximum for a total of 50 cycles

minimum. This should bring the clutch up

to operating torque capacity.

Cycle the clutch using the

controls inside the car or electrical system

damage could result.

Note: The shims (8) may compress when the

shaft nut (11) is tightened; therefore, recheck

the airgap at three locations 120° apart.

Figure 7

Warner Electric • 800-825-9050 P-1401 • 819-0316

6

Page 7

Troubleshooting Checklist

For failure diagnosis of the clutch being replaced, (the failed clutch), refer to the Warner Electric

Troubleshooting Guide (form P-1011) and the appropriate A/C manufacturer's Service Manuals.

Use the guide below to troubleshoot the new clutch.

A. Symptom: Clutch will not disengage

Possible Causes Solution

• Improper hub/armature to rotor/pulley • Reset air gap (See Figure 7)

air gap (too small)

• Current is always on • Check electrical system

• Rotor/pulley snap ring not installed • Install per instructions (See Step 2)

correctly

B. Symptom: Clutch will not engage

Possible Causes Solution

• Improper hub/armature to rotor/pulley • Reset air gap (see Figure 7)

air gap (too big)

• Field coil electrical wiring is not connected • Connect field coil wiring

• Faulty field coil • Check field coil for continuity

• Less than 10.8 volts supplied to field coil • Check electrical system

(all accessories on)

C. Symptom: Clutch is noisy

Possible Causes Solution

• Field coil or rotor pulley snap rings • Check for correct installation (See Step 2)

are not installed correctly

• Belts too loose • Tighten per A/C manufacturer’s service manual

• Bearing noisy (new clutch only) • Return to manufacturer

• Clutch not burnished • Burnish per instructions (See Step 5)

D. Symptom: Clutch slips

Possible Causes Solution

• Belts too loose • Tighten per A/C manufacturer’s service manual

• Voltage to field coil less than 10.8 volts • Check electrical system

(all accessories on)

• Improper wiring or connections • Check electrical system

• Oil or grease on friction surfaces • Replace clutch

• Clutch not burnished • Burnish clutch per instructions (See Step 5)

Warner Electric • 800-825-9050 P-1401 • 819-0316

7

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner

Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges

prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be obtained

by writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit,

Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made, without

charge, together with a refund for transportation costs. If found not to be defective, you will be notified

and, with your consent, the item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not

apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other warranty

or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER

WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice.

Weights do not include weight of boxing for shipment. Certified prints will be furnished without charge on

request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1401 • 819-0316 6/12 Printed in USA

Loading...

Loading...