Page 1

CBPC-3590

Clutch-Brake Positioning Controller

P-291-1

819-0526

Service & Installation Instructions

Warner Electric • 800-825-9050 P-291-1 • 819-0526 1

Page 2

Contents

compensation is maintained in the stop position

from cycle to cycle.

Introduction ............................2

Theory of Operation ......................2

Specications...........................3

Mechanical Installation....................4

Dimensional Information ..................5

Electrical Wiring .........................7

Start Up ...............................9

Programming Information ................11

RS-485 Programming ...................12

Troubleshooting ........................18

Warranty ............................. BC

instructions may result in product damage,

equipment damage, and serious or fatal injury

to personnel.

Only Authorized Personnel to set

up and maintain this unit.

Failure to follow these

Introduction

The CBPC-3590 Clutch Brake Positioning Control

is a dedicated control incorporating a counter

system, control logic, and clutch brake power

supply for closed loop control operation. The

controller uses an incremental encoder input with

marker pulse to register position for single

revolution operation.

The one board design eliminates interconnec-

tion between numerous boards and controls and

improves reliability by removing unnecessary

interconnecting cables. With everything located

on one board, replacement of the control board is

simplied.

An external start input signal is used to provide

the start input to the controller which applies

power to the clutch. The encoder registers the

position to the controller and when the preset

count is reached turns power on to the brake. An

internal averaging circuit takes the actual stop

position from the required stop position and

compensates so the controller provides the stop

at the precise position. In this method,

The control has front panel indicators to tell when

the clutch is on, brake is on, a fault has occurred

and a home pulse indicator. In addition, a front

panel run-jog switch allows the user to operate the control in normal running mode or in jog

mode for set up and troubleshooting purposes.

When in the jog mode, the jog push-button allows

the clutch to be activated at a preset level below

the maximum set output level. The clutch will be

engaged as long as the push-button is held in and

brake is actuated as soon as it is released.

This control will directly replace the older style

CBC1500-AHFC controller. Connectors are

provided on the housing of the control for

hook-up to existing cables where the

CBC1500-AHFC is used. If existing cables are

non-existent, optional cable accessories are

available.

Set up has been simplied to minimize the

number of steps necessary to commission the

unit. All functions are accessed internally in the

controller via the keypad and display. Once the

unit is set up and closed, the operator does not

have access to any of the functions without going

into the controller. Remote indicators on the

faceplate show the status of the controller.

Theory of Operation

The CBPC-3590 operation is simple and straight

forward. The unit is typically setting with the brake

output engaged. A “start input” signal is received

by the control from the external signal source. The

controller disengages the brake and applies

power to the clutch. The output level to the clutch

is adjustable via the programming mode to obtain

the proper engagement of the clutch. With the

clutch engaged, the drive mechanism starts to

rotate generating a signal to the controller from

the encoder. The controller counts the encoder

pulses and the display (internal) counts in an up

direction. If the count is in the reverse direction,

then the encoder signals “A” and “B” are

improperly connected and need to be reversed for

2 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Page 3

correct operation. Additionally a marker pulse is

generated by the encoder to the controller which

looks at this pulse and internally in the processor matches the system count with the encoder

count. When the system count is equal to the

preset count (600 minus the braking distance) a

brake output signal is generated and the

controller applies the brake. Brake torque is

adjustable to obtain optimum stop conditions.

Specications

Input Power: 120 VAC, +/- 10%, 50-60 Hz, Single

Phase, 300 VA maximum

Fusing: 1.6 Amp, 250 V fast acting (5x20mm)

Output: Adjustable 0 – 90 VDC pulse width

modulated full wave rectied DC via keypad.

1 Amp per channel maximum

The controller internally compares the actual stop

point with the desired stop point based on the

preset distance, the braking distance, and any

over or undershoot that might occur. This brak-

ing distance is averaged on a continuous basis

to provide a stopping point as close to the preset

point as possible.

The controller also can handle multiple start signal

inputs so that the controller can make numerous moves and yet still return to the correct stop

point. This is accomplished through the integrated

control logic of the processor on the board.

A batch counter is also incorporated into the

controller to keep track of the number of

operation cycles the unit operates. This can be

useful in both troubleshooting as well as

scheduling preventative maintenance on the

machine.

Output Frequency: Adjustable from 60 to 400 Hz

via keypad

Start Input: 120 VAC, 50-60Hz signal. Minimum

on time of 0.02 seconds (20 milliseconds),

maximum on time 0.100 seconds

(100 milliseconds)

Front Panel Switches

Power: On-Off power switch with internal

indicator

Run-Jog: Allows for operation of the control in

normal run or in jog mode for set-up and

troubleshooting

Jog Push-button: Allows for jogging when switch

is depressed. When released, brake is

re-engaged. Active only when Run-Jog switch is

in Jog mode.

During normal operation if any one of a number

of faults would occur; the controller will provide a

visual indication via the front panel “LED” marked

fault as well as tripping an internal relay which can

be wired to external alarms or sensors for

detection purposes. Additionally, the display will

provide a reference as to which fault possibly

occurred.

Front Panel Indicators

Power on: Integral to Power On-Off Switch

Clutch on: Green LED

Brake on: Red LED

Home Marker: Yellow LED

Fault: Red LED

Enclosure Connectors

5 Pin Brad Harrison for encoder connections:

Mating connector for wiring to encoder cable:

Brad Harrison # 1A5000-34 screw terminal

connections

Warner Electric • 800-825-9050 P-291-1 • 819-0526 3

Page 4

9 Pin Brad Harrison for clutch, brake, power and

switching.

Mating connector for wiring to power, load, and

switching circuits:

Brad Harrison

# 309002A01F030 with 3 foot pigtails

# 309002A01F060 with 6 foot pigtails

# 309002A01F120 with 12 foot pigtails

Certications

®

IND. CON. EQ.

763R

Internal Connections and Functions

Internal Wiring Connections: via plug on Molex

type terminal blocks

Internal Switches: SW1: Set-up/Normal switch

used for initial set up and calibration of control

Keypad functions: 0 through 9 numeral inputs

when in programming mode

Start and Stop functions:

Clutch-Brake Output Level: Programmable via

display and keypad

Output Frequency: Programmable via display and

keypad

Communications: RS-485 communications port

via terminal strip

Optional OEX function card: An optional OEX

function card can be added for special

applications that require reduced build-up times

of the clutch or brake magnets.

Input/Outputs: Additional programmable inputs

and outputs available but not active for other

specic functions and typically are not used when

this controller is used for replacing the

CBC1500-AHFC or being used in pusher type

applications. Consult factory for further

information.

Control Part Number: 6051-448-002 CBPC-3590

Control

Encoder Part Number: 6060-101-061 Encoder,

600 PPR with marker pulse and cable

Note: Start key also functions as the home set

Installation

up key in set-up mode.

Replacing CBC1500-AHFC Control with

Up, Down and right arrow keys for scrolling and

CBPC-3590 Control

selecting data

q 1. Insure that power is turned off and

Edit Key: Run/PGM Key for entering set up

disconnected to the CBC1500-AHFC control.

modes

q 2. Disconnect both the encoder cable

Reset/Clear Key: For resetting variables or

clearing data in programming mode

connector and the main power/clutch-brake

wire connector from the plugs on the control-

ler.

Fault Relay: In the event of a fault, relay contacts

via terminal strip for external customer

connections.

q 3. Remove the 4 bolts or nuts fastening the

controller to the isolation mounts on the

machine frame.

Contacts: Rated at 1 Amp, 120 VAC resistive load

q 4. Remove the controller and set aside.

Fault Conditions: Low voltage, feedback too fast,

process time fully utilized

q 5. Install the CBPC-3590 controller on the

isolation mounts and reattach with either the

bolts or nuts depending on what was originally

used. Make sure bolts or nuts are securely

4 Warner Electric • 800-825-9050 P-921-1 • 819-0526

tightened.

Page 5

q 6. Reconnect the power/clutch-brake wiring

connector to the large plug on the CBPC-3590

control and tighten snugly.

q 7. Reconnect the encoder cable connector to

the small plug on the CBPC-3590 control and

tighten snugly.

q 8. Insure everything is connected properly and

the control is secured properly to the machine

frame.

q 4. Mount and attach the CBPC-3590

controller to the other side of the vibration

isolator mount. Insure that control and mounts

are fastened securely at both the control and the

machine frame.

q 5. With the control mounted, route the wiring cables

such that they can be easily attached to the

external connectors on the control. Insure sufcient

length so that undue stress is not placed on either

the connectors or the cables to the control.

q 9. This completes the replacement of the

control. Proceed to the Start-Up Section on

page 9 for set up and programming.

First Time New Installation of CBPC-3590

Control

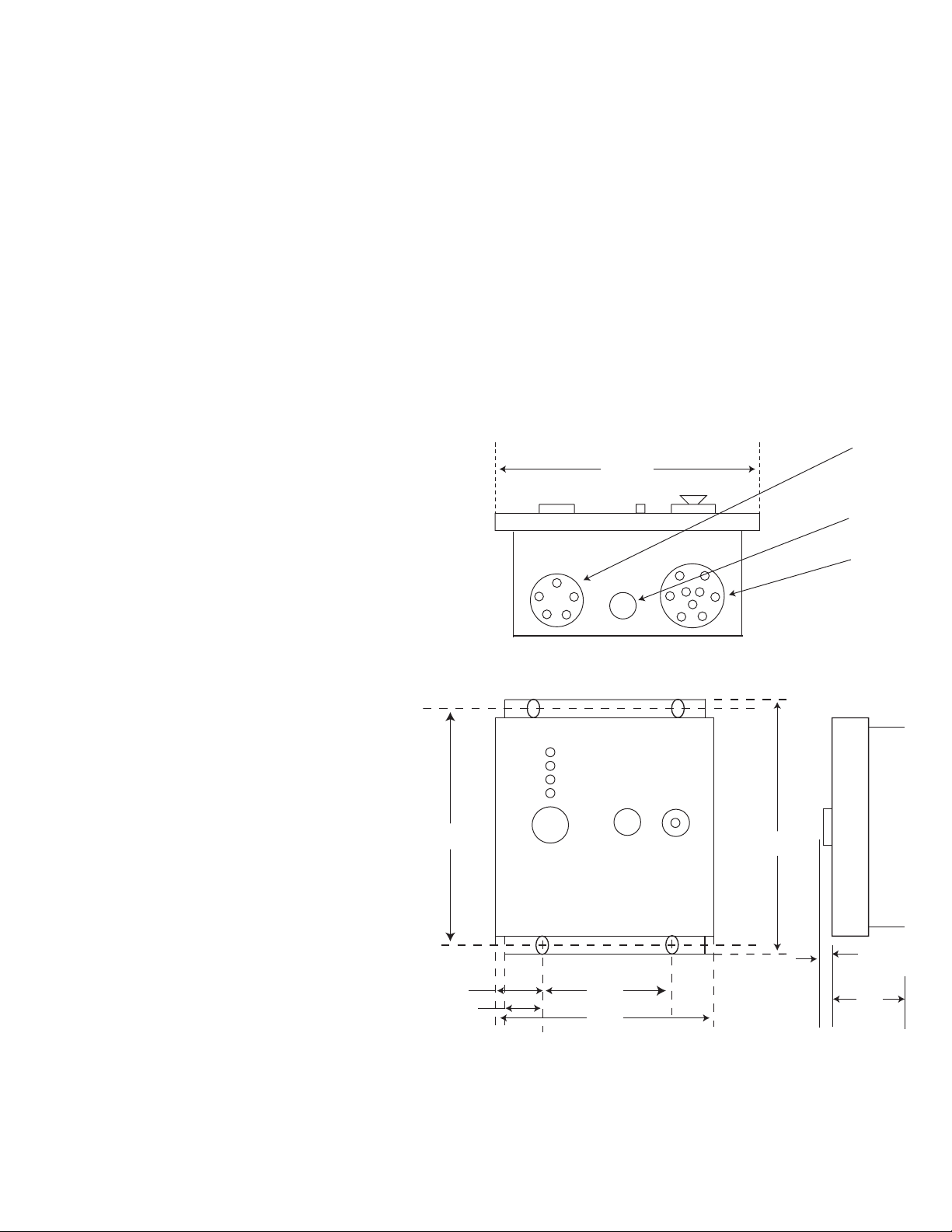

Refer to the dimensional diagram, Figure 1 for

actual mounting dimensions.

q 1. Select the location where the control will be

mounted. Insure that mounting will not

interfere with anything else and that wiring

access will not be impeded.

q 2. Using the dimensional information from the

diagram below, drill 4 mounting holes to

accept ¼-20 studs from the vibration

mounts for attaching the controller to

the machine frame.

q 3. Depending on the type of vibration

isolator mounts used, male to male or

male to female, attach one end of the

mount to the machine frame at all 4

10.500

points.

Note: For new installations where no wiring previously

exists, see the connector wiring diagram, Figure 4 for

pin/function descriptions.

5 Pin Socket

8.250

11.500

(Encoder)

Optional Hole

(Aux. Wiring)

9 Pin Socket

(CI-Bk/Power)

0.700

1.850

1.400

4.125

7.000

4.275

Figure 1

Dimensional Diagram

Warner Electric • 800-825-9050 P-291-1 • 819-0526 5

Page 6

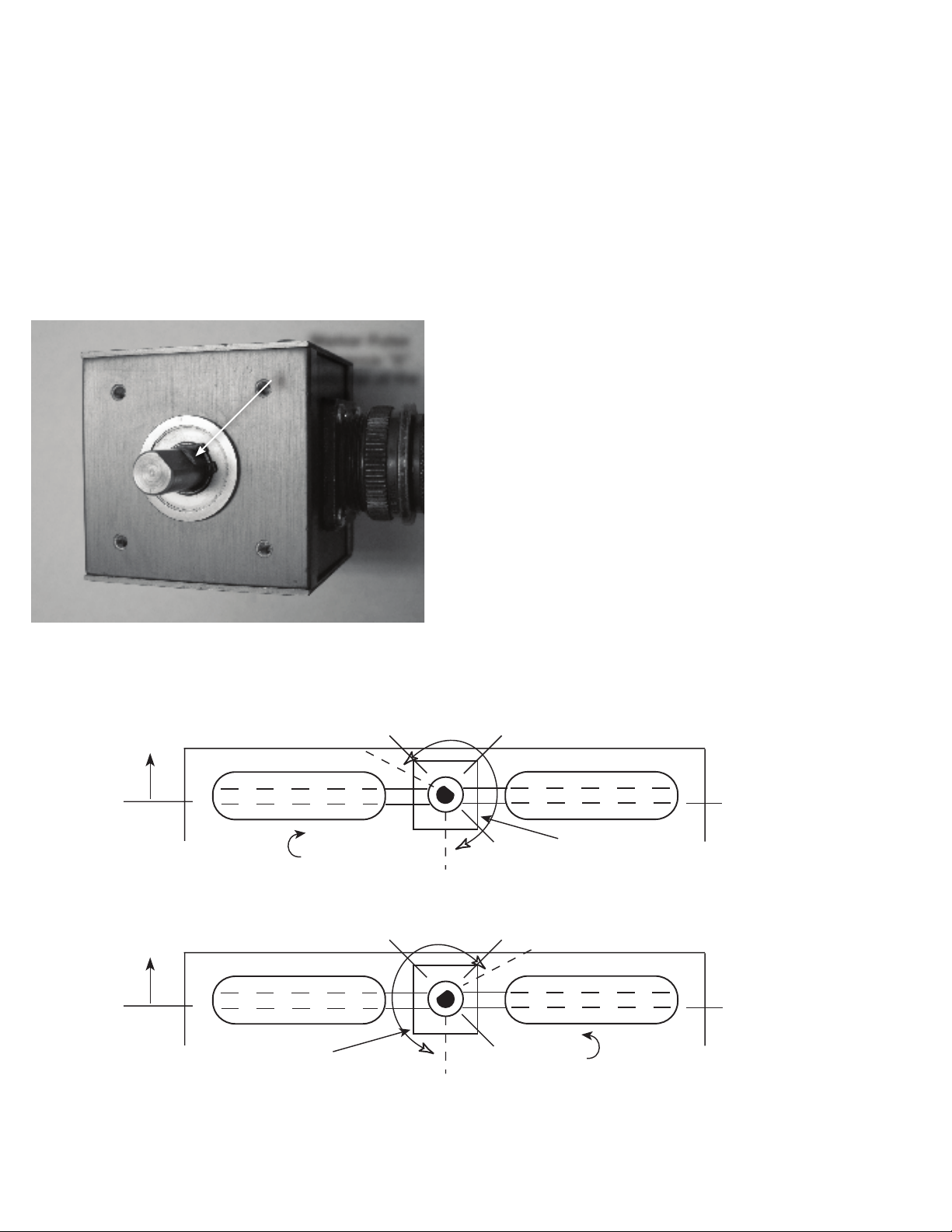

Encoder Mounting & Installation

Normally, if the CBPC-3590 is replacing an existing

CBC1500-AHFC control, the encoder has already

been installed and set-up correctly.

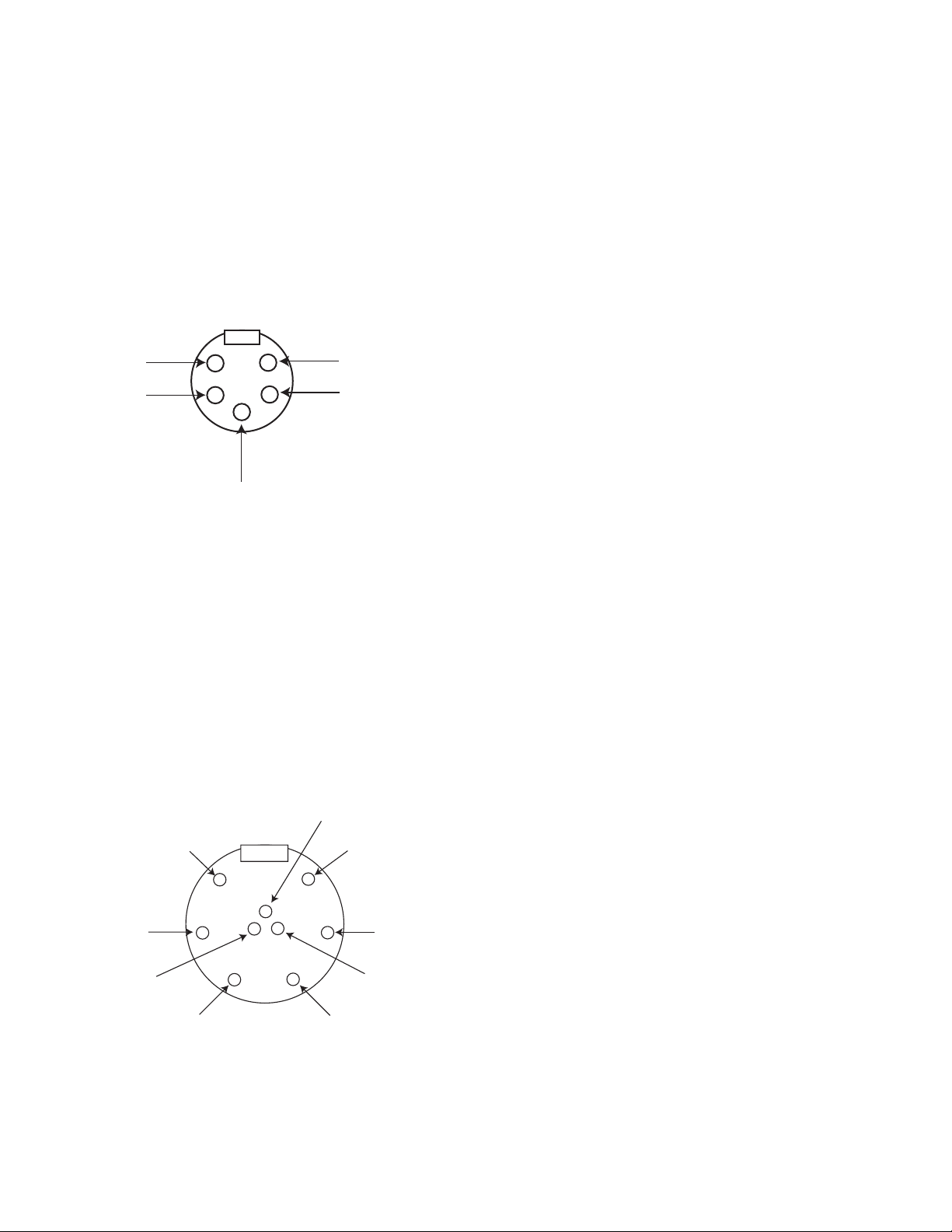

new installations follow the procedure below

For

referring to gures 2 and 3 for correct encoder

mounting and positioning.

q 1. Taking the encoder, position the at on the

shaft to the position shown in Figure 2 below.

Marker Pulse

reference “X”

with at of the

X

shaft

q 2. Position the paddles on the pusher parallel to

the length of the pusher. This will be the position

the paddles are in when the pusher is static or not

rotating.

q 3. Determine if the pusher operates in a clockwise

(CW) or counter-clockwise (CCW) direction when

operating.

q 4. Mount the encoder with the bracket into the

pusher shaft keeping the shaft aligned in the

position as shown or as close as possible using

gures 3A or 3B for positioning the marker pulse

within the desired range.

q 5. Double check mounting and insure encoder is

fastened properly.

q 6. Connect encoder cable and tighten connector

securely.

q 7. This completes encoder mounting for new

application.

Figure 2

Encoder Marker Pulse Position Reference

Front

CW

Front

Ø

180

Note: Properly mounting the encoder in this method

insures the marker pulse will occur in the 50 to 450

pulse count range consistently. This is mandatory for

proper control operation.

90

270

180

Encoder

Marker Pulse Locating

Position 30° to 270°

Long Axis

Figure 3a

90

Ø

Long Axis

270

CCW

Marker Pulse Locating

Position 30° to 270°

Encoder

Figure 3b

6 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Page 7

System Wiring

Figure 4 - Connector Pinouts and

Designations

Encoder Connector (5 Pin) Inside Wire Colors

Wiring the Warner Electric encoder

(6060-101-061) and cable to the connector

q 1. Route the encoder cable to avoid strains,

kinking and interference with mechanical

components.

Pin 1 – Encoder Signal “A” White

Pin 2 – Encoder +12 VDC Power Red

Pin 3 – Encoder Signal “Z” - Ref Green

Pin 4 – Encoder Signal “B” Orange

Pin 5 – Encoder DC Common Black

1

2

5

4

3

Power/Clutch-Brake Connector (9 Pin) Inside Wire Colors

Pin 1 – AC Start Signal (Hot 120 VAC) Orange/Black

Pin 2 – Channel 1 output (-) Brake Blue

Pin 3 – Channel 2 output (-) Clutch Red/Black

Pin 4 – Channel 2 output (+) Clutch Green/Black

Pin 5 – AC Power 120 VAC neutral line White

Pin 6 – AC Power 120 VAC hot line Red

Pin 7 – AC Earth Ground Green/Yellow

Pin 8 – Channel 1 output (+) Brake White/Black

Pin 9 – AC Start Signal (Neutral 120 VAC) Green/Black

q 2. Once cable has been routed and excess

length remains, cut the excess length off but

allow sufcient length for connection to

control. Strip the outer jacket to the

appropriate length for insertion of the wires

into the connector assembly.

q 3. Open the connector by removing the strain

relief nut and removing the rubber bushing

inside the housing. Snap the two halves of the

housing apart and separate from the header

connector.

q 4. Thread the encoder cable through the

strain relief nut and the rubber bushing pulling

enough cable through to strip and work on the

header and cable.

q a. Strip the cable jacket approximately ¾”

from the end of the wires.

q b. Strip the red lead (+12 VDC)

approximately ¼” and fasten to terminal 2 of

the connector and fasten securely.

Mating connector accessory are called out in the

specication section, Pages 3 and 4.

q c. Strip the black lead (DC Com)

approximately ¼” and fasten to terminal 5 of

7

1

6

the connector and fasten securely.

q d. Strip the orange lead (Signal A)

approximately ¼” and fasten to terminal 1 of

the connector and fasten securely.

2

5

q e. Strip the brown lead (Signal B)

approximately ¼” and fasten to terminal 4 of

8

3

9

4

the connector and fasten securely.

q f. Strip the green lead (Signal Z ref)

approximately ¼” and fasten to terminal 3 of

the connector and fasten securely.

Warner Electric • 800-825-9050 P-291-1 • 819-0526 7

Page 8

Note: This wiring is for clockwise (CW) opera-

tion. If during start up, the counter operates in the

reverse direction (that is, counter counts down

instead of up) or counter-clockwise (CCW)

operation is required, reverse the connections on

terminals 1 and 4 on external encoder connector

plug.

q 5. Reassemble the connector assembly by

snapping the two halves together over the

header connector. Slide the rubber bushing up

into the housing assembly and then thread the

strain relief grip onto the assembly snugly. The

outer jacket of the encoder cable should be

held by the strain relief grip.

q 6. This completes the wiring of the encoder

cable to the connector assembly using the

Warner encoder. If other than a Warner Electric

encoder is used, proceed to the next section

for wiring a different encoder.

Wiring other than the Warner Electric encoder

and cable assembly to the connector.

q 1. Route the encoder cable to avoid strains,

kinking and interference with mechanical

components.

q 2. Once cable has been routed and excess

length remains, cut the excess length off. Allow

sufcient length for connection to

control.

Strip the outer jacket to the appropriate

length (¾” typically) for insertion of the wires

into the connector.

q b. Determine which lead on the encoder

cable is the DC common and strip the lead

approximately ¼” and attach to terminal 5 of

the connector and tighten securely.

q c. Determine which lead on the encoder

cable is the Signal A and strip the lead

approximately ¼” and attach to terminal 1 of

the connector and tighten securely.

q d. Determine which lead on the encoder

cable is the Signal B and strip the lead

approximately ¼” and attach to terminal 4 of

the connector and tighten securely.

q e. Determine which lead on the encoder

cable is the Signal Z ref and strip the lead

approximately ¼” and attach to terminal 3 of

the connector and tighten securely.

Note: This wiring is for clockwise (CW) opera-

tion. If during start up, the counter operates in the

reverse direction (that is, counter counts down

instead of up) or counter-clockwise (CCW)

operation is required, reverse the connections on

terminals 1 and 4.

q 4. Reassemble the connector assembly by

snapping the two halves together over the

header connector. Slide the rubber bushing up

into the housing assembly and then thread the

strain relief grip onto the assembly snugly. The

outer jacket of the encoder cable should be

held by the strain relief grip.

q 5. This completes the wiring of the encoder

cable to the connector assembly.

q 3. Open the connector by removing the strain

relief nut and removing the rubber bushing

inside the housing. Snap the two halves of the

Connecting the encoder cable and power/

switching/and clutch-brake cables to the

controller.

housing apart and separate from the header

connector.

q 1. Connect the encoder cable connector by

locating the tab on the control male plug to the

q a. Determine which lead on the encoder

cable is the +12 VDC power and strip the

lead approximately ¼” and attach to terminal

2 of the connector and tighten securely.

tab on the encoder female connector and insert

and tighten securely. Do not force the female

connector into the male connector as damage

to the pins could occur if they are not properly

aligned. This is what the locating tab is for and

if connector tabs are properly aligned, they will

slide together easily.

8 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Page 9

q 2. Determine if an interconnect cable with

connectors on each end will be used or a cable

with a connector on one end and pig tails

on the other end will be used for the power/

switching/and clutch-brake connections.

Note: If an intermediate switch disconnect panel

is used then typically wiring is done inside the

panel for interconnection of power, start signal,

and clutch-brake wiring. This will typically have a

connector for wiring to the controller.

q 3. Connect the interconnect cable connector

by locating the tab on the control male plug

to the tab on the cable female connector and

insert and tighten securely. Do not force the

female connector in the male connector as

damage to the pins could occur if they are

not properly aligned. This is what the locating

tab is for and if connector tabs are properly

aligned, they will slide together easily. Make

sure the connector on the other end at the

disconnect panel is connected and secured

properly.

Auxiliary Relay Wiring for Fault

Detection

for switching external circuits. Remember with

the control powered off, the normally open and

normally closed contacts will be reversed once

power is applied.

See Figure 6, page 10 for specic location of

terminal block.

q a. Typically the common contact and the

normally closed contact would be used to

control an external alarm or switching

circuit in the event of a fault condition.

q 4. This completes the wiring for the auxiliary

relay if used.

The control is now ready for commissioning.

Proceed to the Start-Up Section of the manual.

Start-Up

Start-up and calibration of this controller is much

simpler than the previous CBC1500-AHFC

controller in that most of the programming and

calibration steps associated with the previous

controller has been eliminated. Refer to Figure 5,

page 10 for switch locations.

The CBPC-3590 control was designed to provide

certain fault indications as well as providing an

interface to external control systems via an

internal relay. The relay activates on power up and

is designed to drop out in the event of a fault to

alert the user.

To wire the relay to an external control circuit

follow the steps below:

q 1. Remove the insert cover between the two

cable connectors on the CBPC-3590

controller. Refer to Figure 1, page 5.

q 2. Using a 3/4” seal tight connector, insert into

the conduit hold and securely tighten.

q 3. Wire the terminal block according to the

requirements of the system for contact

switching. The relay provides a common,

normally open, and normally closed contacts

q 1. Turn power on to the system and the

CBPC-3590 control. Push the power button on

the front of the controller and the red indica-

tor light on the power switch should illuminate.

The controller should power up with the brake

engaged and the front brake light LED

illuminated.

q 2. Place the front panel run/jog switch in the

jog position.

q 3. Push the front panel jog button until the

pusher paddles are in the proper home

position. This may require pushing the button

and cycling the load through a complete cycle

until the proper position is desired.

q 4. Once the paddles are in the desired home

position, place the front panel run/jog switch in

the run position.

Figure 5. Faceplate functions and Indicators

Warner Electric • 800-825-9050 P-291-1 • 819-0526 9

Page 10

Power Switch

Push - “ON”

Push - OFF”

Step 1

Run/Jog Switch

Up - “JOG”

Down - “RUN”

Step 2

Step 4

Jog Pushbutton

Step 3

q 5. Open the controller front cover. This will give

you access to the control board and the keypad/

display portion of the controller.

Refer to Figure 6, below, for internal display/keypad

and set up control functions.

q 9. Move the normal/set-up switch, to the

normal position.The “Normal” position is in the

down mode. The “Calibrate LED” should go out

at this time.

q 10. This completes the set-up and calibration

procedure for the control.

q 11. After calibration is complete, press the start

button on the display/keypad panel and the

control should cycle each time the switch is

pressed.

q 12. The display should be reading the count

position on each cycle and the load should be

returning to its home position each cycle.

Start Key

Step 8

Step 11

Reset/Clear Key

Step 6

Fault Relay

Terminal Block

Calibrate LED

On - “Calibrate”

Off - “Normal”

Normal/Set-up Switch

Up - “Set-up”

Down - “Normal”

Step 7

Step 9

Figure 6.

Internal Set Up Switches/Indicators

and Keypad/Display Layout

q 6. Press the reset/clear key on the keypad/

display.

q 13. Cycle the control about 5 to 6 times so that

the braking distance average will average out

correctly observing the stop point on the

counter. Close and latch the control.

If the pusher does not stop in the correct home

position after several start cycles, follow the

instructions below to resolve the problem.

q a. Press the RUN/PGM key on the keypad

q b. Enter 1, 0, 0, 0, and then press the down

arrow key once.

q c. The display should show “h” and some

number value.

q d. Insure the value displayed is between 50

and 450.

q e. If the value is outside the above range, the

encoder must be reset physically.

q 7. Move the normal/set-up switch to the set up

position. The set up position is with the lever in

q f. Follow the procedure below to reset the

encoder position.

the up position. In the set-up position the

Set-Up LED will illuminate.

Pusher must be disabled and

appropriate lock-out procedures

q 8. Press the start key on the keypad. The

controller will make one or more complete cycles

and stop.

Note: Once the calibration cycle has completed, the

paddles can stop in any location, not necessarily the

followed to

prevent accidental starts. Failure to do so could

result in system damage, injury or even death.

q 1. Loosen the encoder bracket and rotate

encoder at least 90 degrees.

home position.

10 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Page 11

q 2. Re-tighten encoder bracket securely.

q 3. Proceed to step 1 of the start-up procedure,

page 9 to recalibrate the system.

Note: If in doubt about encoder positioning, refer to

new encoder installation procedure, page 6.

If unit has problems such as “windmilling” program

default needed, do the following steps:

q a. Press the RUN/PGM key on the keypad.

q b. Enter 1, 0, 0, 0 and then press the down arrow

repeatedly until the end display reads: “t8.rdy”.

q c. Press the arrow right button.

q d. Press the RUN/PGM key.

q e. Proceed to step 1 of the start-up procedure

on page 9 to recalibrate the system.

This completes the installation and set-up of the

CBPC-3590 control. Close and latch the control

securely.

As the controller has been designed as an improved

version of the CBC1500-AHFC with additional

features and improved performance and reliability,

programming of the various parameters should only

be accomplished by qualied personnel.

To Enter the programming mode, follow the steps

below:

Open the controller front cover for access to the

keypad/display. Press the RUN PGM key on the

keypad/display

Display will show LOC. 0

Then press 1, 0, 0, 0

Display will show LOC. 1000

This has now placed you in the programming mode

where various parameters can be changed by using

the down arrow key to increment through the various

parameters.

Programming Functions:

Default Settings

Default

Press Display Value Function

↓ h xxx -- Home Position

↓ bd. xx -- Brake Distance, PPR

↓ bdAue. 3 3 Cycles Averaged

↓ cc. 0.5000 0.5000 Count Correction

↓ dP. oFF oFF Decimal Point

↓ FrSt. oN oN Front Panel Reset

↓ PLoc. oFF oFF Panel Lock

↓ CrEt. oFF oFF Count Retention

↓ ArSt. oN oN Auto Reset

↓ o1. 0.20 0.20 Start Signal, ms

↓ o2. 0.01 0.01 Early Warning, ms

↓ o3. 0.20 0.20 Stop Signal, ms

↓ o4. 0.10 0.10 Zero Speed, ms

↓ o5. 0.05 0.05 Zero Speed + delay 1, ms

↓ o6. 0.05 0.05 Zero Speed + delay 2, ms

↓ o8. LatCH LatCH Batch Auto Reset

↓ d1. 0.10 0.10 Delay 1, ms

↓ d2. 0.01 0.01 Delay 2, ms

↓ 05P .25 .25 Zero Speed Window, sec

↓ 5 -.-.-.-.-.-. -.-.-.-.-.-. Start Release

↓ L -.-.-.-.-.-. -.-.-.-.-.-. Move Preset Release

↓ E -.-.-.-.-.-. -.-.-.-.-.-. Early Warning Release

↓ r -.-.-.-.-.-. -.-.-.-.-.-. Reset Release

↓ bd. OFF OFF Baud Rate

↓ Par. None None Parity

↓ PFr. 80 80 Output Frequency, Hz.

↓ cPr. 90 90 Clutch Output Percentage

↓ bPr. 75 75 Brake Output Percentage

↓ JPr. 40 40 Jog Output Percentage

↓ cBt 15 15 Clutch Boost Percentage **

↓ bBt 40 40 Brake Boost Percentage **

↓ Id.no. xxx xxx Unit Number (Up to 3 digits)

↓ t0. rdy rdy Keyboard test

↓ t1. rdy rdy RAM test

↓ t2. rdy rdy Inputs test

↓ t3. rdy rdy Outputs test

↓ t4. rdy rdy Display test

↓ t5. rdy rdy Memory test

↓ t6. rdy rdy Date Code

↓ t7. rdy rdy Serial Test

↓ t8. rdy rdy Reset Default Program

** Only when the OEX add-on board is installed in the CBPC-3590 are

these two functions active and operational for programming.

Warner Electric • 800-825-9050 P-291-1 • 819-0526 11

Page 12

Pressing RUN PGM Key exits the programming

mode and returns the display for normal count

function.

RUN PGM CNT xxx

Often problems encountered by the CBPC-3590 can

be resolved by resetting the control or resetting the

program to its default settings.

To reset the controlller:

q 1. Turn off power via the front panel power

switch.

q 2. Wait 5 seconds or more.

q 3. Turn power back on to the control.

To reset the program to the original default values,

follow the steps below.

RS-485 Hook Up and Programming

The CBPC-3590 Control was designed to accept an

RS-485 serial interface connection for programming

and data collection. Keypad and some external

control inputs are supported. Additionally, facilities

are provided for individual (local) and group (global)

control of single and multiple unit congurations

respectively. Knowledge of serial communications

and the ASCII data format is required by the user

who wishes to use the remote capabilities or to

integrate the control into a larger system.

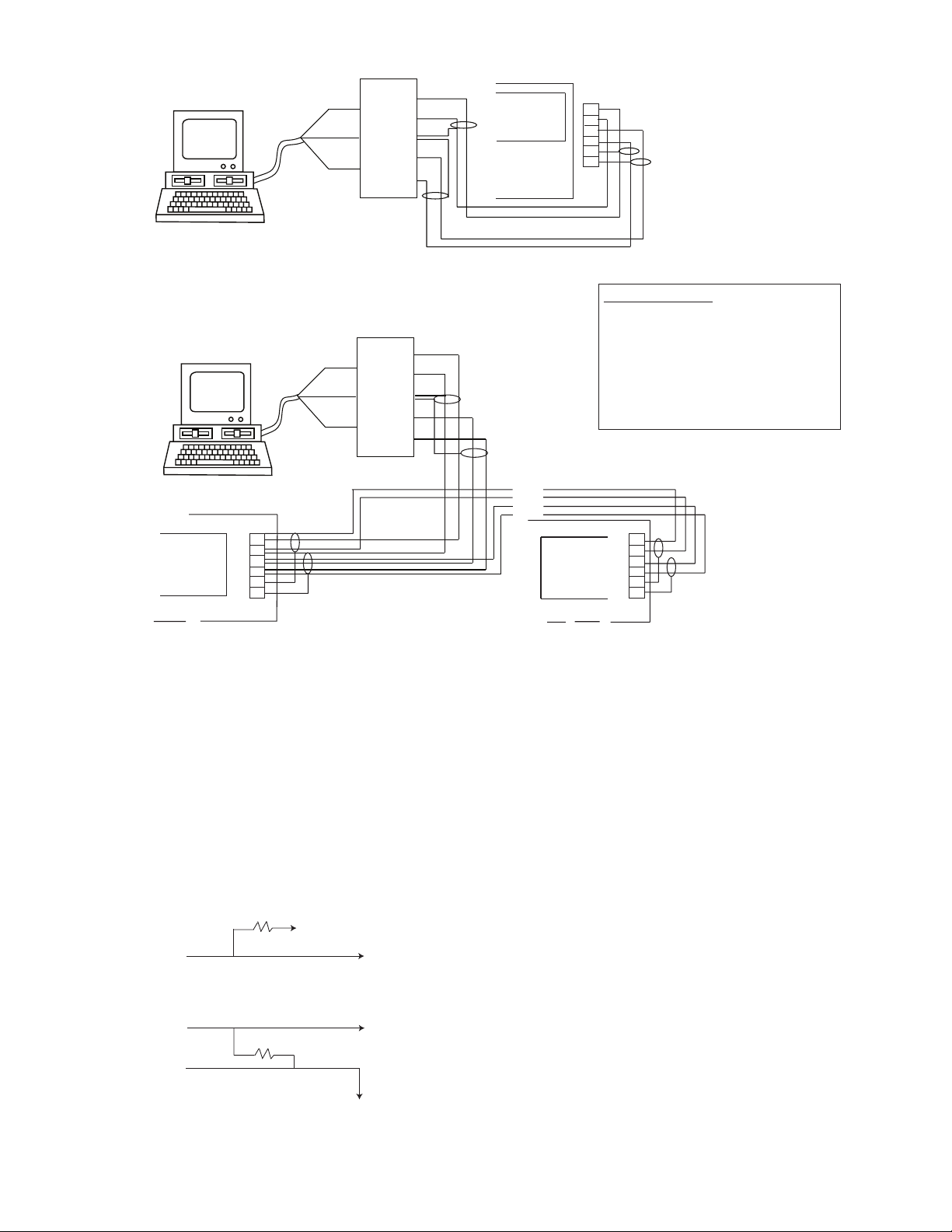

Two applications will be discussed. The rst consists of a single CBPC-3590 and a display termi-

nal. It explains the use of the serial commands

that mimic the keypad operation and some control

inputs. These are the LOCAL commands. Next, an

application of multiple units under the control of a

host computer will be discussed. The GLOBAL

commands will also be discussed in this section.

q 1. Press the RUN PGM key

Display will show LOC. 0

q 2. Enter 1,0,0,0

Display will show LOC. 1000

q 3. Using the down ↓ key, scroll down until the

display shows t8. rdy

q 4. Using the right → key, change the display to

show t8. run

q 5. Press the RUN PGM key to exit the

programming mode.

Display will show CNT xxx

This completes the program reset function.

Note: After resetting program, control must be

recalibrated.

12 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Page 13

RS232 to

RS422/485

Converter

RXD

COM

TXD

TXD+

TXD-

SHLD

RXD-

RXD+

Display/Keypad

CBPC-3590

Twisted Pairs with Shields

Figure 7a Single Unit Wiring

RS232 to

RS422/485

Converter

RXD

COM

TXD

TXD+

TXD-

SHLD

RXD-

RXD+

J4

6

5

4

3

2

1

J4 Connections

Pin 6 TXD+

Pin 5 TXD-

Pin 4 RXD-

Pin 3 RXC+

Pin 2 Shield to Chassis End

Pin 1 Shield to Chassis En

d

J6

Keypad/Display

CBPC-3590

6

5

4

3

2

1

Figure 7b Multiple Unit Wiring

Termination

The RS-422A/485 receivers require termination to

minimize the effects of noise while the bus is not

being driven. The CBPC-3590 incorporates the

terminations shown below internally. When

connection is made to a RS-422/485 device other

than the CBPC-3590, the receiver should be

terminated as shown.

+5V

TXD+

from

CBC-1000

TXD-

2

10 k Ω max. to

100 Ω min.

to

receiver

} {

J4

Keypad/Display

CBPC-3590

Cable Selection

The CBPC-3590 serial interface uses a simple

interconnect scheme and low cost wiring mak-

ing it superior to parallel data transfer schemes.

Through two (2) wire shielded pairs, remote

operation at distances up to 5,000 feet can be

implemented. The following general guidelines

should be observed.

1. Use # 24 AWG twisted pair, overall shielded

cable.

2. Use a “daisy chained” connection scheme for

bus systems.

6

5

4

3

2

1

3. If a “multidrop” system is used, keep the drop

COM

length at 10% of the main line.

4. Tie the cable shield to the Building Ground at

the CBPC-3590 end of the cable.

Warner Electric • 800-825-9050 P-291-1 • 819-0526 13

Page 14

Single Unit Operation

The operator can monitor the control locally via

the keypad and display located inside the control

housing. The serial interface extends these

monitoring activities to a remote location. The

connection of a remote display terminal is

straightforward. The ID number of the control

should be set to “0” (line 32 in the program table).

When power is applied to the CBPC-3590 control,

it will start a continuous serial transmission of the

count:

CBPC-3590 R: CNT. 123456

when in the run mode.

The function keys (1,2,3,6,7, & 8) are used to scroll

down through the eight RUN mode lines. For

example:

terminal ‘1’ CBPC-3590 R: CNT. 123456

terminal ‘2’ CBPC-3590 R: Mov.Pst. 600

terminal ‘3’ CBPC-3590 R: E.W. 50

terminal ‘6’ CBPC-3590 R: BCH. 100

terminal ‘7’ CBPC-3590 R: BCH.Pst. 0

terminal ‘8’ CBPC-3590 R: Bd. 25

In the RUN mode, the numbers 1,2,3,6,7, & 8

cause new lines to be transmitted.

The control remains active (in the RUN mode)

until the proper LOC combination is entered. Each

numeric entry is entered from right to left

“calculator style”. The character sequence

1-0-0-0 would produce the following display on

the terminal:

terminal ‘1’ CBPC-3590 R: LOC. 1

terminal ‘0’ CBPC-3590 R: LOC. 10

terminal ‘0’ CBPC-3590 R: LOC. 100

terminal ‘0’ CBPC-3590 R: LOC. 1000

When this combination is correctly entered with

the down cursor (‘D’ character), the control exits

the RUN mode and enters the PROGRAM mode

and returns with the following.

terminal ‘D’ CBPC-3590 P: h. ---

Note that the PROGRAM (‘P’) prompt is now

shown. You are at the top of the PROGRAM table

(line 1) as shown on page 11. Once the

PROGRAM mode has been entered it is pos-

sible to program any line in the table. Refer to the

COMMAND CHARACTER table for keypad

equivalent serial characters. A programming

example is shown below:

terminal ‘C’ CBPC-3590 P: Mov.Pst. 000

terminal ‘6’ CBPC-3590 P: Mov.Pst. 6

terminal ‘0’ CBPC-3590 P: Mov.Pst. 60

terminal ‘0’ CBPC-3590 P: Mov.Pst. 600

We have now seen how the CBPC-3590 control

works for remote viewing; we will now see how

programming may be done from a remote location.

You may program only one CBPC-3590 control

at a time. If the unit is in the program mode via

the keypad then it will not respond to the serial

input. To enter the PROGRAM mode you must rst

send the RUN/PGM (“P”) character. The control

will “answer” by transmitting the LOC entry line as

shown below:

terminal ‘P’ CBPC-3590 R: LOC 0

14 Warner Electric • 800-825-9050 P-921-1 • 819-0526

The rst serial entry (‘C’) clears the data eld for

the current line. As can be seen in the COMMAND

CHARACTER table, this character mimics the

RESET/CLEAR key. Numeric data entry is

self-explanatory.

Multiple Unit Operation

For multiple unit systems (up to 999) a special

addressing scheme is implemented in order that

no conicts arise on the serial bus. Each unit is

given a unique address (ID number entered on line

32). Such a system application is shown on page

16. All units are programmed with the same baud

rate and parity. It is advised that the initial ID

number programming be done before the units

are bussed together.

Page 15

To control one CBPC-3590 in a bus oriented system the host must rst address it by sending an

ADDRESS COMMAND SEQUENCE. This is shown

below:

host: (ESC) A nnn (where nnn is the unit

number from 1 to 999)

This escape code sequence will suspend the

transmission from all units including the one that is

addressed. The addressed unit will respond to all

subsequent commands while the other units just

“listen” on their receive input and turn their transmit

output off.

To receive data from an addressed unit the host

sends it a command to resume transmission using

the RESUME control character, (CTRL Q).

Remote Operation

Some of the unit’s CONTROL inputs are

effectively duplicated by serial commands, so it is

possible to implement a single or multiple unit

system with remote capability. Such a system can

be used for multiple machines. Keep in mind the

addressing requirements for multiple unit systems

previously discussed.

Two types of commands are available, LOCAL

and GLOBAL. LOCAL commands affect only the

unit that is currently addressed. GLOBAL com-

mands on the other hand affect all units regardless

of address. In this way it is possible to command

many units to begin control at the same point in

time. The table below lists the LOCAL and GLOBAL

commands that are supported.

If you wish to suspend data transmission you may

do so by using the SUSPEND control character,

(CTRL S).

In some cases the host may want to send many

commands to a CBPC-3590 control without waiting

for responses. This may be done by rst suspending

transmission (CTRL S) then by requesting a single

UPDATE.

host: (ESC) U

Setup Mode Operation

The SETUP mode may be entered directly from the

RUN mode by cursoring to the desired SETUP lines

(4 – 8) using the ‘D’ command character then

sending the ‘L’ command character which mimics

the KEY keypad key. This action will place the

control in the SETUP mode allowing the user to

change the data in lines 3 through 8 in the program

table. Refer to page 11 for a complete operational

description.

Preset setpoints are changed using the numeric,

RST/CLR and DOWN cursor keys. The SETUP mode

is exited by sending another ‘L’ command character

at which time the controls reverts back to the RUN

mode.

Local and Global Commands

Control

Commands Local Global Comments

Control (ESC) LO (ESC) GO Simulates Output

Output Control Input

Batch (ESC) LB (ESC) GB Resets Batch

Reset to zero

Counter (ESC) LR (ESC) GR Resets Counter

Reset to zero

Formats and Protocol

Character Format

The serial interface sends and receives

information by characters consisting of 10 bits. The

RS422A/485 interface requires a 0.2 V minimum

differential across the + and – terminals. A logic

high (mark) is a positive differential and a logic low

(space) is a negative differential.

Note: Connection to EIA-422/485 equipment that

uses the opposite polarity requires swapping the +

and – connections at the other equipment.

Warner Electric • 800-825-9050 P-291-1 • 819-0526 15

Page 16

The character format is as follows:

(sp)(sp) (sp) (cr)(cr) R : Co . 12 3 . 45 6

ʻSʼ

“U”

ʻCʼ

“Q”

ʻDʼ

thru

ʻEʼ

ʻRʼ

ʻPʼ

ʻ0ʼ THRU ʻ9ʼ

RUN

PGM

EDITSTOP

0

START

RESET

CLEAR

(sp)(sp) (sp) (cr)(cr) R

:

Co . 12 3 . 45 6

Start bit (“low” logic level)

ASCII data (7 bits), least to most signicant

Parity bit (programmable)

Stop bit (“high” logic level)

HIGH

LOW

SD0D1D2D3D4D5D6P S

Parity Bit

The parity bit is programmable as “Odd,” “Even,”

or “No” parity. Odd and Even parity force the total

number of data bits to be an even or odd for data

that is transmitted by the CBPC-3590 control.

Incoming parity is always compared to the

calculated parity. Characters with parity errors are

discarded. If No parity is selected incoming parity

is ignored. Characters are transmitted with Odd or

Even parity as selected on line 25 of the program

table. If No parity is selected then “high” bit is

added as an extra stop bit.

Baud Rate

Select the baud rate to match the device

communicating with the control. You may select:

300, 600, 1200 or 2400 baud on line 24 of the

program table. Baud rate is common to both

transmitter and receiver.

Line Format

The CBPC-3590 control transmits only complete

lines. The driver is turned off when not

transmitting causing the bus to enter a “oat”

state, ignoring data on the bus during this “oat”

time. Unless otherwise commanded the

CBPC-3590 control continuously transmits the

Count Value. The line format is as follows:

Note: To make changes in Parity or Baud Rate

power must rst be removed and reapplied after

program changes to either are made. Both Parity

and Baud Rate are initialized when the control

“powers up”.

Command Characters

Command Characters mimic the operation of the

keypad. Below is a list of the serial equivalents of

the keypad keys.

RUN

START

RESET

CLEAR

ʻSʼ

“U”

ʻCʼ

ʻEʼ

“Q”

ʻDʼ

thru

0

EDITSTOP

ʻRʼ

ʻ0ʼ THRU ʻ9ʼ

PGM

ʻPʼ

Control Characters

Two control characters are used to start and stop

the transmission from the CBPC-3590 control.

They are shown below:

(CTRL) S Suspends transmission following

the completion of a line being sent.

The driver will then be turned Off.

(CTRL) Q Resumes transmission from a unit

that had been turned Off. The RUN

mode line currently selected will be

continuously updated.

- a carriage return at the beginning of a line

- a prex indicating RUN, SETUP, or PROGRAM

- a unique line mnemonic

- a ve digit data eld with decimal point

- a carriage return at the end of the line

:

16 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Co . 12 3 . 45 6

(sp)(sp) (sp) (cr)(cr) R

Page 17

Escape Code Sequences

Escape code sequences are a group of special

commands used for bus oriented systems. Every

CBPC-3590 control recognizes these commands.

The two listed below are in addition to those

listed in the table of LOCAL and GLOBAL

commands.

(ESC) A nnn The Address command is used

to select a single control within a

system. Only that unit whose

serial I.D. number matches the

three digit serial address (nnn)

will be selected. Only that unit

will respond to subsequent

serial commands. All units, even

the addressed one, suspend

transmission.

(ESC) U The Update command instructs

the currently addressed unit to

transmit a single line only.

Protocol

The CBPC-3590 will “buffer” up to 16 Command

and Control Characters (but not Escape Code

Sequences), listed above, sent in “burst mode”.

Those characters are read, in order, every 20

milliseconds. The protocol should be careful

not to overow the receive buffer. Additionally,

Escape Code Sequences should not be sent until

the buffer has emptied and all characters have

been processed.

Warner Electric • 800-825-9050 P-291-1 • 819-0526 17

Page 18

Troubleshooting

Only Authorized Personnel to Set Up and Maintain this Unit.

The CBPC-3590 control has several internal diagnostic features that illuminate an indicator light showing

fault condition and a fault indication on the display. Once a fault condition occurs, the control has to be

opened to access the display panel and read the fault condition. Not every fault that is possible will be

displayed with an indication, only the most prevalent ones.

The following conditions will cause the front panel fault LED to illuminate and the fault relay internal to

the control to drop out.

Fault Display Corrective Action to be Taken

Low Voltage Lo Volt After normal voltage is restored, unit

returns to normal operation.

Red fault LED “On”

Fault Relay drops out

Feedback too fast Error 2 Reset clears fault.

Speed or encoder resolution must be reduced

Red fault LED “On” or corrected to prevent further errors.

Fault Relay drops out

Process time fully Error 3 Reset clears fault.

utilized Speed or encoder resolution must be

Red fault LED “On” reduced or corrected to prevent further

Fault Relay drops out errors.

Additionally, other faults can occur with the CBPC-3590 which can effect the operation of the system. Some common

faults that could occur are listed below.

Fault Possible Cause Solution

Count direction negative Encoder signals “A” and Reverse signal “A” and “B” wiring on

rather than positive “B” reversed encoder connector plug.

Unit does not start when Start signal voltage Check switching voltage on start input

external start signal is incorrect or not present line (120 VAC) or make sure start switching

applied circuit is functional.

If system will start with start key on keypad,

then fault is external to the control.

Control does not operate No power to control Check that power light in “On/Off” switch is

turned on.

Check that the AC power is applied to control

at control cable.

Check fuse.

Check that “On/Off” power switch is turned on.

Clutch-Brake not connected Check that the clutch-brake is mounted and

connected to output of control.

Cables are not connected Check that both encoder cable and power/

to control CI-Bk cable is connected to controller.

18 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Page 19

Fault Possible Cause Solution

Unit does not stop Brake not completely Cycle unit several hundred cycles to

accurately burnished burnish brake properly.

Not enough cycles Cycle unit several times to get braking

completed to get average distance calculation based on average

braking distance calculation number of cycles set point.

Unit does not stop at all Unit is not getting encoder Check that encoder is providing both “A”

signals and “B” signals to the control.

Check that encoder is providing “Z” pulse by

checking that home indicator LED ashes every

360 degree cycle.

Check that Z signal (home position) marker pulse

is between 50 and 450 counts. See “h” on

programming setup, page 11.

Stop point varies from Brake output level set Set output level to brake higher by entering

cycle to cycle too low program mode and going to line 28 in

programming mode and increasing output level.

Brake is possibly worn out Check number of cycles on brake and

replace if worn excessively.

Count jumps when system Electrical noise being Determine source of electrical noise and

is at standstill generated and coupled to suppress appropriately.

control via wiring or air

Reroute control wiring if necessary and isolate

power and signal lines.

Excessive vibration on Check encoder mounting and isolate if

machine necessary.

During start, clutch does Clutch output level set too Set output level to clutch higher by entering

not seem to have enough low program mode and going to line 27 in

torque to drive load programming mode and increasing output level.

Clutch is new and has not Cycle clutch until burnish is obtained.

been burnished as yet Number of cycles will be dependent on

loading.

Clutch is possibly worn out Check number of cycles on clutch and

replace if worn excessively.

By no means does this cover every possible fault that could be encountered with the control and

clutch-brake. This is only a basic overview of the more common faults that occur with the control. If a

specic problem is encountered that cannot be resolved the best solution is to contact your local Warner

Electric Distributor, Representative, or the factory for further assistance in resolving your problem.

Warner Electric • 800-825-9050 P-291-1 • 819-0526 19

Page 20

Notes and Set Up Information

20 Warner Electric • 800-825-9050 P-921-1 • 819-0526

Page 21

Warner Electric • 800-825-9050 P-291-1 • 819-0526 21

Page 22

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and sold

by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original purchase

for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s prior

consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to the

appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer Satisfaction

Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found defective

under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for transportation

costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or replaced and

returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and in no

event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by reason of

the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any other person

to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF

AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which vary

from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

P-291-1 • 819-0526 5/12

Warner Electric

449 Gardner Street • South Beloit, IL 61080 - USA

800-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

Printed in USA

Loading...

Loading...