Page 1

CBC-750 Series Clutch/Brake Controls

P-270

819-0494

Installation & Operating Instructions

Page 2

Introduction

Warner Electric’s CBC-750 Series of Constant

Current Overexcitation Clutch-Brake Controls

are solid-state electronic controls designed to

increase the cycle rate capabilities and accuracies

of electromagnetic clutches and brakes. The controls

accomplish this by sending a momentary high

voltage overexcitation spike to the clutch and/or

brake magnetic coil to build a high density magnetic

flux field almost instantaneously. By using overexcitation, the response time is reduced as dramatically

as performance is increased. For example, the

current build up time of a 5 inch, 6 volt magnet is

reduced from 84 milliseconds to 2 milliseconds.

The CBC-750 user selects either 120, 220, or 240 VAC

operation at the time of installation. Models with 6

volt, 24 volt, or 90 volt clutches and brakes are

available.

LED indicators on the faceplate of each control

tell the user the status of input signals, output

activation and any auxiliary inputs. A reset switch

resets the output should a short be detected.

Remote torque adjust potentiometer inputs are also

provided. Appropriate current range for each size

clutch or brake is selected by a dip switch. Constant

current for each level is assured by the control’s

design

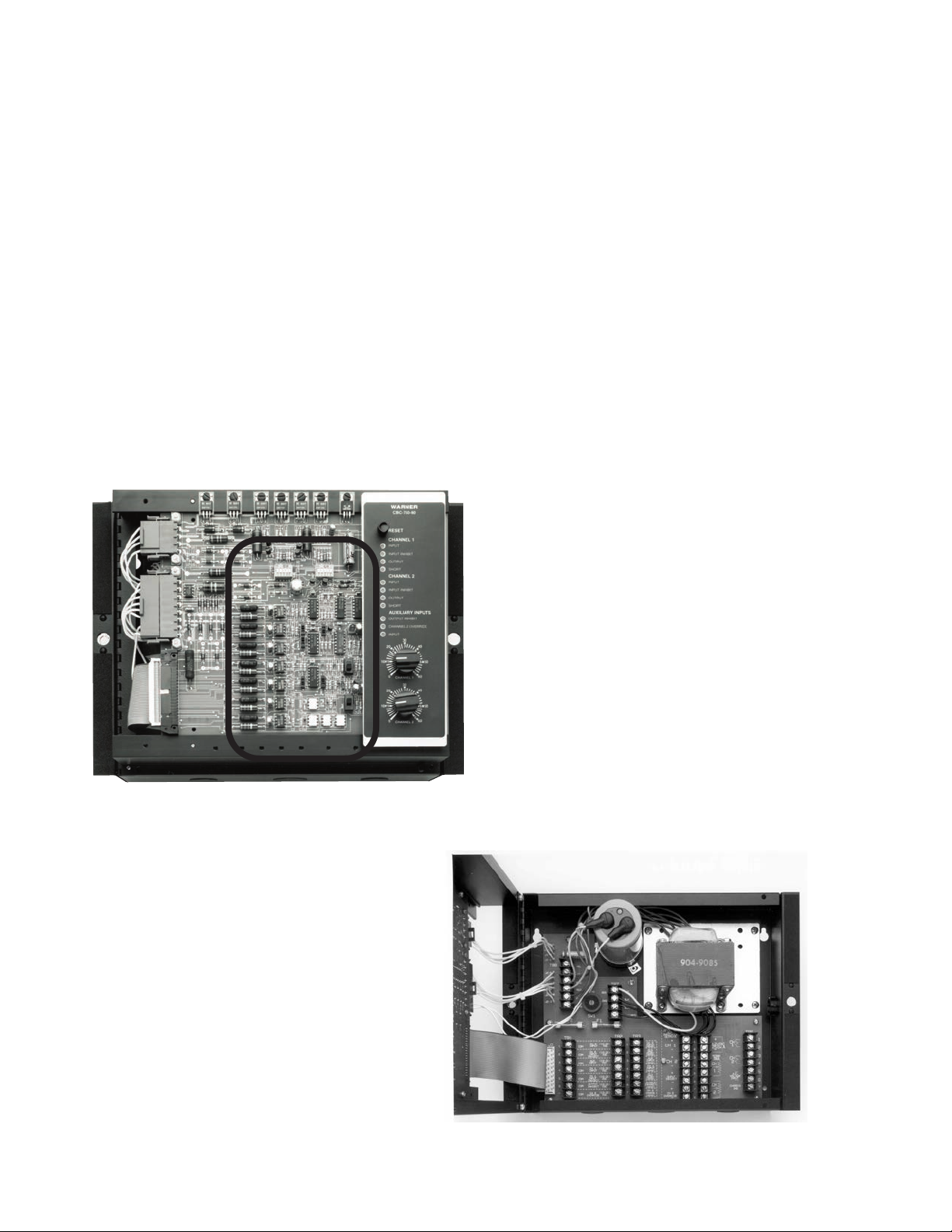

The CBC-750 printed circuit

board and control panel are

shown here. The seven individual

function switches and two range

switches evident in this photo

are detailed in Figure 8, page 10.

Releasing the lock pins and lifting the

top cover reveals the CBC-750’s lower

level where wire connections are

made. Schematic versions of these

terminal boards are found in this

manual on pages 8-10.

Warner Electric • 800-825-9050 819-0494

2

Page 3

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . 3

Technical Specifications . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Wiring

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . 6

AC Input Power. . . . . . . . . . . . . . . . . . . . . . . . 7

Clutch-Brake Wiring . . . . . . . . . . . . . . . . . . . . 7

Switching Inputs . . . . . . . . . . . . . . . . . . . . . . 8

Auxiliary Outputs . . . . . . . . . . . . . . . . . . . . . . 9

Remote Torque Adjust Potentiometers. . . . . 9

System Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . 11

System Troubleshooting . . . . . . . . . . . . . . . . . . 14

Replacement Parts Listing . . . . . . . . . . . . . . . . 16

Failure to follow these instructions

may result in product damage, equipment damage,

and serious or fatal injury to personnel.

Theory Of Operation

The CBC-750 Series of controls will operate all

Warner Electric clutches and brakes with the

exception of the 1525 HT. Two devices may be

operated from the control; however, only one

device is energized at a time.

The CBC-750’s operate from either 120, 220, or 240

VAC, 50 or 60 Hertz, line voltage. Input voltage is

switch selectable on the Terminal Block Board. A

transformer converts the AC input line voltage to

the three different voltage levels required for the

controls’ internal functioning.

Warranty . . . . . . . . . . . . . . . . . . . . . . . . Back Page

LIST OF FIGURES

Figure #

1 Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 C/B and Power Terminal Connection . . . . . . . . 7

3 AC Selector Switch. . . . . . . . . . . . . . . . . . . . . . . 7

4 I/O Terminal Connection . . . . . . . . . . . . . . . . . . 8

5 Auxiliary Connection . . . . . . . . . . . . . . . . . . . . . 9

6 Remote Potentiometer Connection . . . . . . . . . 9

7 Terminal Board Overview - Inside . . . . . . . . . 10

8 Main Board Switches - Black Switches . . . . . 10

9 I/O Relationships . . . . . . . . . . . . . . . . . . . . . . . 12

The control logic circuits operate from a regulated

12 VDC supply, which can also provide output for

external sensor connections via the terminal strip. A

filtered, unregulated supply provides the necessary

voltages for operation of the over-excitation circuits

as follows:

CBC-750-6: 75 VDC

CBC-750-24 and -90: 240 VDC

These voltages vary within the tolerance limits

necessary to maintain steady state currents.

Normally, a brake operating alone is connected to

Channel 1 output and the clutch is connected to the

Channel 2 output when a combination clutch and

brake is used. Other connections are possible.

A green LED located on the control faceplate

illuminates when the adjacent channel is active.

The steady state output to the clutch and brake is

adjusted by either the torque adjust potentiometers

on the control faceplate or optional external torque

adjust potentiometers. A switch on the main logic

board selects local or remote torque adjust.

Short circuit protection is provided on both output

channels. In case of a short circuit, a red LED

indicator illuminates on the control faceplate for

the output channel affected. Activation of the short

circuit scheme turns the output off until the short is

cleared and the reset pushbutton is activated.

Input switching via opto-isolated input circuits allow

for a variety of interface configurations and make

the control PC compatible in all respects. This

means that switching can be accomplished with

either AC or DC signals as well as electromechanical

contact closures.

Warner Electric • 800-825-9050 819-0494

3

Page 4

A switch on the main logic board selects level

control switching on the Channel 2 input or pulse

control input switching on both Channels 1 and 2

inputs.

The following is a brief description of how the

system controls outputs:

1. When an input switches on a given channel,

the previous “on” channel switches off. But

this does not happen instantly. Current in the

channel being de-activated is monitored until

it reaches approximately 10% of its steady

state on value. Then the channel being activated is switched on. Automatic torque overlap

protection is achieved by monitoring the

decay current in the channel being de-activated. Current monitoring eliminates the need for

adjustment potentiometers for set-up.

Technical Specifications

Input Power: 120, 220. or 240VAC, ±10%

50/60 Hz single Phase, 350

VA Max.

Output Pulse width modulated full

(Clutch-Brake): wave rectified DC constant

current, switch selectable

ranges

CBC-750-6: Range .900 to

4.340A

CBC-750-24: Range .204 to

1.175A

CBC-750-90: Range .060 to

.310A

Output 12 VDC ±.6 VDC, 250 mA

(Auxiliary): Max.

2. Overexcitation current is monitored on the

output channel being switched on.

Overexcitation

current is twice steady state current in the

CBC-750-90 and three times it in the CBC-7506

and -24.

3. Once the overexcitation current level is

reached, it is turned off and steady state

holding current is applied to the magnet or

field coil.

This sequence occurs for both channels for either

level of pulse input switching.

Additional input functions are also incorporated into

the control to provide versatility. These include:

• Channel 1 and Channel 2 input inhibit which

inhibits the inputs when activated.

• Output inhibit which de-activates both output

channels on activation.

• A Channel 2 override input which applies full

output current to the Channel 1 load when

activated.

Terminal strip connections for power inputs and

outputs and auxiliary functions are located in the

lower housing of the control. Conduit entrances

are provided in the enclosure. Auxiliary optoisolated

outputs are provided for wiring remote status

monitoring indicators. this allows the user to

monitor control status when the control is remotely

mounted in the machine.

Ambient 0°f to +113°F (-18°C to

Temperature +45°C) with cover installed

Range: 0°F to +140°F (-18°C to

+60°C) with cover removed

Steady State Via front panel potentiomeCurrent Adjust: ters or remote potentio-

meters when operated in

remote mode

Remote Current Via customer supplied

Adjust: potentiometers

5K ohm ±10%, 1/4 watt

minimum

Overexcitation CBC-750-6: 75VDC Nominal

Voltage: CBC-750-24: 240VDC

Nominal

CBC-750-90: 240VDC

Nominal

Circuit Internal short circuit protection

Protection: on each output channel

Fusing: AC input line: 2A Slo-Blo, 250V

OEX Supply:

CBC-790-6: 10A-32V Slo-Blo

CBC-750-24: 5A-250V Slo-Blo

CBC-750-90: 1A-250V Slo-Blo

Auxiliary Opto-isolated NPN transistors,

Indicator 24VDC maximum applied voltage, Outputs: 20 mA maximum

current, series connected diode

for reverse polarity protection

Control Opto-isolated, 10VDC @ 10 mA

Inputs: nominal to 30VDC @ 35 mA

nominal sinking or sourcing,

24VAC, 50/60 Hz @ 22 mA

nominal,

Warner Electric • 800-825-9050 819-0494

4

Page 5

120VAC, 50/60 Hz @ mA

nominal

Maximum Off < 2 mA (Inputs)

State Leakage:

Internal 8 selector switches which set

Adjustments: control operating modes, two 5

range dip switches which select

output current levels

Wiring 5 conduit entrances provided:

Entrance: • 2 openings for 3/4” conduit

• 3 openings for 1/2” conduit

Enclosure: Rated NEMA 1 with optional

cover installed

Sample

Check off each step when completed.

Refer to Figure 1, Page 6, for dimensional data and

mounting hole locations.

1. Pick a suitable location for mounting the

control based on application requirements.

2. Open the control by pulling up on the two

plastic pin connectors that hold the main

board assembly to the lower chassis

assembly.

3. Using the dimensional data in Figure 1, Page

6, mark and drill four (4) mounting holes using

a #21 drill. Tap the four (4) holes using a

#10-32 tap.

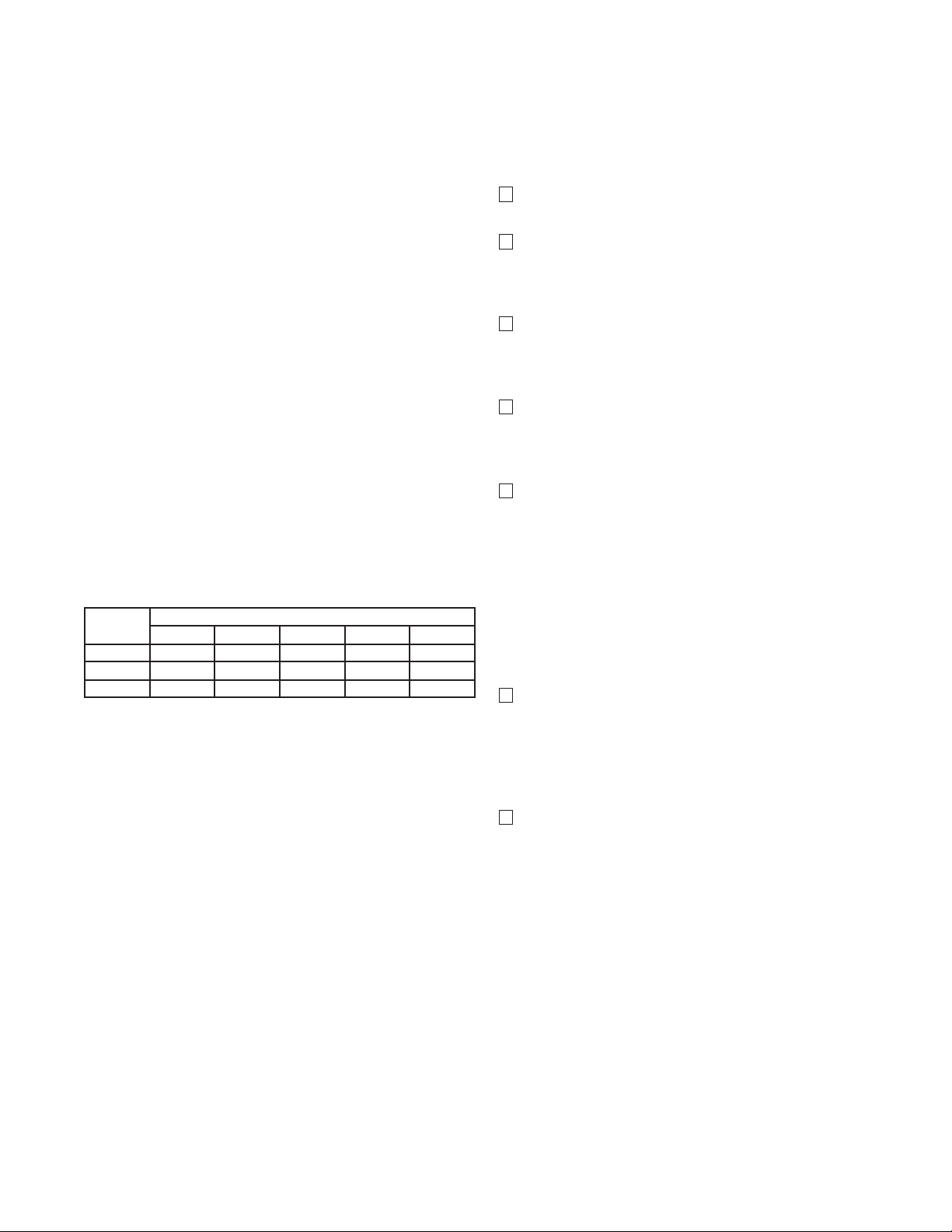

CBC 750 Maximum Current by Dip Switch

Installation

This installation and operations manual has been

arranged for the systematic installation and startup

of your Warner electric clutch-brake control system.

To achieve the best possible results, check off each

completed step in the space provided before proceeding to the next step.

Nominal

Voltage

6 0.910 2.350 3.183 3.760 4.340

24 0.227 0.641 0.881 0.940 1.175

90 0.060 0.176 0.256 0.282 0.310

1 2 3 4 5

Switch Setting

4. Start the top two (2) screws in the mounting

holes but do not tighten. Leave sufficient

space between the mounting surface and the

screw heads to mount the control.

5. Carefully slide the large slots of the top two

(2) mounting screw holes in the control

chassis over the heads of the mounting screws

already installed. Slide the control all the way

down on the screws.

Note: If the slots will not fit over the screw

heads, the two mounting screws must

be turned out (CCW) to increase

clearance before the control can be

mounted.

6. With the control chassis held firmly in place,

start the bottom two mounting screws into

their mounting holes. The ribbon connector

may have to be disconnected from the upper

terminal board to start the lower left hand

screw. Do not tighten the screws yet.

7. Line up the control squarely and tighten all

four mounting screws securely. Reconnect the

ribbon connector.

Note: If the control is mounted inside a control

enclosure and wires enter the control without

conduit, use plastic bushings to protect wires

entering the conduit entrance holes.

This completes the mounting installation of the

CBC-750 control chassis. Proceed to the wiring

section for control wiring information.

Warner Electric • 800-825-9050 819-0494

5

Page 6

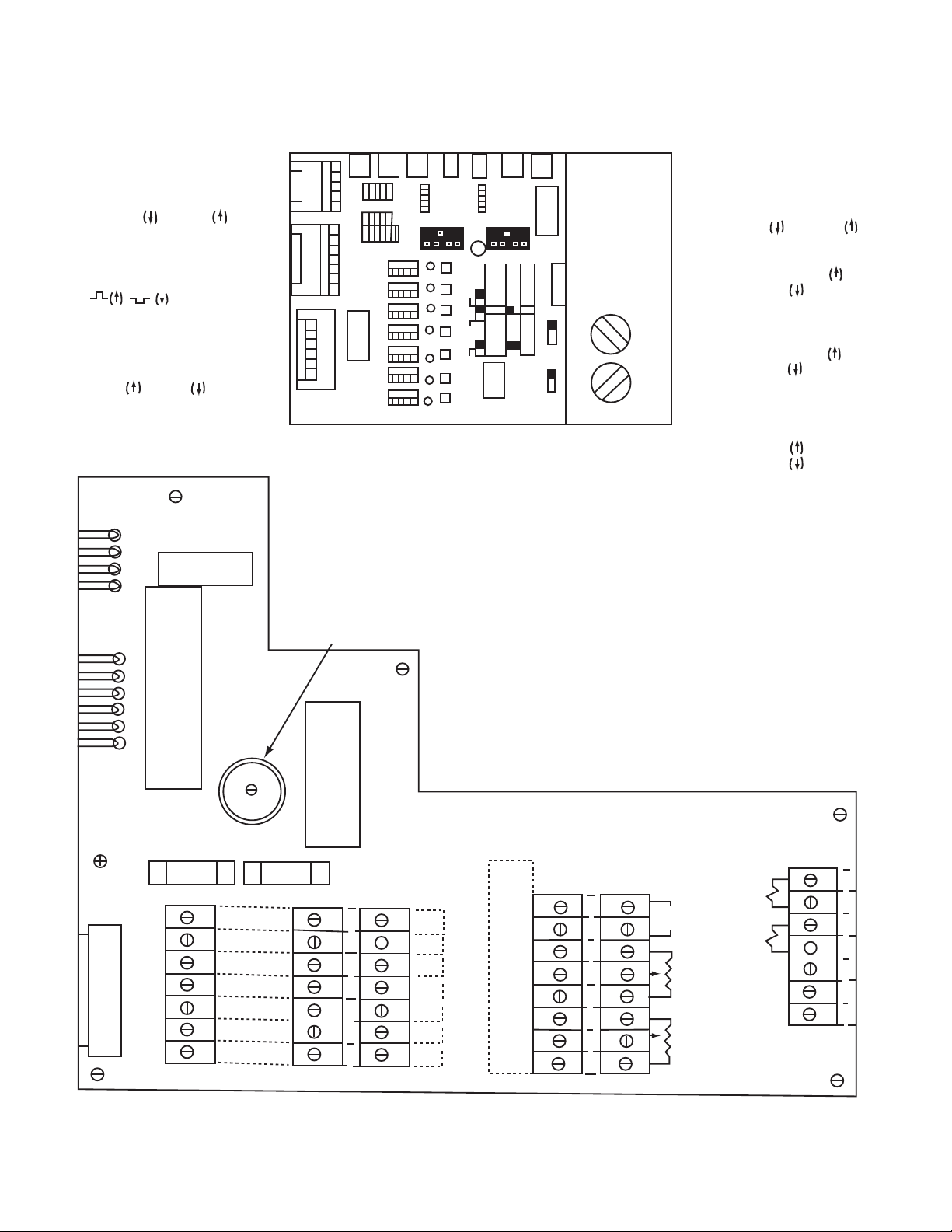

CH

1

CH

2

A.C

Voltage

Input

Chassis

Gnd

2

3

4

5

6

7

1

TB6

Electrical Connections

System Wiring

5.69" (144.53)

14.01" (355.85)

13.00" (330.20)

11. 50" (292.10)

7.50"

(190.50)

9.56"

(242.82)

9.77"

(244.16)

4.78"

(121.41)

10.75"

(273.05)

3.09"

(78.49)

1.12" (28.45) DIA.

1.25" (31.75)

2.69"

(68.33)

.88" (22.35) DIA.

CONDUIT ENTRANCE (3)

3.16"

(80.26)

3.00"

(76.20)

.218" (5.54) DIA.

MTG. HOLES (4)

Wiring Precautions

Figure 1 - Outline Dimensions

These wiring precautions will help you properly

install and wire a trouble free control system.

However, they are intended as a guide only. Good

wiring practices as dictated by local codes should

always be followed when wiring the control system.

Contact with the electrical voltages

present in the CBC-750 series controls can cause

injury or death. To avoid these consequences, make

sure that all power is off.

1. Use proper gauge wire for Ac input Power,

clutch/brake wiring and DC switching circuits.

2. Do not run leads for the clutch/brake or

switching circuits in the same conduit or race

ways with other high voltage Ac or DC circuits

3. If wiring runs between the control and the

on the same machine.

clutch/brake or switching circuit are long, use

shielded cable with the shield grounded at the

control end to reduce noise pickup and

electrical interference.

4. Do not incorporate switching circuits in series

with clutch or brake outputs of the control as

this will cause damage to the control and will

void the warranty.

Warner Electric • 800-825-9050 819-0494

6

5. Do not run more than one magnet load from

each output channel as this may result in

erratic operation or damage to the control and

will void the warranty.

6. Use the control only as a clutch/brake power

source, not as a stand alone power supply.

Using the control other than in the manner

intended will void the warranty.

7. Do not switch between outputs to a single

clutch/brake as this may damage the control

and will void the warranty.

AC Input Power Wiring

Refer to Figure 2, below, for terminal strip wiring.

Figure 2 - C/B and Power Terminal Connection

Page 7

120

220

240

SW1

Figure 3 - AC Power Selector Switch

1. Connect a ground wire from terminal 7

or terminal board TB-6 to a good ground

point on the machine frame or in the control

panel. Tighten both connections.

2. Connect a wire from terminal 6 of TB-6

to the hot side of the AC input line power

buss. Tighten both connections.

2. Connect the brake magnet wires to

terminals 1(+) and 2(-) of TB-6. Wiring to the

brake field or magnet may be either by

screw terminals or lead wires depending on

the Warner Electric model. Tighten the control terminal connections and insure that the

brake magnet connections are properly

fastened and secured.

Note: If shielded wire is used for wiring the clutch

field or magnet and brake magnet, connect

the shield at the control end to Terminal 7 of

TB-6. Do not connect the shield at the magnet

end.

Insure that the shield lead at the

control end does not contact any of the other

terminal connections as shorting and control

damage may result.

3. Connect a wire from terminal 5 of TB-6

to the neutral side of the AC input power

buss. Tighten both connections.

4. Set the AC input power selector switch

SW-1 for the proper AC input level.

Refer to Figure 7, Page 10 for location of

switch SW1, which is also diagrammed

below.

Clutch-Brake Wiring

Refer to Figure 2 for terminal strip connections.

Note: Normally, the brake magnet should be

connected to Channel 1 output and the

clutch field or magnet connected to Channel 2

output for proper functioning of the various

input control circuits. Other connections are

possible.

1. Connect the clutch field or magnet wires to

terminals 3(+) and 4(-) of TB-6. Wiring to the

clutch field or magnet may be either by

screw terminal or lead wires depending on

the model of the Warner Electric clutch.

Tighten the control terminal connections

and insure that the clutch field or magnet

connections are securely fastened.

Switching Inputs

Warner Electric’s CBC-750 Series Controls have been

designed to provide the user with numerous switching and signal input configurations. figures 4a - 4f,

starting below, describe them. Terminal blocks TB-1,

TB-2 and TB-3 provide for input connection depending on the type of device being used for switching

input. Select the proper diagram depending on your

input and wire according to the steps listed.

Note: Only two of the three terminals designated

for each input function are used, regardless of

the input switching.

All inputs shown are connected to the Channel 2

Input. The other input connections are identical to

those of Channel 2 Input. The (X) designation noted

below refers to any one of terminals 1-7 of the

appropriate terminal strip, depending on the function being used. See Figure 7, Page 10 to determine

the terminals to be used, which depend on function

and setup.

Warner Electric • 800-825-9050 819-0494

7

Page 8

(COMMON)

TB-1

(10-30VDC/24VAC)

TB-2

(120VAC)

TB-3

1

1

1

120VAC, 50/60HZ

+

(COMMON)

TB-1

(10-30VDC/24VAC)

TB-2

(120VAC)

TB-3

1

1

1

120VAC, 50/60 HZ

(Common)

TB-1

(10-30VDC/240VAC)

TB-2

(120VAC)

TB-3

(10-30VDC)

_

+

1 1

1

1

1

(Common)

TB-1

(10-30VDC/24VAC)

TB-2

(120VAC)

TB-3

24VAC, 50/60 Hz

1

11

(Common)

TB-1

(10-30VDC/24VAC)

TB-2

(120VAC)

TB-3

(10-30VDC)

+

1

11

(Common)

TB-1

(10-30VDC/24VAC)

TB-2

(120VAC)

TB-3

10 to 30VDC or 24VAC

+

Figure 4a - NPN Transistor Connection

1. Connect neutral side of 24VAC to terminal (X)

of TB-1.

2. Connect output side of triac switch to terminal

(X) of TB-2.

Figure 4d - Switch or Relay Contact

Connections

1. Connect negative (-) or neutral side of

voltage source to terminal (X) of TB-1.

2. Connect output side of relay or switch to

terminal (X) of TB-2.

1. Negative (-) side of supply connected to

2. Connect output side of triac switch to

Figure 4c - Triac Connection for AC Input (24V)

1. Connect neutral side of 24VAC to terminal (X)

2. Connect output side of triac switch to

Figure 4b - PNP Transistor Connection

terminal (X) of TB-1

terminal (X) of TB-2.

of TB-1.

terminal (X) of TB-2.

Figure 4 - Typical Input Connections. Note that terminal strip TB-3 is not used.

Figure 4e - Switch or Relay Contact

1. Connect neutral side of 120 VAC source to

terminal (X) of TB-1.

2. Connect output side of relay or switch to

terminal.l (X) of TB-3.

Connections (120 VAC)

Figure 4f - Triac Connection for AC Input (120

V)

1. Connect neutral side of 120 VAC source to

terminal (X) of TB-1.

2. Connect output side of relay or switch to terminal (X) of TB-3.

Warner Electric • 800-825-9050 819-0494

8

Page 9

Auxiliary Outputs

TB-4

CHANNEL 1

CHANNEL 2

OUTPUT INHIBIT

CHANNEL 2 OVERRIDE

FIGURE 4

(+)

+

+

+

+

(-)

24VDC MAXIMUM

-

-

-

-

1

2

3

4

5

6

7

8

-.

C

TB -5

12VDC +

250 ma. MAX -.

CH1

REMOTE TORQUE

ADJUSTMENT

CH2

REMOTE TORQUE

ADJUSTMENT

1

2

3

4

5

6

7

8

Auxiliary indicator outputs are provided for optional

indicators to monitor the status of Channel 1,

Channel 2, output inhibit, and Channel 2 override.

These are opto-isolated NPN outputs.

Refer to Figure 5, below, for connections.

Figure 5 - Auxiliary Indicator Connections

Note: All resistors and LED’s shown are furnished

by the user. The power source may be either

external user furnished or the CBC-750’s

12VDC auxiliary power supply.

Remote torque Adjust

Potentiometers

Optional remote torque adjust inputs are provided

for torque adjust potentiometer connection.

Refer to Figure 6, below, for connections.

Note: The remote potentiometer should be wired

using shielded cable to prevent noise pick

up. The shield should be connected only

to chassis ground at terminal 7 of TB-6.

Your CBC-750 control has now been completely

wired. Before proceeding to the set-up and start-up

sections of this manual, double check to insure that

the control is properly wired.

Do not use incandescent lamps

because their high inrush current may destroy the

opto-coupler on the CBC-750.

Figure 6 - Remote Potentiometer Connection

Warner Electric • 800-825-9050 819-0494

9

Page 10

SW8

Channel 2 current

range selector

SW7

Channel 1 current

range selector

SW8 SW7

SW6

SW10

SW3

SW11

SW2

SW4

SW5

J1-4

J1-3

J1-2

J1-1

J2-8

J2-7

J2-6

J2-5

J2-4

J2-3

C47

TB8

YEL

YEL

RED

RED

BLUE

BLUE

120

220

240

SW1

TB7

AC Voltage Selection

WHT

BLK

BLK/WHT

BLK/RED

P1

P2

J3

TB1

TB2

TB3

TB4

TB5

1

1

2

2

3

3

4

4

5

5

6

6

7

7

COM

COM

COM

COM

COM

COM

COM

CH 2

Input

CH 1

Input

Inhibit

CH 2

Input

Inhibit

AUX

Input

CH 1

Input

Output

Inhibit

CH 2

Override

(10-30)

VDC

(10-30)

VDC

(10-30)

VDC

(10-30)

VDC

(10-30)

VDC

(10-30)

VDC

(10-30)

VDC

(120 VAC )

CH 2

Input

CH 1

Input

Inhibit

CH 2

Input

Inhibit

AUX

Input

CH 1

Input

Output

Inhibit

CH 2

Override

Optional

AUX

Indicator

Outputs

+

+

+

+

_

_

_

_

CH 1

CH 2

Output

Inhibit

CH 2

Override

+

_

12VDC

250 mA

Optional

Remote

Torque

CH

CH

1

2

Optional

Remote

Torque

SW6

Channel 2 OEX

Enable /disable

SW10

Channel 1

input invert

SW3

Level/pulse selector

level , pulse

SW11

Auxiliary input selector

Channel 1

Channel 2

SW5

Channel 1 OEX

enable / disable

SW2

Channel 1 local

or remote

torque adjust

SW4

Channel 2 local

or remote

torque adjust

7

6

1

2

3

4

5

TB6

CH

1

CH

2

A.C.

Voltage

Input

Chassis

GND

Figure 8 - Main Board Switches - Black

Switches

Warner Electric • 800-825-9050 819-0494

10

Figure 7 - Terminal board Overview - Inside

Page 11

System Start-Up

Do not apply power to the control

at this time.

1. Double check all control and magnet

wiring connections to insure that they are

exactly in accordance with the appropriate

wiring diagrams.

6 Volt Table

Models Range #

EC 650, 1000 4

SF 650, 1000

AT 55

SF 500, 825 Brg, 1000, 1525 5

EC 825, 1225

AT 115

2. Turn the Channel 1 and Channel 2 torque

adjust potentiometers fully counterclockwise, their minimum output settings.

3. For future reference, record the model

numbers and voltages of the clutch/brake

magnets and /or fields in the blank spaces

below:

Channel 1___________ Voltage___________

Channel 2___________ Voltage___________

4. Refer to dip switch selection charts below

and Figure 8, facing page. Set dip switches

SW7 and SW8 for the proper range settings

based on magnet and field sizes. Switch SW7

sets the current ranges for Channel 1 and

switch SW8 sets the range for

Channel 2.

CBC-750

Current Range Selections

For Dip Switches SW7 and SW8

6 Volt Table

Models Range #

SF/PB 120, 170, 250, 400 1

EC/EB 375, 475 2

EM 50, 180

PB/PC 500, 1225, 1525 3

EB 1225

EM 210

AT 25

PB/PC 825, 1000 4

PB 650

EC/EB 650, 825, 1000

24 Volt Table

Models Range #

SF/PB 120, 170, 250, 400 1

EC/EB 375, 475 2

EM 4, 5 2

PC/PB 500, 825, 1225 3

SF 825

EC/EB 825

EB 1225

AT 25

PC/PB 1000, 1525 4

PB 650

EC/EB 650, 1000

SF 650, 1225

EM 6

AT 55

SF 500, 1000, 1225, 1525 5

90 Volt Table

Models Range #

SF/PB 120, 170, 250, 400 1

EC/EB 375, 475 2

EM 50 , 180

PC/PB 1225, 1525 3

PB 650

SF 825, 1225

EB 650, 1225

EM 210

AT25

Warner Electric • 800-825-9050 819-0494

11

Page 12

90 Volt Table (Cont'd)

Channel

Input

(See Note 1)

Channel 1 Input

Inhibit

Channel 2

Input

Channel 2 Input

Inhibit

Auxiliary

Input

(See Note 2)

Output Inhibit

Input

Channel 2 Override

Input

Channel 1

Output

Channel 2

Output

Off

Off

On

On

2 Inputs/Channel 1 & 2

Full On

Not Adj.

On

Adj.

C

Channel 2

Input

Channel 2

Input Inhibit

Auxiliary

Input

(See Note)

Output Inhibit

Input

Channel 2

Override

Input

Channel 1

Output

Channel 2

Output

Models Range #

PC/PB500, 1000 4

EC/EB 1000

SF 1525

AT 55

PB/PC 825 5

EC 650, 1225

EC/EB 825

SF 500, 650, 825 Brg, 1000

AT 115, 205

5. Refer to Figure 8, Page 10. Set the input voltage selector switch SW1 for the AC input

being used.

6. Refer to Figure 8, Page 10. Set switches

SW2 and SW4 in accordance with either of

the following:

• If local torque adjust potentiometers are

used, set to “up” position.

Notes:

1. Channel 1 input signal can be configured by

SW10 to provide same function with inverted

signal.

2. Auxiliary input shown configured as a Channel 1

input, can be configured by SW11 to provide

same operation as a Channel 2 input.

3. Diagram reflects current flow through opticallyisolated control inputs in either sourcing or

sinking made.

4. See set-up switches on back cover.

• If external or remote torque adjust potentiometers are wired to the control, set to

“down” position. Refer to Figure 9 below.

Input/Output signal Relationships, when

makingthe settings required in steps 7 -

10. Circuit logic is diagrammed here for

your convenience.

7. Proper operating mode setting (switch SW3)

depends on how the control inputs are wired:

• Set SW3 in the “up” position for level

input operation from a single switching

device. Channel 2 input controls output

switching when the control is operated in

this mode.

• Set switch SW3 in the “down” position for

pulse input mode operation. This requires

input switching on both Channel 1 and

Channel 2 inputs.

Notes:

1. Auxiliary input shown configures as a Channel 2

input. Auxiliary input non-functional if configured

as a Channel 1 input when control is configured

for a singal input from Channel 2.

2. Diagram reflects current flow through opticallyisolated control inputs in either sourcing or

sinking mode.

3. See set-up switches on back cover.

8. Overexcitation Set-up

Switch SW5 controls the overexcitation pulse

to Channel 1 while switch SW6 controls the

overexcitation to Channel 2. to enable the

OEX, set the switch in the “down” position for

the channel to be overexcited. The “up”

positions disable the OEX pulses.

Warner Electric • 800-825-9050 819-0494

12

Figure 9 - Input/Output Relationships

Page 13

9. Channel 1 input invert switch SW10 selects the

Channel 1 input for normal or inverted signals.

Set the switch for the desired response when

the control is operated in the pulse mode:

• “Down” position applies voltage for control

response.

• “Up” position removes voltage from control

response.

16. Observe that the Channel 1 output should also

be off. Slowly rotate the Channel 2 torque

adjustment potentiometer CW noting that its

LED illuminates and increases in intensity as

the maximum setting is approached.

17. If input inhibit functions are used, activate the

inputs. Check to insure that input inhibit LED’s

illuminate, and that switching inputs do not

affect the output state.

10. If an auxiliary input sensor such as a photoelectric scanner is used, auxiliary input switch

SW11 must be set for either Channel 1 or

Channel 2 input:

• “Up” position inputs to Channel 1

switching.

• “Down” position inputs to Channel 2

switching.

11. Double check all switch settings to insure they

are in the proper position for the desired

functions.

12. Apply power to the CBC-750 control. The

machine must not be running during

preliminary tests.

13. Observe the front panel indicator LED’s as

follows:

• With the torque adjust potentiometers set

at minimum, the output indicators should

be “off”.

18. if any of the auxiliary inputs are used, check

that indicator LED’s illuminate and control

response is proper.

19. Set the system to cycle automatically between

Channel 1 and Channel 2 outputs. Observe the

front panel indicators for proper functioning

based on actual inputs and outputs. Check that

short circuit indicators do not illuminate.

20. Start the machine and observe the control and

the machine for proper operation.

21. Set the Channel 1 and Channel 2 torque adjust

potentiometers to the desired level.

Setting the torque adjustments too

low will cause excessive clutch and brake slip

leading to excessive magnet and/or rotor wear.

22. Shut down the machine and turn off the control.

23. Latch the top board assembly to the chassis by

pushing down on the plastic locking pins.

• Check to insure that Channel 1 and

Channel 2 short circuit indicator LED’s are

not illuminated.

• If short circuit lights illuminate, press reset

button on front panel to clear the short

light(s). If short LED’s illuminate again,

immediately shut off AC power and follow

the instructions in the troubleshooting

section of this manual on page 14 to

located the short circuit.

14. Slowly rotate the Channel 1 torque adjust

potentiometer CW to maximum output, noting

that the Channel 1 output LED illuminates and

24. Install the cover (if used) on the chassis by

sliding the two clips upward, latching the

cover in place.

This completes the installation and start-up of the

CBC-750 control system. If problems are encountered during start-up and check-out, refer to the

troubleshooting section of this manual.

if any problems can not be resolved by following

troubleshooting procedures, and the control is

properly installed and wired, contact your local

Warner Electric Market Representative or our

Applications Engineering Group at (815) 389-3771

for further assistance.

gradually brightens.

15. Activate the switching device to switch from

Channel 1 to Channel 2 output.

Warner Electric • 800-825-9050 819-0494

13

Page 14

General

The chart below will be helpful in solving problems which may be encountered in both start-up and normal

operation. If situations are encountered which are beyond the scope of this troubleshooting guide, please

contact your local Warner Electric Market Representative or ask for applications assistance by phoning (815)

389-3771 and asking for the Application Engineering department.

Symptom A: Indicator LED’s do not illuminate when power is applied.

Probable Cause Solution

No power applied to control Check that AC power to control is on.

Check for proper AC power at terminals 5 and 6 of TB-6

Input line fuse is blown Check for blown power fuse F1. Replace if blown.

Interboard connectors are loose Check that cables and connectors are securely fastened

to main control board.

torque adjust pots set at minimum Turn torque adjust potentiometer CW to increase torque level.

No internal power Check for AC input. Check for 12VDC at terminals 1 and 2 of

TB-5 and across channel 1 and channel 2 outputs. If no

voltage present, replace main board.

Symptom B: Short circuit LED’s illuminate

Probable Cause Solution

I

mproper magnet or field Coil voltage Check magnets and fields for proper coil voltage ratings.

Replace if wrong voltage.

Shorted magnet or field coil Check resistance of magnet coils. Replace magnet or field if

shorted.

Wiring between control and magnets or Check for shorted conditions in wiring between controls

fields shorting and magnets or fields. Replace if defective.

Transient noise Check for source of transient noise and suppress. Wire

control using shielded cables. Segregate wiring runs.

Symptom C: Magnets or fields do not engage when power is applied

Probable Cause Solution

Torque adjust set at zero (0) Increase torque setting.

Current range switches improperly set check dip switch settings per charts found on page 12

and reset if required.

No power applied to control Refer to symptom A above.

Output inhibit input activated Check input status on output inhibit input.

System incorrectly wired Check wiring per the wiring diagram and rewire if

necessary.

Warner Electric • 800-825-9050 819-0494

14

Page 15

Symptom D: Magnet or field on channel 1 does not disengage when input is switched

Probable Cause Solution

Channel 2 override input activated Check status of channel 2 override, and release if

activated.

Faulty control Replace main control logic board.

Symptom E: Magnets or fields do not appear to have enough torque

Probable Cause Solution

Dip switches improperly set Check dip switch settings per chart found on page 9 and

reset if necessary.

Magnets or fields incorrectly wired Check wiring between control and magnets or fields.

Require if necessary.

Torque adjust potentiometers set too low Check setting of torque adjust potentiometers and

increase if required.

Clutches or brakes incorrectly sized Verify proper size by repeating sizing process in Warner

Electric Master Catalog, form P-137.

Symptom F: Outputs don’t switch; inputs don’t switch

Probable Cause Solution

Input incorrectly wired Check for proper wiring schemes and Require if necessary.

Faulty switching device Check for proper operation and replace if defective.

Control switches on main board not set Check positions of switches on main board and reset for

properly proper configuration.

Faulty control Replace main control logic board.

Replacement Parts

CBC-750-6 Complete Control Less Cover 6041-448-001

Main Control Logic Board Assembly 6041-101-001

Cover 6041-101-001

Fuse F1 458-8001-074

Fuse F2 458-8001-010

CBC-750-24 Complete Control Less Cover 6041-448-002

Main Control Logic Board Assembly 6041-101-002

Cover 6041-101-004

Fuse F1 458-8001-074

Fuse F2 458-8001-028

CBC-750-90 Complete Control Less Cover 6041-448-003

Main control Logic Board Assembly 6041-101-003

Cover 6041-101-004

Fuse F1 458-8001-074

Fuse F2 458-8001-026

Warner Electric • 800-825-9050 819-0494

15

Page 16

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original purchase for consumer,

commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable

without Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product,

transportation charges prepaid, to the appropriate Warner Electric LLC factory. Additional

warranty information may be obtained by writing the Customer Satisfaction Department,

Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling

815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service

is rendered. If found defective under the terms of this warranty, repair or replacement will be

made, without charge, together with a refund for transportation costs. If found not to be

defective, you will be notified and, with your consent, the item will be repaired or replaced

and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above

limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of

the defective product and in no event shall Warner Electric LLC be liable for consequential,

indirect, or incidental damages of any kind incurred by reason of the manufacture, sale or

use of any defective product. Warner Electric LLC neither assumes nor authorizes any other

person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty gives you specific

legal rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change

without notice. Weights do not include weight of boxing for shipment. Certified prints will be

furnished without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771

www.warnerelectric.com

P-270 819-0494 6/12 Printed in USA

• Fax: 815-389-2582

Loading...

Loading...