Page 1

Warnings and Cautions

As you read these instructions, you will see

WARNINGS, CAUTIONS, NOTICES and NOTES.

Each message has a specific purpose. WARNINGS

are safety messages that indicate a potentially

hazardous situation, which, if not avoided could

result in serious injury. CAUTIONS are safety

messages that indicate a potentially hazardous

situation which, if not avoided, could result in minor

or moderate injury. A CAUTION may also be used to

alert against unsafe practice. CAUTIONS and

WARNINGS identify the hazard, indicate how to

avoid the hazard, and advise of the probable

consequence of not avoiding the hazard. NOTICES

are messages to avoid property damage. NOTES

are additional information to help you complete a

procedure. PLEASE WORK SAFELY!

WARNING

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to severe injury or death.

To avoid injury to hands or fingers:

• Always keep hands clear of rope, hook

loop, hook and fairlead opening during

installation, operation and when spooling in

or out.

• Always use extreme caution when handling

hook and rope during spooling operations.

General Safety Precautions

WARNING

CHEMICAL AND FIRE HAZARD

Failure to observe these instructions could

lead to severe injury or death.

• Always remove jewelry and wear eye

protection.

• Never lean over battery while making

connections.

• Always verify area is clear of fuel lines, fuel

tank, brake lines, electrical wires, etc. when

drilling.

• Never route electrical cables:

- Across any sharp edges.

- Through or near moving parts.

- Near parts that become hot.

• Always insulate and protect all exposed

wiring and electrical terminals.

• Always install terminal boots as directed in

installation instructions.

WARNING

Failure to observe these instructions could

lead to property damage, severe injury, or

death

• Never exceed the maximum recommended

hydraulic pressure or flow for any of the

components used.

• Always connect the winch to the hydraulic

system as shown in the hydraulic schematic.

• Always use the correct type of control valve

as shown in the hydraulic schematic.

• Always Stand clear of hydraulic lines during

operation.

• Always install hydraulic components in

accordance with manufacturer’s

recommendations.

1

Page 2

General Safety Precautions

CAUTION CAUTION

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

General Safety:

• Always know your winch. Take time to fully

read the Installation and Operations Guide

in order to understand your winch and its

operation.

• Never operate this winch if you are under

16 years of age.

• Never operate this winch when under the

influence of drugs, alcohol or medication.

• Never exceed winch or rope capacity listed

on product data sheet. Double line using a

snatch block to reduce winch load.

Installation Safety:

• Always choose a mounting location that is

sufficiently strong to withstand the

maximum pulling capacity of your winch.

• Always use factory approved mounting

hardware, components, and accessories.

• Always use grade 8 or better mounting

hardware.

• Never weld mounting bolts.

• Always use care when using longer bolts

than those supplied from factory. Bolts that

are too long can damage the base and/or

prevent the winch from being mounted

securely.

• Always position fairlead with WARNING

label on top.

• Always prestretch wire rope and respool

under load before use. Tightly wound wire

rope reduces chances of “binding”, which

can damage the rope.

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

• Always inspect, rope, hook, and slings

before operating winch. Damaged

components must be replaced before

operation. Protect parts from damage.

• Never hook rope back onto itself. This

damages the rope.

• Always use a choker chain, choker rope, or

tree trunk protector on the anchor.

• Always remove any element or obstacle

that may interfere with safe operation of the

winch.

• Always take time to use appropriate rigging

techniques for a winch pull.

• Always be certain the anchor you select

will withstand the load and the strap or

chain will not slip.

• Never engage or disengage clutch if winch

is under load, rope is in tension or drum is

moving.

• Always double line or pick distant anchor

point when rigging. This maximizes pulling

power and avoids overloading the winch.

• Never winch with less than 5 wraps of rope

around the drum. The rope could come

loose from the drum.

• Never touch rope or hook while in tension

or under load.

• Never touch rope or hook while someone

else is at the control switch or during

winching operation.

• Always stand clear of rope and load and

keep others away while winching.

• Always be aware of stability of vehicle and

load during winching. Alert all bystanders of

any unstable condition.

2

Page 3

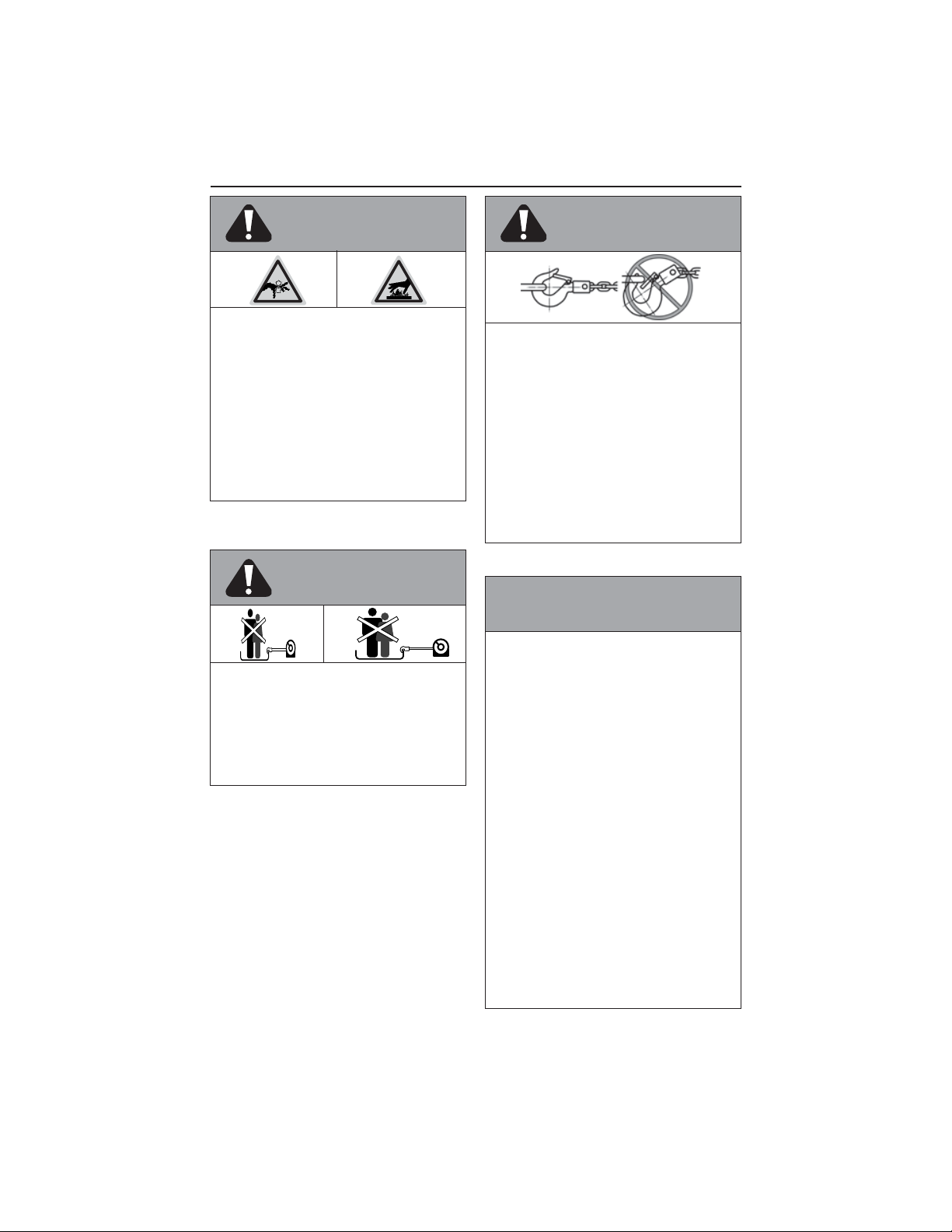

General Safety Precautions

CAUTION

CUT AND BURN HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

To avoid injury to hands and fingers:

• Always wear heavy leather gloves when

handling a wire rope.

• Never let rope slip through your hands.

• Always be aware of possible hot surface at

winch motor, drum or rope during or after

winch use.

WARNING

FALLING OR CRUSHING HAZARD

Failure to observe these instructions could

lead to severe injury or death.

• Never use winch to lift or move persons.

• Never use winch as a hoist or to suspend a

load.

CAUTION

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor to moderate injury.

• Always use a hook with a latch

• Always insure hook latch is closed and not

supporting load.

• Never apply load to hook tip or latch. Apply

load only to the center of hook.

• Never use a hook whose throat opening has

increased, or whose tip is bent or twisted.

NOTICE

AVOID WINCH AND EQUIPMENT

DAMAGE

• Always avoid side pulls which can pile up

rope at one end of the drum. This can

damage rope or winch.

• Always ensure the clutch is fully engaged or

disengaged.

• Never use winch to tow other vehicles.

Shock loads can momentarily exceed

capacity of rope and winch.

• Always use care to not damage the vehicle

frame when anchoring to a vehicle during a

winching operation.

• Never “jog” rope under load. Shock loads

can momentarily exceed capacity of rope

and winch.

• Never use winch to secure a load during

transport.

• Never submerge winch in water.

• Always store the remote control in a

protected, clean, dry area.

3

Page 4

WARN Industrial Winches

What is a Winch?

WARN Industries produces a large family of

winches and hoists. But what makes a winch

different than a hoist?

Winches and hoists look alike. Both consist of a

motor, a rotating drum with rope, reduction gears,

a base, and usually an electrical control system.

However, winches and hoists are used for

different purposes.

Winches are used to pull a load horizontally

across the ground, while hoists are used to lift a

load into the air. Unlike hoists, the operator of a

winch may unwind cable by “free spooling” or

disengaging the motor from the gear train using

the built-in clutch. Then the operator reverses the

position of the clutch to connect the motor to the

gears and pull the load.

Pre-Install Checklist

1 Check to see that you have received the

following:

• The winch

• The winch mounting hardware

2 Upon removing winch from packaging, check

for damage including bent or cracked tie rods,

tie bars, or housings. Correct any damage

before installing winch.

3 Make sure the environment surrounding

winch and controller is free of :

• Combustible vapors

• Chemical fumes

• Oil vapors

• Corrosive material

4 Make sure that the air temperature

surrounding the winch and controller stays

within 120° F (49° C) and -20° F (-29° C).

5 Make sure that the mounting structure can

withstand the full rated pull of the winch.

Mounting the Winch

Mounting Bolts:

Use the supplied fasteners whenever possible or

SAE Grade 8 bolts of the same thread size. The

tie plates, tensioner bracket, and spacers

supplied with the winch should NOT be removed.

Mounting brackets (if required) should be added

to the tie plates and spacers supplied with the

winch. Mounting brackets thicker than ½ inch

(12mm) in thickness may require longer mounting

bolts to be used. The bolt threads must extend a

minimum of ¾ inch (19mm) into the drum

supports. Bolts that are too long or too short will

fail to anchor the winch securely and may cause

a failure of the winch mounting.

Mounting Brackets:

When foot mounting the winch, the mounting

plate should be a minimum of ½ inch thick steel.

A thinner mounting plate will not support the

winch properly and may cause a failure of the

winch mounting. Foot mounting plates thicker

than 1/2 inch (12mm) will require longer mounting

bolts.

When side mounting the winch, brackets must be

a minimum of 4 inch (100mm) by 4 inch (100mm)

by ½ inch (12mm) thick angle iron or larger.

Mounting brackets with inadequate thickness

may cause a failure of the winch mounting. Side

mounting brackets thicker than 1/2 inch (12mm)

will require longer mounting bolts.

1 Make sure that the mounting surface is flat

within +/-0.020 in. (0.50 mm). If the surface is

not flat, use shim stock as needed to avoid

straining the winch.

2 Torque all mounting bolts to the

recommended values on the product data

sheet.

3 Use the mounting hole locations provided on

the product data sheet.

4

Page 5

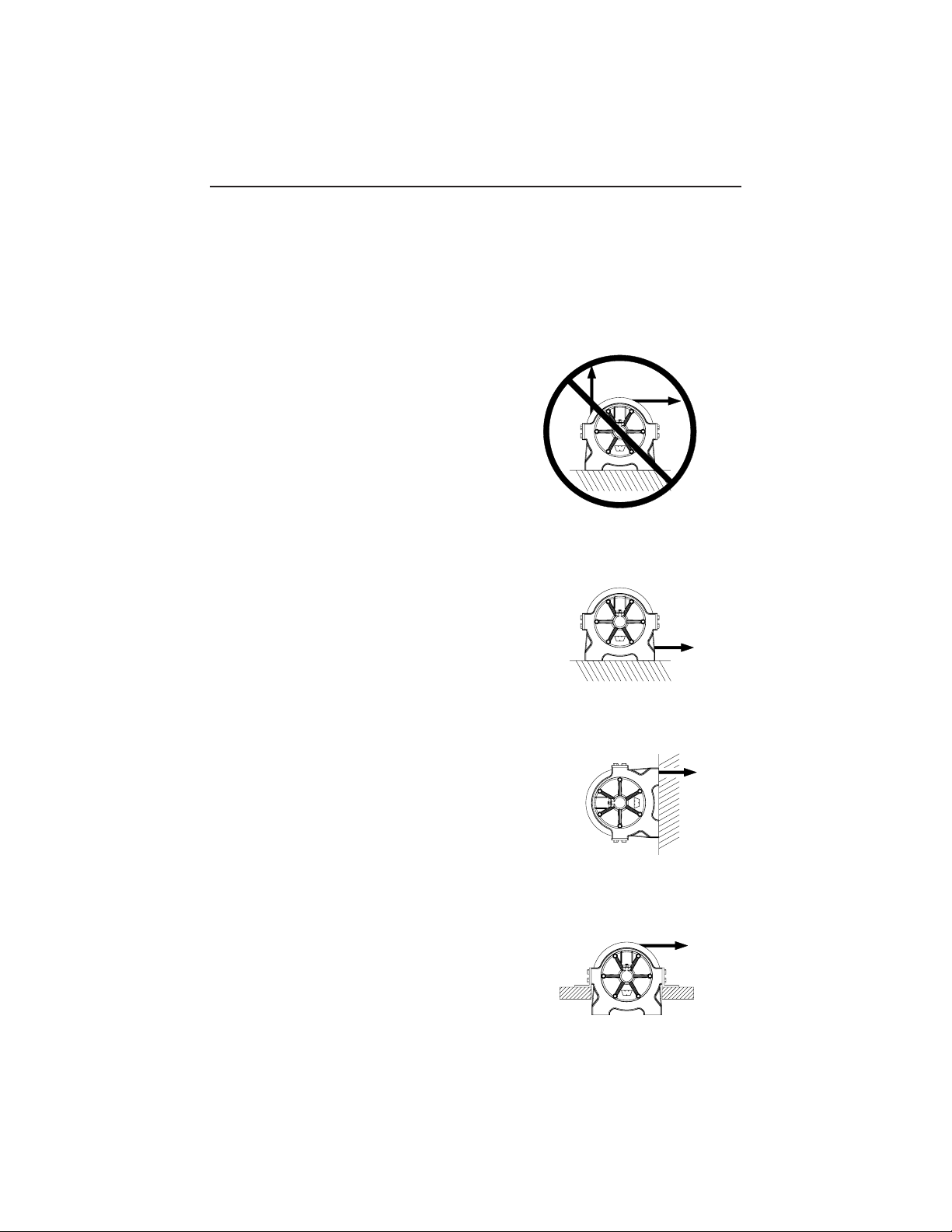

Mounting Configurations

This section illustrates the recommended

mounting configurations for the Series XL winch.

This section does not include every possible

mounting configuration, but illustrates the correct

methods for mounting the winch.

Foot Down Mounting Position:

DO NOT wind the rope from the top of the drum.

DO NOT position the load direction away from

the mounting surface.

Foot Down Mounting Position:

DO wind the rope from the bottom of the drum.

WARN Industrial Winches

Foot Forward Mounting Position:

DO wind the rope from the top or bottom of the

drum towards the direction of the mounting

surface.

Side Mount:

DO wind the rope from the top of the drum.

5

Page 6

WARN Industrial Winches

Mounting Bolt Patterns

6

Page 7

WARN Industrial Winches

Hydraulic Winches: General Information

NOTE: The hydraulic system diagram and

component descriptions are provided for general

reference. Consult a knowledgeable hydraulics

representative for specific recommendations on

component selection, interconnection, layout,

and best practice.

The pressure rating of the winch motor is

determined by (a) the maximum allowable

pressure at the motor inlet port and (b) the

maximum allowable pressure drop across the

motor. Pressure drop is defined as the difference

between the inlet port pressure and the outlet

port pressure at the winch motor. Exceeding the

maximum inlet pressure may damage the winch

motor. Exceeding the maximum pressure drop

may cause failure of winch components.

The recommended operating temperature range

of the hydraulic motor is 100°F to 150°F (38°C to

66°C). The maximum operating temperature

range is -6°F to 180°F (-21°C to 82°C). Do NOT

exceed the flow rating of the hydraulic motor.

See the product data sheet for specific hydraulic

specifications.

Failure to observe these instructions could

lead to property damage, severe injury, or

death

• Never exceed the maximum recommended

hydraulic pressure or flow for any of the

components used.

• Never use a relief valve that exceeds the

hydraulic motor pressure rating. Use of the

incorrect relief valve can overload the winch

or cause hose or fitting failure.

• Always use an open-center type control

valve (A & B work ports drain to tank) to

ensure proper brake operation.

• Always make sure all hydraulic system

components are functioning correctly.

HYDRAULIC FLUID: The hydraulic fluid used

with the winch must be an extreme pressure,

anti-wear hydraulic oil with oxidation and

corrosion inhibitors. It must contain a foam

suppressant, and have a viscosity rating of 100300 SUS at 60°F to 115°F (15°C to 46°C). The

recommended nominal filtration level is 10

microns or finer.

WARNING

7

Page 8

WARN Industrial Winches

Brake System

WARN Series XL winches are equipped with a 2part hydraulic braking system.

1 Dual counterbalance valves mounted to the

winch motor provide dynamic braking to

control the load when it is moving (i.e. power

out function).

2 A spring applied hydraulically released

(SAHR) disc brake prevents movement of the

winch drum and load when the winch is

stopped (i.e. control valve OFF position).

Both braking components are designed to

operate in either direction, which allows flexibility

in the rope winding direction.

Never attempt to adjust or remove the

Counterbalance Valves installed in the winch

hydraulic manifold.

In order for the brake system to function properly,

the winch must be connected to the proper

system Control Valve. The Control Valve must

be a 3-position, 4-way, spring return valve as

shown in the Hydraulic Schematic. The Control

Valve and hydraulic plumbing must allow both

motor ports (Port A and Port B) to drain freely to

the hydraulic system reservoir in the center

(OFF) position. Hydraulic system back pressure

(return line pressure) must not exceed 100 psi.

Use of the incorrect control valve or plumbing

may cause failure of the brake system.

Freespool Clutch

Operation

WARN Series XL winches are equipped with

either a manual or air operated freespool clutch

depending on the model. The freespool clutch

allows the operator to rapidly spool out the wire

rope. The freespool clutch disconnects the winch

drum from the winch brake.

MANUAL CLUTCH OPERATION

The manual freespool clutch is operated by

depressing the detent latch and turning the clutch

lever as indicated on the winch label.

AIR CLUTCH OPERATION

The air freespool clutch is operated by

application of air pressure to the fitting supplied

on the winch gearbox housing. The fitting is

designed to accept ¼” rigid plastic tubing.

1. To release the clutch (freespool operation):

Apply 50-120 psi air pressure to the air fitting.

2. To engage the clutch (winch operation):

Remove air pressure (0 psi) from the air

fitting.

WARNING

Failure to observe these instructions could

lead to property damage, severe injury, or

death.

· Always ensure the clutch is fully engaged

before operating the winch.

· Never release the clutch under load.

· Never operate the winch motor for a

prolonged period while the clutch is in

freespool mode.

· Never exceed 120 psi air pressure.

· Never use oil or other liquids to operate the

air clutch.

8

Page 9

Installation Final

Check

• Recheck mounting hardware for loose bolts,

etc.

• Be sure all hydraulic system components

and connections are correct

• Be sure all connections are tight and secure

• Check motor rotation: The drum should

rotate counterclockwise when viewed from

the motor end when hydraulic fluid is

supplied to Port A of the motor.

• To ensure maximum hydraulic motor life,

the winch should be operated for one hour

at no more than 30% of rated load before

application of full load.

Installing the Wire

Rope

WARN Industrial Winches

WARNING

Failure to observe these instructions could

lead to property damage, severe injury, or

death.

• Always maintain a minimum of five (5)

wraps ofrope on the drum.

• Always use wire rope specified on the

product data sheet.

• Always install rope according to the

illustration below.

The wire rope may be spooled on the winch drum

in either direction. Always follow the guidelines

for pull direction listed under Mounting the Winch.

1 Insert the end of the wire rope into the anchor

hole in the drum flange. NOTE: A small

piece of tape around the end of the wire rope

will make installation much easier. The wire

rope must extend to the other end of the hole.

2 Torque the set screws to 12-15 lb-ft (16-20 N-

m). Do not overtighten as this may cause the

screw threads to be damaged. Ensure both

(2) set screws secure the wire rope. Ensure

both (2) set screws do not protrude from the

drum flange.

3 With end of rope securely installed, carefully

wind the rope evenly onto the drum. Keep

the rope under tension at all times.

4 Always maintain a minimum of five (5) wraps

of rope on the drum. Fewer wraps may cause

the end of the rope to pull free of the drum

and drop the load.

Anchoring Wire Rope on Drum

9

Page 10

WARN Industrial Winches

Operating Instructions

WARNING

Failure to observe these instructions could

lead to property damage, severe injury or

death.

Always watch for hazards from the cable,

drum pinch points, uncontrolled loads, and

rope or rigging under tension.

• Never touch rope or rigging while pulling a

load, while anyone is at controls, or while

operating winch.

• Never put rope around an object and hook

it back on itself. This will damage the rope.

• Never use winch with less than five (5)

wraps of rope around winch drum. The

cable anchor is not designed to hold the

rated load. The rope may pull free and

release the load with fewer than five wraps

of rope on the winch drum.

• Never let the rope slip through your hands.

Safe Operating Procedures

NEVER:

• Never place any part of your body or

clothing near rotating or moving parts.

Rotating drum with rope under tension can

create a pinch point.

• Never handle ropes or operate winch

without wearing eye protection and heavy

gloves.

• Never stand close to winch when operating.

If rope breaks it can fly back with

tremendous force.

• Never lift, pull, or otherwise transport

people with winch.

• Never lift, pull, support or otherwise

transport loads over people.

• Never attempt to pull loads greater than

rated capacity of the winch.

• Never pull a load until it jams and causes

the drum and motor to stall.

Note: The two conditions above produce

excess load on the winch. Excess loads

may cause winch, rope or structural failure.

Excess loads can create undetectable

damage, which may cause the winch to fail

even when pulling loads within its rated

capacity.

• Never allow hydraulic system or gearbox to

overheat.

ALWAYS:

• Always inspect and carefully rewind rope

after each use. Cuts, kinks, or frayed areas

reduce the tensile strength of rope. Replace

rope if damaged.

• Always inspect hydraulic system

connections before using winch.

• Always stand clear of the rope and load

during winch operation.

• Always make sure that other winch

operators understand the potential hazards

and have been trained in proper use of the

winch.

• Always make sure that the control valve

and winch assembly are installed, operated,

adjusted, and serviced by qualified

personnel familiar with its construction and

operation.

10

Page 11

Spooling Guidelines

Stretching wire rope

WARN Industrial Winches

The life of a wire rope directly relates to its use

and to the care it receives. A new wire rope must

be “stretched” or spooled onto the drum under a

load of at least 500 lb. (227 kg.). The objective of

“stretching” is to produce tight even wraps on the

inner and outer layers of the rope, thus

preventing damage to the rope from binding and

kinking.

To accomplish the stretching operation, follow the

guidelines and safety precautions in the Basic

Guide to Winching Techniques. Set up your

vehicle and winch for a straight-line pull on flat

ground. Spool out all but the last five wraps.

Attach the rope to an anchor point or load.

Operate the winch using the remote switch as

you sit in the driver’s seat keeping light pressure

on the brake. Spool the final few feet of rope

while griping the hook with a hook strap.

Spooling out

Freespooling is generally the quickest and

easiest way to spool out wire rope. Before

freespooling, power out enough rope to remove

any tension the rope may be under. Disengage

the clutch. Now freespool by manually pulling out

enough wire rope for the winching operation.

Always leave at least 5 wraps on the drum.

Spooling in under load

Never exceed the rated line pull of the winch.

Power in the wire rope evenly and tightly on the

drum. This prevents the outer wire wraps from

drawing into the inner wraps, binding, and

damaging the wire rope.

Avoid shock loads when spooling by using the

control switch intermittently to take up wire rope

slack. Shock loads can momentarily far exceed

the winch and wire rope ratings. The maximum

recommended fleet angle (side pull angle) is 5

degrees. Exceeding the recommended fleet

angle will cause damage to the winch drum and/

or rope tensioner. A suitable fairlead must be

mounted for pulling angles that exceed 5

degrees.

Spooling in under no load

Assisted - Have your assistant hold the hook with

the hook strap putting as much constant tension

on the wire rope as possible. While keeping

tension, the assistant should walk toward the

winch while you operate the control switch.

Release the switch when the hook is 8 ft. (2.4 m.)

from the fairlead opening. Spool in the remainder

for storage.

Unassisted - Arrange the wire rope to be spooled

so it will not kink or tangle when spooled. Be sure

any wire rope on the drum is tightly and evenly

layered. Spool enough wire rope to complete the

next full layer on the drum. Tighten and

straighten the layer. Repeat the process until the

hook is 8 ft. (2.4 m) from the fairlead opening.

Spool in the remainder for storage.

Spooling remainder for storage

Secure the hook to a suitable anchor point near

the winch. Carefully power in the remaining wire

rope, jogging the control switch to take up the

last of the slack. Be careful to not over tighten or

damage may occur to the wire rope or anchor

point.

11

Page 12

WARN Industrial Winches

Periodic Preventive Maintenance

• Keep winch free of dirt, oil, grease, water

and other substances. Remove any

overflow grease from bearings.

• Check all mounting bolts and make sure

they are tightened to proper torque.

Replace any damaged fasteners.

• Periodically check all hydraulic connections

to be sure they are tight and free of

corrosion.

Preventive maintenance schedule

ytivitcaecnanetniaM

srenetsafkcehC

ciluardyhkcehC

snoitcennoc

eporkcehcdnatuoloopS

sehsurbrotomkcehC

hcniwfokcehclausiV

evlavlortnocdna

noitarepo

XX

XX

XX X

• Check rope for visible damage every time

winch is operated. Examples of damage

are: cuts, knots, mashed or frayed portions,

and broken strands. Replace rope

immediately if damaged. Failure to replace

a damaged rope could result in breakage.

• If winch drum continues to turn after

controls are released, brake may need to

be replaced.

tsrifretfA

erofeB

esuhcae

hcaeretfaroyllaunna-imeS

noitarepofosruoh52

X

X

NOTE: Hydraulic system failures typically follow the same pattern: a gradual or sudden loss of

pressure or flow resulting in a loss of motor power. Any one of the system components may be at fault.

Refer to the table for general recommendations. If necessary, consult a knowledgeable hydraulics

representative.

NOTE: See product data sheet for hydraulic specifications.

12

Page 13

Trouble Shooting:

WARN Industrial Winches

Note: These trouble shooting tips apply to

Series XL hydraulic winches only. Repair

activities should only be performed by qualified

persons.

melborP esuacelbissoP noitcaevitcerroC

gnitarhcniwsdeecxedaoL

seodhcniW

dlohton

nehwdaol

deppots

ytluciffiD

gniloopsnu

epor

nekorb

dellatsnievlav

lftneB

degagnesid

tsiwtothcniw

ronrowyldabsiekarB

lortnoc

ciluardyhtcerrocnI

murdnoegna

sgnihsubmurdnroW

ylluftonsihctulcloopseerF

degamadsihctulC

murdnopudnuobsiepoR

esuaceb,sdnibmurD

sesuacgnitnuomreporpmi

WARNING

PERSONAL INJURY

Failure to observe these instructions

could lead to severe injury or death.

wruoyrofgnitarllup

.hcni

.decalperebtsum

rutergnirpsepyt"retnec

.noitisop

.yrassecen

ht

.)ylnohctulc

dehttahtdnayleerf

.)ylno

psnI.eerf

frus

eniltcerrocehtrofteehsatadtcudorpehtotrefeR

ylbmessaekarberitnE:ETON.ekarbecalpeR

-nepo"nasievlavlortnocciluardyhehttahtyfireV

ciluardyhllatahtdnaevlavn

FFOehtnidesaelersihcniwehtoterusserp

.deriaperdnadevomerebtsummurd

asgnihsubtcepsnI.murdevomeR

ladnadaolaothcniwehttcennoC

tneB.segnalftnebroftcepsnidnamurdetatoR

fiecalperdn

tahtyfireV.yleerfsetatorrevelhctulctahtyfireV

yfireV.noitisopesaelerehtotdenrutsirevelhctulc

ria(isp021-05sihctulcehtoterusserpriata

sevomtfahsevirdtahtyfirevdnahcniwelbmessasiD

.degamadtonsignirpstfahsevir

hctulcria(degamadtonsignir-OnotsiptahtyfireV

-rewopyletanret

flestikrowyllausulliweporehT.tuo-rewopdnani

fiecalperdnaegamadrofeporehttce

.NOITUACEMERTXEESU.yrassecen

dnasnoitacificepsgniwollofhcniwehttnuomeR

gnitnuomeruseB.launamsihtniserudecorp

fismihsesU.hcni020.nihtiwottalfsieca

.thgiterastlobgnitnuomeruseB.yrassecen

uR

wol

ooterutarepmettneibmA

.erutarepmetgnitarepootxobraeg

ehtmrawotsetunimlarevesrofhcniwehtn

13

Page 14

WARN Industrial Winches

melborP esuacelbissoP noitcaevitcerroC

omreporpmi

dega

gne

dna,sevlav,retlif,leveldiulfkcehC

ooterusserpdiulfciluardyH

wolootetarwolfrowol

esuaceb,sdnibmurD

tsiwtothcniw

sesuacgnitnu

.thgiterastlob

tonsihctulcloopseerF

ireV.noitisop

.)ylnohctulcria(isp0sihctulc

rehto

.tsilaicepsciluardyhatlusnoC.stnenopmoc

snoitacificepsgniwollofhcniwehttnuomeR

eruseB.launamsihtniserudecorpdna

nihtiwottalfsiecafrusgnitnuom

.hcni020.

gnitnuomeruseB.yrassecenfismihsesU

yfireV.yleerfsetatorrevelhctulctahtyfireV

tcerrocehtotdenrutsirevelhctulctaht

ehtoterusserpriatahtyf

sgnihsubmurdnroW

skcalhcniW

sllup,rewop

rosllats,ylwols

.llatanurtonlliw

ardyH

wol

egamadlanretni

degamad

egamaD

ro,gnidnib,raewxobraeG

sirotomcilu

desaelertonsiekarbcsiD

noitanimatnocro

dlofinamciluardyhfo

ooterutarepmettneibmA

gamad

.yrassecenfiecalper

.esaergPEhtiwetacirbul

.rotomciluardyhecalpeR

errotsujdaottpmettaTON

.sevlavecnalabretnuoc

dnasgnihsubtcepsnI.murdevomeR

roftcepsnI.xobraeghcniwelbmessasiD

fonoitatoreerf,stnenopmocde

.noitanimatnocro,gnidnib,sraegtenalp

dnastnenopmocdegamadecalpeR

otdeilppasierusserpciluardyhtahtyfireV

.noitarepohcniwgnirudekarbcsid

.decalperebtsumylbmessa

ecalpeR

ekarberitnE:ETON.yrassecenfiekarb

eritnE:ETON.dlofinamciluardyhecalpeR

OD.decalperebtsumylbmessadlofinam

ehtevom

ehtrofFº6-evobaebtsumerutarepmeT

.y

lreporpnoitcnufotmetsysciluardyh

14

Page 15

WARN Industrial Winches

Customer Support

Should you have any questions about this product or these instructions, please call WARN’s customer

service through the numbers below, Monday through Friday between 7:00 AM and 4:00 PM Pacific

Time for assistance. Or for e-mail support, visit our web site www.WARN.com and click on customer

service section.

Note: Only qualified persons should undertake repair activities on WARN winches.

setatSdetinU lanoitanretnI

)ylnoSU(6729-345

-008ro0021-227-305:enohP

0003-227-305:XAF5003-227-305:XAF

8003-227-305enohP

15

Page 16

WARN Industrial Winches

Warranty

WARN® Commercial Products Limited One (1) Year Warranty Statement

Warn Industries, Inc. (WARN) warrants to the original purchaser that the mechanical components and

electrical components of the “WARN” Products specified below will be free of defects in material and

workmanship for a period of one (1) year from the original date of purchase. This Warranty applies only to

the original purchaser of the Products. To obtain any warranty service, you must provide WARN with proof

of purchase and date of purchase acceptable to WARN, such as a copy of your purchase receipt. This

warranty does not cover the removal or reinstallation of the Product. WARN will, at its option, repair,

replace or refund the purchase price of a defective Product or component, provided you return the defective

Product or component during the warranty period, transportation charges prepaid, to Warn Industries

Service Department or a Factory Authorized Service Center. Attach your name, address, telephone

number, a description of the problem, and a copy of your receipt and original bill of sale bearing the WARN

serial number of the defective Product and date of purchase.

This warranty does not apply (i) to parts or components excluded below, or (ii) if the Product has been

damaged by accident, abuse, misuse, collision, overloading, modification, misapplication, improper

installation, or improper service. This warranty is void if any WARN serial number has been removed or

defaced.

THE WARRANTY SET FORTH ABOVE IS THE ONLY WARRANTY. THERE ARE NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

ANY IMPLIED WARRANTY WHICH BY LAW MAY NOT BE EXCLUDED IS LIMITED IN DURATION TO

ONE (1) YEAR FROM THE DATE OF ORIGINAL RETAIL PURCHASE OF THE PRODUCT.

WARN SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOST PROFITS, DOWN TIME OR LOSS OF USE)

UNDER ANY LEGAL THEORY, EVEN IF WARN WAS ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES.

Some states do not allow the exclusion of implied warranties or the exclusion or limitation of liability for

incidental or consequential damages, or limitations on how long an implied warranty lasts, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights. You may also

have other rights that vary from state to state.

WARN reserves the right to change Product design without notice. In situations in which WARN has

changed a Product design, WARN shall have no obligation to upgrade or otherwise modify previously

manufactured Products.

No WARN dealer, agent or employee is authorized to make any modification, extension or addition to this

warranty.

Warranty inquires and Products returned for warranty service should be sent to:

WARN INDUSTRIES, INC.

Customer Service Department

12900 SE Capps Road

Clackamas, OR 97015

1-800-543-WARN (1-800-543-9276)

Products covered by this warranty Products not covered by this warranty

WARN Series XL winches Product paint and finish including corrosion damage

Wire Rope

16

Loading...

Loading...