GB Instructions For Use Machine Light ABLTL 1

Safety instructions

! DANGER

Danger caused by wrong

mounting or handling!

Wrong mounting or handling of this

unit can result in serious injuries

or death.

¾ First read these ins-

tructions and, where

appropriate, any other

instructions and information

attached to the unit!

¾ Please observe the warnings

and notes included in the instructions and attached to the

unit!

! DANGER

This symbol identifies items that

may directly result in serious injuries or death in case of non-observance or wrong handling.

! WARNING

This symbol identifies items that

may result in serious injuries or

death in case of non-observance

or wrong handling.

! CAUTION

This symbol identifies items that

may result in injuries or material

damage in case of non-observance or wrong handling.

NOTICE

This symbol identifies items that

may result in material damage in

case of non-observance or wrong

handling.

19

GB Instructions For Use Machine Light ABLTL 1

Safety instructions

20

! DANGER

Explosion hazard!

Operating the light in rooms subject to explosion hazards can trigger an explosion.

¾ Operate in rooms not subject to

explosion hazards only!

! WARNING

Danger due to electrical shock

in case of contact!

Maintenance or repair work carried

out incorrectly may result in serious

injuries or death.

¾ Disconnect the light from the

mains before carrying out any

maintenance or repair work!

¾ Maintenance and repair work

must be carried out by a skilled

electrician only!

¾ Only parts released by the

manufacturer may be used as

spare parts!

NOTICE

Damage caused by wrong mains

voltage!

A wrong mains voltage can result in

damaging or destroying the lamp.

¾ Operate units of protec-

tion class III with safety

extra low voltage (SELV) only!

¾ Connection only by a skilled

electrician!

¾ Before putting the light into

operation, the user has to check

whether the mains voltage is

identical with the rated voltage

specified on the rating plate.

GB Instructions For Use Machine Light ABLTL 1

Safety instructions

! WARNING

Risk of blinding!

Looking directly into the light source may cause temporarily impaired

vision and afterimages. This may

result in irritations, inconveniences,

impairments or even accidents.

¾ Looking directly into the light

source must be avoided.

¾ Position light in such a way that

looking directly into the light

source is avoided.

NOTICE

Damage caused by the incident

laser beam!

Direct or indirect incidence of a

laser beam may result in the destruction of the LED.

¾ Use the light only outside the

range of action of high-performance lasers (e.g. cutting laser,

welding laser).

21

GB Instructions For Use Machine Light ABLTL 1

Description

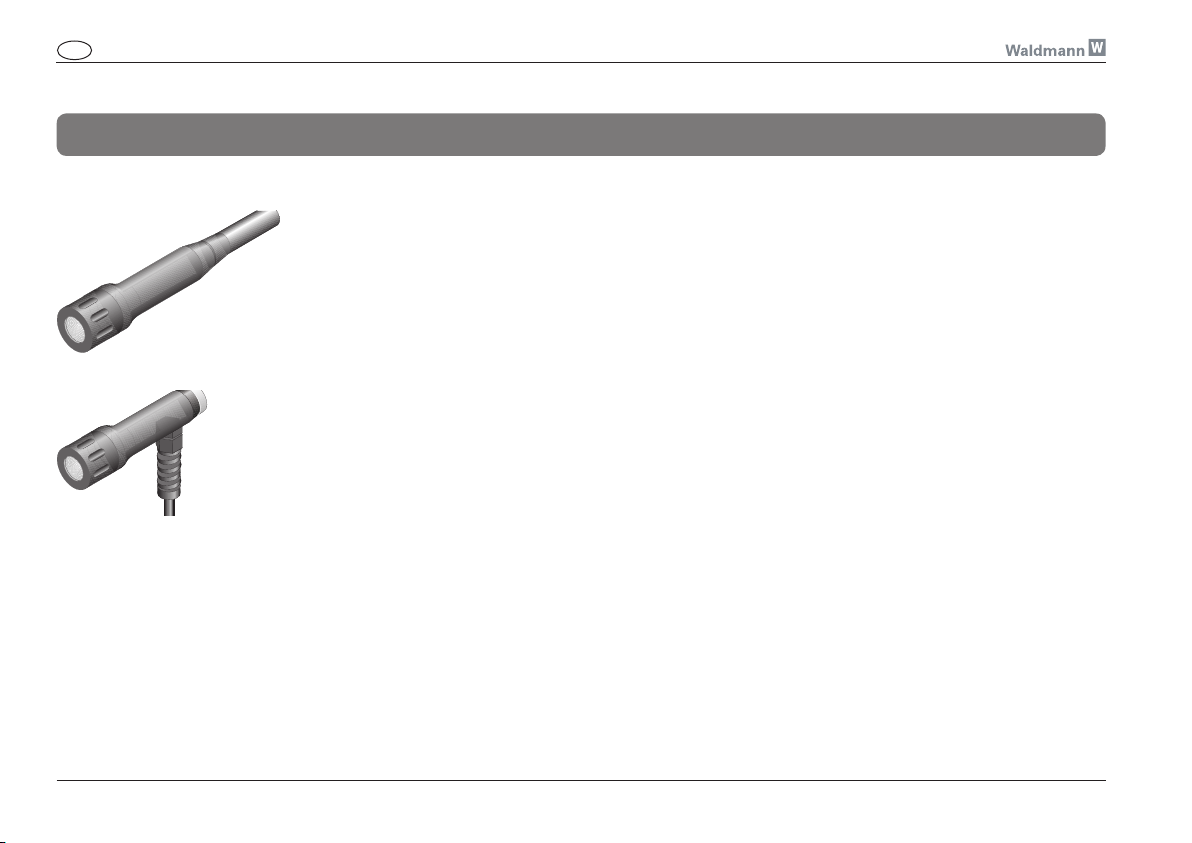

Fig. 11a

Fig. 11b

According to standard DIN EN 1837, an illuminance of 500 lx is required in the work area of machines. This is

often impossible to achieve using a light that is not in the immediate proximity of the tool. However, only in rare

cases is it possible to attach a light directly to the tool slide, since the restricted room available in the interior of

the machine room does not allow this.

In the ideal case, a well illuminated machining area is can be achieved by combining 2 or more lights:

a) Light for basic illumination of the machining area (using, for example, a Waldmann protective-tube light)

b) additionally mounted light for the immediate machining area (e.g. Waldmann machine light ABLTL 1).

The machine light ABLTL1 meets the requirements of the standard since the flexible light-supporting hose (swan

neck) allows virtually any positioning of the light. Mounting such a light, in addition to the basic illumination already

in place, offers a maximum degree of illumination comfort at the machine.

The use of light emitting diodes (LED) instead of halogen lights allows a significantly higher service life to be

achieved. This results in fewer machine downtimes as a result of maintenance work.

A housing made of anodized aluminum and a protective borosilicate glass pane are resistant to hot and sharpedged chips. The housing is waterproof and, like the PUR cable, resistant to coolants and lubricants.

The selection between 3 variants of different radiation characteristics (6°, 15°, 25°) makes for universal use.

22

GB Instructions For Use Machine Light ABLTL 1

Designated use Abbreviations and symbols

Intended purpose:

Machine light - light for illuminating

the work area on machines.

Safety or warning

instructions!

Important information!

Place of use:

Only suitable for rooms not subject

to explosion hazards.

Not for use in the range of action

of high-performance lasers.

Operating mode:

The light is designed for continuous

operation.

The manufacturer cannot be held liable for damage caused by using the unit for purposes contrary

to the designated use or by ignoring safety instructions and warnings.

Unit corresponds to international protection class III

(Operation with savety

extra low voltage (SELV))

The light is suitable for

mounting on normally inflammable surfaces

Observe the disposal

instructions!

LED Light Emitting Diode

VDE Approval

ENEC Approval

SEV Approval

CE

Conformity mark

23

GB Instructions For Use Machine Light ABLTL 1

Mounting

Fig. 12

Fig. 13

45 mm

6.2 mm (4 x)

45 mm

! CAUTION

Danger due to insufficient fastening!

When mounted incorrectly, the

light may fall down.

¾ Mounting to a surface suitable

for mounting only!

¾ Mounting by a skilled electri-

cian only!

NOTICE

Damage caused by the incident

laser beam!

Direct or indirect incidence of a

laser beam may result in the destruction of the LED.

¾ Use the light only outside the

range of action of high-performance lasers (e.g. cutting laser,

welding laser).

Standard version

The light-supporting hose can be

mounted on a through hole of approximately 12.5 mm in diameter

(using the enclosed disks and nut)

or directly on the M12 thread (see

Fig. 12).

Light with screw down lash

Mount light in stable position by

means of suitable screws (see

Fig.13).

24

GB Instructions For Use Machine Light ABLTL 1

Connection

NOTICE

Damage caused by wrong connection!

Wrong connection may result in

the light being damaged or destroyed.

¾ Operate the light with the ope-

rating units proposed by the

manufacturer only.

¾ Connect the light only when the

operating device is off!

¾ Install the switch always in the

primar y electric circuit (see

fig. 14)!

¾ Connection only by a skilled

electrician!

¾ The operating unit must be

positioned in accordance with

its type of protection.

Fig. 14

Operating

Unit

Connection

Important Information

See connection diagrams on page

31.

Depending on the mains voltage

and the selected operating current, different operating units are

suitable.

Suitable operating units can be

found in the Appendix (page 30).

Connect the light as shown on

page 31.

Two versions of the the Waldmann

operating unit are available, which

have different operating currents.

Note: Higher operating current

means higher light yield and shorter useful life.

25

GB Instructions For Use Machine Light ABLTL 1

Operation

Fig. 15a

Fig. 15b

15.1

15.3

15.4

15.2

Positioning

Via the flexible light-supporting

hose (15.2) (swan neck), the light

can be swung virtually into any

desired position.

In the version with external cable

duct (15.4), the light module (15.1)

is maintained in the light-supporting hose (15.3) via a magnet. It can

be pulled off without any problem

(see Fig. 15b).

Note!

In the standard version, the light

module cannot be pulled off!

Fig. 16

Operating

Unit

Switching ON/OFF

The light is not equipped with

a switch of its own. It is usually switched on/off via external

switching elements.

Important information

Install the switch always in the primary electric circuit (see fig. 16)!

26

GB Instructions For Use Machine Light ABLTL 1

Maintenance and repair

! WARNING

Danger due to electrical shock

in case of contact!

Maintenance or repair work carried

out incorrectly may result in serious

injuries or death.

¾ Disconnect the light from the

mains before carrying out any

maintenance or repair work!

¾ Maintenance and repair work

must be carried out by a skilled

electrician only!

¾ Only parts released by the

manufacturer may be used as

spare parts!

Maintenance

The light module ist maintenancefree.

NOTICE

Loss in tightness!

The main parts of the light module

are bonded to each other. When the

two parts are separated from one

another, tightness may get lost.

¾ Do not separate the light parts

from one another!

Defective light source

The light works with one

light emitting diode (LED).

The useful life of LEDs exceeds by

far that of conventional lamps (e.g.

light bulbs). Therefore, a replacement of the light source is rarely

necessary.

If nevertheless the LED should

break down, the entire LED module

[Fig. 17] must be replaced. To do

so, send the complete light to

the manufacturer.

Fig. 17

27

GB Instructions For Use Machine Light ABLTL 1

Care Disposal

28

NOTICE

Risk of damage through wrong

care!

Wrong care may destroy the unit.

¾ Clean the transparent cover at

regular intervals!

¾ Clean the light parts only with

a cloth impregnated with a

suitable household cleaning

agent!

¾ Make sure the agents used

are compatible with paints and

plastics!

NOTICE

Environmental hazard!

Wrong disposal endangers our

environment.

¾ Return the unit at the

end of its useful life to

the available recycling

systems!

GB Instructions For Use Machine Light ABLTL 1

Technical data

Dimensions

Standard version (Fig. 2a):

Luminaire approx. Ø 29 x 755 mm

Cable approx. 5000 mm

Version 112373000 (Fig. 2b):

Light module

approx. Ø 29 x 113 mm

Light-supporting hose

approx. 655 mm

Cable approx. 600 -2000 mm

Classification

Protection class III

Protection type see rating plate *

Operating mode

Continuous operation

Technical safety check

according to EN 60598-1

Rating according to DIN 60825-1

and VDE 0837 Laser class 1

* Example of a mixed

protection type:

IP20 [IP67] means

Light IP20

Light module IP67

Electrical values

Operation with Waldmann type A

operating unit or VLM operating

unit type 1

Operating current 700 mA

Power approx. 3.0 W

Useful life * approx. 50,000 h

Operation with Waldmann type C

operating unit or VLM operating

unit type 2

Operating current 350 mA

Power approx. 1.5 W

Useful life ** approx. 50,000 h

* Decrease in luminous flux

approx. 70 %

** Decrease in luminous flux

approx. 50 %

NOTICE

Risk of damage due to differences from the standard design.

If required, this series of units will

be supplemented by further variants. The technical data may therefore be subject to modifications.

¾ Always observe the data and

symbols given on the rating

plate!

29

GB Instructions For Use Machine Light ABLTL 1

Appendix

Suitable operating units

For 230 V AC (700 mA)

VLM type 1 operating unit

Order No. 209 585 019

Input voltage 95-240 V

Frequency range 50/60 Hz

Output current 700mA

Assembly:

Adapter plate including clip for

mounting rail

Operating unit/light module line

length max. 10 m

a maximum of 3 light modules

can be connected (in series)

For 230 V AC (350 mA)

VLM type 2 operating unit

Order No. 209 595 019

Input voltage 95-240 V

Frequency range 50/60 Hz

Output current 350mA

Assembly:

Adapter plate including clip for

mounting rail

Operating unit/light module line

length max. 10 m

a maximum of 3 light modules

can be connected (in series)

For 24 V AC/DC (700 mA)

Waldmann-type A operating unit

Order No. 209 582 019

Input voltage 19.2-28.8 V

Frequency range 50/60 Hz / DC

Output current 700 mA

Assembly:

Housing for mounting to mounting rail

Operating unit/light module line

length max. 10 m

a maximum of 3 light modules

can be connected (in series)

For 24 V AC/DC (350 mA)

Waldmann-type C operating unit

Order No. 209 582 039

Input voltage 19.2-28.8 V

Frequency range 50/60 Hz / DC

Output current 350 mA

Assembly:

Housing for mounting to mounting rail

Operating unit/light module line

length max. 10 m

a maximum of 3 light modules

can be connected (in series)

30

Fig. 25bFig. 25a

Fig. 25c Fig. 25d

GB Instructions For Use Machine Light ABLTL 1

Appendix

Fig. 26a

1 (+)

Fig. 26b

brown

(+)

2 (_)

white

(_)

Fig. 27

Output

Operating unit

Input

230 V AC

Waldmann operating unitVLM operating unit

Fig. 28

Output

Operating unit

Input

24 V DC

24 V AC

NOTICE

Damage caused by wrong connection!

Wrong connection may result in

the light being damaged or destroyed.

¾ Operate the light only with a

suitable operating unit.

¾ Connect the light only when the

operating device is off!

¾ Install the switch always in the

primary electric circuit (see fig.

14 on page 25)!

¾ Connection only by a skilled

electrician!

31

Loading...

Loading...