Page 1

Owner’s Manual

1-800-880-0993

Wagner Technical Service

1770 Fernbrook Lane, Plymouth, MN 55447

http://www.wagnerspraytech.com

Register your product online at:

Read this manual for complete instructions

This pump is available in a stand model (9145) and cart models (9155,

9175 and 9195). All information given for the stand model applies to the

cart models except where indicated.

Twin Stroke

Piston Pump

Models: 9145

9155

9175

9195

Table of Contents

Safety ................................................................................2-3

Components and Description ........................................4-5

Assembly.............................................................................6

Before You Begin ...............................................................7

Locking the Spray Gun .................................................7

Pressure Relief Procedure ...........................................7

Grounding the Spray Gun ............................................7

Preparing the Sprayer ........................................................8

Preparing the Spray Hose..................................................9

Practice / Spraying Technique ........................................10

Spraying Troubleshooting ..........................................11-12

Unclogging the Spray Tip ........................................... 11

Cleaning the Spray Gun Filter .................................... 12

Cleaning the Inlet Filter ..............................................12

Cleanup ........................................................................13-17

Cleanup for Latex materials ..................................13-14

Cleanup for Oil-based materials .................................15

Cleaning the Suction Set ............................................16

Cleaning the Spray Gun Components ........................17

Short-Term Storage ..........................................................18

Long-Term Storage ..........................................................19

Cleaning the Inlet Valve ...................................................20

Fluid Section .....................................................................21

Troubleshooting / Maintenance ......................................22

Français .............................................................................23

Español..............................................................................45

Parts List ......................................................................67-70

Accessories ......................................................................71

Warranty ............................................................................72

Need Help? Call us rst for answers

Call toll-free if you have any comments or

fast.

problems with this product.

Technical service hours: Monday through Friday, 8:00 am to 4:30 pm Central Time

1208 • Form No. 0523860A

English

Page 2

Important Safety Information · Read all safety information before operating

the equipment. SAVE THESE INSTRUCTIONS.

To reduce the risks of re or explosion, electrical shock and the injury to persons, read and understand all instructions included in

this manual. Be familiar with the controls and proper usage of the equipment.

This symbol indicates a hazardous situation, which, if

not not avoided could result in death or serious injury.

HAZARD: INJECTION INJURY

A high pressure paint stream produced by this equipment

can pierce the skin and underlying tissues, leading to

serious injury and possible amputation. See a physician

immediately.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT!

Injection can lead to amputation. See a physician immediately.

The maximum operating range of the gun is 3000 PSI/207 BAR uid

pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• Do not aim the gun at, or spray any person or animal.

• NEVER allow any part of the body to touch the uid stream. DO

NOT allow body to touch a leak in the uid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the pump off, and release all

pressure before servicing, cleaning the tip or guard, changing

tip, or leaving unattended. Pressure will not be released by

turning off the motor. The PRIME/SPRAY knob must be turned

to PRIME to relieve the pressure. Refer to the Pressure Relief

Procedure (page 7) described in the pump manual.

• ALWAYS keep the tip guard in place while spraying. The tip

guard provides some protection but is mainly a warning device.

• ALWAYS remove the spray tip before ushing or cleaning the

system.

• Paint hose can develop leaks from wear, kinking and abuse. A

leak can inject material into the skin. Inspect the hose before

each use. Do not use hose to lift or pull equipment.

• NEVER use a spray gun without a working trigger lock and

trigger guard in place.

• All accessories must be rated at or above 3000 PSI/207 BAR.

This includes spray tips, guns, extensions, and hose.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is important to

treat the injury as soon as possible. DO NOT delay treatment

to research toxicity. Toxicity is a concern with some coatings

injected directly into the blood stream. Consultation with

a plastic surgeon or reconstructive hand surgeon may be

advisable.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite. Property

damage and/or severe injury can occur.

PREVENTION:

• Provide extensive exhaust and fresh air introduction to keep the

air within the spray area free from accumulation of ammable

vapors. Solvent and paint fumes can explode or ignite.

• Do not spray in a conned area.

• Avoid all ignition sources such as static electric

sparks, open ames, pilot lights, electrical

appliances, and hot objects. Connecting or

disconnecting power cords or working light

switches can make sparks. Paint or solvent

owing through the equipment is able to result in

static electricity.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working order.

• Place pump at least 20 feet (6.1 meters) from the spray object in

a well ventilated area (add more hose if necessary). Flammable

vapors are often heavier than air. Floor area must be extremely

well ventilated. The pump contains arcing parts that emit sparks

and can ignite vapors.

• The equipment and objects in and around the spray area must

be properly grounded to prevent static sparks.

• Keep area clean and free of paint or solvent containers, rags

and other ammable materials.

• Use only conductive or grounded high pressure uid hose. Gun

must be grounded through hose connections.

• Power cord must be connected to a grounded circuit.

• Always ush unit into a separate metal container, at low pump

pressure, with spray tip removed. Hold gun rmly against side

of container to ground container and prevent static sparks.

• Follow the material and solvent manufacturer’s warnings and

instructions. Know the contents of the paints and solvents being

sprayed. Read all Material Safety Data Sheets (MSDS) and

container labels provided with the paints and solvents. Follow

the paint and solvent manufacturer’s safety instructions.

• Use extreme caution when using materials with a ashpoint

below 70ºF (21ºC). Flashpoint is the temperature that a uid

can produce enough vapors to ignite.

• Plastic can cause static sparks. Never hang plastic to enclose

a spray area. Do not use plastic drop cloths when spraying

ammable materials.

• Use lowest possible pressure to ush equipment.

• Do not spray onto pump assembly.

HAZARD: EXPLOSION HAZARD DUE TO

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other materials can

be harmful if inhaled or come in contact with the body.

Vapors can cause severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be inhaled.

Read all instructions supplied with the mask to be

sure it will provide the necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by coating

manufacturer.

2

English

Will cause property damage or severe injury.

PREVENTION:

• Do not use materials containing bleach or chlorine.

• Do not use halogenated hydrocarbon solvents such as bleach,

• Contact your coating supplier about the compatibility of material with

INCOMPATIBLE MATERIALS

mildewcide, methylene chloride and 1,1,1 - trichloroethane. They

are not compatible with aluminum.

aluminum.

Page 3

Important Safety Information · Read all safety information before operating

Cord gauge Maximum cord length

12 200 feet

14 100 feet

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

the equipment. SAVE THESE INSTRUCTIONS.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before operating

equipment.

• Follow all appropriate local, state, and national codes governing

ventilation, re prevention, and operation.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act

(OSHA). These standards, particularly part 1910 of the General

Standards and part 1926 of the Construction Standards should

be consulted.

• Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specications and safety requirements of the pump

manufacturer.

• Before each use, check all hoses for cuts, leaks, abrasion or

bulging of cover. Check for damage or movement of couplings.

Immediately replace the hose if any of these conditions exist.

Never repair a paint hose. Replace it with another grounded

high-pressure hose.

• All hoses and ttings must be secured before operating spray

pump. Unsecured parts can eject at great force or leak a high

pressure uid stream causing severe injury.

• All hoses, swivels, guns, and accessories must be pressure

rated at or above 3000 PSI/207 BAR.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

• Do not operate or spray near children. Keep children away from

the equipment at all times.

• Do not overreach or stand on an unstable support. Keep

effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the inuence of

drugs or alcohol.

NOTE - THE 9145 AND 9155 SERIES UNITS ARE PROVIDED

WITH A NON-RESETABLE THERMAL OVERLOAD. THE

9175 AND 9195 SERIES UNITS ARE PROVIDED WITH A

REPLACEABLE FUSE.

• Always disconnect the motor from the power supply before

working on the equipment.

The cause of the overload should be corrected before

restarting. Take to Service Center.

Grounding Instructions

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect

the green grounding wire to either at blade terminal. The wire with

insulation having a green outer surface with or without yellow stripes is

the grounding wire and must be connected to the grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt

as to whether the product is properly grounded. Do not modify the

plug provided. If the plug will not t the outlet, have the proper outlet

installed by a qualied electrician.

Important Electrical Information

NOTICE - Use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition. When

using an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and overheating. A 14 or 12

gauge cord is recommended (see chart below). If an extension cord

is to be used outdoors, it must be marked with the sufx W-A after the

cord type designation. For example, a designation of SJTW-A would

indicate that the cord would be appropriate for outdoor use.

Do not use more than 100 feet of spray hose. If you need to

spray further than 100 feet from your power source, use more

extension cord, not more spray hose.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make sure that

the product is connected to an outlet having the same conguration as

the plug. No adapter should be used with this product.

If you experience problems with your

sprayer at any time during assembly,

operation, or cleanup, please refer to

the Troubleshooting section of this

manual (page 22), or call customer

service at:

1-800-880-0993

3

English

Page 4

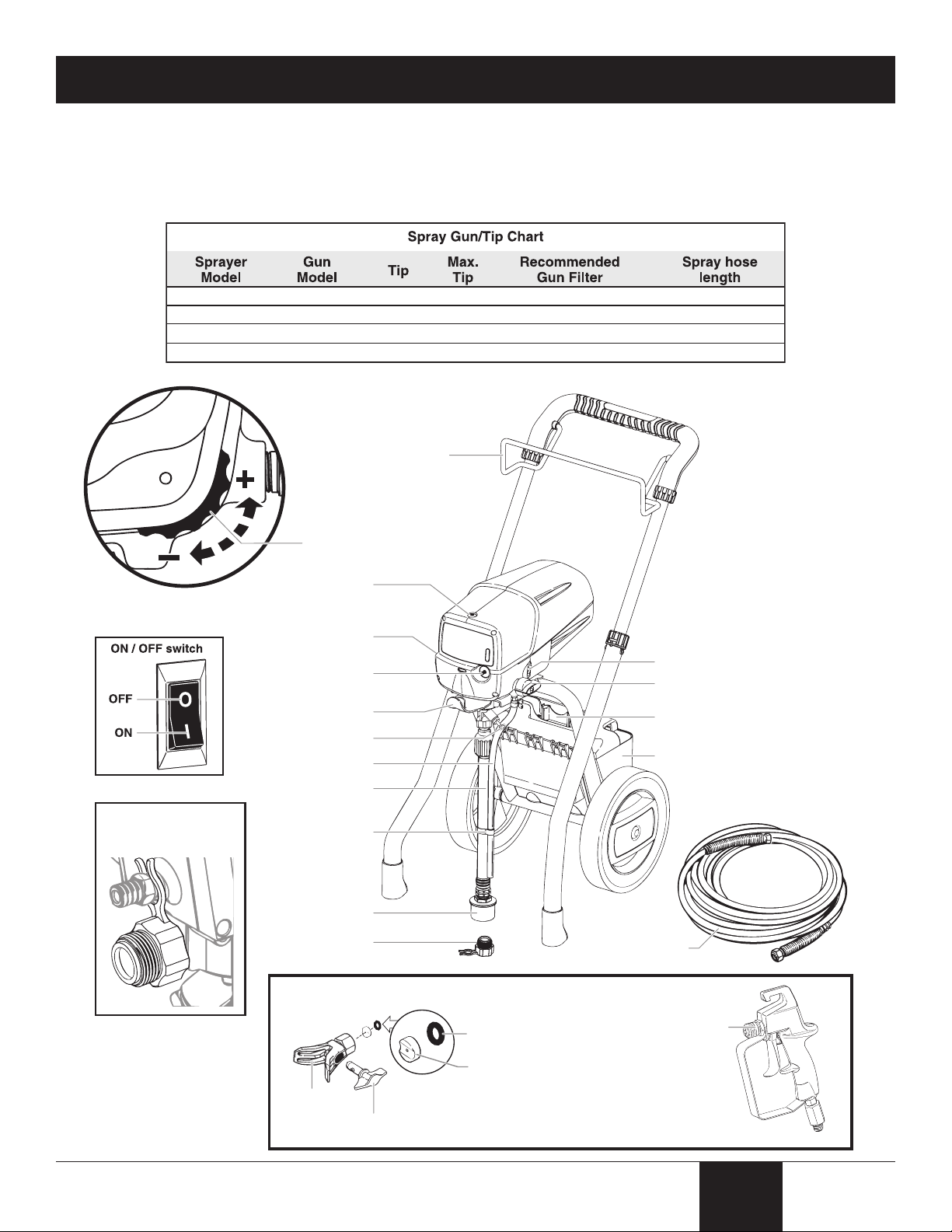

Components and Description

Components Tools Needed for Assembly

The shipping carton for your painting system contains the

following:

• Suction tube and return tube

• Pump cleaning adapter

• Spray gun with lter

• Spray tip assembly (see chart on next page)

• 25’ (9145, 9155) or 50’ (9175, 9195), 1/4” diameter

pressure hose

• Instruction manual

• Two adjustable wrenches

• Extension cord (refer to Important Electrical

Information, page 3).

Controls and Functions

ON/OFF Switch ..............................The ON/OFF switch turns the power to the sprayer on and off (O=OFF, l=ON).

Suction tube ................................... Fluid is drawn through the suction tube into the pump.

Fluid Section .................................. A piston in the uid section moves up and down to create the suction that draws uid through the

suction tube.

Spray Gun ......................................The spray gun controls the delivery of the uid being pumped. The gun model you have depends

on your sprayer model (refer to Spray Gun/Tip Chart, next page).

Spray Hose ..................................... The spray hose connects the gun to the pump.

Return Tube ...................................Fluid is sent back out through the return tube to the original container when PRIME/SPRAY knob is

in PRIME position.

Pump Cleaning Adapter ................ The adapter allows you to attach a garden hose to the suction tube for easy cleanup (latex

materials only).

PRIME/SPRAY Knob ...................... The PRIME/SPRAY knob directs uid to the spray hose when set to SPRAY or the return tube

when set to PRIME. The arrows on the PRIME/SPRAY knob shows the rotation directions for

PRIME and SPRAY.

The PRIME/SPRAY knob is also used to relieve pressure built up in the spray hose (see Pressure

Relief Procedure, page 7).

Pressure Control Dial ................... The pressure control dial regulates the amount of force the pump uses to push the uid.

Oiler ................................................(9155, 9175, and 9195 only) The oiler is designed to provide lubrication to the uid section of the

pump.

Pusher Stem................................... The pusher stem is designed to keep the inlet valve open and from sticking due to dried materials.

Specications

Capacity:

9145 .............. Up to .25 gallon (0.95 liter) / minute

9155 .............. Up to .29 gallon (1.10 liters) / minute

9175 ............. Up to .33 gallon (1.25 liters) / minute

9195 .............. Up to .42 gallon (1.60 liters) / minute

Power source:

9145..............1/2 Hp universal motor

9155..............5/8 Hp universal motor

9175..............3/4 Hp permanent magnet DC motor

9195 .............7/8 Hp permanent magnet DC motor

Power requirement:

15 amp minimum circuit on 115 VAC, 60 Hz current

Generator power requirement:

8000 Watt

Safety features:

Spray gun trigger lock and pressure diffuser; built-in tip

safety guard; PRIME/SPRAY knob for safe pressure

release.

Capability:

Sprays a variety of paints, primers, stains, preservatives

and other nonabrasive materials, including pesticides and

liquid fertilizers.

This pump should not be used with textured materials,

block ller, or asphalt sealer.

4

English

Page 5

Components and Description

Oiler (9155, 9175

and 9195 only)

Spray hose port

(reverse side)

Pail bracket

Oiler button (9155,

9175 and 9195 only)

Pusher stem

Suction set filter

*Pump cleaning

adapter

Spray hose

Suction tube

Return tube

Clip

Hose bracket

PRIME/SPRAY knob

ON / OFF switch

Cord wrap / Tip holder (9155,

9175 and 9195 only)

Toolmate™ Tool box

(9175 and 9195 only)

*The pump cleaning

adapter can be clipped

to the spray hose port

Spray Gun Assembly

Spray gun (see chart above

for models, GX-07 shown)

Spray

guard

Spray tip

Saddle seat**

Washer**

Saddle seat and washer come

pre-assembled inside spray guard

**

Pressure control dial

(rear of sprayer)

9155

9175

9195

GX-07

GX-07

GX-08

415

517

517

517

519

521

Yellow (fine)

9145 GX-05 415 415 Yellow (fine)

White (medium)

White (medium)

25 feet

25 feet

50 feet

50 feet

This pump is available in two models: a stand model (9145) and cart models (9155, 9175 shown below, and 9195). All

information given for the stand model applies to the cart models except where indicated.

NOTICE

Some of the graphics in this manual may not exactly match your sprayer and spray gun. All information and instructions

given in this manual applies to all models except where noted.

5

English

Page 6

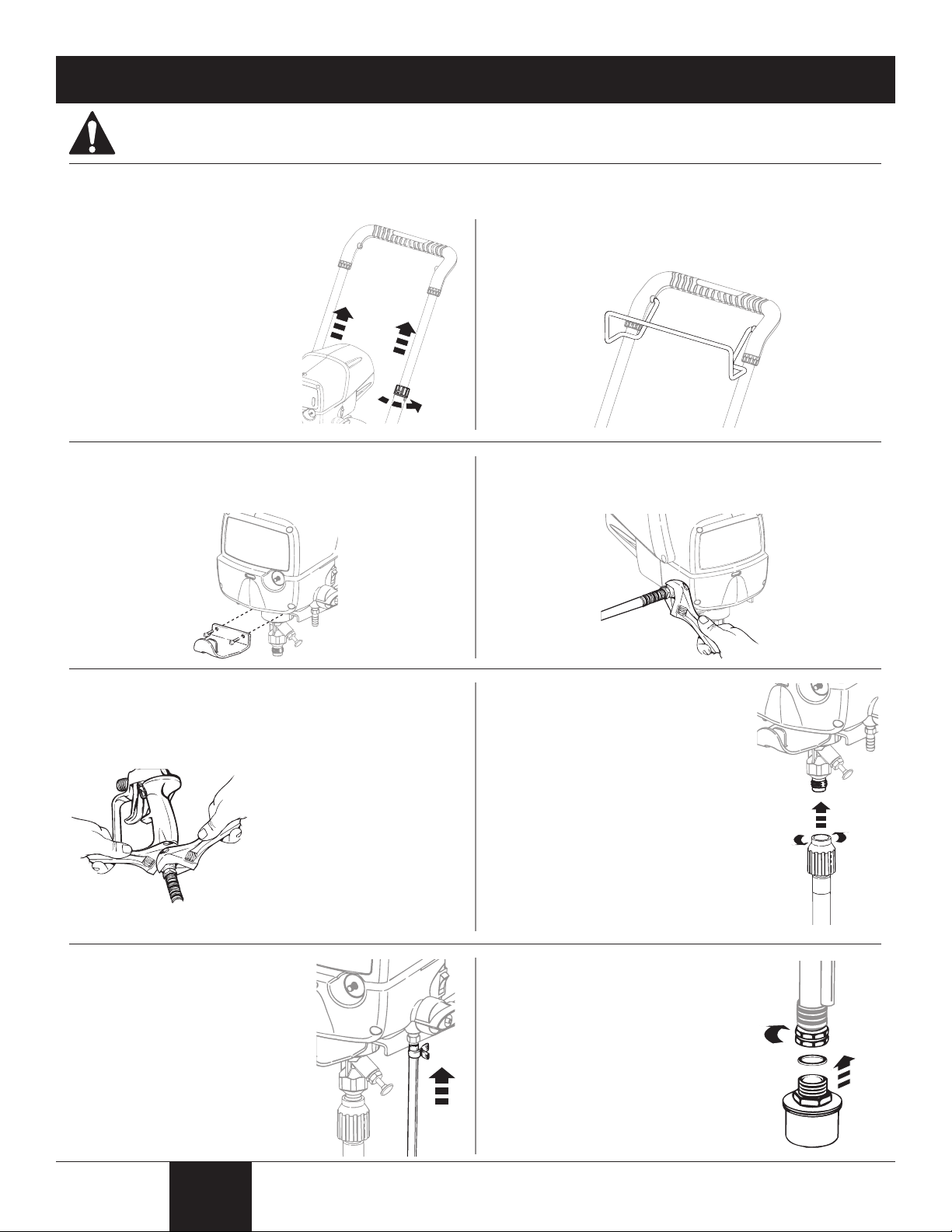

Assembly

Do not plug in the power cord until assembly is complete.

If you have one of the cart models, follow these assembly instructions. If you have the model 9145 sprayer, skip to item 4,

below.

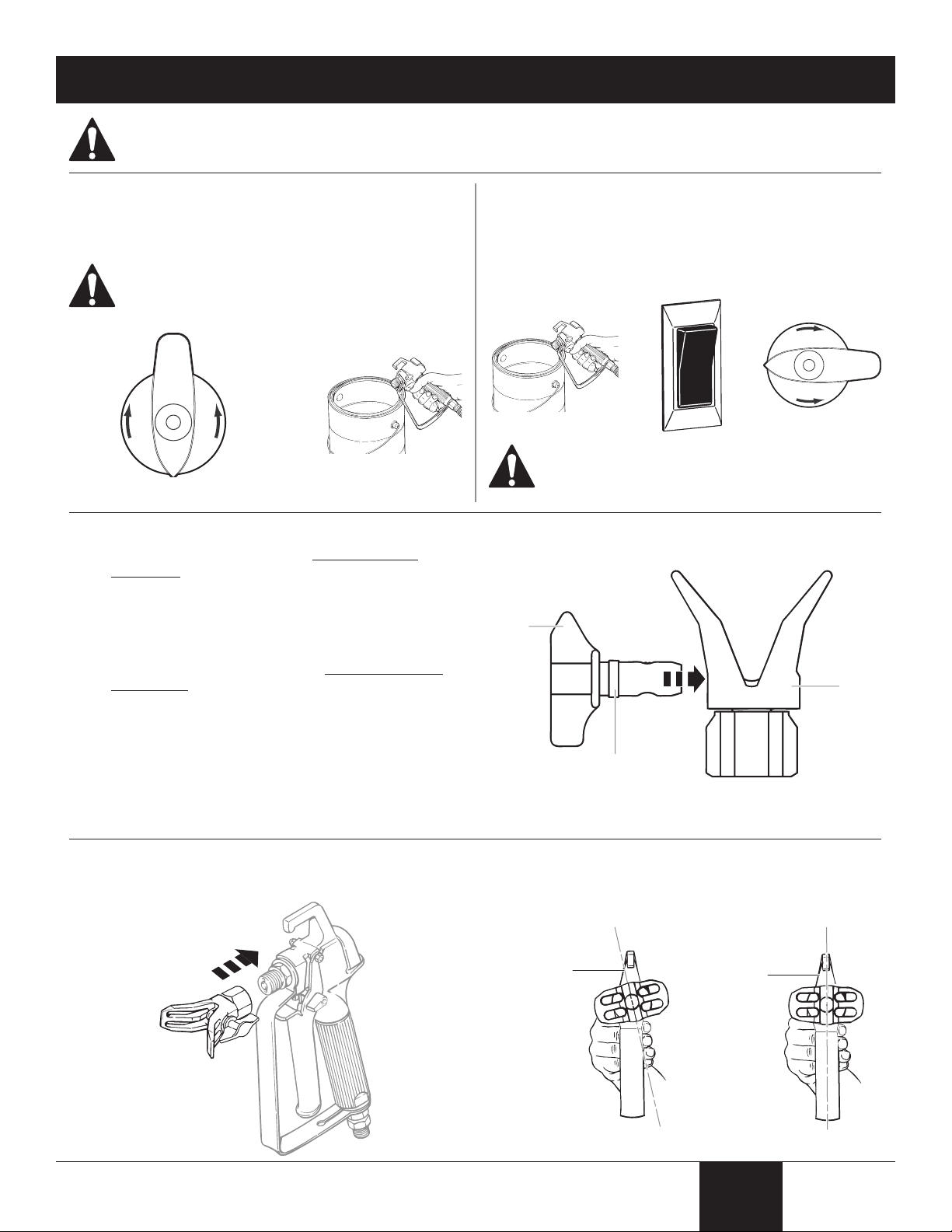

1. Twist the knobs on

either side of the handle

counterclockwise to

unlock the handle. Pull

the handle out fully, and

turn knobs clockwise to

lock into place.

3. Attach the pail bracket. Line up the holes in the bracket

with the holes in the sprayer. Insert and tighten the

screws using a 3/16” allen wrench.

2. Insert the ends of the hose bracket into the holes of the

handle as shown.

4. Thread one end of the high pressure spray hose to

the spray hose port. Hold the port with an adjustable

wrench, and tighten the hose with the other.

5. Thread the other end of the hose to the spray gun. Hold

the gun with one adjustable wrench, and tighten the

hose nut with the other.

The spray tip should not

be attached until after the

sprayer and spray hose have

been purged and primed.

7. Press the return tube onto

the return tube tting.

Squeeze clip over the return

tube tting to secure the

return tube.

6. Thread the suction tube onto the

inlet valve and tighten rmly by

hand. Be sure that the threads

are straight so that the tting

turns freely.

8. Verify that the seal is

present inside the suction

tube. Thread the inlet lter

into the end of the suction

tube.

6

English

Page 7

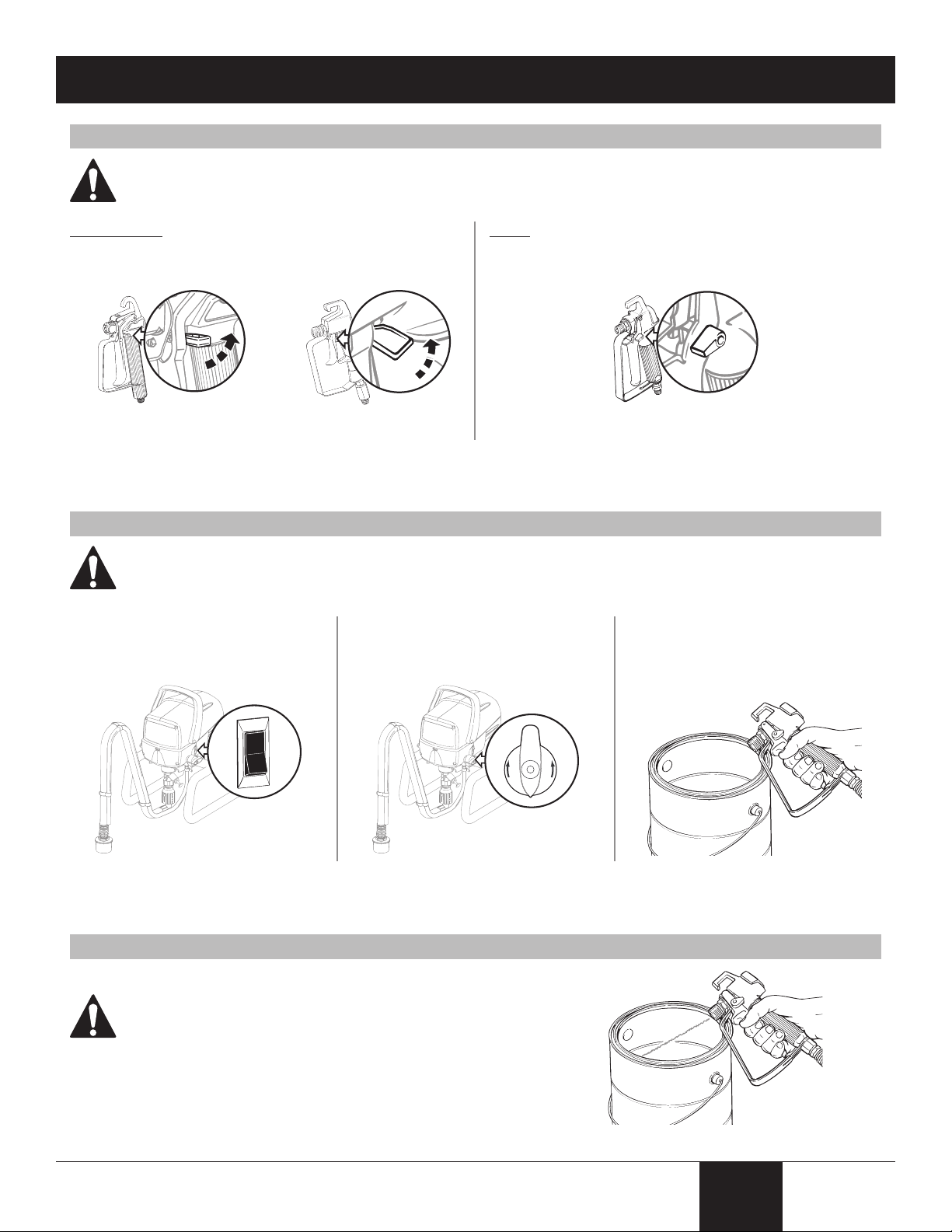

Before you Begin -

GX-05

GX-07

GX-08

O

SPRAY

PRIME

Locking the Spray Gun

Always lock the trigger off when attaching the spray

tip or when the spray gun is not in use.

This section contains instructions that

will be repeated throughout this manual.

GX-05 / GX-07

The gun is locked when the trigger lock is at a 90º angle

(perpendicular to the trigger in either direction).

Pressure Relief Procedure

Be sure to follow the Pressure Relief Procedure when shutting the unit off for

any purpose. This procedure is used to relieve pressure from the spray hose.

1. Lock the spray gun off (see

directions above). Flip the ON/

OFF switch to the OFF position.

2. Turn the PRIME/SPRAY knob to

PRIME.

GX-08

To lock the gun, turn the trigger lock forward and slightly down

until it stops.

3. Unlock the spray gun and trigger

spray gun into the side of the

material bucket. Lock the spray

gun.

Grounding the Spray Gun (oil-based materials only)

If spraying or cleaning with with oil-based materials, the

spray gun must be grounded while preparing the spray

hose or cleaning.

Ground the gun by holding it against the edge of a metal

container while purging. Failure to do so may lead to a

static electric discharge which may cause a fire.

Keep hands clear of the fluid stream.

7

English

Page 8

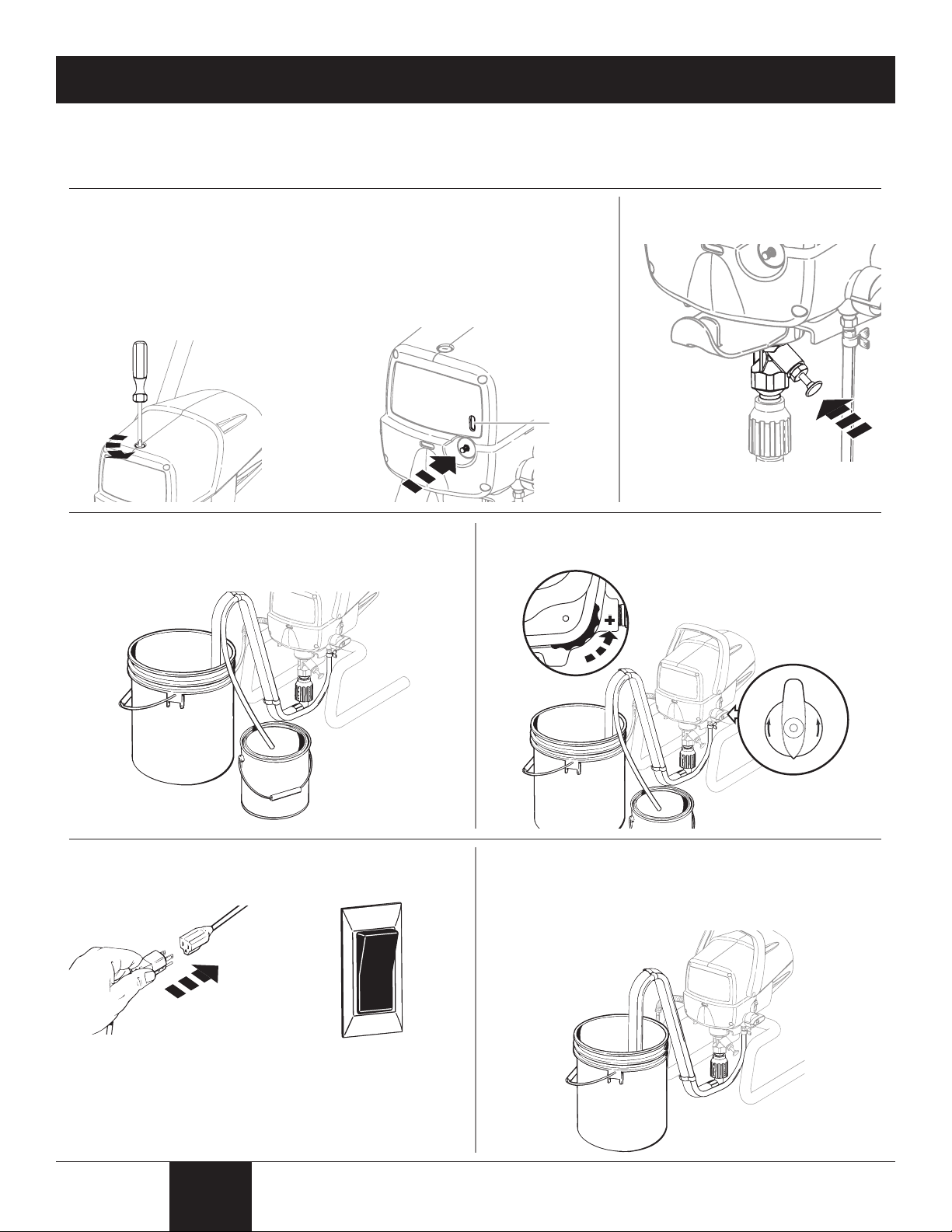

Preparing the Sprayer

(a)

(b)

(a)

l

SPRAY

PRIME

All new units are performance-tested at the factory and are shipped with test uid in the uid section to prevent corrosion

during shipment and storage. If you have already used your pump, some water or solvent used in cleaning may remain

in the uid section. Whether your sprayer is new or if you have already used it, this uid must be purged and thoroughly

cleaned out of the system prior to use. Follow the steps below.

9155, 9175 and 9195 only.

1. Remove oiler cap using a straight-

slot screwdriver. Squirt separating

oil P/N 0516913 supplied with

your sprayer into the oiler

(approximately 1 ounce). Light

household oil can be substituted if

necessary. Replace cap.

4. Place a full container of spraying material underneath

the suction tube (a). Secure the return tube (b) into a

waste container.

2. After lling, push button on front of

face plate 2-5 times to lubricate the

uid section. Press once for every

eight hours of usage. Be sure to

check reservoir level (a) and rell as

necessary.

3. Fully depress the pusher stem to

make sure the inlet ball is free.

5. Turn the pressure control dial to maximum pressure (+).

Turn the PRIME/SPRAY knob to PRIME.

6. Plug in the sprayer and move the ON/OFF switch to the

ON (l) position.

The unit will begin to draw material up the suction tube,

into the pump, and out the return tube. Let the unit cycle

long enough to remove test uid from the pump, or until

spray material is coming from the return tube.

8

English

7. Switch the pump OFF (O). Remove the return tube from

the waste container and place it in its operating position

above the container of spraying material. Use the metal

clip to bind the two hoses together.

Page 9

Preparing the Spray Hose and Spray Gun

(a)

(c)

(b)

SPRAY

PRIME

SPRAY

PRIME

l

Begin

tightening

the tip at

this angle

. . .to achieve

the desired

spray angle

when tight.

The spray tip assembly should not be attached to the spray gun when purging the spray hose. Failure to comply

could result in an injection injury.

1. Unlock the spray gun and turn the PRIME/SPRAY knob

to PRIME.

2. PULL the trigger and aim the spray gun at the side wall

of a waste container.

If using oil-based materials, the spray gun must be

grounded (see Grounding the Spray Gun, page 7).

4. Release trigger and perform the Pressure Relief

Procedure, page 7).

5. Lock the spray gun trigger.

3. While pulling the trigger, switch the pump ON (l), and

turn the PRIME/SPRAY knob to SPRAY. Hold the

trigger until all air, water, or solvent is purged from the

spray hose and material is owing freely.

+ +

Whenever the PRIME/SPRAY knob is still on

SPRAY, there will be high pressure in the hose

and spray gun until the PRIME/SPRAY knob is

turned to PRIME.

6. Make sure the saddle seat and black seal are in

place inside the tip guard nut (see Components and

Description, page 5).

7. Insert spray tip (a) into the side of the spray guard (b).

The pointed end (c) of the spray tip should be facing

forward as shown.

8. Thread the spray tip guard assembly onto the gun.

Tighten by hand.

9

English

Page 10

Practice / Spraying Technique

Good spray pattern

Paint tailing pattern

(pressure too low,

clogged tip)

Heavy CoatLight Coat Light Coat

Approximately

10 to 12 inches

Right way

Wrong way

Approximately

10 to 12 inches

Keep stroke

even

Start

stroke

End

stroke

Pull

trigger

Release

trigger

Move

steadily

l

SPRAY

PRIME

IMPORTANT: Be sure that the paint hose is free of kinks and clear of objects with sharp cutting edges.

1. Switch the pump ON (l). Turn the PRIME/SPRAY knob

to SPRAY. Turn the pressure control dial to maximum

pressure (+). The spray hose should stiffen as paint

begins to ow through it.

The key to a good job is an even coating over the entire surface.

This is done by using even strokes. Follow the TIPS, below.

Tip:

Keep the spray gun at right angles to the

surface. This means moving your entire

arm back and forth rather than just exing

your wrist.

2. When motor shuts off, unlock the spray gun and spray a

test area to check the spray pattern.

The motor will cycle on and off automatically as it needs

pressure.

The pressure control dial can be be adjusted up or down

to achieve the desired spray pattern.

Tip:

Keep the spray gun perpendicular to the

surface, otherwise one end of the pattern

will be thicker than the other.

Tip:

Trigger gun after starting the stroke.

Release the trigger before ending the

stroke. The spray gun should be moving

when the trigger is pulled and released.

Overlap each stroke by about 30%. This

If you expect to be away from your sprayer for

more than one hour, follow the Short-Term Storage

instructions (page 18).

10

will ensure an even coating.

English

Page 11

GX-05 / GX-07

GX-08

CLEAN

Spraying Troubleshooting - Unclogging the Spray Tip

SPRAY

GX-08

GX-05 / GX-07

SPRAY

PRIME

If the spray pattern becomes distorted or stops completely while the gun is triggered, follow these steps.

Do not attempt to unclog or clean the tip with your

finger. High pressure fluid can cause injection injury.

IMPORTANT: Do not use a needle or other sharp pointed

instrument to clean the tip. The hard tungsten carbide can chip.

Trigger locked

1. Release the trigger and lock the trigger off (see

page 7). Rotate the reversible tip arrow 180º so

that the point of the arrow is toward the rear of

the gun (CLEAN position).

Under pressure, the spray tip may be very

difcult to turn. Turn the PRIME/SPRAY knob

to PRIME and trigger the gun. This will relieve

pressure and the tip will turn more easily.

(see page 7)

2. Turn the PRIME/SPRAY knob to SPRAY.

3. Unlock the trigger and squeeze the trigger, pointing the

gun at a scrap piece of wood or cardboard. This allows

pressure in the spray hose to blow out the obstruction.

When the nozzle is clean, material will come out in a

straight, high pressure stream.

If material still will not spray from the spray tip,

follow the Cleaning the spray gun lter instructions,

page 12.

4. Release the trigger and lock the trigger off (see

page 7). Reverse the tip so the arrow points

forward again (SPRAY position). Unlock the gun

and resume spraying.

Trigger locked

(see page 7)

11

English

Page 12

Spraying Troubleshooting - Cleaning the Spray Gun Filter

Ta pered

end

(filter top)

Hole

Spray gun model

GX-07

Spring

Filter

Ta pered

end

(filter top)

Hole

Spray gun models

GX-05 and GX-08

Filter

housing

Trigger

guard

Filter

Fitting

The lter must be cleaned every time you use your sprayer. When using thicker spray materials, the lter might need to

be cleaned more often.

1. Perform Pressure Relief Procedure, page 7.

2a. Model GX-07 - Unscrew the tting from the bottom of

the spray gun using an adjustable wrench, making sure

not to lose the spring.

2b. Models GX-05 and GX-08 - Unclip the trigger guard

from the lter housing by pulling outward from the lter

housing. Unscrew the lter housing.

3. Remove the lter from the spray gun housing and clean

with the appropriate cleaning solution (warm, soapy

water for latex paints, mineral spirits for oil-based

materials).

4. Inspect the lter for holes (see inset, right). Replace if

holes are found.

NOTE - NEVER POKE THE FILTER WITH A SHARP

INSTRUMENT!

5. Replace the cleaned lter, tapered end rst, into the

gun housing. The tapered end of the lter must be

loaded properly into the gun. Improper assembly

will result in a plugged tip or no ow from the gun.

6. Reassemble the spray gun.

Spraying Troubleshooting - Cleaning the Inlet Filter

The screen at the bottom of the suction tube may also need cleaning. Check it every time you change spray containers.

1. Remove the lter by unscrewing it from the suction tube.

Clean the lter with the appropriate cleaning solution

(warm, soapy water for latex materials, mineral spirits for

oil-based materials).

2. Thread the lter back into place.

If after completing all of the steps in Spraying

Troubleshooting you are still experiencing problems

spraying, refer to the Troubleshooting section (page 22).

12

English

Page 13

Cleanup

(b)

(c)

(d)

(a)

Important Cleaning Notes - Read before cleaning

• When using latex materials, clean your sprayer and

components with water. When using oil-based materials, use

mineral spirits. DO NOT use gasoline to clean your sprayer.

• Do not use mineral spirits on latex materials, or the mixture

will turn into a jelly-like substance which is difcult to remove.

• No matter which cleaning solution you use, make sure to

dispose of it properly when nished cleaning your sprayer.

• Thorough cleaning and lubrication of the sprayer is the most

important step you can take to ensure proper operation after

storage.

Call 1-800-880-0993 if you have any problems or questions regarding the cleaning of your sprayer.

Follow these steps if you used latex materials and if you have a garden hose available. If you do not have a garden hose

available, follow the Cleanup - Oil-Based Materials instructions.

1. Lock the gun and remove the spray tip assembly. Place

the suction tube and return tube into an empty waste

container.

2. Using a garden hose, rinse off the suction tube, return

• Always ush spray gun at least one hose

• If collecting ushed solvents in one gallon

• Area must be free from vapors.

• Follow all cleanup instructions.

• DO NOT use gasoline to clean your sprayer.

tube and inlet lter. Empty the waste container.

Follow these steps whenever cleaning with

mineral spirits:

length away from spray pump.

metal container, place it into an empty ve

gallon container, then ush.

Empty waste

container

3. Remove the inlet lter from the suction tube and place

into the waste container.

13

4. Verify that the seals

are present inside the

adapter and suction

tube (a). Thread the

pump cleaning adapter

(b) onto a garden hose

(c). Connect hose and

adapter to the tting on

the end of the suction

tube (d).

Continued on next page.

English

Page 14

Cleanup - Latex materials (continued)

SPRAY

PRIME

Waste

container

Containers should

be touching

Original

material

container

Hold trigger

Hold trigger

Spray material

into original container

Spray water into

waste container

SPRAY

PRIME

5. Unclip the return tube from the suction tube and place it

into the waste container. Turn the PRIME/SPRAY knob

to PRIME.

7. Place the original material container next to the waste

container. Aim the spray gun into the side of the

original material container and hold the trigger.

6. Turn water supply on. Turn pump ON (l). Water will go

into the suction tube and out through the return tube.

Let pump run for a few minutes to allow the return tube

to be ushed.

Leave pump running

through steps 7 and 8.

8. While pulling the trigger, turn the PRIME/SPRAY knob

to SPRAY to purge material from the hose back into the

original container.

9. When cleaning solution ows from the spray gun, keep

10. Trigger the gun until the uid owing out of the gun is

11. Turn the PRIME/SPRAY knob to PRIME and trigger gun

Move on to Cleaning the Spray Gun Components.

14

holding the trigger and aim the spray gun into the side of

the waste container.

clear. You may need to empty the waste container and

continue ushing.

to relieve pressure.

English

Keep holding trigger through next steps.

Page 15

Cleanup - oil-based materials

Spray material into

original container

Spray cleaning solution

into waste container

Hold trigger

Containers should

be touching

Original

material

container

Hold trigger

Waste

container

1. Lock the gun and remove spray tip assembly.

Submerge suction set into a bucket with appropriate

cleaning solution.

Bucket with

cleaning solution

3. While pulling the gun trigger, turn the pump ON (l),

and turn the PRIME/SPRAY knob to SPRAY to purge

material from the hose back into the original container.

2. Place a waste container next to the original material

container. Aim the spray gun into the side of the

original material container and hold the trigger.

• Hold trigger

• Turn pump ON (l)

• Turn PRIME/SPRAY knob to SPRAY

Keep holding trigger through next steps.

4. When cleaning solution ows from the spray gun, keep

holding the trigger and aim the spray gun into the side

of the waste container (ground gun with a metal

container if ushing with ammable solvent).

5. Trigger the gun until the uid owing out of the gun

is clear. You may need to dispose and obtain new

cleaning solution.

6. Turn the PRIME/SPRAY knob to PRIME and trigger gun

once to relieve pressure.

Move on to Cleaning the Suction Set.

15

English

Page 16

Cleaning the Suction Set

SPRAY

PRIME

GX-05

GX-08

GX-07

l

O

(a)

1. Lock the gun and turn the pump OFF (O).

3. When suction set is clean, thread the suction tube back

into the inlet valve, and replace the return tube onto the

return tube tting. Replace clip.

2. Remove the suction hose and return tube and clean it

using the appropriate cleaning solution. You should also

wipe the threads of the inlet nut (a) and remove and

clean the inlet lter.

4. Submerge the suction set into a bucket of new cleaning

solution.

5. Turn the PRIME/SPRAY knob to PRIME. Turn the pump

ON (l), and trigger the gun once into a waste container

to relieve pressure.

16

English

6. Let the pump circlulate cleaning solution through the

suction set for 2-3 minutes. Turn the pump OFF.

2 to 3 minutes

IMPORTANT!

If you used oil-based materials, you must ush the pump

again using water to prepare it for storage. Repeat #1 #11 in Cleanup- Latex materials, instructions.

Move on to Cleaning the Spray Gun Components.

Page 17

Cleaning the Spray Gun Components

O

SPRAY

PRIME

GX-07GX-05

GX-08

GX-07GX-05

GX-08

(b)

(c)

(a)

(b)

(c)

(a)

1. Make sure the pump is switched OFF (O). Make sure

the PRIME/SPRAY knob is turned to PRIME. Unplug

the sprayer.

3. Remove lter from spray gun (refer to Cleaning the

Spray Gun Filter, page 12).

2. Remove spray gun from the paint hose using adjustable

wrenches.

4. Remove spray tip (a) from spray guard assembly. Clean

spray tip with a soft-bristled brush and the appropriate

cleaning solution. Be sure to remove and clean the

washer (b) and saddle seat (c) located in the rear of the

spray tip assembly.

5. Install gun lter tapered-end rst. Reassemble spray

gun.

7. Thread the spray gun back onto the paint hose. Tighten

with a wrench.

17

6. Install spray tip (a), saddle seat (c) and washer (b), and

replace spray guard assembly.

English

Page 18

Short-Term Storage (up to 16 hours)

SPRAY

PRIME

SPRAY

PRIME

O

l

GX-05

GX-07

GX-08

Follow these steps when using latex materials only. If using materials that are oil-based, follow the Cleanup and LongTerm Storage steps.

Title

Shutdown

1. Lock the spray gun off.

2. Turn the PRIME/SPRAY knob to PRIME. Switch the

pump OFF (O). Unplug the sprayer.

Startup

1. Remove the gun from the plastic bag. Stir the water into

the paint.

3. Pour 1/2 cup water slowly on the top of the paint to

prevent the paint from drying. Wrap the spray gun

assembly in a damp cloth and place it in a plastic bag.

Seal the bag shut. Place the sprayer in a safe place out

of the sun for short-term storage.

2. Turn the PRIME/SPRAY knob to PRIME. Plug sprayer

in. Turn the switch to ON (I).

3. Turn the PRIME/SPRAY knob to SPRAY. Test the

sprayer on a practice piece and begin spraying.

18

English

Page 19

Long-Term Storage

Follow these instructions only after all cleanup steps have been performed.

1. Fill a cup or other container with two ounces of

separating oil (P/N 0516913, sold separately) and

submerge the inlet valve into the oil. Light household oil

can be substituted.

Separating oil

2. Place a rag over the spray hose port, and turn the switch

ON (l). When the oil has been pumped from the cup,

turn the pump OFF (O).

3. Wipe the entire unit, hose and gun with a damp cloth to

remove accumulated paint. Replace the high pressure

hose to the paint hose port.

If you have a cart model (9155, 9175 or 9195), you can collapse the cart handle for easier storage.

1. Twist the knobs on either side

of the cart counterclockwise.

2. Slide the handle into the cart.

19

English

Page 20

Cleaning the Inlet Valve

(a)

(b)

Cleaning or servicing the inlet valve may be required if the unit has priming problems. Priming problems may be

prevented by properly cleaning the sprayer and following the long-term storage steps.

1. Remove the suction set.

3. Lubricate the O-ring on the inlet valve (b). Replace inlet

valve assembly by screwing it into the sprayer. Torque

to 23-27 ft lbs (9145, 9155) or 32-38 ft lbs (9175. 9195).

2. Unscrew the inlet valve assembly (a) from the sprayer.

Visually inspect the inside and outside of the inlet valve

assembly. Clean any paint residue with the appropriate

cleaning solution.

4. Replace suction set and hand-tighten.

If priming problems persist, you may need to replace the

inlet valve assembly. Call Technical Service (1-800-880-

0993) to order new inlet valve assembly.

20

English

Page 21

Fluid Section Seal Replacement Instructions

Insertion

tool

0512221 kit

(9145, 9155)

0512178 kit

(9175, 9195)

0512178 kit

(9175, 9195)

Top seal

(cup

down)

Top nut

0512221 kit

(9145, 9155)

Piston/seal

assembly

O-ring

NOTE - DO NOT attempt

to remove the seals from

the piston.

Inlet valve assembly

Dowel

Yoke

Screw

Washer

Kit Part Number 0512221A (9145 and 9155) Kit Part Number 0516724 (9175 and 9195)

Always wear protective eye wear while servicing the pump. Be sure to follow the Pressure Relief Procedure

(page 7) when shutting the unit down for any purpose, including servicing or adjusting. After performing

the Pressure Relief Procedure, be sure to unplug the unit before servicing or adjusting. Area must be free of

solvents and paint fumes.

Disassembly of the Fluid Section

1. Remove the suction set.

2. Remove the front cover and the four screws that secure it

using a T20 Torx head driver.

3. Remove the yoke screw and washer that secures the

dowel pin. The dowel pin connects the yoke to the piston.

4. Using a pliers, pull the dowel pin out.

5a. For models 9145 and 9155, rotate the pump shaft so the

piston is in the top dead center position. This can be done

by pushing on the yoke. This is required to disassemble

all the parts.

5b. For models 9175 and 9195, inspect the yoke assembly

and piston. In order to remove all the necessary parts, the

piston must not be in the bottom dead center position. If

the piston is at the bottom of the stroke, install the front

cover and screws, turn the pump on briey to index the

piston, unplug the unit, and repeat step 2.

6. Unscrew and remove the inlet valve assembly (see page

20).

7. Remove the piston assembly by pushing down on the

piston near the yoke.

8. Unscrew and remove the top nut using and adjustable

wrench.

9. Remove the worn seals using a at head screwdriver or

punch. Remove the top seal from the top and the bottom

seal from the bottom by pressing against the side of

the seal and popping it out. Be sure not to scratch the

housing where the seals are located.

10. Clean the area where the new seals are to be installed.

the bottom (inlet) of the housing, and tighten with an

adjustable wrench. This will drive the bottom seal into the

correct position.

5. Align the piston with the yoke. Be careful not to damage

the piston.

6. Apply any type of household grease to the piston and yoke

area to prolong life. Apply to the holes in the yoke where

the dowel is inserted.

7. Install the dowel pin to connect the yoke to the piston.

The piston may have to be moved up or down to do this.

8. Install the yoke screw and washer to secure the dowel pin.

9. Turn pump right side up and apply a few drops of

Separating Oil or light household oil between the top nut

and piston. This will prolong the seal life.

10. Install front cover and four (4) screws.

11. Replace inlet valve. Install the suction set.

Assembly of the Fluid Section

1. Lubricate the new top seal with Separating Oil (P/N

0516913, sold separately) or light household oil and by

hand place the seal (cup side of seal down) into the top

port of the housing.

2. Place a small amount of anit-seize on the threads of the

top nut. Place the top nut into the top of the housing and

tighten with an adjustable wrench. This will drive the top

seal into the correct position.

3. Turn the pump upside down.

Lubricate the seal on the piston/

seal assembly similar to the

top seal. Place the piston/seal

assembly into the bottom of the

housing. Insert the plastic insertion

tool and thread into position to

properly seat the piston/seal.

Thread fully until tight. Remove the

insertion tool.

4. Install the new O-ring on the inlet valve assembly,

lubricate with Separating Oil (P/N 0516913), thread into

21

English

Page 22

Troubleshooting / Maintenance

Title

Before servicing, always release system pressure by

following Pressure Relief Procedure (page 7).

Problem

A. The sprayer does not start.

B. The sprayer starts but does

not draw in paint when the

PRIME/SPRAY knob is set to

PRIME.

C. The sprayer draws up paint

but the pressure drops when

the gun is triggered.

D. The PRIME/SPRAY valve is

on SPRAY and there is ow

through the return tube.

E. The spray gun leaks.

Cause

1. The sprayer is not plugged in.

2. The ON/OFF switch is set to OFF.

3. The sprayer was turned off while still under

pressure.

4. No voltage is coming from the wall plug.

5. The extension cord is damaged or has too

low a capacity.

6. A fuse is blown in the sprayer.

7. There is a problem with the motor.

1. The paint bucket is empty or the suction

tube is not totally immersed in the paint.

2. The suction set is clogged.

3. The suction tube is loose at the inlet valve.

4. The inlet valve is stuck.

5. The outlet valve is stuck.

6. The inlet valve is worn or damaged.

7. The PRIME/SPRAY valve is plugged.

1. The spray tip is worn.

2. The suction set screen is clogged.

3. The gun lter is plugged.

4. The paint is too heavy or coarse.

5. The inlet valve assembly is damaged or

worn.

6. The suction tube is loose.

1. The PRIME/SPRAY valve is dirty or worn.

1. Internal parts of the gun are worn or dirty.

Solution

1. Plug the sprayer in.

2. Turn the ON/OFF switch to ON.

3. Turn the pressure control knob to maximum pressure

(+), or relieve pressure by turning the PRIME/

SPRAY valve to PRIME.

4. Properly test the power supply voltage.

5. Replace the extension cord.

6. Take sprayer to Authorized Service Center.

7. Take sprayer to Authorized Service Center.

1. Rell the bucket or immerse the suction tube in paint.

2. Clean the suction set.

3. Clean the tube connection and tighten it securely.

4. Clean the inlet valve. Inlet may be stuck from old

paint. Depress pusher stem to release.

5. Outlet may be stuck from old paint. Remove inlet

valve. Insert pen or pencil in housing to release.

6. Replace the inlet valve.*

7. Take sprayer to Authorized Service Center.

1. Replace the spray tip with a new tip.**

2. Clean the suction set screen.

3. Clean or replace the proper lter. Always keep extra

lters on hand.

4. Thin or strain the paint.

5. Replace the inlet valve.*

6. Tighten the suction tube.

1. Take sprayer to Authorized Service Center.

1. Take the sprayer to a Authorized Service Center.

F. The tip guard assembly leaks.

G. The spray gun will not spray.

H. The paint pattern is tailing.

1. The tip was assembled incorrectly.

2. The washer is worn.

1. The spray tip or the gun lter is plugged.

2. The spray tip is not fully in the SPRAY

position.

1. The pressure is set too low.

2. The gun or the suction lter is plugged.

3. The suction tube is loose at the inlet valve.

4. The tip is worn.

5. The paint is too thick.

6. Pressure loss.

1. Check the tip assembly and assemble properly (see

page 17).

2. Replace the washer.* (see page 17)

1. Clean the spray tip or gun lter.

2. Put the tip in the SPRAY position.

1. Increase the pressure.

2. Clean the lters.

3. Tighten the suction tube tting.

4. Replace the spray tip.

5. Thin the paint.

6. Refer to Causes and Solutions for problem C.

* Special repair kits with instructions are available for these procedures. Refer to the Maintenance section of this manual for a list

of the kits and their part numbers.

** Additional parts are available for this procedure. Refer to the Accessories (page 71) section of this manual for a list of the parts

and their part numbers.

Daily Maintenance

The only daily maintenance necessary is thorough cleaning and lubricating

after usage. Follow the cleaning and lubricating procedures in this manual.

Extended Maintenance

Some pump parts eventually wear out from use and must be replaced. The

following list indicates the available repair kits for the parts replaced by each kit.

However, pump performance is the only reliable indicator of when to replace

wear parts. Refer to the Troubleshooting section for more information on

when to use these kits.

Kit Part # Description

0512221 Fluid Section Seal Kit (9145, 9155)

0512178 Fluid Section Seal Kit (9175, 9195)

0516292 Inlet valve kit (9145, 9155)

0516296 Inlet valve kit (9175, 9195)

22

English

Page 23

TitleParts List • Liste de pièces • Lista de piezas

5

12

6

4

3

1

23

4

5

6

Title

Model GX-05 spray gun (9145)

Modèle du pistolet GX-05 (9145)

Modelo de pistola GX-05 (9145)

Model GX-07 spray gun (9155, 9175)

Modèle du pistolet GX-07 (9155, 9175)

Modelo de pistola GX-07 (9155, 9175)

GX-05

Item

Article

Articulo

1 0501011 Guard assembly Protège-embout et ses composants Ensamblaje de protección 1

2 0501415 Spray tip, 415 Embout de pulvérisation, 415 Boquilla de rociadora, 415 1

3 0523954 Complete gun assembly (no swivel) Pistolet et ses composants (sans

4 0154675 Filter (yellow)* Filtre (jaune)* Filtro (amarillo)*

5 0515332 Seal Joint d’étanchéité Sello 1

6 0515329 Filter housing Logement de ltre Alojamiento de ltro 1

Part No.

Nº de piéce

Pieza No.

English

Description

Français

Description

pivot)

Español

Descripción

Ensamblaje de la pistola (no

oscilador)

Quantity

Quantite

Cantidad

1

GX-07

Item

Article

Articulo

1 0512127 Complete gun assembly (9155) Pistolet et ses composants (9155) Ensamblaje de la pistola (9155) 1

1 0501011 Guard assembly Protège-embout et ses composants Ensamblaje de protección 1

2 0501415 Spray tip, 415 Embout de pulvérisation, 415 Boquilla de rociadora, 415 1

4 0515220 Filter (yellow, 9155)* Filtre (jaune, 9155)* Filtro (amarillo, 9155)*

5 0515330 Spring Ressort Resorte 1

6 0278257 Cap, lter housing Capuchon, logement de ltre Tapa, Alojamiento de ltro 1

* 2-pack replacement kit

* Emballage de 2 pour rechange

* Ensamblaje de 2 para el reemplazo

67

67

Part No.

Nº de piéce

Pieza No.

0501004 Complete gun assembly (9175) Pistolet et ses composants (9175) Ensamblaje de la pistola (9175) 1

0515252 Filter (white, 9175)* Filtre (blanc, 9175)* Filtro (blanco, 9175)*

English

Description

Français

Description

Español

Descripción

Español Français English

Quantity

Quantite

Cantidad

Page 24

Parts List • Liste de pièces • Lista de piezas

8

7

6

5

4

3

2

1

10

11

12

13

14

15

16

17

18

9

Model GX-08 spray gun (9195)

Modèle du pistolet GX-08 (9195)

Modelo de pistola GX-08 (9195)

Title

Item

Article

Articulo

1 0501517 Tip, 517 Embout, 517 Boquilla, 517 1

2 0501011 Guard assembly Protège-embout Ensamblaje de la protección 1

3 0296404 Diffuser, 7/8” Pistolet et ses composants Difusor 7/8” 1

4 0296270 Valve spring unit Ressort de soupape Unidad del resorte de la válvula 1

5 0296230 Trigger guard Protège-doigts Protector del gatillo 1

6 0296285 Trigger assembly Détente et ses composants Ensemble del gatillo 1

7 580-513 Trigger screw (short) Vis de détente (courte) Tornillo del gatillo (corto) 1

8 0296228 Gun housing Corps du pistolet Alojamiento de la pistola 1

9 9910201 Hex nut Écrou hexagonal Tuerca hexagonal 1

10 0296222 Retainer block Bloc de retenue Bloque de retención 1

11 580-025 Sliding pin Cheville coulissante Pasador deslizante 2

12 580-512 Trigger screw (long) Vis de détente (longtemps) Tornillo del gatillo (de largo) 1

13 0515252 Filter (white)* Filtre (blanc)* Filtro (blanco)* 1

14 0296289 Washer Rondelle Arandela 1

15 0296342 Handle Poignée Mango 1

16 0296343 Spring Ressort Resorte 1

17 9970123 Sealing ring Bague d’étanchéité Aro sellador 1

18 0296301 Fitting Raccord Ensamblaje del collarín 1

Part No.

Nº de piéce

Pieza No.

English

Description

Français

Description

Español

Descripción

Quantity

Quantite

Cantidad

68

EspañolFrançaisEnglish

Page 25

Parts List • Liste de pièces • Lista de piezas

1

2

3

4

5

7

6

Suction Set

Dispositif d’aspiration

Juego de succión

Item

Article

Articulo

1 0516197 Suction set (9145) Dispositif d’aspiration (9145) Juego de succión (9145) 1

2 0512389 Return tube (9155, 9175, 9195) Tube de retour (9155, 9175, 9195) Tubo de retorno (9155, 9175, 9195) 1

3 0512390 Clip Agrafe Abrazadera 1

4 0516697 Filter Filtre Filtro

5 0327226 Squeeze clip Agrafe de compression Abrazadera del apretón 1

6 9885553 Return tube tting Raccord de tube de retour Conector del tubo de retorno 1

7 0515146 Pump cleaning adapter Adaptateur de nettoyage de pompe Adaptador de limpieza de bomba 1

Part No.

Nº de piéce

Pieza No.

0516196 Suction set (9155, 9175, 9195) Dispositif d’aspiration (9155, 9175,

English

Description

Français

Description

9195)

Español

Descripción

Juego de succión (9155, 9175, 9195) 1

Quantity

Quantite

Cantidad

69

Español Français English

Page 26

TitleParts List • Liste de pièces • Lista de piezas

1

4

2

3

5

Title

Item

Article

Articulo

1 0516772 Stand assembly (9145 only) Support et ses composants (9145

2 0523320 Hose bracket Support de exible Soporte de manguera 1

3 0523207A Cart assembly (9155) Chariot et ses composants (9155) Ensamblaje de carrito (9155) 1

4 0516581 Oiler cap Bouchon de graisseure Tapa de lubricador 1

5 0523322 Pail bracket assembly Ensamble de support du seau Ensamblaje de soporte para el bote 1

Part No.

Nº de piéce

Pieza No.

0523206A Cart assembly (9175) Chariot et ses composants (9175) Ensamblaje de carrito (9175) 1

0523205A Cart assembly (9195) Chariot et ses composants (9195) Ensamblaje de carrito (9195)

English

Description

Français

Description

seulement)

Español

Descripción

Ensamblaje de soporte (9145

solamente)

Quantity

Quantite

Cantidad

1

70

EspañolFrançaisEnglish

Page 27

TitleAccessories • Accessoires • Accesorios

Title

Item

Article

Articulo

0516913 Separating oil Huile séparatrice Lubricante de empaques

0270192 Hose, Wireless, 25’ x 1/4" Flexible, 7,6 m x 0,6 cm Manguera 25’ x 1/4"

0270118 Hose, Wireless, 50’ x 1/4" Flexible, 15,2 m x 0,6 cm Manguera 50’ x 1/4"

0093896 Hose Connector, 1/4” x 1/4” Raccord de exible, 0,6 cm2 Conector de manguera, 1/4" x 1/4"

0088154 Pressure Gauge (0-5000 psi) Manomètre (0-5000 psi) Manómetro (0-5000 psi)

0512130 Tip Extension, 12” Rallonge d’embout, 30,5 cm Extensión de la boquilla, 12"

0512131 Tip Extension, 24” Rallonge d’embout, 61,0 cm Extensión de la boquilla, 24"

0515902 Power Roller Gun Attachment Rouleau électrique, accessoire pour pistolets Aditamento de la pistola del rodillo automático

0155206 9" Roller Cover, 3/8” Nap Manchon de rouleau de 22,9 cm, grain de 1,0 cm Funda del rodillo 9", pelillo de 3/8"

0155208 9" Roller Cover, 3/4” Nap Manchon de rouleau de 22,9 cm, grain de 1,9 cm Funda del rodillo 9", pelillo de 3/4"

0501002 GX-08 Four Finger Airless Spray Gun Pistolet sans air à détente allongée - métal

0501004 GX-07 Two Finger Airless Spray Gun Pistolet sans air à détente courte- métal (GX-07) Pistola rociadora sin aire del dos dedos GX-07

0523954 GX-05 Airless Spray Gun Pistolet sans air (GX-05) Pistola rociadora sin aire GX-05

0501011 Guard Assembly, G-Thread Protège-doigts, lets « G » Ensamblaje de protección, Roscado G

0279974 3 Foot Pole Extension w/Swivel Rallonge de manche, avec pivot, 0,9 m Tubo de extensión de 92 cm c/oscilador

0279976 6 Foot Pole Extensionw/Swivel Rallonge de manche, avec pivot, 1,8 m Tubo de extensión de 1.8 m c/oscilador

0501411 411 Spray Tip Embout de pulvérisation, 411 Boquilla rociadora 411

0501413 413 Spray Tip Embout de pulvérisation, 413 Boquilla rociadora 413

0501415 415 Spray Tip Embout de pulvérisation, 415 Boquilla rociadora 415

0501417 417 Spray Tip Embout de pulvérisation, 417 Boquilla rociadora 417

0501419 419 Spray Tip Embout de pulvérisation, 419 Boquilla rociadora 419

0501515 515 Spray Tip Embout de pulvérisation, 515 Boquilla rociadora 515

0501517 517 Spray Tip Embout de pulvérisation, 517 Boquilla rociadora 517

0501519 519 Spray Tip Embout de pulvérisation, 519 Boquilla rociadora 519

0501521 521 Spray Tip Embout de pulvérisation, 521 Boquilla rociadora 521

0156113 TR-10 Telescoping Roller, 9", 3/8" Nap Manche de rouleau télescopique TR-10,

0154919 Green Gun Filter (2 pack) Filtre de pistolet vert (quantite 2) Filtro de pistola verde (cantidad 2)

0154675 Yellow Gun Filter (2 pack) Filtre de pistolet jaune (quantite 2) Filtro de pistola amarillo (cantidad 2)

0154842 White Gun Filter (2 pack) Filtre de pistolet blanc (quantite 2) Filtro de pistola blanco (cantidad 2)

0154918 Red Gun Filter (2 pack) Filtre de pistolet rouge (quantite 2) Filtro de pistola rojo (cantidad 2)

0154839 Pump Saver Plus Protector Lubriant Pump Saver Plus (lubriant) Protector Pump Saver Plus (lubricante)

English

Description

Français

Description

(GX-08)

manchon de 22,9 cm, grain de 1,0 cm

Español

Descripción

Pistola rociadora sin aire del cuatro dedos GX-08

Rodillo telescópico TR-10, pelillo de 9", 3/8"

71

Español Français English

Page 28

Warranty • Garantié • Garantía

LIMITED WARRANTY - AIRLESS PAINT SPRAY EQUIPMENT

This product, manufactured by Wagner Spray Tech Corporation (Wagner), is warranted to the original retail purchaser against defects in material and workmanship for

one year from date of purchase.

This warranty does not cover damage resulting from improper use, accidents, user’s negligence or normal wear. This warranty does not cover any defects or damages

caused by service or repair performed by anyone other than a Wagner Authorized Service Center. This warranty does not apply to accessories.

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO ONE YEAR FROM DATE OF PURCHASE.

WAGNER SHALL NOT IN ANY EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER FROM BREACH OF THIS

WARRANTY OR ANY OTHER REASON.

If any product is defective in material and/or workmanship during the applicable warranty period, return it with proof of purchase, transportation prepaid to any Wagner

Authorized Service Center. (Service Center listing is enclosed with this product.) Wagner’s Authorized Service Center will either repair or replace the product (at Wagner’s

option) and return it to you, postage prepaid.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE LIMITATION AND EXCLUSION MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

GARANTIE LIMITÉE - MATÉRIEL DE PULVÉRISATION DE PEINTURE SANS AIR

Ce produit, fabriqué par Wagner Spray Tech Corporation (Wagner), est garanti, au bénéce de l’acheteur au détail d’origine, contre tout vice de matières et toute malfaçon

pour un an à compter de la date d’achat.

La présente garantie ne s’applique pas aux dégâts entraînés par une utilisation incorrecte, par la négligence de l’usager ou par l’usure normale. La présente garantie ne

s’applique pas non plus aux défectuosités ou dommages résultant de l’entretien ou de la réparation que fait une personne quelconque qui ne soit pas membre d’un centre

d’entretien autorisé pour les produits Wagner. La présente garantie ne s’applique pas aux accessoires.

TOUTE GARANTIE IMPLICITE DE QUALITÉ MARCHANDE OU D’ADAPTATION À UN USAGE PARTICULIER EST LIMITÉE À UNE PÉRIODE DE 30 JOURS POUR

UNE UTILISATION PROFESSIONNELLE OU DE LOCATION ET D’UNE ANNÉE POUR L’UTILISATION DOMESTIQUE, À COMPTER DE LA DATE D’ACHAT.

TOUTE GARANTIE IMPLICITE DE VENDABILITÉ OU DE CONVENANCE À UNE DESTINATION PARTICULIÈRE EST LIMITÉE À UN AN À COMPTER DE LA DATE

D’ACHAT.

Si un produit est défectueux en ce qui concerne les matériaux ou l’exécution pendant la période de garantie applicable, vous devez le retourner, avec une preuve d’achat

et frais de port payés, à n’importe quel centre d’entretien autorisé pour les produits Wagner. (Une liste de ces centres d’entretien est jointe à ce produit.) Le centre

d’entretien autorisé pour les produits Wagner réparera ou remplacera le produit (à la discrétion de Wagner) et vous le retournera par la poste, avec frais de port payés.

CERTAINES PROVINCES INTERDISENT LES RESTRICTIONS SUR LA DURÉE D’UNE GARANTIE IMPLICITE OU L’EXCLUSION DES DOMMAGES ACCESSOIRES

OU INDIRECTS. IL SE PEUT DONC QUE LA RESTRICTION ET L’EXCLUSION ÉNONCÉES CI-DESSUS NE S’APPLIQUENT PAS À VOUS.

LE PRÉSENTE GARANTIE VOUS ACCORDE DES DROITS JURIDIQUES SPÉCIFIQUES, ET VOUS AVEZ PEUT-ÊTRE D’AUTRES DROITS, QUI PEUVENT VARIER

D’UNE PROVINCE À L’AUTRE.

Title

GARANTÍA LIMITADA - EQUIPO DE ATOMIZACIÓN DE PINTURA SIN AIRE

Este producto, fabricado por Wagner Spray Tech Corporation (Wagner), está garantizado ante el comprador original contra defectos de materiales y mano de obra

durante un año contado a partir de la fecha de compra.

Esta garantía no cubre los daños que sean resultado de un uso inapropiado, accidentes, negligencia del usuario o un desgaste normal. Esta garantía no cubre ningún

defecto o daño que haya sido causado por los servicios o reparaciones llevadas a cabo por alguien que no sea un técnico del Centro de Servicio Autorizado de Wagner.

Esta garantía no es válida para ningún accesorio.

CUALQUIER GARANTIA IMPLICITA DE COMERCIALIZACION O IDONEIDAD PARA CUALQUIER PROPOSITO EN PARTICULAR QUEDA LIMITADA A UN AÑO A

PARTIR DE LA FECHA DE COMPRA.

WAGNER NO SERÁ EN NINGÚN CASO RESPONSABLE DE NINGÚN DAÑO INCIDENTAL O DE CONSECUENCIA DE NINGUNA CLASE, QUE RESULTE DE VIOLAR

ESTA GARANTÍA O POR CUALQUIER OTRA RAZÓN.

Si algún producto llegara a tener defectos de material y/o mano de obra durante el período de validez de la garantía, devuélvalo junto con el comprobante de compra y

ete previamente pagado, a cualquier Centro de Servicio Autorizado de Wagner. (La lista de Centros de Servicio viene adjunta con este producto.) El Centro de Servicio

Autorizado de Wagner reparará o reemplazará el producto (según la opción de Wagner) y se lo devolverá, con porte previamente pagado.

ALGUNOS ESTADOS NO PERMITEN LIMITACIONES EN CUANTO A LA DURACIÓN DE UNA GARANTÍA IMPLÍCITA O LA EXCLUSIÓN DE DAÑOS

INCIDENTALES O DE CONSECUENCIA, DE MANERA QUE LA LIMITACIÓN Y EXCLUSIÓN ANTERIORES PODRÍAN NO SER VÁLIDAS PARA USTED.

ESTA GARANTÍA LE CONCEDE DERECHOS LEGALES ESPECÍFICOS, PERO USTED PODRÍA TENER DERECHO A OTROS, LOS CUALES VARÍAN DE UN

ESTADO A OTRO.

Wagner Spray Tech

1770 Fernbrook Lane

1-800-880-0993

Plymouth, MN 55447

U.S. Patent Nos.

6,435,846 6,599,107

Other patents pending

72

72

EspañolFrançaisEnglish

Loading...

Loading...