Page 1

English

Printed in the U. S. A.

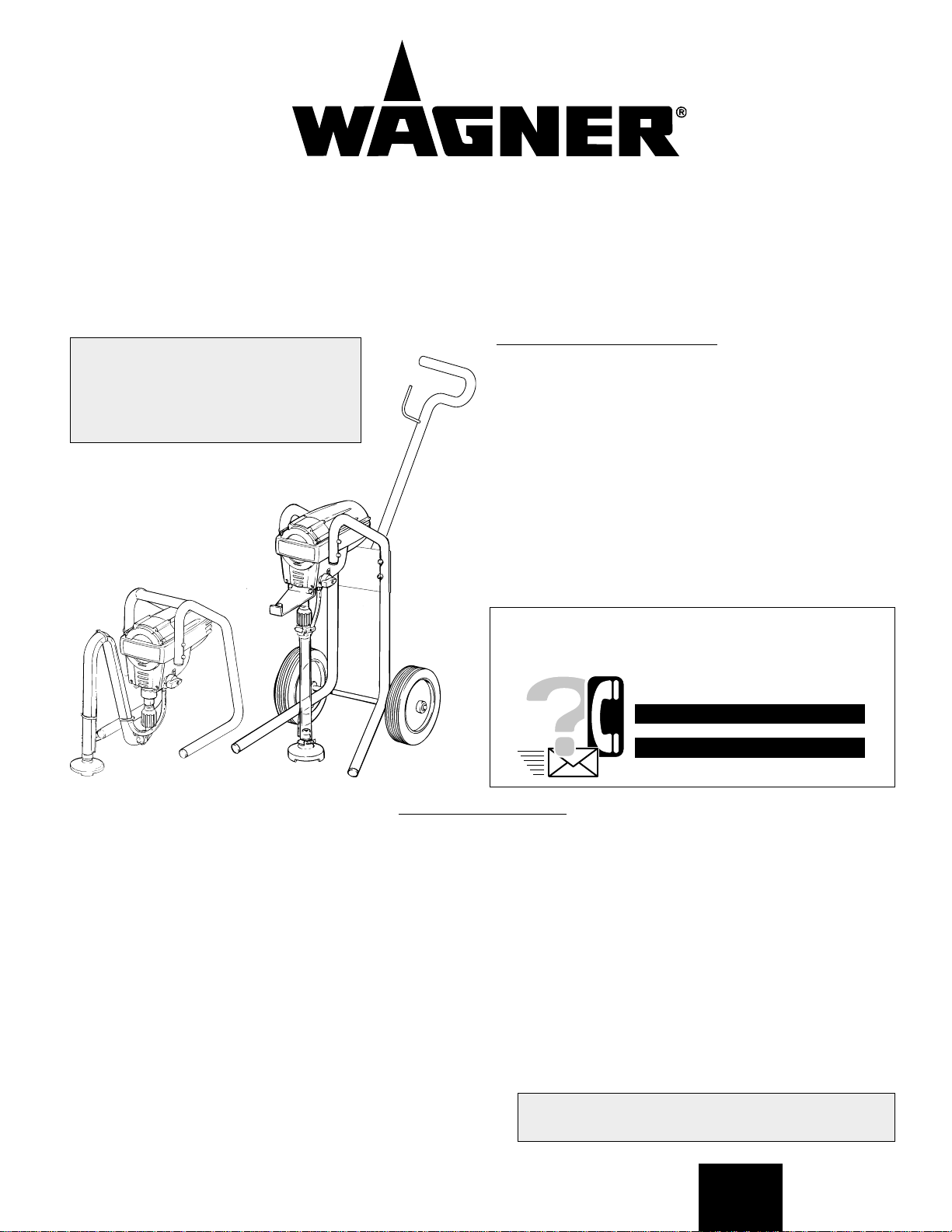

MODELS 9140, 9140S, 9150, 9170, 9190 AND 9210

H

IGH PERFORMANCE AIRLESS SPRAYER

TABLE

OF CONTENTS:

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

COMPONENTS AND DESCRIPTION . . . . . . . . . . . . . . . . . . 4

SETUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PLUGGING IN THE SPRAYER. . . . . . . . . . . . . . . . . . . . . . . 6

PRESSURE RELIEF PROCEDURE . . . . . . . . . . . . . . . . . . . 6

PURGING AND PRIMING. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SPRAYING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SPRAYING TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . 9

CLEANUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

FLUID SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-51

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

OWNER’

S MANUAL • READ THIS MANUAL FOR COMPLETE INSTRUCTIONS

0803 • Form No. 0512731G

SPECIFICATIONS:

Weight .............................. 25 lbs (9140S)

31 lbs (9140, 9150)

36 lbs (9170, 9190)

40 lbs (9210)

Capacity ...........................Up to .25 gallon (1 liter) per minute (9140,

9140S, 9150)

Up to .33 gallon (1.25 liter) per minute (9170)

Up to .42 gallon (1.6 liter) per minute (9190)

Up to .45 gallon (1.71 liter) per minute (9210)

Power source ...................1/2 Hp universal motor (9140, 9140S, 9150)

5/8 Hp permanent magnet DC motor (9170)

3/4 Hp permanent magnet DC motor (9190)

7/8 Hp permanent magnet DC motor (9210)

Power requirement...........15 amp minimum circuit on 115 VAC, 60

Hz current

Generator .........................15 amp A/C

Spraying pressure............Up to 2800 PSI

Safety features.................Spray gun trigger lock and guard;

built-in tip safety guard; priming

knob for safe pressure release.

Capability..........................Sprays a variety of paints, oil

base, latex, primers, stains,

preservatives and other

nonabrasive materials.

Do not use materials with flash

points below 70°F (21°C).

U.S. Patent No. 6,435,846

This pump is available in two models: a

stand model and a cart model. The cart

model is shown in this manual. All

information given for the cart model

applies to the stand model except where

indicated.

This pump should not be used with textured materials,

block filler, or asphalt sealer.

Need help? Call us first for answers fast.

Call Wagner Spray Tech toll-free if you have any

comments or problems with this product.

1-800-880-0993

Wagner Technical Service

Visit us on the world wide web!

http://www.wagnerspraytech.com

1770 Fernbrook Lane, Minneapolis, MN 55447

Page 2

HAZARD: INJECTION INJURY

A high pressure paint stream produced by

this equipment can pierce the skin and

underlying tissues, leading to serious injury

and possible amputation. SEE APHYSICIAN

IMMEDIATELY.

DO NOT TREAT AN INJECTION INJURY AS A SIMPLE CUT!

Injection can lead to amputation. See a physician

immediately.

The maximum operating range of the gun is 2800

PSI/193BAR fluid pressure.

PREVENTION:

• NEVER aim the gun at any part of the body.

• NEVER allow any part of the body to touch the fluid stream.

DO NOT allow body to touch a leak in the fluid hose.

• NEVER put your hand in front of the gun. Gloves will not

provide protection against an injection injury.

• ALWAYS lock the gun trigger, shut the pump off, and

release all pressure before servicing, cleaning the tip or

guard, changing tip, or leaving unattended. Pressure will

not be released by turning off the motor. The

PRIME/SPRAY knob must be turned to PRIME to relieve

the pressure. Refer to the PRESSURE RELIEF

PROCEDURE (page 6) described in the pump manual.

• ALWAYS keep the tip guard in place while spraying. The

tip guard provides some protection but is mainly a warning

device.

• ALWAYS remove the spray tip before flushing or cleaning

the system.

• Paint hose can develop leaks from wear, kinking and

abuse. Aleak can inject material into the skin. Inspect

the hose before each use.

• NEVER use a spray gun without a working trigger lock

and trigger guard in place.

• All accessories must be rated at or above 2800 PSI/193

BAR. This includes spray tips, guns, extensions, and hose.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insecticides, and other

materials can be harmful if inhaled or come in

contact with the body. Vapors can cause

severe nausea, fainting, or poisoning.

PREVENTION:

• Use a respirator or mask if vapors can be

inhaled. Read all instructions supplied

with the mask to be sure it will provide the

necessary protection.

• Wear protective eyewear.

• Wear protective clothing as required by

coating manufacturer.

NOTE TO PHYSICIAN:

Injection into the skin is a traumatic injury. It is important

to treat the injury as soon as possible. DO NOT delay

treatment to research toxicity. Toxicity is a concern with

some coatings injected directly into the blood stream.

Consultation with a plastic surgeon or reconstructive

hand surgeon may be advisable.

2 1-800-880-0993 © 2003 Wagner Spray Tech - All rights reserved.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite.

Property damage and/or severe injury can occur.

PREVENTION:

• Provide extensive exhaust and fresh air

introduction to keep the air within the spray area free from

accumulation of flammable vapors.

• Avoid all ignition sources such as static

electric sparks, open flames, pilot lights,

electrical appliances, and hot objects.

Connecting or disconnecting power cords

or working light switches can make sparks.

• Do not smoke in spray area.

• Fire extinguisher must be present and in good working

order.

• Place paint pump at least 20 feet from the spray object in a

well ventilated area (add more hose if necessary).

Flammable vapors are often heavier than air. Floor area

must be extremely well ventilated. The paint pump contains

arcing parts that emit sparks and can ignite vapors.

• The equipment and objects in and around the spray area

must be properly grounded to prevent static sparks.

• Use only conductive or grounded high pressure fluid hose.

Gun must be grounded through hose connections.

• Power cord must be connected to a grounded circuit.

• Always flush unit into a separate metal container, at low

pump pressure, with spray tip removed. Hold gun firmly

against side of container to ground container and prevent

static sparks.

• Follow the material and solvent manufacturer's warnings

and instructions.

• Use extreme caution when using materials with a

flashpoint below 70° F (21° C). Flashpoint is the

temperature that a fluid can produce enough vapors to

ignite.

• Plastic can cause static sparks. Never hang plastic to

enclose a spray area. Do not use plastic drop cloths

when spraying flammable materials.

• Use lowest possible pressure to flush equipment.

GAS ENGINE (WHERE APPLICABLE)

Always place pump outside of structure in fresh air. Keep all

solvents away from the engine exhaust. Never fill fuel tank with

a running or hot engine. Hot surface can ignite spilled fuel.

Always attach ground wire from pump unit to a grounded object,

such as a metal water pipe. Refer to enigine owner’s manual

for complete safety information.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS

Will cause property damage or severe injury.

PREVENTION:

• Do not use materials containing bleach or

chlorine.

• Do not use halogenated hydrocarbon solvents such as

bleach, mildewcide, methylene chloride and 1,1,1 trichloroethane. They are not compatible with aluminum.

• Contact your coating supplier about the compatibility of

material with aluminum.

English

SAFETY INFORMATION • READ ALL SAFETY

INFORMATION BEFORE OPERATING THE EQUIPMENT

Page 3

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

• Read all instructions and safety precautions before

operating equipment.

• Follow all appropriate local, state, and national codes

governing ventilation, fire prevention, and operation.

• The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

• Use only manufacturer authorized parts. User assumes

all risks and liabilities when using parts that do not meet

the minimum specifications and safety requirements of the

pump manufacturer.

• Before each use, check all hoses for cuts, leaks, abrasion

or bulging of cover. Check for damage or movement of

couplings. Immediately replace the hose if any of these

conditions exist. Never repair a paint hose. Replace it

with another grounded high-pressure hose.

• All hoses, swivels, guns, and accessories must be

pressure rated at or above 2800PSI/193 BAR.

• Do not spray outdoors on windy days.

• Wear clothing to keep paint off skin and hair.

I

MPORTANT E

LECTRICAL INFORMATION

Use only a 3-wire extension cord that has a 3-blade grounding

plug and a 3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss

of power and overheating. A14 or 12 gauge cord is

recommended. If an extension cord is to be used outdoors, it

must be marked with the suffix W-Aafter the cord type

designation. For example, a designation of SJTW-A would

indicate that the cord would be appropriate for outdoor use.

THE 9140, 9140S AND 9150 SERIES UNITS ARE

PROVIDED WITH A NON-RESETABLE THERMAL

OVERLOAD. THE 9170, 9190 AND 9210 SERIES UNITS

ARE PROVIDED WITH A REPLACEABLE FUSE.

• Always disconnect the motor from the power supply

before working on the equipment.

The cause of the overload should be corrected before

restarting. Take to Service Center.

Do not use more than 100 feet of hose. If you need to

paint further than 100 feet from your power source,

use more extension cord, not more paint hose.

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This product

is equipped with a cord having a grounding wire with an

appropriate grounding plug. The plug must be plugged into an

outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is

necessary, do not connect the green grounding wire to either

flat blade terminal. The wire with insulation having a green

outer surface with or without yellow stripes is the grounding

wire and must be connected to the grounding pin.

Check with a qualified electrician or serviceman if the

grounding instructions are not completely understood, or if you

are in doubt as to whether the product is properly grounded.

Do not modify the plug provided. If the plug will not fit the

outlet, have the proper outlet installed by a qualified electrician.

This product is for use on a nominal 120 volt circuit and has a

grounding plug that looks like the plug illustrated below. Make

sure that the product is connected to an outlet having the

same configuration as the plug. No adapter should be used

with this product.

IF YOU EXPERIENCE PROBLEMS WITH YOUR

SPRA YER AT ANY TIME DURING ASSEMBLY

,

OPERA TION OR CLEANUP, PLEASE REFER TO

THE TROUBLESHOOTING SECTION OF THIS

MANUAL

(PAGE 15), OR CALL CUSTOMER

SERVICE AT

:

1-800-880-0993

© 2003 Wagner Spray Tech - All rights reserved. 1-800-880-0993 3

English

SAFETY INFORMATION • READ ALL SAFETY

INFORMATION BEFORE OPERATING THE EQUIPMENT

WARNING

CAUTION

CAUTION

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

Page 4

Customer Service: 800-880-0993 4 © 2003 Wagner Spray Tech - All rights reserved.

English

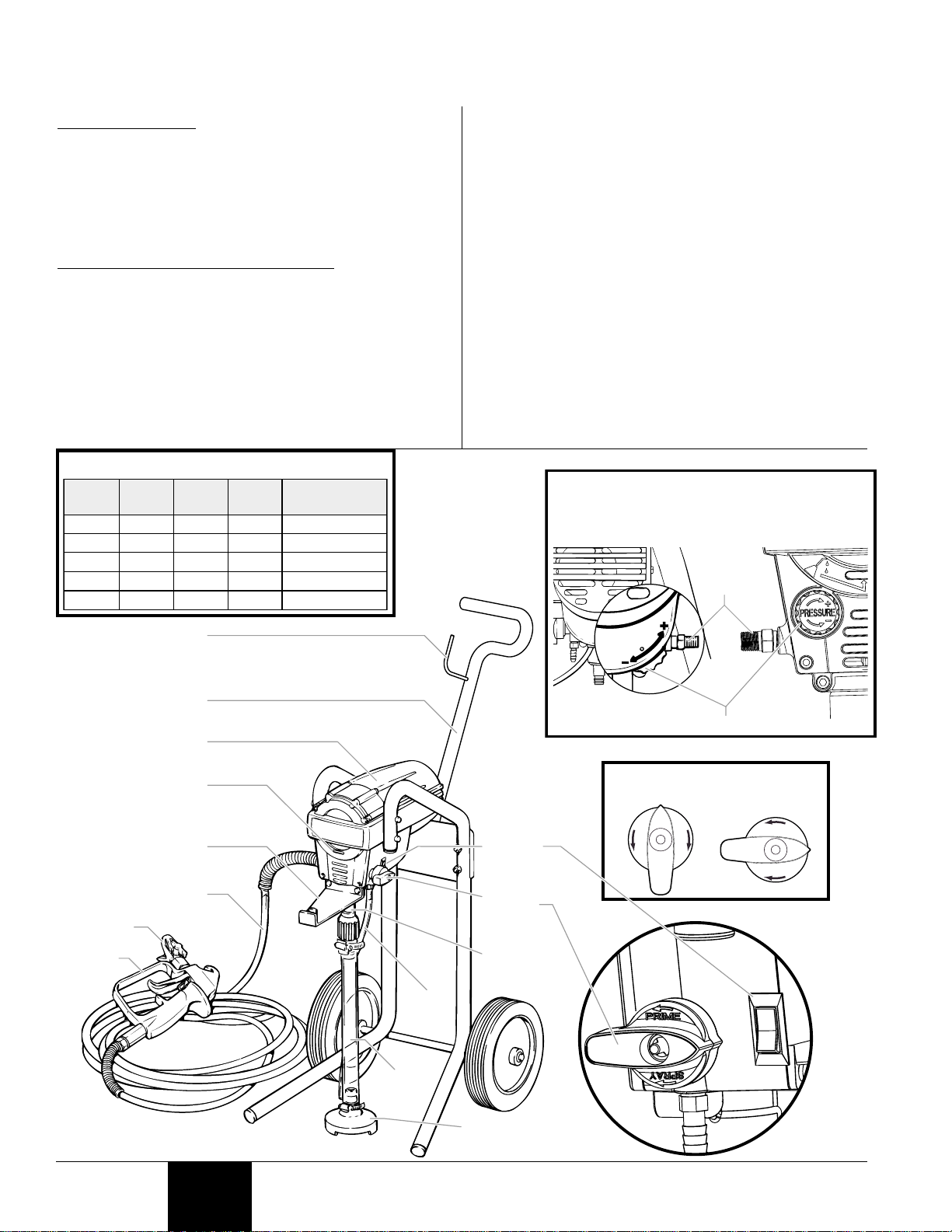

COMPONENTS AND DESCRIPTION

C

OMPONENTS

The shipping carton for your painting system contains the following:

• Suction set and return tube

• Spray gun with filter

• Spray tip assembly (see chart below)

• 25 foot long, 1/4 inch diameter pressure hose (9140, 9140S, 9150)

• 50 foot long, 1/4 inch diameter pressure hose (9170, 9190, 9210)

• Separating Oil

CONTROLS

AND FUNCTIONS

ON/OFF Switch................The ON/OFF switch turns the unit on

and off (O=OFF, l=ON).

Suction Set.......................Fluid is drawn through the suction

set into the pump.

Fluid Section ....................A piston in the fluid section moves up

and down to create the suction that

draws fluid through the suction set.

Spray Gun........................The spray gun controls the delivery

of the fluid being pumped. The gun

model you have depends on your

sprayer model (refer to Spray

Gun/Tip Chart, below).

Spray Hose ......................The spray hose connects the gun to

the pump.

Return Tube......................Fluid is sent back out through the

return tube to the original container.

PRIME/SPRAY Knob........The PRIME/SPRAY knob directs fluid

to the spray hose when set to SPRAY

or the return tube when set to PRIME.

The arrows on the PRIME/SPRAY

knob shows the rotation directions for

PRIME and SPRAY.

The PRIME/SPRAYknob is also used

to relieve pressure built up in the

spray hose (Pressure Relief

Procedure, page 6)

Pressure Control Dial.......The pressure control dial controls

the amount of force the pump uses

to push the fluid (see graphic below

for locations).

Sprayer

Model

9140/S GX-06 .013 .015 Yellow (fine)

9150

9170

9190

9210 GX-10 .017 .021 White (medium)

Model

GX-07

GX-07

GX-08

Spray Gun/Tip Chart

Gun

Tip

Size

.013

.015

.017

Max.

Size

.015

.017

.019

Recommended

Filter

Yellow (fine)

Yellow (fine)

White (medium)

Rear of motor shroud,

(9140, 9140S, 9150,

9170, and 9190).

Pressure Control Dial

Front face plate,

9210 model

Spray hose

port

Spray

Spray

gun

Hose

bracket

Handle

Motor

housing

Lubricating

area (on front

face plate)

Pail bracket

Spray hose

tip

Return

Suction

tube

tube

ON/OFF switch

O = OFF

l = ON

PRIME/

SPRAY

knob

Fluid

section

Pressure Control Dial

PRIME/SPRAY knob

PRIME position SPRAY position

SPRAY

PRIME

PRIME

SPRAY

O

l

Suction set screen

Page 5

© 2003 Wagner Spray Tech - All rights reserved. 5 Customer Service: 800-880-0993

English

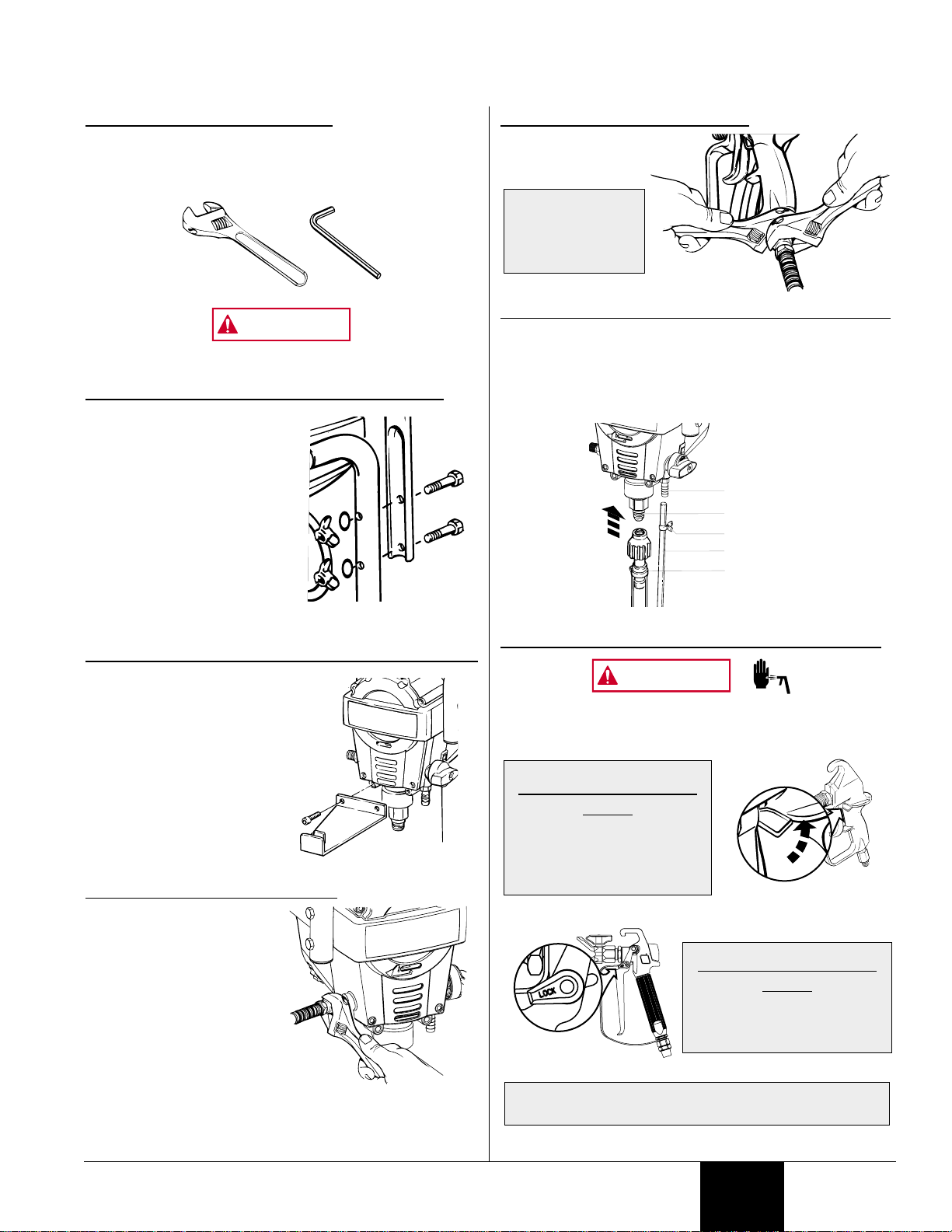

TOOLS NEEDED FOR SETUP

• Two adjustable wrenches

• 3/16” allen wrench

• Extension cord (refer to Important Electrical Information

(page 3).

Do not plug in the unit until setup is complete.

ATT

ACHING THE HANDLE (CART MODELS)

1. Position the handle

against the cart so that

the holes in the handle

line up with the holes in

the cart.

2. Insert the bolts through

the holes in the handle

and cart and locking

washers.

3. Tighten the wing nuts

onto the bolts by hand.

ATTACHING THE PAIL BRACKET (CART MODELS)

1. Position the pail bracket

against the unit so that

the holes in the unit line

up with the holes in the

bracket.

2. Insert the bolts through the

holes in the bracket and

the unit.

3. Tighten the bolts with a

3/16” allen wrench.

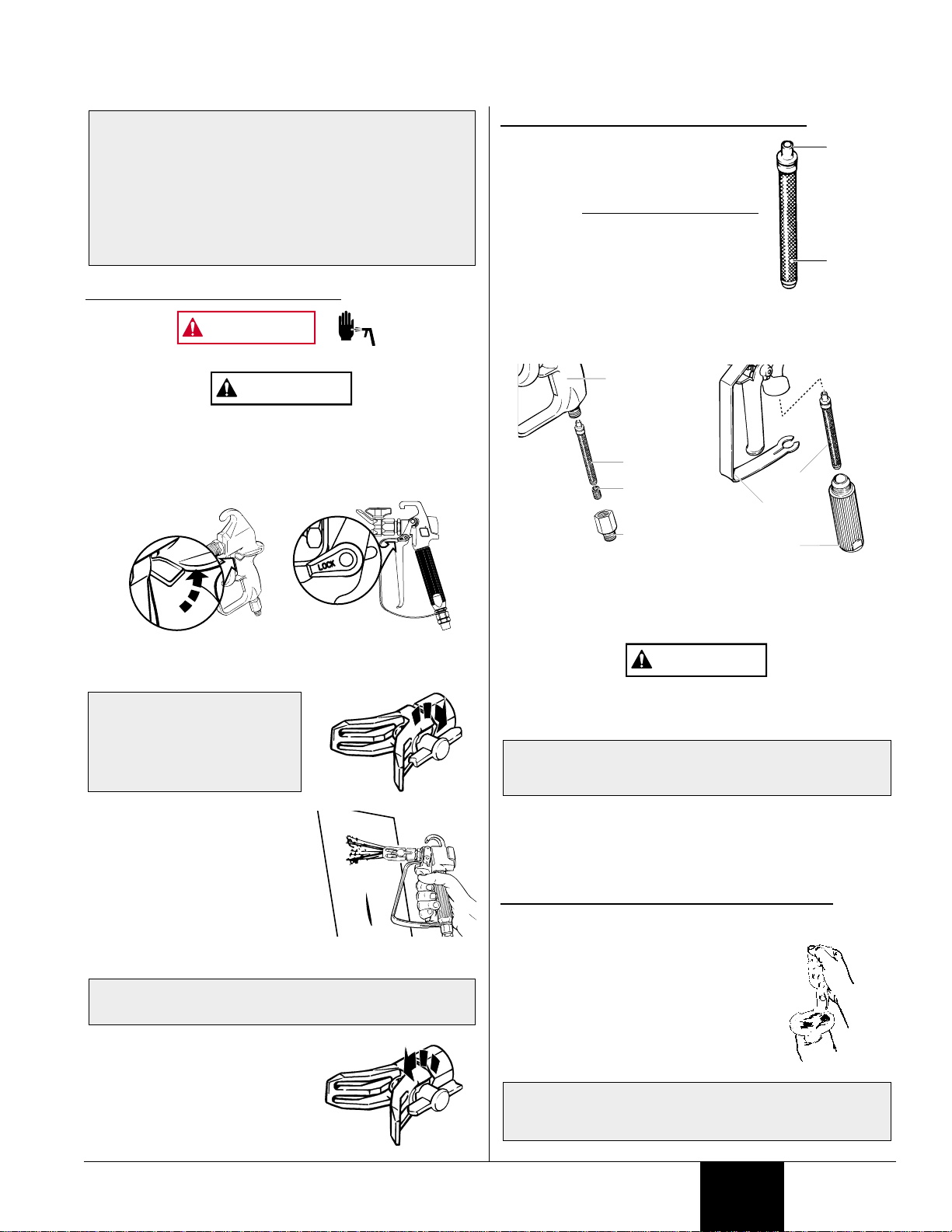

ATTACHING THE PAINT HOSE

1. Thread the high pressure

hose to the paint hose

port.

2. Tighten with an adjustable

wrench.

3. Remove pusher stem

from inlet valve.

ATTACHING THE SPRAY GUN

1. Thread spray gun

onto the other end

of the hose.

ATTACHING THE SUCTION S ET & RETURN TUBE

1. Attach the suction tube to the inlet valve and tighten firmly

by hand. Be sure that the threads are straight so that the

fitting turns freely.

2. Press the return tube onto the return tube fitting.

3. Squeeze clip over the return tube fitting to secure return

tube.

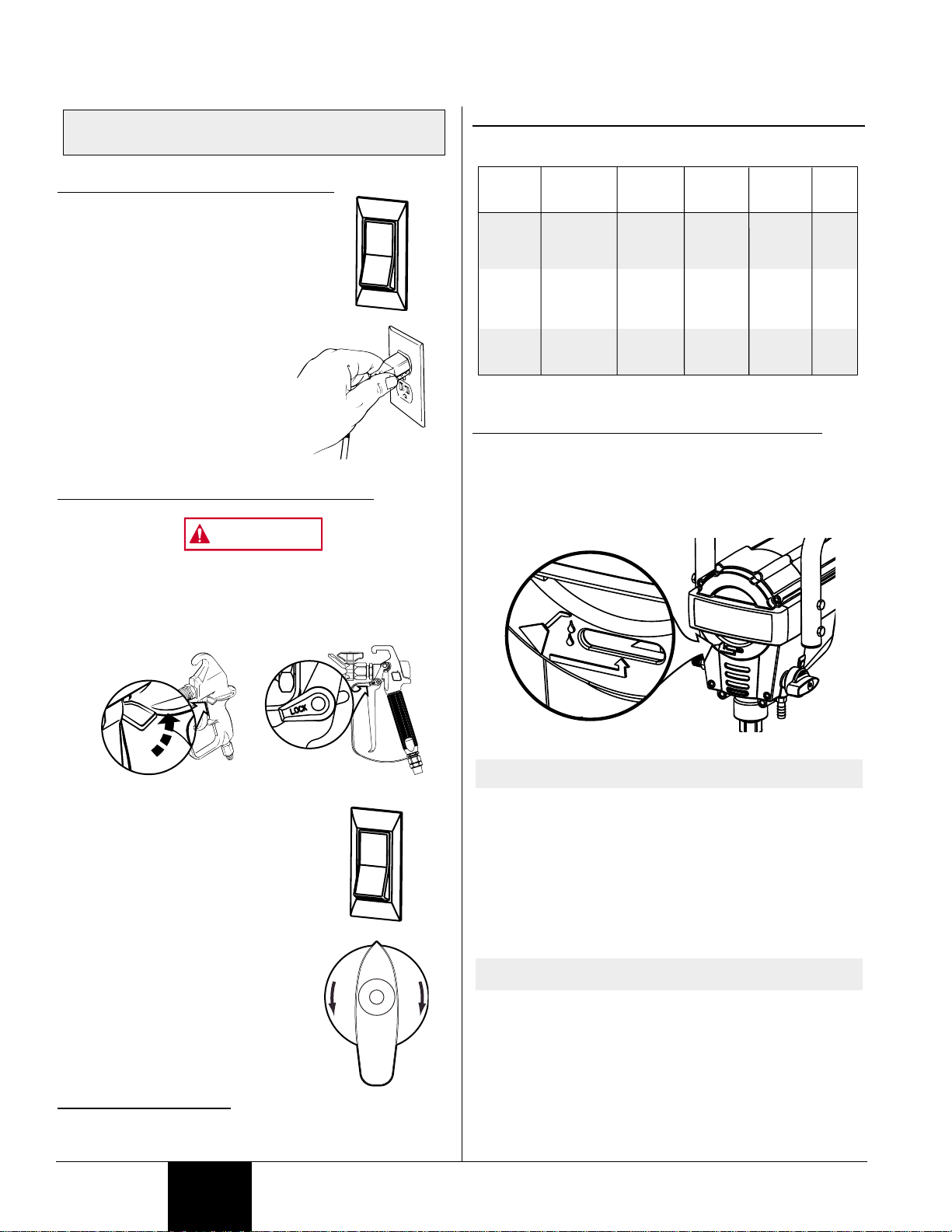

LOCKING AND UNLOCKING THE SPRAY GUN

Always lock the trigger off when attaching the spray tip or

when the spray gun is not in use. Refer to Spray Gun/Tip

Chart on page 4 to determine the gun model you have.

The spray tip SHOULD NOT be attached until after the

sprayer and paint hose have been purged and primed.

GUN MODELS GX-08 AND

GX-10

To lock the gun, turn the trigger

lock forward and slightly down

until it stops.

GUN MODELS GX-06 AND

GX-07

The gun is secured when the

trigger lock is at a 90° angle

(perpendicular) to the trigger in

either direction.

Hold the gun with

one adjustable

wrench, and tighten

with the other.

SETUP--ASSEMBLING THE SPRAYER

WARNING

Return tube

fitting

Inlet valve

Clip

Return tube

Suction set

WARNING

GX-06/07

Gun locked

(gun will not spray)

GX-08/10

Gun locked

(gun will not spray)

Page 6

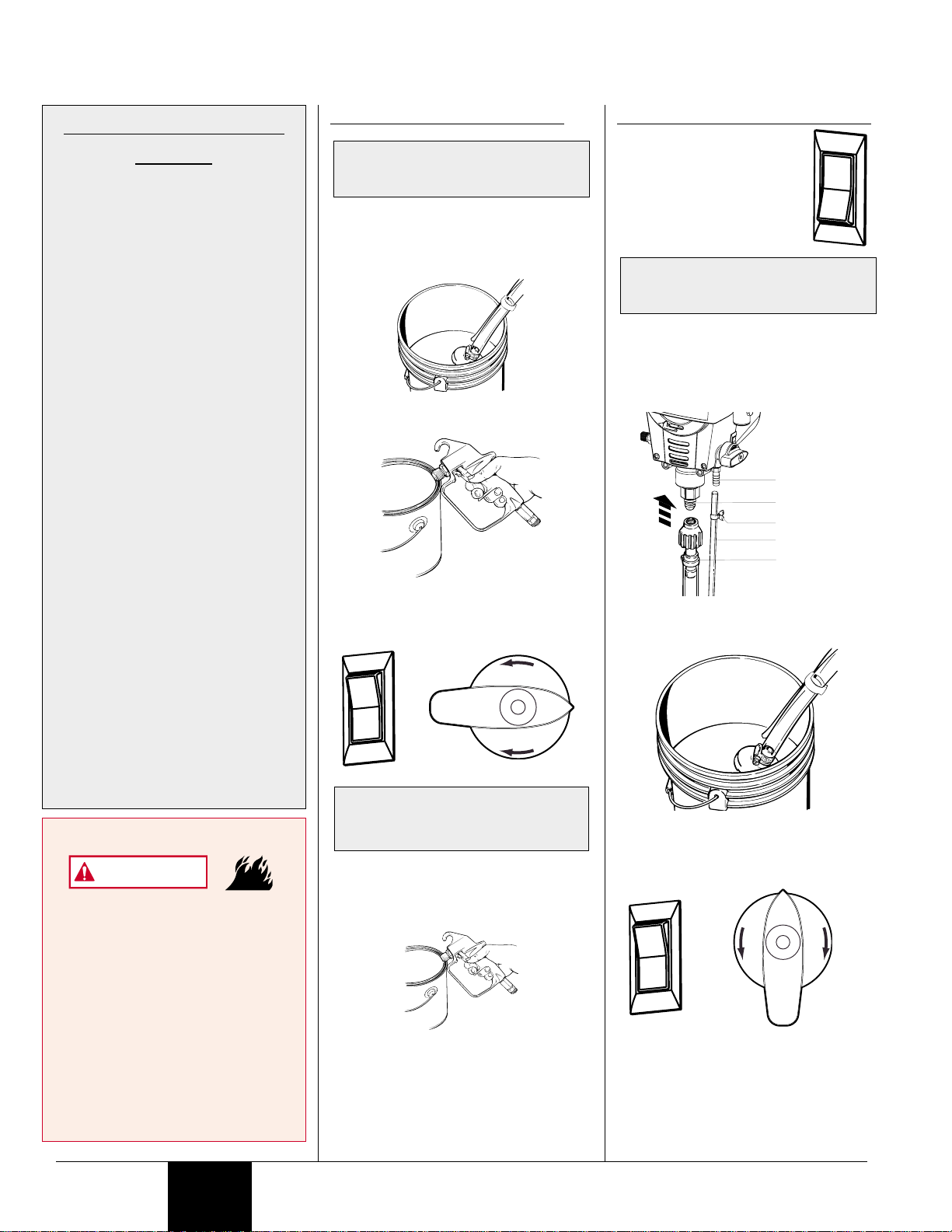

PLUGGING IN THE SPRAYER

1. Check that the ON/OFF

switch is in the OFF

position.

2. Plug the sprayer into a

heavy duty grounded

extension cord. Refer to

Important Electrical

Information, page 3).

P

RESSURE RELIEF PROCEDURE

Be sure to follow the pressure relief procedure (page 6)

when shutting the unit off FOR ANY PURPOSE. This

procedure is used to relieve pressure from the spray hose.

1. Lock the spray gun off.

2. Flip the ON/OFF switch to

the OFF (O) position.

3. Unlock the spray gun,

turn the PRIME/SPRAY

knob to PRIME, and

trigger spray gun into

paint bucket.

4. Lock the spray gun.

PAINT STRAINING

It is recommended that in order to avoid premature tip and gun

clogging you should strain your paint before spraying. Follow

manufacturer’s recommendations.

This column contains instructions that will be repeated

throughout this manual.

Customer Service: 800-880-0993 6 © 2003 Wagner Spray Tech - All rights reserved.

CHOOSING THE CORRECT SPRA Y GUN FILTER

Use the proper gun filter based on the tip size being used.

BEFORE YOU PRIME THE SPRAYER

Before priming, squirt a teaspoon of separating oil (P/N

0154908 included with unit) into the indicated area. Light

household oil can be substituted if necessary. Do not put

more than a teaspoon into the lubricating area. Too much oil

will leak down into your paint.

All units are performance-tested at the factory and are shipped

with test fluid in the fluid section to prevent corrosion during

shipment and storage.

• Whether you are going to spray latex or oil-based

paints, this fluid must be purged and thoroughly cleaned

out of the system (follow Purging and Priming the Pump

steps, page 7).

If the pump has already been used you will need to purge the

water or solvent used in cleanup and storage.

IF YOUR UNIT HAS ALREADY BEEN USED. . .

IF YOUR UNIT IS NEW. . .

English

BEFORE YOU BEGIN

WARNING

o

Part No. Tip Size Filter

Type

0154918 .011 Extrafine

0154675 .013 - .015 Fine

0154842 .017 - .023 Medium

Mesh

Number

180 mesh

0.084 mm

100 mesh

0.140 mm

50 mesh

0.315 mm

Filter

Body

red

yellow

white

Qty.Color of

2 pack

2 pack

2 pack

GX-06/07

GX-08/10

o

SPRAY

PRIME

Page 7

© 2003 Wagner Spray Tech - All rights reserved. 7 Customer Service: 800-880-0993

English

PURGING & PRIMING

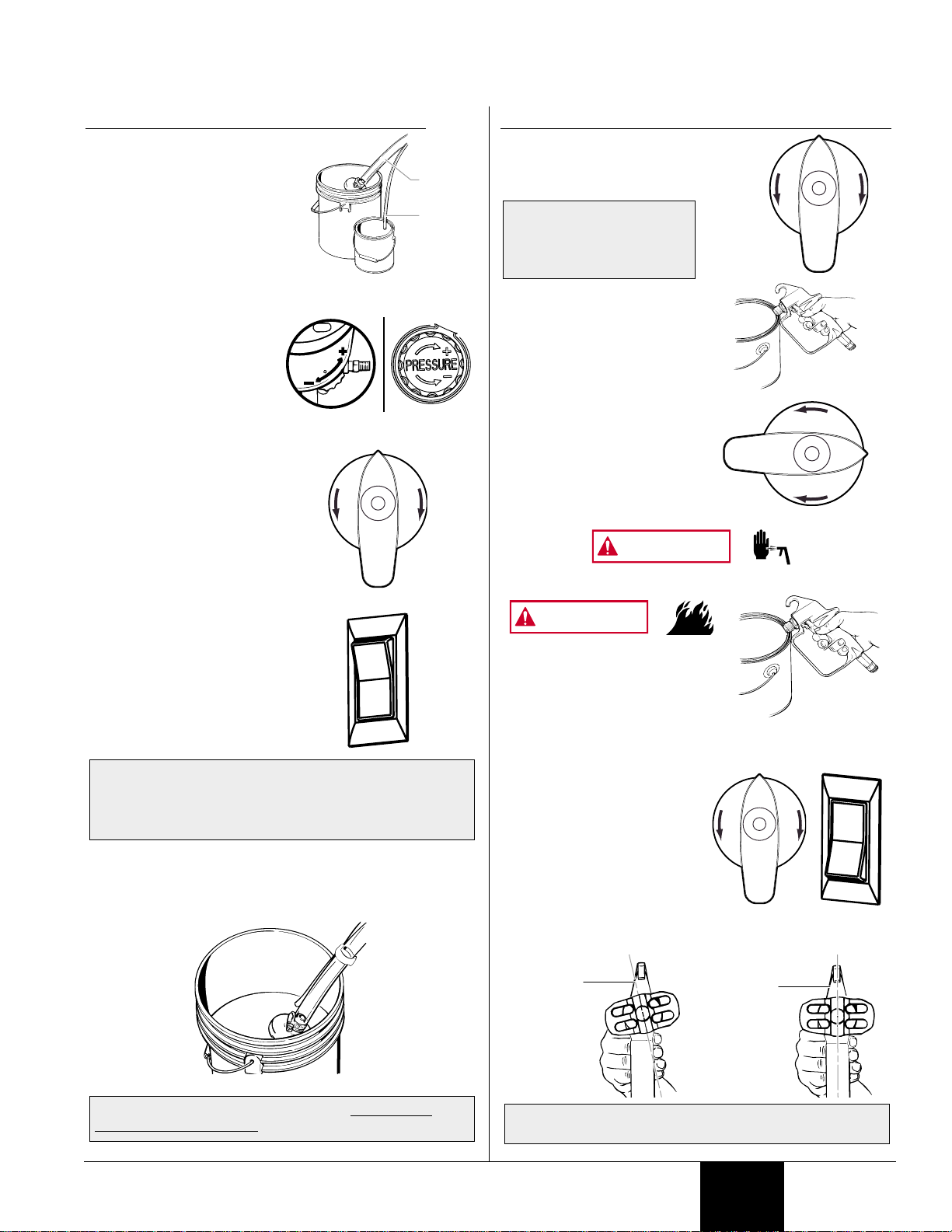

PURGING AND PRIMING THE PUMP

1. Place a full container of

paint underneath the

suction tube.

2. Secure the return tube

into a waste container.

3. Turn the pressure control

dial to maximum pressure

(+).

4. Turn the PRIME/SPRAY

knob to PRIME.

5. Plug in the sprayer, and

move the ON/OFF switch

to the ON position.

6. Switch the pump to OFF (O).

7. Remove the return tube from the waste container and

place it in its operating position above the container of

paint. Use the metal clip to bind the two hoses together.

Your sprayer is now purged. Move to Purging and

Priming the Spray Hose.

The unit will begin to draw paint up the suction tube,

into the pump, and out the return tube. Let the unit

cycle long enough to remove test fluid from the pump,

or until paint is coming from the return tube.

PURGING AND PRIMING THE SPRAY HOSE

1. Unlock the spray gun and

turn PRIME/SPRAY knob

to PRIME.

2. Trigger and HOLD the

spray gun into a waste

container.

3. While holding the trigger,

switch the pump ON (l).

4. While holding the trigger,

turn the PRIME/SPRAY

knob to SPRAY. Hold the

trigger until all air, water, or

solvent is purged from the

spray hose and paint is

flowing freely (read

warnings below).

Keep hands clear from fluid stream.

Using a metal container, ground

the gun by holding it against the

edge of the container while

flushing. Failure to do so may

lead to a static electric discharge

which may cause a fire.

If the PRIME/SPRAY knob is still

on SPRAY, there will be high pressure in the hose and

spray gun until the PRIME/SPRAY knob is turned to PRIME.

5. Release trigger, turn the

PRIME/SPRAY knob to

PRIME and turn pump

OFF (O).

6. Trigger the gun into the

waste container once more

to be sure that no pressure

is left in the hose.

7. Lock the spray gun off.

8. Thread the spray tip guard assembly onto the gun.

Tighten by hand.

Your hose is now purged and primed. You are ready to

paint.

Begin

tightening

the tip at

this angle

to achieve

the desired

spray angle

when tight.

Your spray tip SHOULD

NOT be attached to your

spray gun when purging

your spray hose.

SPRAY

PRIME

Suction

tube

Return

tube

WARNING

PRIME

PRIME

SPRAY

SPRAY

l

WARNING

PRIME

SPRAY

o

Page 8

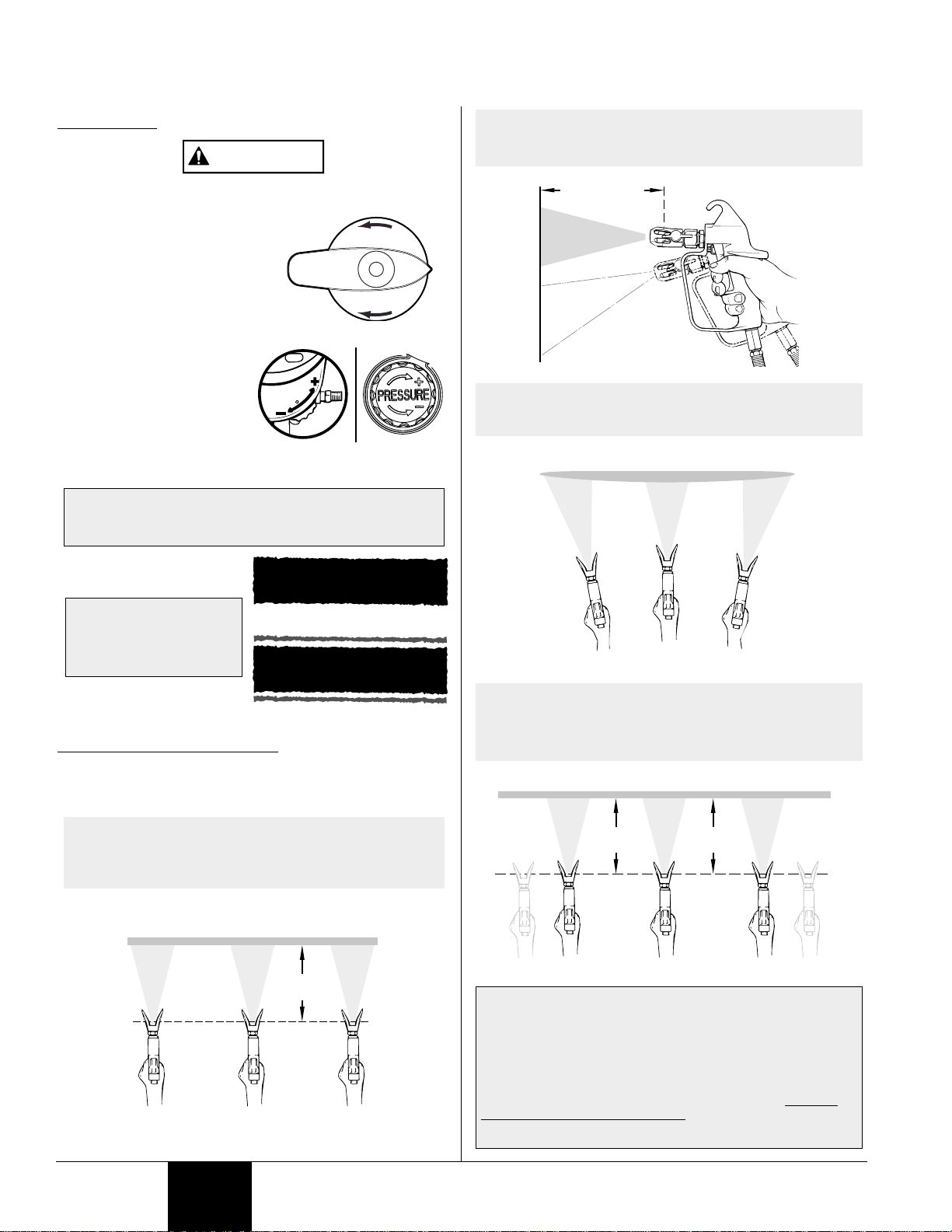

PRACTICE

Be sure that the paint hose is free of kinks and clear of

objects with sharp cutting edges.

1. Switch the pump ON (l)

and turn the

PRIME/SPRAY knob to

SPRAY.

2. Turn the pressure contol

dial to its highest setting

(+). The spray hose

should stiffen as paint

begins to flow through it.

3. When the motor shuts off, unlock the spray gun and spray

a test area to check the spray pattern.

SPRAYING TECHNIQUE

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Follow the TIPS,

below.

TIP: Keep your arm moving at a constant speed and

keep the spray gun at a constant distance from

the surface. The best spraying distance is 10 to

12 inches between the spray tip and the surface.

The pressure control

dial can be adjusted up

or down to achieve the

desired spray pattern.

Good spray pattern

Paint tailing pattern

When enough pressure has built up in the hose, the

motor will shut off automatically. The motor will cycle

on and off automatically as it needs pressure.

Customer Service: 800-880-0993 8 © 2003 Wagner Spray Tech - All rights reserved.

ADDITIONAL TIPS

Overlap each stroke by about 30%. This will ensure an

even coating.

When you stop painting, follow PRESSURE RELIEF

PROCEDURE.

IF YOU EXPECT TO BE AWAY FROM YOUR SPRAYER

FOR MORE THAN ONE HOUR, FOLLOW THE SHORT

TERM CLEANUP PROCEDURE DESCRIBED IN THE

STORAGE SECTION OF THIS MANUAL (page 12).

Proper way to trigger the spray gun

Approximately

10 to 12 inches

Keep stroke

even

Start stroke End strokePull trigger Release triggerKeep steady

TIP: The spray gun should be triggered by turning it

on and off with each stroke. Do not trigger the

gun during the middle of a stroke. This will result

in an uneven spray and splotchy coverage.

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

TIP: Keep the spray gun at right angles to the

surface. This means moving your entire arm

back and forth rather than just flexing your wrist.

TIP: Keep the spray gun perpendicular to the

surface, otherwise one end of the pattern will

be thicker than the other.

English

SPRAYING

CAUTION

PRIME

SPRAY

Approximately

10 to 12 inches

Right way

Wrong way

Even coat throughout

Keep stroke smooth and at an even speed.

Approximately

10 to 12 inches

Page 9

© 2003 Wagner Spray Tech - All rights reserved. 9 Customer Service: 800-880-0993

English

UNCLOGGING THE SPRAY TIP

Do not attempt to unclog or clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide can chip.

If the spray pattern becomes distorted or stops completely

while the gun is triggered, follow these steps:

1. Release the trigger and lock the gun off.

2. Rotate the reversible tip arrow 180° so that the point of

the arrow is toward the rear of the gun (CLEAN position).

3. Turn the PRIME/SPRAY knob

to SPRAY.

4. Unlock the gun and squeeze

the trigger, pointing the gun at

a scrap piece of wood or

cardboard. This allows

pressure in the spray hose to

blow out the obstruction.

When the nozzle is clean, paint

will come out in a straight, high pressure stream.

5. Release the trigger and lock the gun off.

6. Reverse the tip so the

arrow points forward

again (SPRAY position).

7. Unlock the gun and

resume spraying.

If paint still will not spray from the spray tip, follow the

other steps on the next column.

Under pressure, the spray tip

may be very difficult to turn.

Turn the PRIME/SPRAY knob

to PRIME and trigger the gun.

This will relieve pressure and

the tip will turn more easily.

The following is a short list of minor difficulties you might

encounter while spraying. If any of these occur, it will

reduce the flow of paint, making your spray pattern poor, or

paint will fail to spray from the gun.

• Clogged spray tip

• Clogged gun filter

• Clogged suction set screen

Follow the guidelines on this page to correct any one of

these problems.

CLEANING THE SPRAY GUN FILTER

This filter must be cleaned every time you

use your sprayer.

When using thicker paints, the filter might

need to be cleaned more often.

1. Perform Pressure Relief Procedure

(page 6).

2a. If you have a model GX-06/07 spray

gun, unscrew the fitting from the

bottom of the spray gun using an

adjustable wrench, making sure not to

lose the spring.

2b. If you have a model GX-08/10 spray gun, unclip the

trigger guard from the filter housing by pulling outward

from the filter housing. Unscrew the housing.

3. Remove filter from spray gun housing and clean with the

appropriate cleaning solution (warm, soapy water for latex

paints, mineral spirits for oil-based materials).

4. Inspect the filter for holes (see Hole picture, above).

Replace if holes are found.

NEVER POKE THE FILTER WITH A SHARP INSTRUMENT!

5. Replace the cleaned filter, tapered end first, into the gun

housing.

6a. For the GX-06/07, replace the spring and the fitting.

Tighten with an adjustable wrench.

6b. For the GX-08/10, replace the housing and snap the

trigger guard back into the housing.

CLEANING THE SUCTION SET SCREEN

The screen at the bottom of the suction set may also need

cleaning. Check it every time you change paint buckets.

1. Remove the screen by pulling it out

of the retainer with a plier.

2. Clean the screen with the

appropriate cleaning solution (warm,

soapy water for latex paints, mineral

spirits for oil-based paints).

If after having completed all of the steps on this page

you are still experiencing problems spraying, refer to the

TROUBLESHOOTING guide (page 15).

The tapered end of the filter must be loaded properly

into the gun. Improper assembly will result in a

plugged tip or no flow from the gun.

SPRAYING TROUBLESHOOTING

WARNING

CAUTION

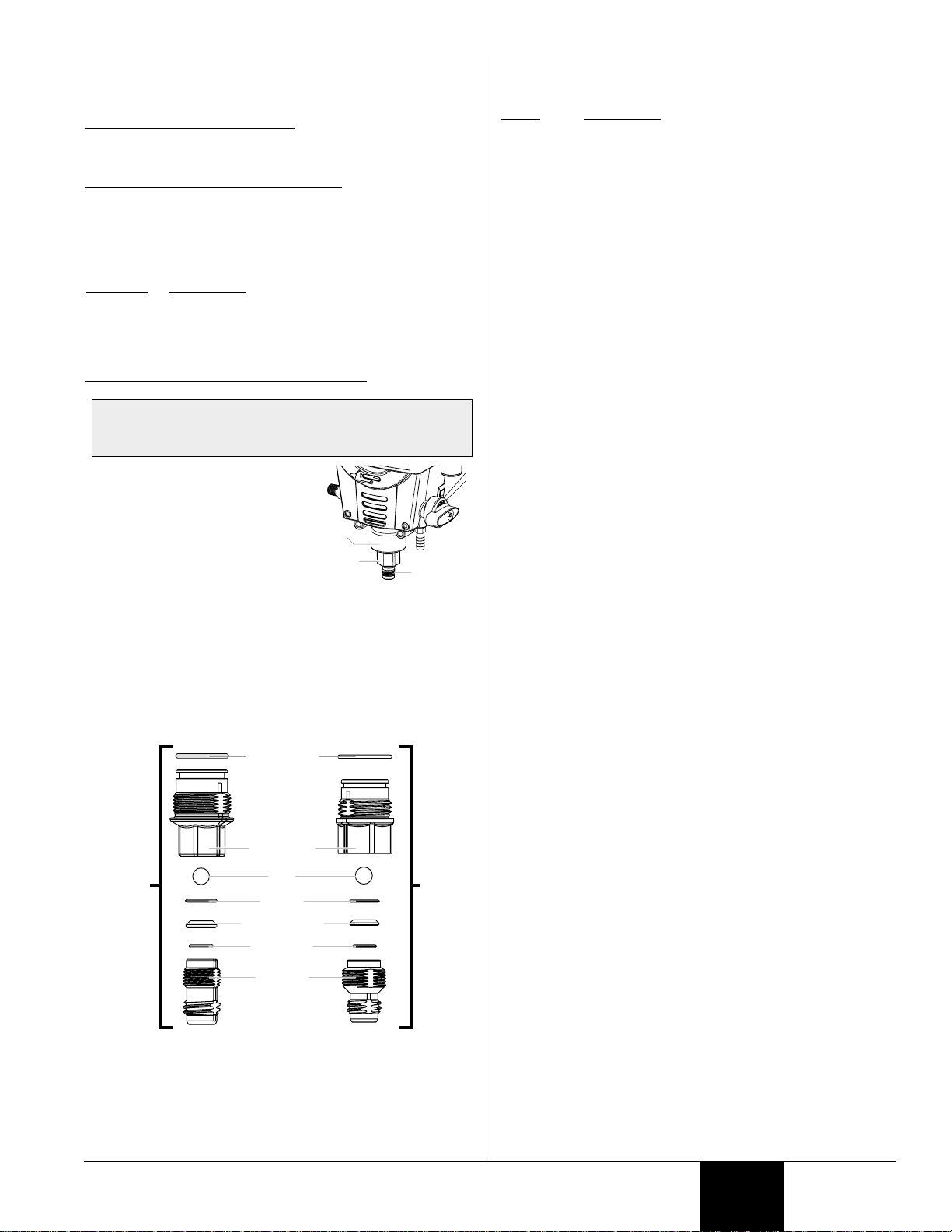

GX-06/07

GX-08/10

Housing

GX-06/07

Filter

Spring

Fitting

Filter

Trigger

guard

Housing

Filter top

Pin hole

GX-08/10

CAUTION

Page 10

IMPORTANT CLEANING

N

OTES!

READ THESE NOTES AND

WARNINGS BEFORE YOU

S

TART TO CLEAN YOUR

SPRAYER!

• When using latex paints, clean

your sprayer and components

using warm, soapy water.

When using oil-based paints,

use mineral spirits.

• Do not use mineral spirits on

latex paint, or the mixture will

turn into a jelly-like substance

which is difficult to remove.

• No matter which cleaning

solution you use, make sure to

dispose of it properly when

finished cleaning your sprayer.

• Thorough cleaning and

lubrication of the sprayer is

the most important step you

can take to ensure proper

operation after storage.

CALL

1-800-880-0993

IF YOU HAVE ANY QUESTIONS

REGARDING THE CLEANUP OF

YOUR SPRAYER

Customer Service: 800-880-0993 10 © 2003 Wagner Spray Tech - All rights reserved.

English

CLEANUP

PURGING THE PAINT HOSE

1. Lock the gun and remove spray tip

assembly.

2. Submerge suction set into a bucket

with appropriate cleaning solution.

3. Hold the spray gun against the side of

the paint can and hold the trigger.

4. While holding the trigger, turn the

pump ON (l), and turn the

PRIME/SPRAYknob to SPRAY.

5. Release the trigger.

6. Hold the spray gun against the side of

a separate container and hold the

trigger.

7. Trigger the gun until the fluid coming

out of the gun is clear.

8. Turn the PRIME/SPRAY knob to

PRIME and trigger gun once more to

relieve pressure.

9. Move on to Cleaning the Suction

Set.

Let the pump run until all paint is

purged from the hose and cleaning

solution is coming out of the gun.

These steps will allow you to

recover excess paint left over in the

paint hose.

CLEANING THE SUCTION SET

1. Lock the gun and turn

the pump OFF (O).

2. Remove the suction

hose and return tube

and clean it using the

appropriate cleaning

solution.

3. When suction set is clean, thread the

suction tube back onto the inlet

valve, and replace the return tube

onto the return tube fitting. Replace

clip.

4. Submerge the suction set into a

bucket of NEW cleaning solution.

5. Turn the PRIME/SPRAY knob to

PRIME, turn the pump to ON (l), and

trigger the gun into a waste container

to relieve the pressure.

6. Let the pump circulate the cleaning

solution through the suction set for 23 minutes.

7. Turn the pump OFF (O).

8. Move on to Cleaning the Spray

Gun, next page.

You should also wipe the threads of

the inlet valve, and remove and

clean the suction set screen.

Special cleanup instructions for use with

flammable solvents:

• ALWAYS FLUSH SPRAY GUN AT

LEAST ONE HOSE LENGTH

AWAY FROM SPRAY PUMP.

• If collecting flushed solvents in

one gallon metal container, place

it into an empty five gallon

container, then flush.

• Area must be free from vapors.

• Follow all cleanup instructions.

PRIME

Return tube

fitting

Inlet valve

Clip

Return tube

Suction set

o

WARNING

l

SPRAY

SPRAY

PRIME

l

Page 11

© 2003 Wagner Spray Tech - All rights reserved. 11 Customer Service: 800-880-0993

English

CLEANUP (CONTINUED)

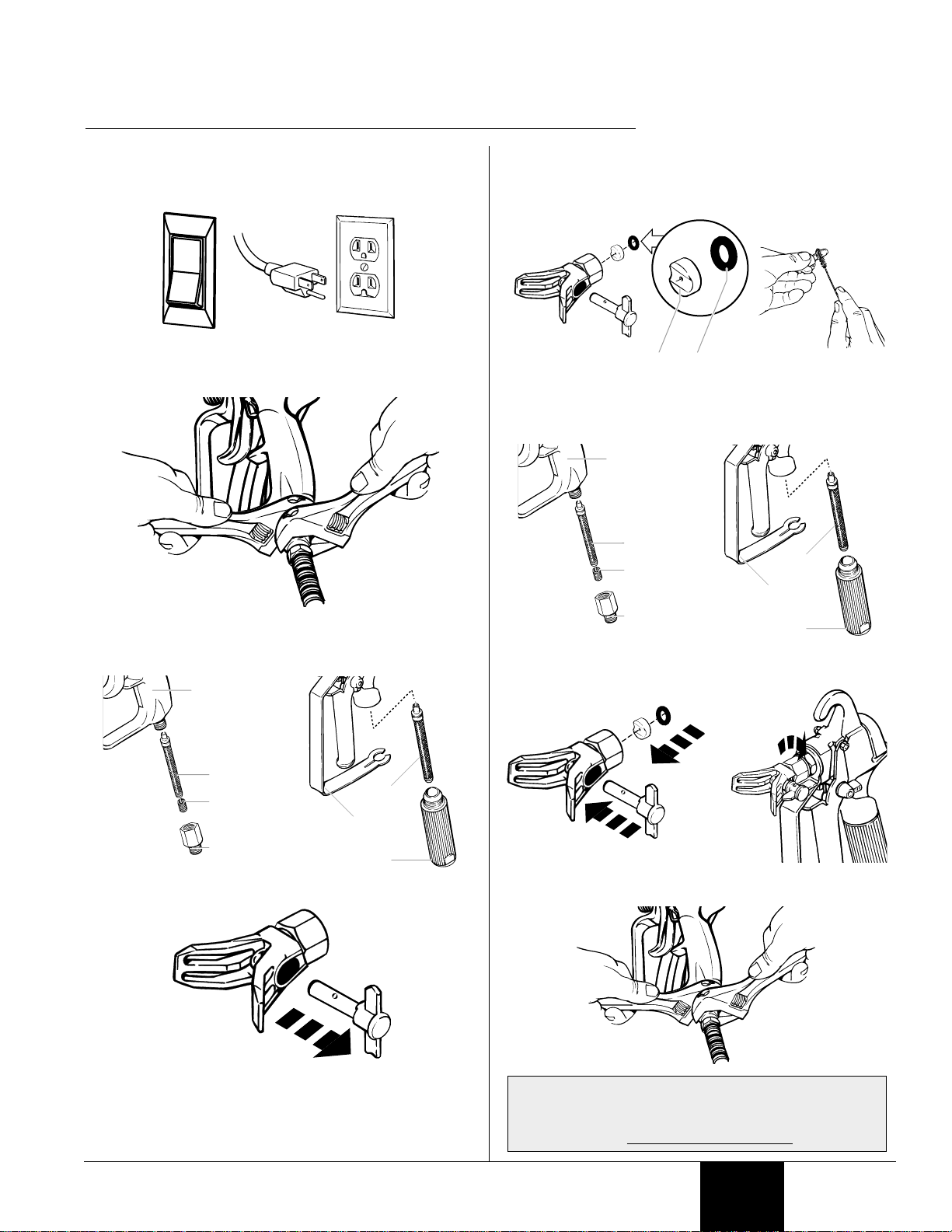

1. Make sure the pump is switched OFF (O), the

PRIME/SPRAY knob is turned to PRIME, and unplug the

sprayer.

2. Remove spray gun from the paint hose using adjustable

wrenches.

3. Remove filter from spray gun (refer to Cleaning the

Spray Gun Filter, page 9).

4. Remove spray tip from spray guard assembly.

Continue cleaning instructions on next column

5 Clean spray tip and filter with a soft-bristled brush and the

appropriate cleaning solution. Be sure to remove and

clean the washer and saddle seat located in the rear of

the spray tip assembly.

6. Reassemble spray gun:

• install gun filter tapered-end first, and

• install spray tip, saddle seat and washer, and replace

spray guard assembly.

7. Thread the spray gun back onto the paint hose. Tighten

with a wrench.

IMPORTANT!

If you used oil-based paints, you must flush the pump

again using warm, soapy water to prepare it for

storage. Repeat Cleaning the Suction Set

instructions.

CLEANING THE SPRAY GUN FILTER AND TIP ASSEMBLY

o

GX-08/10

Housing

seat

Housing

GX-06/07

Filter

Spring

Fitting

WasherSaddle

GX-08/10

Filter

Trigger

guard

Housing

GX-06/07

Filter

Spring

Fitting

Filter

Trigger

guard

Housing

Page 12

SHORT-TERM STORAGE ( UP TO 16 HOURS)

SHUTDOWN

1. Lock the spray gun off.

2. Turn the PRIME/SPRAY knob to PRIME.

3. Switch the pump OFF, and unplug the sprayer.

4. Pour 1/2 cup water slowly on the top of the paint to

prevent the paint from drying.

5. Wrap the spray gun assembly in a damp cloth and place it

in a plastic bag. Seal the bag shut.

6. Place the sprayer in a safe place out of the sun for shortterm storage.

STARTUP

1. Remove the gun from the plastic bag.

2. Stir the water into the paint.

3. Check to be sure that the PRIME/SPRAYknob is set to

PRIME.

4. Plug sprayer in and

turn the switch to

ON.

5. Turn the

PRIME/SPRAY

knob to SPRAY.

6. Test the sprayer on

a practice piece and begin spraying.

Follow these steps when using latex paints only. If

using materials that are oil-based, follow the long-term

storage steps.

Customer Service: 800-880-0993 12 © 2003 Wagner Spray Tech - All rights reserved.

PREPARING THE SPRAYER FOR LONG-

TERM STORAGE

1. Fill a cup or other container with separating oil

(approximately 2 ounces) supplied with the unit and

submerge the inlet valve into the oil.

2. Place a rag over the spray hose port, and turn the switch

ON (l).

3. When the oil has been sucked from the cup, switch the

pump OFF.

4. Insert the pusher stem into the inlet valve. Make sure the

pusher stem is inserted fully.

5. Wipe the entire unit, hose and gun with a damp cloth to

remove accumulated paint.

6. Replace the high pressure hose to the paint hose port.

The pusher stem is designed to do two things:

• It holds the oil in the valve to keep the carbide

seat from rusting.

• Secondly, it will keep the ball off of the seat to

prevent any paint residue deposits that will cause

the ball to stick to the seat. Paint deposits or rust

formed on the carbide seat will cause priming and

operation problems during repeated uses.

English

STORAGE

GX-06/07

GX-08/10

SPRAY

PRIME

o

l

PRIME

SPRAY

Inlet

valve

Page 13

© 2003 Wagner Spray Tech - All rights reserved. 13 Customer Service: 800-880-0993

English

DAILY MAINTENANCE

The only daily maintenance necessary is thorough cleaning.

Follow the cleaning procedures in this manual.

EXTENDED MAINTENANCE

Some pump parts eventually wear out from use and must be

replaced. The following list indicates the available repair kits

for the parts replaced by each kit. However, pump

performance is the only reliable indicator of when to replace

wear parts. Refer to the Troubleshooting section for more

information on when to use these kits.

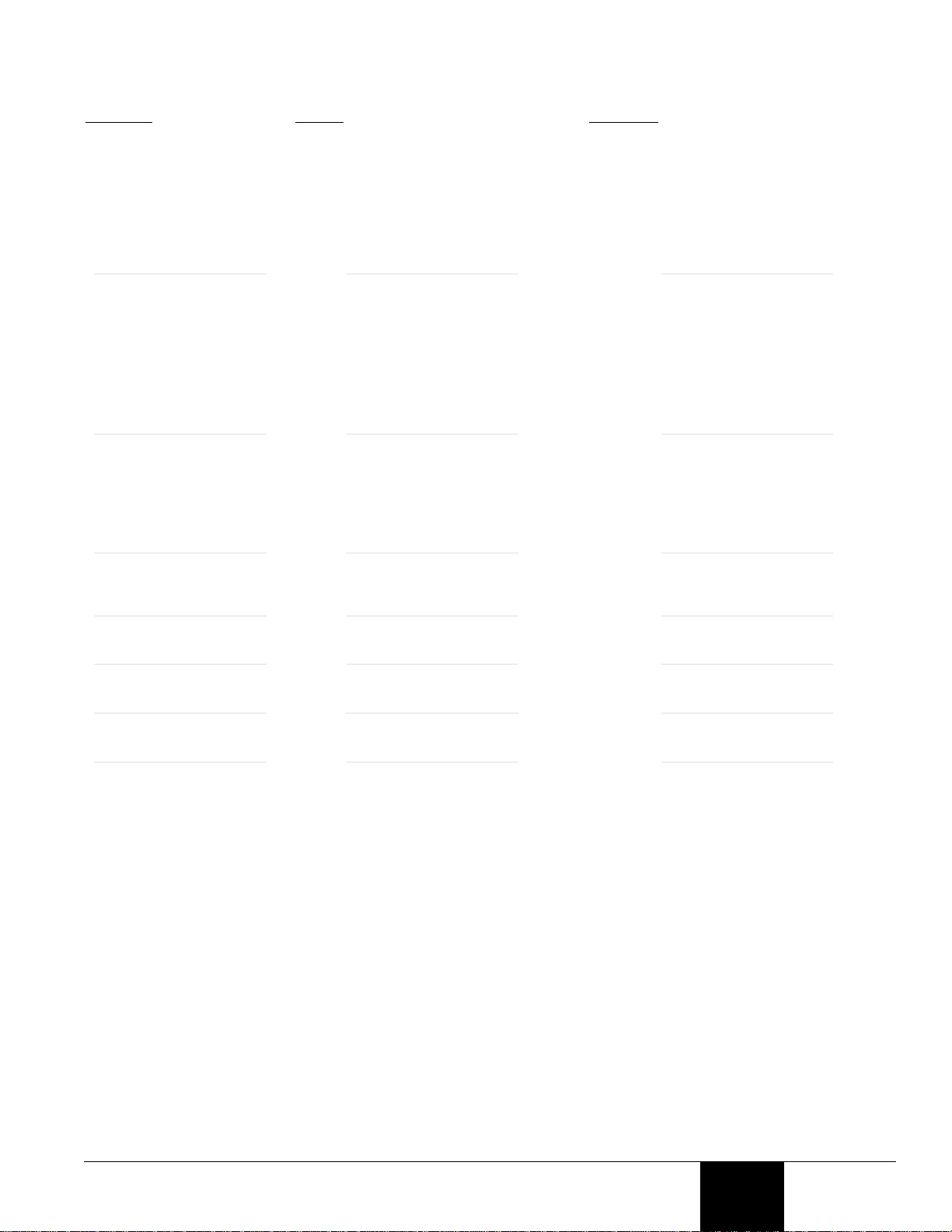

Kit Part #

Description

0512228 Fluid Section Seal Kit (9140, 9140S, 9150)

0512222 Valve Replacement Kit (9140, 9140S, 9150)

0512229 Fluid Section Seal Kit (9170, 9190, 9210)

0512224 Valve Replacement Kit (9170, 9190, 9210)

CLEANING THE

INLET V

ALVE

1. Unscrew the inlet valve

assembly from the unit

with a crescent wrench.

2. Unscrew the inlet nut

using a 3/8 inch allen

wrench.

3. Remove excess paint or

rust from the ball and seat or replace with new parts from

kit P/N 0512222 (9140, 9140S, 9150) or P/N 0512224

(9170, 9190, 9210). You may also have to clean excess

paint inside the housing.

4. Inspect the inlet O-ring on the inlet valve. Clean or

replace, and lubricate with a light household oil.

4. Reassemble ball, carbide seat, and O-rings in the order

shown below into the inlet valve.

5. Install inlet nut back into inlet valve. Torque to 12 ± 2

ft/lbs if you have torque wrench.

6. Make sure the inlet valve O-ring is installed on the inlet

valve, then install entire inlet valve assembly back into

unit. Tighten with an adjustable wrench.

Inlet valve

assembly

Housing

Inlet nut

Cleaning or servicing the inlet valve may be required if

the unit has priming problems. This may be caused by

improper cleaning and/or storage.

Part # Description

0154908 Separating Oil

0154830 Hose, Whip End, 5’ x 3/16”

0270192 Hose, Wireless, 25’ x 1/4"

0291000 Hose, Wireless, 50’ x 1/4"

0279667 Hose Connector, 1/4” x 1/4”

0088154 Pressure Gauge

0508910 Tip Extension, 12”

0508914 Tip Extension, 24”

0152001 Power Roller Gun Attachment

0155206 9" Roller Cover, 3/8” Nap

0152307 9" Roller Cover, 1/2” Nap

0155208 9" Roller Cover, 3/4” Nap

0152310 9" Roller Cover, 1-1/4” Nap

0512181 GX-08 Four Finger Metal Airless Spray Gun

0512180 GX-07 Two Finger Metal Airless Spray Gun

0512179 GX-06 Two Finger Plastic Airless Spray Gun

0512182 GX-10 Two Finger Metal Airless Spray Gun w/Swivel

0501010 Guard Assembly, F-Thread

0512508 Guard Assembly, G-Thread

0279974 3 Foot Pole Extension w/Swivel

0279976 6 Foot Pole Extension w/Swivel

0512134 180 Degree Swivel

0508931 F- to G-Thread Adapter

0154832 Suction Set Filter (2 Pack)

0512500 411 Trade Spray Tip

0512501 413 Trade Spray Tip

0512502 415 Trade Spray Tip

0512503 417 Trade Spray Tip

0501419 419 Trade Spray Tip

0512504 515 Trade Spray Tip

0512505 517 Trade Spray Tip

0512506 519 Trade Spray Tip

0093930 Anti-Seize Compound

0156113 TR-10 Telescoping Roller, 9", 3/8" Nap

0089959 Yellow Gun Filter

0089958 White Gun Filter

0279109 Pump Saver Plus Protector

MAINTENANCE ACCESSORIES

Inlet O-ring

Inlet valve

Ball

O-ring

Carbide seat

inlet valve assembly

Models 9140, 9140S and 9150

O-ring

Inlet nut

inlet valve assembly

Models 9170, 9190, and 9120

Page 14

Customer Service: 800-880-0993 14 © 2003 Wagner Spray Tech - All rights reserved.

English

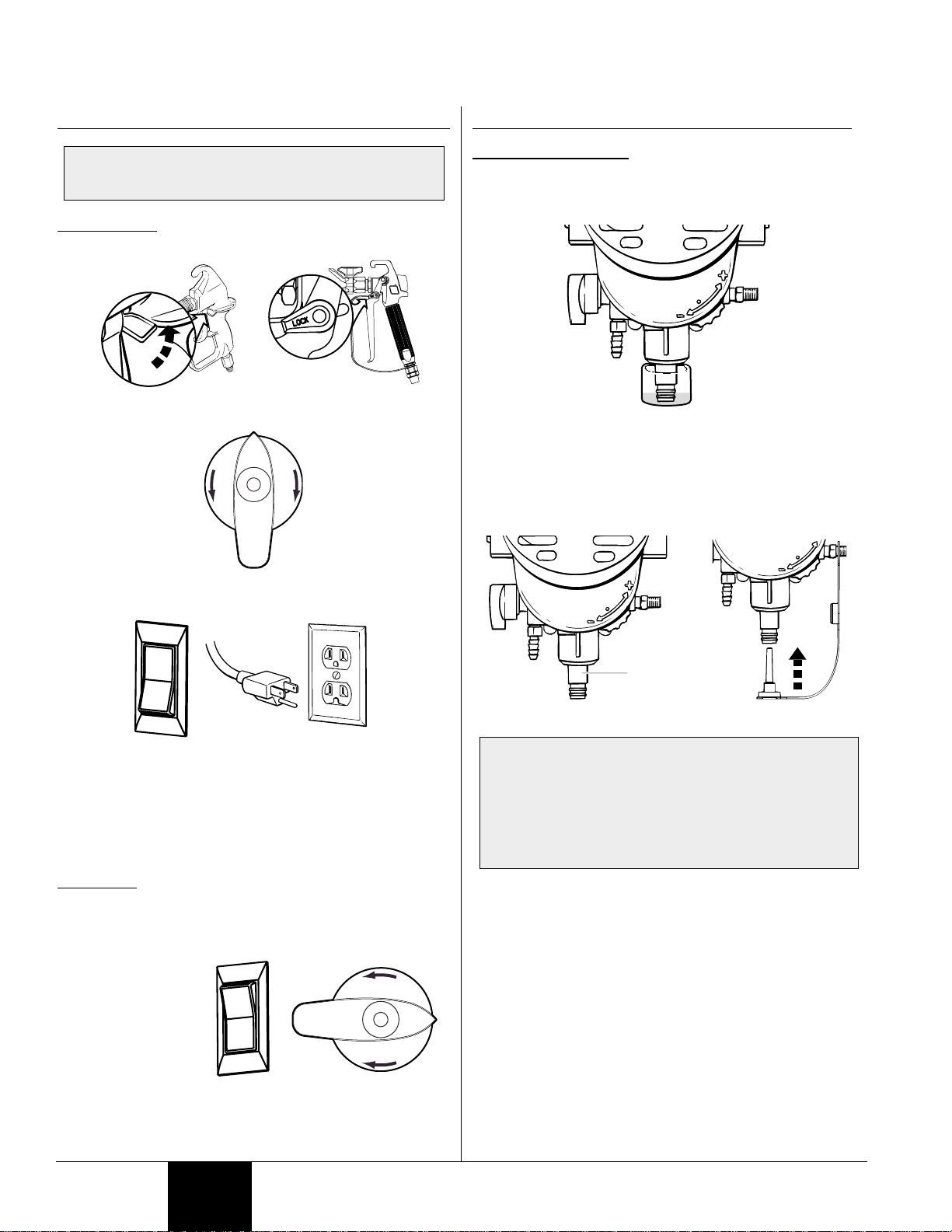

DISASSEMBLY OF THE FLUID SECTION

1. Remove the suction set.

2. Remove the front cover and the four

screws that secure it using a T20

Torx head driver.

3. Remove the yoke screw and washer

that secures the dowel pin. The

dowel pin connects the yoke to the

piston.

4. Using the pliers, pull the dowel pin

out.

5a. For models 9140, 9140S, and 9150, rotate the pump

shaft so the piston is in the top dead center position. This

can be done by pushing on the yoke. This is required to

disassemble all the parts.

5b. For models 9170, 9190, and 9210, inspect the yoke

assembly and piston. In order to remove all the necessary

parts, the piston must not be in the bottom dead center

position. If the piston is at the bottom of the stroke, install

the front cover and screws, turn the pump on briefly to

index the piston, unplug the unit, and repeat step 2.

6. Unscrew and remove the inlet valve assembly using an

adjustable wrench.

7. Remove the piston assembly by pushing down on the

piston near the yoke.

8. Unscrew and remove the top nut using and adjustable

wrench.

9. Remove the worn seals using a flat head screwdriver or

punch. Remove the top seal from the top and the bottom

seal from the bottom by pressing against the side of the

seal and popping it out. Be sure not to scratch the

housing where the seals are located.

10. Clean the area where the new seals are to be installed.

ASSEMBLY OF THE FLUID SECTION

1. Lubricate the new top seal with Separating Oil (P/N

0154908) or light household oil and by hand place the seal

(cup side of seal down) into the top port of the housing.

2. Place a small amount of anti-seize on the threads of the

nut. Place the top nut into the top of the housing and

tighten with an adjustable wrench. This will drive the top

seal into the correct position.

3. Turn the pump upside down.

Lubricate the seal on the

piston/seal assembly similar to

the top seal. Place the

piston/seal assembly into the

bottom of the housing. Insert

the plastic insertion tool and

thread into position to properly

seat the piston/seal. Thread

fully until tight. Remove the

insertion tool.

4. Install the new O-ring on the inlet valve assembly,

lubricate with Separating Oil (P/N 0154908), thread into

the bottom (inlet) of the housing, and tighten with an

adjustable wrench. This will drive the bottom seal into the

correct position.

5. Align the piston with the yoke. Arubber mallet may be

used. Be careful not to damage the piston.

6. Apply any type of household grease to the piston and yoke

area to prolong life. Apply to the holes in the yoke where

the dowel is inserted.

7. Install the dowel pin to connect the yoke to the piston. The

piston may have to be moved up or down to do this.

8. Install the yoke screw and washer to secure the dowel pin.

9. Turn pump right side up and apply a few drops of Wagner

Separating Oil or light household oil between the top nut and

piston. This will prolong the seal life.

10. Install front cover and four (4) screws.

11. Install the suction set.

Dowel

Screw

0512229 Kit

(9170, 9190,

and 9210)

0512228 Kit

(9140, 9140S

and 9150)

0512229 Kit

(9170, 9190,

and 9210)

0512228 Kit

(9140, 9140S,

and 9150)

Washer

Retaining

ring

Yoke

Piston/seal

assembly

Top seal

(cup down)

Top nut

O-ring

Inlet valve assembly

CAUTION! DO NOT

attempt to remove the

seals from the piston.

Insertion

tool

FLUID SECTION SEAL REPLACEMENT INSTRUCTIONS

KIT 0512228 (MODELS 9140, 9140S, AND 9150)

KIT 0512229 (MODELS 9170, 9190, AND 9210)

Always wear protective eye wear while servicing the pump. Be sure to follow the PRESSURE RELIEF PROCEDURE (page 6)

when shutting the unit down for any purpose, including servicing or adjusting. After performing the pressure relief

procedure, be sure to unplug the unit before servicing or adjusting. Area must be free of solvents and paint fumes.

SER

VICE NOTE--MODEL 9210

The inlet check ball is a wear part. Erosion of the check

ball can result in a loss of performance similar to a worn

piston and seals. Inspect the inlet ball by removing the

inlet valve assembly. If worn, replace the assembly with

P/N 0512224. This part number is available at Wagner

authorized service centers or by calling 1-800-880-0993.

WARNING

Page 15

© 2003 Wagner Spray Tech - All rights reserved. 15 Customer Service: 800-880-0993

English

TROUBLESHOOTING

PROBLEM

A. The sprayer does not start.

B. The sprayer starts but does

not draw in paint when the

PRIME/SPRAY knob is set to

PRIME.

C. The sprayer draws up paint

but the pressure drops when

the gun is triggered.

D. The PRIME/SPRAY valve is

on SPRAY and there is flow

through the return tube.

E. The spray gun leaks.

F. The tip assembly leaks.

G. The spray gun will not spray.

H. The paint pattern is tailing.

CAUSE

1. The sprayer is not plugged in.

2. The ON/OFF switch is set to OFF.

3. The sprayer was turned off while still under

pressure.

4. No voltage is coming from the wall plug.

5. The extension cord is damaged or has too

low a capacity.

6. A fuse is blown in the sprayer.

7. There is a problem with the motor.

1. The unit will not prime properly or has lost prime.

2. The paint bucket is empty or the suction

tube is not totally immersed in the paint.

3. The suction set is clogged.

4. The suction tube is loose at the inlet valve.

5. The inlet or outlet valve is stuck.

6. The inlet valve is worn or damaged.

7. The PRIME/SPRAY valve is plugged.

1. The spray tip is worn.

2. The suction set screen is clogged.

3. The gun or spray tip filter is plugged.

4. The paint is too heavy or coarse.

5. The outlet valve assembly is dirty or worn.

6. The inlet valve assembly is damaged or worn.

1. The PRIME/SPRAY valve is dirty or worn.

1. Internal parts of the gun are worn

or dirty.

1. The tip was assembled incorrectly.

2. A seal is worn.

1. The spray tip or the gun filter is plugged.

2. The spray tip is in the CLEAN position.

1. The pressure is set too low.

2. The gun, the tip, or the suction filter

is plugged.

3. The suction tube is loose at the inlet valve.

4. The tip is worn.

5. The paint is too thick.

6. Pressure loss.

SOLUTION

1. Plug the sprayer in.

2. Turn the ON/OFF switch to ON.

3. Turn pressure control knob to maximum setting (+),

or relieve pressure by turning the PRIME/SPRAY

valve to PRIME.

4. Properly test the power supply voltage.

5. Replace the extension cord.

6. Take sprayer to Wagner Authorized Service Center.

7. Take sprayer to Wagner Authorized Service Center.

1. Try to prime the unit again.

2. Refill the bucket or immerse the suction tube in

paint.

3. Clean the suction set.

4. Clean the tube connection and tighten it securely.

5. Clean the inlet and outlet valves and replace any

worn parts.* Inlet may be stuck from old paint.

Insert pusher stem to release

6. Replace the inlet valve.*

7. Take sprayer to Wagner Authorized Service Center.

1. Replace the spray tip with a new tip.**

2. Clean the suction set screen.

3. Clean or replace the proper filter. Always keep

extra filters on hand.

4. Thin or strain the paint.

5. Clean or replace the outlet valve assembly.*

6. Replace the inlet valve.*

1. Take sprayer to Wagner Authorized Service Center.

1. Take the sprayer to a Wagner Authorized Service

Center.

1. Check the tip assembly and assemble properly.

2. Replace the seal.*

1. Clean the spray tip or gun filter.

2. Put the tip in the SPRAY position.

1. Increase the pressure.

2. Clean the filters.

3. Tighten the suction tube fitting.

4. Replace the spray tip.

5. Thin the paint.

6. Refer to Causes and Solutions for problem C.

* Special repair kits with instructions are available for these procedures. Refer to the Maintenance (page 13) section of this

manual for a list of the kits and their part numbers.

** Additional parts are available for this procedure. Refer to the Accessories (page 13) section of this manual for a list of the

parts and their part numbers.

Page 16

Page 17

Français

Impression aux É.-U.

PULVÉRISATEUR SANS AIR PERFORMANT,

MODÈLES 9140, 9140S, 9150, 9170, 9190 ET 9210

MANUEL DE L

’UTILISATEUR • LIRE CE MANUEL POUR OBTENIR DES DIRECTIVES COMPLÈTES

TABLE DES MATIÈRES :

SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

DESCRIPTION ET COMPOSANTS . . . . . . . . . . . . . . . . . . 20

PRÉPARATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

BRANCHEMENT DU PULVÉRISATEUR. . . . . . . . . . . . . . . 22

DÉCOMPRESSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PURGE ET AMORÇAGE . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PULVÉRISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PROBLÈMES POTENTIELS. . . . . . . . . . . . . . . . . . . . . . . . 25

NETTOYAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

RANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ACCESSOIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

TRONÇON D’ACHEMINEMENT DU PRODUIT. . . . . . . . . . 30

DÉPANNAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LISTE DE PIÈCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-51

GARANTIE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CHARACTÉRISTIQUES TECHNIQUES :

Poids ................................11.3 kg (9140S)

14 kg (9140, 9150)

16.3 kg (9170, 9190)

18.1 kg (9210)

Capacité ...........................Jusqu’à 1 l/min (9140, 9140S, 9150)

Jusqu’à 1,25 l/min (9170)

Jusqu’à 1,6 l/min (9190)

Jusqu’à 1,71 l/min (9210)

Source de puissance........Moteur universel de 1/2 ch (9140, 9140S,

9150)

Moteur c.c. à aimant permanent de 5/8 ch (9170)

Moteur c.c. à aimant permanent de 3/4 ch (9190)

Moteur c.c. à aimant permanent de 7/8 ch (9210)

Exigences en matière

d’alimentation ...................Circuit d’au moins 15 A, à courant de 115

V c.a./60 Hz

Génératrice.......................8 000 W

Pression de pulvérisation...Jusqu’à 2 800 lb/po2 (193 bar)

Caractéristiques de sécurité.Serrure et garde de

déclenchement de pistolet de

pulvérisation; protège-embout

intégré; bouton d’amorçage

permettant la décompression en

toute sécurité.

Possibilitiés.......................Pulvérisation de divers types de

peintures (au latex ou à huile),

d’apprêts, de teintures, d’agent

d’imprégnation et d’autres

substances non abrasives.

Ne pas employer de matériaux

avec un point d’éclair au-dessous

de 70°F (21°C).

Ne pas utiliser cet appareil pour pulvériser des

matériaux grumeleux, des enduits pour béton ou des

scellants d’asphalte.

U.S. Patent No. 6,435,846

Cette pompe est offerte en deuz modèles : le

modèle sur support et le modèle sur chariot.

Le modèle sur support est illustré dans le

présent manuel. Toutes les données fournies

pour le modèle sur support s’appliquent au

modèle sur chariot, sauf indication contraire.

Besoin d'aide?

rapidement conseil. Composez le numéro sans

frais de Wagner Spray Tech si vous éprouvez

des difficultés ou avez des commentaires à

formuler (services en anglais seulement).

Appelez-nous d'abord pour obtener

1-800-880-0993

Service technique de Wagner

Rendez-nous visite sur le Web!

www.wagnerspraytech.com

1770 Fernbrook Lane, Minneapolis, MN 55447 - USA

Page 18

DANGER : INJECTION CUTANÉE

Le jet de haute pression produit par cet appareil

peut transpercer la peau et les tissus sousjacents, causant des blessures graves pouvant

aller jusqu’à l’amputation.

NE PAS TRAITER CE TYPE DE BLESSURE

COMME UNE SIMPLE COUPURE! Une amputation peut en

résulter. ON DOIT CONSULTER UN MÉDICIN SUR-LE-CHAMP.

La pression maximale de ce pulvérisateur est d’environ 2 800

PSI/193 bar

MESURES PRÉVENTIVES :

• NE JAMAIS pointer le pistolet vers une partie du corps.

• NE JAMAIS mettre une partie du corps devant le jet de produit.

NE JAMAIS toucher les fuites du flexible de pulvérisation.

• NE JAMAIS mettre la main, même gantée, devant le pistolet

(les gants n’offrent aucune protection contre les blessures par

injection).

• TOUJOURS verrouiller la détente, arrêter la pompe et relâcher

toute la pression avant d’effectuer la maintenance de l’appareil

ou de le laisser sans surveillance, d’en nettoyer le protègeembout ou l’embout, ou de remplacer ce dernier. La pression

ne sera pas relâchée par le simple arrêt du moteur; pour ce

faire, on doit se servir du bouton PRIME/SPRAY(se reporter à

la section DÉCOMPRESSION, page 22, du présent manuel).

• TOUJOURS s'assurer que le protège-embout est en place

avant de pulvériser. Il est cependant à noter que, s’il assure

une certaine protection, ce dispositif joue surtout un rôle

préventif.

• TOUJOURS retirer l’embout avant de vidanger ou de nettoyer

l’appareil.

• TOUJOURS inspecter le flexible avant de procéder; celui-ci

peut présenter des fuites attribuables à l’usure, à une flexion

excessibe ou à un traitement abusif, lesquelles fuites

présentent des risques d’injection cutanée.

• NE JAMAIS utiliser de pistolet sans verrou de détente et

protège-doigts.

• Tous les accessoires (pistolets, embouts,

rallonges, flexibles etc.) doivent pouvoir subir une pression

nominale de 2 800 PSI/193 bar ou plus.

DANGER : ÉMANATIONS DANGEREUSES

Certains produits (peintures, solvants, insecticides ou

autres) peuvent être nocifs s’ils sont inhalés ou

entrent en contact avec l’organisme. Les émanations

de ces produits peuvent provoquer de graves

nausées, évanouissements ou empoisonnements.

MESURES PRÉVENTIVES :

• Se servir d’un masque ou d’un respirateur s’il y a risque

d’inhalation (lire toutes les directives concernant ces dispositifs

afin de s’assurer qu’ils offrent la protection requise).

• Porter des lunettes de protection.

• Porter les vêtements de protection prescrits par

le fabricant du produit utilisé.

REMARQUE À L’INTENTION DES MÉDECINS :

Les injections cutanées sont des lésions traumatiques; il

importe donc de les traiter sans délai. On NE DOIT PAS

retarder ce traitement sous prétexte de vérifier la toxicité

du produit en cause, celle-ci n’étant conséquente que dans

le cas d’injection directe de certains produits dans le

système sanguin. Il pourrait s’avérer nécessaire de

consulter un plasticien ou un spécialiste en chirurgie

reconstructive de la main.

18 1-800-880-0993 © 2003 Wagner Spray Tech - Tous droits réservés

DANGER : EXPLOSION OU INCENDIE

Les émanations de certains produits peuvent

exploser ou s’enflammer, et risquent d’entraîner

des dommages matériels ou de graves blessures.

MESURES PRÉVENTIVES :

• S’assurer que l’aire de travail est dotée de

moyens d’évacuation d’air vicié et d’introduction

d’air frais pour éviter l’accumulation de vapeurs inflammables

• Ne pas travailler près de sources d’ignition

(décharges électrostatiques ou étincelles

provoquées par le branchement/débranchement

d’appareils ou la commutation d’interrupteurs,

appliances eléctriques, flammes nues,

veilleuses, objets chauds, etc.).

• Ne pas fumer dans l’aire de travail.

• L’aire de travail doit être munie d’un extincteur en bon état de marche.

• Prévoir un espace d’au moins 6 mètres entre la pompe et l’objet à

pulvériser s’ils sont dans la même pièce bien ventilée (rallonger le

flexible au besoin). Les vapeurs inflammables étant souvent plus

lourdes que l’air, l’espace au-dessus du plancher doit être

particulièrement bien aéré. Cet appareil est doté de composants

susceptibles de former des arcs électriques pouvant enflammer

les émanations présentes.

• Les appareils et objets à l’intérieur ou à proximité de l’aire de

travail doivent être adéquatement mis à la terre pour éviter

les décharges électrostatiques.

• Les flexibles dont on se sert doivent être conçus pour subir

les pressions élevées et faits de matériaux conducteurs ou

mis à la terre adéquatement; le pistolet sera mis à la terre par

le biais de ses raccords aux flexibles.

• Le cordon d’alimentation doit être branché à un circuit trifilaire.

• L’appareil doit toujours être vidangé à basse pression,

embout retiré, dans un contenant métallique distinct. Tenir le

pistolet contre la paroi du contenant de manière à mettre ce

dernier à la terre et à prévenir les décharges électrostatiques.

• Toujours respecter les mises en garde et les directives du

fabricant des produits et solvants utilisés.

• Faire preuve d’extrême prudence en présence de produits

dont le point d’éclair est inférieur à 21 °C (le point d’éclair

correspond à la température à laquelle un liquide peut

produire suffisamment d’émanations pour s’enflammer).

• Le plastique est générateur de décharges électrostatiques; ne

jamais en suspendre pour fermer une aire de travail ou en

utiliser en guise de toile de protection lorsqu’on pulvérise un

produit inflammable.

• Se servir de la pression la plus basse possible pour vidanger

l’appareil.

MOTEUR À GAZ (LE CAS ÉCHÉANT)

Les pompes dotées d’un moteur à gaz doivent toujours être à l’extérieur des

structures, à l’air frais. On doit tenir tout solvant éloigné de l’échappement du

moteur. Ne jamais remplir le réservoir quand le moteur tourne ou est encore

chaud, au risque d’enflammer le carburant accidentellement déversé.

T oujours raccorder un cavalier entre la pompe et un objet mis à la terre (une

conduite d’eau métallique, par exemple). Consulter les consignes de sécurité

relatives aux dispositifs munis d’un moteur à gaz.

DANGER : EXPLOSION CAUSÉE PAR DES

PRODUITS INCOMPATIBLES

Ce type d’explosion peut entraîner des

dommages matériels ou des blessures graves

• Ne pas utiliser de produits contenant du chlore

ou du javellisant.

• Ne pas utiliser de solvants à base de halons comme l’eau de

javel, les agents antimoisissure, le chlorure de méthylène et le

trichloroéthane-1-1-1, lesquels ne sont pas compatibles avec

l’aluminium.

• Communiquer avec le fournisseur du produit concerné pour en

connaître la compatibilité avec l’aluminium.

CONSIGNES DE SÉCURITE • LIRE TOUTES CES

CONSIGNES AVANT D

’UTILISER L’APPAREIL

Français

Page 19

DANGER : GÉNÉRALITÉS

D’autres dangers peuvent entraîner des dommages matériels ou

des blessures graves.

MESURES PRÉVENTIVES :

• Lire toutes les directives et consignes de sécurité avant

d’utiliser l’appareil.

• Observer tous les codes locaux, provinciaux, d’état et

nationaux régissant la ventilation, la prévention des incendies

et le fonctionnement de l’appareil.

• Aux États-Unis, le gouvernement a adopté des normes de

sécurité en vertu de l’Occupational Safety and Health Act

(OSHA). Le cas échéant, on doit les consulter, notamment les

parties 1910 des normes générales et 1926 des normes de

construction.

• N’utiliser que les pièces autorisées par le fabricant; les

utilisateurs qui choisiront d’utiliser des composants dont les

caractéristiques techniques et les exigences en matière de

sécurité sont inférieures devront en assumer tous les risques

et responsabilités.

• Avant chaque usage, examiner tous les flexibles afin de

confirmer l’absence de coupures, de fuites, d’abrasions ou de

renflements. Vérifier également l’intégrité des raccords.

Remplacer sans délai les pièces qui semblent présenter des

défectuosités. Ne jamais tenter de réparer un flexible;

remplacer ceux qui font défaut par des modèles haute

pression, avec mise à la terre.

• Tous les flexibles, pistolets et autres accessoires doivent

pouvoir subir une pression nominale de 2 800 PSI/193 bar ou

plus.

• Ne pas pulvériser à l’extérieur par grands vents.

• Porter des vêtements aptes à protéger la peau et les cheveux

du produit utilisé.

RENSEIGNEMENTS IMPORTANTS SUR

L’ÉLECTRICITÉ

Si l’application requiert l’utilisation d’une rallonge, celle-ci doit être

trifilaire et dotée d’une fiche à trois broches et d’un connecteur à trois

fentes pouvant accepter la fiche de l’appareil. Cette rallonge doit être

en bon état. On doit en outre s’assurer qu’elle est d’un calibre

suffisant pour éviter les baisses de tension susceptibles de provoquer

des pertes de puissance ou une surchauffe de l’appareil. On

recommande l’utilisation d’un cordon de calibre 14 ou 12. Si la

rallonge doit servir à l’extérieur, on doit opter pour un type de cordon

dont la désignation arbore le suffixe « W-A» (ex. SJTW-A).

LE MODÈLES 9140, 9140S, ET 9150 EST MUNI D’UN DISPOSITIF

THERMIQUE NON RÉCLENCHABLE DE PROTECTION CONTRE

LES SURCHARGES, TANDIS QUE LES MODÈLES 9170, 9190 ET

9210 SONT DOTÉS D’UN FUSIBLE REMPLAÇABLE.

• Toujours débrancher l’appareil de la source d’alimentation

avant d’en effectuer la maintenance ou d’en modifier la

configuration.

Les causes de surcharge doivent être éliminées avant de

redémarrer l’appareil. En cas de doute, apporter ce dernier à

un centre de service.

Comme le flexible ne peut être plus long que 30 mètres,

si l’objet à pulvériser est à une distance supérieure, il

faut plutôt allonger le cordon l’alimentation.

DIRECTIVES DE MISE À LA TERRE

Cet appareil doit être mis à la terre. En cas de court-circuit, cette

précaution réduit les risques de choc en procurant un parcours au

courant électrique. Le cordon de l’appareil est doté d’un fil de terre

relié à la troisième broche de sa fiche. Cette dernière doit être

branchée dans une prise correctement câblée et mise à la terre

conformément aux codes et règlements locaux.

Le fait de ne pas brancher correctement la

fiche trifilaire de l’appareil peut entraîner des

risques de choc électrique.

Si on doit réparer ou remplacer le cordon ou la fiche, ne pas

raccorder le fil de terre à la borne des broches plates (lames) de

cette dernière. Ce fil, normalement vert (avec ou sans rayures

jaunes), doit être relié à la broche de terre.

Consulter un technicien ou un électricien qualifié à défaut de

comprendre l’ensemble des présentes directives ou en cas

d’incertitude quant à la mise à terre de l’appareil.

Ne pas modifier la fiche de l’appareil; si elle ne s’adapte pas dans

la prise voulue, faire remplacer cette dernière par un électricien

qualifié.

Conçu pour les circuits de 120 V, cet appareil est doté d’une fiche

ressemblant à celle illustrée ci-dessous. Veuillez-vous assurer que

le produit est connecté à une prise électrique ayant la même

configuration que la fiche mâle. Ne pas utiliser d’adaptateur avec

ce produit.

EN CAS DE PROBLÈME D’ASSEMBLAGE,

D’UTILISATION OU DE NETTOYAGE DU

PUL VÉRISA TEUR

, SE REPORTER À LA

SECTION DÉP ANNAGE DU PRÉSENT MANUEL

(PAGE 31) OU COMMUNIQUER AVEC LES

TECHNICIENS DU SERVICE À LA CLIENTÈLE EN

COMPOSANT LE

:

1-800-880-0993

(

SERVICES EN ANGLAIS SEULEMENT)

© 2003 Wagner Spray Tech - Tous droits réservés 1-800-880-0993 19

CONSIGNES DE SÉCURITE • LIRE TOUTES CES

CONSIGNES AVANT D

’UTILISER L’APPAREIL

Français

MISE EN GARDE

Prise trifilaire

AVERTISSEMENT

AVERTISSEMENT

Broche de mise à la terre

Plaque murale de la prise

Page 20

COMPOSANTS

Le carton d’expédition de cet appareil contient les éléments suivants :

• un dispositif d’aspiration et un tube de retour;

• un pistolet muni d’un filtre;

• un embout et ses composants (se reporter au tableau ci-dessous);

• un flexible haute pression d’un diamètre de 0,6 centimètre, long de

7,6 mètres (9140, 9140S, 9150);

• un flexible haute pression d’un diamètre de 0,6 centimètre, long de

15,2 mètres (9170, 9190, 9210);

• de l’huile séparatrice.

COMMANDES

ET FONCTIONS

Interrupteur.........................L’interrupteur permet de mettre

l’appareil sous et hors tension (O =

hors tension, l = sous tension).

Dispositif d’aspiration ..........Dispositif qui achemine le produit dans

la pompe.

Tronçon d’acheminement

du produit............................Ce tronçon contient un piston qui, en se

déplaçant de haut en bas, aspire le

produit dans le dispositif d’aspiration.

20 800-880-0993 © 2003 Wagner Spray Tech - Tous droits réservés.

Pistolet................................Le pistolet permet de réguler le débit

du produit aspiré par la pompe. Le

modèle de pistolet dépend de celui du

pulvérisateur (se reporter au Tableau

des pistolets/embouts ci-dessous).

Flexible de pulvérisation......Ce flexible relie le pistolet à la pompe.

Tube de retour....................Ce tube sert à renvoyer le produit dans

son contenant original.

Bouton PRIME/SPRAY .......Ce bouton permet de diriger le produit

vers le flexible quand il est réglé à

SPRAYet vers le tube de retour quand il

est réglé à PRIME. Les flèches indiquent

dans quelle direction le tourner.

On utilise également ce bouton pour

relâcher de la pression accumulée dans

le flexible (se reporter à la section

DÉCOMPRESSION, page 22).

Bouton de régulation

de la pression .....................Ce bouton permet de réguler la force

exercée par la pompe pour pousser le

produit (emplacement indiqué sur

l’illustration ci-dessous).

Français

DESCRIPTION ET COMPOSANTS

Tableau des pistolets/embouts

Modèle Pistolet

9140/S GX-06 0,013 0,015 Jaune (fin)

9150

9170

9190

9210 GX-10 0,017 0,021 Blanc (moyen)

GX-07

GX-07

GX-08

Numéro

d'embout

0,013

0,015

0,017

Numéro

max.

0,015

0,017

0,019

recommandé

Jaune (fin)

Jaune (fin)

Blanc (moyen)

Filtre

(modèles 9140, 9140S,

9150, 9170 et 9190)

Bouton de régulation de la pression

Arrière du carter

Raccord de

flexible

Face avant

(modèle 9210)

Aire de lubrification

pulvérisation

Embout de

pulvérisation

Pistolet

Support

de flexible

Guidon

Carter du

moteur

(face avant)

Support de

contenant

Flexible de

Tube de

retour

Tube

d'aspiration

Interrupteur

O = Hors tension

l = Sous tension

Bouton

PRIME/

SPRAY

Tronçon

d'acheminement

du produit

Bouton de régulation de la pression

Bouton PRIME/SPRAY

Position PRIME Position SPRAY

SPRAY

PRIME

PRIME

SPRAY

O

l

Crépine du dispositif

d'aspiration

Page 21

OUTILS REQUIS

• Deux clés à molette

• Une clé hexagonale (0,475 cm)

• Une rallonge (se reporter à la section RENSEIGNEMENTS

IMPORTANTS SUR L’ÉLECTRICITÉ, page 19).

Ne pas brancher le pulvérisateur avant d’avoir terminé les

préparatifs.

FIXATION DU GUIDON (MODÈLES DU CHARIOT)

1. Placer le guidon contre le

chariot de manière à ce que

leurs orifices s’alignent.

2. Insérer les boulons à travers

le guidon, le chariot et une

rondelle de blocage.

3. Serrer à la main les écrous

papillons sur les boulons.

FIXATION DU SUPPORT DE CONTENANT

(MODÈLES DU CHARIOT)

1. Placer le support contre

l’appareil de manière à ce

que leurs orifices s’alignent.

2. Insérer les boulons dans les

orifices alignés.

3. Serrer les boulons au moyen

d’une clé hexagonale de

0,475 cm.

FIXATION DU FLEXIBLE DE PULVÉRISATION

1. Visser le flexible haute

pression sur son raccord.

2. Serrer au moyen d’une clé à

molette.

3. Retirer l’arrêtoir de la

soupape d’entrée.

FIXATION DU PISTOLET

1. Visser le pistolet sur

l’autre extrémité du

flexible.

FIXATION

DU DISPOSITIF D’ASPIRATION ET DU

TUBE

DE RETOUR

1. Fixer le tube d’aspiration à la soupape d’entrée et serrer

fermement à la main. S’assurer que les filets sont bien droits,

de manière à ce que le raccord tourne librement.

2. Enfoncer le tube de retour sur son raccord.

3. Serrer l’agrafe sur le raccord de manière à bien assujettir le tube.

VERROUILLAGE ET DÉVERROUILLAGE DU PISTOLET

La détente doit toujours être verrouillée quand on fixe l’embout

ou quand le pistolet n’est pas utilisé. Se reporter au Tableau

des pistolets/embouts (page 20) pour déterminer le modèle en

présence.

La buse NE DOIT PAS être attachée juste après que le

pulvérisateur et le flexible aient été purgé et amorcé.

PISTOLETS GX-08 ET GX10

Pour bloquer le pistolet, on doit

tourner le verrou de détente avant

et légèrement vers le bas jusqu’à

ce qu’elle s’arrête.

PISTOLETS GX-06 ET GX-07

Le pistolet est bloqué quand le

verrou forme un angle de 90°

(perpendiculaire) avec la détente

dans l’une ou l’autre des

directions.

Tenir le pistolet dans

une clé à molette et

serrer au moyen

d’une autre.

© 2003 Wagner Spray Tech - Tous droits réservés. 800-880-0993 21

Français

PRÉPARATION--ASSEMBLAGE DU PULVÉRISATEUR

MISE EN GARDE

Raccord de

tube de retour

Soupape d'entée

Agrafe

Tube de retour

Dispositif

d'aspiration

MISE EN GARDE

GX-06/07

Pistolet bloqué

(impossible de

GX-08/10

Pistolet bloqué

(impossible de

pulvériser)

pulvériser)

Page 22

BRANCHEMENT DU PULVÉRISATEUR

1. Mettre l’interrupteur hors

tension (O).

2. Brancher le pulvérisateur

dans une rallonge trifilaire de

service robuste. Se reporter à

la section

RENSEIGNEMENTS

IMPORTANTS SUR

L’ÉLECTRICITÉ, page 19.

D

ÉCOMPRESSION

S’assurer de suivre cette procédure pour relâcher la pression à

l’intérieur du flexible de pulvérisation (page 22) CHAQUE FOIS

que l’appareil est mis hors tension.

1. Verrouiller le pistolet.

2. Mettre l’interrupteur hors

tension (O).

3. Deverrouiller le pistolet, régler

le bouton PRIME/SPRAY à

PRIME, pointer le pistolet

vers le contenant de produit

et serrer la détente.

4. Verrouiller le pistolet.

FILTRAGE DU PRODUIT

On recommande de tamiser les produits avant de les pulvériser afin

d’éviter l’usure prématurée de l’embout et du filtre; suivre les

directives du fabricant à cet égard.

La colonne ci-dessous contient des renseignements qui

seront répétés plus loin dans le manuel.

22 800-880-0993 © 2003 Wagner Spray Tech - Tous droits réservés.

CHOIX DU FILTRE DE PISTOLET APPROPRIÉ

On doit se servir du filtre qui convient à l’embout utilisé.

AVANT D’AMORCER LE PULVÉRISATEUR

Avant de procéder à l’amorçage, injecter une cuillère à thé d’huile

séparatrice (n° 0154908, fournie avec l’appareil) à l’endroit indiqué. On

peut également se servir d’huile domestique légère en guise de

substitut. Ne pas mettre trop d’huile, puisque celle-ci pourrait alors

couler dans le produit à pulvériser.

À l’usine, on vérifie le fonctionnement de chaque appareil au moyen

d’un liquide d’essai, lequel permet également d’éviter la corrosion du

tronçon d’acheminement pendant le stockage et l’expédition.

• Quel que soit le produit à pulvériser (à l’huile ou au latex), ce

liquide doit d’abord être purgé et l’appareil, nettoyé en

profondeur (suivre les étapes de la section PURGE ET

AMORÇAGE DE LA POMPE, page 23).

L’appareil ayant déjà été utilisé, on doit purger l’eau ou le solvant

utilisé lors des dernières procédures de nettoyage et de rangement

.

SIL’APPAREIL A DEJA SERVI. . .

SIL’APPAREIL N’A JAMAIS SERVI. . .

Français

AVANT DE COMMENCER

MISE EN GARDE

o

N° de

pièce

0154918 .011 Extrafin

0154675 .013 - .015 Fin

0154842 .017 - .023 Moyen

Numéro

d'embout

N° de

filtre

Maille Qté.

180 maille

0,084 mm

100 maille

0,140 mm

50 maille

0,315 mm

Coleur

du corps

rouge

jaune

blanc

Emb.

de 2

Emb.

de 2

Emb.

de 2

GX-06/07

GX-08/10

o

SPRAY

PRIME

Page 23

PURGE ET AMORÇAGE DE LA POMPE

1. Mettre un contenant plein de

produit sous le tube

d’aspiration.

2. Fixer le tube de retour à un

contenant de vidange.

3. Tourner le bouton de

régulation de la pression

jusqu’au maximum (+).

4. Régler le bouton

PRIME/SPRAY à PRIME.

5. Brancher le pulvérisateur et

mettre l’interrupteur sous

tension (l).