Page 1

Model VC940: OPERATING MANUAL

Chapter Title Page

1 Before You Start

Overview

Unpacking Inspection

Safety Information

Rules For Safe Operation

International Electrical Symbols

2 Getting Acquainted

Turning the Meter On

Battery Considerations

Automatic Power Off

Automatic Backlight Off

Low Battery Indication

The Meter Structure

Rotary Switch

Functional Buttons

The Meter Functions Vs Displays

Selecting the Range

Understanding the Display

Analogue Bar Graph

Using MAX MIN

3 Making Measurements

A. Measuring Voltages

B. Measuring Currents

C. Measuring Resistance

D. Testing for Continuity

E. Testing Diodes

F. Measuring Capacitance

G. Measuring Frequency / Duty Cycle

H. Measuring Temperature

I. 4~20mA loop current as % readout

J. Power Measurement

4 Using Stores, Recall and Send Features

Introduction

Storing and Clearing Readings

Recalling Stored Readings

Using Send

Sleep Mode

5 Changing the Default Setting

Introduction

Selecting Setup Options

Saving Setup Options

6 Maintenance

A. General Service

B. Replacing the Fuses

C. Replacing the Battery

7 Specifications

Safety and Compliances

Physical Specifications

General Specifications

Feature Summary

Basic Specifications

Detailed Accuracy Specifications

A. DC Voltage

B. AC Voltage

C. DC Current

D. AC Current

E. Resistance

F. Continuity Test

G. Diode Test

H. Capacitance

I. Frequency

J. Temperature

Degrees Celsius

Fahrenheit

K. 4~20mA loop current

L. Power Measurement

Table of Contents

1

Page 2

Model VC940: OPERATING MANUAL

Table Title Page

1-1 Unpacking Inspection

1-2 International Electrical Symbols

2-1 Rotary Switch Selections

2-2 Functional Buttons

2-3 Functions Vs Displays

2-4 Display Features

5-1 Setup Selections

List of Tables

2

Page 3

Model VC940: OPERATING MANUAL

Figure Title Page

2-1 Meter Structure

2-2 Display Features

3-1 Voltages Measurement

3-2 Currents Measurement

3-3 Resistance Measurement

3-4 Continuity Test

3-5 Diode Test

3-6 Capacitance Measurement

3-7 Frequency / Duty Cycle Measurement

3-8 Temperature Measurement

3-9 Power Measurement

6-1 Fuse Replacement

6-2 Battery Replacement

List of Figures

3

Page 4

Model VC940: OPERATING MANUAL

Chapter 1

Before You Start

Overview

This Operating Manual covers information on safety and cautions. Please read the relevant information carefully and observe all the Warnings and Notes strictly.

Warning

To avoid electric shock or personal injury, read the “Safety Information” and “Rules for Safe Operation” carefully before using the Meter.

Digital Multimeter VC940 (hereafter referred to as “the Meter”) is a 39999 counts and 4 3/4 digits with steady operations, fashionable structure and auto ranging instrument. The

Meter has analog bar graph, ACV & ACA True RMS and full range overload protection.

The Meter not only can measure AC voltage and current, DC voltage and current, Resistance, Capacitance, Temperature, Frequency, Diodes, Continuity, 4~20mA Loop,

Max/Min, Relative Mode but also has Low Battery Display, Store, Recall, Data Hold, Automatic Power Off and power features.

Unpacking Inspection

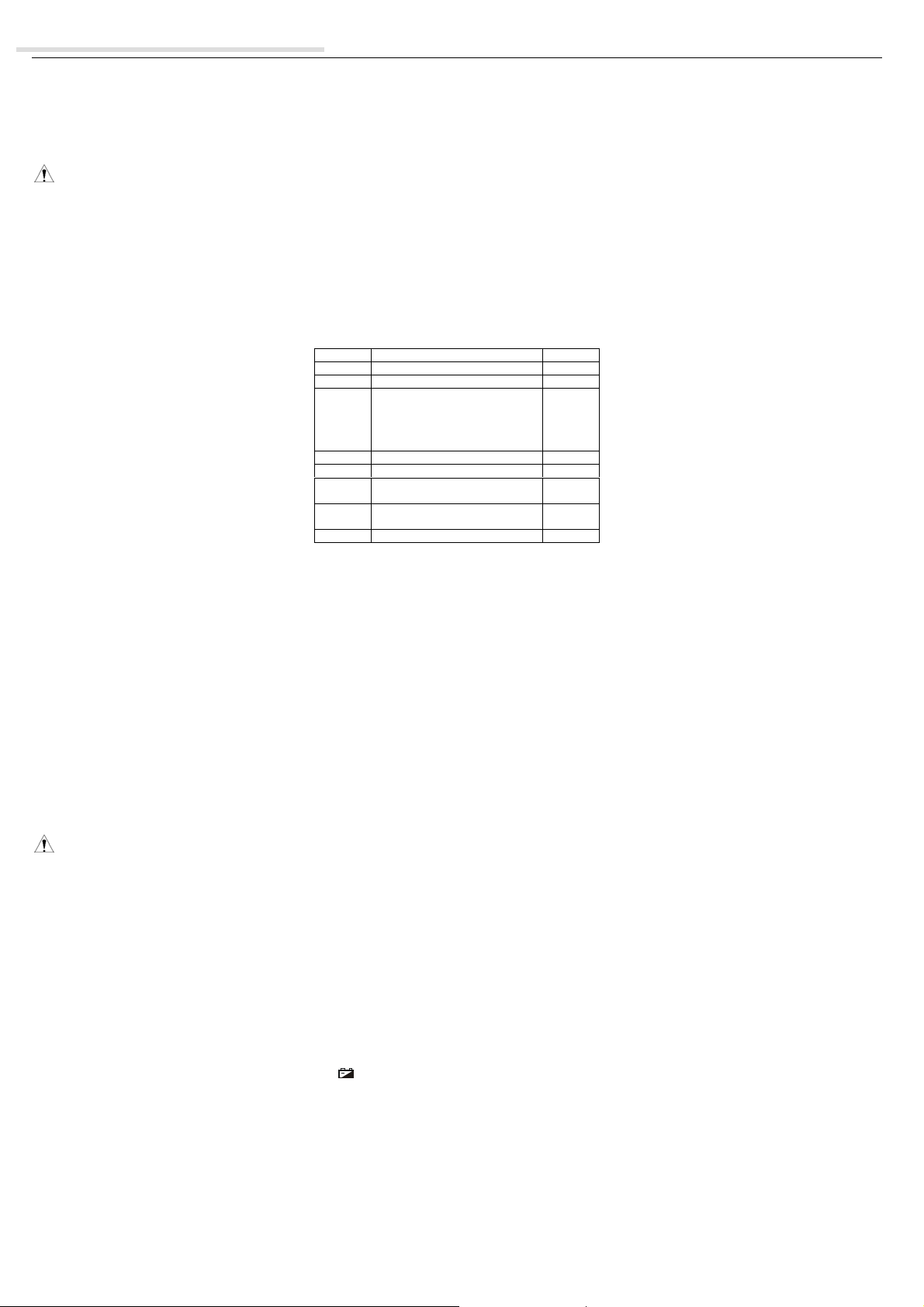

Open the package case and take out the Meter. Check the items shown on Table 1-1 carefully to see any missing or damaged part:

Item Description Qty

1 English Operating Manual 1 piece

2 Test Lead 1 pair

3

5 Alligator Clip 1 piece

6 RS232C interface cable 1 piece

7 CD-ROM (Installation Guide &

8 9V Battery (NEDA 1604, 6F22,

9 Power Adaptor 1 piece

In the event you find any missing or damage, please contact your dealer immediately.

Table 1-1. Unpacking Inspection

K-Type (nickel chromium ~

nickel silicon) Point Contact

Temperature Probe (It is only

suitable for measuring

temperature under 230

Computer Interface Software)

006P)

1 piece

1 piece

1 piece

Safety Information

This Meter complies with the standards IEC61010 safety measurement requirement: in pollution degree 2, overvoltage category (CAT. III 1000V, CAT. 600V) and double

insulation.

CAT. III: Distribution level, fixed installation, with smaller transient overvoltage than CAT. IV

CAT.: Primary supply level, overhead lines, cable systems etc.

Use the Meter only as specified in this operating manual, otherwise the protection provided by the Meter may be impaired.

In this manual, a Warning identifies conditions and actions that may pose hazards to the user, or may damage the Meter or the equipment under test.

A Note identifies the information that user should pay attention to.

International electrical symbols used on the Meter and in this Operating Manual are explained on page XX.

Rules For Safe Operation

Warning

To avoid possible electric shock or personal injury, and to avoid possible damage to the Meter or to the equipment under test, adhere to the following rules:

z Before using the Meter inspect the case. Do not use the Meter if it is damaged or the case (or part of the case) is removed. Look for cracks or missing

plastic. Pay attention to the insulation around the connectors.

z Inspect the test leads for damaged insulation or exposed metal. Check the test leads for continuity. Replace damaged test leads with identical model

number or electrical specifications before using the Meter.

z Do not apply more than the rated voltage, as marked on the Meter, between the terminals or between any terminal and grounding.

z The rotary switch should be placed in the right position and no any changeover of range shall be made during measurement is conducted to prevent

damage of the Meter.

z When the Meter working at an effective voltage over 60V in DC or 30V rms in AC, special care should be taken for there is danger of electric shock.

z Use the proper terminals, function, and range for your measurements.

z If the value to be measured is unknown, use the maximum measurement position.

z Do not use or store the Meter in an environment of high temperature, humidity, explosive, inflammable and strong magnetic field. The performance of the

Meter may deteriorate after dampened.

z When using the test leads, keep your fingers behind the finger guards.

z Disconnect circuit power and discharge all high-voltage capacitors before testing resistance, continuity, diodes.

z Before measuring current, check the Meter’s fuses and turn off power to the circuit before connecting the Meter to the circuit.

z Replace the battery as soon as the battery indicator

and personal injury.

z When servicing the Meter, use only the same model number or identical electrical specifications replacement parts.

z The internal circuit of the Meter shall not be altered at will to avoid damage of the Meter and any accident.

z Soft cloth and mild detergent should be used to clean the surface of the Meter when servicing. No abrasive and solvent should be used to prevent the surface of

the Meter from corrosion, damage and accident.

z The Meter is suitable for indoor use.

z Turn the Meter off when it is not in use and take out the battery when not using for a long time.

z Constantly check the battery as it may leak when it has been using for some time, replace the battery as soon as leaking appears. A leaking battery will damage

the Meter.

appears. With a low battery, the Meter might produce false readings that can lead to electric shock

International Electrical Symbols

Symbols used on the Meter and in this manual are explained in Table1-2.

4

Page 5

Model VC940: OPERATING MANUAL

AC or DC

Grounding

Double Insulated

Warning. Refer to the Operating Manual

Deficiency of Built-In Battery

Conforms to Standards of European Union

Table 1-2. International Electrical Symbols

5

Page 6

Model VC940: OPERATING MANUAL

Chapter 2

Getting Acquainted

Turning the Meter On

To turn the Meter on, turn the rotary switch from OFF to any switch setting.

Battery Considerations

The Meter uses one 9V Battery (NEDA 1604, 6F22, 006P). The following paragraphs describe several techniques used to conserve battery power.

Automatic Power Off

The display blanks and the Meter goes into a “sleep” mode if you have not changed the rotary switch position or pressed a button for a set period. While in Sleep mode,

pressing the blue button or turning the rotary switch could turn the Meter on. The Meter then returns to the display for the function selected with the rotary switch; all previously

activated button features are discarded.

The automatic power off is preset to 30 minutes. From the Setup menu (see Chapter 5), you could specify a time (10 minutes, 20 minutes, 30 minutes or OFF). If you set to

OFF, the Meter retains on until you turn the rotary switch to OFF or the battery becomes too weak.

Automatic Backlight Off

Press LIGHT button to turn the backlight on and press

LIGHT again to turn it off.

Press SELECT to select the backlight level (low or high). In Setup menu (see Chapter 5), you could specify a time to automatically turn off the backlight (10 seconds, 20

seconds, 30 seconds or OFF). If the period is set to OFF, the backlight feature is disabled.

Low Battery Indication

A constant battery icon ( ) in the upper left corner of the display notifies you that the batteries are low and should be replaced.

Warning

To avoid false readings, which could lead to possible electric shock or personal injury, replace the battery as soon as the battery icon (

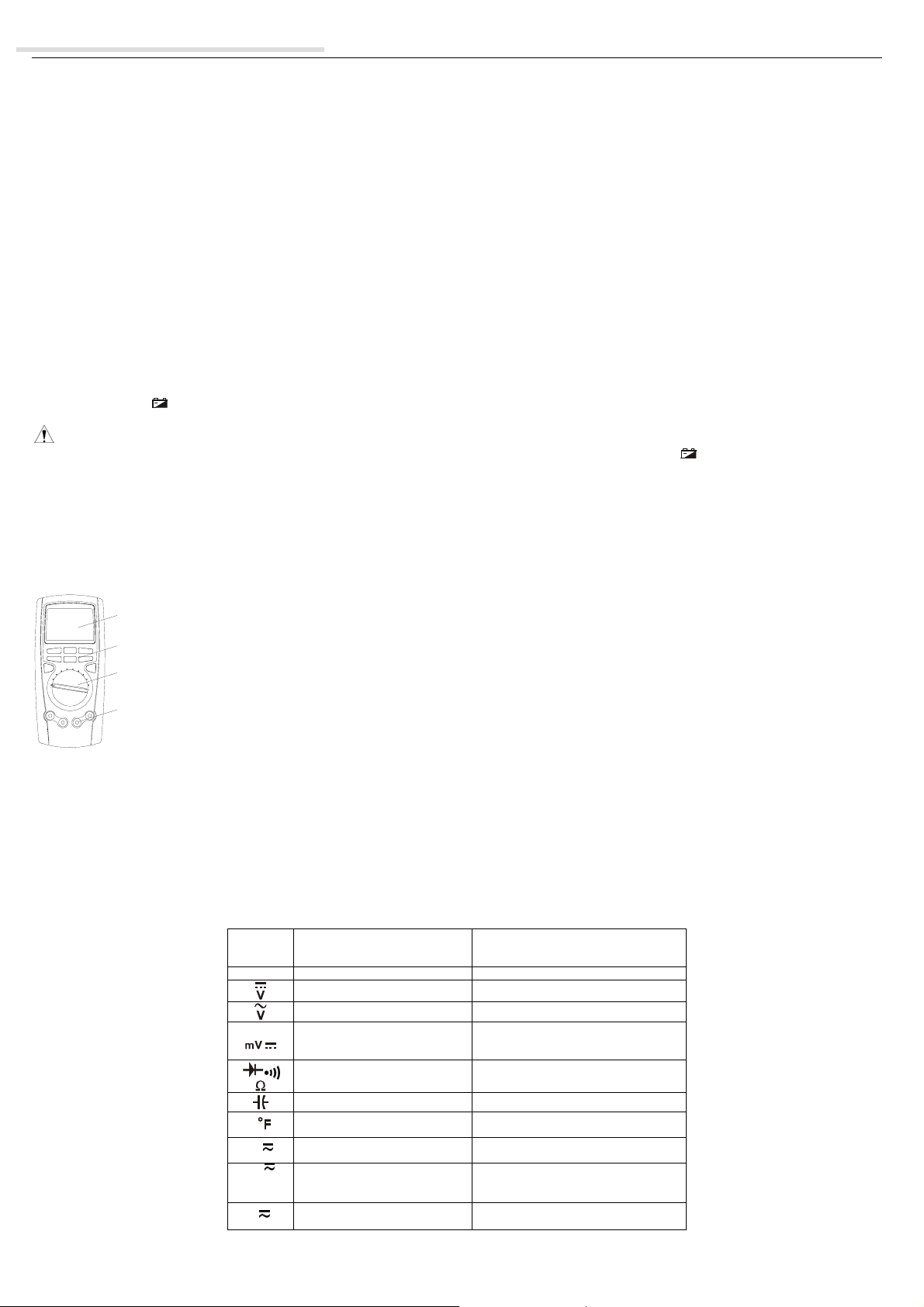

The Meter Structure

The Figure 2-1 shows the Meter structure.

1. LCD Display

2. Functional Buttons

3. Rotary Switch

4. Input Terminals

) appears.

1

2

3

4

Figure 2-1. Meter Structure

Rotary Switch

Turn the Meter on by selecting any measurement function. The Meter presents a standard display for that function. The display may also be influenced by some of the choices

made in Setup.

Use the blue button to select any rotary switch alternate function (labeled in blue letters).

When you turn the rotary switch from one function to another, a display for the new function appears. Button choices made in one function do not carry over into another

function.

The Table 2-1 described each rotary switch position

Rotary

Switch

Position

OFF Turn the Meter off None

Hz

µA

mA

(4~20mA)

%

A

Rotary Switch Function Blue Key Function

DC voltage measurement

AC voltage measurement

DC millivoltage measurement

Resistance measurement

Capacitance measurement

Centigrade temperature

measurement

AC or DC current measurement

(400µA , 4000µA)

AC or DC current measurement

(40mA , 400mA)

AC or DC current measurement

(10A)

Table 2-1. Rotary Switch Selections

None

None

z Frequency measurement

z Frequency signal duty cycle

measurement

z Diode test

z Continuity test

None

Fahrenheit temperature measurement

Toggle between AC or DC current

Toggle between AC or DC current

4~20mA loop current as % reading

Toggle between AC or DC current

6

Page 7

Model VC940: OPERATING MANUAL

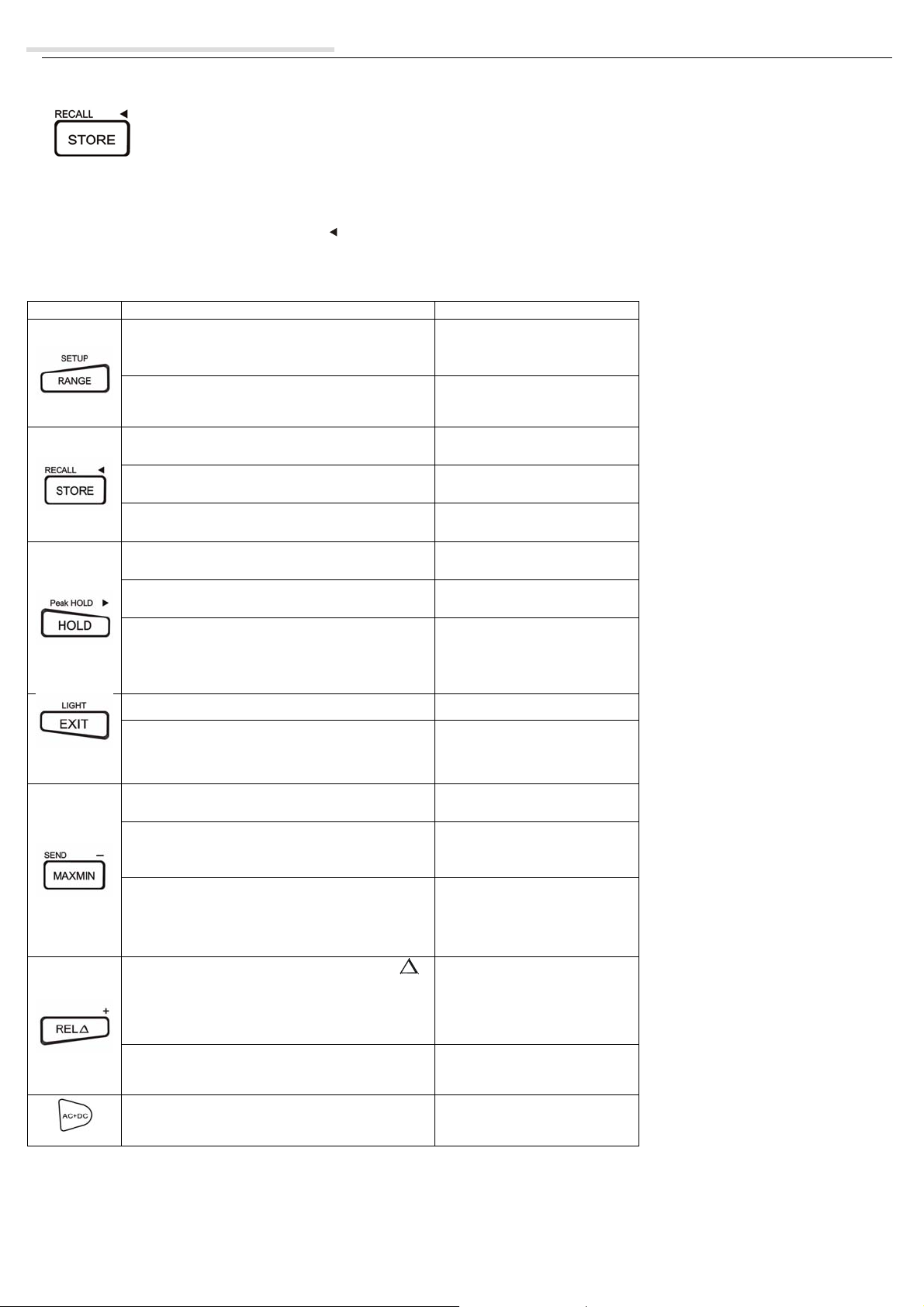

Functional Buttons

The buttons activate features that augment the function selected with the rotary switch. The buttons are shown in Table 2-2.

Press the button once to access the main feature (e.g. STORE).

To access the first additional feature of the button (e.g. RECALL), press and hold the button for over 1 second to access this additional feature. This additional feature appears

right above or on the left hand side of the appropriate keys.

To access the second additional feature of the button (e.g.

second additional feature appears on the right hand side above the appropriate keys.

The RANGE and EXIT buttons has only one additional feature.

Button Description Access Method

Range feature:

Exit AUTO and enter MANUAL ranging. In MANUAL, select

next input range. EXIT to return to AUTO. AUTO is default.

), press once the button again while the Meter has already entered the first additional feature (e.g. RECALL). The

Table 2-2. Functional Buttons

Press the button once.

Yellow Button

Setup feature:

Access Setup selections, the display shows “SET”.

Press and hold the button for more

than 1 second

In the Setup mode, each press of SETUP button steps to the

next Selection

Store feature:

Store the current measurement value. Press EXIT to exit the

Press the button

once.

Store feature.

Recall feature:

Recall the stored value. Press EXIT to exit the Recall

Press and hold the button for over 1

second

feature.

Setup feature:

In Setup, press to select OFF at the selection of HIGH and

Press the button

once after entering Setup mode.

LOW

Hold feature:

Press the button once.

Press HOLD to freeze the displayed value. Press EXIT to

release the display.

Peak Hold feature:

Press to access Peak Hold feature, the primary display

Press and hold the button for over 1

second.

shows PEAK HOLD. Press EXIT to exit.

z In Setup, each press to select the digit you want to

edit.

Press the button once after entering

Setup or Recall or Store mode.

z In Recall, press to enable SEND feature

z In Store, press to toggle between clearing all the

stored reading or start storing reading from the current

index number.

Press to exit certain button functions Press the button once.

Press to turn the backlight on. It is possible to toggle

between 1

st

and the 2nd backlight and Exit the feature by

Press and hold the button for over 1

second.

pressing the button. After exiting the light feature, it is

necessary to press and hold the button for over 1 second to

turn the backlight on again.

Press to display max, min and average values.

Press the button once.

Press EXIT to stop and return to current measurement mode.

Press to output the data, AUTO mode switch off. The primary

display shows “SEND”.

Press and hold

the button for over 1 second.

Press EXIT to exit.

In Setup, each press to decrement an Option.

In Recall, each press to go back to the previous stored

Press the button once after entering

SEND mode.

reading.

In Store, each press to decrease a second on the storing

interval.

Press EXIT to exit

Press to enter relative mode, the primary display shows .

Press the button once.

The left secondary display shows the present measurement

value. The right secondary display shows the stored value.

The primary display shows the present measurement value

minus the stored value.

Press EXIT to exit relative mode.

In Setup, each press to increment an Option.

In Recall, each press to recall the next stored reading.

Press and hold the button for over 1

second.

In Store, each press to increase a second on the storing

interval.

When it is at AC measurement mode, press the button to

Press the button once

display AC+DC True RMS value in the primary display and

the left secondary display “AC+DC”.

7

Page 8

Model VC940: OPERATING MANUAL

Blue Button

Use the blue button to select any rotary switch alternate

function (labeled in blue letters).

Press and hold the Button while turning on the Meter to

toggle to 4000 counts.

It is faster when the Meter is at 4000 counts measurement

mode.

After the Meter is resuming from Automatic Power Off or turn

on and off again, the Meter will back to normal measurement

mode (40000 counts).

Press the button once

The Meter Functions Vs Displays

Table 2-3 shows the cross reference of function and display:

Function Primary Display Right Secondary Display Left Secondary Display

DCV The tested DC voltage value No display Full range: 4, 40, 400, 1000

ACV The tested AC voltage value The tested frequency value: 45kHz~ 400kHz Full range: 4, 40, 400, 750

DCmV The tested DCmV value No display Full range 400

Ω The tested resistance value No display Full range: 400, 4, 40, 400, 4, 40

Hz The tested frequency value No display Full range: 40, 400, 4, 40, 400, 4, 40, 400

The tested value No display 1000

The tested value No display 1832

DCµA The tested DCµA value N/A Full range: 400, 4000

ACµA The tested ACµA value The tested frequency value: 45kHz~10kHz Full range: 400, 4000

DCmA The tested DCmA value No display Full range: 40, 400

ACmA The tested ACmA value The tested frequency value: 45kHz~10kHz Full range: 400, 4000

DCA The tested DC current value No display

ACA The tested AC current value The tested frequency value: 45kHz~10kHz Full range: 4, 40, 400, 750

w The tested power value Apparent power value Power factor value

STO

RCL The recalled value The total number of stored value. Index number: no.01~no.10

MAX MIN Chapter 2 Getting Acquainted – Using MAX MIN

REL

The tested resistance value No display Full range value: 400

The tested resistance value No display Full range 4

The tested capacitance value No display Full range: 40, 400, 4, 40, 400, 4, 40

The current measurement reading The value of the corresponding index number Index number increase one.

The present measurement value minus the

stored value

Table 2-3 Functions Vs Displays

Index number: no.01~no.10

The stored value The present measurement value.

Selecting the Range

Press RANGE to select either a fixed range or the autorange feature.

Autoranging (AUTO lighted in the display) always comes on initially when you select a new function. In autorange, the Meter selects the lowest input range possible, ensuring

that the reading appears with the highest available resolution.

If AUTO is already on, press RANGE to enter MANUAL ranging in the present range. You can then select the next manual range each time you press RANGE. Return to

autoranging by press EXIT.

Note that there is no MANUAL ranging on REL feature.

Understanding the Display

Display features are shown in Figure 2-2 and described in Table 2-4.

Figure 2-2. Display Features

No. Symbol Meaning

1

2 No The sequence of the reading.

3 , Degrees Celsius (default) or Fahrenheit.

4

5 Indicates negative reading

6

7

8 Tr ueRM S Indicator for True RMS value.

9 AC+DC

MAX Maximum reading displayed.

MIN

AV G Average reading displayed

SET

Minimum reading displayed

H: Hour

µ: Micro

m: Minutes (Milli)

S: Second

The battery is low.

Warning: To avoid false readings, which could lead to

possible electric shock or personal injury, replace the battery

as soon as the battery indicator appears.

Setup feature is on.

For DCV and DCA functions, reading represents the True RMS total

of AC and DC measurements

Table 2-4. Display Features

8

Page 9

Model VC940: OPERATING MANUAL

Ω, kΩ, MΩ

kΩ:Kilohm. 1×10

MΩ:Megaohm. 1×10

Ω: Ohm. The unit of resistance.

Hz, kHz,

MHz

10

mV, V

Hz : Hertz. The unit of frequency in cycles/second.

kHz: Kilohertz. 1×10

MHz: Megahertz, 1×10

V: Volts. The unit of voltage.

mV: Millivolt. 1×10

3

or 1000 ohms

6

or 1,000,000 ohms

3

or 1000 hertz

6

or 1,000,000 hertz.

-3

or 0.001 volts

A: Amperes (amps). The unit of current.

µA, mA, A

nF,µF,

mF

11

mA: Milliamp, 1×10-3 or 0.001 amperes.

µA:Microamp.1×10

Farad. The unit of capacitance

nF: Nanofarad. 1×10

µF:Microfarad.1×10

mF: Millifarad. 1×10

-6

or 0.000001 amperes.

-9

or 0.000000001 farads.

-6

or 0.000001 farads.

-3

or 0.001 farads.

Automatic power off feature is on

12 Continuity test

13

14

15

16 AUTO

STO Data store is on

RCL Data recall is on

The relative mode is on to display the present value minus the

stored value.

LOW

HIGH

The indicator for the lowest setup limit.

The indicator for the highest setup limit.

The Meter is in the auto range mode in which the Meter

automatically selects the range with the best resolution.

17 SEND Data output is in progress

18

Backlight feature is on

19 HOLD Data hold mode is active

20

PEAK

HOLD

21

22

%

Peak hold mode is active

Diode test

z Frequency signal duty cycle.

z 4~20mA loop current as % reading

22 The input value is too large for the selected range.

Analogue

23

Bar Graph

Provides an analog indication of the present input, quick response.

Analogue Bar Graph

The bar graph provides an analogue indication of the measured input. For most measurement functions, the bar graph updates 10 times per second.

Using MAX MIN

The MAX MIN mode stores minimum (MIN) and maximum (MAX) input values. When the input goes below the stored minimum value or above the stored maximum value, the

Meter beeps and stores the new value.

Press MAX MIN to enter MAX MIN mode. The sampling time is every 2 seconds. The maximum reading and MAX are shown on the left secondary display. The minimum

reading and MIN are shown on the right secondary display. The primary display shows the present measurement reading.

Press MAX MIN the second time, the present measurement reading is shown on the left secondary display. The minimum reading and MIN are shown on the right secondary

display. The primary display shows the maximum value.

Press MAX MIN the third time, the present measurement reading is shown on the left secondary display. The maximum reading and MAX are shown on the right secondary

display. The primary display shows the maximum value.

Each subsequent press of MAX MIN steps through the above three modes.

To exit MAX MIN mode, press EXIT. Also, press HOLD could stop the Meter updating reading.

MAX MIN mode can only be used under MANUAL ranging mode.

9

Page 10

Model VC940: OPERATING MANUAL

Chapter 3

Making Measurement

Introduction

Chapter 3 explains how to make measurements. Most measurement functions can be selected by using the rotary switch.

While letters or symbols identify primary functions; blue letters or symbols identify alternative functions. Press the BLUE button to access these alternate functions.

A. Measuring Voltages

Black

Red

Figure 3-1. Voltages Measurement

Warning

To avoid harms to you or damages to the Meter from electric shock, please do not attempt to measure voltages higher than 1000V, although readings may be

obtained.

To measure voltages, set up the Meter as Figure 3-1 and do the following:

1. Insert the red test lead into the V terminal and the black test lead into the COM terminal.

2. Set the rotary switch to

Connect the test leads across with the object

3.

being measured.

4. The measured value shows on the display.

AC measurement displays the True RMS value.

DC measurement displays the effective value of sine wave (mean value response).

or or

When a ACV function is selected, you can press the Yellow Button to view the AC + DC True RMS value in the primary display. To exit, please EXIT button.

The BLUE button cycles among

, frequency and duty cycle.

Note

z When measuring voltage, the Meter acts a 10MΩ(

and ) or 2.5GΩ ( ) impedance in parallel with the circuit. This loading effect can cause measurement errors in

high impedance circuits. In most cases, the error is negligible (0.1% or less) if the circuit impedance is 10kΩ or less.

z Special care should be taken when measuring high voltage.

z When voltage measurement has been completed, disconnect the connection between the testing leads and the circuit under test and remove testing leads away from the

input terminals of the Meter.

B. Measuring Currents

Black

Figure 3-2. Currents Measurement

Warning

If the fuse burns out during measurement, the Meter may be damaged or the operator himself may be hurt.

To avoid possible damage to the Meter or to the equipment under test, check the Meter’s fuses before measuring current. Use proper terminals, function, and

range for the measurement. Never place the testing leads in parallel with any circuit or component when the leads are plugged into the current terminals.

To measure AC or DC current, set up the Meter as Figure 3-2 and proceed as follows:

1. Turn off power to the circuit. Discharge all high-voltage capacitors.

2. Insert the red test lead into the mAµA or A terminal and black test lead into the COM terminal.

3. If you are using the A terminal, set the rotary switch to A

current above 40000µA.

4. DC measurement is default, press blue button to select AC measurement.

5. Open the circuit path to be tested. Touch the red testing leads to the more positive side of the break; touch the black probe to the more negative side of the bread.

Reversing the leads will produce a negative reading, but will not damage the Meter.

6. Turn on power to the circuit; then read the display.

AC measurement displays the True RMS value.

DC measurement displays the effective value of sine wave (mean value response)

7. Turn off power to the circuit and discharge all high-voltage capacitors. Remove the Meter and restore the circuit to normal operation.

When a ACA function is selected, you can press the Yellow Button to view the AC + DC True RMS value in the primary display. To exit, please EXIT button.

Note

z If the value to be measured is unknown, use the maximum measurement position and reduce the range step by step until a satisfactory reading is obtained.

z When the measured current is ≤ 5A, continuous measurement is allowed.

Red

.

If you are using mAµA terminal, set the rotary switch to µA for currents below 40000µA , or mA for

10

Page 11

Model VC940: OPERATING MANUAL

z When the measured current is between 5A-10A, continuous measurement ≤ 10 seconds and interval more than 15 minutes.

z When current measurement has been completed, disconnect the connection between the testing leads and the circuit under test and remove testing leads away from the

input terminals of the Meter.

C. Measuring Resistance

Black

Red

Figure 3-3. Resistance Measurement

Warning

To avoid harms to you, please do not attempt to input voltage higher than 60V DC or 30V rms AC.

To avoid possible damages to the Meter or to the devices under test, disconnect circuit power and discharge all the high-voltage capacitors before measuring

resistance.

To measure resistance, set up the Meter as shown in Figure 3-3 and follow the following procedure:

1. Insert the red test lead into the

2. Set the rotary switch to

3. Connect the test leads across with the object being measured.

The measured value shows on the display.

The BLUE button cycles among resistance, continuity, and diode.

Note:

z When measuring low resistance, the test leads can add 0.1Ω to 0.2Ωof error to resistance measurement. To test the leads, touch the probe tips together and read the

resistance of the leads. If necessary, you can press REL to automatically subtract this value.

z For high-resistance measurement (>1MΩ), it is normal taking several seconds to obtain a stable reading. In order to obtain precision readings, use the test lead as short

as possible.

z If Ω reading with shorted test leads is not ≤0.5Ω, check for loose test leads, wrong function selected or other causes.

z The LCD displays OL indicating open-circuit or the tested resistor value is higher than the maximum range of the Meter.

z When resistance measurement has been completed, disconnect the connection between the testing leads and the circuit under test and remove testing leads away from

the input terminals.

Ωterminal and the black test lead into the COM terminal.

; press BLUE button to selectΩmeasurement mode.

Ω

D. Testing for Continuity

Black

Red

Figure 3-4. Continuity Test

Warning

To avoid harms to you, please do not attempt to input voltage higher than 60V DC or 30V rms AC.

To avoid possible damages to the Meter or to the devices under test, disconnect circuit power and discharge all the high-voltage capacitors before measuring

continuity.

To test for continuity, set up the Meter as Figure 3-4 and do the following:

1. Insert the red test lead into the Ω terminal and the black test lead into the COM terminal.

2. Set the rotary switch to

Ω ; press BLUE button to select measurement mode and connet the test leads across with the object being tested.

3. The beeper comes on continuously for open conditions, that is test resistance ≤ 50Ω.

The BLUE button cycles among resistance, continuity, and diode.

Note

z Open circuit voltage around –1.2V and range is 400Ω measurement range.

z When continuity testing has been completed, disconnect the connection between the testing leads and the circuit under test and remove the test leads away from the

input terminals.

E. Testing Diodes

11

Page 12

Model VC940: OPERATING MANUAL

Black

Red

Figure 3-5. Diode Test

Warning

To avoid harms to you, please do not attempt to input voltages higher than 60V DC or 30V rms AC.

To avoid damages to the Meter or to the devices under test, disconnect circuit power and discharge all the high-voltage capacitors before testing diodes.

Use the diode test to check diodes, transistors, and other semiconductor devices. The diode test sends a current through the semicondutor junction, then measure the voltage

drop across the junction. A good silicon junction drops between 0.5V and 0.8V

To test the diode out of a circuit, set up the Meter as Figure 3-5 and proceed as follows:

1. Insert the red test lead into the Ω terminal and the black test lead into the COM terminal.

2. Set the rotary switch to

Ω ; and press BLUE button to select measurement mode.

3. For forward voltage drop readings on any semiconductor component, place the red test lead on the component’s anode and place the black test lead on the component’s

cathode. The red test lead polarity is “+” while the black test lead polarity is “— “.

The measured value shows on the display.

The BLUE button cycles among resistance, continuity, and diode.

Note

z In a circuit, a good diode should still produce a forward voltage drop reading of 0.5V to 0.8V; however, the reverse voltage drop reading can vary depending on the

resistance of other pathways between the probe tips.

z Connect the test leads to the proper terminals as said above to avoid error display.

z The LCD will display OL indicating either open circuit or wrong polarity connection.

z The unit of diode is volt (V), displaying the positive-connection voltage-drop value.

z Open circuit voltage approximate 2.8V.

z When diode testing has been completed, disconnect the connection between the testing leads and the circuit under test and remove the test leads away from the input

terminals.

F. Measuring Capacitance

Black

Red

Figure 3-6. Capacitance Measurement

Warning

To ensure accuracy, the Meter inside is discharged against the tested capacitor. “DIS.C” will be shown on the display w hen it is under discharging, this process will

be quite slow.

To avoid damage to the Meter or to the equipment under test, disconnect circuit power and discharge all high-voltage capacitors before measuring capacitance.

Use the DC Voltage function to confirm that the capacitor is discharged.

To measure capacitance, set up the Meter as shown in Figure 3-6 and proceed as follows:

1. Insert the red test lead into the

2. Set the rotary switch to

the tested value must subtract the internal distributed capacitor value to maintain the accuracy.

To improve the measurement accuracy of small value capacitors (less than 10nF), press REL

and leads.

Note

z The LCD displays OL indicating the tested capacitor is shorted or it exceeds the maximum range.

z Capacitors larger than 400µF take longer time. The analogue bar graph shows the time left before finishing the measurement.

z When capacitance measurement has been completed, disconnect the connection between the testing leads and the circuit under test and remove the test leads away from the

input terminals of the Meter.

terminal and the black test lead into the COM terminal.

measurement mode, the Meter may display a fixed reading which is a internal distributed capacitor value. For testing less than 10nF capacitor,

with the test leads open to subtract the residual capacitance of the Meter

G. Measuring Frequency / Duty Cycle

12

Page 13

Model VC940: OPERATING MANUAL

Black

Red

Figure 3-7. Frequency / Duty Cycle Measurement

Warning

To avoid harms to you, please do not attempt to input voltage higher than 30V rms.

To measure frequency and duty cycle, connect the Meter as Figure 3-7 and do the following:

1. Insert the red test lead into the Hz terminal and

the black test lead into the COM terminal.

2. Set the rotary switch to

The BLUE button cycles among

3. Connect the test leads across with the object

being measured.

The measured value shows on the primary display.

Note

z The requirement of Input amplitude “a” is as follows:

When 10Hz~40MHz: 200 mV≤a≤30Vrms;

40MHz: Un-specified

z When Hz measurement has been completed, disconnect the connection between the testing leads and the circuit under test and remove the test leads away from the

input terminals.

and press BLUE button to select the Hz measurement mode for frequency measurement or % for duty cycle measurement.

, frequency and duty cycle.

H. Measuring Temperature

Figure 3-8. Temperature Measurement

Warning

To avoid harms to you, please do not attempt to input voltages higher than 60V DC or 30V rms AC.

To measure temperature, set up the Meter as shown in Figure 3-8 and proceed the following.

1. Set the rotary switch to , the primary display shows the room temperature.

The Meter is default to Celsius degree unit, you can change units by press the BLUE button once you have selected the temperature function.

2. Insert the point contact temperature probe into the Meter as figure 10.

3. Place the temperature probe to the object being

measured.

The measured value shows on the display after several seconds.

Note

z Place the Meter in an environment of 18~23 otherwise false reading may be obtained especially in testing low temperature.

z The included point contact temperature probe can only be used with temperature 230 below.

z When temperature measurement has been completed, remove the temperature probe away from the multi-purpose socket, and remove the multi-purpose socket away

from the Meter.

I. 4~20 mA loop current as % readout

It shows the mA measured value or output level in %, in a 4-20mA scale.

4~20mA Loop feature, connect the Meter as follows:

To u s e

1. Set the rotary switch to , and press BLUE button to select (420mA)% feature.

2. The rest procedure, please follow B. Measuring Current: DC current measurement (Figure 3-2).

3. When the readings obtained is:

z < 4mA, the primary display shows LO

z 4mA, the primary display shows 0%. ….

20mA, the primary display shows 100%

z > 20mA, the primary display shows HI

J. Power Measurement

13

Page 14

Model VC940: OPERATING MANUAL

A

W

B

C

A = Plug to the outlet

B= Outlet of the power adaptor

C = Power Adaptor

Figure 3-9. Power Measurement

Warning

To avoid damages to the Meter, please do not attempt to input higher than 250V from outlet altogether reading may be obtained.

Take extra care during measurement to avoid electric shock.

Switch off the power before the Meter and the object being measured connect to the circuit.

To measure power, proceed the following:

1. Set the rotary switch to W.

2. Insert the power adaptor to the corresponding input terminals, and plug the power adaptor to the outlet.

3. Insert the object to be measured into the outlet of the power adaptor.

4. The measured value shows on the display. The primary display shows the power value, the left secondary display show the power factor value and right secondary

display shows the apparent power value.

Note

z The current of the object being measured must > 10A.

≤5A continuous measurement is allowed.

5A~10A, only ≤10 seconds continuous measurement is allowed and the interval between each measurement must be greater than 15 minutes.

z When power measurement has been completed, first switch off the power, then disconnect the connection between the adaptor and the outlet.

.

14

Page 15

Model VC940: OPERATING MANUAL

Chapter 4

Using Stores, Recall & Send Features

Introduction

Chapter 4 shows you how to use stores, recall and communication features available on the Meter

Storing and Clearing Readings

To store readings, proceed as follows:

z Press STORE once, STO and no appears to confirm the operation and the left secondary display shows the current measurement reading. Press

clearing the stored readings and start from the zero readings or start from the last stored reading.

z Press STORE the second time, STO appears. The left secondary display shows the storing time interval in second, it is preset to zero. To change the interval in second

by pressing + or - button. The interval can be as high as 255 seconds or as low as 0 second. Press and hold STORE to access the quick setting.

z Press STORE the third time, STO and no appears. The left secondary display shows the index number and store a reading. The right secondary display shows the

current stored reading, the primary display shows the current measurement reading.

z If there is not set time to store the reading, each press of STORE to store one reading. An index number increase one.

z The maximum number of stored reading is 10. When the stored readings memory is full, the Meter will stop storing data.

z To exit, press EXIT.

Recalling Stored Readings

Use the following procedure to recall the stored reading:

z Press RECALL to recall the stored value and RCL appears to confirm the operation.

z The left secondary display shows the index number no.---.

z The primary display shows the corresponding recalled data.

z The right secondary display shows the total number of the stored data.

z Press button to enable the SEND feature to export the data to the computer via RS232C or USB. The software shows the data storing time and also the data value..

After the data transferring is completed, the SEND feature will be disabled automatically.

z Press + or - button to view additional stored reading. Press and hold RECALL to access quick recalling.

z Press EXIT to exit recalling.

Using Send

When using a Send feature, please refer to the Installation Guide of the included CD-ROM.

,

to toggle between

15

Page 16

Model VC940: OPERATING MANUAL

Changing the Default Setting

Introduction

The Meter allows you to change the default operating configuration of the Meter by changing setup options made at the factory.

These settings are stored and can be changed in the Setup mode using the procedure described in this chapter.

Selecting Setup Options

To enter the Setup mode, turn the Meter on and press and hold RANGE button for over 1 second.

In the Setup mode, each press of Setup button steps to the next Selection. Each press of – or + button decrement or increment an Option.

Each Setup Selection and Option appears in the primary display in the sequence shown in Table 5-1.

To exit the Setup mode, press

Selection Option Factory

HIGH Max. 40000

LOW Max. –40000

Analogue Bar

Graph

Setup. Be sure to save your last selection by press EXIT.

Table 5-1. Setup Selections

Default

Press

to select OFF

Press

to select the digit you want

to edit

Press

to select OFF

Press

to select the digit you want

to edit

10 10 mins power off

20 20 mins power off

30 30 mins power off

OFF

S1 Beeps continuously and icon lights on

OFF

10 Backlight turn off in 10 seconds

20 Backlight turn off in 20 seconds

30 Backlight turn off in 30 seconds

OFF

Zero is in the left hand side.

Zero is in the center

OFF Over the upper limits, beeps not

OFF Over the lower limits, beeps not

10 mins

Zero is

in the

center

Description

continuously.

continuously.

Power off feature is disabled

S1

No beep, icon flashes

10

Disable backlight feature.

It can only apply to DCV, DCI and C/°F

functions.

Chapter 5

Saving Setup Options

At each setup Option, store your choice and exit setup by press EXIT, advance to the next Option by press +.

To exit the Setup mode without saving the present Option, press Setup.

16

Page 17

Model VC940: OPERATING MANUAL

Chapter 6

Maintenance

This chapter provides basic maintenance information including battery and fuse replacement instruction.

Warning

Do not attempt to repair or service your Meter unless you are qualified to do so and have the relevant calibration, performance test, and service information.

A. General Service

z Periodically wipe the case with a damp cloth and mild detergent. Do not use abrasives or solvents.

z To clean the terminals with cotton bar with detergent, as dirt or moisture in the terminals can affect readings.

z Turn the Meter to OFF when it is not in use.

z Take out the battery when it is not using for a long time.

z Do not use or store the Meter in a place of humidity, high temperature, explosive, inflammable and strong magnetic field.

B. Replacing the Fuses

Figure 6-1. Fuse Replacement

Warning

To avoid electrical shock or arc blast, or personal injury or damage to the Meter, use specified fuses ONLY in accordance with the following procedure.

Follow Figure 6-1 and proceed as follows to replace the Meter’s fuse:

z Turn the rotary switch to OFF and remove all connections from the terminals.

z Remove the 5 screws from the case bottom.

z Remove the fuse by gently prying one end loose, then take out the fuse from its bracket.

z Install ONLY replacement fuses with the identical type and specification as follows and make sure the fuse is fixed firmly in the bracket.

Fuse 1: 0.5A, 250V, fast type fuse, ø5×20mm

Fuse 2: 10A, 250V, fast type fuse, ø5×20mm

z Rejoin the case bottom and case top, and install the 5 screws.

Replacement of the fuses is seldom required. Burning of a fuse always results from improper operation.

C. Replacing the Battery

Figure 6-2. Battery Replacement

Warning

To avoid false readings, which could lead to possible electric shock or personal injury, replace the battery as soon as the battery indicator “

Make sure the test leads are disconnected from the circuit being tested before opening the case bottom.

Follow Figure 6-2 and proceed as follows to replace the battery:

z Turn the rotary switch to OFF and remove all connections from the terminals.

z Remove the screw from the battery compartment, and separate the battery compartment from the case bottom.

z Replace with a new 6F22 9V battery.

z Rejoin the case bottom and battery compartment, and reinstall the screw.

” appears.

17

Page 18

Model VC940: OPERATING MANUAL

Safety and Compliances

Maximum Voltage

between any Terminal and

Grounding

Certification

Compliances IEC 61010 CAT.1000V, CAT.600V overvoltage and

Fused Protection for

µAmA input terminal:

Fused Protection for A

input terminal:

Refer to different range input protection voltage

double insulation standard

0.5A, 250V, fast type fuse, ø5×20mm

10A , 250V,fast type fuse, ø5×20mm

Physical Specifications

Display (LCD) Digital: 40000 counts on primary display. Except resistance range has only 4000

Operating

Temperature

Storage

Temperature

Relative

Humidity

Battery Type 9V NEDA 1604 or 6F22 or 006P.

Electromagnetic

Compatibility

Dimensions (H x

W x L)

Weight Approx.340g (including battery)

counts; updates 2-3 times / second.

4000 counts on two secondary displays.

Analog: 40 segments; updates 10 times / second.

0~40 (32~104)

-10~50 (14~122)

≤75% 0~30 below;

≤50% 30~40:

z In a radio field of 1 V/m below:

Overall Accuracy = Specified Accuracy + 5% of Range

z In a radio field of 1 V/m above:

No assigned accuracy is specified.

177 x 85 x 40mm.

Chapter 7

Specifications

General Specifications

Range Auto

Polarity Auto

Overloading Display OL

Battery Deficiency

(except at 4~20mA Loop range which

display HI or LO)

Display

Feature Summary

Tri Digital Displays

Analogue Bar Graph

Backlight with 2

brightness levels

Autorange The Meter automatically selects best range

AC+DC True RMS, AC

RMS

Data Hold Holds readings on display

Continuity Beeper sounds for resistance readings below threshold.

Bar Graph 40 segments

Duty Cycle Measure signal on or off time in %.

MAX MIN Mode Record maximum and minimum

Battery Access Door Battery replaceable.

Primary: 40,000 counts (except resistance range has 4000 counts)

Left Secondary: 4000 counts

Right Secondary: 4000 counts

Bar Graph: 40 segments, updates 10 times / second

Bright backlight for clear readings in poorly lighted areas.

Choices for AC only or AC+DC readings

Basic Specifications

Function Ranges / Description

DC Voltage 0 to 1000V

AC Voltage, True RMS 0 to 750V, 400kHz bandwidth

Basic Accuracy DC Voltage: 0.025%

DC Current 0 to 10A (5~10A for ≤10 seconds, interval ≥ 15

AC Current, True RMS 0 to 10A (5~10A for ≤10 seconds, interval ≥ 15

Resistance 0 to 40MΩ

Capacitance 0 to 40mF

Frequency 0~400MHz

Temperature -40~1000 (-40~1832)

STORE Readings Up to 10 readings for may be saved by the user

AC Voltage: 0.5%

minutes)

minutes)

in a memory. These readings may be viewed

by using Recall feature.

Detailed Accuracy Specifications

Accuracy: ±([% of reading] + [number of least significant digits), guarantee for 1 year.

Operating temperature: 18~28

Relative humidity: ≤75%RH

A. DC Voltage

Range Resolution Accuracy

Overload

Protection

Input

Impedance

18

Page 19

Model VC940: OPERATING MANUAL

400mV 0.01mV ±(0.025%+8)

4V 0.0001V

40V 0.001V

400V 0.01V

1000V 0.1V

±(0.05%+5)

Around 2.5GΩ

1000V

Around 10MΩ

B. AC Voltage (AC+DC measurement is available)

Range Resolution

4V 0.0001V

40V 0.001V

750V 0.1V

Remarks:

Input Impedance: Approx 10M

z

z Overload Protection: 1000V.

Display:

z

a) True rms are valid from 10% of range to 100% of range

b) AC crest factor can be up to 3.0 except 750 where it is 1.5.

c) A residual reading of 80 digits with test leads shorted, will not affect stated accuracy.

d) When frequency is lower than 100kHz, the accuracy guarantee range 10%-100%.

e) When frequency is high than 100kHz, the accuracy gaurantee range 15%~100%

f) When making AC+DC measurment, the accuray need to add (1%+ 35 digits) of reading based on the above table.

Bandwidth Accuracy

45Hz~1kHz ±(0.5%+5)

1kHz~10kHz ±(0.8%+8)

10kHz~120kHz ±(3%+8)

120kHz~250kHz ±(4%+8)

250kHz~400kHz ±(10%+50)

45Hz~1kHz ±(0.5%+5)

1kHz~10kHz ±(1%+8)

10kHz~100kHz ±(3%+8)

100kHz~400kHz Not Specified

45Hz~1kHz ±(0.5%+5)

1kHz~10kHz ±(4%+8)400V 0.01V

10kHz~250kHz Not Specified

45Hz~1kHz ±(1%+8)

1kHz~5kHz ±(5%+8)

5kHz~10kHz ±(10%+8)

Ω.

Accuracy

C. DC Current

Range Resolution Accuracy

400µA 0.01µA ±(0.25%+10)

4000µA 0.1µA

40mA 0.001mA

400mA 0.01mA

10A 0.001A

Remarks:

At 10A range:

z When the measured current is ≤ 5A, continuous measurement is allowed.

z When the measured current is between 5A-10A, continuous measurement ≤ 10 seconds and interval more than 15 minutes.

±(0.8%+10)

±(1.5%+20) 10A, 250V, fast type fuse,

Overload Protection

0.5A, 250V, fast type fuse,

ø5×20mm

ø5×20mm

D. AC Current (AC+DC measurement is available)

Range Resolution

400µA 0.01µA

4000µA 0.1µA

40mA 0.001mA

400mA 0.01mA

10A 0.001A

Remarks:

Display:

z

a) True rms are valid from 10% of range to 100% of range

b) AC crest factor can be up to 3.0.

c) A residual reading of 80 digits with test leads shorted, will not affect stated accuracy.

d) When frequency is lower than 100kHz, the accuracy guarantee range 10%-100%.

e) When frequency is high than 100kHz, the accuracy gaurantee range 15%~100%

f) When making AC+DC measurment, the accuray need to add (1%+ 35 digits) of reading based on the above table.

z At 10A range:

a) When the measured current is ≤ 5A, continuous measurement is allowed.

b) When the measured current is between 5A-10A, continuous measurement ≤ 10 seconds and interval more than 15 minutes.

E. Resistance

Range Resolution Accuracy

400Ω 0.1Ω ±(0.8%+10)+test leads open circuit value

4kΩ 0.001kΩ

40kΩ 0.01kΩ

400kΩ 0.1kΩ

4MΩ 0.001MΩ

40MΩ 0.01MΩ ±(1.5%+20)

Accuracy

Bandwidth Accuracy

45Hz~1kHz

1kHz~10kHz

45Hz~1kHz ±(0.8%+5)

1kHz~10kHz ±(1.5%+5)

±(0.5%+5)

±(1%+5)

±(0.5%+10)

Overload Protection

0.5A, 250V, fast type fuse,

ø5×20mm

10A, 250V, fast type fuse,

ø5×20mm

Overload

Protection

1000V

F. Continuity Test

19

Page 20

Model VC940: OPERATING MANUAL

Range Resolution Overload Protection

Remarks:

z Open circuit voltage approximate -1.2V.

z The buzzer does not sound when the test resistance is 50Ω.

z The beeper comes on continuously for open conditions, that is test resistance is ≤ 50Ω.

G. Diode Test

Range Resolution Overload Protection

Remarks:

z Open circuit voltage approximate 2.8V.

z A good silicon junction drops between 0.5V and 0.8V

0.01Ω 1000V

0.0001V 1000V

H. Capacitance

Range Resolution Accuracy

40nF 0.001nF

400nF 0.01nF

4µF 0.0001µF

40µF 0.001µF

400µF 0.01µF

4mF 0.0001mF ±(5%+20)

40mF 0.001 mF Not specified

±(1%+20)+ capacitance value of

open circuit test leads

±(1%+20)

Overload

Protection

1000V

I. Frequency

Range Resolution Accuracy

40Hz~400MHz 0.001Hz~0.01MHz ±(0.01%+8) 1000V

Remarks:

z Input amplitude “a” as follows; (DC electric level is zero)

When 10Hz~40MHz : 200mV≤a ≤30Vrms;

When 40MHz : Not specified

Overload

Protection

K. Temperature

Degrees Celsius

Range Resolution Accuracy

-40~40 ±(3%+30)

40~400 ±(1%+30)

400~1000

Fahrenheit

Range Resolution Accuracy

-40~32 ±(4%+50)

32~752 ±(1.5%+50)

752~1832

0.1

±2.5%

0.1

Overload

Protection

1000V

Overload

Protection

1000V

±3%

Remarks:

z Included is a K-Type (nickel chromium ~ nickel silicon) point contact temperature probe which could only measure temperature below 230. If you want to measure

temperature higher than 230, you must use the rod contact temperature probe.

K. 4~20 mA loop current

Range Resolution Accuracy Overload Protection

(4~20mA)

%

Remarks:

When the readings obtained is:

z < 4mA, the primary display shows LO

z 4mA, the primary display shows 0% ….

z > 20mA, the primary display shows HI

0.01% ±(1%+50)

20mA, the primary display shows 100%

0.5A, 250V, fast type fuse, ø5×20mm

M. Power Measurement

Range Resolution Accuracy Current Overload

Protection

2500W 0.1W ±(2%+50)

Remarks:

z Power factor input range: 0.00~1.00

z Voltage input impedance: around 10MΩ

z Voltage input range: AC50~250V

10A, 250V, fast type

fuse, ø5×20mm

Voltage Overload

Protection

1000V

** END **

20

Page 21

Model VC940: OPERATING MANUAL

This operating manual is subject to change without notice.

○CCopyright 2005 Uni-Trend International Limited.

All rights reserved.

Manufacturer:

Uni-Trend Technology (Dongguan) Limited

Dong Fang Da Dao

Bei Shan Dong Fang Industrial Development District

Hu Men Town, Dongguan City

Guang Dong Province

China

Postal Code: 523 925

Headquarters:

Uni-Trend International Limited

Rm901, 9/F, Nanyang Plaza

57 Hung To Road

Kwun Tong

Kowloon, Hong Kong

Tel: (852) 2950 9168

Fax: (852) 2950 9303

Email: info@uni-trend.com

http://www.uni-trend.com

21

Loading...

Loading...