Page 1

Universal System

Instruction Manual

Page 2

Catalogue

Brief …………………………………………………………………2

Ⅰ Panel Operation Instruction … ……………………………………3

Ⅱ Operation Cautions … … …………………………………………4

Ⅲ Frequency Counter (FC)Operation Instruction … … ……………5

Ⅳ Function Generator(FG) Operation Instruction …………………7

Ⅴ DC Power Supply (DPS)Instruction … …………………………10

Ⅵ Digital Multimeter (DMM) Instruction …………………………11

Ⅶ Accessories … … …………………………………………………31

Ⅷ Maintenance and Service …………………………………………31

1

Page 3

Brief

Thanks for your purchasing universal system.

To ensure the correct operations, please read the manual carefully before using

it. After that, please keep it well.

The instrument is produced according with the strict quality control standard.

All the components are selected and aged in full range. It passes a series

environmental experiments and it will be in optimum working state in the indicated

working environment.

Service after sales: Please contact our customer service office if the instrument

is defective to get effective service after sales.

Composition:

1. DDS signal generator: it adopts digital synthetic technology which can generate

5 waves of sine, square, triangle, pulse and TTL. The frequency range is 0.1Hz~

10MHz.

2. Frequency Counter:The frequency range is 1Hz~ 2.7GHz with high

measurement accuracy and can realize equal accuracy measurement.

3. DC Power Supply: It is composed of four groups’ outputs, 0~30V/0~

3A adjustable voltage output, + 15V/1A fixed voltage output, -15V/1A

fixed voltage output and +5V/2A fixed voltage output.

4. DMM: It has about 50 kinds of measurement functions with multi display:

master display 80000 count, slave display 80000 count and 20 segments of

bar graph. The max. AC/DC voltage is up to 600V DC/450V AC and DC/AC

current up to 10A. Resistor measuring range is 0.01Ω~80MΩ, 10MΩ~

1000MΩ, capacitor measuring range is 1pF~100μF and the temperature

range is -50~1300,-58~ 2372(with external sensor). It has 16 kinds

of frequency (0.5Hz~5kHz) and adjustable pulse waveform output of 1%~

99% duty cycle.

2

Page 4

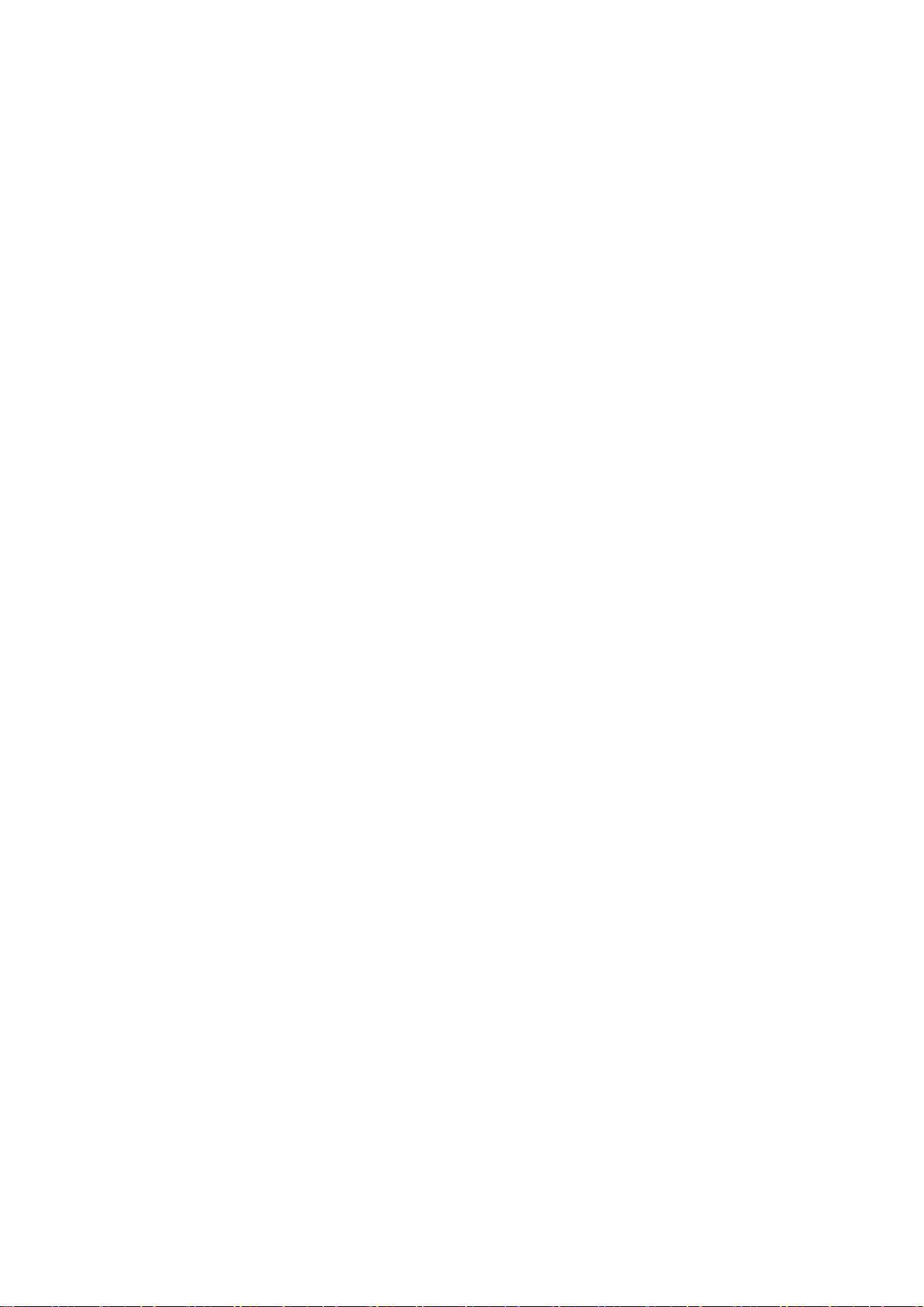

Ⅰ Panel Operation Instruction

Diagram of Front Panel

Diagram of Rear Panel Operation Instruction

3

Page 5

○,1 Display window of FC ○,2 Reset of FC

3

○,

Data hold of FC ○,4 Gate time key of FC

5

○,

Channel select key of FC ○,6 Low pass filter key of FC

7

○,

CHB input of FC ○,8 CHA input of FC

9

○,

Frequency variable knob of FG ○,10 Keyboard operation zone of FG

11

○,

Input of ext amplitude of FG ○,12 TTL output of FG

13

○,

Signal output of FG ○,14 Duty variable knob of FG

15

○,

DC offset variable knob of FG ○,16 Amplitude variable knob of FG

17

○,

Output on/off control key of FG ○,18 Output impedance select key of FG

19

○,

Display control key of FG ○,20 Display window of DMM

21

○,

Auxiliary function key zone of DMM ○,22 Power switch of DMM

23

○,

Function keys zone of DMM ○,24 Input terminal of 10A current of DMM

25

○,

Input terminal of mA current of DMM ○,26 Input terminal of voltage and current

measurement

of DMM

27

○,

Common terminal of DMM ○,28 Voltage variable knob of DPS

29

○,

Current variable knob of DPS ○,30 Fix +5V/2A output terminal of DPS

31

○,

Constant current indicator of DPS ○,32 Fix ±15V/1A output terminal of DPS

33

○,

Voltage/current display select switch of

○,34 0~30V/0~3A output terminal of DPS

DPS

35

○,

Grounding terminal ○,36 Main power switch

37

○,

Display window of DPS ○,38 Power switch of FG

39

○,

Power switch of FC

○,40 10A current measurement fuse of DMM

○,41 mA current measurement fuse of DMM ○,42 AC115V/AC230V select switch

43

○,

Power socket

Ⅱ Operation Cautions

1. The instrument has already been done ex-factory inspection strictly. Please first

check whether the instrument is damaged or not during the transportation once

the user opens the package box.

2. Don’t put it in chilly outside. The optimum operating temperature is 5°C~35°C.

3. Don’t expose it at the sunshine or heat source such as stove, for long time.

4. Don’t remove it from heat to chilly environment abruptly or vise versa which will

cause frozen in the inner.

5. Keep it from humidity, water and dust. Otherwise the instrument maybe occur

malfunctions. The optimum relative humidity is 35%~75%.

6. Keep it from the strong shocking environment. Otherwise the instrument maybe

occur malfunctions.

4

Page 6

7. Keep it far away from the high magnetic field and don’t operate it near to

magnetic field. Do not expose it to strong sunshine or ultraviolets directly.

8. Don’t put other objects on it and don’t block the vent holes.

9. Don’t insert lead or pin into the vent holes.

10. Don’t drag it through cables.

11. Don’t put soldering iron on its surface or plastic frame.

12. Don’t invert it for long time during storage and transportation.

13. Check steps before operation:

13.1 Check voltage

Refer to the suitable working voltage as below before the power is on.

Rated voltage Working voltage

AC230V AC230V±10%

AC110V AC99V~121V

13.2 Make sure the fuse should be suitable.

To avoid the circuit damage caused by over current, please use the correct fuse.

Power fuse: AC230V T250V 4A

Shape: 5×20mm

Type: slow-break

DMM fuse: mA current: F 690V 1A

Shape: 10×38mm

Type: fast-break

10A current division: F 690V 12.5A

Shape: 10×38mm

Type: fast-break

*Note: The voltage of the original fuses installed in this product is 690V. In

replacement of the fuse, please choose fuses of voltage higher than 600V.

Ⅲ Frequency Counter (FC) Operation Instruction

1. Technical Specifications

1.1 Freq. measurement range: CHA 1Hz~100MHz

CHB 100MHz~2.7GHz

1.2 Input sensitivity: CHA 50mVrms for sine wave

150mVpp for pulse wave

CHB -13dB(100MHz~1GHz)

-7dB(1GHz~2.7GHz)

1.3 Measurement accuracy: ±(100ns/Gate Time+ Timebase Error+Trigger Error)x

the Frequency of the measured signal

5

Page 7

Note: Time base Error: ≤10ppm(at normal temperature)

Trigger Error≤0.3% when SNR(Signal-to-Noise Ratio)>40dB

1.4 Dynamic Range: CHA 50Vrms~1.5Vrms

CHB -13dBm~+13dBm (100MHz-1GHz)

-7dBm~+13dBm (1GHz-2.7GHz)

1.5 Max. undamage voltage: CHA 35Vpp

CHB 3Vpp

1.5 Input impedance: CHA 1MΩ//40pF

CHB 50Ω

1.6 Time base frequency: 10MHz

1.7 Resolution: ±(100ns/Gate times)x measured signal frequency

2. Basic Operation

2.1 Please check voltage and fuse before the power is on. Turn on main power switch

(○,36)and then turn on FC power switch(○,39)which is on the rear panel of

instrument and then preheat 20 minutes.

2.2 After the power is on, the display window(○,1) of FC indicates “0000000”, the

indicator of CHA will be on. The strobe time is 1s and the indicator of strobe is

on. The indicators of Hold and Low pass filter (LPF-A) will be off.

2.3 LPF-A key(○,6): bandwidth about 100kHz at 3dB, Open LPF (indicator of

LPF-A will be on) to eliminate the HF disturb of the LF signal below 100 kHz

which will make the measured result more reliable.

2.4 Channel key(○,5): It is used to select the measured channel. CHA can be used to

measure 1Hz ~ 100MHz signal frequency. CHB can be used to measure

100MHz~2.7GHz signal frequency.

2.5 For CHA,

a. When frequency is <100 kHz, please turn on the low pass filter (LPF-A).

b. When the amplitude of frequency is >5V, please use external attenuators, such

as oscilloscope-probes.

2.6 Strobe time select key(○,4): It should choose a suitable strobe time if a suitable

resolution is needed. Once the period of the measured signal is more than strobe

time, the measurement time is regarded as a period time of the measured signal.

2.7 Data Hold(○,3): Press it down, the Hold indicator will be on. Then the FC will

stop measurement. The display window will always keep the last measured data

even the signal frequency is changed or test dot is broken. Press Hold again, its

indicator will be off. Then FC re-starts to measure and the display window will

record new frequency measurement data.

2.8 Reset(○,2): It is used to reset the FC.

6

Page 8

2.9 Over-flow indicator(OFL): When the measured signal frequency is over the

range, the over-flow indicator (OFL) will be on, and “ ” will be

on the display window(○,1).

2.10 When both FC and FG are working, both powers need to be turned on. To turn

off FG and keep FC working, please press the DISPLAY key (○,19). After the

“F/C” indicator lights, the display window(○,1) shows the measured frequency

by FC. Then turn off the FG’s power switch.

Ⅵ Function Generator (FG) Operation Instruction

1. Technical Specification

1.1 Waveform characteristic:

1.1.1 Waveform type: sine, triangle, square.

1.1.2 Sine harmonious wave distortion(1Vpp,50Ω): <20kHz -50dBc

20 kHz~1MHz -40dBc

1MHz~10MHz -35dBc

1.1.3 Sine wave distortion: ≤1%(0.1Hz~100 kHz)

1.1.4 Square wave Rise/Fall time: ≤50ns(1MHz, 50Ω, output voltage 5Vpp)

1.1.5 Square overshot: ≤5%

1.1.6 Square duty cycle range: 15%~85%(≤10kHz)

1.1.7 Waveform asymmetry: <1.5%+20ns of period(≤100 kHz)

1.1.8 Triangle linearity: <1%(≤100 kHz)

1.2 Frequency characteristic:

1.2.1 Frequency range: Sine wave 0.1Hz~10 MHz (50Ω)

Square wave 0.1Hz~1 MHz(200mVpp~10Vpp,50Ω)

Triangle waveform 0.1Hz~1MHz

1.2.2 Frequency accuracy: ±(5×10-5+80mHz)

1.2.3 Frequency stability: 50ppm(long term)(Generally, calibration at 1 time/year)

1.2.4 Max. Resolution: 0.01Hz

1.3 Amplitude Characteristic:

1.3.1 Output amplitude range: 100mVpp~20Vpp(High impedance)

1.3.2 Amplitude flatness: ±5% (in 0.1Hz~10MHz at 50Ω)

1.3.3 Output impedance: 50Ω±10%/600Ω±10%

1.4 Overshot Characteristic:

1.4.1 DC offset range: Vpp AC+DC: ±10V(600Ω); ±5V(50Ω)

1.5 Sweep Frequency Characteristic:

1.5.1 Type: Linearity or Log

1.5.2 Sweep frequency: Negative or positive

1.5.3 Sweep range: 1Hz~10MHz

7

Page 9

1.5.4 Sweep freq velocity: 0.01Hz~100Hz

1.6 Attenuation:

1.6.1 Attenuation: -20dB

1.6.2 Error: ±3%(open circuit)

1.7 External Amplitude Input:

1.7.1 Input impedance: 1kΩ

1.7.2 Ext amplitude freq range: 0.1Hz~20kHz(the output impedance of modulation

source is 50Ω)

1.7.3 Ext amplitude sensitivity: 0~5Vpp±2%

1.7.4 Amplitude depth: 0~100%

1.8 TTL Output:

1.8.1 Output amplitude: “0” level ≤0.3V; “1” level ≥3.3V

1.8.2 Output impedance: 50Ω ±10%

2. Panel Layout

13

○,

2.1 There are 3 ports on panels, signal output port(

port(

12

○,

)and ext amplitude signal input port(○,11).

), TTL synchronized output

2.2 There are four variable knobs on panels, freq variable knob(○,9)to adjust output

frequency of signal and change setting of sweep frequency parameter, Duty

variable knob(○,14)used to adjust duty ratio of square wave, DC offset variable

knob(○,15) used to adjust DC offset of signal and Amplitude variable knob

(○,16) used to adjust amplitude of the output signal.

2.3 There are 14 keys on keyboard operation zone: 10 number keys (number【0】~

【9】);2 direction keys(left【<】, right【>】); 1 decimal point(【.】); 1

OK key(【OK】). There are three function keys: One is signal output switch

(○,17)which is used to control whether FG output signal or not. Press it, FG

output is switched between on/off state. The indicator above the key is

corresponding to the FG output state; the secondly is output impedance key

(○,18), the indicator above the key is corresponding to FG output impedance.

Press it, FG output impedance will be switched between 50Ω and 600Ω; The

19

○,

thirdly is display function switch key (

function of window(

1

○,

). When the F/C indicator is on, the display window will

) which is used to change the display

be used to display the measured frequency of the FC and when F/G indicator is

on, the display window will be used to display the frequency of the FG. Once the

power is on, the default state of the display window(○,1) is to display the

frequency of the FG.

2.4 The secondary function key: Once the power is on, the indicator “FUNC” above

key 【OK】 will be on. The below keys, keys【1】~【7】, decimal point

【.】and 【OK】, are used for the second functions which are indicated

above the keys,

3. Basic Operation

8

Page 10

3.1 FC display window(○,1)displays frequency. 6 digits of FG.

3.2 The frequency can be adjusted by hand wheel or enter numbers directly.

Once the power is on, the default output frequency is 1 kHz. At the time,

number “1” is flashing. Remove the flashing number horizontally by【<】

and【>】and the flashing number can be changed through rotating the

hand wheel. Press【 .】, indicator “Range” above 【.】 will be on. Then the

frequency unit indicator will be flashing to indicate which unit should be

applied to the value shown on the display window (○,1). Rotate the hand

wheel; the value will be changed as ×10 times or 1/10 times each time.

Press 【.】 again, the “Range” indicator will be off and re-start adjustment

mode by hand wheel. Press【OK】, “Func” indicator will be off, frequency

on window is cleared and enter into state of entering numbers directly. All

the entered numbers will be flashing and they are can be deleted freely

from left to right through【<】, which can correct the numbers. And also

units, such as MHz, kHz, Hz, can be selected through【>】. Press【OK】

again after entering numbers, the key of “Func” will be on; the signal

frequency will be displayed on frequency window.

3.3 The operation of Secondary function key.

Once the power is on, the “Func” indicator above 【OK】will is on. Parts

of keys are corresponding to the secondary functions which are indicated

on panel.

【-20dB】: Press【1】,the indicator “-20dB” will be on. The attenuation

amplitude of output signal is -20dB of the original output amplitude.

Press the key again, the indicator “-20dB” will be off, the amplitude of

output signal will not be attenuated.

【Duty】: Press【2】,the indicator above “Duty” will be on. Adjust the

Duty cycle variable knob(○,14) to change duty ratio of square wave.

Press the key again, the indicator “Duty” will be off, the output duty cycle

of square wave is 50%. At the time, the Duty variable knobs(○,14)do not

work.

【Offset】:Press【3】,the indicator above “Offset” will be on. Adjust the

DC offset variable knob(○,15), DC offset of output waveform can be

adjusted. Press the key again, the indicator “offset” will be off, the output

waveform is back to normal. At the time, the DC offset variable knob

(○,15)won’t be work.

【Wave】:When the power is on, the default output of FG is sine wave.

The ”Sine” indicator will be on. Once press number 【4】 each time,

output waveform of FG will be switched between sine, square and triangle

in turn.

9

Page 11

【Line】:Press【5】,the “Line” indicator will be on, the FG is in the state

of linearity sweep frequency mode. F1 indicator is on above number key

【7】, and then the first frequency of linearity sweep frequency can be set.

Press【7】, indicator “F2” will be on, then the end frequency can be set.

Press【 7】again, indicator “Rate” is on, and then sweep frequency velocity

can be set. Press number key【5】,indicator “Line” will be off. All the

indicators above【7】are off, FG will quit sweep frequency mode.

【Log】: Press number key【 6】,indicator “Log” will be on. FG is in the

state of log sweep frequency mode. At the same time, indicator “F1” will

be on. Then the first frequency of log sweep frequency can be set. Press

【7】,indicator “F2” will be on. At the same time, the end frequency of

log sweep frequency can be set. Press【7】 again, indicator “Rate” will be

on, and then the velocity of sweep frequency can be set. Press number key

【5】,indicator “Log” will be off. All the indicators above 【7】 are off;

FG will quit the sweep frequency mode.

【Func】:When the power is on, the indicator “Func” above【OK】is on,

it is in the state of function setting. Press【 OK】,the indicator “Func” will

be off. At the time, the window is cleared up and enters the state of

entering number.

【Range】:Press【 .】, the indicator “Range” will be on. Then the indicator

for frequency unit (MHz or KHz or Hz) will flicker. Rotate the hand

wheel(○,9),the value will be changed as ×10 times or 1/10 times. Press

【.】again, the indicator “Range” will be off and it goes again in mode of

frequency adjustment by the “Freq.Adj” knob.

Ⅴ DC Power Supply (DPS) Instruction

1. Technical Specification

1.1 CH1 output(output terminal ○,34)

1.1.1 Output voltage: 0~30V

1.1.2 Output current: 0~3A

1.1.3 Ripple and noise: ≤1mVrms

1.1.4 Load effect: 0.1%+5mV

1.1.5 Source effect: 0.1%+5mV

1.1.6 Max. Output current: ≥3.2A

1.1.7 Display accuracy: Voltage ±1%+2 digits; Current ±2%+2 digits

1.2 CH2 output(output terminal ○,32)

1.2.1 Output voltage: fixed ±15V±2.5%

1.2.2 Output current: 1A

1.2.3 Ripple and noise: ≤2mVrms

10

Page 12

1.2.4 Load effect: 0.1%+50mV

1.2.5 Source effect: 0.1%+30mV

1.2.6 Max. Output current: ≥1.2A

1.3 CH3 output(output terminal ○,30)

1.3.1 Output voltage: fixed +5V±3%

1.3.2 Output current: 2A

1.3.3 Ripple and noise: ≤2mVrms

1.3.4 Load effect: 0.1%+70mV

1.3.5 Source effect: 0.1%+30mV

1.3.6 Max. Output current: ≥2.2A

2. Basic Operation

2.1 Please check the fuses before the power is on. Disconnect all the cables

29

connected to the output terminals. Adjust Current knob(○,

)clockwise to

maximum to set the current to the max output value.

2.2 Press Power switch (○,

36

) . DPS window (○,37) will display output

current/voltage value of CH1(output terminal ○,34). The indicator of CH2

(output terminal ○,32)& CH3(output terminal ○,30)will be on. And there will

be outputs in the three channels of the DPS.

2.3 Display window(○,37)can display voltage value or current value. When the key

33

○,

is not pushed down, the display window(○,37)will show the output voltage

value of CH1(output terminal ○,34). When the key is press down, the display

window(○,37)will show the output current value of CH1(output port ○,34).

2.4 Voltage variable knob(○,28)is used to change CH1(output port ○,34) output

voltage value. Once adjust it clockwise, the voltage value will be bigger

gradually and vise versa. Please note that there is no stopper for this voltage

variable knob(○,28). Above 30V, the knob still can be turned clockwise, but the

value of output voltage will not increase. Current variable knob is used to set

CH1(output port ○,34)max. current value. Adjust it clockwise, the current

value will be bigger gradually and vise versa.

2.5 Once the value of the output current is higher than the set max. current output

value, CH1(output port ○,34)will go inot the constant current state. At this time,

the indicator C.C will be on. The extra current will cause the voltage down.

2.6 Warning: For CH2 outputs, if using the left blue terminal of the -15V/1A output

with the right red terminal of the +15V/1A output, you can get a 30V/1A output!

But the +30V/1A output cannot work together with the +15V/1A output and

-15V/1A output, otherwise the values of the output voltage and current will be

reduced.

11

Page 13

Ⅵ Digital Multimeter (DMM) Operation Instruction

1. Safe Operation Rules

1.1 It is suitable for the over voltage standard of IEC 61010 CAT II 600V

1.2 Please check whether the shell, test lead and isolating layer are perfect

and without any damage before use it.

1.3 Please check the voltage to confirm the meter is in good working state.

Otherwise, please contact to repair immediately instead of using it.

1.4 Please use the terminals and select divisions of function and range

correctly when measure it.

1.5 Please don’t measure the voltage when the test lead is inserted into the

current terminal.

1.6 Please don’t use voltage more than the indicated rated voltage (Refer to

the sign ) between any terminal and earth.

1.7 When undertaking measurement, keep your fingers behind the guards’s

plant on the test leads or probes. Please care for the voltage more than

33Vrms AC or 70VDC in normal condition to avoid electric shock.

1.8 Disconnect the power and discharge all high-voltage capacitors before

testing in resistance, continuity and diode functions.

1.9 Please don’t store and operate the meter under the environment of high

temperature, high humidity, flammable and strong magnetic field.

1.10 The correct procedure to turn off the DMM is to turn off the DMM

power switch ○,

22

firstly before turn off the main power switch○,

you turn off the main power switch directly to turn off the DMM, when

you start the DMM again, the LCD display may show messy codes or a

pure white screen. At the time, turn off the DMM power switch and turn

on the DMM again, the messy codes or white screen will disappear.

2. Panel Instruction

2.1 Refer to Table 1 for terminals(Chart 1)

Chart 1.

Table 1

Terminal symbol Function

36

. If

12

Page 14

COM For all the common terminals

mA mA current input terminal

10A 10A current input terminal

VΩHz

2.2 Refer to Table 2 for Function keys(○,

Voltage, resistance, continuity, diode, capacitor, frequency,

temperature measurement and square wave output terminal.

23

)

Chart 2.

Table 2:

Key Description Key Description

V DC voltage Test for diode, Continuity

V AC voltage Capacitor

mV DC/AC mV voltage Hz/DUTY Freq/Duty ratio

mA DC/AC mA current TEMP Temperature

10A DC/AC 10A current

OUT Square wave output

Ω Resistance POWER Power switch

2.3 Auxiliary function keys(○,

21

)

When press these keys, the corresponding symbol will be on LCD alongside a

buzz.

13

Page 15

Chart 3.

Notice: Because this DMM has complicated functions, when pressing these keys,

the meter has to make logic judge which takes some time. Please make

measurements after the display is stable.

2.3.1【SELECT】

● Press【SELECT】to select the needed measurement state.

● When the DMM output square wave, please press 【SELECT】 to change duty

of square wave signal. Press it each time, it will change 1% (The variable

change 1%~99%).

2.3.2【RANGE】

● Once the power is on, the DMM is in AUTO range state. Press【RANGE】can

select your measurement range. Press it quickly to select the range you needed.

And press it once, it change a range.

● When the【SET】key is in operation,【RANGE】will be change as【▲】(moving

up). Press it to move setting digits up.

● Press【RANGE】lasting more than 2s,it will be back to AUTO range.

2.3.3【MAX/MIN】

● Press【MAX/MIN】, it will be dynamic record mode which can capture and

record MAX, MIN and MAX-MIN from variable input signal and calculate AVG

of all readings. Press 【MAX/MIN】 to display MAX/MIN/(MAX-MIN)/AVG

in sequence on slave display.

● Press【MAX/MIN】lasting more than 2s,it will be back to normal mode.

● In state of MAX/MIN,the record time is 36 hours.

● After run【SET】,【MAX/MIN】will be change as【◄】(moving left). Press

it to move setting digits left.

2.3.4【A-H】

● Press 【A-H】, the DMM will enter the Automatic Peak Hold mode and “A—H”

appear on display screen.

● This function can hold the displayed value. When the actual measured value is

higher than the held value, the displayed value will be automatically updated to

the new peak value alongside a buzzer.

● Press the button again, it will display “PH+/PH-”. PH+ means to hold the

positive peak value and PH- means to hold the negative peak value.

“PH+/PH-“ only works in DC voltage and current tests.

14

Page 16

● Press【A-H】lasting more than 2s to exit Peak Hold mode and return to normal

mode.

2.3.5【2nd VIEW】

● In Table3 measuring state, press 【2nd VIEW】to switch and display each

function in slave display.

Table 3:

Function key

position

V

V

mV

Hz/DUTY

OUT

Measure state Master display

ACV+ Hz ACV Hz/ %/ %/ ms/ ms

AC dBm+Hz AC dBm Hz/ACV

(ACV+DCV) +Hz ACV+DCV Hz/ACV

dBm+Hz dBm Hz/ACV/DCV/ACV+DCV

ACmV+ Hz ACmV Hz/ %/ %/ ms/ ms

dBm+Hz dBm Hz/ACmV/DCmV/ACmV+DCmV

Hz Hz %/ %/ ms/ ms

OUT

Press【2nd VIEW】

to change output

signal frequency

Slave(switch them by pressing

【2nd VIEW】)

Press【SELECT】to change duty of

output signal

● Press【2nd VIEW】to select output frequency of square wave when the DMM is

in Square wave output mode:

0.5000Hz/1.0000Hz/2.0000Hz/10.000Hz/50.000Hz/60.24Hz/74.63Hz/100.00Hz

/151.5Hz/200.00Hz/303.00Hz/606.1Hz/1.25kHz/1.6660kHz/2.5kHz/5.0000kHz

● Press【2nd VIEW】lasting more than 2s,the output square wave will return to

default 606.1Hz and 50% duty cycle.

● When the 【SET】 key is in operation,the key 【2nd VIEW】will be changed

as 【▼】(moving down). Press it to move setting digits down.

2.3.6【REL】

● Press【REL】,it will be in state of relative measurement function and at the same

time, symbol “REL▲” will be displayed. It indicates the different between

measuring value and reference value which means press【REL】,it will treat

current measurement value as reference value(Ref). After that, REL▲ or REL%

is on the reading of master display and reference value on slave display. Press

【REL】 again, the measured value will be on slave display again.

● In the state of【REL】,Press【SELECT】to select “REL▲” or “REL%”. And at

the same time, “REL%” and “REL▲” will be on screen.

REL▲=measured value- reference value

REL%=(REL▲/ REL)×100%

● After run【SET】,【REL】will be change as【►】(moving right). Press it, the

pre-setting value can be removed towards right.

15

Page 17

● Press 【REL】lasting more than 2s, it will be back to normal .

● Setting of relative measured value:

○,1 Press【RANGE】to select the suitable range.

○,2 Press【SET】once and press【SELECT】twice, it will be in state of relative

value setting and at the same time【▲】,【▼】,【◄】and【►】are workable.

○,3 After setting, please press【SET】to confirm it.

2.3.7【SET】

● When the 【SET】 key is in operation, the 【RANGE】 keyn is used as a moving

up key ( ), the 【2nd VIEW】 key as a moving down button ( ), the

【MAX/MIN】as a moving left button ( ), and 【REL】as a moving right ( ). In

this case, the 【RANGE】,【2nd VIEW】, 【MAX/MIN】 and 【REL】’s original

functions are disabled. keys can be used to enter and adjust the

setting values.

3. Display(○,20)

Chart 4.

The following Table 4 gives descriptions of the symbols displayed on the LCD.

Table 4:

Number Symbol Description

1 Bar graph : display bar graph of the current input signal

2,3,15 - Negative sign

4 Out Square wave output

5 Hi High frequency measurement or thermocouple

temperature measurement

6 Low Battery

7 Diode test, Continuity test

8 REL▲ REL% Symbols of relative measuring value and relative percent

measurement value

9,17 AC AC+DC DC AC, AC+DC, DC voltage or current

10 PH+ PH- Positive peak, negative peak

16

Page 18

11 A─H Automatic Peak Hold

12 AVG Record average value

13 AUTO Auto range

14 MAX MIN MAX-MIN MAX reading, MIN reading, MAX-MIN reading

18 mV/V/mA/A Voltage and current units on slave display

19 Hz/kHz/MHz/Ω/kΩ/MΩ Frequency and resistance units on slave display

20 % % ms ms Duty cycle unit and pulse width unit

21 nF/μF Capacitance unit: nF or μF

22 mV/V/mA/A Voltage and current unit on primary display

23 dBm Level unit: dBm

24 Hz/kHz/MHz/Ω/kΩ/MΩ Frequency and resistance unit on primary display

25,16 Temperature unit: Celsius and Fahrenheit

OL Over Range indication (as below picture)

4. Special Function

4.1 Set measurement time

● Except diode, frequency and square wave output, the other functions division

can be used to set measure time.

● The displayed time style is “0.00.00”(on slave display),the first number as hour,

second and third as minute and the fourth and fifth as second. The max time is

“9.59.59”。

● Press【TIMER】to enter the mode of time setting(“0.00.00” on slave display);

Press 【SELECT】 to set time. At the time, the last number of time “0” is

flashing. Press【◄】 and 【►】to set time numbers and press【▲】and【▼】

to set time value. Press 【TIMER】again to confirm the set time. From now on,

the measure begins to count time.

● During the set period, it does measurement normally. Once the time counting

is finished, it will buzz continuously.

● Once the clock function is activated, the set time and time counting won’t be

affected by the function changes and operations. Only when【A-H】is activated,

the time counting will stop and the counted time will be cleared. If you need to

restart time counting again, repeat the above operations.

17

Page 19

4.2 Set upper and lower limits for measurement

● Procedures to set upper and lower measurement limits.

○,1 Upper limit set: Turn on the power. Select the functions state and select

suitable range with 【RANGE】. Press【SET】to run setting mode ( “ ”

will be on slave display). Press【◄】,【►】,【▲】 and 【▼】to set the upper

limit value. Press【SET】to confirm it.

○,2 Lower limit set: Turn on the power. Select the functions state and select

suitable range with 【RANGE】. Press 【SET】 and then 【SELECT】to

run setting mode ( “ ” will be on slave display). Press【◄】,【►】,

【▲】and【▼】to set the lower limit value. Press【SET】to confirm it.

● Measurement can be carried out after setup of upper and lower limits is finished.

There are three kinds of display mode according to the measurement results:

○,1 If the measured value is higher than the upper limit, the measured value will

be on the master display and “ ” will be on the slave display.

2

○,

If the measured value is less than the lower limit, the measured value will be

on the master display and “ ” will be on the slave display.

○,

3

If the measured value is between upper and lower limits, the measured value

will be on the master display and “ ” will be on the slave display.

4.3 Analog Bar Graph Display

The Function of bar graph is imitating the analog needle of meter but without

overshoot, and refreshes 40 times per second. Because the graph responds 10

times faster than the digital display it is useful for peak value test, zero

calibration and observing rapid changing signals. The bar graph has 20 segments.

The number of the shown segments at a moment is relative to the proportion of

the measured value to the full-scale value of the selected range. One segment

represents 4000counts except the situation that the DMM is in the relative

measurement mode. The polarity is indicated at the left of the bar graph, (“+”

polarity is not indicated).

4.4 Square wave output

The square wave output is a useful function. The frequency and duty cycle are

adjustable, which helps users to do a lot of tests, such as the PWM (Pulse Width

Modulation) output, adjusting the voltage control, timer to control circuit , clock

syntherization, etc.

5. Instructions for Measuring Functions

5.1 DC Voltage measurement

Warnings: the measured DC voltage must not

exceed DC 600V because the high voltage

standard of this DMM is IEC 61010 CAT II 600V!

18

Page 20

● Press【V 】and it will be in DC voltage

measurement .

● There are 3 measurement modes: DCV,DCV+ACV

and dBm. Press【SELECT】to select one of them.

Chart 5 DC Voltage Measurements

● When the power is on, the measurement will be on AUTO state. Press【RANGE】

to select range manually: 8.0000V/80.000V/600.00V

● According with the user’s requirements, press(【REL】 【MAX/MIN】 and

【2nd VIEW】)to do test and record. All of them will be on slave display.

● Insert the red test leads into “VΩHz” terminal and the black test lead into “COM”

terminal. Contact the test points with the test leads. Please refer to Chart 5. The

measured value and relative symbols will be on master and slave screen at the

same time. Please refer to Table 5:

Table 5:

State(Press【SELECT】to select state)

DCV DCV

DCV+ACV DCV ACV/Hz

dBm dBm Hz/DCV/ACV/DCV+ACV

Master

isplay

Slave Display(switch between them by

pressing【2nd VIEW】)

● In dBm test,the default impedance is 600Ω. Press【RANGE】to change the load

impedance and the selectable values are as below: 4Ω, 8Ω, 16Ω, 32Ω, 50Ω, 75Ω,

93Ω, 110Ω, 125Ω, 135Ω, 150Ω, 200Ω, 250Ω, 300Ω, 500Ω, 600Ω, 800Ω, 900Ω,

1000Ω and 1200Ω. In dBm measurement mode, the decimal point of dBm is

fixed between the second and third digits and 【REL】, 【MAX/MIN】and 【P-H】

are disabled.

5.2 AC Voltage measurement

Warning: The measured voltage must not exceed AC 450V because the high

voltage standard of this DMM is IEC 61010 CAT II 600V!

Note: Before tests on low voltage, please connect the test leads in

short-circuit and press【REL】to make zero for a better accuracy!

● Press【V 】 to enter AC voltage function

● AC voltage has three states of ACV,ACV+Hz

and dBm. Press【SELECT】 to choose one of them.

When the power is on, the measurement is

in AUTO state. Press【RANGE】 to select

suitable range. The selectable ranges are as

below: 8.0000V/80.000V/450.00V

● Press (【REL】,【MAX/MIN】 and

【2nd VIEW】)to do relative test and

record. All of them can be on slave

19

Page 21

display.

● Insert red test leads into “VΩHz” and

black into “COM” and contact the test

point via lead’s pin. Please refer to

Chart6 for the measurement mode. Chart 6. AC Voltage Measurement

The measured values and relative symbols will be on master and slave display at

the same time. Please refer to Table 6:

Table 6:

Press【SELECT】to choose state

ACV ACV

ACV+Hz ACV Hz/ %/ %/ ms/ ms

dBm dBm Hz/ACV

Master

isplay

Slave Display(switch between them by pressing

【2nd VIEW】)

● In dBm test,the default impedance is 600Ω. Press【RANGE】to change the load

impedance and the selectable values are as below: 4Ω, 8Ω, 16Ω, 32Ω, 50Ω, 75Ω,

93Ω, 110Ω, 125Ω, 135Ω, 150Ω, 200Ω, 250Ω, 300Ω, 500Ω, 600Ω, 800Ω, 900Ω,

1000Ω and 1200Ω. In dBm measurement mode, the decimal point of dBm is

fixed between the second and third digits and 【REL】, 【MAX/MIN】and 【P-H】

are disabled.

● Notes: If a ACV measuring is chosen and the two test leads are short-connected,

it takes a long time until the value goes down. This process is normal. This is

because that the high impedance inside takes some residual voltage. In this

process, the filtering capacitors slowly discharges to keep the potential. But this

does not affect the ACV accuracy. When the displayed value is not down to zero

yet and an ACV test is done at the time, the value measured will still be accurate.

5.3 AC/DC milli voltage measurement

Warning: The measured voltage

should not exceed DC 250V or AC

peak to peak voltage at the input

terminal!

● Press【mV 】to enter the function of

AC/DC milli voltage measurement.

● It has three modes: DCmV,ACmV+

Hz,dBm. Press【SELECT】to select

one of them.

● When the power is on, it will be in

AUTO state. Press 【RANGE】 to

select the suitable ranges manually.

20

Page 22

The selectable ranges are:

80.000mV/800.00mV.

● Press【REL】, 【MAX/MIN】and Chart 7. AC/DC mV Measurement

【2nd VIEW】)to do the relative test or record which will be in slave display.

● Insert red test leads into “VΩHz” and black into “COM” and contact the test

point via lead’s pin. Please refer to Chart 7. for the measurement mode. The

measured values and relative symbols will be on master and slave display at the

same time. Please refer to Table 7:

Table 7:

Press(【SELECT】to choose state)

DCmV DCmV

ACmV+Hz ACmV Hz/ %/ %/ ms/ ms

dBm dBm Hz/ACmV/DCmV/DCmV+ACmV

Master

isplay

Slave Display(switch between them by pressing

【2nd VIEW】)

● In dBm test,the default impedance is 600Ω. Press【RANGE】to change the load

impedance and the selectable values are as below: 4Ω, 8Ω, 16Ω, 32Ω, 50Ω, 75Ω,

93Ω, 110Ω, 125Ω, 135Ω, 150Ω, 200Ω, 250Ω, 300Ω, 500Ω, 600Ω, 800Ω, 900Ω,

1000Ω and 1200Ω. In dBm measurement mode, the decimal point of dBm is

fixed between the second and third digits and 【REL】, 【MAX/MIN】and 【P-H】

are disabled.

● Note: In order to reduce the attenuation effect to the small input signal and

enhance the accuracy, the resistance is very big for AC mV auto range, more

than 1000MΩ. If the probes is connected but in open status and no signal is

applied on the input terminal, it will normally be over the range. At the time,

there will be “OL” shown in the display with the overload buzzer keeping

buzzing. The slave display at the time is showing the frequency of the

surrounding interference signal on the open-circuit.

In milli voltage measurement mode, in order to obtain DC+AC function, the

●

input terminal of ADC does not employ coupling capacitor. Therefore, never

apply a voltage over double value of DC or AC voltage of the rated value of this

range

5.4 AC/DC Current Measurement

Warnings for AC/DC Current measurement

To avoid damage to the meter or injury and never attempt an in-circuit current

measurement when the fuse is blown, or when the voltage between open circuit

and the ground is 600V.

Do not make 20A current measurements for longer than 15 seconds.

Exceeding 15 seconds may cause damage to the meter and/or the test leads.

21

Page 23

To avoid damage to the meter, check the meter’s fuse before tests.

Before current measurement, turn off the DMM power supply, discharge the

high voltage capacitance.

Do not place the probes in parallel with a circuit or component when the leads

are plugged into the current terminals.

Do not test voltage when the test leads are plugged in “mA” or “10A” terminals.

Use the proper terminals, functions, and ranges for your measurement.

5.4.1 DC/AC mА Current Measurement

Note: Before tests on low AC mA current, please have the two test leads in

open-circuit status and press【REL】to make zero for a better accuracy!

● Press【mA 】to enter the function of

AC/DC milli current measurement.。

● It has four modes: DCmA,ACmA ,

ACmA+Hz,DCmA+ACmA. Press

【SELECT】to select one of them.

● When the power is on, the

measurement mode will be in AUTO

state. Press 【RANGE】 to select the

suitable ranges. The selectable ranges

are: 80.000mA/800.00mA.

● Press【REL】, 【MAX/MIN】and

【2nd VIEW】)to do the relative

test or record Chart 8. AC/DC mA Measurement

which will be displayed in slave display.

● Insert the red test leads into “VΩHz” terminal and the black test lead into

“COM” terminal and contact the test points with the test leads. Please refer to

Chart 8. for the measurement mode. The measured values and relative symbols

will be on master and slave display at the same time. Please refer to Table 8:

Table 8:

Press 【SELECT】to Choose State Master display Slave display

DCmA DCmA

ACmA ACmA

ACmA+Hz ACmA Hz

DCmA+ACmA (DC+AC)mA ACmA

5.4.2 AC/DC Ampere Current Measurement

22

Page 24

Note: Before tests on small AC current, please have the two test leads in

open-circuit status and press【REL】to make zero for a better accuracy!

Do not make 20A current measurements for longer than 15 seconds.

Exceeding 15 seconds may cause damage to the meter and/or the test leads.

● Press【10A 】 to enter the function.

● It has three states of DCA, ACA, ACA

+Hz, DCA+ACA. Press【SELECT】

to select one of them.

● When the power is on, the

measurement mode will be in AUTO

state. Press【RANGE】to select the

suitable ranges manually. The

selectable ranges are

8.0000A/10.000A

● Press【REL】, 【MAX/MIN】to do

the relative test or record which will be

in slave display.

● Insert the red test leads into “10A”

terminal and the black test lead into

the “COM”terminnal and contact the

test points with the test leads.

Please refer to Chart 9. Chart 9. AC/DC Ampere Measurement

for the connection mode.

The measured values and relative symbols will be on the master and the slave

display at the same time. Please refer to Table 9.

Table 9:

Press 【SELECT】to Choose State Master display Slave display

DCA DCA

ACA ACA

ACA+Hz ACA Hz

DCA+ACA (DC+AC)A ACA

5.5 Resistance Measurement(Ω)

Warning: To avoid damage to the meter or to this equipment under test,

disconnect circuit power and discharge all high-voltage capacitors before

measuring resistance. Use the DC function to confirm that the capacitor is

discharged.

Note: In measuring low resistance, the resistance of the test leads may cause

23

Page 25

an error of 0.1Ω~0.5Ω in the test results. To avoid this error, first short the

test leads, next press 【REL】key. The master display will be zero and the

slave display displays the resistance of test lead. .

● Press【Ω】 to the function of resistor

measurement.

● The measurement has three modes:

noraml (Ω) , Continuity ( ) and

hi-impedance(Hi). Press

【SELECT】to select one of them.

● Normal resistance check(Ω)

○,1 When the power is on, the measurement mode will be in

AUTO state. Press【RANGE】to

select the suitable ranges manually. The selectable

ranges are: 800.00Ω / 8.0000kΩ

/ 80.000kΩ / 800.00 kΩ / 8.0000MΩ

/ 80.000MΩ

Chart 10. Resistance Measurement

○,2 Press【REL】, 【MAX/MIN】to do the relative test or record which will be

in slave display.

○,3 Insert the red test leads into “VΩHz” terminal and the black test lead into

“COM” terminal and contact the test points with the test leads. Please refer to

Chart10 for the connection mode. The measured values and relative symbols

will be on the master and slave display at the same time. Please refer to Table

10.

Table 10:

Measurement state Master display Slave display

Ω Ω/kΩ/MΩ Relative to MAX/MIN and REL

● Continuity test( )

Press【SELECT】to select the “ “ range. Once the measured resistor is less than

50Ω, it will buzz. Please note that continuity can only be judged by the buzzer

sound and the display is no meaning at the time.

● High resistance measurement(Hi)

This function is used to measure the resistance above 80MΩ.

Press 【SELECT】 SELECT button to select “HiΩ” range. The master display

will display “Hi”.

A single range is 1000.0MΩ. If the testing points resistance falls below 10MΩ

and above 8000.0MΩ, “OL” will appear on the display.

24

Page 26

5.6 Capacitance Measurement( )

Warning: To avoid damage to the meter or the testing equipments disconnect circuit

power and discharge all high voltage capacitors before measuring capacitance. Use the DC

function to confirm that the capacitor is discharged.

Notes:

Some capacitors have polarities. In measuring polarities capacitors, touch the red

test lead to the positive polarity and the black test lead to the negative polarity.

In measuring low capacitance, the resistance of the test leads may cause an error

in the test results. To avoid this error, first short the test leads, next press REL△

button. The master display will be null and the secondary display displays the

resistance of test lead. Measure the to-be tested resistance and the result will be

displayed on the master display.

Capacitor is capable of storing electric charge. When testing capacitance, only the

value on a stable display is the correct result.

Press【 】to enter capacitor measurement

function.

● When the power is on, it will be in

AUTO state. Press【RANGE】to select

the suitable range manually:

1.0000nF/10.000nF/100.00nF/1.0000

μF/10.000μF/ 100.00μF.

● Insert the red test leads into “VΩHz” terminal

And the black test lead into “COM” terminal

and contact the test points with the test leads.

Please refer to Chart11 for the connection mode.

The measured values and relative

symbols will be on the master and slave

displays at the same time. Please refer to Table 11.

Table 11:

Measurement State Master Display Slave Display

nF/μF

Chart 11. Capacitance Measurement

Relative to MAX/MIN and REL

5.7 Measurements of Frequency(Hz)

● Press【Hz/DUTY】to enter the function of frequency measurement.

● It has three states of NORMAL and HiHz. Press【SELECT】to choose one of

them.

● In the normal measurement mode , the

25

Page 27

frequency range is as follows :

999.99Hz / 9.9999kHz/ 99.999kHz/

999.99kHz/ 5.0000MHz. When test it,

it will be always in state of auto

range.Then frequency range is

0.5Hz~5MHz.

● In the state of HiHz,the frequency is

9.9999MHz/99.999MHz/999.99MHz.

Use other high frequency accessories

to measure frequency above 10MHz.

During measurement, it will be always

in auto measurement

Mode. The frequency range is 8MHz

~1000MHz in such state. Also, the Chart 12. Frequency Measurement

Master and slave display will be

combined into a 10-digit display. The

former displays the higher 5 digits of

and the latter displays the lower 5

digits, i.e., master display + slave

display = 10 digits reading.

● Insert the red test leads into “VΩHz” terminal and the black test lead into “COM”

terminal and contact the test points with the test leads. Please refer to Chart12 for

the connection mode. The measured values and relative symbols will be on the

master and slave displays at the same time. Please refer to Table 12.

● Note: There is a middle state, which shows “00.000” in master display. It has no

meaning.

Table 12:

State(Press【SELECT】to choose)

Hz Hz/kHz/MHz

HiHz 00000 00000MHz

(middle state) 00.000

Master Display

Slave Display(switch between them by pressing【2nd

VIEW】)

%/ %/ ms/ ms

5.8 Temperature Measurement(TEMP)

● Warning: please disconnect all the test

leads/ probes from DMM before

connecting the thermocouple to DMM

● Display mode: to read “℃” on the

master display and “℉” on the slave

display.

26

Page 28

● Press【TEMP】to enter the function of

temperature measurement. It has two

measurement modes: normal and Hi.

● Press【SELECT】to select Hi or normal

mode. Chart 13. Temperature Measurement

● When “Hi” is displayed on the master

display, use K type thermoucouple to

measure temperature.

The temperature range is -50~

1300 and -58~2372。

● When “Hi” appears from the display,

the displayed temperature on the

master display is the inside

temperature of this instrument. Please

note this temperature value is just for

reference and has no measurement

meanings.

● Insert positive (red) into “VΩHz” and

negative (black) into “COM”. Please

refer to Chart 13.

5.9 Measurement of Diode ( )

To avoid damage to the meter or

the testing equipments disconnect

circuit power and discharge all

high voltage capacitors before

measuring. Use the DC function

to confirm that the capacitor is discharged.

Chart 14. Diode and Switching Check

● Press【 】to enter the function of diode measurement.

● Insert the red test lead into “VΩHz” terminal and the black test lead into “COM”

terminal and contact the test points with the test leads. Please refer to Chart 14.

for the connection mode. The measured values and relative symbols will be on

the master and slave display at the same time. Please refer to Table 13.

● Insert red test lead into the positive of the measured diode and black into the

negative of diode. The voltage drop of diode will be on master display and a

27

Page 29

good voltage drop is approximately 0.5V~0.8V. If no diode measurement is

done, the master display shows the testing voltage “3.3 V”

● When using this function as continuity test, the display at the time has no

meaning, the continuity can only be judged by the beeper. If the beeper sounds,

it means the circuit/component is shorted.

Table 13:

Measurement State Master Display Slave Display

V

(Voltage

Drop)

: voltage drop>2V, the diode is in open circuit or

inverted connection

: voltage drop is within 0.1~2V, the diode is normal.

: voltage drop is within 0~ 0.1V, the diode is in

short-circuit and the buzzer will sound.

5.10 Square wave output signal( OUT)

● Press【 OUT】,it will be treated as

a square wave source. And square

signal is output through terminals of

“VΩHz” and “COM”.

● The output square wave frequency is :

0.5000Hz/1.0000Hz/2.0000Hz/10.000

Hz/50.000Hz/60.240Hz/74.63Hz/100.

00Hz/151.50Hz/200.00Hz/303.00Hz/6

06.10Hz/1.2500kHz/1.6660kHz/

2.5000kHz/5.0000kHz

● Press【 2nd VIEW】 to change

frequency. For square wave signal.

Press 【SELECT】 to change duty Chart 15. Output of square wave

cycle rate. Press【SELECT】one time,

the duty cycle rate will change 1%. Press down【2nd VIEW】for more than 2s,

the square wave signal will return to default 606.1Hz and 50% duty cycle.

● Please see Chart 15. The output frequency and relative parameters will be on the

master and slave displays at the same time. Please refer to Table 14.

Table 14:

Measurement State Master display Slave display

OUT Hz %

6. Technical specification

Temperature environment: 18~28 and humidity 0~75%. The accuracy

validity is one year.

28

Page 30

The accuracy is indicated as: ±(a%× reading +n)

a-relative factor of measurement error

n-absolute error with numbers.

6.1 DC Voltage Measurement

Range Resolution Accuracy Remark

80mV 1µV ±(0.3% +15)

800mV 10µV

8V 0.1mV

80V 1mV

600V 10mV ±(0.15% +15)

±(0.10% +15)

Input impedance:

80mV~800mV>1000MΩ

8V~600V:10MΩ

6.2 True RMS of AC voltage

Accuracy (F:frequency)

Range Resolution

80mV 1μV ±(2.0% +50) Note: For this 80mV range, the test frequency is only 50Hz~5KHz

800mV 10μV ±(1.0% +50) ±(5.0% +50) ±(8.0% +50)

8V 0.1mV

80V 1mV 50Hz~10KHz: <75% Range:±(1.0% +50) & >75% Range ±(8.0% +50)

450V 10mV

<75% Range:

50Hz≤f<20kHz

<1V: ±(5.0% +50)

1V~6V:±(2.0% +50)

50Hz~1kHz: <90% Range:±(1.0% +50) & >90% Range:±(5.0% +50)

<75% Range:

20kHz≤f≤50kHz

±(5.0% +50) ±(8.0% +50)

>75% Range:

50Hz~20kHz

Remark: Input impedance: 80mV~800mV>20MΩ;8V~600V: 10MΩ

Parallel capacitance: <100pF

Frequency on slave display (Sensitivity:≥200mVrms; Max. Input:≤2Vpp)

Please short-connect the test leads to make zero before test for better

accuracy.

6.3 DC Current

Range Resolution Accuracy Remark

80mA 1µA

800mA 10µA

8A 0.1mA ±(0.8% +15)

10A 1mA ±(1.5% +15)

±(0.2%g+15)

Fuse: F 600V 1A F600V 12.5A

Voltage drop: ≤800mV

Max. input current: 20A(less than 15s every 15 minutes)

6.4 True RMS of AC Current

Range Resolution Accuracy Remarks

80mA 1µA

±(1.5% +20)

800mA 10µA

Fuses : F 600V 1A F600V 12.5A

Voltage drop: ≤800mV

29

Page 31

8A 0.1mA ±(1.5% +20)

10A 1mA ±(2.0% +20)

Sensitivity : mA Range is 50Hz

Max. Input Current: 20A(up to 15 seconds every 15 minutes)

~5kHz, A Range is 50Hz~500Hz

Note: For small current, please connect the test lead in open status to make zero

before tests for better accuracy.

6.5 Resistor

Range Resolution Accuracy Remark

800Ω 0.01Ω

8kΩ 0.1Ω

80kΩ 1Ω

800kΩ 10Ω

8MΩ 100Ω ±(0.3% rdg+10)

80MΩ 1kΩ

HiΩ:1000MΩ 0.1MΩ ±(5.0 % +50)

≤

40MΩ:±(2.5 % +10)

±(0.3% +10)

(≤

10Ω

: 0.5%+15)

±(0.3% +5)

>

40MΩ: ±(3.5% +10)

For small resistance, please

short-connect the test leads to

make zero for better accuracy.

Overload protection: 250Vrms

6.6 Diode

Function Range Accuracy Resolution Remarks

Diode 0~3V ±(3.0% +5) 0.0001V Diode positive voltage drop; overload protection: 250Vrms

6.7 dBm

Function Range Accuracy Resolution

dBm

-80.00dBm~ +80.00dBm

±1.0% 0.01dBm

6.8 Frequency

Range Resolution Accuracy Remarks

999.99Hz 0.01Hz

9.9999kHz 0.1Hz

99.999kHz 1Hz

999.99kHz 10Hz

5.000MHz 100Hz

9.9999MHz 1kHz

99.999MHz 10kHz

999.99MHz 100kHz

6.9 Capacitor

Range Resolution Accuracy Remark

1nF 1pF

10nF 10pF

100nF 100pF

1µF 1nF

10µF 10nF

±(0.05% +5)

±(0.1% +5)

±(5.0% +50)

Overload protection: 250Vrms

Sensitivity: ≥200mVrms

Max. Input: ≤2Vpp

Should be with accessories

Overload protection: 250Vrms

<10nF, the external interference are big,

please make zero first to eliminate the error

30

Page 32

100µF 100nF

6.10 Temperature

Temperature Accuracy Resolution Remark

-50℃~1300℃

<0 or 32:±(10% +5°)

≥0 or 32 & ≤1000

-58℉~2372℉

0℃~80℃ ±(10% +3°+100dgts)

32℉~176℉ ±(10% +3°+20dgts)

>

1000

or 1832:±(3.0% +20°)

or 1832:±(2.0% +2°)

0.1

0.1

0.001

0.01

type K thermocouple

(The accuracy by K type

thermocouple is tested

under the condition that the

Inner Temperature is within

23℃±5℃)

Inner Temperature

(for reference only!)

6.11 Square wave output

Description

Voltage amplitude 3V approx.

0.5Hz/1.0Hz /2.0Hz /10Hz /50/60.24Hz /74.63Hz /100Hz

Frequency

Duty cycle

/151.5Hz /200Hz /303Hz /606.1Hz /1250Hz /1666Hz

/2500Hz /5000Hz

1%~99%

Ⅶ Accessories

The standard accessories are as below:

1. Universal system … …………………………………………………………1pc

2. Power cord … ………………………………………………………………1pc

3. User manual …………………………………………………………………1pc

4. BNC-BNC cable …… ………………………………………………………1pcs

5. BNC-Crocodile clip cable …………………………………………………1pcs

6. Connection cable ……………………………………………………………2pairs

7. 50 ohm matching equipment ………………………………………………1pc

8. F 690V 1A(10×38mm)fuse … … …………………………………………1pc

9. F 690V 12.5A(10×38mm)fuse ………………………………………………1pc

10. T 250V 4A(5×20mm)fuse … … …………………………………………2pcs

11. Test leads(red, black) … … … ………………………………………………1pair

Ⅷ Maintenance and Service

It is one kind of precision instrument. Please don’t repair it by yourself unless you

are professional serviceman and familiar with service manual.

Some parts of it are composed of intelligent instruments which is auto-calibrated.

Except some components noted changeable, please don’t replace other components

randomly to avoid technical deviations.

31

Page 33

Please clean the shell with soft cloth or neutral detergent. The dirt on terminals and

test leads will affect the readings. Please clean them with cotton balls moist with

detergent.

When it is only stored, please pull out the key of power switch. And it should take off

the external connected power cord if it is not used for long time.

The instrument should not be stored in place of humidity, high temperature and

strong magnetic filed.

If the instrument seems defective, please check power supply and fuse. According

with the operation procedures of the instruction, if you diagnose it is defective,

please contact with customer service department or contact Sales department directly.

32

Loading...

Loading...