Page 1

ENGLISH

Operator’s Manual

HEAVY DUTY CAYENNE® GAS CHAR BROILER

Item Model Description BTU/hr Gas Type

924CG CBL2024 Gas Char Broiler Radiant/Lava 24” 80,000 Natural Gas or Propane*

936CG CBL2036 Gas Char Broiler Radiant/Lava 36” 120,000 Natural Gas or Propane*

948CG CBL2048 Gas Char Broiler Radiant/Lava 48” 160,000 Natural Gas or Propane*

960CG CBL2060 Gas Char Broiler Radiant/Lava 60” 200,000 Natural Gas or Propane*

972CG CBL2072 Gas Char Broiler Radiant/Lava 72” 240,000 Natural Gas or Propane*

*Shipped setup for Natural Gas and includes a kit for conversion to Propane Gas

Conforms to ANSI

Z83.11b -2009

Certified to CSA

STD 1.8b - 2009

Thank you for purchasing this Vollrath equipment. Before operating the equipment, read and familiarize yourself with the following operating

and safety instructions. SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE. Save the original box and packaging. Use this

packaging to ship the equipment if repairs are needed.

Conforms to

NSF Std. 4

Item No. 2350069-1 en Rev 06/14

Page 2

Safety PrecautionS

To ensure safe operation, read the following statements and

understand their meaning. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause

severe personal injury, death, or substantial property damage if the

warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can

cause minor personal injury or property damage if the caution is

ignored.

NOTE

Note is used to notify people of installation, operation, or

maintenance information that is important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow

these precautions could result in injury to yourself and others.

function and PurPoSe

This equipment is intended to be used for grilling foods in commercial

foodservice operations only. It is not intended for household, industrial or

laboratory use.

FOR YOUR SAFETY

Do not store or use gasoline or other ammable vapors

or liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, injury

or death. Read the installation, operating and

maintenance instructions thoroughly before installing

or servicing this equipment.

WARNING

FIRE, INJURY or DEATH HAZARD

Have this equipment installed by a qualied installer in

accordance with all federal, state and local codes. Failure to

install this equipment properly can result in injury or death.

WARNING

FIRE, INJURY or DEATH HAZARD

This appliance must be installed and adjusted by a qualied

technician in accordance with all federal, state and local

codes. Failure to install, adjust or maintain this equipment

properly can result in property damage, injury or death.

ENGLISH

unPacking the equiPment

When no longer needed, dispose of all packaging and materials in an

environmentally responsible manner.

1. Remove all packing material and tape, as well as any protective plastic

from the equipment.

2. Use caution and assistance from others in lifting and moving this

equipment.

3. Clean any glue residue left over from the plastic or tape.

4. Place the equipment in the desired position and height.

5. Install the four (4) legs (A) and feet (B) onto the equipment. See Figure 1.

6. Before using this equipment it must be cleaned and dried thoroughly.

initial SetuP

NOTE: It is vital that the purchaser of this equipment post in a prominent

location instructions to be followed in the event that the user smells gas.

This information shall be obtained by consulting the local gas supplier. The

purchaser of this equipment must post in a prominent location

WARNING

Read and understand all instructions and

warnings before using this equipment. Retain this

manual for future reference.

WARNING

FIRE HAZARD

Do not install or use without 4” legs. Use of this equipment

without legs can cause the appliance to overheat and cause

a re.

WARNING

FIRE, INJURY or DEATH HAZARD

This appliance is for use in non-combustible locations only.

WARNING

FIRE and INJURY OR DEATH HAZARD

Injuries or death can occur if this equipment is not used

properly. To reduce risk of injury or death:

Keep the appliance area free and clear from combustibles

Do not obstruct the ow of combustion and ventilation air

Do not spray controls or the outside of the appliance with liquids

or cleaning agents

Let hot appliance cool before cleaning or moving

The appliance should only be used in a at, level position

Do not operate unattended

2

OperatOr’s Manual

Page 3

The installation of this appliance must conform with local codes, or

in the absence of local codes, with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54, or the Natural Gas and Propane Installation Code, CSA

B149.1, as applicable.

The appliance and its individual shutoff valve must be disconnected from

the gas supply piping system during any pressure testing of that system

at test pressures in excess of ½ psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

½ psi (3.5 kPa).

Clearance and positioning around the appliance: This appliance

must be installed adjacent to non-combustible surfaces only with a minimum

spacing of 6” from all sides. This appliance must be a minimum distance of

6” from another appliance. The appliance must have the supplied 4” legs

installed and be placed on a non-combustible surface.

Air supply and ventilation: The area in front and around the appliances

must be kept clear to avoid any obstruction of the ow of combustion and

ventilation air. Adequate clearance must be maintained at all times in front of

and at the sides of the appliance for servicing and proper ventilation.

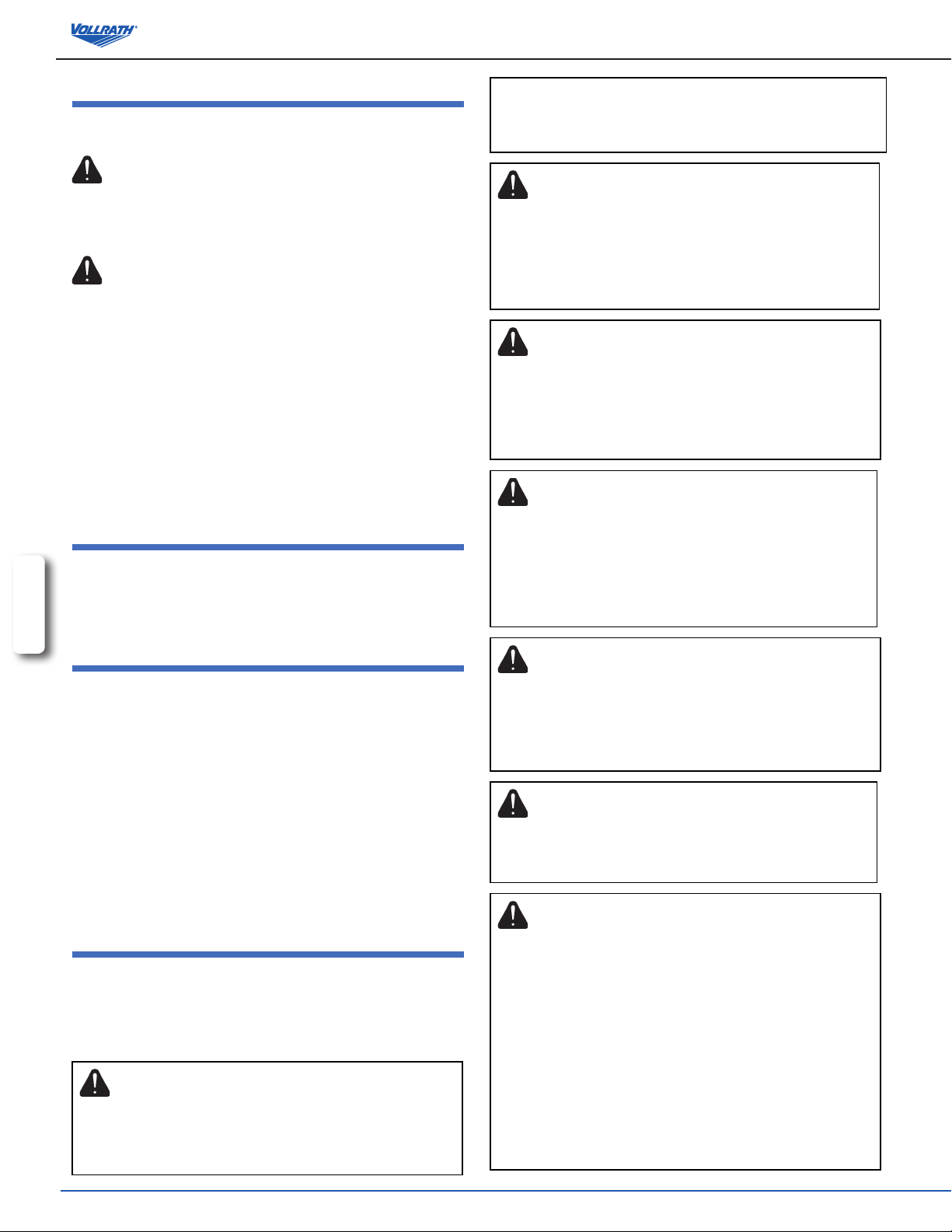

Pressure regulator: All commercial cooking equipment must have

a pressure regulator on the incoming service line for safe and efcient

operation. The regulator provided for this appliance is adaptable for both

Natural gas and LP gas. A conversion kit with separate instructions is

included explaining this procedure in detail.

Regulator information: ¾” NPT inlet and outlet; factory adjusted for 5” WC

Natural Gas standard and may be converted by qualied personnel to be

used for Propane at 10” WC.

Gas piping : Gas piping shall be of such size and so installed as to provide

a supply of gas sufcient to meet the full gas input of the appliance. If the

appliance is to be connected to existing piping, it shall be checked to determine

if it has adequate capacity. Joint compound (pipe dope) shall be used sparingly

and only on the male threads of the pipe joints. Such compounds must be

resistant to the action of LP gases.

Any loose dirt or metal particles, which are allowed to enter the gas lines

on this appliance, will damage the valve and affect its operation. When

installing this appliance, all pipe and ttings must be free from any internal

contaminates. It is recommended that a “drip leg” be installed in-line

before the regulator.

Manual shut off valve: A manual shut off valve should be installed

upstream from the manifold, within 4 ft. (1.2 m) of the appliance and in a

position where it can be reached in the event of an emergency.

Checking for gas leaks: Using a gas leak detector or a soapy water

solution is recommended for locating gas leaks. Matches, candle ame or

other sources of ignition shall not be used for this purpose. Check entire piping

system for leaks.

Exhaust canopy: Cooking appliances inherently create a good deal of heat

and smoke and should be installed under an efcient exhaust hood with ame

proof lters. A vertical distance of not less than 4 ft. (1.2m) shall be provided

between the top of the appliance and lters or any other combustible material.

FIRE DEATH HAZARD

If you smell gas follow the instructions provided by the gas

supplier.

Do not touch any electrical switch; do not try to light the

burner; do not use a telephone within close proximity.

CAUTION

WARNING

ENGLISH

Lighting the pilot: The manifold units are equipped with standing pilots, and

Connection

diagram

Prior to connecting the regulator, check the incoming line pressure. The

regulator can only withstand a maximum pressure of ½ PSI (14” WC). If

the line pressure is beyond this limit, a step down regulator before the

regulator provided will be required. The arrow forged into the bottom of the

regulator body shows gas ow direction, and should point downstream to the

appliance.

Gas conversion: Conversion from Natural Gas to Liquid Propane (LP)or

vice versa may only be performed by a qualied technician or service agent.

In the case of troubleshooting, ensure that the correct orice sizes of the

spuds have been provided.

Natural Gas Orice #46

LP Gas Orice #40

NOTE: The orice size is marked on the spud.

Gas connection: The appliance comes tted with a ¾” N.P.T male adapter

for connection to the pressure regulator.

Maintenace: A qualied service company should check the unit for safe and

efcient operation on an annual basis. Contact the factory representative or

local service company to perform maintenance and repairs.

each should be lit immediately after the gas is supplied to the appliance.

1. Before attempting to light pilots, turn off the main gas valve to the appliance

and wait 5 minutes to clear the gas.

2. Turn off all gas control knobs (E). See Figure 1.

3. Turn on control valve and light all pilots.

4. The pilot burner must be lit at the end of the tube. Hold an ignition source

through the pilot light hole (D) in the front panel at the pilot tube. When the

ame is established remove ignition source.

5. To shut down the appliance turn off the main gas valve to the appliance.

NOTE: Smoke appearing on initial use of the appliance is normal. This is as a

result of the rust preventative coating burning off. Allow the appliance to ‘burn

in’ for at least 15 minutes before the rst use.

Pilot ame regulation: The pilot ame on the appliance has been factory

adjusted. When adjustment is necessary, adjust the pilot ames as small as

possible, but high enough to light the burner immediately when burner valve

is turned to the ‘High’ setting. Access to the pilot ame adjustment screw is

obtained by removing the front panel.

Burner adjustment: Remove the front panel to gain access. Turn burner

valve knob to ‘High’ position. Slowly decrease mixing ring aperture to give a

soft blue ame having luminous tips, then slowly increase opening to a point

where the yellow tips disappear and a hard blue ame is obtained.

OperatOr’s Manual

3

Page 4

featureS and controlS

F

G

D

E

G

E

G

D

E

G

C

B

Figure 1. Features and Controls.

A

LEG. Supports the equipment.

B

ADJUSTABLE FEET. Used to adjust the level of the equipment.

C

DRIP TRAY. A tray that collects grease and oil. This tray can be removed

for cleaning. It is recommended that water be in the drip tray to reduce

are-ups and smoking.

ENGLISH

D

PILOT LIGHT ACCESS HOLE. Allows access to the pilot light.

E

GAS CONTROL KNOB. Used to set or adjust the temperature of the

grilling surface.

F

GRILL GRATES. Cooking surface.

G

KNOB GUARD. Helps protect the control knob from damage.

WARNING

FIRE HAZARD

If you smell gas follow the instructions provided by the

gas supplier. Do not touch any electrical switch; do not

try to light the burner; do not use a telephone within close

proximity.

Before initial use, turn the gas control knob to the maximum setting,

and allow equipment to burn-in for 15 minutes. You will notice smoke

appearing due to the cooking surface burning-in. This is normal. After 15

minute burn in period the equipment is ready for use.

To adjust the leveling feet:

1. Hold the leg (A) and rotate the adjustable feet (B) so the equipment is

level. See Figure 1.

2. It is recommended that the grill grates (F) be set at the full tilt position

A

to start. This will allow grease to run down the grill grate(s) (F) and into

the drip tray (C) and will reduce are-ups.

3. Check the drip tray (C) frequently and add water as necessary.

Water vapor rising from the drip tray (C) and through the combustion

chamber will help to reduces are-ups.

4. To ignite the burners, depress and turn the gas control knob (E) to

‘High’ position.

5. Allow the appliance to pre-heat before attempting to use.

6. Adjust the valve set-point to obtain the desired level of heat.

WARNING

FIRE, INJURY or BURN HAZARD

Never attempt to move grates while cooking. Flare-ups

can occur unexpectedly and cause injury. Turn unit off and

allow the grill grate(s) (F) to cool.

7. To adjust the grill grate(s) (F), raise or lower the back of the grates.

Turn unit off and allow the grill grate(s) (F) to cool. Use pot holders or

gloves to reposition.

4

oPeration

WARNING

FIRE, INJURY or DEATH HAZARD

Contact a qualied technician or service agent for any

adjustments, maintenance or repairs. This appliance is not

user serviceable.

WARNING

BURN HAZARD

Hot liquids and steam can burn skin. Never pour any liquid

other than oil to be used for cooking on to hot surfaces.

OperatOr’s Manual

cleaning

To maintain the appearance and increase the service life, clean your

equipment daily.

NOTE:

Do not clean the equipment with steel wool.

1. Allow the equipment to cool completely before cleaning.

2. Using a wire brush, scrape the grill grate(s) (E) to remove any food

residue.

3. Using a damp cloth, sponge dipped in soapy water or metal scraper to

clean the equipment; rinse and dry thoroughly.

4. Dry grates thoroughly to prevent rusting. This may be done by placing

the grates in place and heating the unit as described in the Operation

Section.

5. Empty and clean the drip tray (C). Place the drip tray (C) into the

equipment.

Page 5

converting from lava rock to radiant

converting from radiant to lava rock (hd modelS)

1. Allow the equipment to cool completely before converting.

2. Remove the lava rock (A) and save for future reuse. See Figure 2.

3. Remove the wafe grate(s) (B) and save for future reuse.

4. Remove the lava rock cover(s) (C) and save for future reuse.

5. Place the radiant cover(s) (D) over the burner tubes. See Figure 3.

A

B

C

Figure 2. Lava Rock Components.

1. Allow the equipment to cool completely before converting.

2. Remove the radiant cover(s) (D) and save for future reuse. See Figure 3.

3. Place the lava rock cover(s) (C) over the burner tubes. See Figure 2.

4. Set the wafe grate(s) (B) into place.

5. Set the lava rock (A) onto the wafe grate(s) (B) and spread out evenly.

D

Figure 3. Radiant Components.

ENGLISH

OperatOr’s Manual

5

Page 6

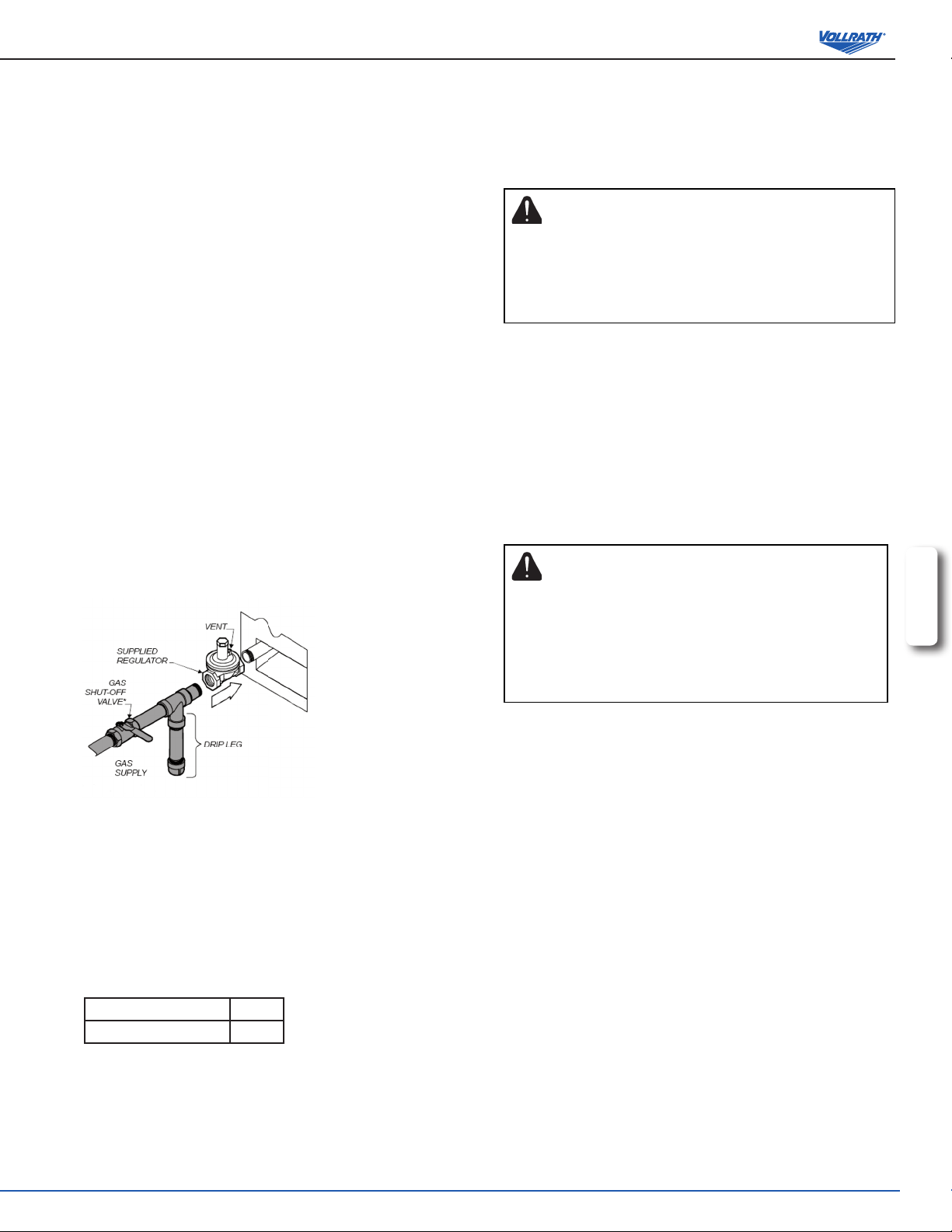

28.7” (729.50 mm)

Item A ” (cm) Burners

28.7” (729.50 mm)

5”

(127 mm)

8.3”

ENGLISH

( 212 mm)

924CG 24” (60.7) 4

936CG 36” (91.5) 6

948CG 48” (122.0) 8

960CG 60” (152.5) 10

972CG 72” (182.9) 12

5”

(127 mm)

8.3”

( 212 mm)

A

6

OperatOr’s Manual

3.3”

( 85 mm)

3.3”

( 85 mm)

Page 7

Service and rePair

There are no user serviceable parts within this appliance. To avoid serious injury or damage, never attempt to repair the Char Broiler yourself. Do not send units

directly to the Vollrath Company. Please contact the qualied professional repair service listed below.

VOLLRATH Technical Service • 1-800-628-0832 • Email: techservicereps@vollrathco.com

When contacting the Authorized Professional Service Center, please be ready with the item number, model number (if applicable), serial number, and proof of

purchase showing the date the unit was purchased.

Warranty Statement for the vollrath co. l.l.c.

This warranty does not apply to products purchased for personal, family or household use, and The Vollrath Company LLC does not offer a written warranty to

purchasers for such uses.

The Vollrath Company LLC warrants the products it manufactures or distributes against defects in materials and workmanship for a period of one year, except as

specically described in our full warranty statement. In all cases, the warranty runs from the date of the end user’s original purchase date found on the receipt.

For complete warranty information, product registration and new product announcement, visit www.vollrath.com.

www.vollrath.com

The Vollrath Company, L.L.C.

1236 North 18th Street

Sheboygan, WI 53081-3201

U.S.A.

Main Tel: 920.457.4851

Fax: 800.752.5620

Technical Services: 800.628.0832

Service Fax: 920.459.5462

Canada Service: 800.695.8560

© 2014 The Vollrath Company, L.L.C.

Item No. 2350069-1 en Rev 06/14

Loading...

Loading...