VOLKSWAGEN Phaeton User Manual

Service.

Self-Study Programme 270

The Phaeton

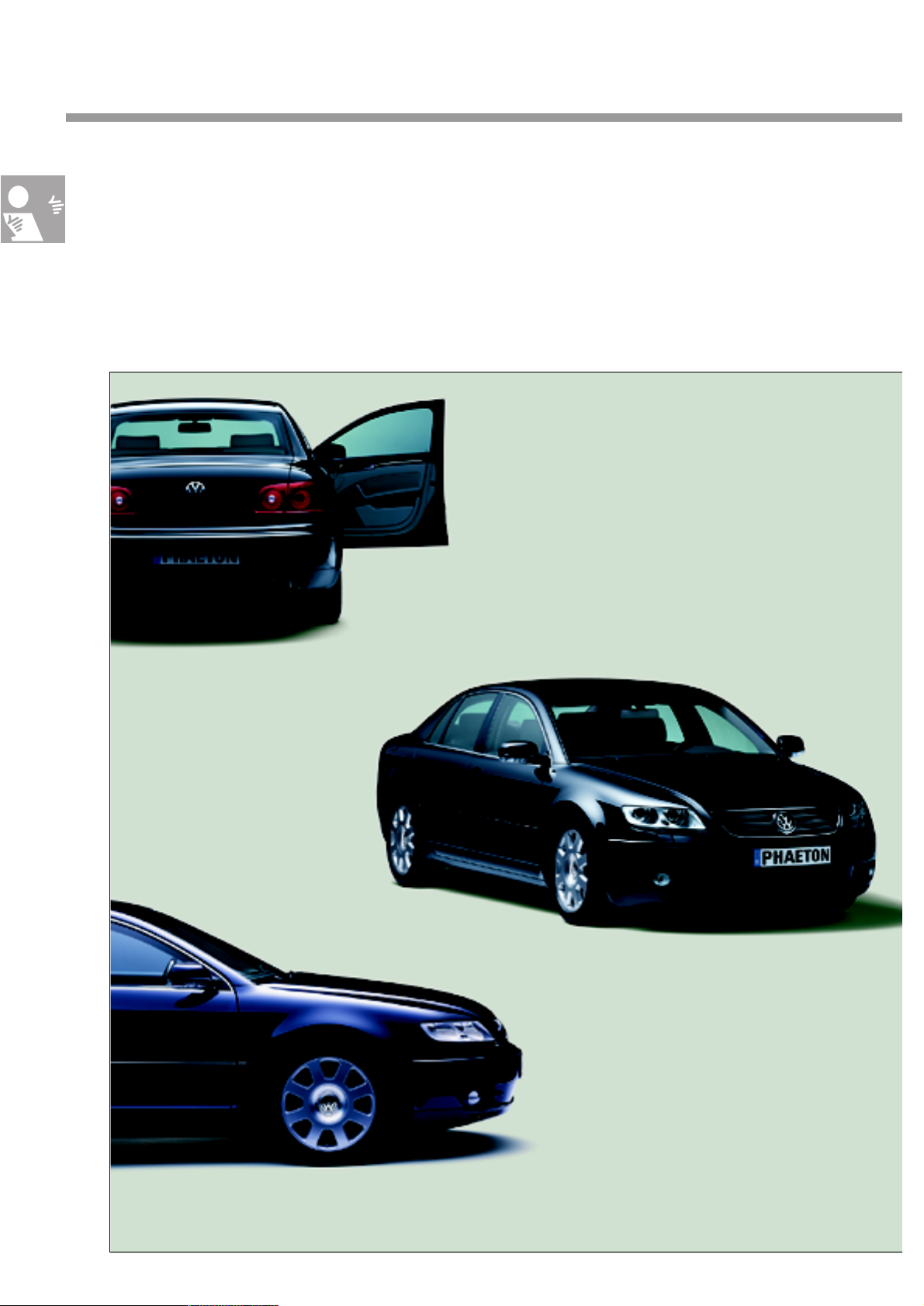

The Phaeton — Volkswagen's flagship — is

based on developments in the international market for luxury goods: a product's quality alone is

no longer sufficient to guarantee success in

highly-developed markets. The prestige and

value of the brand are decisive in influencing

purchase decision-making.

Customers' brand awareness is becoming

increasingly manifest, thereby necessitating

Volkswagen's entry into the higher-class segment.

The launch of the Phaeton witnesses the development of a product which meets customers' technical requirements as well as satisfying the value

and prestige demands made on the Volkswagen

brand.

There are separate self-study programmes on the following topics:

W-engines (SSP248/250),

Air-conditioning/Heating (SSP271),

On-board network (SSP272),

Convenience and safety electronics (SSP273),

Infotainment (SSP274),

Air suspension (SSP275),

Automatic distance control ADC (SSP276),

Chassis (SSP277).

The self-study programme illustrates the structure

and operation of new developments!

Contents will not be updated.

2

270_241

NEW Caution

Note

Please refer to the appropriate service material for current

test, setting and repair instructions.

At a Glance

In a nutshell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Passenger protection. . . . . . . . . . . . . . . . . . . . . . . . . . .26

Engines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Convenience electronics . . . . . . . . . . . . . . . . . . . . . . . .52

Electrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Heating/air-conditioning system . . . . . . . . . . . . . . . . .66

Infotainment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3

In a nutshell

The Phaeton name

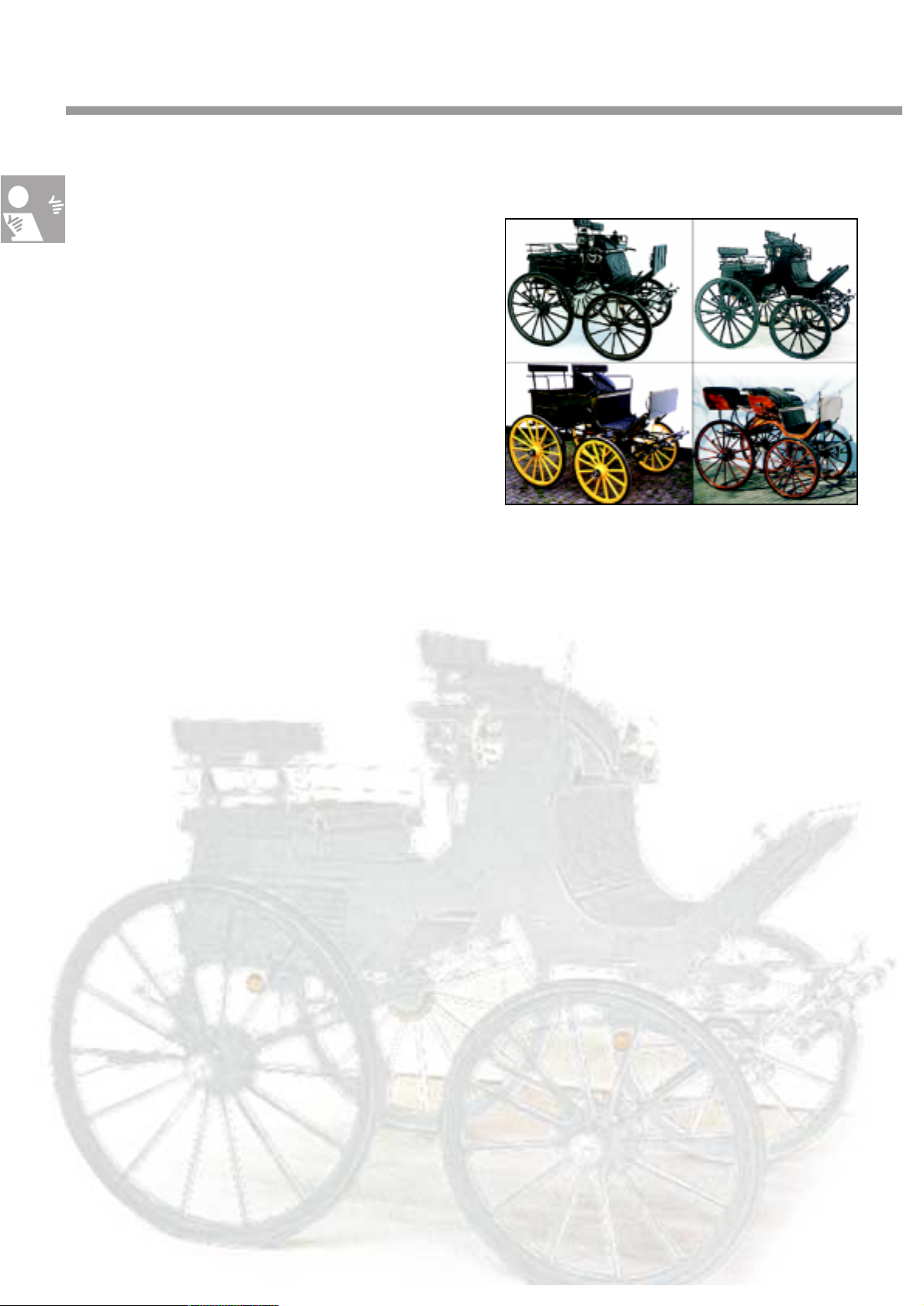

The Phaeton or Phaethon name is originally

derived from Greek mythology. Phaeton (the

'incandescent') was the son of the sun god

Helios, who was the owner of the sun chariot.

Derived from this, Phaetons also refer to the

four-wheeled walking coaches which have been

popular since the 18th century. This refers to open

owner-driver carriages, featuring a trestle seat

for 2 persons with or without a canopy top.

Behind the trestle seat there is a seat for one or

two passengers facing forwards.

Even nowadays, these Phaetons are driven at

special tournaments - original specimens having

become extremely coveted collector items.

At the onset of the 20th century, the term

Phaeton stood for touring carriages with a fabric

canopy and without side windows.

The name’s phonetics*

Phaeton - How’s it pronounced?

Phaeton is pronounced as follows:

Fay - ton.

270_150

The ending is spoken with an unvoiced 'N', comparable with the pronunciation of the word Futon, Fla-

con or Anton.

*Phonology

270_151

4

4

Phaeton’s place in

automotive history

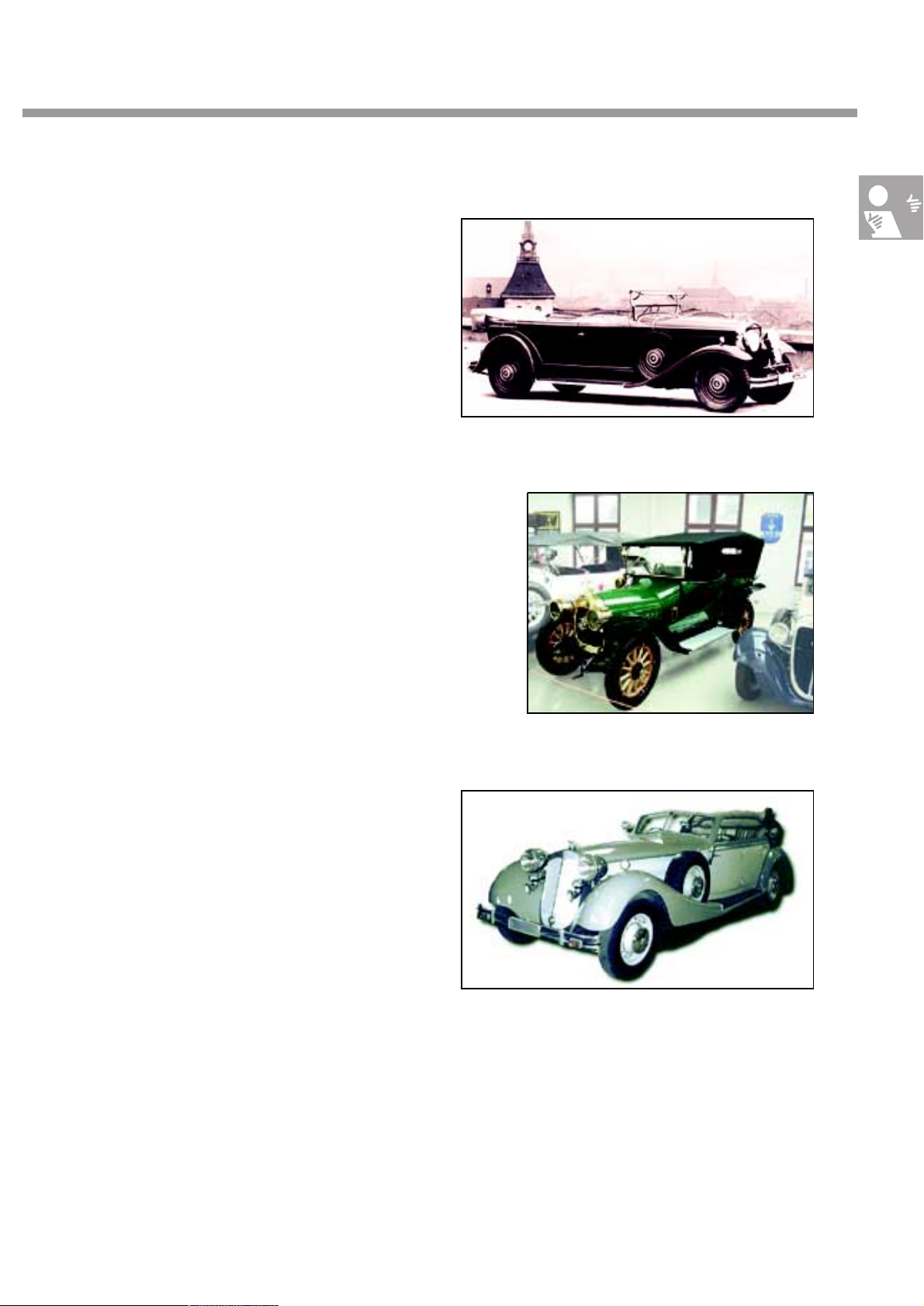

Since 1910, August Horch endowed some of

his models with the “Phaeton” suffix.

The Horch 18/90 bhp 450 Phaeton 1931, the

Horch 12/28 bhp Phaeton 1911 as well as the

Horch 853A Parade Phaeton with only three

specimens dating from 1937, the last remaining model of which is being traded at

US$ 334,000, are just a few examples.

The fact that Volkswagen has chosen the

name Phaeton for the group's flagship is an

indication of the continuation of a tradition of

making superior quality-control requirements

in the production phase, thus providing the

ultimate in exclusivity for each future owner of

a Phaeton.

270_169

Horch 18/90 bhp 450 Phaeton, 1931-32

Horch 12/28 bhp Phaeton, 1910-11

Horch 853A Parade Phaeton, 1937

270_170

270_168

5

In a nutshell

The concept

The transparent factory represents a further

significant milestone for Volkswagen's customer-oriented manufacturing and delivery.

Not only has the exclusive Phaeton led to the

building of an impressive production line in

Dresden, but it has also engendered the

inception of a polished and precisely-functioning logistics concept. In addition to these

outstanding technical production details, purchasers of this high-grade automobile can

expect a perfectly-arranged vehicle transfer

corresponding to an event of superlative

pomp.

The Transparent

270_128

The production

Contrary to the popular opinion that automobile

manufacture is irrevocably linked with dirt and oil,

the vision of manufacturing evident in Dresden

depicts production in an almost noble light. The core

element of the manufacturing process features overlapping conveyor belts with fine wood parquet

instead of metal lines. This high-grade optical characteristic in the production line is reminiscent of a

manufacturing atmosphere otherwise witnessed

only in elite luxury sports car forges.

6

6

Factory

The logistics

An automated system steers the baskets containing the vehicles' individual components

through the factory. The basket 'accompanies'

the corresponding vehicle throughout the

assembly stage. This avoids unnecessary journeys. The chassis, including the engine, gearbox and exhaust system, as well as the body

are simultaneously mounted on different

floors, being transported to a different level in

a glass elevator, before being finally assembled into the complete vehicle. Once the manufacturing process has been completed, the

Phaeton is once again placed on the overlapping conveyor belt before receiving its finishing touches and its final check.

270_130

The event*

An exclusive automobile cries out for the

appropriate stage-management of its delivery. Customers are the centre of attention in

the transparent factory's emotionally and

technologically impressive discovery area.

Potential Phaeton owners are treated to a

birds-eye view of production via livecam during a Virtual Production Tour.

*happening, show

7

7

In a nutshell

The Phaeton

This two-page spread affords an overview of technical innovations. Detailed descriptions of the individual topics can be found in this and other Phaeton self-study programmes.

Phaeton innovations

● Rear window heated by practically invisible

tungsten threads

● Mudguards and spare tyre recess made of plastic

● Fully-galvanised body

● Tail lights with

2-colour LED technology

● Antennae invisibly

integrated in the rear window

● Extremely narrow body jointing, PVC-free

underbody protection

● Doors, engine bonnet and tailgate

made of aluminium

● Superior paintwork, anti-scratch,

exceptional brilliancy

● Air-conditioned 12- and

18-position seats, keyless access

function, automatic distance control,

multifunctional steering wheel

270_053

● Infotainment system with navigation, TV and radio/CD, CD changer in the glove

compartment, 4-zone air-conditioning, solar roof

8

● Surrounding illumination via front, rear and forward lighting

simplifies orientation when getting out of the car in the dark

● 4-corner air suspension with automatic control

● Electro-mechanical high-pressure nozzles for cleaning headlights

● Xenon headlights with

automatic headlight range

control

● Heated, heat-insulating and infrared-reflecting windscreen

● Side and rear windows made of twin-pane laminated safety glass

270_054

9

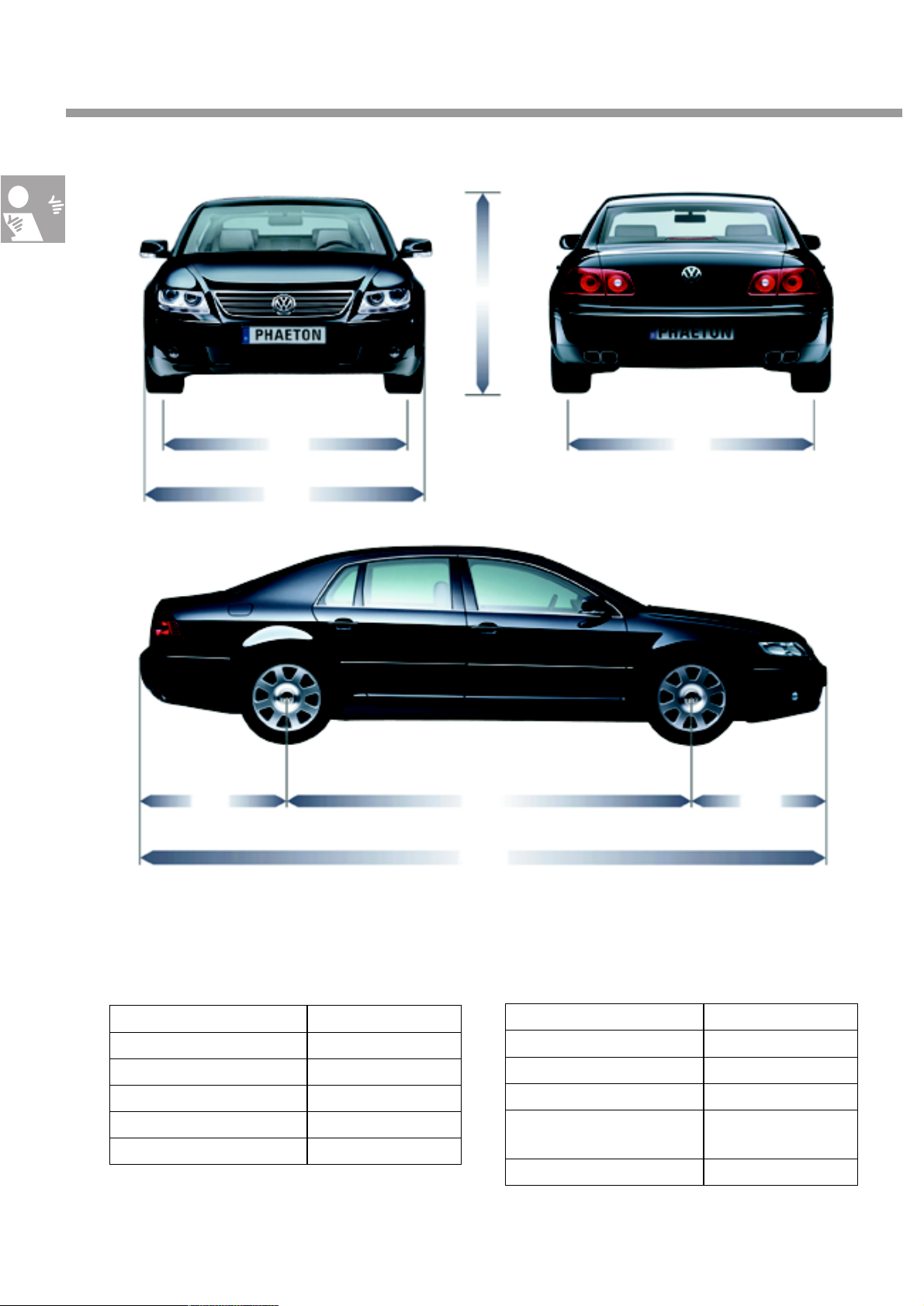

Technical data

1450

1628

1903

1612

2881 10511121

5055

270_118

10

Dimensions and weights

Length 5,055 mm

Width 1,903 mm

Height 1,450 mm

Wheelbase 2,881 mm

Turning circle 12 m

Ta nk vo lu me 9 0 l

Front track width 1,628 mm

Rear track width 1,612 mm

Total permitted weight 2,600 - 2,990 kg*

Empty weight 1,995 -2,413 kg*

Luggage compartment

space

Drag coefficient 0.32 c

500 l

w

*depending on the engine

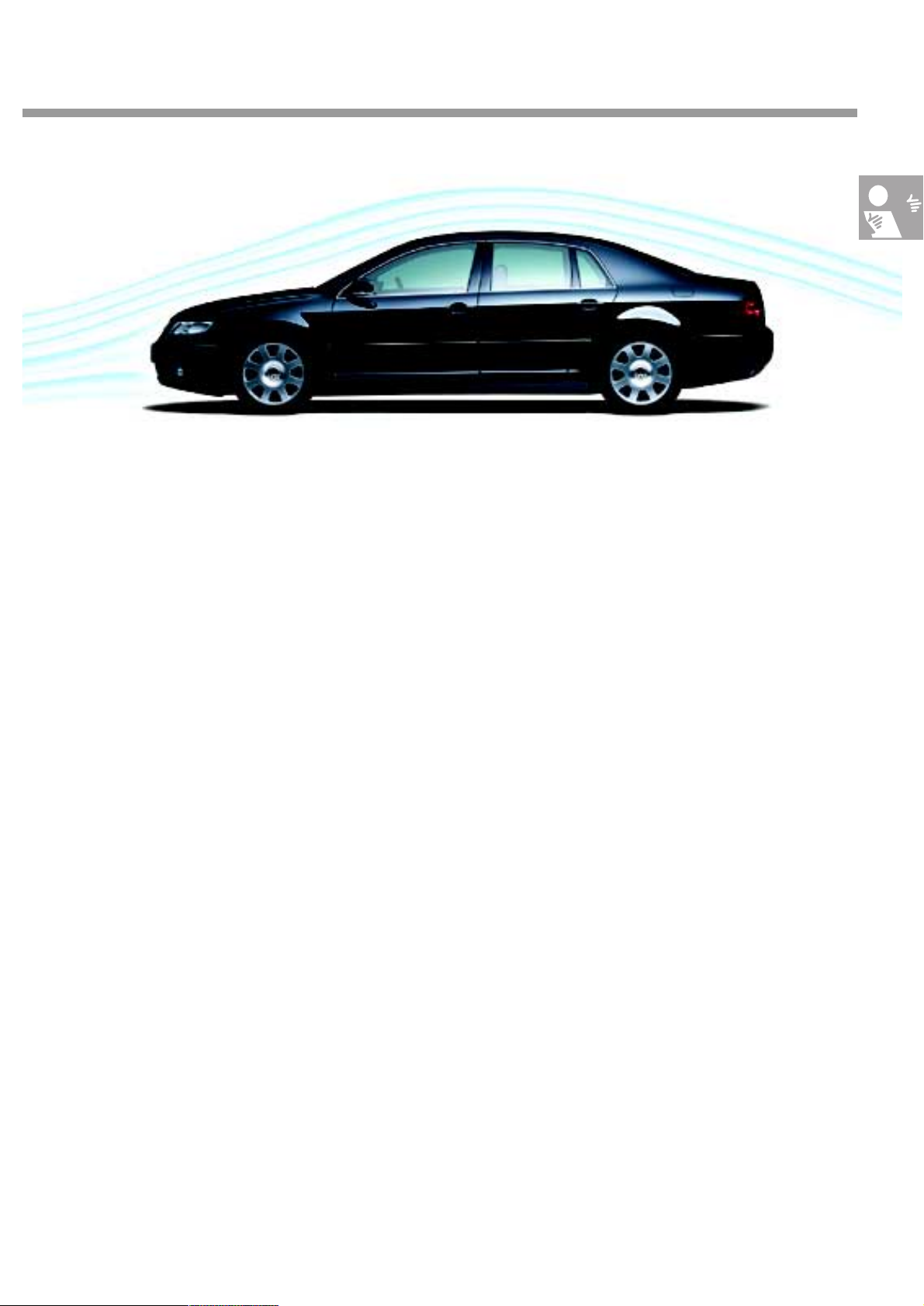

Aerodynamics

270_047

The aerodynamics

The Phaeton has a low drag coefficient of 0.32 cw — a level which was achieved by applying various

measures:

● The underbody has an extremely smooth design,

● The windscreen wipers are embedded,

● The body gap dimensions are very low,

● The front has an arrow-shaped design and

● The body is lowered at higher speeds.

Small features such as the retractable headlight cleaning nozzles, the antenna-free body and the smooth

body transitions are also responsible for this low drag coefficient.

11

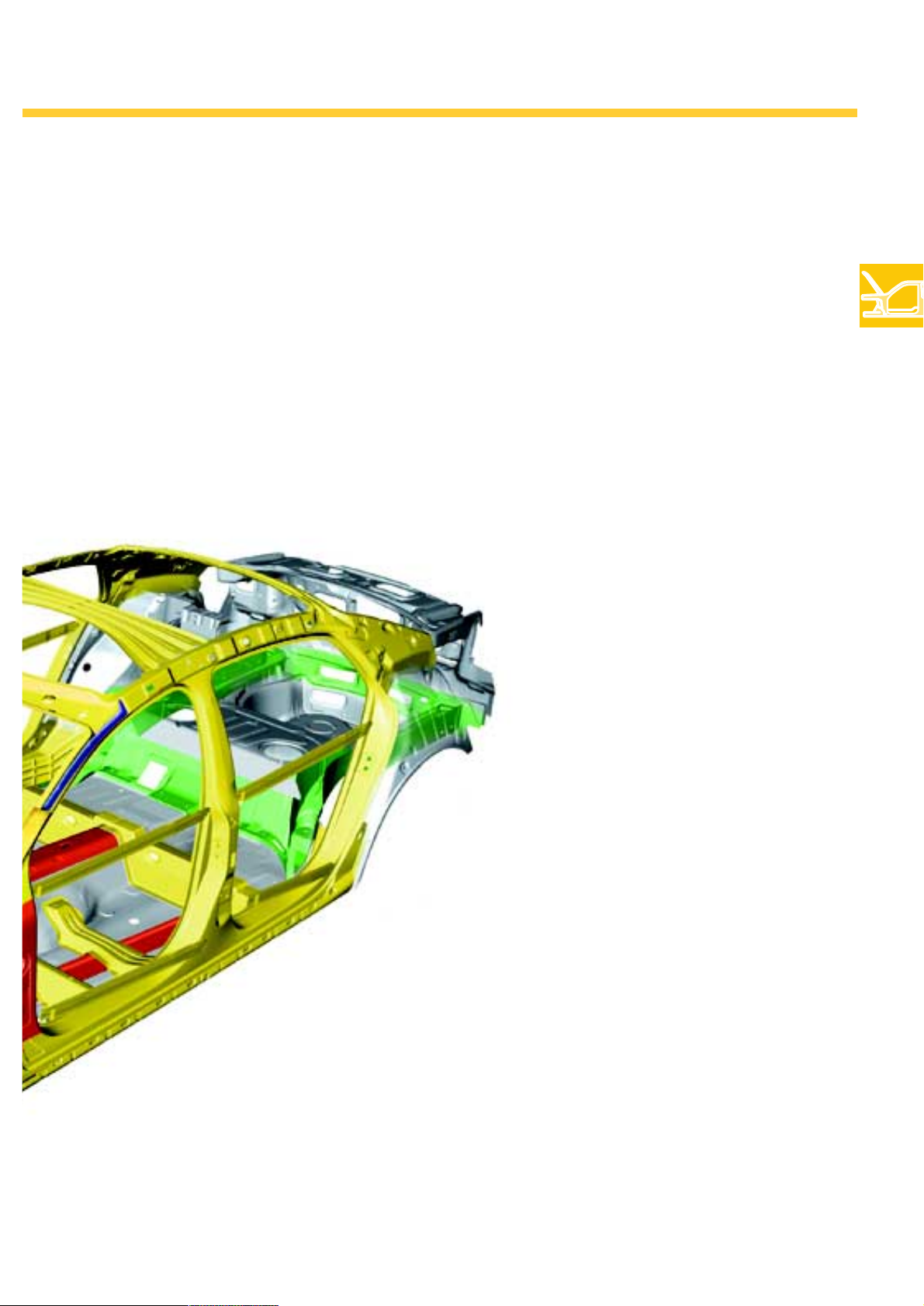

Bodywork

The raw bodywork of the Phaeton

The body structure

The Phaeton's bodywork is a complete innovation.

The core design focus involved a high level of

crash safety and body rigidity. The gap dimensions of the flaps and doors prove to be very low

due to the high body rigidity.

Static rigidity

The extremely high static rigidity is a

prerequisite for:

- optimal chassis design

due to almost complete lack of inherent

movement within the bodywork and

- excellent door and flap functioning

with the tightest of gap dimensions.

Doors and flaps are made of aluminium and the

front mudguards are made of plastic in order to

limit the weight while still observing the high

safety and comfort requirements.

Furthermore, the bodywork consists of highgrade and super high-strength steels and is completely galvanised.

12

270_154

Safety features of the raw bodywork

● High energy absorption at the front and

rear of the vehicle

● Stable passenger compartment

● High protection in event of side impact

due to the:

- bonding of the B-pillar made of super

high-strength steel with the side member,

- high-strength aluminium profiles in

the doors

● Partner protection: Due to the relatively soft

external bodywork areas, the crash

performance is designed to afford maximum

protection to other parties involved in

an accident.

● Use of high-grade and super

high-strength steel

in important areas

Dynamic rigidity

The high dynamic rigidity is a

prerequisite for:

- advantageous vibration

characteristics and thus for a high

level of comfort and

- acoustic comfort

(no noises caused by movement of

270_155

the interior panelling).

Key:

red = main frontal crash area

yellow = passenger compartment

green = main rear crash area

dark blue = epoxy resin foam

light blue = plastic reinforcement

13

Bodywork

Bodywork attachments

Aluminium parts

● Engine bonnet

● Reinforced doors

● Ta il g at e

Plastic parts

● Front mudguard

● Fuel cap

● Spare tyre recess

● Front and rear bumpers

14

Key:

blue = aluminium parts

brown = plastic

270_114

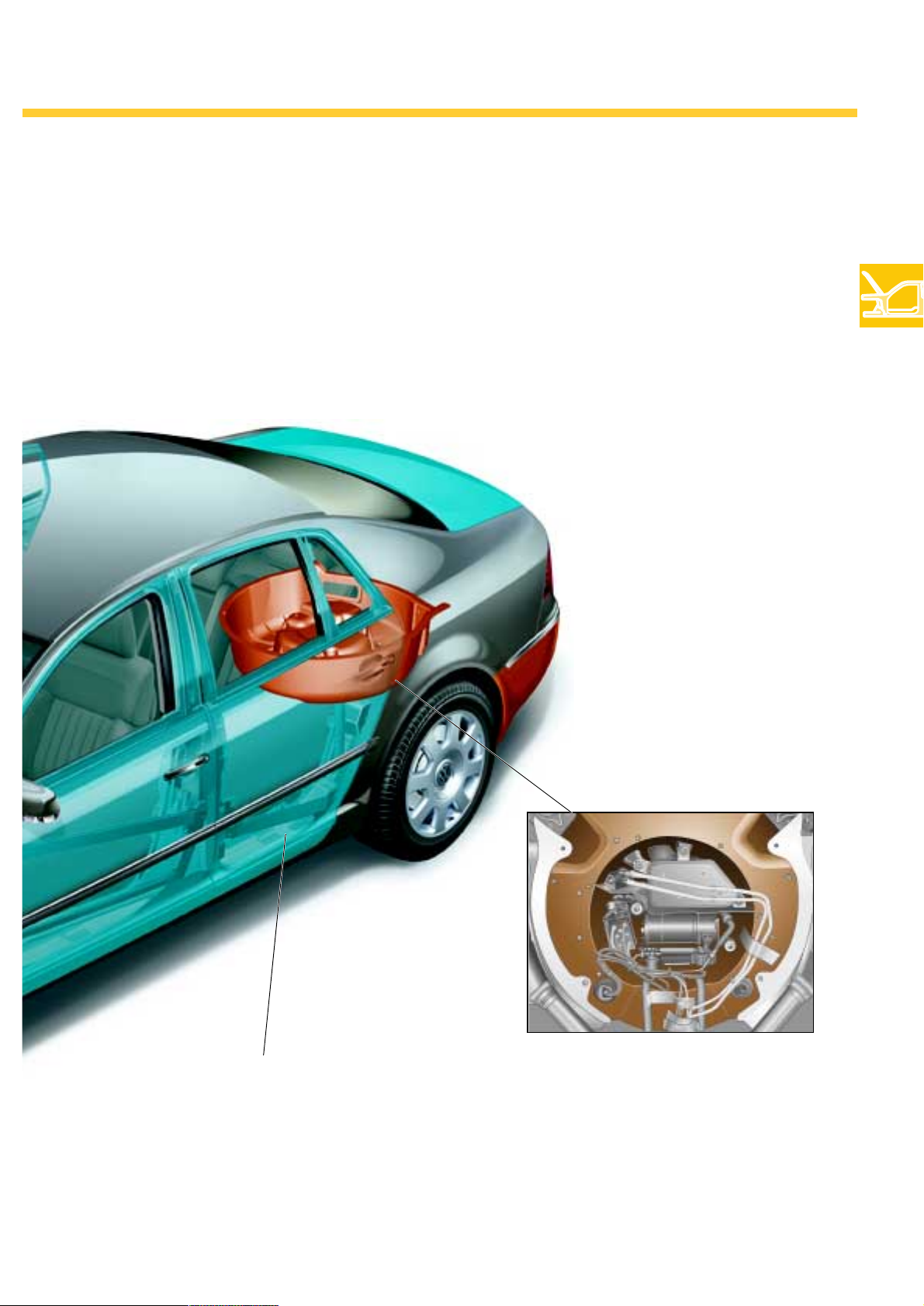

Glued-in-place plastic spare tyre recess

The following components are integrated in the spare tyre recess:

- Compressor for air suspension,

- Activated carbon filter and

- Spare wheel.

Doors with high-strength inner sections made

of die casting, laser-welded

270_115

270_004

Detailed view of spare tyre cavity, from below

15

Bodywork

The silencers

Sound deadening was already a major issue when developing the body-in-white. The consistent deployment of absorption materials in the engine compartment, tunnel, luggage compartment and behind the

panelling has led to the attainment of an above-average reduction in noise.

Diesel and petrol engine

The two-tone insulating foils demonstrate the different insulation methods in the diesel and petrol engine.

16

270_182

Key:

blue = aluminium expansion foil, 4.5 mm sandwich

green = bitumen plastic-foil, pressure-sensitive bonding, 2 mm

red = bitumen plastic-foil, magnetised, thermoplastic bonding 2 mm

orange = bitumen plastic-foil, thermoplastic bonding 2 mm

pink = bitumen foil with aluminium foil, magnetised, 3 mm

blue/red = blue - diesel, red - petrol engine

blue/orange = blue - diesel, orange - petrol engine

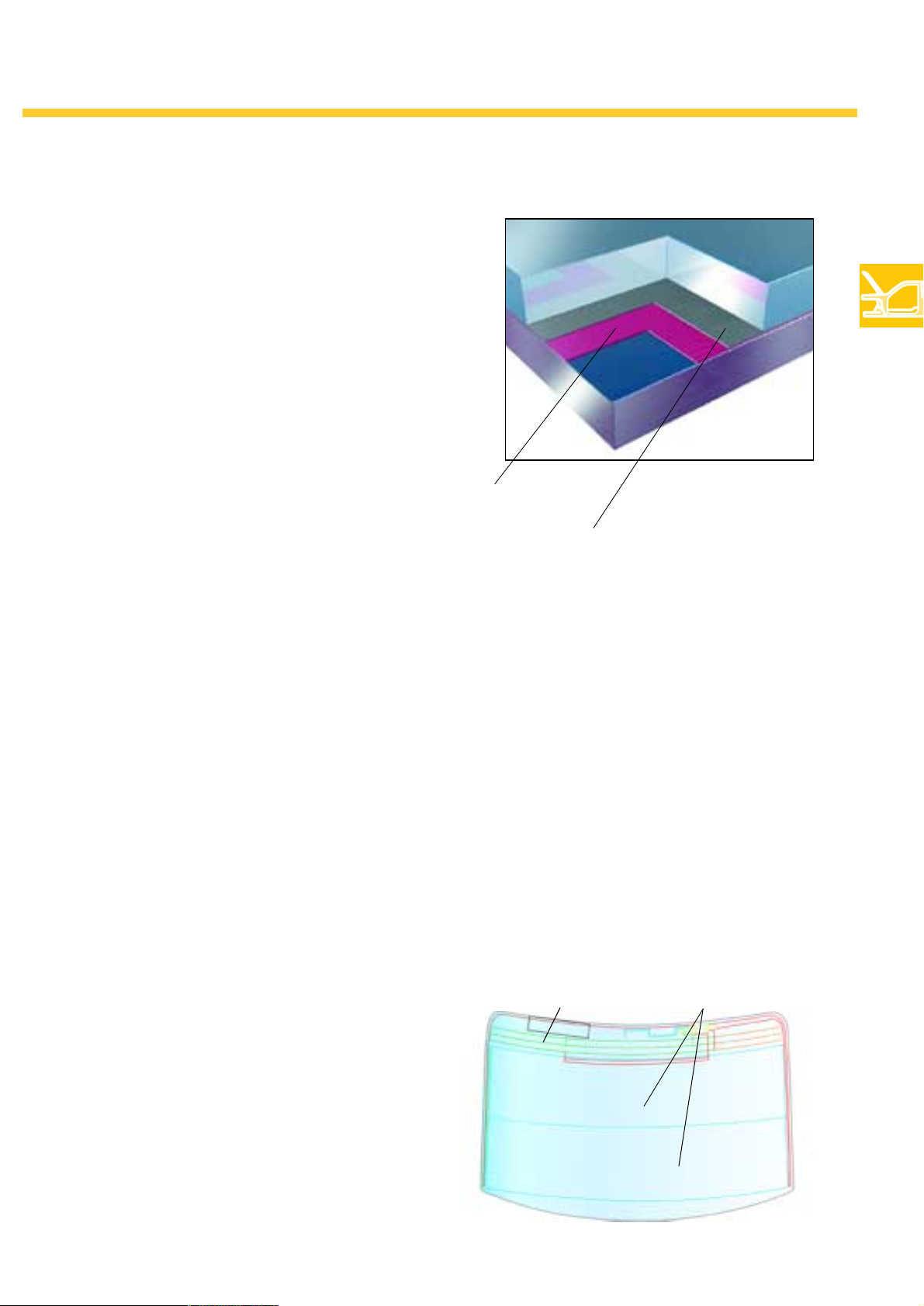

High-insulation glazing & laminated glass

The high-insulation glazing made of laminated

glass distinguishes itself with its improved reduction of thermal exposure, however, without influencing permeability to light.

The glazing reduces ultraviolet radiation and

contributes to an improved noise insulation. This

is facilitated by two foils incorporated into the

glazing. The rear and side windows are also

manufactured with thermally-tempered laminated glass with an infrared reflective coating.

This improves safety as laminated glass panes

cannot shatter due to their incorporated safety

foils.

270_040

Ultraviolet protective foil

Infrared reflective coating

(heated windscreen)

Windscreen

● Two-layer, burglar-inhibiting,

heat-insulating, laminated safety glass

● Electric windscreen heating

(optional) with invisible filaments

through an electrically conductive

infrared reflective coating.

● The heated windscreen is switched on and off

using the 'Defrost' button at the

display and operating unit at the front

Rear window with tungsten threads

The rear window is heated by practically invisible

tungsten threads which are embedded between

the inner and outer pane. Furthermore, all antennae are integrated in the upper third of the rear

window. The external streamlined quality is therefore not impeded by bothersome antennae.

Heating duration depending on

outside temperature:

5 to 0 °C = 2 minutes

-20 °C = 4 minutes

-40 °C = 6 minutes

In order not to overload the on-board network,

the heating is switched off after a specific timeframe, depending on the outside temperature.

Antennae Heated sections

270_178

17

Bodywork

The tailgate

Power-assisted closing of the tailgate

The Phaeton is also available with a system allowing the

driver to automatically open and close the tailgate.

This power-assisted closure is not only a comfort feature

but is also an enhancement of the entire locking mechanism.

270_001

Retractable rear lock with closing aid

The lock is retracted when opening the tailgate,

thereby eliminating the risk of injury. The retraction of the lock also prevents the possible soiling

of clothing by the oil or grease present in the

lock.

When closing the tailgate, the lock re-emerges

from the tailgate into locking position during the

final third of the closing procedure. Then it pulls

the tailgate the final centimetres into the lock and

locks it (closing aid).

18

Retractable rear lock

270_123

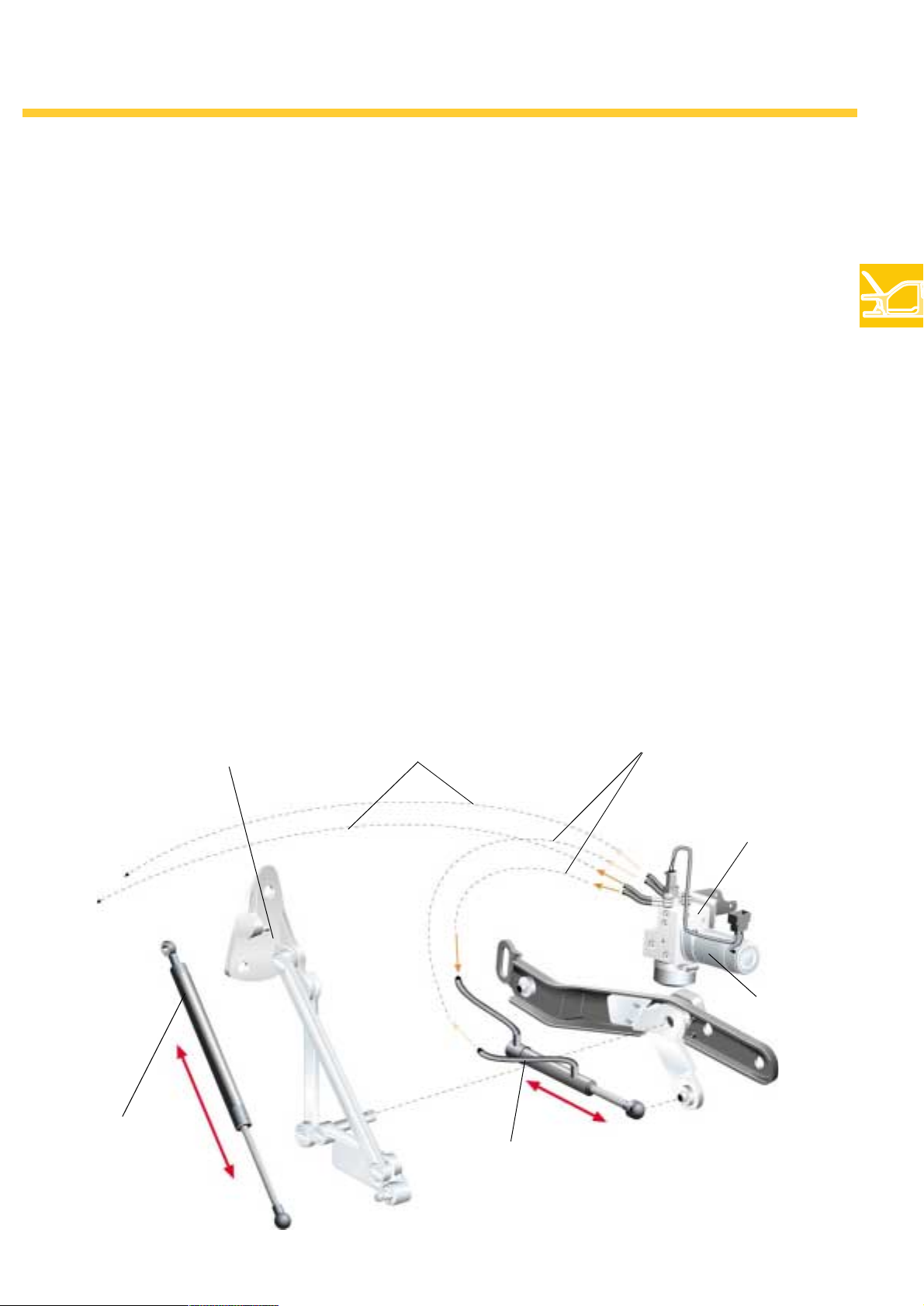

Function of the power-assisted closing

Closing

The power-assisted closing is based on an electro-hydraulic system. Oil is pumped into the

hydraulic line system by an electric pump. The

feeding of oil to the piston or piston-rod end of

the hydraulic cylinder facilitates the opening or

closing of the flap via a driving shaft at the door

hinge. The pump is incorporated at the right of

the tail section.

Opening

To open the tailgate, operate either the switch in

the door panelling, the microswitch in the VW

emblem on the tailgate or the radio-wave remote

control.

The switch in the tailgate serves the purpose of

closing the tailgate.

Safety equipment

The power-assisted closing has an anti-trap feature. If the electric motor in the hydraulic component perceives resistance which exceeds a

defined level, power-assisted closure is not

merely stopped but reversed* a little in order to

release the jammed object. The same procedure

is adopted when opening. If, for example, it hits

a low garage roof, the motor stops for a moment.

However, the tailgate then remains in this position without reversing. Renewed actuation is then

required.

*moves back

Door hinge

Gas-assisted shock

absorber

Oil supply, left

hydraulic element

Oil supply, right

hydraulic element

Hydraulic

component

Electric motor

Hydraulic cylinder

270_122

19

Bodywork

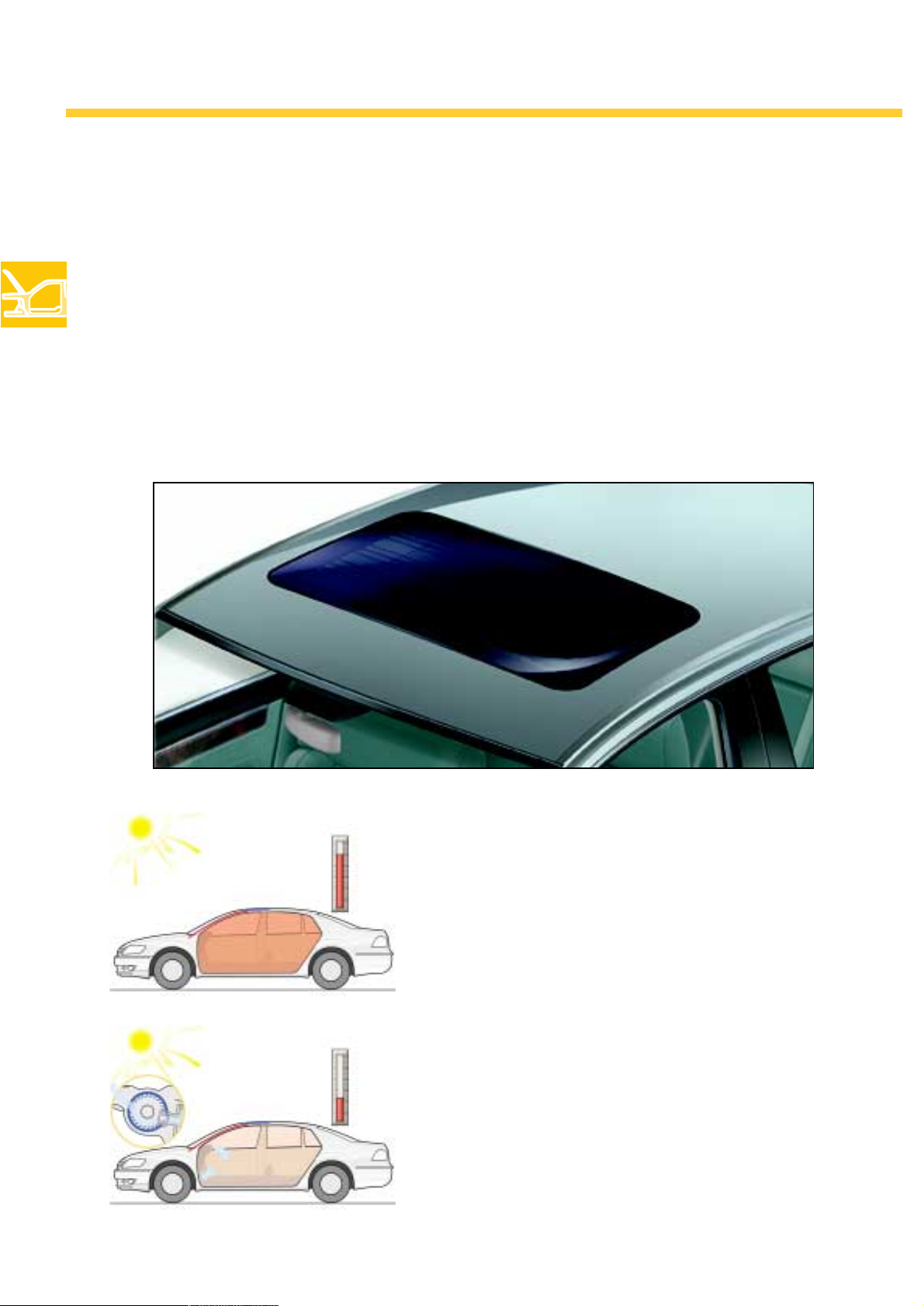

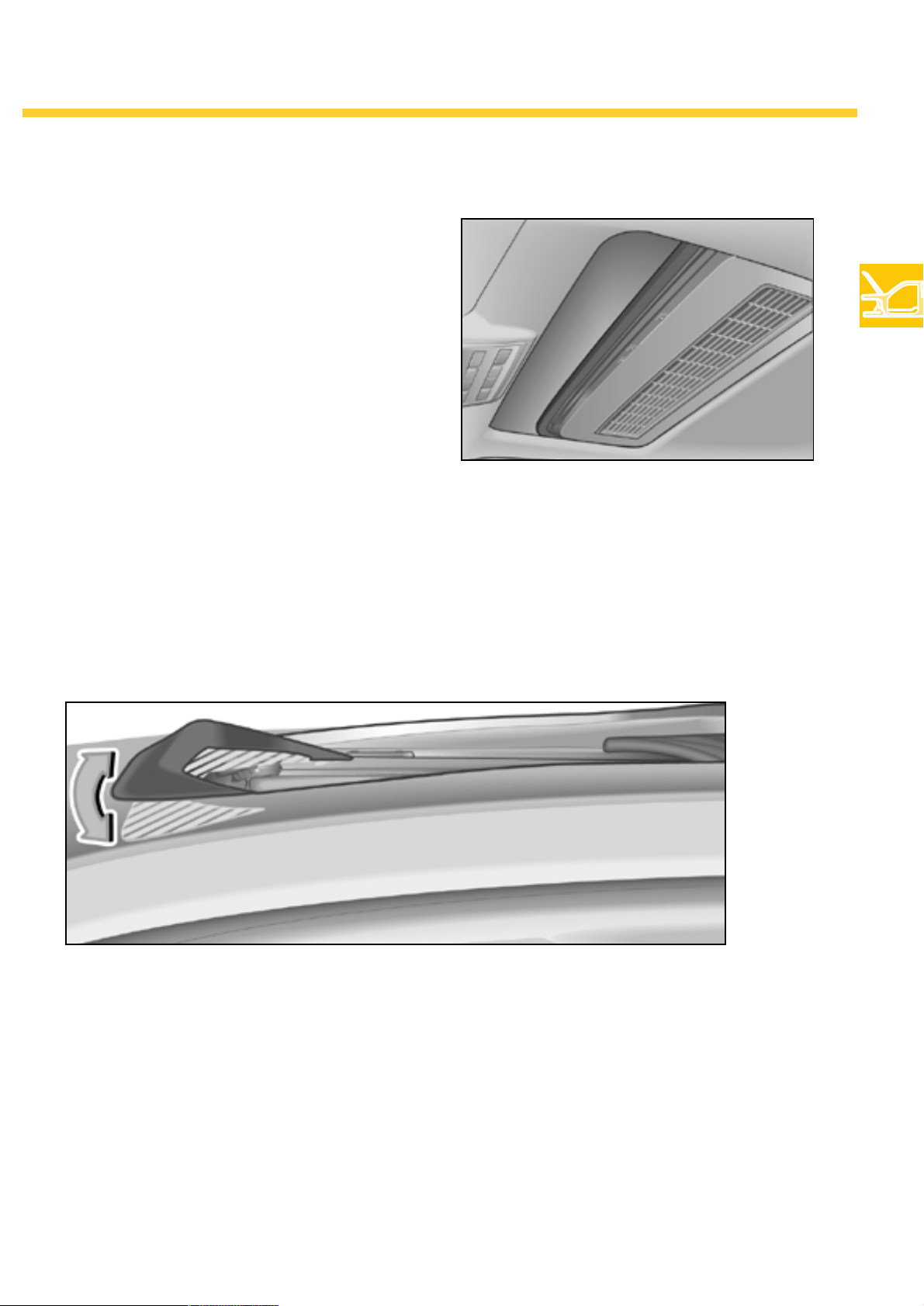

The sliding roof

The Phaeton is available with a solar sliding roof with a fixed inside roof lining and a sliding roof / lifting

roof with a separate electrically-sliding inside roof lining.

Solar sliding roof

The solar roof's 28 monokristallin solar cells supply an electrical output of 37 watts. This energy is used to

operate the interior ventilator which is capable of reducing the temperature by up to 20 °C, when the

vehicle is parked, by feeding fresh air into the vehicle's interior.

270_124

270_125

270_177

If the interior ventilation has been activated via

the Infotainment system, the interior ventilator

starts operating when there is sufficient sunlight.

This cools down the interior at high temperatures.

The circulation of air prevents the windows from

misting in winter.

20

Sliding roof / lifting roof with solar shading and an electrical wind deflector

A separate electric motor moves the inside roof

lining at the same time as the glass roof is

opened or closed. This can also be adjusted

regardless of the glass roof's position.

All closing procedures are electronically monitored and have an anti-trap feature.

270_166

Depending on the driving speed and the roof opening, the wind deflector is controlled electromechanically in order to prevent wind noise and draughts.

270_167

21

Seats

The front seats

The Phaeton is also available with air-conditioned seats. Air-conditioning is provided

through the interaction between the seat heating

and ventilators.

The ventilators, which are integrated in the seat

frames, feed the air heated by the seat heating

to the occupants through fine perforations in the

seat leather. The massage function is imple-

The 12-position seat

Adjustment function

As standard, the Phaeton comes with 12-position

seats. The following functions are electrically

adjustable: longitudinal direction, seat height

and inclination, as well as the backrest inclination. Furthermore, the movement direction of the

lumbar support is adjustable both backwards/

forwards and up/down.

mented by a slow adjustment of the lumbar support. The belt mechanism integrated in the seat

endows the Phaeton with an even greater level of

comfort. Furthermore, the optional second automatic belt in the 18-position seat gives increased

belt comfort and improved safety. The Phaeton

also has an active headrest system (AKS).

Memory functions

The memory package for the 12-position seats

includes a range of saveable functions. In addition to the seat settings, the memory function can

also save the positions of the steering column,

the mirror and the seat belts.

Easy-entry function

The easy-entry function facilitates the convenient

getting in and out of the vehicle by automatically

moving the steering column into its uppermost

and furthest-forward position.

Air-conditioning / massage function

Air-conditioning in the 12-position seats is provided by ventilators - which are integrated in the

seats - and which feed temperate air through the

fine perforations in the leather. The massage

function is implemented through the mechanical

270_147

4-position lumbar support.

The lumbar support is moved automatically up

and down, thus facilitating the relaxation of the

spine and back muscles.

22

The 18-position seat

Adjustment function

As an optional extra, the Phaeton comes with

high-quality 18-position seats.

They also offer the option of adjusting the backrest head and the seat depth, as well as an electrical adjustment of the headrest.

The 18-position seat can be equipped with an

automatic lap belt on request.

Memory functions

In addition to the functions featured in the 12position seat, the memory package for the 18position seat also offers the option of saving the

positions of the headrest, the seat depth and the

backrest head.

Air-conditioning / massage function

The range of air-conditioning functions in the

18-position seats is equivalent to that of the

12-position seats.

270_146

23

Loading...

Loading...