1

The Passat, Model Year 2001

Self-Study Programme 251

Service.

2

New Important

Note

The Passat, Model Year 2001

This Self-Study Programme summarises the

design features of the Passat 2001. It provides

you with information about the various engines

and gearboxes, the front and rear axle

configurations, the electronics and the

modifications to the convenience system. The

design and function of the various components

and modules will not be explained in depth in

this SSP.

Descriptions of modifications always refer to the

predecessor model. A number of the

technologies cited in this Self-Study Programme

have previously been described in other

Self-Study Programmes. To enable you to brush

up your knowledge of specific technologies, we

have enclosed an index at the back of this SSP. It

refers you to the relevant Self-Study Programmes

by keywords such as "T

UMBLE INTAKE PORT".

(In the case of the "tumble intake port" you are

referred to SSP 195 - the SSP in which this

technical feature is described.)

The Self-Study Programme presents the

design and function of new developments.

The contents are not updated!

Please always refer to the relevant Service literature fo r current

inspection, adjustment and repair instructions.

Keywords are always given in SMALL

CAPITALS.

3

At a glance

Concisely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Environmental protection . . . . . . . . . . . . . . . . . . . . . . 10

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

The engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Running gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

The electrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4

Brief description of vehicle

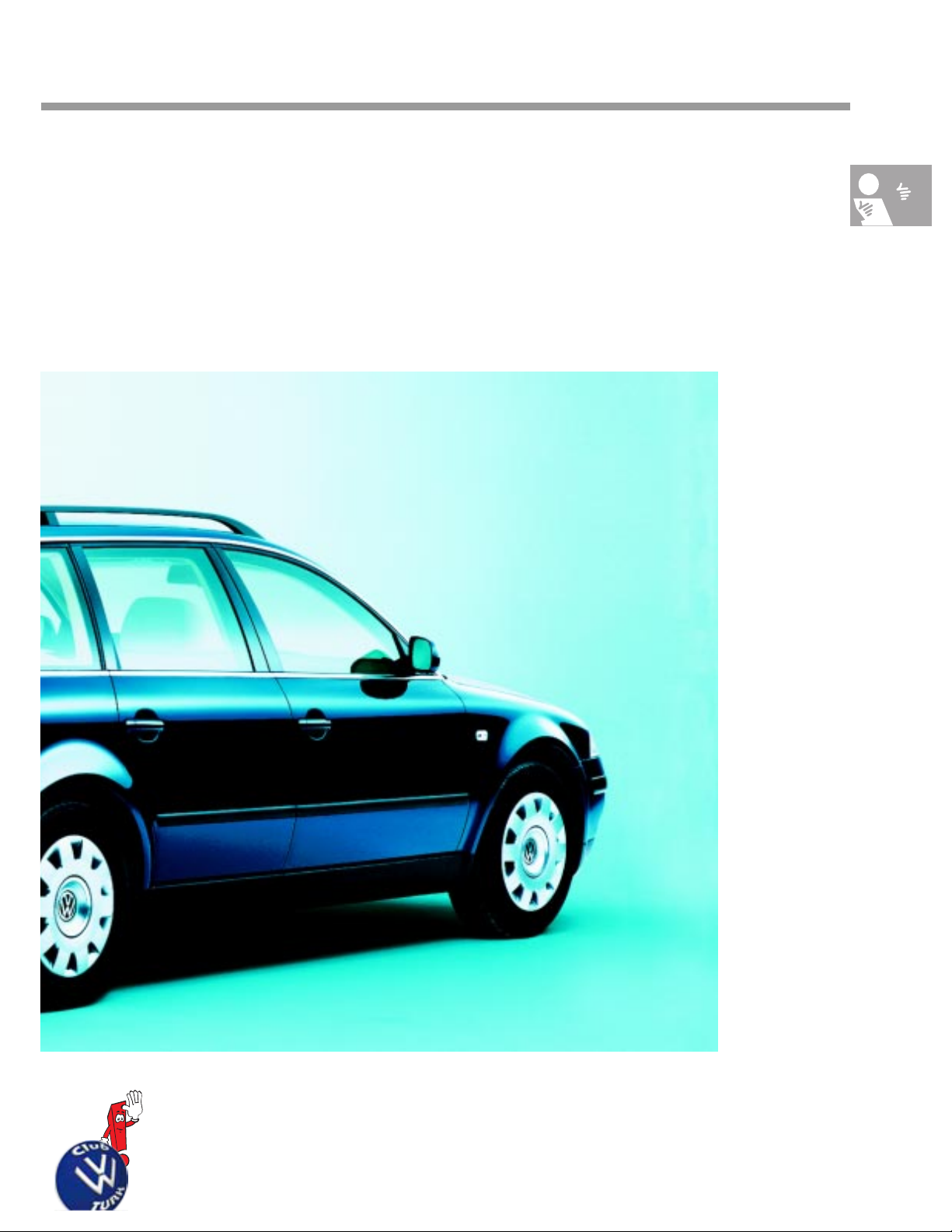

The Passat 2001 is based on the highly successful

predecessor model. In revising the vehicle,

Volkswagen's designers retained the

characteristic basic shape of the saloon, with its

distinctive dome roof.

The front end of the Passat has been redesigned,

and particularly the bonnet, the wings and the

radiator grille. The bumpers now have full-length

rubbing strips.

Concisely

Saloon

● Third-generation immobiliser

● TV tuner

● Anti-vibration measures

(40Hz body)

● Dynamic navigation

New features of the Passat, model year 2001

5

Concisely

● Improved crash concept

● Solar roof

251_103

The headlights have clear lenses and the

indicator lights are built into the headlights.

BI-xenon headlights with dynamic headlight

range control are also available.

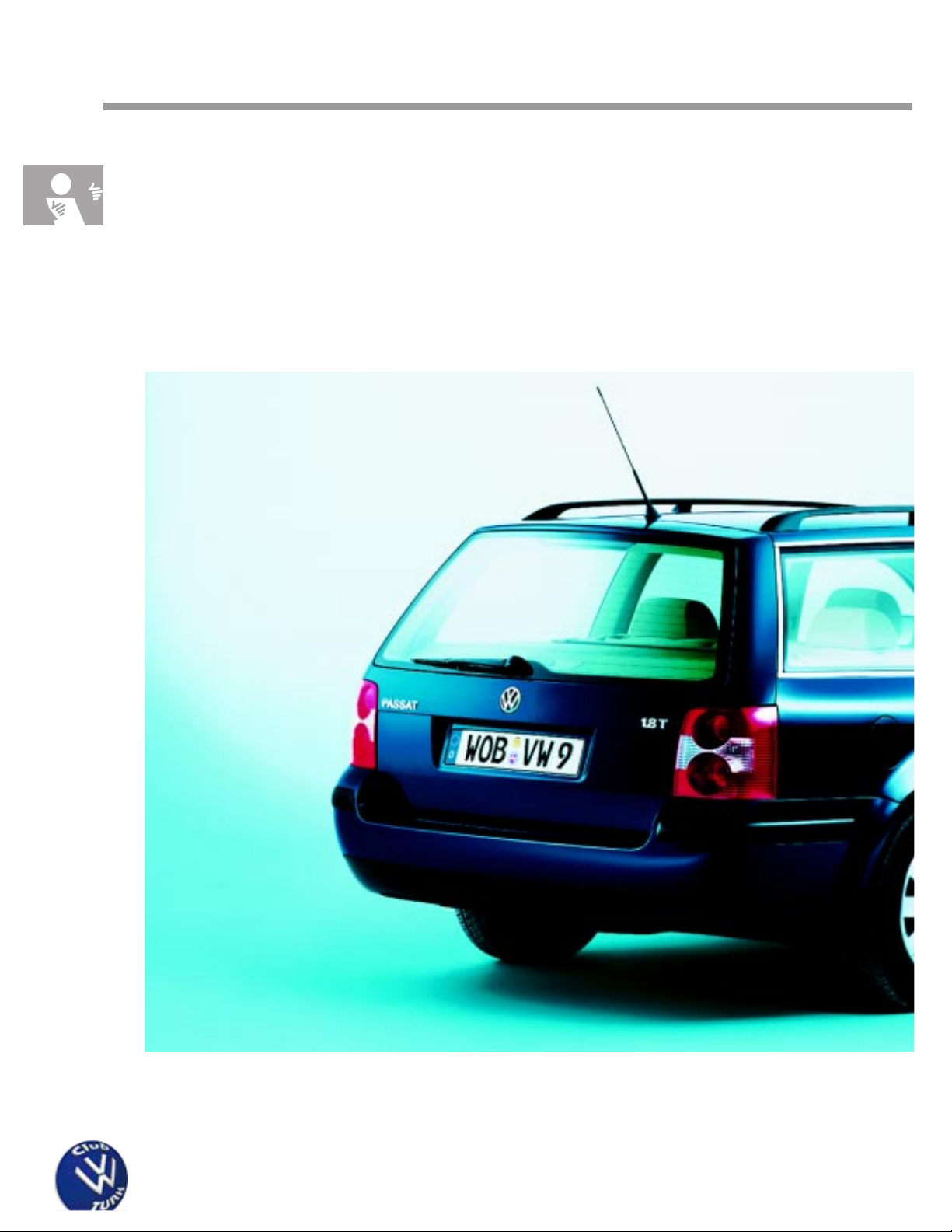

The rear end has been revised also, including the

rear lights.

6

Concisely

The Variant has been revised, too. In addition to

the new front-end design, which is identical in the

Variant and saloon, the rear end and the rear

lights have been redesigned in the Variant.

Var ian t

● New locking concept with

radio wave folding key (fob) built into

the driver's door.

7

Concisely

All technical modifications apply to saloon and Variant.

● Distance control

● Comfort-enhanced air conditioning system

● Spare wheel fitted with ready-for-road

tyre

251_104

The Passat has a new locking concept. All models

come with radio wave folding keys. There is no lock

cylinder on the front passenger's door and the

tailgate is separately released.

8

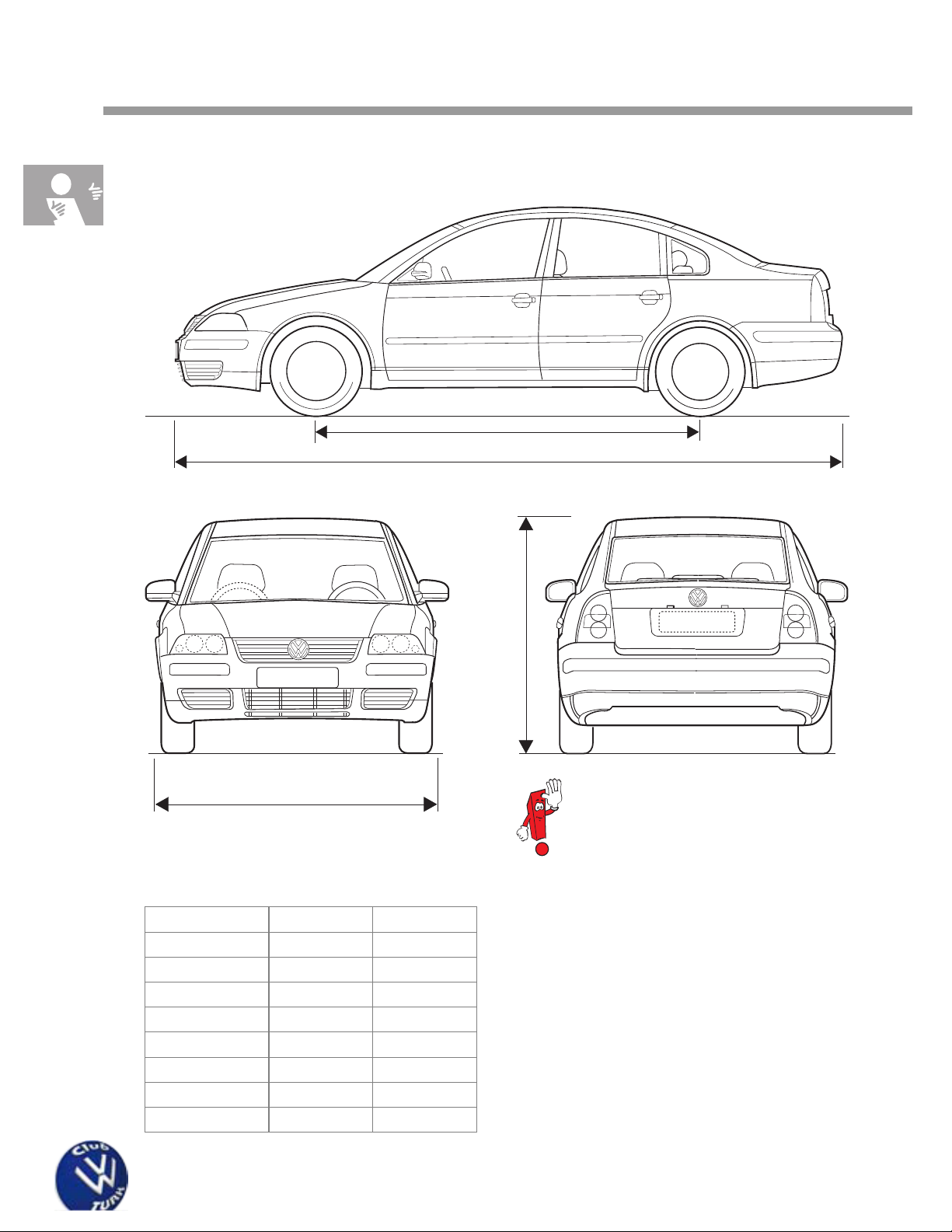

Concisely

Saloon

Dimensions and weights

Model MY 2001 MY 1997

Length 4703 mm 4675 mm

Width 1746 mm 1740 mm

Height 1462 mm 1459 mm

Wheelbase 2703 mm 2707 mm

Turning circle 11.4 m 11.4 m

Tank capacity 62 l 62 l

Drag coefficient 0.27 c

w

0.27 cw

Weight (unladen) 1277 kg 1233 kg

2703 mm (2707)

4703 mm (4675)

1746 mm (1740)

1462 mm (1459)

251_016

251_018

The figures quoted in brackets refer to

the predecessor model.

9

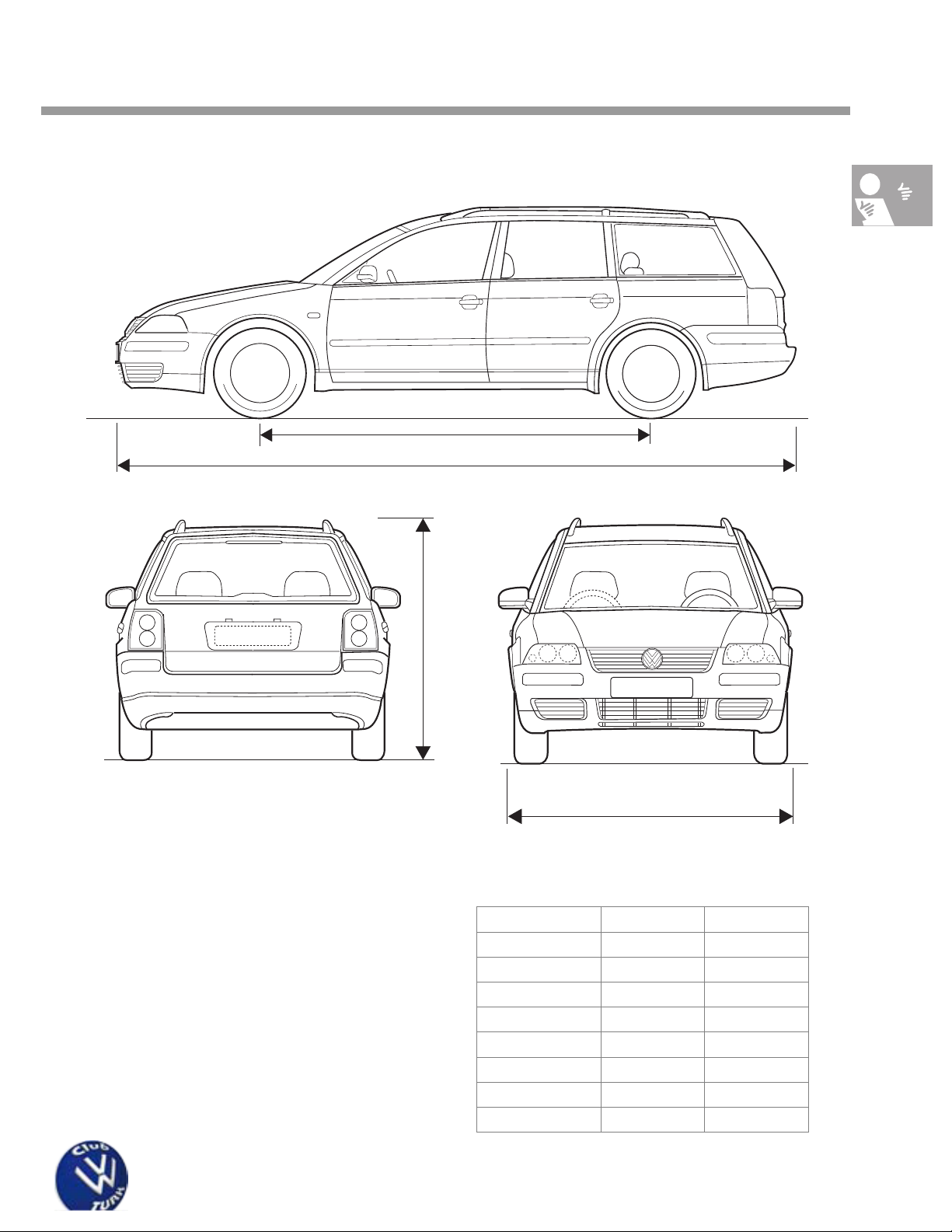

Concisely

Vari an t

Dimensions and weights

Model MY 2001 MY 1997

Length 4682 mm 4675 mm

Width 1746 mm 1740 mm

Height 1470 mm 1459 mm

Wheelbase 2705 mm 2707 mm

Turning circle 11.4 m 11.4 m

Tank capacity 62 l 62 l

Drag coefficient 0.27 c

w

0.27 cw

Weight (unladen) 1319 kg 1282 kg

2705 mm (2707)

4682 mm (4675)

1746 mm (1740)

1470 mm (1459)

251_054

251_055

251_056

10

Environmental Protection

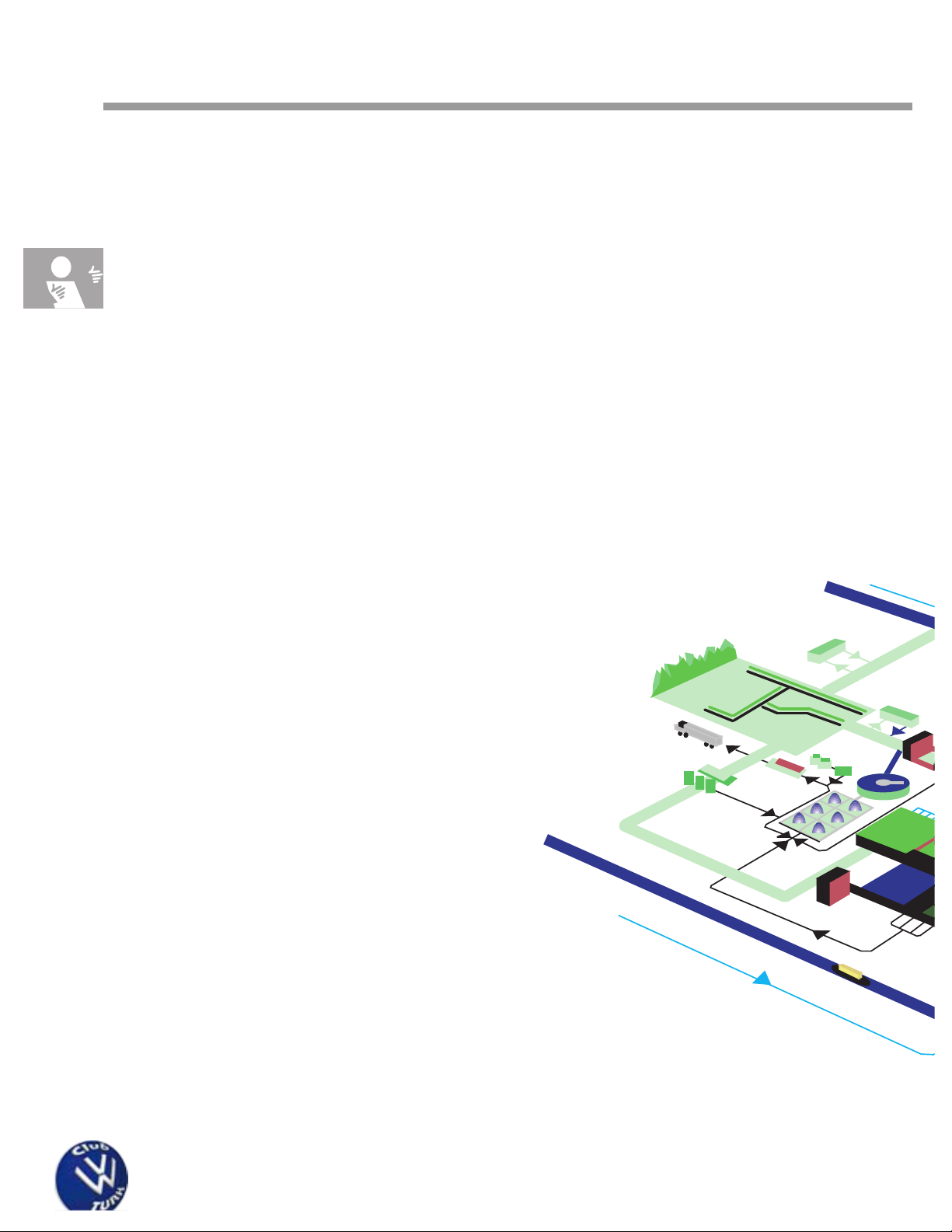

The water management plan

The water management plan for Wolfsburg plant

Environmental protection is a matter of

fundamental importance. Each and everyone of

us should strive to protect the environment

wherever possible, day by day. You are required

to think pro-environmentally when you repair

and service vehicles. And we must do likewise in

vehicle manufacture.

To demonstrate our commitment to in-plant

environmental protection throughout all stages

of the vehicle production process through to

delivery of the finished product, we will be

dealing time and again with the topic of

environmental protection in the next Self-Study

Programmes.

Our customer have high expectations of our

products in several respects:

reliability, convenience, quality and, not least,

environmental compatibility. Firstly, the vehicle

itself should pollute the environment as little as

possible. This means raising fuel economy,

reducing pollutant emissions in exhaust gases

and ensuring a high degree of recyclability of

the individual components of a car at the end of

its life cycle. Secondly, our customers also expect

their vehicles to be made in a production facility

that meets stringent environmental protection

standards.

Volkswagen can look back on a long tradition of

protecting the environment. When it built its first and, to date, largest - plant in Wolfsburg,

Volkswagen even then thought about ways of

using the natural resource of water as

economically as possible for example.

Volkswagen currently circulates and reprocesses

more than 95 percent of process water within the

plant.

The amount of fresh potable water which

Volkswagen annually feeds into its circulation

system from external sources accounts for less

than five percent of total volume.

Process water retention tank

1,500,000m

3

Measuring station

to landfill

Process water

treatment

Was t e w a t er

treatment plant

(biological)

Filtration

press

Mittelland

Canal

Drinking water

procurement (from

the Harz mountains)

11

Environmental Protection

The Emden plant

The Emden plant, where

the majority of Passat

models are built, was the

first automobile

manufacturing plant in

Europe to be certified (in

September 1995). The plant

was re-audited and recertified in September 1998.

West combined heat and power station

Procurement of drinking water

Filtration sta-

tions

to landfill

Cyclator

Chem. waste

water treatment

plant

To ta l

demineralisation

Canal water cycle

Sewage water

pumping station

Cooling circuits

production

Rainwater

P

r

e

t

r

e

a

t

m

e

n

t

p

l

a

n

t

To ensure that we maintain

high standards in

environmental protection, our

plants are audited and

certified by an independent

expert. Our European plants

were certified according to the

EU eco audit regulations while

our non-European plants were

certified according to the

international

ISO 14001 standard.

251_092

251_091

12

Safety

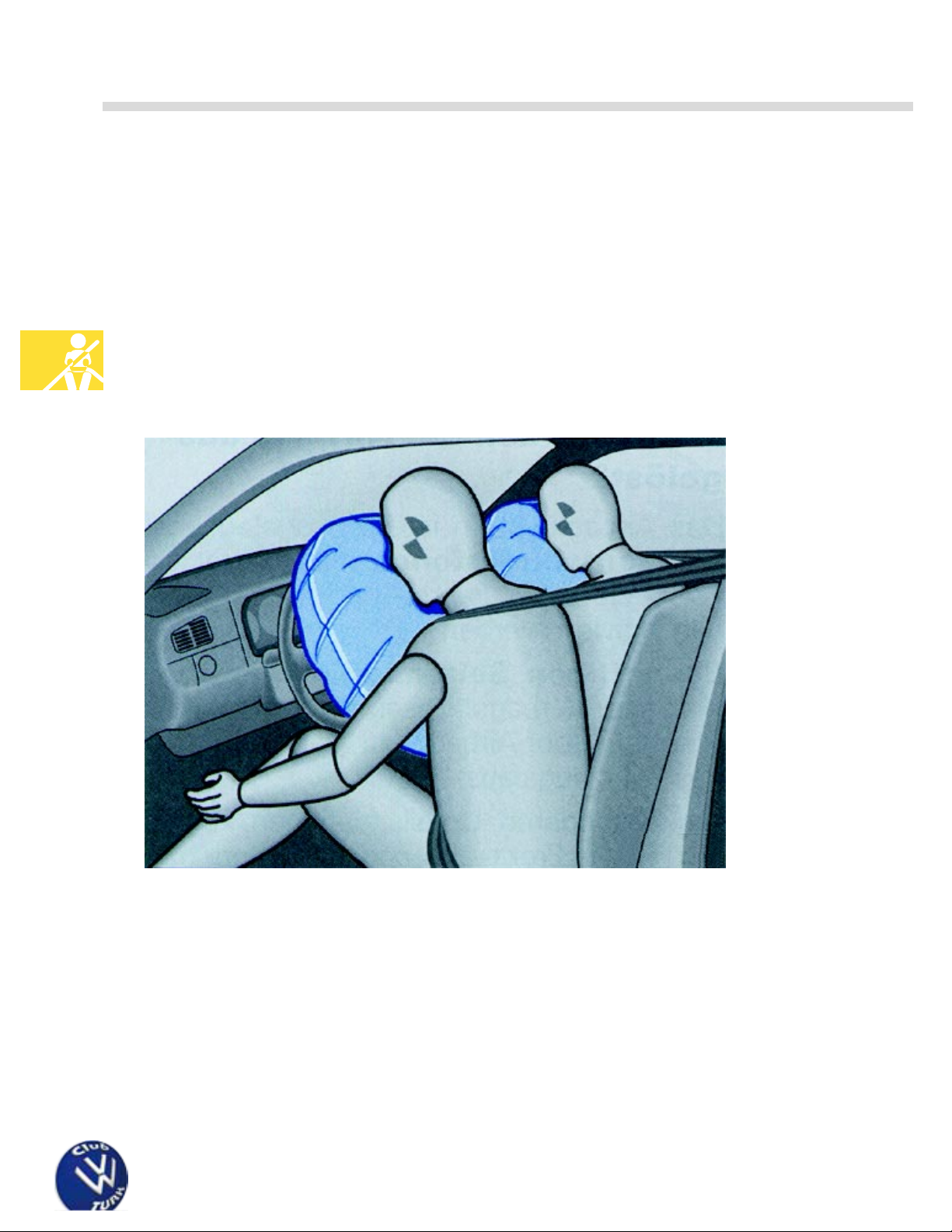

Occupant protection

The front airbags

Full-size airbags are fitted in the Passat 2001 on

the driver's and front passenger's sides. As in the

predecessor model, the airbags have filling

volumes of approximately 64 and 120 litres

respectively.

The central airbag control unit is located behind

the central console, above the tunnel.

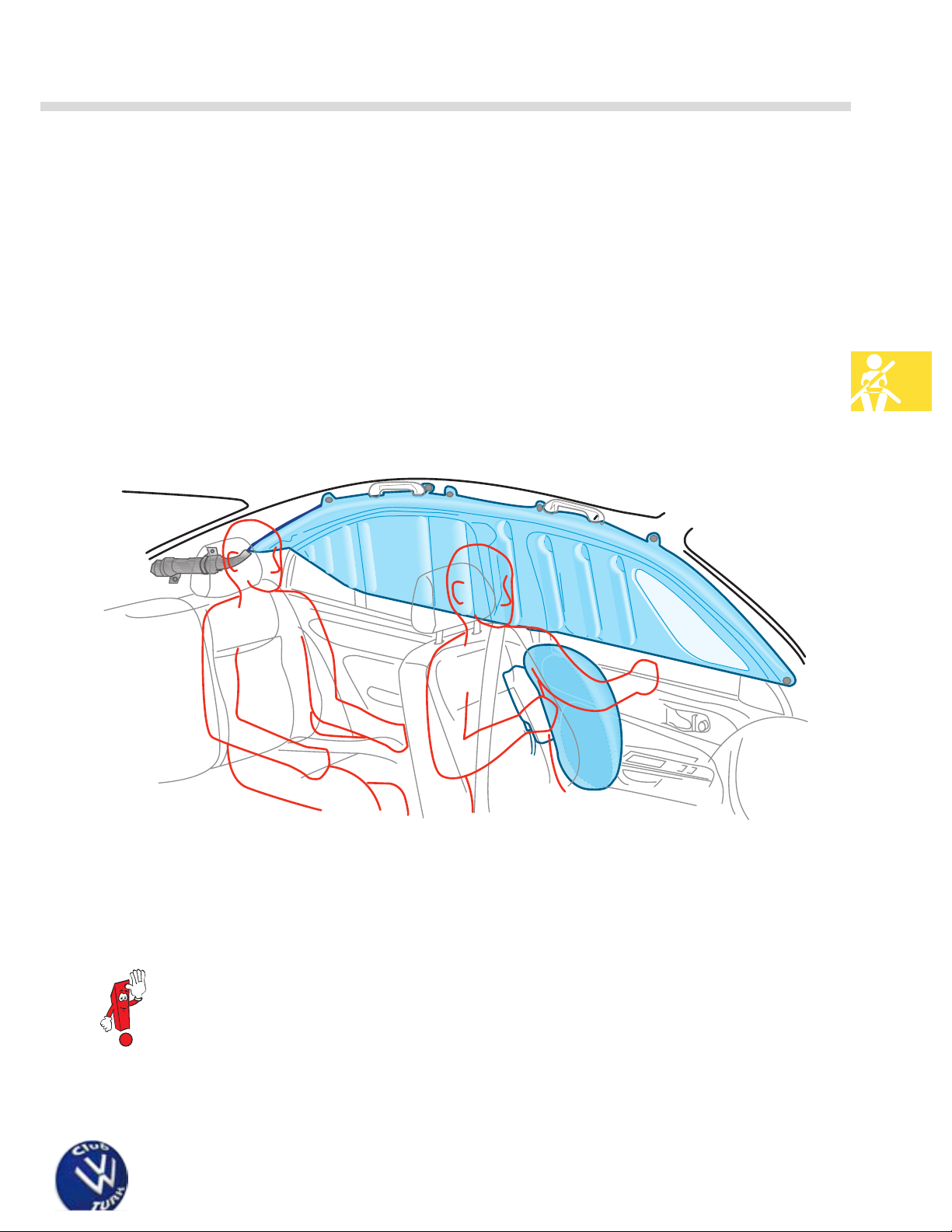

The side and head airbags

The side and head airbags afford excellent side

impact protection. The two side airbags,

integrated in the front seats, have a filling

volume of approximately 12 litres.

The head airbag has a filling volume of

approximately 26 litres and is integrated in the

vehicle headlining, above the doors.

251_082

13

Safety

The complete part number of the airbag control unit, together with the index (colour code) must

be quoted when ordering side impact sensors because these sensors are not labelled with a

parameter index. The part number and the colour index can only be read out, or reproduced,

from the production data (VIN, year of manufacture, list of PR numbers) by using the workshop

tester.

As before, the system has two lateral

acceleration sensors, located beneath the seats.

The lateral acceleration sensors are

programmed with a vehicle-specific parameter

when they are replaced.

Where repair or replacement of defective parts

is needed, it is important to specify the correct

SP-number.

251_069

14

Safety

Belts and BELT TENSIONERS round off the restraint

system. Standard belt tensioner systems are used

in the outer seat positions, front and rear.

These systems deploy mechanically and

pyrotechnically.

The upper part of the belt buckles in the new Passat is flexible.

The lower part is rigidly bolted to the bracket.

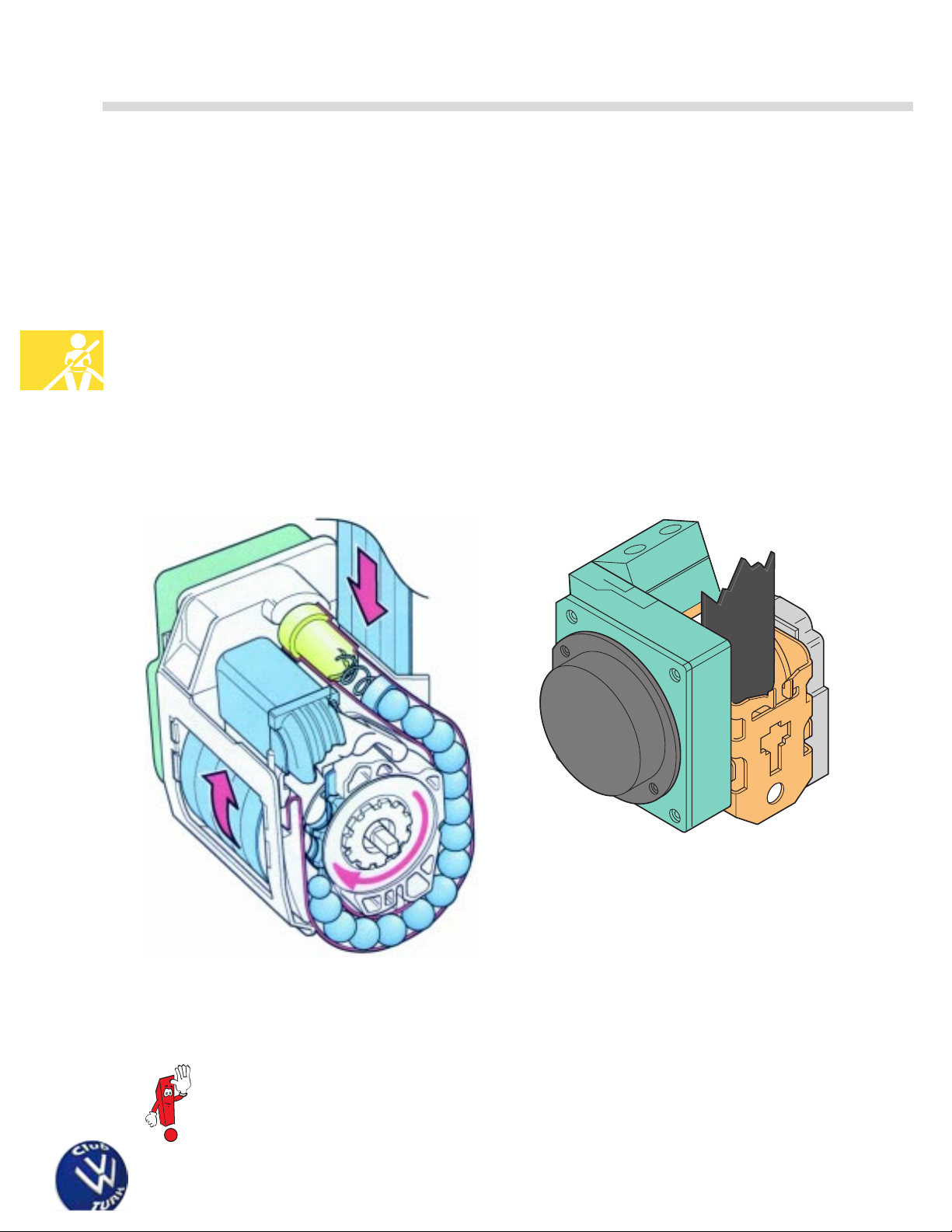

Rotary belt tensioner

The belt tensioner/belts

Ball-type tensioner

Ball-type tensioners are used in the front seating

positions. In comparison with the predecessor

model, they are rotated through 180°.

The rear seating positions have rotary belt

tensioners.

251_075

251_066

15

Safety

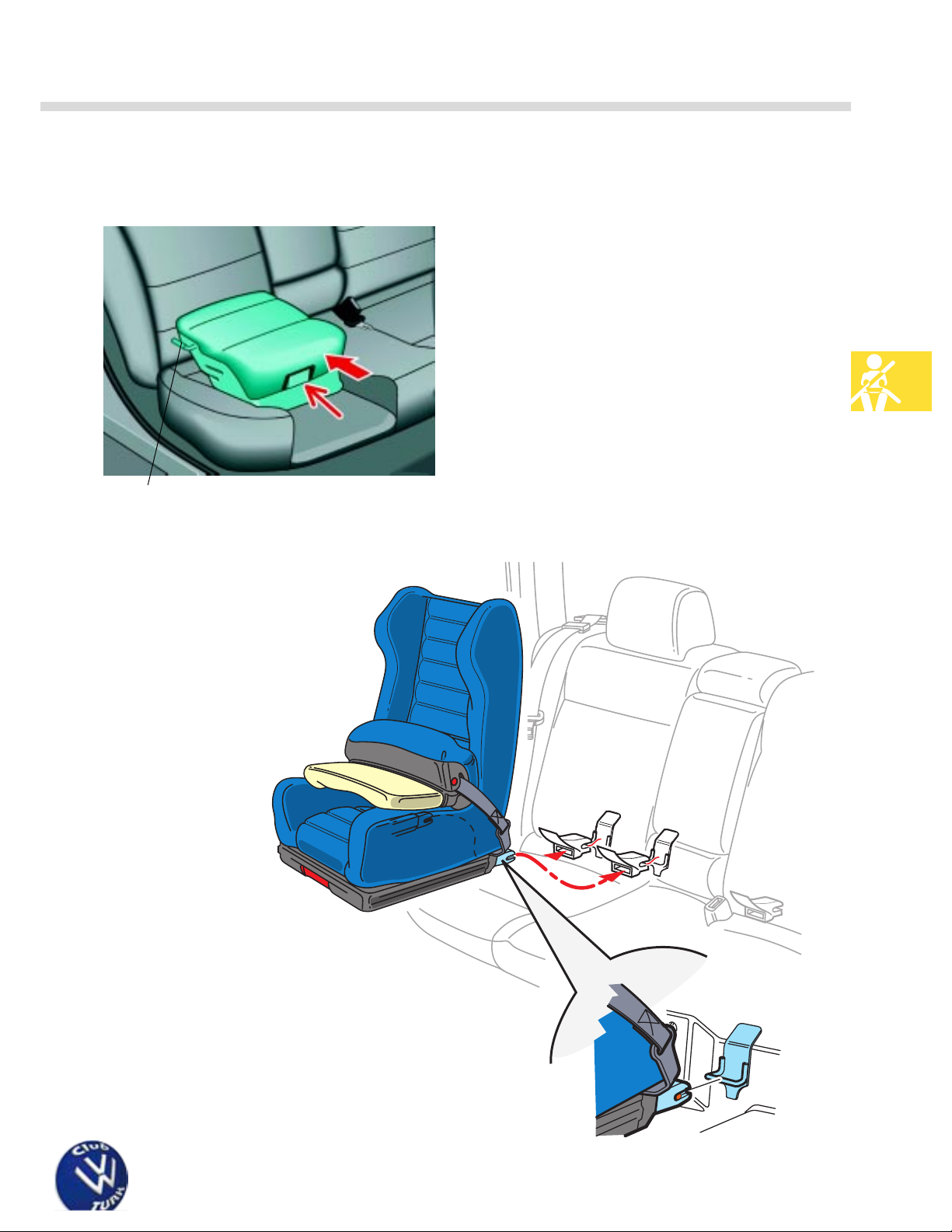

Child restraint systems

To make use of the integrated child safety seats,

the elements of the seat cushion have to be

raised and locked in place. An additional

shoulder belt guide corrects the belt position for

children with a height from 1.3m - 1.5m. A belt

guide hook on the booster cushion ensures an

ideal belt position around the child's pelvis.

Integrated child safety seats

The Isofix system

The new Passat comes as standard

with an attachment point for the fastening clips

of the I

SOFIX system. Child safety seats integrated

in the rear bench seat are optional.

Belt guide hook

251_010

251_011

16

Body

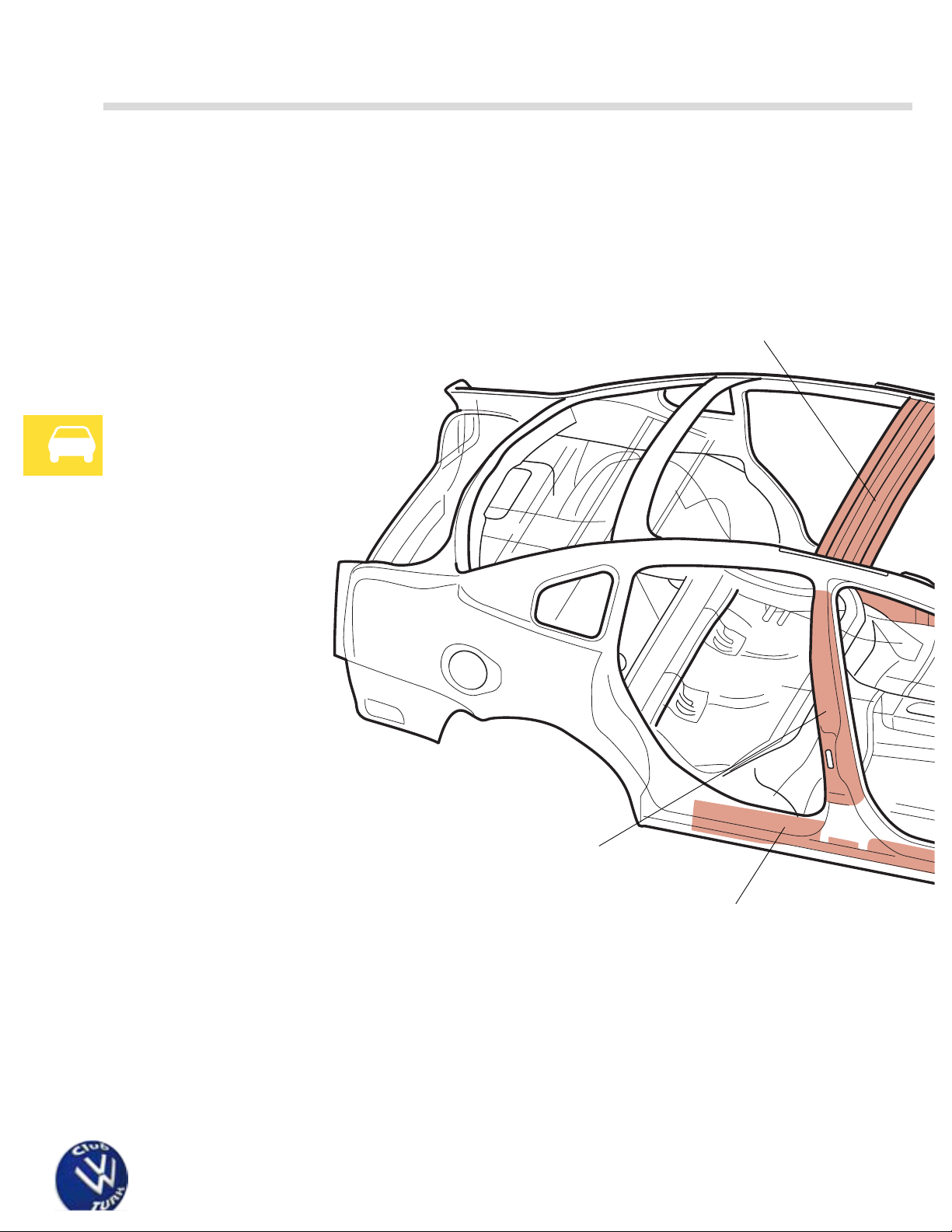

Body reinforcements

The body of the Passat 2001 was reinforced in the zones described below.

In other words, the body panels have been thickened and the spot welds

have been supplemented with laser-welded seams.

Roof cross strut

Side member, right

B-pillar, right

17

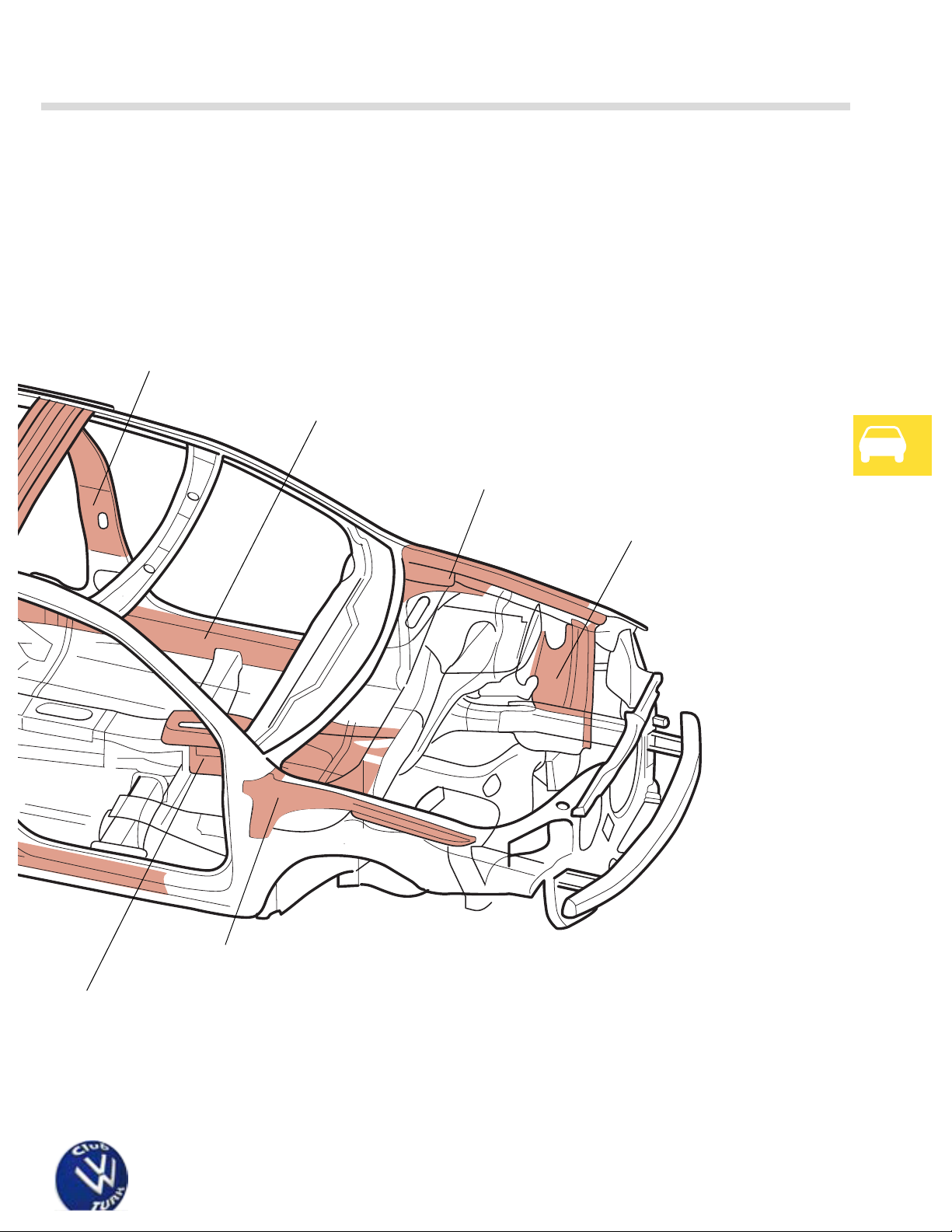

Body

Vehicle safety and natural body vibration (40 Hz)

have been greatly improved as a result of these

modifications.

Wheel housing, inner

surface (sheet-metal

reinforcements have been

welded in on the left and

right )

B-pillar, left

Side member, left

Side member, top right

Side member, top left

251_041

Tunnel reinforcement

18

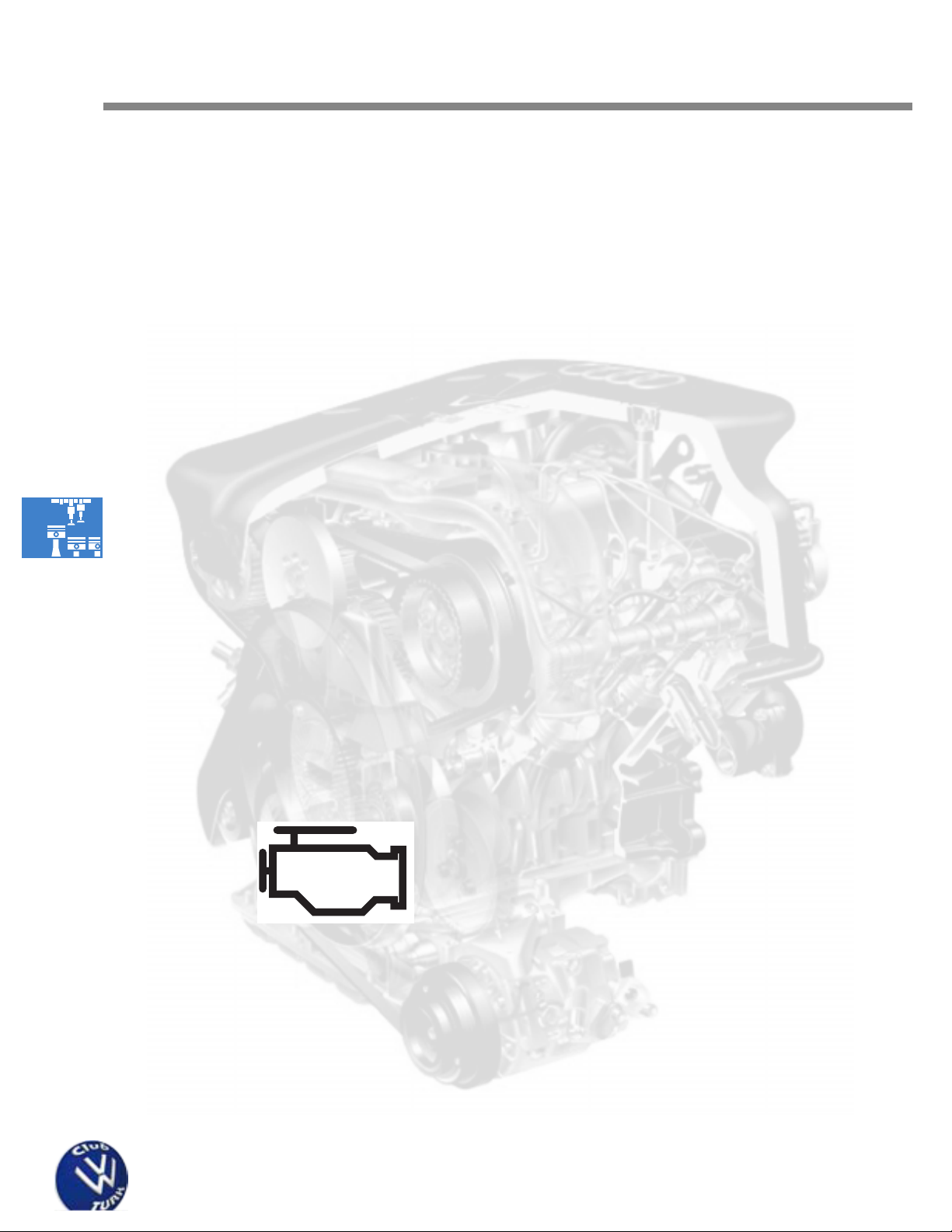

The engines

On the following pages, you will find

descriptions of the engines to be used in the new

Passat. They include specifications, torque and

performance curves, as well as details of

technical features and engine modifications.

In developing all engines, special emphasis was

put on raising fuel economy and reducing

exhaust emissions.

These engines now meet the following standards:

● all petrol engines conform to the EU 4 exhaust

emission standard and

● all diesel engines conform to the EU 3 exhaust

emission standard.

Engines in general

All engines have an electrical throttle control. For

more effective antitheft protection, the engine–

control unit communicates with the immobiliser

control unit via CAN databus (3rd generation

immobiliser).

If a component with a bearing on exhaust

emissions fails while the vehicle is in operation

(e.g. misfiring), the self-diagnosis fault warning

lamp begins to flash. If a component is identified

as being defective while the vehicle is in

operation, the self-diagnosis fault warning lamp

lights up continuously.

In both cases, the engine must be inspected

immediately.

A self-diagnosis fault warning lamp is now

integrated in the dash panel insert in all petrolengined vehicles.

251_044

19

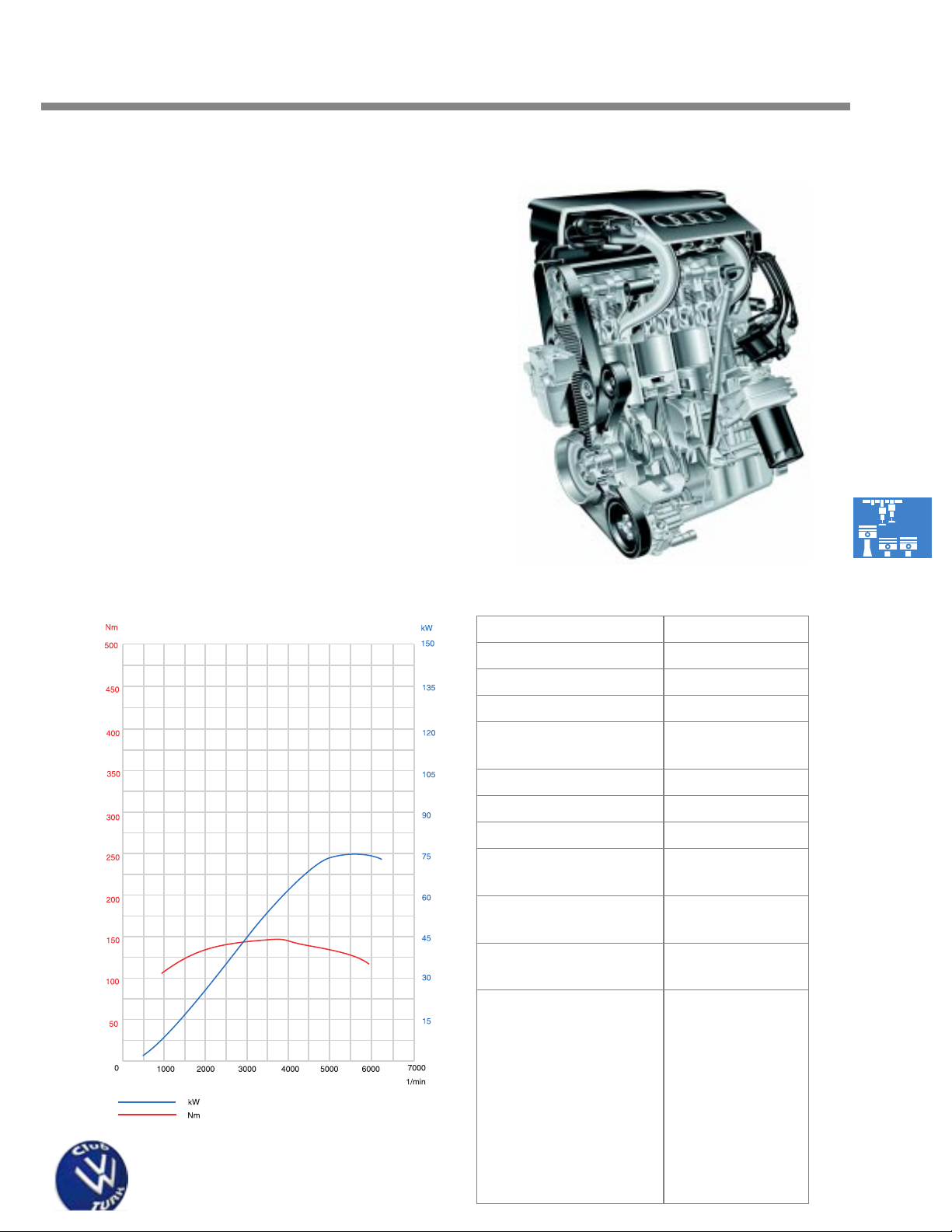

The Engines

The engine is an improved version of the

1.6-litre petrol engine developing 74kW.

The following components were optimised with

regard to friction work and mass for higher fuel

economy:

● the conrods (

TRAPEZOIDAL CONRODS) were opti-

mised for mass

● the piston lands were lowered to reduce pis-

ton mass

●

ALUMINIUM CYLINDER HEAD WITH ROLLER CAM

FOLLOWERS

Specifications

Engine code ALZ

Displacement 1595 cm

3

Type Row

Number of cylinders 4

Number of valves per

cylinder

2

Compression ratio 10.3:1

Bore 81.0 mm

Stroke 77.4 mm

Max. power 75 kW/102 bhp

@ 5600 rpm

Max. torque 148 Nm

@ 3800 rpm

Engine management

system

Simos 4

Fuel grades RON 95 unleaded

petrol

(the Passat also

operates on RON

91 unleaded

petrol, with

reduced engine

power)

1.6-litre 75 kW petrol engine

251_070

251_022

20

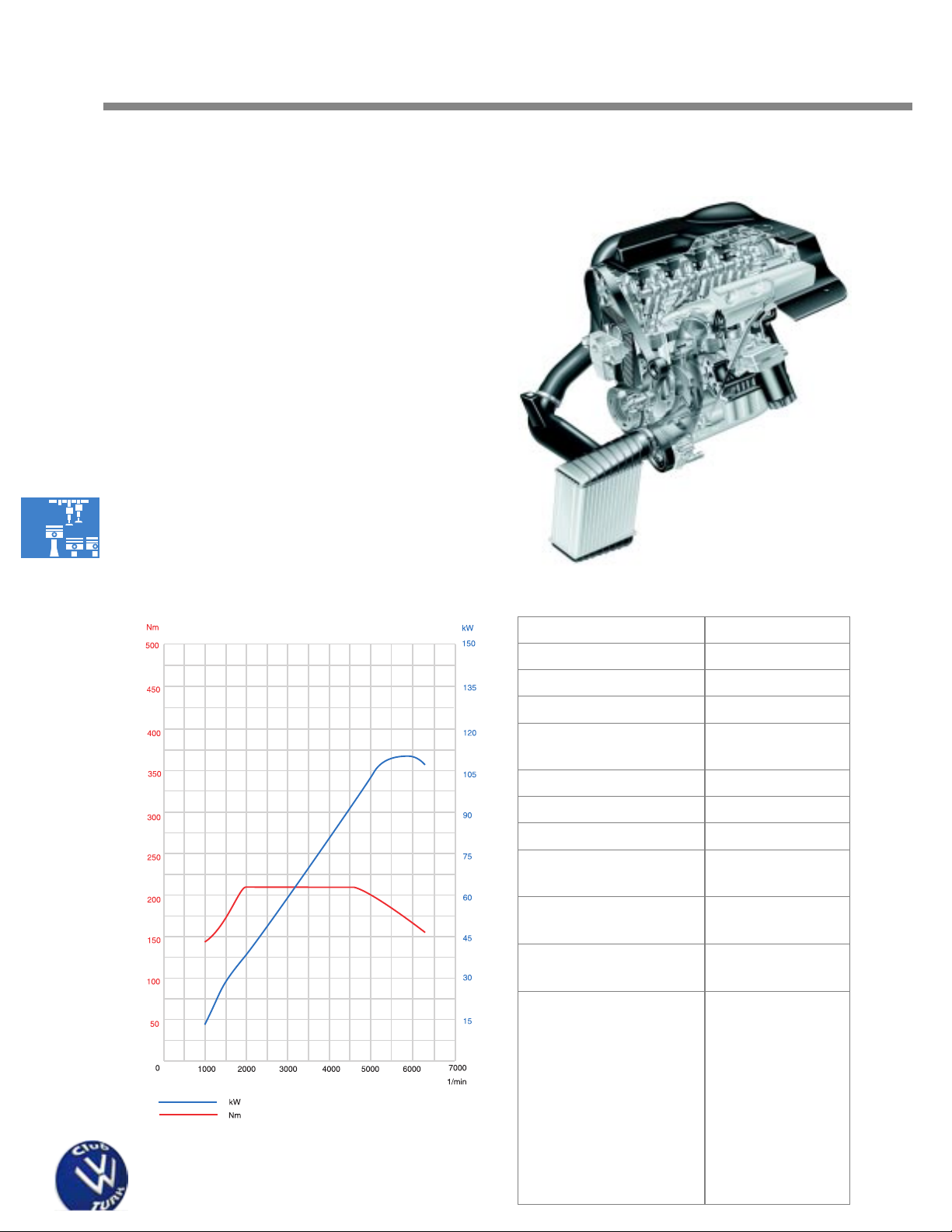

The Engines

1.8-litre 110 kW petrol engine with 5 valves per cylinder and

turbocharger

The engine was adopted from the predecessor

model and adapted to meet the applicable

exhaust emissions regulations, as outlined below.

● No intermediate shaft

● Oil pump is chain driven

● Piston crown cooling via oil spray jet

● Rod-type ignition coils with integrated output

stage

● P

LANAR PROBE BEFORE CATALYST

● Camshaft timing control - timing chain

adjuster, inlet camshaft only

● The water pump is driven by a toothed belt

Specifications

Engine code AWT

Displacement 1780 cm

3

Type Row

Number of cylinders 4

Number of valves per

cylinder

5

Compression ratio 9.3:1

Bore 81.0 mm

Stroke 86.4 mm

Max. power 110 kW/150 bhp

@ 5700 rpm

Max. torque 210 Nm

@ 1750-4600 rpm

Engine management

system

Bosch Motronic

ME 7.5

Fuel grades RON 95 unleaded

petrol

(the Passat also

operates on RON

91 unleaded

petrol, with

reduced engine

power)

251_071

251_023

21

The Engines

2.0-litre 85 kW petrol engine

The 2.0-litre engine was adopted from the

predecessor model.

In vehicles which have automatic transmission,

an electrical vacuum pump produces the vacuum

required for the brake booster (see page 43).

Specifications

Engine code AZM

Displacement 1984 cm

3

Type Row

Number of cylinders 4

Number of valves per

cylinder

2

Compression ratio 10.3:1

Bore 82.5 mm

Stroke 92.8 mm

Max. power 85 kW/110 bhp

@ 5000 rpm

Max. torque 172 Nm

@ 3500 rpm

Engine management

system

Simos 3.2

Fuel grades RON 95 unleaded

petrol

(the Passat also

operates on RON

91 unleaded

petrol, with

reduced engine

power)

251_031

251_026

22

The Engines

The following modifications have been made to

this engine:

● 4 valves per cylinder

● R

OLLER CAM FOLLOWER valve gear

● B

UILT-UP CAMSHAFT

● C

AMSHAFT TIMING CONTROL intake and

exhaust camshafts

● Plastic twin-path intake manifold

● E

LECTRIC THROTTLE DRIVE

● "TUMBLE" INTAKE PORT

These modifications provide higher power output

and torque, and hence better driving

performance.

The 2.3-litre 125 kW V-5 petrol

engine with 4 valves per cylinder

Specifications

Engine code AZX

Type VR

Number of cylinders 5

Number of valves per

cylinder

4

Compression ratio 10.75:1

Displacement 2326 cm

3

Bore 81.0 mm

Stroke 90.3 mm

Max. power 125 kW/170 bhp

@ 6200 rpm

Max. torque 225 Nm

@ 3200 rpm

Engine management

system

Bosch Motronic

ME 7.1

Fuel grades RON 98 unleaded

petrol

(the Passat also

operates on RON

95 unleaded

petrol, with

reduced

power output)

251_030

251_027

23

The Engines

2.8-litre 142 KW V-6 petrol engine

with 5 valves per cylinder

The Passat is still powered by the highperformance 2.8-litre V-6 petrol engine.

The following improvements were made to this

engine:

● 2 lambda probes were integrated in the

exhaust line before the catalyst and

● after the catalyst.

These modifications allow the engine to meet the

stringent EU 4 exhaust emission standard.

Specifications

Engine code AMX

Type V

Number of cylinders 6

Number of valves per

cylinder

5

Compression ratio 10.6:1

Displacement 2771 cm

3

Bore 82.5 mm

Stroke 86.4 mm

Max. power 142 kW/193 bhp

@ 6000 rpm

Max. torque 280 Nm

@ 3200 rpm

Engine management

system

Bosch Motronic

ME 7.1

Fuel grades RON 98 unleaded

petrol

(the Passat also

operates on RON

95 unleaded

petrol, with

reduced

power output)

251_077

251_029

24

The Engines

1.9-litre 74 kW TDI engine with

The 1.9-litre 74 kW TDI engine is based on

the 1.9-litre TDI engine developing 85 kW.

It differs from the basic engine in the following

respects:

● The software used in the engine control unit

was adapted to the lower engine power.

● The injectors have smaller

nozzle holes.

Specifications

Engine code AVB

Type In-line engine

Number of cylinders 4

Number of valves per

cylinder

2

Compression ratio 19:1

Displacement 1896 cm

3

Bore 79.5 mm

Stroke 95.5 mm

Max. power 74 kW/100 bhp

4000 rpm

Max. torque 250 Nm

@ 1900 rpm

Engine management

system

BOSCH EDC 15 P

Mixture preparation Direct injection by

pump injection

system

Fuel grades 49 CN diesel,

biodiesel

pump injection system

251_034

251_024

25

The Engines

The 1.9-litre 96 kW TDI engine with

pump injection system

The 1.9-litre 96 kW TDI engine differs from 1.9litre 74kW TDI engine with pump injection

system in the following respects:

● The software used in the engine control unit

was adapted to the higher engine power.

● The injectors have larger

nozzle holes.

● The

TURBOCHARGER is larger.

● The crankcase is made of stronger material.

● The crank pin diameter of the

crankshaft has been enlarged.

● The conrods are made of stronger material.

Specifications

Engine code AVF

Type In-line engine

Number of cylinders 4

Number of valves per

cylinder

2

Displacement 1896 cm

3

Bore 79.5 mm

Stroke 95.5 mm

Compression ratio 19:1

Max. power 96 kW /130 bhp

4000 rpm

Max. torque 310 Nm

@ 1900 rpm

Engine management

system

BOSCH EDC 15 P

Mixture preparation Direct injection by

pump injection

system

Fuel grades 49 CN diesel,

biodiesel

251_034

251_025

26

The Engines

The 2.5l V-6 TDI ENGINE DEVELOPING 110 KW has

demonstrated its success in the predecessor

model and will also be used in the Passat 2001

The 2.5-litre V-6 TDI engine

developing 110 kW

The following technical innovations were

employed to improve mixture preparation and

reduce exhaust emissions:

● The number of pump pistons in the

radial-piston distributor injection pump was

increased by 1, thereby raising the

maximum

INJECTION PRESSURE.

● The 5-hole injector has been replaced by a 6-

hole injector

● Improved

CRANKCASE VENTILATION

Specifications

Engine code AKN

Type V-engine

Number of cylinders 6

Number of valves per

cylinder

4

Displacement 2496 cm

3

Bore 78.3 mm

Stroke 86.4 mm

Compression ratio 19.5 : 1

Max. power 110kW/150 bhp

4000 rpm

Max. torque 310 Nm

@ 1500-3200

rpm

Engine management

system

Bosch EDC 14 M

Mixture preparation Direct injection by

electronically

controlled

distributor

injection pump

Fuel grades 49 CN diesel,

biodiesel

251_078

251_028

27

Manual gearboxes

5-speed manual gearbox 012/01W

The 012 or 01W manual gearbox has a proven

service record in the predecessor model.

It will be installed as a 5-speed gearbox in

combination with all petrol engines and also in

the 74 kW diesel engine.

5-speed manual gearbox 01A

The 01A four-wheel drive manual gearbox from

the predecessor model will be installed as a

5-speed gearbox in combination with the

2.0-litre, 2.3-litre and 2.8-litre petrol engines.

The 01E manual gearbox will be installed as a

5- or 6-speed manual gearbox in combination

with the turbodiesel engines developing 96 kW

and in the V-6 TDI.

5- and 6-speed manual gearbox 01E

will be installed in the Passat 2001 as a 6-speed

gearbox in combination 4- and 6-cylinder

turbodiesel engines from 96 kW.

The 01E four-wheel drive manual gearbox

(4 Motion)

Power Transmission

251_061

251_052

251_053

251_062

28

Power Transmission

Automatic gearbox

The new Passat is available with the same

automatic transmission as in the predecessor

model. The design and function of both

automatic transmissions have been adopted

without change.

The 01N four-speed automatic gearbox is

notable for:

● driver- and situation-dependent

driving programs, fuzzy logic controlled

● a drag-dependent driving program

● a torque converter with

lock-up clutch

The five-speed automatic transmission 01V has:

● a dynamic shift program (DSP)

● Tiptronic

● a torque converter with torque converter lock-

up clutch

The 5-speed automatic gearbox is also

available as a 4 Motion gearbox.

4-speed automatic gearbox 01N

5-speed automatic gearbox 01V

251_065

251_063

29

Power Transmission

Engine/gearbox combinations

1.6-litre ALZ

1.8-litre AWT

2.0-litre AZM

2.3-litre AZX

2.8-litre AMX

1.9-litre AVB

1.9-litre AVF

2.5-litre AKN

012 / 01W

012 / 01W

01 E

01 E

01N

01N

01 V

01 V

01N

01 V

01 V

01 A

01 A

01 A

01 A

01 V

01 V

012 / 01W

012 / 01W

012 / 01W

Front 4 Motion

251_094

30

Running Gear

The FRONT AXLE is a four-link front suspension. It

has been is accomodated to the modified vehicle

dimensions and axle loads, as compared to the

previous Passat.

The rack-and-pinion steering system

The new Passat has

HYDRAULIC POWER STEERING as standard.

The four-link front suspension

Tubular subframe

Bearing bracket

251_072

251_101

31

The torsion beam rear axle

In the TORSION BEAM REAR AXLE, the spring/

damper settings have been adapted to the

modified axle loads.

Modified offset depth

Rim offset depth was reduced to 37 mm from 45 mm,

with the result that the wheel is now flush with the body

exterior. Wheels fitted with winter tyres with ET45 offset

depth can still be used, except on the Passat 2001 with

large brake discs. This model has a wheel fitted with a

winter tyre in size 6Jx16 ET40.

Running Gear

Rear axle bearing

Shock absorber

Coil spring

Wheel bearing unit

251_074

251_099

Offset depth 37 mm

Offset depth 45 mm

32

Running Gear

The brakes

The front and rear disc brakes are configured for

excellent deceleration under braking. New,

larger brakes will therefore be used in the new

Passat depending on engine type.

The new Passat still has a Bosch 5.3 anti-lock

braking system with ESP. This system allows the

driver to maintain control over the vehicle at all

times, even in critical driving situations.

● 280 x 22 mm

● 288 x 25 mm

● 312 x 25 mm

● 245 x 16 mm

● 256 x 22 mm

● 269 x 22 mm

Front disc brakes

Bosch 5.3 anti-lock braking system

251_095

251_098

Rear disc brakes

33

Running Gear

All petrol engines which have automatic

transmission conforming to exhaust emission

standard EU4 will have an electrical vacuum

pump for brake servos.

This pump is required:

because not enough vacuum is provided for the

brake booster via the intake manifold during the

cold-starting phase.

For more detailed information, refer to the

separate SSP on the electrical vacuum pump.

The electronic vacuum pump

The electrical vacuum pump makes for reliable

pneumatic brake boosting.

It is activated by the engine control unit as

required.

251_058b

251_058a

34

Running Gear

The 4-wheel-drive version of the Passat has a

double wishbone rear suspension with a closed

tubular subframe attached to which are the track

control arms for wheel location and the

differential.

Insulating bonded rubber bushes provide good

acoustic isolation from the vehicle body.

The flat-type construction of the rear axle

provides a spacious interior.

This type of construction proved successful

in the predecessor model.

Four-wheel drive

The double wishbone rear suspension

Rubber mounting

Suspension strut

Subframe

Upper track control arm

Lower track control arm

Prop shaft

Torsen differential

Gearbox

251_073

251_093

35

Running Gear

Notes

36

The Electrics

is distributed, as in the Passat 97.

The fitting locations of the fuse holders, relay carriers, auxiliary relay

carriers and connector stations have been adopted without change.

The wiring harnesses have been extended to include new systems

(solar roof, distance control, dynamic navigation with

TV etc.) and the connector stations have been reorganised

accordingly.

The vehicle electrical system

Automatic gearbox

control unit

(in footwell on right)

Front-end connection

Airbag control unit

(in gearbox tunnel)

RNS-D

radio with dynamic

navigation

Electronics box in the

plenum chamber

- Engine control unit

- Relay station

- Connector station

-Fuses

Connector station in

right A-pillar

37

The Electrics

Window lifter motor

with integrated

door control unit

Control unit for distance control

(in luggage compartment on right)

TV tuner

CD changer

DSP

Dash panel insert with

immobiliser control unit

and diagnosis interface

(Gateway)

Window lifter motor

with integrated

door control unit

Convenience control

unit in the footwell left

Connector station

in left A-pillar

Fuse holder dash panel

left

251_003

38

The Electrics

A BI-xenon headlight is available as an optional

extra in place of the standard triaxial ellipsoid

headlight. In this headlight module, a gas

discharge lamp produces both the low and high

beams. The high beam is intensified by a H7

lamp which

also bridges the period until the gas discharge

lamp has reached its full luminous intensity. The

H7 lamp is also used for the flasher function.

Gas discharge lamp (GDL) with

BI-xenon bulb

High beam

(H7 lamp)

Low beam

Indicator

lights

Headlights

Two types of headlights are available for the

new Passat. The basic specification consists of a

clear glass triaxial ellipsoid headlight with a H7

bulb as a high beam headlight.

H7 lamp

(additional high

beam)

Indicator lights

Gas discharge headlight

(low beam and high beam)

For trips in countries where vehicles drive on the left-hand side of the road, both these

headlights can be adjusted from asymmetrical low beam to symmetrical low beam.

Please note the information given in the Workshop Manual.

Standard headlights

251_005

251_006

39

The Electrics

More light means more safety

The Passat, model year 2001, uses the BI-xenon

headlight system. The system's improved

luminous efficiency provides higher active

driving safety, because hazards can now be

recognised sooner.

The wider range and increased brightness of the

light beam enable the driver to recognise

hazards and reduce speed earlier. Provided the

driver reacts in time, he will be able to stop the

vehicle ahead of the hazard and thereby avoid a

collision.

Stopping distance 28m

Stopping distance 28m

without xenon headlight

with xenon headlight

Vehicle speeds:

Car: 50 kph

Bicycle: 25 kph

a) represents the time gain

provided by BI-xenon.

In this example,

exactly 1 s is gained.

Without xenon headlights, the driver does not

see the cyclist until much later.

With xenon headlights, the driver sees the cyclist

earlier and still has enough time to reduce speed.

A

251_019

251_021251_020

40

The Electrics

Until now, no single gas discharge headlight has

been capable of producing both low and high

beams. Hence, it was not possible to adjust the

light/dark boundary while driving.

A solenoid-operated mechanical shutter is used

to produce the xenon low and high beams.

This mechanism screens off a portion of the light

generated in the lamp to produce the low beam.

In the high beam setting, the mechanism allows

all of the light generated in the lamp to pass

through.

Lens

Reflector

Solenoid

251_311

Design of a BI-xenon headlight module

The headlight module comprises:

● electronic ballast (EVG)

● headlight range control motor

● conventional light bulbs

● gas discharge headlight module

● housing with bonded clear glass lens

shutter

ballast

251_006

251_067

Gas discharge headlight

41

The Electrics

Statutory requirements

Where gas discharge headlights are used in a vehicle, the following

auxiliary equipment is required to be installed to avoid dazzling other road users:

● a headlight cleaning system

● automatic headlight range control

251_306

251_307

The shutter screens off part of the

light cone generated.

(light/dark boundary)

The shutter is electromagnetically adjusted to

produce the high beam. The entire light cone

now becomes effective. The H7 lamp is also

switched on.

42

The Electrics

The Passat 2001 with BI-xenon headlights has automatic headlight range control.

The task of the automatic headlight range control

is to adjust the headlights to compensate for

variation in ride height as a function of payload.

The automatic headlight range control also

compensates for variation in headlight range

caused by dynamic effects under braking and

acceleration, for example.

The headlight range control system comprises:

Headlight range control, control unit J431

receives signals from two level sensors (one on

the front axle and one on the rear axle) and the

road speed signal. Having evaluated the signals,

the system activates the control motors in the

headlights and thereby compensates for

variation in vehicle level.

The headlight control motors are configured as

stepping motors. They can perform the full range

of headlight adjustments within approximately 1

second.

The control unit has self-diagnostic capability

and can be addressed with address word 55.

Task

Automatic dynamic headlight range control (LWR)

Function:

Road speed signal

Self-diagnosis

Vehicle "level"

senders

G76

and G78

stepping motor, right

V49

stepping motor, left

V48

Headlight range control,

control unit J431

in the luggage

compartment, left

Term i n a l 15

Term i n a l 31

Terminal 56

Input signal

Output signal Earth

+

251_004

43

The Electrics

The dash panel insert

The dash panel insert is the Group dash panel

insert with blue backlighting and translucent red

dials.

The modified design and chrome-bezeled

instruments stand out. The instruments are now

operated by stepping motors.

The dash panel insert is available in three

versions. They mainly differ with regard to the

display options in the central display.

● Integrated third-generation immobiliser con-

trol unit (see Immobiliser)

● The interface to the CAN databus, i.e. the

dash panel insert, is connected to the drivetrain CAN databus and convenience CAN

databus. The rev counter is activated by signals from the drivetrain CAN bus, for example, and the status of the doors/tailgate can

be displayed in the dash panel insert via the

convenience CAN bus.

● The diagnosis interface (Gateway) in the dash

panel insert is necessary for communication

between the various CAN databuses. Diagnosis data is also transferred via CAN through

this interface to the K-wires (see CAN networking).

Central display

Selector lever range indicator

New functions

251_049

44

The Electrics

New warning lamps:

Designation Symbol Function

Selector lever lock K169 serves to remind the driver to depress the brake. The

selector lever lock on automatic

transmissions is released in this way

Door/tailgate open warning

lamps (K116/K123-K127)

indicates open doors/tailgate. In vehicles with a

multifunctional display, this warning is issued as a

symbol.

Cruise control system warning

lamp K31

comes on when the cruise control system (CCS) is

switched on. For vehicles with cruise control system

only.

Exhaust emissions warning lamp

K83

If a fault detrimental to exhaust gas quality occurs in

the vehicle, the fault is saved to fault memory and

the exhaust emissions warning lamp is activated.

The exhaust emissions warning lamp begins to flash

if there is a danger of the catalyst becoming

damaged due to misfiring.

45

The Electrics

Function

The first phase (key recognition) is identical to

that of function immobiliser II. However, the

mode of communication between the engine

control unit and the immobiliser control unit has

changed.

The engine control unit generates a number

(variable code) by means of a random-number

generator.

The engine control unit and the immobiliser

control unit each calculate a result based on a

table of formulae. The engine control unit

compares the result returned by the immobiliser

control unit with its own result. This process of

communication takes place along the CAN

databus.

If the results match up, the immobiliser control

unit allows the engine to be started.

Third-generation immobilisation

General notes:

● The keys are marked W3.

● For service personnel, the key adaption

procedure is unchanged. The keys are

electronically locked while being adapted. As

a result, they cannot be used to open any

other vehicle.

● The adaptation procedure in case of

component parts replacement has changed.

CAN databus

251_037

Immobiliser control unit

Engine

control unit

46

The Electrics

Networking of CAN systems

Injection pump

(V-6 TDI)

Gearbox control

unit

Brake control unit

(ABS, ESP,...)

Airbag control

unit

Wheel angle sen-

sor (for ESP)

Radio

(Double DIN

US market)

Multifunctional

steering wheel

Fuel tank sender

(B5-W8 only)

Climatronic

Driver door con-

trol unit

Front passenger

door control unit

Driver's seat

(memory)

Convenience

system control

unit

Door control unit,

rear left

Door control unit,

rear right

DSP

CAN Infotainment on CAN convenience control units (physically the same CAN)

are directly connected to the diagnosis plug.

Control units are direct connected to the diagnosis plug via the Gateway.

Drivetrain CAN bus

Convenience CAN bus

Convenience CAN bus

251_057

Engine

control unit

CAN-Infotainment

47

The Electrics

The Gateway must be informed of the CAN users

by means of the "Encode control units“ function.

The address word for the Gateway control unit

is 19.

All control units from the drive train are connected to

the drivetrain CAN bus (highspeed).

All control units for convenience systems are

connected to the convenience CAN bus and

infotainment CAN bus

(physically one databus = low-speed).

The transmission rates of CAN High-speed and

Low-speed are 500 kBaud and 100 kBaud

respectively, i.e. 500 000 bits or 100 000 bits are

transmitted per second.

The diagnosis interface (Gateway) is integrated

in the dash panel insert and has the following

tasks:

● To transfer diagnosis data from the drivetrain

CAN bus and convenience CAN databus to

the K-wire so that they can be used by the

self-diagnosis. This is a basic requirement for

self-diagnosis of certain systems

(the memory seat does not have its own Kwire, for example).

● To facilitate communication/data exchange

between users of a databus and between

users of different databus systems.

48

The Electrics

● Standard radio wave remote control with

additional button for tailgate remote release

(RLR)

● The lock cylinder on the front passenger's side

has been deleted.

● New tailgate locking concept

The tailgate can be released:

- by pressing the button in the new

driver's door switch unit. This function can

be disabled by key switch.

- by means of the handle switch in

the tailgate.

This function can be disabled by the key

switch in the tailgate.

- The radio wave remote control.

1. Basic position

The tailgate can be opened by

means of the lock handle.

2. Service position

In this position, the tailgate cannot

be opened by the lock handle.

3. Mechanical emergency opening

The CAN databus introduced in the convenience

system (Low-speed) of the Passat ’97 has been

modified as follows:

- the transmission rate has been increased to

100 kBaud from 62.5 kBaud.

- Interface to convenience CAN databus and

connection to dash panel insert. This allows

an open door to be represented symbolically

in the dash panel insert, for example .

Convenience system

The key switch in the non-visible part of the

tailgate has three tasks:

The convenience system was modified as follows:

251_038

251_316

251_013

Driver's door switch unit

Tailgate locking concept

Lock handle

Key switch

49

The Electrics

Memory seat

The electronic seat adjustment was improved

in the following areas:

● The memory control unit now has a

nonvolatile memory which retains stored

seating positions while the battery terminals

are disconnected.

● It is no longer necessary to initialise the seat

after having disconnected a battery.

● The tone generator emits an

acknowledgement signal after the seating

position is stored.

The tone generator is no longer built into the

memory control unit, rather it is activated via

CAN databus in the dash panel insert.

Seat/mirror position control unit,

driver's side J394

251_086

251_043

251_039

Operator switches for seat adjustment and

Memory

50

The Electrics

The solar roof generates electric current via

integrated solar cells. This powers the fresh air

blower, which cools down the vehicle interior to

approx. 20°C. The system operates when the

ignition is off and when the sliding roof is open or

tilted.

A DC/DC converter is mounted

on the underside of the sliding roof.

The DC/DC converter serves the purpose of current/

voltage adaptation between the solar generator

(solar module) and the blower. It converts the high

voltage and low current intensity which the solar

module supplies into a low voltage and high current

intensity since the blower motor requires a very high

starting current.

An electronic circuit in the DC/DC converter

only enables the fresh air blower motor if the

voltage is above a threshold value of 2 V. This

avoids damage to the blower bearings.

Sliding roof/solar roof

Contact switch in

sliding roof F289

+ from blower control

Terminal 15

Solar cell

isolation relay

J309

Earth

Solar cell contact

switch

F288

Solar cells C20

Fresh air blower V2

Solar roof control

unit

J355

When the ignition is off, the contact is in this position.

This allows the fresh air blower to receive its voltage

supply from the solar roof.

251_035b

251_035

251_040

51

The Electrics

The distance control (ADK) aids parking in

reverse. For this purpose, four ultrasound

converters are built into in the rear bumper. The

control unit is located in the luggage

compartment on the rear left. The tone generator

is under the rear window shelf in the saloon and

built into the control unit in the Variant.

Distance control (ADK)

Tone generator

The distance warning system begins to emit

acoustic signals when the vehicle reverses to

within a distance of 1.60 m of an obstacle. The

frequency of the audio signal varies with

decreasing distance to the obstacle. The

intermittent audio signal becomes a continuous

tone when the vehicle reverses to within 20 cm of

the obstacle.

The system is active as soon as the ignition is

turned on and reverse gear is selected.

Continuous tone Intermittent audio signal

with variable frequency

Control unit

Switch reverse

Ultrasound converter

251_051

251_002

52

The Electrics

The radio navigation system

MFD radio navigation system with dynamic

route guidance

The traffic data used by the system is based on

the RDS TMC service which is supported by radio

stations and soon to be available throughout

Europe. Use of a RDS-TMC control unit allows

the driver to freely select a radio station for data

reception. This means that TMC data and normal

radio are received with different receivers.

All traffic information available within a radius

of approx. 200 km is utilised. If the dynamisation

function is activated by traffic conditions, the

driver is informed of this by the announcement:

„The route is being recalculated on the basis of

traffic information!“

Traffic delays (road closures, traffic jams and

slow-moving traffic) are visualised in the map

and are displayed as text messages.

Glossary

● MFD = multifunctional display

● RDS = Radio Data System

● RNS - High/D = radio navigation with

5“ screen and D for dynamic

navigation

● TMC = Traffic Message Channel

● CAN = CAN bus with proprietary protocol,

incompatible with the

CAN databus protocol to VW' specification

● GPS = Global Positioning System

RNS High/D with tuner

3-line bus

CAN

Antenna

RDS-TMC tuner

control unit

A radio navigation system with dynamic route guidance is also available as two-colour display

(low-end). In this system the RDS-TMC tuner is integrated in the radio navigation system.

251_096

53

The Electrics

In comparison to older systems, which can only

display the position of the vehicle on the planned

route (static route guidance), the new

navigation system also displays information on

traffic conditions and updates the planned route

to a destination in the event of traffic delays

(dynamic route guidance).

To facilitate vehicle navigation, a GPS receiver

and a direction sensor are fitted in the vehicle.

The system determines and displays the exact

location of the vehicle based on acquired data

and a digital map. The route guidance function

permits navigation to pre-entered destination. By

processing digital traffic information broadcast

by radio stations the system can reroute the

vehicle to avoid traffic delays. The driver is only

required to enter his destination. The system

takes care of the rest.

The system constantly collects traffic data, even

when the ignition is off. The system therefore

offers the driver up-to-the-minute traffic

information, which can be retrieved when

needed. Traffic information is provided in text,

graphic or audio form.

Since received traffic data first has to be

converted into voice in the system, traffic

information is available in a range of languages.

The dynamic navigation system is addressed

with the same address word as the standard

navigation system (37) .

Dynamic route guidance

● Automatic rerouting to avoid

traffic delays

● The system assesses traffic delays

(road closure in both directions, traffic jam,

slow-moving traffic) on the basis of the driving

time remaining to destination

● No driver intervention is necessary and the

driver can concentrate fully on the road

ahead.

Radio navigation with dynamic route guidance

54

The Electrics

Public and private

TMC services for broadcasting general traffic

information are freely available in all European

countries.

These messages relate to road safety and

various traffic delays. Europe's free and public

services are collectively known as the "ALERT

Service“. Other TMC services will not be

provided free of charge.

These services relate to value-added information

or messages intended for special user groups.

Services provided in Europe

European TMC services - public and private are already available. A network providing

European-wide coverage was in place by early

2000. Each service relates to a country in which

it provides either regional or nationwide

coverage. By agreement, all national or

international service providers provide crossborder traffic information for long-distance

drivers.

TMC services

What is a TMC service?

A TMC (Traffic Message Channel) service is the

net result of the activities undertaken by a service

provider to broadcast traffic information. To

make use of these services, the road user only

requires an RDS-TMC receiver.

How TMC services work

● Code numbers (TMC Location) have been

assigned to all sections of motorways and

major trunk roads.

● Traffic events (road closure, traffic jam, slow-

moving traffic) have event codes

(TMC Events) corresponding to the extent of

the traffic delay (e.g. length of tailback).

● The navigation computer can refer the

TMC Locations and Events to the maps which

it uses for navigation purposes by means of a

conversion table.

● All data are broadcast nationwide in the

same form.

● As soon as the system receives information on

traffic delays on sections of the planned route,

it reevaluates their viability. If the system

deems recalculating the route necessary, it

may include a detour where required.

55

The Electrics

The TV function is an extended function of the

navigation system. All terrestrial programs can

be received with the TV tuner.

Terrestrial programs are all programs that can

be received using a normal antenna, and not

programs that can only be received by satellite.

The TV tuner is compatible with all current

broadcasting standards such as PAL, NTSC or

Secam. The broadcasting standard used for TV

reception in the country of delivery is preset at

the factory. Teletext is also possible.

Currently available stations are identified

automatically. The system automatically tunes

into the frequency band which provides optimal

reception. When the vehicle leaves a

broadcasting area and enters, for example, an

area with no radio reception or a silent zone, it

enters automute mode.

The equipment includes a preinstalled wiring

harness for connecting external equipment such

as a video recorder or a notebook. However, this

connection is currently unavailable to the user.

The TV is inactive while the vehicle is running.

The TV tuner has a self-diagnosis function

which is activated by address word 57.

Radio navigation system with TV

251_089

56

The Electrics

The system which provides dynamic navigation

and TV tuner includes the following components:

● radio navigation system (RNS) with

multifunctional display

● window aerial with amplifier

● TV tuner with control unit in the luggage com-

partment on the left

Dynamic navigation with TV tuner

The antenna for the TV tuner is integrated

in the rear window in the saloon and in the

two rear side windows in the Variant.

Antenna for radio and

navigation

TV tuner

RNS

RDS-TMC tuner

Global Positioning System (GPS)

Amplifier

251_059

Antenna for TV

tuner

57

The Electrics

A wiring harness for connecting a mobile phone

is available for the Passat 2001. The mobile

phone rest is attached to the dash panel. The

mobile phone is connected to an interface box

fitted below the armrest.

The interface box is the interface between the

mobile phone, the vehicle electrical system and

the antenna.

When the mobile phone is placed in the rest,

the driver can make a telephone call using the

hands-free facility. The radio enters automute

mode while a phone call is being conducted.

The telephone number can be dialled on the

mobile phone. Voice dialling is also possible if

the mobile phone provides this facility.

The mobile phone rest is available in two

versions.

Pre-installed wiring harness for telephone installation

251_009

58

The Electrics

The heating and air conditioning system

The Climatronic air conditioning system has been

provided with an additional temperature sensor,

as compared to the previous model.

The temperature sensor is built in the air duct on

the outlet side of the evaporator. It is designated

"Evaporator vent temperature sender G263".

This sensor provides the Climatronic control unit

with a continuous stream of data on the air

temperature on the outlet side of the evaporator.

Climatronic control unit

(behind the operating unit)

Signal from temperature sensor

to control unit

Evaporator

Climatronic has an additional new feature:

The Climatronic control unit receives a signal

from the wiper motor. When the wiper motor is

running, blower output and temperature are

raised slightly so as to avoid windscreen fogging.

Windscreen wiper system

59

The Electrics

Compressor

Self-diagnosis

A fault in the temperature sensor is entered in the

control unit's fault memory. The signal from the

sensor can be checked in the self-diagnosis data

block.

251_012

This allows the ambient temperature (G17 and

G89) and the air outlet temperature on the outlet

side of the evaporator to be checked and the

control unit to control compressor shutoff more

precisely. Dehumidification of the vehicle interior

is improved because the air is dried more

quickly. Windscreen fogging is thereby largely

eliminated.

60

Index

A

A

LUMINIUM CYLINDER HEAD WITH ROLLER CAM

FOLLOWER (RSH) - SSP 196

B

B

ELT TENSIONERS/BELTS - SSP 192

B

UILT-UP CAMSHAFT - SSP 243

C

C

AMSHAFT TIMING CONTROL - SSP 246

C

RANKCASE VENTILATION - SSP 241

D

D

OUBLE WISHBONE REAR SUSPENSION - SSP 194

E

E

LECTRIC THROTTLE DRIVE - SSP 210

F

F

IVE- AND SIX-HOLE INJECTORS - SSP 241

F

RONT AIRBAGS - SSP 192

F

RONT AXLE- SSP 167

G

H

H

YDRAULIC POWER STEERING - SSP 191

I

I

NJECTION PRESSURE - SSP 241

I

NJECTOR - SSP 241

I

SOFIX - SSP 192

J

K

K

NOCK SENSORS - SSP 233

L

M

N

O

P

P

LANAR PROBE BEFORE CATALYST - SSP 231

Q

R

R

ACK-AND-PINION STEERING - SSP 191

R

ADIAL-PISTON DISTRIBUTOR INJECTION PUMP -

SSP 241

R

OLLER CAM FOLLOWER VALVE GEAR - SSP 196

Index

61

Index

Index

S

T

T

ORSION BEAM REAR SUSPENSION - SSP 102

T

RAPEZOIDAL CONROD - SSP 209

T

UMBLE INTAKE PORT - SSP 198

T

URBOCHARGER - SSP 190

U

V

V-6 TDI

ENGINE - SSP 183

W

X

Y

Z

62

Notes

63

Notes

64

For internal use only © VOLKSWAGEN AG, Wolfsburg

All rights reserved. Technical specifications subject to change without notice.

040.2810.70.20 Technical status: 09/00

❀ This paper is produced from

non-chlorine-bleached pulp.

251

Loading...

Loading...