IP816A-LPC-v2

License Plate Capturing Solution

Highway & Street

Installation Guide

Rev. 1.0

Document part no.: 625041100G

Ordering part no.:

IP816A-LPC-v2 (Highway): 199002900G

IP816A-LPC-v2 (Street): 199002800G

IP Surveillance

CAUTION:

TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT REMOVE COVER.

NO USER SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

UNPACKING:

Unpack carefully. Electronic components can be damaged if improperly handled or

dropped. If an item appears damaged in shipment, place it properly in its carton and

notify the shipper.

IMPORTANT!:

1. Read and follow Instructions: All operating and user instructions should be read and

followed before the unit is to be operated.

2. Electrical Connections: Only a qualied electrician is allowed to make electrical

connections.

Specications

I

Model Number LPC enclosure

Power Input 24V AC

Max. Output power budget 48W (Street); 80W (Highway)

Power Consumption Window heater: 10W; Blower: 2W; Camera: 6 ~ 8W

Environmental Operation Temp. -20°C ~ +50°C (-4°F ~ +149°F)

Protection Level IP68, IK10

Mounting Bracket Fully-cable Management

Construction Die-cast Aluminum Alloy

Coating White epoxy powder coating

Dimensions 502.8 (L) x 170 (W) x 400 (H) mm

Net Weight 6,482g (9.24 lb)

2

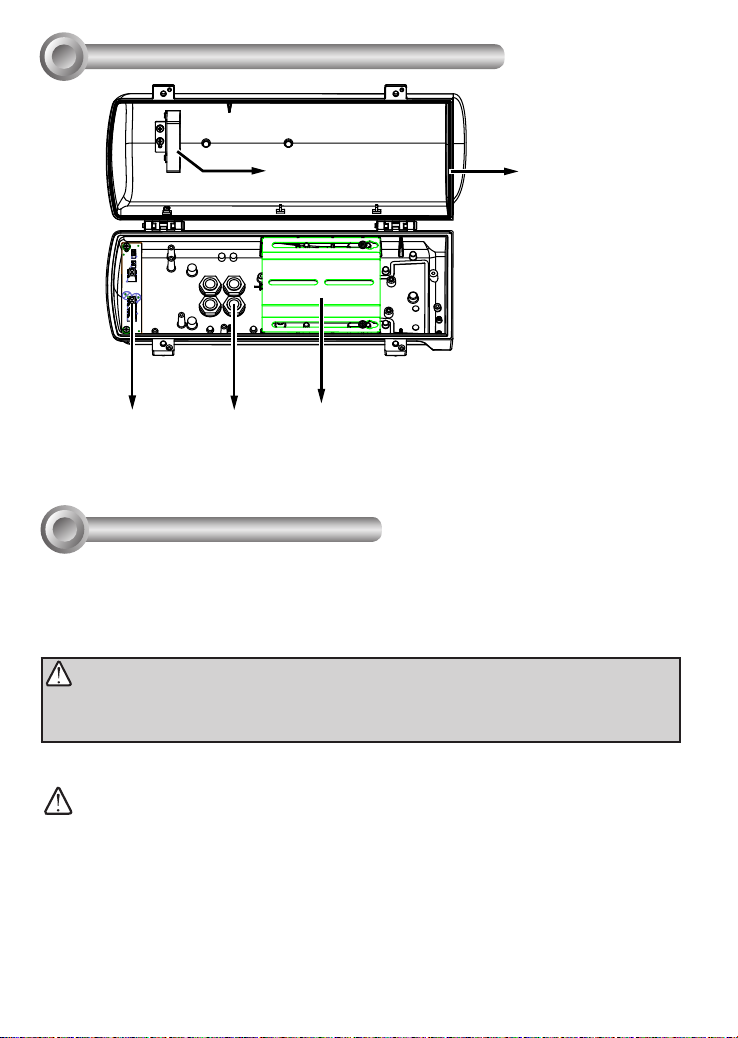

Mounting Conguration & Dimensions

II

Swivel Positions and Directions

English

135.5 mm

158.5 mm

77.4 mm

170

170 mm

105 mm

USABLE

AREA

502.8 mm

400 mm

255 mm

USABLE AREA

502.8

400

3

Component Description

III

Window frame heater

coil

Power distribution

board

Installation Suggestions

IV

M16 1/2" Waterproof cable gland

Ventilation fan

Camera Mounting Platform

If you plan to install this camera enclosure into a tropical, sea coastal, or an environment

where salt water or corrosive industrial waste water/moist are present, please seal each

stainless steel screws and ttings with a silicon grease compounds. This will help prevent

electrolysis to occur and extend the life span of the camera and housing.

IMPORTANT:

1. Disconnect devices: A readily accessible disconnect device in the building installation wiring

should be incorporated.

2. Electrical Connection: Only a qualied electrician is allowed to make electrical connections.

WARNING:

• Please avoid eye exposure or apply appropriate protection, such as wearing a pair of Infrared

protection glasses, when working with the product. Always use camera live view to oberve IR

lighting effects.

4

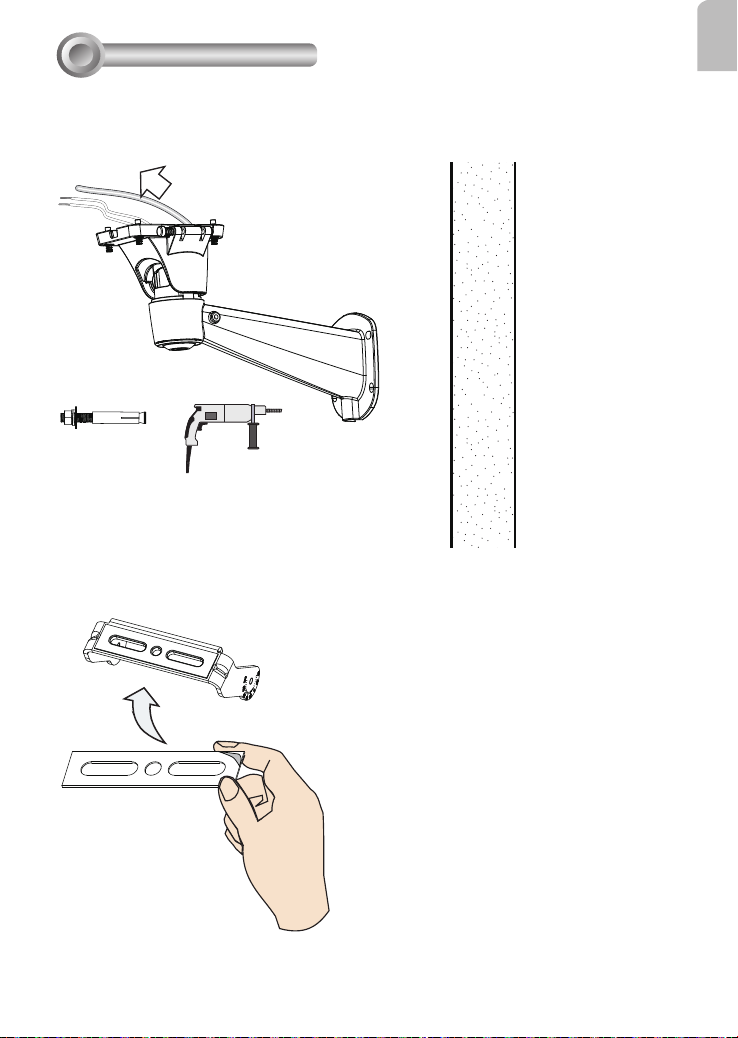

Installation

V

Install the wall-mount bracket to a preferred location at your installation site. Drill

1.

mounting holes and a cable routing hole (if preferred) on a wall. Install the bracket.

Prepare and route the wiring, Ethernet and 24V power source.

Install the IR illuminator to the bottom of the housing. Attach the included grip stricker

2.

to the U bracket.

English

5

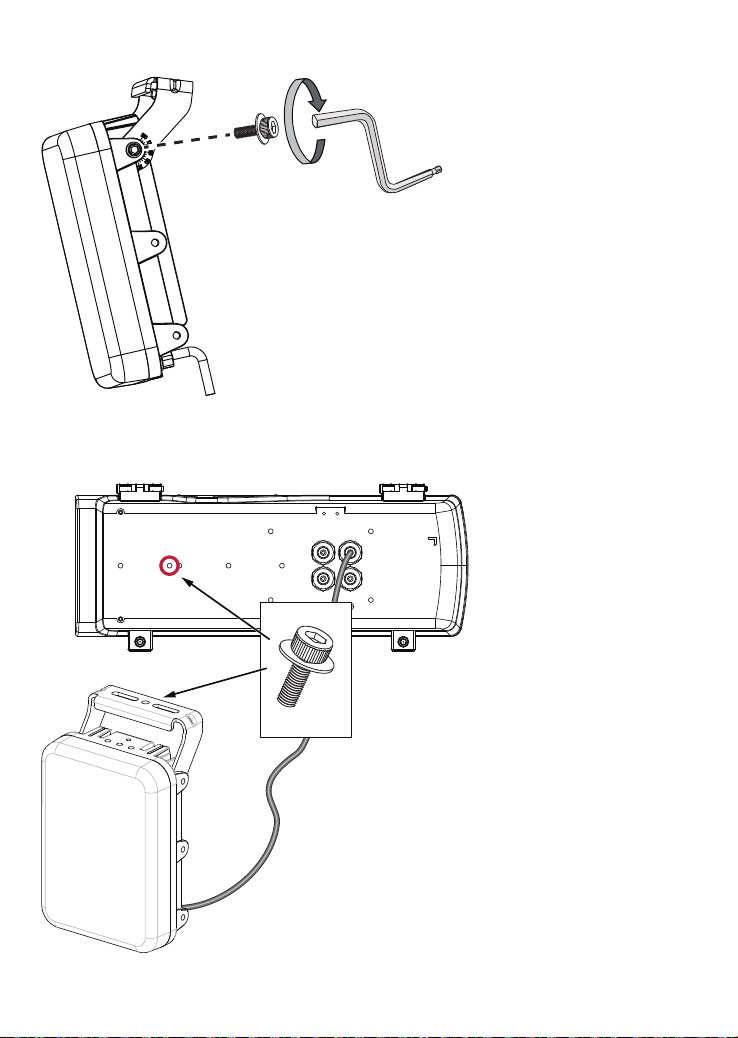

Secure the U bracket to the IR illuminator using the included wrench and hex screws.

3.

Flip the housing over and place it on a clean, stable surface. Secure the IR illuminator

4.

to the bottom of the housing using the included wrench and a hex socket screw.

6

You can turn the IR illuminator so that its at side is parallel with the housing, and that

5.

you can turn the assembly over and work on the inside of the housing.

Prepare power wires, a ground wire, and a CAT5e Ethernet cable. Pass them through

6.

the M16 waterproof connectors under the housing.

Ethernet cable Ø4 ~ 6.5mm

English

Power wires & DI/DO wires,

a combo cable from IR illuminator

7

You may need to remove the RJ45 connector, and use a crimping tool to connect the

Ethernet wires to an RJ45 connector inside the enclosure. Use an Ethernet cable of the

width of 4 ~ 6.5mm.

o: white/orange stripe

O: orange solid

g: white/green stripe

B: blue solid

b: white/blue stripe

G: green solid

br: white/brown stripe

BR: brown solid

When done, tighten up and install the waterproof connectors.

7.

Assemble the camera components, e.g., the CS ring and lens module. Secure the

8.

o

O

g

B

b

G

br

BR

1

2

3

4

5

6

7

8

mounting plate to the bottom of the camera (the label side) using the included screw.

There is a plastic mount pad in the package. You do not need the mounting pad

using the VIVOTEK camera.

8

Adjust the camera's position so that the lens module can ush align with the tempered

9.

glass. Secure the camera using the screws and washers to the bottom of the housing.

Lens flush

w/ edge of

enclosure

Connect 24V power source to the power input terminal. Connect power wires from

10.

the DC 12V output to the camera. Connect the 24V power output to drive the external IRs.

English

Ground

Not used for this model

DC 12V OUT - to camera

AC 24V OUT - to external IR

AC 24V IN - external power

source

9

You should prepare a power adaptor of the sufcient capacity for supplying 24V input.

Below are the requirements:

Total consumption Power adaptor

LPC Highway 80W 7A

LPC Street 48W 5A

Connect the Ethernet cable to the camera's RJ45 socket.

11.

Also pass the combo cable of the IR illuminator through a waterproof connector.

12.

Connect the day/night signal lines from the IR unit to the DI/DO connectors on the

13.

camera's terminal block.

AC/DC pwr

DO+

DO-

DI1+

DI2+

AC/DC pwr

DI3+

DI-

RS485-

RS485+

The day/night mode DI connection enables the synchronization of IR light and the

automated day/night switching mechanism on the camera.

Cable Pinouts (IR Illuminator)

Name Color Gauge Description

V+ Red (20AWG) Power input

V- Black (20AWG)

DI+ Green (26AWG) LED ON/OFF control

DI- Yellow (26AWG) Ground

DO+ Purple (26AWG) Light sensor status output

DO- Blue (26AWG) Ground

RS485+ Orange (26AWG) RS485 interface control

RS485- Brown (26AWG)

12~24V DC±10%

24V AC±10% (50~60Hz), (14.5VDC current controlled)

* Dry contact

Logic level 1(Open) = LED off

Logic level 0(Close to GND) = LED on

* Wet contact

Logic level 1: 4V~40 V = LED off

Logic level 0: 0.8V MAX = LED on

1. Open = Day

2. Short = Night (20 lux for IR ON)

10

A sample connection diagram consisting of CaMate's IR illuminators and the IP816A

camera is shown below. Please refer to your camera's documentation if your camera

comes with different pinouts.

AC/DC pwr

AC/DC pwr

DO+

DO-

DI1+

DI2+

DI3+

DI-

RS485-

RS485+

English

DC 12V

AWG20

AWG26

DI+:

DI-:

DO+:

DO-:

RS485+:

RS485-:

Green

Yellow

Purple

Blue

Orange

Brown

AC24V

AC24V

input

You can connect the ground wires together and connect them to the DI- ground pin

14.

on the terminal. Use a small at blade screwdriver to press the lever on the terminal block.

DI-

DO-

11

Secure the intersection bracket to the bottom of the housing by driving two screws.

15.

Install the housing to the wall-mount bracket by aiming and pressing the spring

16.

mortise, and hook the bracket onto the groove in the spring mortise.

12

When mounting the housing, please carefully place the cable within the cutout on the

bracket. There is a cutout for routing the cable.

Secure the housing to the bracket by fasteninng 4 T30 screws.

17.

English

T30 x 4

13

Adjust zoom and focus and open a web console with the camera to tune for the best

18.

image. When zoom and focus is done, Close the top cover and fasten the hex screws

from below.

Firmware congurable options:

19.

Make sure that the external IR is turned on in the night mode, and that the IR cut lter

option is synchronized with the digital input you connected (default is DI3).

When the "Turn on external IR illuminator in night mode" is selected, a digital output signal

will be triggered to turn on the IR illuminators.

Use the Media > Focus function to tune for a best image focus on your target area.

14

In the Conguration > Media > Image settings page, select an application scenario, LPC

Highway, street, or parking lot mode. The related parameters, such as shutter time, will be

automatically changed for the scenario.

LPC-highway

LPC-street

LPC-parking lot

If preferred, e.g., shooting fast moving vehicles, select the 60fps frame rate.

English

15

In the night mode, check if the input signals are correctly detected. You may simulate

the night mode by blocking the IR unit's light sensor. Change the triggering parameters if

necessary.

If your target area is a stretched out eld of view, such as shooting a part of a highway,

nding the best focus can be a problem. You can use the Snapshot Focus utility to make

sure you acquire clear images of the license plates of passing vehicles.

16

Operation Procedure:

1. Press the Snapshot Recording button, e.g.,

when a car is passing the eld of view. A short,

2.5 seconds of video recording will be available

(including 1 second of pre-recording and

another second of post-recording).

2. The recording takes place on Stream 1 with a

focusing result calculated from the full of the

current eld of view.

3. The Snapshot Focus comes with an embedded

Quick time player. Users can review the

current focusing results on a viewing window.

Users can also use

their keyboard to go through the recording in

a frame-by-frame manner (after the video is

played once).

In this way, an installer can immediately

examine whether the focus is optimal when

a fast going car is captured by video. If not,

he can tune the focus again and review the

imaging result until satised.

4. Users can also download the short recording

clip to a PC. Note that if the Snapshot Focus

page is refreshed or the web session is closed,

the recording will be erased.

Note that you can use the arrow buttons on the

sides of the Focus tuning bar to find the best

focus.

the left arrow key

on

English

17

The parameters of IR illuminator can be controlled via the RS485 connection. You can

FF01

enable the connection in

for the IR illuminator: Pelco D, baud rate - 38400, Data bits - 8, Stop bit - 1, Parity - none.

You can create custom buttons on a web console, such as IR brightness (Lux), threshold,

dimming, etc.

The IR control commands come in an 8 byte format. A sample command is shown below:

Conguration

>

PTZ

Mechanical

>

Customizable IR control

window. Select the defaults

Defaults for IR:

Pelco D

38400

8

1

none

FF012101bf0005E7

FF01

Sync Addr Cmd1 Data1 Data2 Data3 Data4 Chks

1111 1111 0000 0001

The format uses Hexadecimal 0-9, A-F. Each 8-bit byte contains two 4-bit hexadecimal

characters. Two hexadecimal characters contained in each 8-bit eld of message.

2101

001000010000 0001 10111111 0000 0000 00000101 1110 0111

bf00

18

05E7

bitbit

031

Below is the table of congurable data bit (Data1 ~ Data4) values:

bit 31 ~ 24 Device ID: 01 (default) ~ 127

bit 23 ~ 21 Baud rate (0)1200, (1)2400, (2)4800, (3)9600, (4)19200, (5)38400 (default), (6)57600,

(7)115200 bps

bit 20 ~ 16 Brightness: (0) ~ (31), brightness from 0 ~ 100% (default), increment unit is 2.5%

bit 15 ~ 13 LED control mode: (0) DI, (1) Direct, (2) Timer, (3) Light sensor, (4) DI pulse, (5) LPR, (6)

LED dimming by light sensor (default).

bit 12 LED status: (0) Off ready only (default), (1) On

bit 11 ~ 10 Fade in/out: (0) Off, (1) Fast, (2) Slow.

bit 9 DI activation polarity: (0) Low (default), (1) High,

bit 8 DO activation polarity: (0) Low (default), (1) High.

bit 7 ~ 6 Reserved

bit 5 ~ 4 DO mode: (0) Light sensor state (default), (1) LED state, (2) Diagnostic

bit 3 ~ 1 Light sensor day/night threshold: (0) 1 Lux, (1) 5 Lux, (2) 10 Lux, (3) 20 Lux, (4) 50

Lux, (5) 100 Lux, (6) Innite.

bit 0 LED indicator control: (0) Off, (1) On (default)

You can create custom command buttons by entering the Button name and the command

itself:

English

Below are some of the command samples:

Threshold 10% Brightness 100% FF012101bf0005E7

Threshold 20% Brightness 100% FF012101bf0007E9

Threshold 50% Brightness 100% FF012101bf0009EB

Brightness 90% FF012101bc0005E4

Brightness 80% FF012101b80005E0

Brightness 70% FF012101b40005DC

Brightness 60% FF012101b00005D8

Brightness 90% FF012101bc0007E6

Brightness 80% FF012101b80007E2

Brightness 70% FF012101b40007DE

Brightness 60% FF012101b00007DA

Brightness 90% FF012101bc0009E8

Brightness 80% FF012101b80009E4

19

Brightness 70% FF012101b40009E0

Brightness 60% FF012101b00009DC

The customized buttons will appear on the main page for easy access to IR control.

20

Loading...

Loading...