Page 1

SERVICE MANUAL

SERVICE MANUAL

GB

CO-3618

MPEG4 PLAYER

Page 2

CONTENTS

1. PRECAUTIONS -----------------------------------------------------------------------------------------------------------------------2

1-1 SAFETY PRECAUTIONS------------------------------------------------------------------------------------------------------------2

1-2 SERVICING PRECAUTIONS--------------------------------------------------------------------------------------------------------3

1-2-1 General Serving Precautions------------------------------------------------------------------------------------------------3

1-2-2 Insulation Checking Procedure ---------------------------------------------------------------------------------------------4

1-3 ESD PRECAUTIONS ---------------------------------------------------------------------------------------------------------------4

2. REFERENCE INFORMATION ----------------------------------------------------------------------------------------------------5

2-1 COMPONENT DESCRIPTIONS-----------------------------------------------------------------------------------------------------5

2-1-1 DVD SANYO HD65 PUH----------------------------------------------------------------------------------------------------5

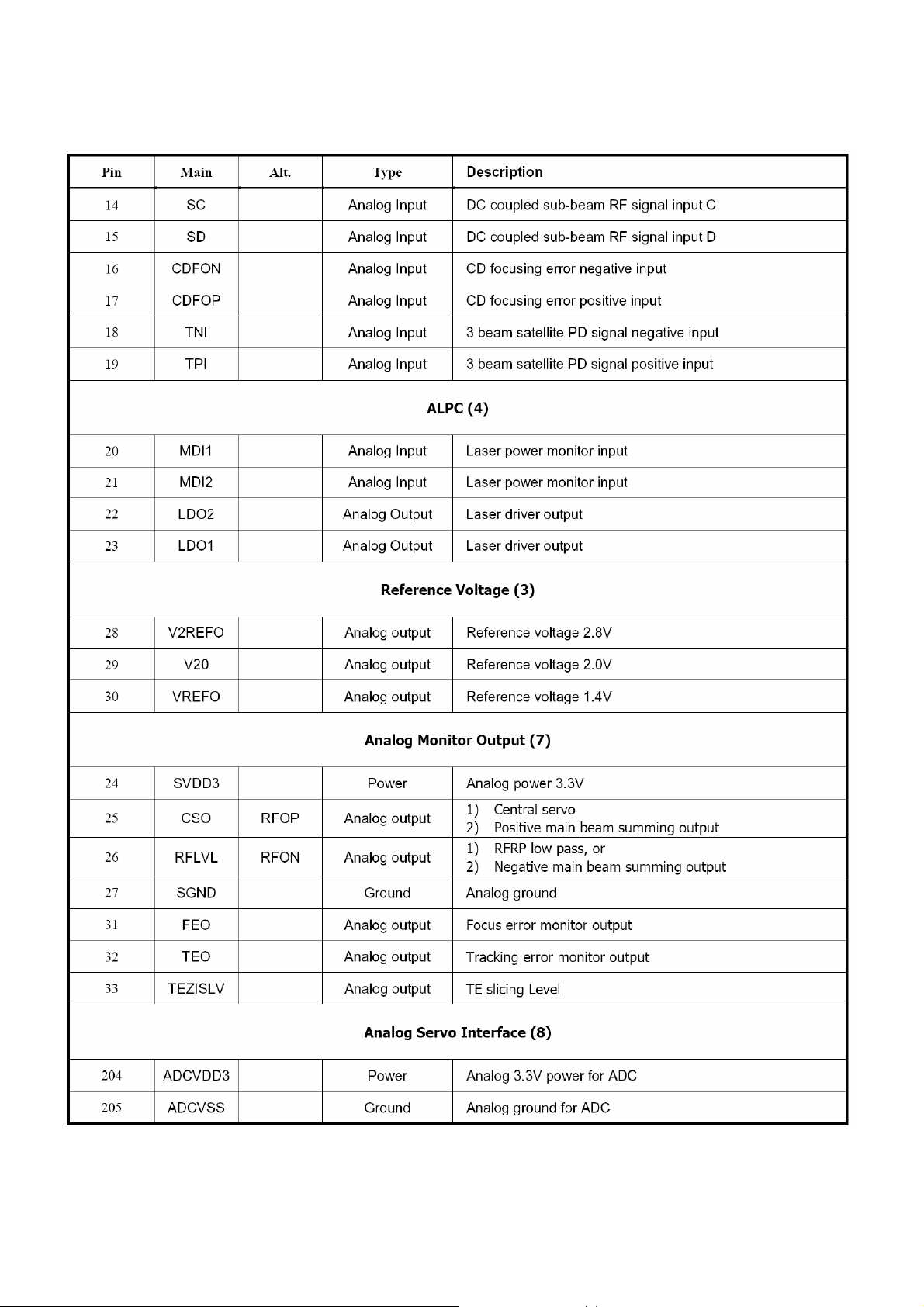

2-1-2 DVD Processor Chip MTK1389F ------------------------------------------------------------------------------------------7

2-1-3 Serial EEPROM, 2K (256 x 8) (24C02) or 16 K (2048 x 8) (24C16)------------------------------------------------ 22

2-1-4: FLASH MEMORY( CMOS 16M (2M 8/1M 16) BIT)

2-1-5 512K X 16 Bit X 2 Banks Synchronous DRAM (A43L0616) ---------------------------------------------------------- 25

3. PRODUCT SPECIFICATIONS -------------------------------------------------------------------------------------------------- 28

4. UPGRADING SYSTEM AND CHANGING THE REGION CODE------------------------------------------------------ 29

5. OPERATING INSTRUCTION---------------------------------------------------------------------------------------------------- 30

----------------------------------------------------------- 22

MAINTENANCE & TROUBLESHOOTING--------------------------------------------------------------------------------------------- 30

6.DISASSEMBLY AND REASSEMBLY------------------------------------------------------------------------------------------ 32

7.TROUBLESHOOTING ------------------------------------------------------------------------------------------------------------- 33

8. BLOCK DIAGRAM ----------------------------------------------------------------------------------------------------------------- 34

9. CIRCUIT DIAGRAMS ------------------------------------------------------------------------------------------------------------- 35

10. WIRING DIAGRAM:-------------------------------------------------------------------------------------------------------------- 36

- 1 -

Page 3

1. PRECAUTIONS

1-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1) Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

remove for servicing convenience.

(2) When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in

place all protective devices, including, but not

limited to, nonmetallic control knobs, insulating

fish papers, adjustment and compartment

covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or permit

it to be operated without all protective devices

correctly installed and functioning.

(2) Be sure that there are no cabinet opening through

which adults or children might be able to insert

their fingers and contact a hazardous voltage.

Such openings include, but are not limited to,

excessively wide cabinet ventilation slots, and an

improperly fitted and/or incorrectly secured

cabinet back cover.

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an

isolation transformer during this test.) Use a

leakage current tester or a metering system that

complies with American National Standards

institute (ANSI) C101.1 Leakage.

Current for Appliances and underwriters

Laboratories (UL) 1270 (40.7). With the

instrument’s AC switch first in the ON position and

then in the OFF position, measure from a known

earth ground (metal water pipe, conduit, etc.) to all

exposed metal parts of the instrument (antennas,

handle brackets, metal cabinets, screwheads,

metallic overlays, control shafts, etc.), especially

and exposed metal parts that offer an electrical

return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the

outlet and repeat the test.

AC Leakage Test

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wore

between the two prongs of the plug. (2) Turn on

the power switch of the instrument. (3) Measure

the resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic

cabinet parts on the instrument, such as

screwheads, antenna, control shafts, handle

brackets, etc. When an exposed metallic part has

a return path to the chassis, the reading should be

between 1 and 5.2 megohm. When there is no

return path to the chassis, the reading must be

infinite. If the reading is not within the limits

specified, there is the possibility of a shock hazard,

and the instrument must be re-pared and

rechecked before it is returned to the customer.

Insulation Resistance Test

- 2 -

Page 4

2) Read and comply with all caution and safety related

notes non or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter of add to the

mechanical or electrical design of this instrument.

Design alterations and additions, including but not

limited to, circuit modifications and the addition of

items such as auxiliary audio output connections,

might alter the safety characteristics of this

instrument and create a hazard to the user. Any

design alterations or additions will make you, the

service, responsible for personal injury or property

damage resulting there from.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts

(be sure that leads and components do not touch

thermally hot parts), (3) the AC supply, (4) high

voltage, and (5) antenna wiring. Always inspect in

all areas for pinched, out-of-place, or frayed wiring.

Do not change spacing between a component and

the printed-circuit board, Check the AC power

cord for damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/or

wiring that meet original specifications.

Additionally determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove and potential safety hazard.

6) Product Safety Notice-Some electrical and

mechanical parts have special safety-related

characteristics which are often not evident from

visual inspection, nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by shading, an (

schematics and parts lists. Use of a substitute

replacement that does not have the same safety

characteristics as the recommended replacement

part might created shock, fire and/or other

hazards. Product safety is under review

continuously and new instructions are issued

whenever appropriate.

) or a ( ) on

1-2 Servicing Precautions

CAUTION: Before servicing Instruments covered by

this service manual and its supplements, read and

follow the Safety Precautions section of this manual.

Note: If unforeseen circument create conflict between

the following servicing precautions and any of the

safety precautions, always follow the safety

precautions. Remember; Safety First

1-2-1 General Serving Precautions

(1) a. Always unplug the instrument’s AC power cord

from the AC power source before (1) removing or

reinstalling any component, circuit board, module

or any other instrument assembly. (2)

disconnecting any instrument electrical plug or

other electrical connection. (3) connecting a test

substitute in parallel with an electrolytic capacitor

in the instrument.

b. Do not defeat any plug/socket B+ voltage

interlocks with which instruments covered by this

service manual might be equipped.

c. Do not apply AC power to this instrument and/or

any of its electrical assemblies unless all

solid-state device heat sinks are correctly

installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before

connecting the test instrument positive lead.

Always remove the test instrument ground lead

last.

Note: Refer to the Safety Precautions section

ground lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When

servicing, follow the printed or indicated service

precautions and service materials.

(3) The components used in the unit have a specified

flame resistance and dielectric strength.

When replacing components, use components

which have the same ratings, by (

in the circuit diagram are important for safety or

for the characteristics of the unit. Always replace

them with the exact replacement components.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed

wiring board for safety. The internal wiring is

sometimes clamped to prevent contact with

heating components. Install such elements as

they were.

(5) After servicing, always check that the removed

screws, components, and wiring have been

installed correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades

of the attachment plus and accessible conductive

parts.

) or by ( )

- 3 -

Page 5

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and

turn the power ON. Connect the insulation resistance

meter (500V) to the blades of the attachment plug. The

insulation resistance between each blade of the

1-3 ESD Precautions

attachment plug and accessible conductive parts (see

note) should be more than 1 Megohm.

Note: Accessible conductive parts include metal

panels, input terminals, earphone jacks, etc.

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid static electricity) devices

can be damaged easily by static electricity.

Such compo9nents commonly are called

Electrostatically Sensitive Devices (ESD). Examples of

typical ESD devices are integrated circuits and some

field-effect transistors and semiconductor chip

components. The following techniques of component

damage caused by static electricity.

(1) immediately before handling any semiconductor

components or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available

discharging wrist strap device, which should be

removed for potential shock reasons prior to

applying power to the unit under test.

(2) after removing an electrical assembly equipped

with ESD devices, place the assembly on a

conductive surface such as aluminum foil, to

prevent electrostatic charge buildup or exposure

of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD device.

(4) Use only an anti-static solder removal devices.

Some solder removal devices not classified as

“anti-static” can generate electrical charges

sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before you

are ready to install it. (Most replacement ES

devices are packaged with leads electrically

shorted together by conductive foam, aluminum

foil or comparable conductive materials).

(7) Immediately before removing the protective

materials from the leads of a replacement ES

device touch the protective material to the chassis

or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling

unpackaged replacement ESD devices.

(Otherwise harmless motion such as the brushing

together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static

electricity sufficient to damage an ESD device).

- 4 -

Page 6

2. Reference Information

2-1 Component Descriptions

2-1-1 DVD SANYO HD65 PUH

Connector Pin Definition

I/F Signals I/O Pin #

F- 1

F+ 2

T+ 3

T- 4

C 5

D 6

CD/DVD 7

RF 8

A 9

B 10

F 11

GND-PD 12

VC 13

VCC 14

E 15

NC 16

VR-CD 17

VR-DVD 18

LD-CD 19

MD 20

HFM 21

NC 22

LD-DVD 23

GND-LD 24

- 5 -

Page 7

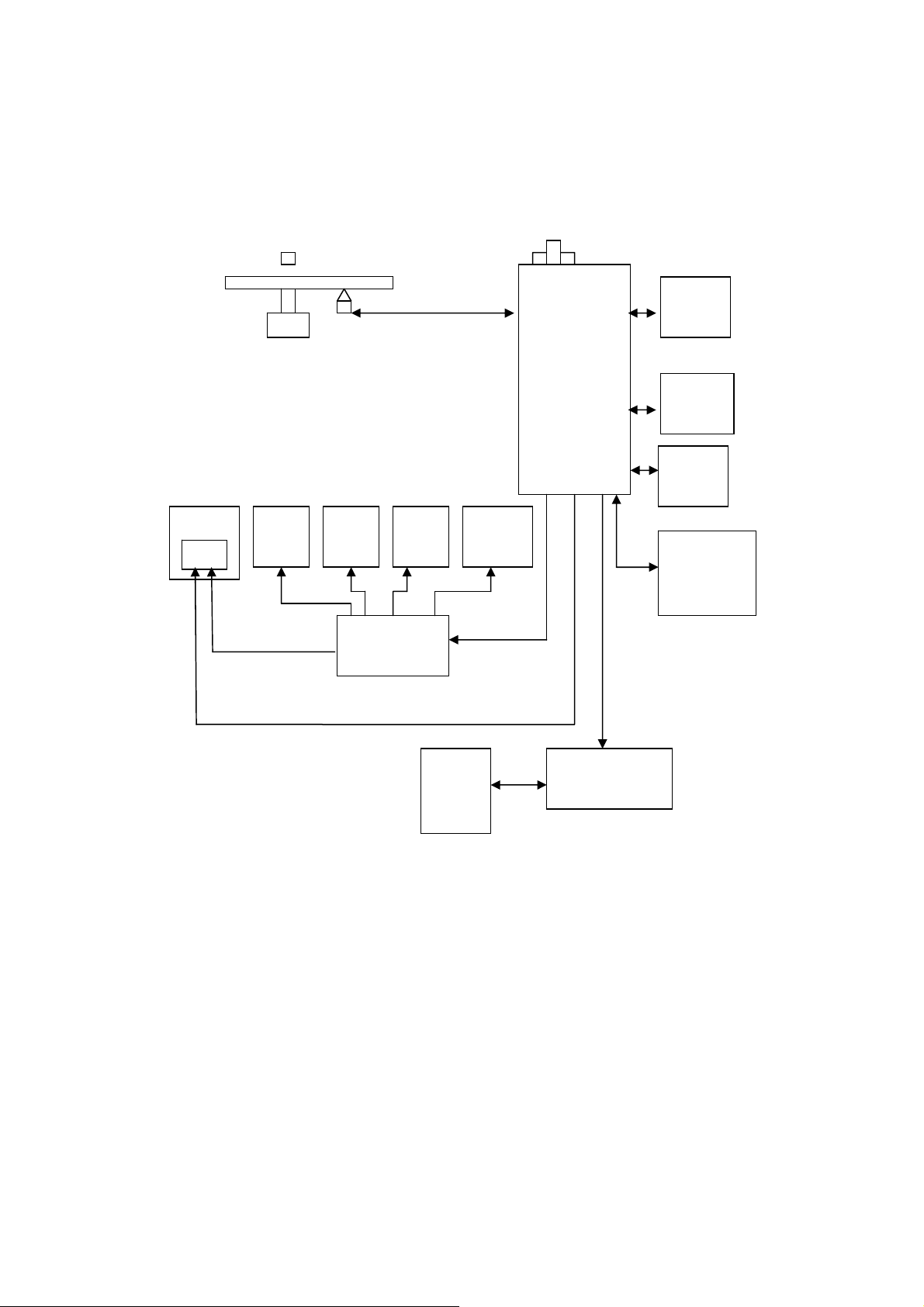

4. Block Diagram

Disc

Disc motor unit

Spindle

Motor

MT1389

(Decode/Servo)

ATAPI

Buffer Manager

Laser

pickup

Focus

Coil

Track

Coil

BA5954FP

4ch motor Drive

Sied

Motor

Loading

Motor

Demodulator

Error Correction

PLI

Focus & Tracking

Loading

SDROM

AuDdio

AMP

Video D/A

Filter

1/F

Conn

(front pannel)

Fiash

Memory

8Mbit

24CO2

System Controller

- 6 -

Page 8

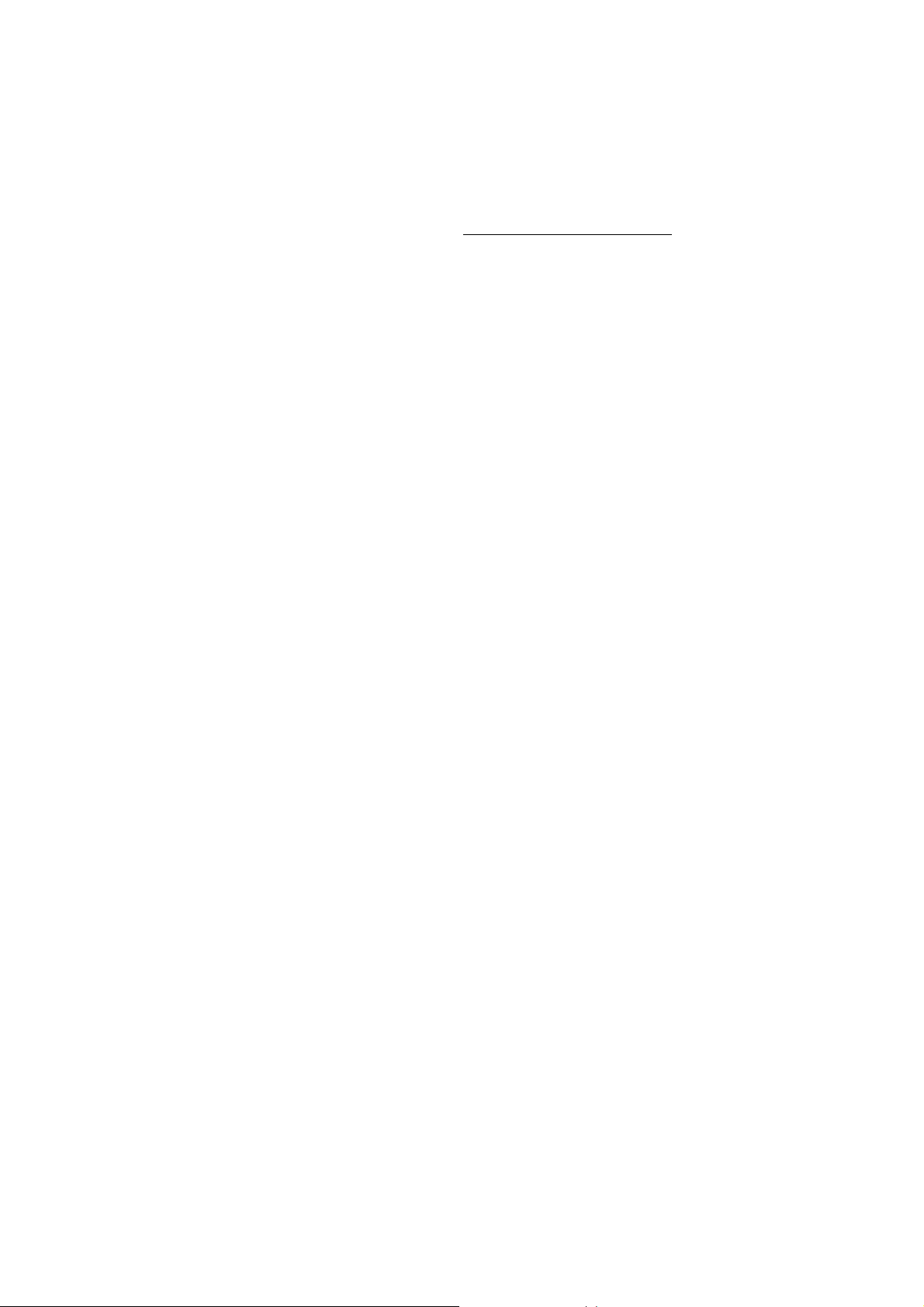

2-1-2 DVD Processor Chip MTK1389F

Features

Super Integration DVD player single chip

z High performance analog RF amplifier

z Servo controller and data channel processing

z Disc compatibility: DVD, DVD-R, DVD-RW, DVD+R, DVD+RW, Audio CD, CD-R, CD-RW, VCD, SVCD,

MP3-CD, MP3-DVD, PCM, JPEG-CD, JPEG-DVD

z Format compatibility:MPEG-1, MPEG-2, MPEG-4,

MP3, WMA, PCM, and JPEG & AVI

Dolby Digital, DTS

z Unified memory architecture

z Versatile video scaling & quality enhancement

z OSD & Sub-picture

z 2-D graphic engine

z Global motion compensation (GMC)

z Quarter pixel accurate motion Compensation (Q-PEL)

z B-frame

z Higher bit-rate up to 10 Mbps

z Full function remote control

z Plays regional code encrypted (RCE) DVDs

z Selectable 4:3 Pan & Scan or 16:9 Widescreen format

z PAL & NTSC playback

z Multi-speed FF/ RW, slow motion & multi level zoom

High Performance Analog RF Amplifier

z Programmable fc

z Dual automatic laser power control

z Defect and blank detection

z RF level signal generato

- Audio

z Dolby Digital (AC -3)/EX decoding

z DTS/DTS -ES decoding

z MLP decoding for DVD-Audio

z MPEG-1 layer 1/layer 2 audio decoding

z MPEG-2 layer1/layer2 2-channel audio

z High Definition Compatible Digital (HDCD)

z Windows Media Audio (WMA)

z Advanced Audio Coding (AAC)

z Dolby ProLogic II

z Concurrent multi-channel and downmix out

z IEC 60958/61937 output

-TV Encoder

z Six 108MHz/12bit DACs

z Support NTSC, PAL-BDGHINM, PAL-60

z Support 525p, 625p progressive TV format

z Automatically turn off unconnected channels

z Support PC monitor (VGA)

z Support Macrovision 7.1 L1, Macrovision 525P

z and 625P

DivX 3.11, DivX 4.x, DivX5.x (Need licence), Xvid,

- 7 -

Page 9

* Pinout Diagram

- 8 -

Page 10

PIN DESCRIPTON

- 9 -

Page 11

- 10 -

Page 12

- 11 -

Page 13

- 12 -

Page 14

- 13 -

Page 15

- 14 -

Page 16

- 15 -

Page 17

- 16 -

Page 18

- 17 -

Page 19

- 18 -

Page 20

- 19 -

Page 21

- 20 -

Page 22

- 21 -

Page 23

2-1-3 Serial EEPROM, 2K (256 x 8) (24C02) or 16 K (2048 x 8) (24C16)

24C02 is used for DVD player while 24C16 is for DVD receiver. The capacity is the only difference between

two kinds of serial EEPROM. Both of them use same package and have same pin configuration.

* Features

z Low-Voltage and Standard-Voltage Operation

-5.0 (V CC = 4.5V to 5.5V)

-2.7 (V CC = 2.7V to 5.5V)

-2.5 (V CC = 2.5V to 5.5V)

-1.8 (V CC = 1.8V to 5.5V)

z Internally Organized 128 x 8 (1K), 256 x 8 (2K), 512 x 8 (4K), 1024 x 8 (8K) or 2048 x 8 (16K)

z 2-Wire Serial Interface

z Schmitt Trigger, Filtered Inputs for Noise Suppression

z Bi-directional Data Transfer Protocol

z 100 kHz (1.8v, 2.5V, 2.7V) and 400 kHz (5V) Compatibility

z Write Protect Pin for Hardware Data Protection

z 8-Byte Page (1K, 2K), 16-Byte Page (4K, 8K, 16K) Write Modes

z Partial Page Writes Are Allowed

z Self-Timed Write Cycle (10 ms max)

z High Reliability

- Endurance: 1 Million Write Cycles

- Data Retention: 100 Years

-

- ESD Protection: >3000V

z Automotive Grade and Extended Temperature Devices Available

z 8-Pin and 14-Pin JEDEC SOIC, 8-Pin PDIP, 8-Pin MSOP, and 8-Pin TSSOP Packages

* Pin Configurations

* Pin Description

Pin Name Function

A0-A2 Address Inputs

SDA Serial Data

SCL Serial Clock input

WP Write Protect

NC No Connect

2-1-4: FLASH MEMORY( CMOS 16M (2M 8/1M 16) BIT)

GENERAL DESCRIPTION

The MBM29LV160TE/BE is a 16M-bit, 3.0 V-only Flash memory organized as 2M bytes of 8 bits each or 1M words

of 16 bits each. The MBM29LV160TE/BE is offered in a 48-pin TSOP (I), 48-pin CSOP and 48-ball FBGA

packages. The device is designed to be programmed in-system with the standard system 3.0 V VCC supply. 12.0

PP and 5.0 V VCC are not required for write or erase operations. The device can also be reprogrammed in

V V

standard EPROM programmers.

The standard MBM29LV160TE/BE offers access times of 70 ns and 90 ns allowing operation of high-speed

microprocessors without wait states. To eliminate bus contention the device has separate chip enable (CE), write

enable (WE), and output enable (OE) controls.

The MBM29LV160TE/BE is pin and command set compatible with JEDEC standard E

written to the command register using standard microprocessor write timings. Register contents serve as input

- 22 -

2PROMs. Commands are

Page 24

to an internal state-machine which controls the erase and programming circuitry. Write cycles also internally latch

addresses and data needed for the programming and erase operations. Reading data out of the device is similar

to reading from 5.0 V and 12.0 V Flash or EPROM devices.

The MBM29LV160TE/BE is programmed by executing the program command sequence. This will invoke the

Embedded Program

TM* Algorithm which is an internal algorithm that automatically times the program pulse widths

and verifies proper cell margins. Typically, each sector can be programmed and verified in about 0.5 seconds.

Erase is accomplished by executing the erase command sequence. This will invoke the Embedded Erase

TM*

Algorithm which is an internal algorithm that automatically preprograms the array if it is not already programmed

before executing the erase operation. During erase, the device automatically times the erase pulse widths and

verifies proper cell margins. (Continued)

(Continued)

Any individual sector is typically erased and verified in 1.0 second (if already preprogrammed).

The device also features sector erase architecture. The sector mode allows each sector to be erased and

reprogrammed without affecting other sectors. The MBM29LV160TE/BE is erased when shipped from the factory.

The device features single 3.0 V power supply operation for both read and write functions. Internally generated

and regulated voltages are provided for the program and erase operations. A low V

inhibits write operations on the loss of power. The end of program or erase is detected by Data Polling of DQ

by the Toggle Bit feature on DQ

6, or the RY/BY output pin. Once the end of a program or erase cycle has been

CC detector automatically

7,

completed, the device internally resets to the read mode.

The MBM29LV160TE/BE also has a hardware RESET pin. When this pin is driven low, execution of any

Embedded

Program Algorithm or Embedded Erase Algorithm is terminated. The internal state machine is then

reset to the read mode. The RESET pin may be tied to the system reset circuitry. Therefore, if a system reset

occurs during the Embedded Program Algorithm or Embedded Erase Algorithm, the device is automatically

reset to the read mode and will have erroneous data stored in the address locations being programmed or

erased. These locations need re-writing after the Reset. Resetting the device enables the system’s microprocessor

to read the boot-up firmware from the Flash memory.

Fujitsu’s Flash technology combines years of Flash memory manufacturing experience to produce the highest

levels of quality, reliability, and cost effectiveness. The MBM29LV160TE/BE memory electrically erases all bits

within a sector simultaneously via Fowler-Nordhiem tunneling. The bytes/words are programmed one byte/word

at a time using the EPROM programming mechanism of hot electron injection.

Embedded EraseTM and Embedded ProgramTM are trademarks of Advanced Micro Devices, Inc.

*:

- 23 -

Page 25

- 24 -

Page 26

2-1-5 512K X 16 Bit X 2 Banks Synchronous DRAM (A43L0616)

Features

JEDEC standard 3.3V power supply

LVTTL compatible with multiplexed address

Dual banks / Pulse RAS

MRS cycle with address key programs

- CAS Latency (2,3)

- Burst Length (1,2,4,8 & full page)

- Burst Type (Sequential & interleave)

All inputs are sampled at the positive going edge of the system clock

Burst Read Single-bit Write operation

DQM for masking

Auto & self refresh

64ms refresh period (4K cycle)

50 Pin TSOP (II)

- 25 -

Page 27

Pin Configuration

- 26 -

Page 28

Block Diagram

Pin Descriptions

Symbol Name Description

CLk System Clock Active on the positive going edge to sample all inputs

CS Chip Select Disables or Enables device operation by masking or enabling

all inputs except CLK, CKE and L(U)DQM

Masks system clock to freeze operation from the next clock cycle.

CKE Clock Enable

CKE should be enabled at least one clock + tss prior to new

command.

Disable input buffers for power down in standby.

A0~A10/AP Address

Row/Column addresses are multiplexed on the same pins.

Row address: RA0 ~ RA10, Column address: CA0 ~ CA7

BA Bank Select Address

Selects bank to be activated during row address latch time.

Selects band for read/write during column address latch time.

RAS Row address Strobe

Latches row addresses on the positive going edge of the CLK with

RAS low.

Enables row access & precharge.

CAS

Column Address Strobe

Latches column addresses on the positive going edge of the CLK

with CAS low. Enables column access.

WE Write Enable Enables write operation and Row precharge.

L(U)DQM

Data Input/Output Mask

Makes data output Hi-Z, t SHZ after the clock and masks the output.

Blocks data input when L(U)DQM active.

DW0-15 Data Input/Output Data inputs/outputs are multiplexed on the same pins.

VDD/VSS Power Supply/Ground Power Supply: +3.3V±0.3V/Ground

VDDQ/VSSQ

Data Output

Provide isolated Power/Ground to DQs for improved noise immunity.

Power/Ground

NC/RFU No Connection

- 27 -

Page 29

3. Product Specifications

Playback System

DVD Video

Video CD (1.1, 2.0, 3.0)

SVCD and CVD

CDDA

CD-ROM with MP3 data

PICTURE CD

Television Signal System

NTSC/PAL

Video Performance

Video Out 1 Vpp into 75 ohm

S-Video Out Y: 1Vpp into 75 ohm

C: 0.286 Vpp into 75 ohm

D/A Converter 27MHz/10bit

Audio Performance

Frequency

Response

Output Level Analog: 2Vrms(1KHZ)

D/A Converter 96KHz/24bit

S/N Ratio 90dB

Connections

Coaxial digital out X1

Audio Analog out for 2-channel X1

S-Video out X1

Power Supply

Power Source AC 230V, 50Hz

Power Consumption 15 Watt

Set

Dimensions (W X H X D) 360 X 45 X 270 (mm)

Net Weight 2.2 Kg

Gross Weight 3.0 Kg

DVD VIDEO (PCM 96KHz) 20Hz~44KHz(±1dB)

DVD VIDEO (PCM 48KHz) 20Hz~22KHz(±0.5dB)

CD: 20Hz~22KHz(±0.5dB)

Digital: 1.15 Vpp

- 28 -

Page 30

4. Upgrading System and Changing the Region

Code

MTK upgrade:

1. Name upgrade file as "MTK.BIN"(must be in big caps)

2. Record it in a CD-R/W (It can be enclosed a sub-directory which size is about 30M, and the file content can

be letter or non used file.)

disc Format: (advise to use the tool NERO burning ROM)

Disc volume: MEDIATEK, ISO9660 LEVEL1, MODE1,not JOILET.

3. Put the recorded disc into the DVD player, on the TV will show "upgrade?" after loading. Press PLAY button,

the player will automatically upgrade.

4. Do not shut down the player during upgrade, it will restart automatically after upgrade.

5. Upgrade finish!

How to change the region code:

1. Power on the machine, and press OPEN button to push the tray out.

2. Press SETUP button to enter the SETUP menu, and go to the PREFERENCE item by pressing left

button, then press 5 buttons in turn: 4,9,5,4,0

3. A edit box will be displayed, you can change the region code to 1-6 with UP/DOWN button, the num 0

means REGION FREE. And then press SETUP button to exit (FOR 1379)

4. A item named VERSION will be displayed, get into the page, you can change the region code to 1-6

with UP/DOWN button, the num 0 means REGION FREE. And then press SETUP button to exit (for

1369)

- 29 -

Page 31

5. Operating Instruction

Please refer to the User’s Manual for the operating instruction

of the system.

Maintenance & Troubleshooting

How to handle discs Disc Compatibility

To handle, clean and protect discs

● Do not touch the playing side of a disc

● Do not stick any paper or glue strip on a

disc.

How to clean discs

● Finger prints and dust on surface can

affect the sound and picture quality.

Clean discs regularly with a soft cotton

cloth from disc center to outside.

● For sticky dust, wipe it with wet cloth and

with dry cloth, Any kind of solvent, such

as diluting agent, gasoline, liquid

detergent, gasoline liquid detergent anti

– static aerosol used for vinylon LP, may

cause disc damage.

How to protect discs

● Keep away from the direct sunshine or

any heat source.

● Do not put discs in damp or dirty places,

such as bathroom or near humidifiers.

Store discs vertically in disc box and

store in a dry place. Piling discs on to top

of each other or excess weight load on

disc box may cause the disc to warp.

● Some DVD discs may have special

requirements for playing, with which this player

may not be compatible. Please refer to

specifications on individual disc.

DISC

TYPE

DVD

CD-DA AUDIO 12CM About 74 minutes

MP3 AUDIO 12CM About 300 minutes

Content Size Total Play time

About 2hrs.

(Single side & single

layer)

About 4hrs.

(Single side & double

AUDIO/

VIDEO

12CM

layer)

About 4hrs.

(Double side & Single

layer)

About 8hrs.

(Double side & double

layer)

Discs types

This DVD player can play the following types of

discs: Discs other than listed above cannot be

player by this player.

This player uses NTSC/PAL color system. It cannot

play discs recorded with other systems, such as

SECAM.

Region code

The region code for this player is 5, which

indicates the applicable. The disc with code

number other than 5 cannot be player on this

player and screen will indicate the unconformity.

Copyright

According to the related law, DVD discs without

proper authorization are not allowed to be copied

broadcast cable broadcast, played publicly or

rented. As DVD discs are anti-piracy the copied

content is distorted.

TV system

Connect this player to a PAL/NTSC compatible TV.

- 30 -

Page 32

Problems and Solutions

If a fault occurs, first check the points listed below before taking the set for repair.

If you are unable to remedy a problem by following these hints, consult your

dealer or service centre.

WAR NING: Under no circumstances should you try to repair the set yourself, as this would invalidate the

guarantee.

Problems Cause Solution

No power

indication

No picture

No sound

Picture

distortion

Brightness

unstable or

noisy

The player

does not

work

No response

to key press

Remote

control does

not work

Battery power exhausted Replace with new batteries.

Power plug not connected

TV has not been set to the

correct video input

Video cable not firmly

connected.

Audio cable not connected

tightly

Power of audio apparatus is

off

Audio output setting is

incorrect

Disc is dirty

Fast forward/backward is

activated

Affected by anti-piracy circuit

No disc Load a disc.

Disc not compatible

Tdohe disc is placed upside

wn

The disc not put in the tray

correctly

Disc is dirty Clean the disc.

Player setting are incorrect Change the setting via the setup menu.

Parental lock is in effect Disable this function or reset the rating level.

Interference of power wave or

other factors such as static

interference

The remote control not

pointed at the remote sensor

on the front panel of the

player

The remote control is out of

specified range

Note:

This produce incorporates copyright protection technology that is protected by method claims of certain of

certain U.S. patent and other intellectual Property rights owned by Macrovision Corporation and other rights

owners. Use of this copyright protection technology must be authorized by Macrovision Corporation and is

intended for home and other limited viewing users only, unless otherwise authorized by Macrovision

Corporation. Reverse engineering or disassembly is prohibited.

Plug the power cord into the power supply

Set correct TV video input format for receiving

the player’s output signals.

Firmly insert the video cable ends to the

related terminals.

Firmly insert the audio cable ends to the

related terminals.

Turn on the power of audio apparatus.

Setup audio output correctly via the setup

menu.

Take out the disc and clean.

The picture may be distorted during fast

forward /backward playback.

Connect the player directly to TV.

Load a compatible disc (Check the disc format

and its colour system).

Load a compatible disc (Check the disc format

and its colour system).

Check disc is put in correctly.

Turn off the main switch or pull out the power

plug, plug it in and turn on the power again.

Point the remote control at the remote sensor.

Make sure the remote control range within 7

meters to the remote sensor.

- 31 -

Page 33

6.Disassembly and Reassembly

- 32 -

Page 34

A

7.Troubleshooting

No power Insert the AC power plug securely into the power outlet.

Make sure that the equipment is connected properly.

No picture

No sound Make sure that the equipment is connected properly.

Distorted sound

No fast forward or fast reverse

No proper aspect ratio

No operations can be performed

with the remote controller

No button operation

udio soundtrack and/or Subtitle

language is not the one you

selected.

No Angle change

Make sure that the input setting for TV is Video (AV).

Make sure that the input settings for the TV and stereo system are

correct.

Some discs may have sections that prohibit fast forward or fast

reverse.

Select the correct setup for TV aspect ratio that matches your TV

set.

Check the batteries are installed with the correct polarities.

Point the remote control unit at the remote control sensor and

operate.

Remove the obstacles between the remote control unit and remote

control sensor.

Set the POWER button to OFF and then back to ON.

Alternatively, turn off the power, disconnect the power plug and

then reconnect it.

If the audio soundtrack and /or subtitle language does not exist on

the disc, the language selected at the initial settings will not be

seen.

This function is dependent on software availability. Even if a disc

has a number of angles recorded, these angles may be recorded

for specific scenes only.

- 33 -

Page 35

8. Block Diagram

- 34 -

Page 36

9. Circuit Diagrams

R42

10K

AVCC

0.1U

C39

RFVDD3

R118

100U/16V

6.8

E11

C114

0.1U

PLLVDD3

V1P4

[1,2]

[1]

JITFN

[1]

JITFO

[1]

X1

[1]

XO

APLLVDD3

AADVDD3

DV33

V18

[1,2]

100K

D-3

G-1

S-2

2SK3018

SPP11N60C3

Q9

J5

SANYO_DU34

HD60-24SMD

FOC-

FOC+

RAD+

RAD-

LDSW

RFO

GND4

V20

VCC2

GND3

DVD_VR

CD_VR

CD_LD

MDI

VCC1

GND2

DVD_LD

GND1

DMSO

[2]

FMSO

[2]

TRSO

[2]

[2]

FOSO

V1P4

R51

C

D

A

B

F

E

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

G

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(13)

(14)

(15)

(17)

(18)

(19)

(20)

(21)

(23)

Q7

3904

S

D

R38

0

FF+

T+

TC

D

IOA

RFO

A

B

F

V20

AVCC1

E

DVD_VR

CD_VR

LD_CD

MD11

AVCC1

LD_DVD

CD_VR

100U/10V

C5

0.015U

R35

S

D

SPP11N60C3

2SK3018

Q8

R36

0

DVD_VR

E15

G

C81

0.1U

10K

R37

100K

C106

0.1U

V20

C83

330P

[1]

600/0603

C3

330P

R11

1

AVCC

[1,2]

FF+

T+

T-

R12

150K

L2

10uH

[2]

[2]

[2]

[2]

FB11

V1P4

IOA

10uH

L1

R27

R95

R97

R29

OP+

[1]

Q6

8550

Q5

8550

47U/10V

[3]

[3]

[2]

R13

R32

B-1

E6

10K

15K

[2]

18K

20K

VSYNC#

HSYNC#

C8

C-3

E-2

TROPEN

STBY

V18

2200P

680K

R34

R33

680K

LDO2

LDO1

C13

C15

C105

C10

0.1U

OPO

4.7

4.7

C16

1U

C17

1U

C14

C109

RFVDD3

0.1U

[1]

[1]

E9

47U/16V

RFV33

E8

47U/16V

1U

1U

1U

NC

V2P8

C9

0.1U

R31

A2

A3

A4

A5

A6

A7

A8

V20

OP-

OP+

RFVDD3

100K

R45

C99

15K

R49

0.1U

RFVDD3

C25

0.1U

1

AGND

2

DVDA

3

DVDB

4

DVDC

5

DVDD

6

DVDRFIP

7

DVDRFIN

8

MA

9

MB

10

MC

11

MD

12

SA

13

SB

14

SC

15

SD

16

CDFON

17

CDFOP

18

TNI

19

TPI

20

MDI1

21

MDI2

22

LDO2

23

LDO1

24

SVDD3

25

CSO/RFOP

26

RFLVL/RFON

27

SGND

28

V2REFO

29

V20

30

VREFO

31

FEO

32

TEO

33

TEZISLV

34

OP_OUT

35

OP_INN

36

OP_INP

37

DMO

FMO

TRO

FOO

0

ADIN

DMO

38

FMO

39

TROPENPWM

40

PWMOUT1/ADIN0

41

TRO

42

FOO

43

FG/ADIN1

44

GPIO0/VSYNC#

45

GPIO1/HSYNC#

46

GPIO2

47

IOA2

48

DVDD18

49

IOA3

50

IOA4

51

IOA5

52

IOA6

53

IOA7

54

HIGHA0

C98

0.1U

212

213

214

215

216

OSP

OSN

IREF

RFGC

AVDD3

IOA1856I0A1957IOWR#58A1659HIGHA760DVDD361HIGHA662HIGHA563HIGHA464HIGHA365HIGHA266HIGHA167IOA2068IOCS#69IOA170I00E#71AD072AD173AD274DVSS75AD376AD477AD578AD679IOA2180ALE81AD782A1783IOA084DVDD18

55

C34

0.1U

0.033U

C91

210

211

RFGND

CRTPLP

1000P

C26

208

209

HRFZC

RFRPAC

20P

0.1U

C24

C33

RFVDD3

205

206

207

RFRPDC

RFVDD3

0.047U

C29

202

203

204

LPFOP

ADCVSS

ADCVDD3

LPFIN

0.047U

C28

200

201

LPFIP

10U/10V

0.47U/NC

E17

C36

PLLVDD3

197

198

199

LPFON

PLLVDD3

IDACEXLP

195

196

JITFN

JITFO

PLLVSS

MT1389E

193

194

XTALI

U4

RFV18

191

192

XTALO

RFVDD18

RFGND18

ADACVDD3

187

188

189

190

ALF(CTR)

ADACVDD1

ADACVDD2

ALS/SDATA0

C32

0.1U

175

176

177

AKIN1

AADVDD

APLLVDD

10U/10V

E16

ADVCM

172

173

174

AKIN2

ADVCM

171

AADVSS

100

180

181

182

ARF(SW)

ADACVSS1

ADACVSS2

C90

1500P

178

179

APLLVSS

APLLCAP

10U/10V

E28

183

184

185

186

ARS

AVCM

AL/SDATA2

AR/SDATA1

UWR#86URD#87DVDD388UP1_289UP1_390GPIO691UP1_492UP1_593UP1_694UP1_795UP3_096UP3_197UP3_498UP3_599GPIO7

85

165

166

167

168

169

170

B/CB/SC

DACVSSB

DACVSSA

DACVDDA

G/Y/SY/CVBS

R/CR/CVBS/SY

ICE

PRST#

INTO#

DQMO#

RD7

101

102IR103

104

105

106

163

164

CVBS

DACVSSC

DACVDDB

VREF

DACVDDC

SPDIF

MC_DATA

ASDATA3

ASDATA2

ASDATA1

ASDATA0

ALRCK

ACLK

ABCK

GPIO5

DVSS

GPIO4

GPIO3

DVDD18

RA4

RA5

RA6

RA7

RA8

RA9

RA11

CKE

DVDD3

RCLK

RA3

RA2

RA1

DVDD18

RA0

RA10

BA1

BA0

RCS#

RAS#

CAS#

RWE#

DQM1

RD8

RD9

DVSS

RD10

RD11

RD12

RD13

RD14

RD15

RD0

RD1

RD2

RD3

RD4

RD6

RD5

DVDD3

107

108

FS

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

FS

VREF

MA4

MA5

MA6

MA7

MA8

MA9

MA11

MA3

MA2

MA1

MA0

MA10

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DQ0

DQ1

DQ2

DQ3

DQ4

DACVDD3

ASPDIF

RGB-SWITCH

FS1

FSO

ASDATA0

MA[0:11]

DQ[0:15]

[3]

[3]

[3]

[2]

[2]

[3]

[1]

[2]

0.1U

TROUT

TRIN

LIMIT

BA1

BA0

CS#

RAS#

CAS#

WE#

DQM1

C22

[2]

[2]

[1]

DCKE

DCLK

[3]

[3]

[3]

[3]

[3]

[3]

[3]

[3]

[3]

R19

560

ACENTER

ALS

AL

AR

ARS

ASUBW

[1]

AKIN-1-2

R

VB

G

CVBS

JITFO

[2]

[2]

[2]

[2]

[2]

[2]

[1]

[1]

[3]

[3]

[3]

[3]

[2]

XO

X1

Y2

27MHz

R39

390P

C30

2.7uH

100K

R46

750K

L3

C37

1000P

C38

33P

C42

33P

JITFN

[1]

C92

0.1U

V20

47U/10V

TO_AV/6P_2.0

E7

C12

0.1U

C6

2200P

URST#

[1]

A[0:21]

AD[0:7]

C110

0.1U

C97

0.1U

J3

[3]

[1]

[3]

[3]

[2]

DV33

DOWNLOAD/4P_2.0

1

2

RXD

3

TXD

4

TRCLOSE

IOA

[1]

DQ7

DQ6

DQ5

DQM0

URST#

SDA

SCL

A1

A9

A18

A19

A16

A14

A15

[3]

[3]

VCC

IR

VSTB

VSCK

VSDA

100U/16V

J4

1

2

3

4

5

6

7

PWR#

[3]

E31

A13

C74

0.1U

A20

A10

A12

A11

VCC

R21

10K

C77NCC84NCC101

PCE#

[3]

AD0

PRD#

[3]

AD1

VCC

AD2

NC

AD3

R3

10K

AD4

AD5

AD6

R5

10K

ASDATA0

A21

AD7

R10

10K

A17

A0

[1]

R25

10

C4

100P

C111

0.1U

C113

0.1U

C27

0.1U

C107

0.1U

C88

0.1U

C93

0.1U

C89

0.1U

C95

0.1U

C96

0.1U

DV33

D1

OP-

R104

10K

E5

100U/16V

SP-

[2]

DV33

R4

10K

SPI-

6

5

4

3

2

1

J1

V2P8

E10

47U/10V

SP+

LIMIT

SLSL+

C11

0.1U

[2]

[2]

[2]

[1]

150K

R30

1N4148

Page 37

VCC

R82

4.7K

D15

1N4148

Q16

3906

D14

1N4148

E38

100U/16V

+12V

R81

22K

R80

470

E34

100U/16V

Q13

3906

AUDIO_MUTE

-12V

R77

100K

R23

100

A_MUTE

J6

[2]

Q14

FB26

FB25

LCH

RCH

[3]

[3]

R7

0 OR NC

AL

[1]

+12V

-12V

1

2

3

4

D10

AKIN-1-2

VCC

R52

[1]

75

[1]

AR

E30

10U/16V

R8

10K

E29

10U/16V

R63

10K

R65

10K

C48

1000P

C49

1000P

R68

30K

R71

5.1K

R70

30K

R76

5.1K

C51

2

3

C52

6

5

100P

A_MUTE

A_MUTE

R86

560

R84

560

Q15

3904

3904

E36

-

+

U9-A

-

+

1

100P

7

U9-B

10U/16V

[2]

E35

10U/16V

[2]

[1]

FSO

+12V

R43

R44

2.2K

1K

R28

1K

Q1

3904

SCART

R48

2.2K

R47

75

Q2

3904

[3]

ASPECT

[2]

DV33

REGO1

TRB1

[2]

Q22

SS8550

R58

R59

10K

10K

D11

R62

R64

10K

10K

Q23

SS8550

V18

TRB2

REGO2

[2]

[2]

[1]

[1]

ASUBW

[1]

ALS

ACENTER

R14

0 OR NC

E44

10U/16V

R15

0 OR NC

E41

10U/16V

R16

0 OR NC

E46

10U/16V

R41

10K

R128

10K

R67

10K

C69

1000P

C65

1000P

C124

1000P

R69

30K

R78

5.1K

R55

30K

R56

5.1K

R129

30K

R130

5.1K

C123

2

3

C68

2

3

C128

6

5

-

+

-

+

-

+

100P

U10-A

100P

U11-B

100P

U11-A

1

7

1

[2]

[2]

[2]

E43

10U/16V

A_MUTE

E40

10U/16V

A_MUTE

E45

10u/16v

A_MUTE

R66

560

R108

560

3904

3904

R40

560

3904

Q19

Q12

Q10

FB31

FB29

FB32

SUB

LSCH

CENT

[3]

[3]

[3]

[2,3]

[1]

MO_VCC

RGB-SWITCH

VCC

[1]

[2]

[1]

[1]

[1]

[1]

[1]

[1]

[1]

R20

4.7K

R18

SL+

FMSO

TRB2

TRSO

V1P4

STBY

R26

T+

SL-

[1]

FS1

FB30

RSCH

[3]

R94

10K

R57

30K

R22

5.1K

DV33

R93

10K

C23

0.1U

R17

68

2.2K

T-

10K

R50

Q3

3906

C75

0.1U

15

16

17

18

19

20

21

22

23

24

25

26

27

28

VOTK+

VOTKVOLD+

VOLDVCC2

NC

VCTL

GND

VINLD

NC

TRB2

VINTK

BIAS

MUTE

R24

4.7K

U6

C63

0.1U

VOFC+

VOFCVOSL-

VOSL+

VOTR+

VOTR-

VCC

REV

FWD

REGO1

VINSL+

REGO2

TRB1

VINFC

[3]

RGB-SW

14

13

12

11

10

9

8

7

6

5

4

3

2

1

F+

[1]

F-

[1]

SP-

[1]

SP+

[1]

LOAD+

[2]

LOAD-

[2]

TROPEN

TRCLOSE

REGO1

DMSO

REGO2

TRB1

FOSO

[2]

[2]

[1]

[1]

[1]

[2]

[1]

MO_VCC

C2

0.1U

E1

100U/16V

[1]

ARS

0 OR NC

E26

10U/16V

[2]

[2]

R60

10K

[1]

[1]

C64

1000P

TRIN

TROUT

LOAD+

LOAD-

C47

6

5

-

+

100P

U10-B

7

[2]

TRAY/5P_2.0

1

2

3

4

5

E42

10U/16V

A_MUTE

J2

R61

560

Q11

3904

MOTOR DRIVER SECTION

Page 38

R1 WAITING TO DEBUG

16MFLASH R20

32MFLASH R20 R21

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

[1]

[1]

[1]

PRD#

PCE#

PWR#

28

12

26

11

14

25

24

23

22

21

20

19

18

48

17

16

10

15

8

7

6

5

4

3

2

1

9

R2

R1

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

G

RP

RB

E

W

(WP)

A[0:21]

U2

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15A-1

BYTE

(VPP)

VSS0

VSS1

VCC

10K

10K

29

31

33

35

38

40

42

44

30

32

34

36

39

41

43

45

47

13

27

46

37

[1]

AD[0:7]

C35

0.1U

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

A0

C1

0.1U

[1]

FB17

600/0603

E4

100U/16V

DV33

DBA0

[1,3]

[1,3]

SDCLK

SDCKE

DCS#

DRAS#

DCAS#

DWE#

DQM0

DQM1

MA[0:11]

[1,3]

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

21

22

23

24

27

28

29

30

31

32

20

19

35

34

18

17

16

15

14

36

33

37

26

50

GND_D

KM416S1020BT

A0

A1

A2

A3

U5

A4

A5

A6

A7

A8

A9

A10

BS/A11

CLK

CKE

CS

RAS

CAS

WE

LDQM

UDQM

NC

NC/VREF

GND3

GND6

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VCC1

VCC4

VCC2

VCC3

VCC5

VCC6

GND1

GND2

GND4

GND5

DQ[0:15]

2

DQ0

3

DQ1

5

DQ2

6

DQ3

8

DQ4

9

DQ5

11

DQ6

12

DQ7

39

DQ8

40

DQ9

42

DQ10

43

DQ11

45

DQ12

46

DQ13

48

DQ14

49

DQ15

1

25

7

13

38

44

4

10

41

47

SD33

GND_D

[1,3]

DV33

FB16

600/0603

100U/10V

E12

FB6

FB10

FB18

FB19

FB20

FB21

FB22

0.1U

C66

GND_D

600/0603

600/0603

600/0603

600/0603

600/0603

600/0603

600/0603

0.1U

C67

0.1U

C70

GND_D

0.1U

C71

0.1U

C72

SD33

0.1U

C73

[1]

[1]

[1]

[1]

0.1U

C7

[1]

[1]

[1]

[1]

BA0

BA1

DCLK

DCKE

CS#

RAS#

CAS#

WE#

RN2

RN1

[1,3]

[1,3]

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

MA[0:11]

33X4

33X4

[1,3]

DQM0

DQM1

DBA0

DBA1

SDCLK

SDCKE

DCS#

DRAS#

DCAS#

DWE#

23

24

25

26

29

30

31

32

33

34

22

35

20

21

38

37

19

18

17

16

15

39

64MB_SDRAM

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

BA0

BA1

CLK

CKE

CS

RAS

CAS

WE

DQML

DQMH

U3

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VCC1

VCC2

VCC3

VCCQ1

VCCQ2

VCCQ3

VCCQ4

VSSQ1

VSSQ2

VSSQ3

VSSQ4

VSS1

VSS2

VSS3

2

4

5

7

8

10

11

13

42

44

45

47

48

50

51

53

1

14

27

3

9

43

49

6

12

46

52

28

41

54

DQ[0:15]

SD33

[1,3]

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

GND_D

DV33

DV33

FB12

FB8

0.1U

600/0603

220U/10V

E25

600/0603

C21

ADACVDD3

6800P

C44

DACVDD3

10U/10V

E13

RFVDD3

C20

2200P

DV33

C19

0.01U

FB1

1000U/10V

600/0603

C18

0.1U

600/0603

E20

RFV33

FB13

AADVDD3

6800P

C87

C43

0.1U

24C02

1

A0

2

A1

3

A2

4

GND5SDA

U1

VCC

WP

SCL

8

7

6

DV33

R61KR9

1K

SCL

SDA

[1]

[1]

[1]

[1]

CVBS

VCC

D4

BA99

CVBS0

[3]

VCC

[3]

[3]

[1]

B/U

R/V

ASPDIF

J10

1

2

3

4

5

R73

75

C55

220P

L6

L

C59

100P

VCC

L

L7

G

R74

75

[3]

G/Y

C56

220P

C60

100P

1

D7

1N4148

D6

1N4148

YUV

J8

G/Y

[3]

[2,3]

[2,3]

[3]

[2]

[2]

[3]

[3]

[3]

[1]

[1]

RCH

LCH

CVBS0

RGB-SW

ASPECT

R/V

G/Y

B/U

HSYNC#

VSYNC#

12

11

10

9

8

7

6

5

4

3

2

1

J12

2

[3]

R/V

3

DV33

FB15

600/0603

C40

0.1U

RFV33

E18

47U/16V

+5V

FB9

C41

0.1U

POWER CON

AVCC

600/0603

E24

47U/10V

E19

220U/10V

E22

47U/10V

V18

C94

0.1U

FB2

RFV18

600/0603

C31

0.1U

[3]

[3]

CVBS0

B/U

L

VB

[1]

DV33

FB14

600/0603

E21

47U/10V

MO_VCC

FB5

7

6

+5V

5

4

3

2

1

+P12

-P12

FB23

FB24

FB4

FB3

L

L

VCC

L

L

600/0603

C50

0.1U

C100

0.1U

+12V

E32

100U/16V

220U/10V

E14

-12V

C53

0.1U

APLLVDD3

C117

0.1U

E37

100U/16V

100U/10V

E23

G1

NEW_PART1

R

X2

X3

2

1

2

[1]

R75

75

R72

75

C57

220P

C54

220P

L5

L

J7

L8

C61

100P

C58

100P

4

5

6

[2,3]

[2,3]

J11

AUDIO2

[2,3]

LCH

RCH

LCH

1

2

3

4

5

VCC

VCC

D9

1N4148

D8

1N4148

D3

1N4148

SC

SY

R/V

B/U

[3]

[3]

[2,3]

[2]

[2]

[2]

[2]

RCH

LSCH

RSCH

CENT

SUB

10

11

12

13

14

6

7

8

9

D2

1N4148

VIDEO FILTER

Page 39

10. Wiring Diagram:

Output

to

Amplifier

Power

AV Output Board

Output

to

TV

Transformer

Power

Audio

stream

Video

stream

MPEG Board

Loader is

on the MPEG board

Front Panel

Control

Stream

- 38 -

Loading...

Loading...