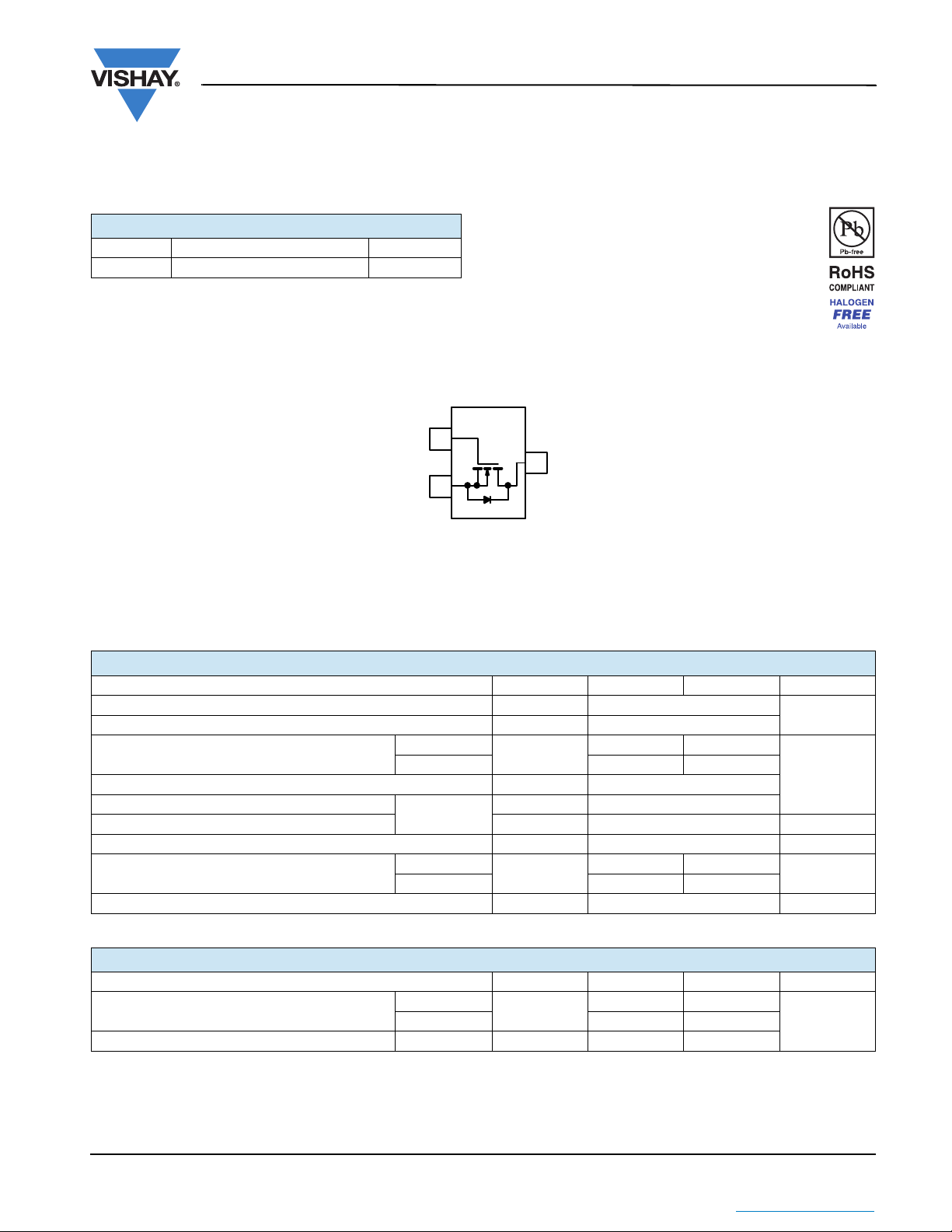

N-Channel 100 V (D-S) MOSFET

G

S

D

Top View

2

3

TO-236

(SOT-23)

1

Si2328DS (D8)*

*Marking Code

Ordering Information:

Si2328DS-T1-E3 (Lead (Pb)-free)

Si2328DS-T1-GE3 (Lead (Pb)-free and Halogen-free)

Si2328DS

Vishay Siliconix

PRODUCT SUMMARY

VDS (V) R

100 0.250 at V

DS(on)

GS

()I

D

(A)

= 10 V 1.5

• Halogen-free According to IEC 61249-2-21

Definition

•100 % R

• TrenchFET

and UIS Tested

g

®

Power MOSFET

• Compliant to RoHS Directive 2002/95/EC

ABSOLUTE MAXIMUM RATINGS (TA = 25 °C, unless otherwise noted)

Parameter Symbol 5 s Steady State Unit

FEATURES

Drain-Source Voltage V

Gate-Source Voltage V

Continuous Drain Current (T

Pulsed Drain Current

Avalanche Current

b

b

= 150 °C)

J

a

Single Avalanche Energy E

Continuous Source Current (Diode Conduction)

Power Dissipation

a

a

TA = 25 °C

T

= 70 °C 1.2 0.92

A

L = 0.1 mH

TA = 25 °C

T

= 70 °C 0.80 0.47

A

Operating Junction and Storage Temperature Range T

DS

GS

I

D

I

DM

I

AS

AS

I

S

P

D

, T

J

stg

1.25 0.73

100

± 20

1.5 1.15

6

6

1.8 mJ

0.6 A

- 55 to 150 °C

V

A

W

Notes:

a. Surface mounted on 1" x 1" FR4 board.

b. Pulse width limited by maximum junction temperature.

Document Number: 71796

S11-2000-Rev. F, 10-Oct-11

THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

THERMAL RESISTANCE RATINGS

Parameter Symbol Typical Maximum Unit

Maximum Junction-to-Ambient

Maximum Junction-to-Foot Steady State R

a

t 5 s

R

thJA

thJF

80 100

°C/WSteady State 130 170

45 55

www.vishay.com

This document is subject to change without notice.

1

Si2328DS

0

3

6

9

12

0246810

VGS = 10 V, 9 V, 8 V

6 V

V

DS

- Drain-to-Source Voltage (V)

- Drain Current (A)I

D

5 V

4 V

7 V

3 V, 2 V, 1 V

Vishay Siliconix

SPECIFICATIONS (TA = 25 °C, unless otherwise noted)

Limits

Parameter Symbol Test Conditions

Static

Drain-Source Breakdown Voltage V

Gate-Threshold Voltage V

Gate-Body Leakage I

Zero Gate Voltage Drain Current I

On-State Drain Current

Drain-Source On-Resistance

Forward Transconductance

a

a

a

Diode Forward Voltage V

Dynamic

b

GS(th)

GSS

DSS

I

D(on)

R

DS(on)

DS

g

SD

Total Gate Charge Qg

Gate-Drain Charge Q

Gate Resistance R

V

fs

gs

1.45

gd

g

VGS = 0 V, ID = 1 mA 100

V

= VGS, ID = 250 µA 2 4

DS

VDS = 0 V, VGS = ± 20 V ± 100 nA

V

V

DS

= 100 V, V

DS

= 100 V, V

GS

15 V, V

DS

V

= 10 V, ID = 1.5 A 0.195 0.250

GS

= 0 V 1

GS

= 0 V, TJ = 70 °C 75

= 10 V 6 A

GS

VDS = 15 V, ID = 1.5 A 4 S

IS = 1 A, V

= 0 V 0.8 1.2 V

GS

3.3 5

V

DS

= 50 V, V

= 10 V, ID = 1.5 A

GS

0.47

0.5 1.3 2.4

Switching

Tur n -O n De l a y T i m e t

Rise Time t

Turn-Off Delay Time t

Fall Time t

Source-Drain Reverse Recovery Time t

d(on)

V

r

915

d(off)

f

rr

I

D

= 50 V, RL = 33

DD

0.2 A, V

= 10 V, Rg = 6

GEN

IF = 1.5 A, dI/dt = 100 A/µs 50 100

711

11 17

10 15

Notes:

a. Pulse test: PW 300 µs, duty cycle 2 %.

b. Guaranteed by design, not subject to production testing.

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation

of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum

rating conditions for extended periods may affect device reliability.

Unit Min. Typ. Max.

V

µA

nCGate-Source Charge Q

ns

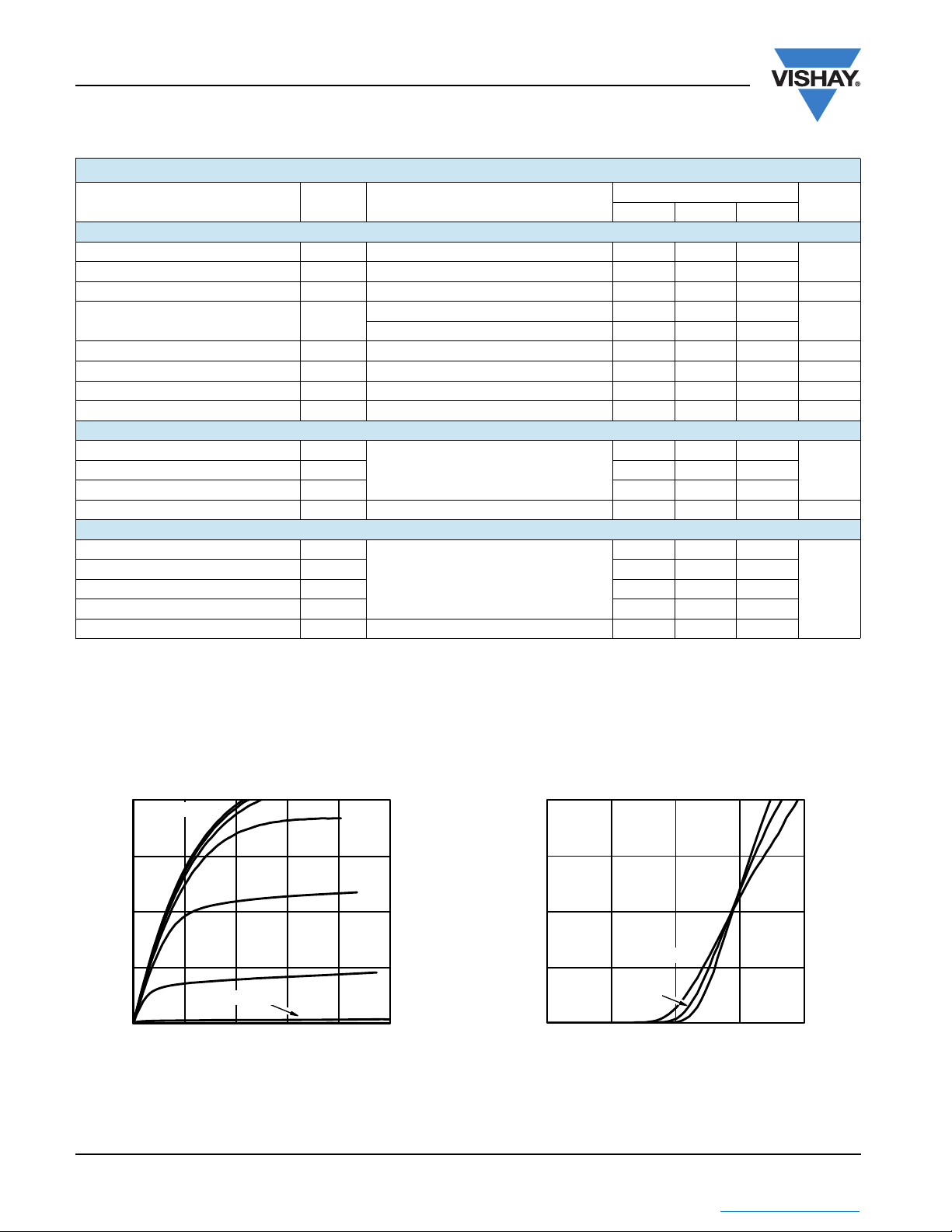

TYPICAL CHARACTERISTICS (25 °C, unless otherwise noted)

www.vishay.com

2

THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Output Characteristics

12

9

6

- Drain Current (A)I

D

3

0

02468

This document is subject to change without notice.

TC = 125 °C

25 °C

- 55 °C

V

- Gate-to-Source Voltage (V)

GS

Transfer Characteristics

Document Number: 71796

S11-2000-Rev. F, 10-Oct-11

TYPICAL CHARACTERISTICS (25 °C, unless otherwise noted)

R

DS(on)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

036912

ID - Drain Current (A)

VGS = 10 V

- On-Resistance ()

0

50

100

150

200

250

0 20406080100

VDS - Drain-to-Source Voltage (V)

C

rss

C

oss

C

iss

C - Capacitance (pF)

0.0

0.5

1.0

1.5

2.0

2.5

- 50 - 25 0 25 50 75 100 125 150

VGS = 10 V

I

D

= 1.5 A

T

J

- Junction Temperature (°C)

R

DS(on)

- On-Resistance (Normalized)

Si2328DS

Vishay Siliconix

On-Resistance vs. Drain Current

20

VDS = 50 V

= 1.5 A

I

D

16

12

8

- Gate-to-Source Voltage (V)

GS

4

V

0

0123456

Qg - Total Gate Charge (nC)

Gate Charge

10

1

TJ = 150 °C

Capacitance

On-Resistance vs. Junction Temperature

0.6

0.5

ID = 1.5 A

0.4

- Source Current (A)I

0.1

S

0.01

0.0 0.2 0.4 0.6 0.8 1.0 1.2

VSD - Source-to-Drain Voltage (V)

Source-Drain Diode Forward Voltage

Document Number: 71796

S11-2000-Rev. F, 10-Oct-11

THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

TJ = 25 °C

This document is subject to change without notice.

0.3

- On-Resistance ()

0.2

DS(on)

R

0.1

0.0

0246810

VGS - Gate-to-Source Voltage (V)

On-Resistance vs. Gate-to-Source Voltage

www.vishay.com

3

Si2328DS

- 1.2

- 0.9

- 0.6

- 0.3

0.0

0.3

0.6

- 50 - 25 0 25 50 75 100 125 150

ID = 250 µA

Variance (V)V

GS(th)

TJ - Temperature (°C)

0.01

0

1

10

12

4

6

100 6000.1

Time (s)

2

8

Power (W)

10

TA = 25 °C

10

-

3

10

-

2

1 10 60010

-

1

10

-

4

100

2

1

0.1

0.01

0.2

0.1

0.05

0.02

Single Pulse

Duty Cycle = 0.5

Square Wave Pulse Duration (s)

Normalized Effective Transient

Thermal Impedance

1. Duty Cycle, D =

2. Per Unit Base = R

thJA

= 176 °C/W

3. T

JM

- TA = PDMZ

thJA

(t)

t

1

t

2

t

1

t

2

Notes:

4. Surface Mounted

P

DM

Vishay Siliconix

TYPICAL CHARACTERISTICS (25 °C, unless otherwise noted)

Threshold Voltage

Normalized Thermal Transient Impedance, Junction-to-Ambient

Single Pulse Power

Vishay Siliconix maintains worldwide manufacturing capability. Products may be manufactured at one of several qualified locations. Reliability data for Silicon

Technology and Package Reliability represent a composite of all qualified locations. For related documents such as package/tape drawings, part marking, and

reliability data, see www.vishay.com/ppg?71796

www.vishay.com

4

THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

.

This document is subject to change without notice.

Document Number: 71796

S11-2000-Rev. F, 10-Oct-11

SOT-23 (TO-236): 3-LEAD

b

3

1

Package Information

Vishay Siliconix

E

E

1

2

S

A

A

2

A

1

Dim

A 0.89 1.12 0.035 0.044

A

1

A

2

b 0.35 0.50 0.014 0.020

c 0.085 0.18 0.003 0.007

D 2.80 3.04 0.110 0.120

E 2.10 2.64 0.083 0.104

E

1

e 0.95 BSC 0.0374 Ref

e

1

L 0.40 0.60 0.016 0.024

L

1

S 0.50 Ref 0.020 Ref

q 3°8°3°8°

ECN: S-03946-Rev. K, 09-Jul-01

DWG: 5479

e

e

1

D

0.10 mm

Seating Plane

C

0.004"

C

C

q

L

L

1

MILLIMETERS INCHES

Min Max Min Max

0.01 0.10 0.0004 0.004

0.88 1.02 0.0346 0.040

1.20 1.40 0.047 0.055

1.90 BSC 0.0748 Ref

0.64 Ref 0.025 Ref

0.25 mm

Gauge Plane

Seating Plane

Document Number: 71196

09-Jul-01

www.vishay.com

1

Mounting LITTLE FOOTR SOT-23 Power MOSFETs

Wharton McDaniel

AN807

Vishay Siliconix

Surface-mounted LITTLE FOOT power MOSFETs use integrated

circuit and small-signal packages which have been been modified

to provide the heat transfer capabilities required by power devices.

Leadframe materials and design, molding compounds, and die

attach materials have been changed, while the footprint of the

packages remains the same.

See Application Note 826, Recommended Minimum Pad

Patterns With Outline Drawing Access for Vishay Siliconix

MOSFETs, (http://www.vishay.com/doc?72286), for the basis

of the pad design for a LITTLE FOOT SOT-23 power MOSFET

footprint . In converting this footprint to the pad set for a power

device, designers must make two connections: an electrical

connection and a thermal connection, to draw heat away from the

package.

The electrical connections for the SOT-23 are very simple. Pin 1 is

the gate, pin 2 is the source, and pin 3 is the drain. As in the other

LITTLE FOOT packages, the drain pin serves the additional

function of providing the thermal connection from the package to

the PC board. The total cross section of a copper trace connected

to the drain may be adequate to carry the current required for the

application, but it may be inadequate thermally. Also, heat spreads

in a circular fashion from the heat source. In this case the drain pin

is the heat source when looking at heat spread on the PC board.

ambient air. This pattern uses all the available area underneath the

body for this purpose.

0.114

2.9

0.081

2.05

0.150

3.8

0.059

1.5

0.0394

FIGURE 1. Footprint With Copper Spreading

1.0

0.037

0.95

Since surface-mounted packages are small, and reflow soldering

is the most common way in which these are affixed to the PC

board, “thermal” connections from the planar copper to the pads

have not been used. Even if additional planar copper area is used,

there should be no problems in the soldering process. The actual

solder connections are defined by the solder mask openings. By

combining the basic footprint with the copper plane on the drain

pins, the solder mask generation occurs automatically.

Figure 1 shows the footprint with copper spreading for the SOT-23

package. This pattern shows the starting point for utilizing the

board area available for the heat spreading copper. To create this

pattern, a plane of copper overlies the drain pin and provides

planar copper to draw heat from the drain lead and start the

process of spreading the heat so it can be dissipated into the

Document Number: 70739

26-Nov-03

A final item to keep in mind is the width of the power traces. The

absolute minimum power trace width must be determined by the

amount of current it has to carry. For thermal reasons, this

minimum width should be at least 0.020 inches. The use of wide

traces connected to the drain plane provides a low-impedance

path for heat to move away from the device.

www.vishay.com

1

RECOMMENDED MINIMUM PADS FOR SOT-23

Application Note 826

Vishay Siliconix

0.106

(2.692)

0.037

(0.950)

0.053

(1.341)

0.097

(2.459)

Recommended Minimum Pads

Dimensions in Inches/(mm)

0.022

(0.559)

0.049

0.029

(1.245)

(0.724)

Return to Index

Document Number: 72609 www.vishay.com

Revision: 21-Jan-08 25

Return to Index

APPLICATION NOTE

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as Halogen-Free follow Halogen-Free

requirements as per JEDEC JS709A standards. Please note that some Vishay documentation may still make reference

to the IEC 61249-2-21 definition. We confirm that all the products identified as being compliant to IEC 61249-2-21

conform to JEDEC JS709A standards.

Revision: 02-Oct-12

1

Document Number: 91000

Loading...

Loading...